Objet 30 scholar 3d printer

Stratasys Objet30 3D Printer Series

THE STRATASYS

The Most Versatile Family of Compact Precision 3D Printers

The Objet30 Series from Stratasys features the Objet30, Objet30 Pro and the Objet30 Prime; the world's most versatile set of desktop 3D printers. With a wide gamut of material options as well as the precision and accuracy of PolyJet technology, your design team will be enabled to create true-to-life prototypes that mimic the look and feel of the end product. With a variety of print modes you are able to 3D print fast, shortening product development cycles and design iterations.

View Video Brochure Request Demo

https://youtu.be/ZdjP7hNR5EY

- Overview

- Key Features

- Advantages

- Objet30 Series

- Materials

- Specifications

- Request a Quote

Bring Precision Prototyping to your Desktop

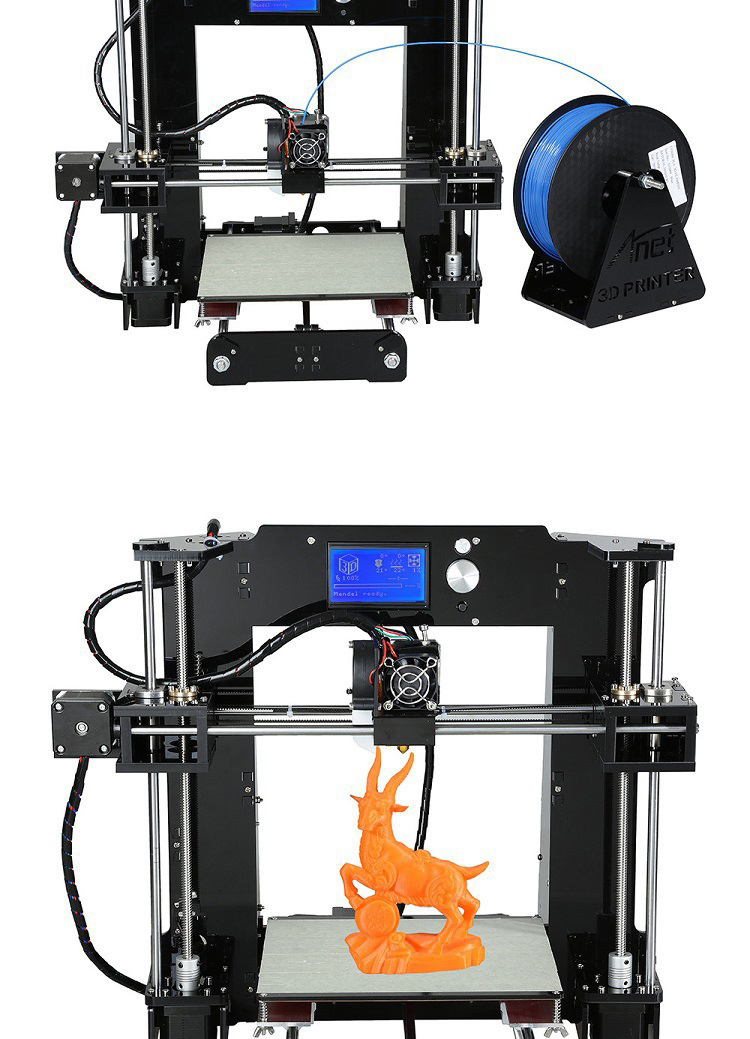

Whether you need to prototype consumer products or print with a range of specialized materials. There is an Objet30 3D printer that will suit your organization and fit right on your desktop. Featuring the Objet30, Objet30 Pro and the Objet30 Prime, each iteration carries a build size of 30 x 20 x 15 cm allowing fast print times with a small footprint. The Pro and Prime models feature an extended list of material capabilities including up to 12 different materials for the best surface resolution in the business.

Big Performance, Small Footprint

The Objet30 Series Printers fit conveniently right in your office and carry a small footprint to allow prototyping as convenient as possible.

Material Variety

The Objet30 Prime can print with a variety of materials such as: Rigid Opaque, Transparent, Simulated Polypropylene, High Temperature, Rubber-like, and bio-compatible

Accuracy

Achieve detailed and precision printing with an accuracy down to 0.1 mm [0.0039 in] across all models in the Objet30 Series.

Build Modes

Get up to three different build modes including Draft, High Speed, and High Quality from the Objet30 Series. Choose the one that’s right for your business.

Choose the one that’s right for your business.

With PolyJet technology you are able to produce smooth and accurate models for a variety of conceptual modeling and prototyping applications.

With microscopic layer resolution and accuracy down to 0.1 mm, PolyJet 3D printing technology is the perfect fit for getting detailed models in a timely manner.

LEARN MORE ABOUT POLYJET

High-Resolution 3D Printing

With 28 micron layers, you don’t have to be a big budget business to create accurate, working models for multiple applications. Speed, reliability and precision – all-in-one.The Objet30 desktop 3D Printer is capable of printing high quality models in 5 different materials. This compact 3D printing solution, brings rapid prototyping capabilities to any office environment. Regardless of their size, product design agencies, service providers, consulting agencies, as well as engineering companies will benefit from the use of the Objet30

Big Power from a Little Package

Objet’s smallest 3D printer family fits compactly on your desktop and emits no toxic fumes, no loud sounds and is completely office friendly. Both designers and engineers can build working models and prototypes featuring ultra-precise details straight from your office desk. With an Objet24 on your desktop you print one part many times, or multiple parts one time throughout the day. The Objet24 lets you rapidly prototype whatever you need , as often as you like, in the convenience of your office – without the hassle of specialist training or equipment.

Both designers and engineers can build working models and prototypes featuring ultra-precise details straight from your office desk. With an Objet24 on your desktop you print one part many times, or multiple parts one time throughout the day. The Objet24 lets you rapidly prototype whatever you need , as often as you like, in the convenience of your office – without the hassle of specialist training or equipment.

The Objet30 Series from Stratasys consists of the Objet30, Objet30 Pro and Objet30 Prime desktop 3D printers. All these systems are designed to help you create high-end prototypes with realistic and specialized material properties.

Objet30

Precision and Versatility for Rapid Prototyping

An office-friendly 3D printer from Stratasys capable of printing high quality models in five different materials. The Objet30 provides accuracy and versatility in a compact footprint- making it great for prototyping consumer products, even with limited space and budget.

Material Options – 3D print with five different materials including a polypropylene mimic.

High Detail and Dimensional Stability – simulate plastics that look, feel and function like the end product.

Applications – With high precision, speed, and material selection the Objet30 is perfect for rapid prototyping, snap fit, and assemblies.

Objet30 Pro

High-End Rapid Prototyping On Your Desktop

Produce high-end prototypes and realistic models with specialized properties with the Objet30 Pro. With its high accuracy and versatility, this system allows you to print your ideas from your desktop.

8 Different 3D Printing Materials – Use materials such as clear, high temperature and simulated polypropylene to create hyper-realistic models.

Best-In-Class Resolution– The Objet30 Pro yields high accuracy and smooth surfaces on even the smallest moving parts and the ability to create thin walls.

Big Tray Size – Print objects such as consumer goods, electronics, medical devices and more.

Objet30 Prime

3D Printing With New Possibilities

Print your biggest ideas right on your desktop with the Objet30 Prime, offering twelve different printing materials and ultimate precision & versatility within your office space. Enjoy three print modes from draft to high quality for every phase of your development cycle.

3 Print Modes – Deliver your boldest ideas with the versatility of three print modes.

Draft Mode– Enable fast and economical printing and prototyping from your earliest concepts.

Silent Operation & Small Footprint – The Objet30 Prime fits unobtrusively in any office space.

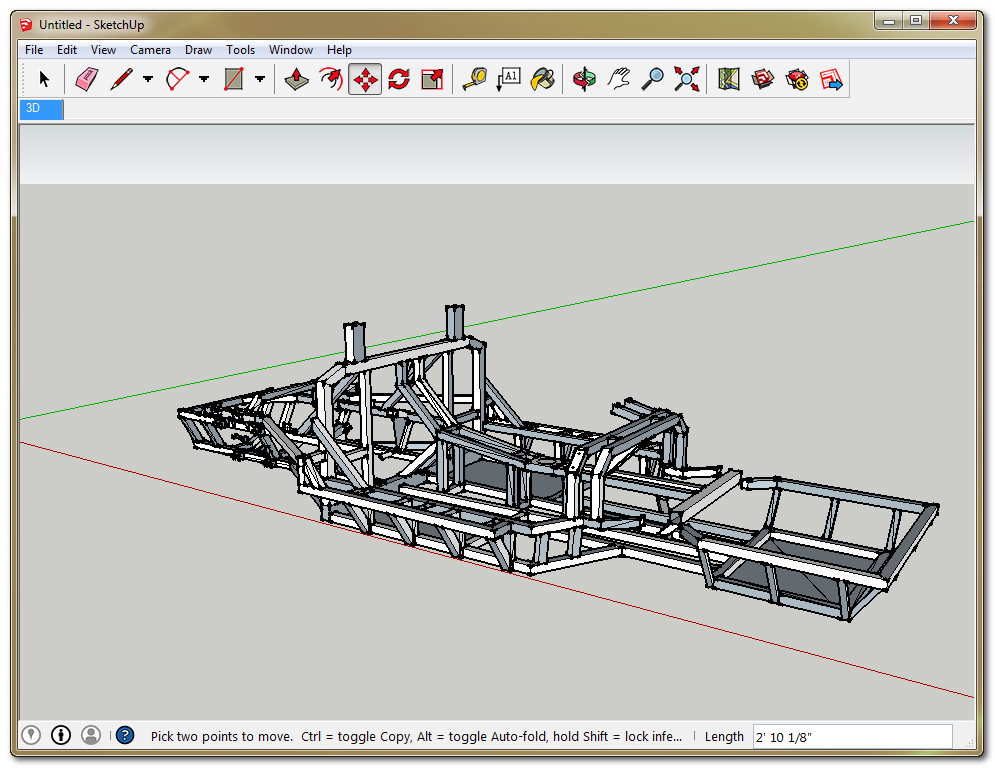

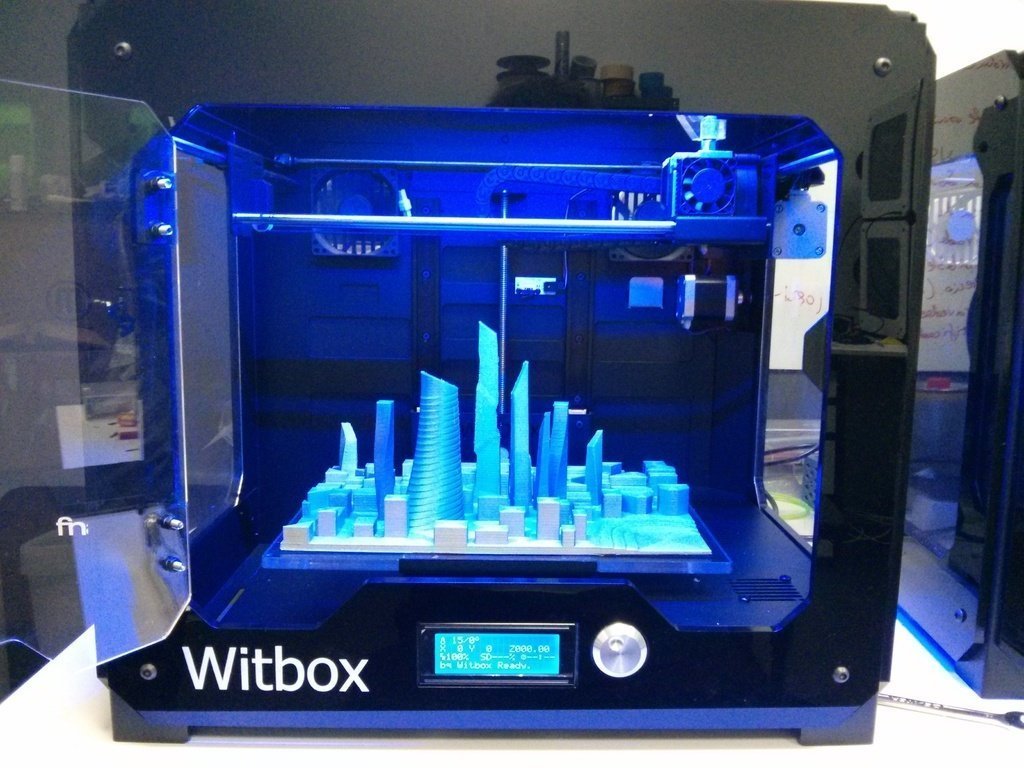

Rietveld Architects

Architecture

Rietveld Architects LLP was established in 1994 in New York City and is known throughout the U. S. and Europe for its creative commercial and residential spaces. Having first learned about 3D printing from NASA, the firm's partners Margaret and Rijk Rietveld saw the potential for this technology to increase productivity and foster more innovative designs.

S. and Europe for its creative commercial and residential spaces. Having first learned about 3D printing from NASA, the firm's partners Margaret and Rijk Rietveld saw the potential for this technology to increase productivity and foster more innovative designs.

View Case Study

Rigid Opaque

Combining dimensional stability and fine detail, Rigid Opaque materials in the Vero family simulate the appearance of production parts, and are even suitable for rapid tooling.

LEARN MORE

Transparent

Using RGD720 and VeroClear, combine features such as clarity, dimensional stability and surface smoothness in your print. Transparent Polyjet material lets you prototype clear & tinted products.

LEARN MORE

Rubber-Like

With Tango Gray and Tango Black material, rubber-like is suitable for a range of applications requiring non-slip or soft surfaces. Simulate rubber with different levels of hardness, elongation & tear resistance.

Simulate rubber with different levels of hardness, elongation & tear resistance.

LEARN MORE

Objet30 | Objet30Rigid opaque white (VeroWhitePlus)Rigid opaque black (VeroBlackPlus ) Rigid opaque blue (VeroBlue) Rigid opaque gray (VeroGray) Polypropylene-like material (DurusWhite) |

Objet30 Prime | Objet30 PrimeRigid Opaque (Vero family) in a variety of colors including white, gray, blue and blackTransparent (RGD720 and VeroClear) for clear and tinted products with great dimensional stability and surface smoothness High Temperature (RGD525) for advanced functional testing, hot air and water flow, and static applications Simulated Polypropylene materials (RGD450 & RGD430) with toughness and durability for smooth prototypes with living hinges, flexible closures and snap-fit parts Rubber-like materials (Tango Gray or Tango Black) for a range of applications requiring non-slip or soft surfaces Bio-compatible (MED610) for medical-device prototyping |

Objet30 Pro | Objet30 ProTransparent (VeroClear), a nearly colorless material featuring great dimensional stability, fine-detail model building, and simulation of transparent thermoplastic such as PMMAHigh Temperature (RGD525) for advanced functional testing, hot air and water flow, and static applications Simulated Polypropylene (RGD450 & RDG430) a material offering toughness and durability for smooth prototypes with living hinges, flexible closures and snap-fit parts |

Objet30 Series Specifications

Build Tray Size | Build Tray Size29. 4 x 19.2 x 14.8 cm [11.57 x 7.55 x 5.85 in] 4 x 19.2 x 14.8 cm [11.57 x 7.55 x 5.85 in] |

Minimum Layer Thickness | Minimum Layer Thickness28 microns [0.0011 in] |

Build Resolution | Build ResolutionObjet30 & Objet30 ProX-axis: 600 dpi Y-axis: 600 dpi Z-axis: 900 dpi Objet30 Prime |

Build Modes | Build ModesObjet30High Speed 30-micron [0.001 in] Objet30 Pro Objet30 Prime |

Model Materials | Model MaterialsObjet30Rigid Opaque, Simulated Polypropylene Objet30 Pro Objet30 Prime |

Support Material | Support MaterialSUP705 (WaterJet removable)SUP706 (soluble) |

Power Requirements | Power RequirementsObjet30Single phase: 100-200V; 50-60Hz; 7A or 200-240V; 50-60Hz 3.  5A 5AObjet30 Pro Objet30 Prime |

System Size & Weight | System Size & WeightObjet30 & Objet30 Pro82.6 x 60 x 62 cm [32.5 x 23.6 x 24.4 in] 106 kg [234 lbs] Objet30 Prime |

Objet30 Pro 3D Printer Review 2022

4.6

See Price

Stratasys’ ambition with the Objet30 Pro is to offer the precision and adaptability of an industrial-grade fast prototyping printer within a device with physical dimensions nearing those of an inkjet printer or office photocopying machine – a compact workhorse capable of highly detailed prints.

We’ve taken a look at the Objet30 Pro to see how well it lives up to these claims. Here’s our honest opionion.

| Printing Area | 294 x 192 x 148.6 mm |

| Layer Resolution | 16 to 28 microns |

| Supported Filament | Rigid Opaque, Transparent, High Temperature, Simulated Polypropylene, FullCure |

| Printing Tech | PolyJet |

| Extruders | 2 |

Table of ContentsShow

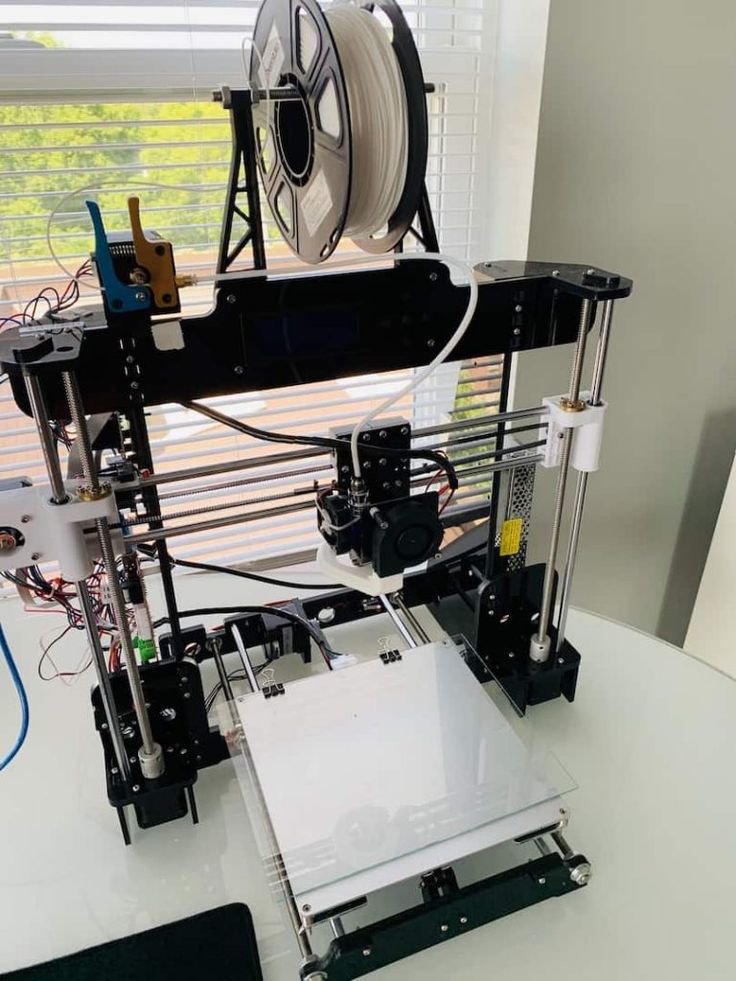

Design & Features

Touted as a desktop printer, the Objet30 Pro has all the allure of a professional grade printer with a sleek black and white color scheme that shapes a rectangular body that interestingly curves inwards vertically towards the center of the unit. The plastic casing will be familiar to anyone having used a consumer-grade ink printer making it very much at home in a design studio, home office or university alongside similar devices.

The total weight of the printer is a robust 106 kg, which apart from making transportation a hassle, ensures near unwavering stability, even when the print heads are whizzing away at the highest speed setting.

The components are all heavy duty and of the highest quality, positioned for maximized functionality but also a certain aesthetic, mechanical appeal especially when opening the hood and peering inside. The extruder mount can only be described as chunky with one of the most prominent profiles we’ve come across from a printer with this footprint.

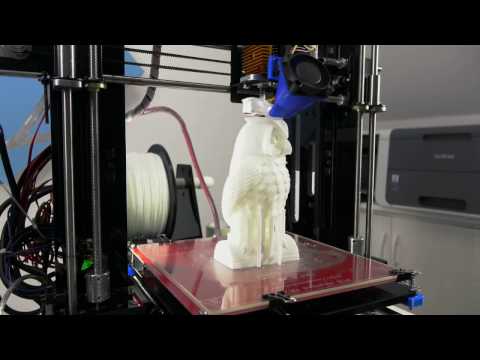

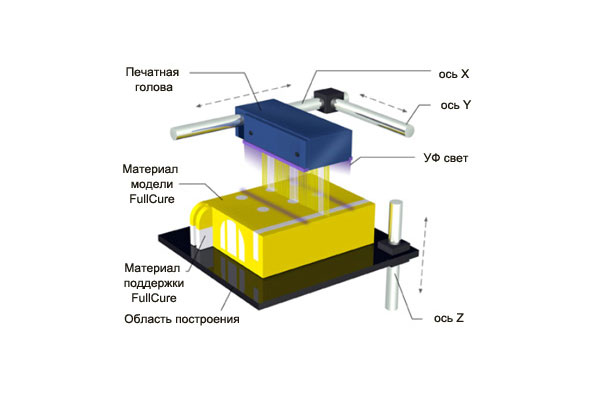

The Objet30 Pro employs Stratasys’ patented PolyJet printing technology, which sits somewhere between typical FDM and precision SLA printers. The process resembles the inkjets found in standard printers whereby a jet places drops of liquid photopolymer material onto the build plate and then hardens or cures it by shining UV light onto it. This method is uncommon with results that offer precision unseen in printers using FDM technology.

The build area tallies up to 294 x 192 x 148.6 mm with axis resolutions of 600 dpi, 600 dpi, and 900 dpi for the X-axis, Y-axis, and Z-axis respectively. Generally speaking, the Objet30 Pro attains software to real-world print accuracy levels correct up to around 0.1mm, but this vacillates important waging on the type of model, size, the materials used, and the complexity of the design.

The Objet30 Pro has a dual extruder setup; one for printing material and the other for support material, both sitting alongside the UV light that does the curing work. The configuration allows layer resolutions ranging from 16 to 28 microns depending on whether it prints on the high quality or high-speed setting. The precision makes it one of the most detailed printers on the market regardless of cost and is a world away from the 100 microns best of most consumer models.

The material support of the Objet30 Pro is where the printer comes into its element with different liquid photopolymers endowed with a range of physical properties for all manner of situations, the only real downside being that only materials sourced from Stratasys are compatible.

Rigid Opaque in white, black, gray, and blue allow for high detailed prints that reach the quality level of end products for prototyping. Transparent VeroClear is ideal for fine-modeling used to simulate end-product transparent materials. High-Temperature RGD525 is geared towards functional testing for scenarios where high temperatures, be it air or liquid, are required. Lastly, the printer supports DurusWhite Simulated Polypropylene designed for durability and robust usage for example low tolerance hinges and snap-fit products.

The printer also uses the non-toxic gelatinous FullCure 705 support material that is not only ideal for crafting complex overhangs and the like but is removable via the DT3 Clean Station that ships with the printer.

The materials are housed in a convenient slide out draw sitting below the main printing area. Should any of the liquid photopolymer cartridges run dry, the printer has an inbuilt feature that pauses the building process to allow the user to load in a replacement, when the device picks up where it left off.

Connectivity is limited to a local network via ethernet cable, which is the standard for industrial sized printers that need a connection to multiple workstations.

As for software, the Objet30 Pro functions with Stratasys’ Objet Studio that converts any STL or SLC 3D CAD file into a sliced model that the printer can interpret and render. All controls are managed from Objet Studio with no LCD or controls on the printer itself.

Functionality ranges from automatic support creation, a range of editing tools, material selection, auto-positioning, maintenance, and the like. Compatibility is reserved for Windows systems. Overall, Objet Studio is as intuitive as it is versatile and rivals open source slicers such as Simplify3D.

Assembly

The Objet30 Pro arrives fully assembled with no installation other than fitting the liquid photopolymer cartridges into the loading tray and loading the roller bath/blade assembly into its berth below the build plate.

The package includes the Objet30 Pro waste containers, roller bath assembly, wiper blade assembly, sanding sponge, ethernet cable, nozzle ruler, loupe, tool kit (scraper, Allen key, mirror, spatula), cleaning cloths, transparency sheets, pink paper, nitrile gloves, scale, spray bottle, support cleaning fluid, model cleaning fluid, user guide notebook, USB flash drive, and a stylus pen.

Due to its complexity, the Objet30 Pro does require quite a bit of maintenance from cleaning the innards, replacing printheads, emptying waste containers, but nothing a versed lab or office technician couldn’t handle.

Printing

For a price tag nearing $20,000, we wouldn’t accept anything short of extraordinary, and the Objet30 Pro fits the bill. Prints are more or less immaculate, and the range of printing materials allow a varied selection of models. All our test prints were smooth, precise, and showed a level detail usually found in pre-assembly line models. We encountered no issues whatsoever with the printing process.

The results are suited to all manner of ends from engineering, consumer goods, low tolerance prototyping, end-user small scale manufacturing, dentistry, electronics, medical, and of course design. Virtually any industry can benefit from the quality of the prints generated by the Objet30 Pro.

Objet Studio is packed with choices and is incredibly simple to use even though it controls such a strong beast of a machine.

Support

As you’d expect from Stratasys, the support is of the highest caliber with a rich vault of guides, tutorials, and videos peppering its web site alongside the Stratasys Service Offering which includes on-site technical service and maintenance, part replacement, user training seminars, and discounts on accessories among other benefits.

Additionally, technical support teams are available throughout the world through phone, email or in person support. The printer itself ships with a standard one-year warranty.

Verdict

When reviewing leviathan grade printers with all the bells and whistle it is hard to produce a verdict other than excellent, but then again this is very much expected from the associated price tag.

The Objet30 Pro follows suits, and if you’ve got the budget to match (including maintenance and on-going production costs), then you quite simply can’t go wrong with this model.

It comes highly recommend for any professional context in need of a reliable, versatile, and precision-oriented 3D printer that won’t take up too much space yet deliver the same level of quality as pricier alternatives.

3D printers and their applications at home, at home, in construction, business, in medicine, in manufacturing, in dentistry, in education

3 D physical object on the digital model by layers. Until quite recently, 3D printers were considered something out of the realm of fantasy, and it was hard to imagine that such a technique would become a reality. But the rapid development of technology entails the emergence of new developments and allows us to observe the use of 3D printers in various fields of human activity: business, construction, manufacturing, medicine, education, clothing, architecture, cooking, etc.

The use of 3D printers in business

The use of 3D printers in business is relevant for both small and large businesses.

It will be a great helper for entrepreneurs who are engaged in:

- small-scale production of souvenirs, gifts, figurines, etc.

It is he who will help you create unique things as a gift, which is always relevant, because every person wants to give a unique and individual thing for any holiday, which will forever be remembered;

It is he who will help you create unique things as a gift, which is always relevant, because every person wants to give a unique and individual thing for any holiday, which will forever be remembered; - repair. The 3D printer has been widely used in the field of repair of plastic products, because it can be used to easily recreate a broken part;

- jewelry business. Its use makes it possible to create ideal molds for casting jewelry from precious metals.

- production of three-dimensional maps showing the exact landscape.

Using a 3D printer, you can create products of very high precision and detail. Ideal for these purposes: printer Picaso 3D Designer, Sharebot XXL.

3D printer in construction

In the construction industry, 3D printer building technologies are widely used. 3D printing makes it possible to produce forms of concrete of any size without formwork, while labor costs and delivery times for the finished object are significantly reduced. It also allows for the phased installation of the foundation, walls, water supply systems and the building frame itself. The finished structure can be built using 3D printers in less than a day. Builders will only have to mount windows and doors.

It also allows for the phased installation of the foundation, walls, water supply systems and the building frame itself. The finished structure can be built using 3D printers in less than a day. Builders will only have to mount windows and doors.

Similar equipment is already used in construction in the USA, Australia and Russia. Its mass use will not only significantly save on building materials, but also halve human intervention in the construction process, as well as significantly reduce the percentage of accidents at the construction site.

Foundry 3D printer

3D technology assists in the production of molds and master models based on CAD files for casting. A 3D printer in production allows designers to produce models with ultra-precise geometric shapes and parameters, which cannot be achieved using traditional methods.

Models of casting molds that are made on the printer are created from materials:

- Wax.

The material melts at a temperature of 60 degrees. Allows you to achieve high accuracy and convey the desired image down to the smallest details.

The material melts at a temperature of 60 degrees. Allows you to achieve high accuracy and convey the desired image down to the smallest details. - Photopolymer. It lends itself to temperatures above 900 degrees and makes it possible to burn out master models for the manufacture of silicone molds.

The most suitable printers for mold production are: printbox3d one etc.

The main advantages of these technologies are the speed of the mold creation process, its economy and minimal manual work.

3D printers in medicine

Now the practice of using 3D printers in medicine is quite extensive, namely:

- prosthetics. With the loss of any part of the body, a stem cell-based 3D printer can model and recreate a lost limb, etc.;

- Implantology. A 3D printer allows you to create a complete prototype of bone tissue in a few weeks (in the USA there was a transplant of a fragment of a skull created by 3D technologies), human organs (a part of the liver has been created, which successfully functions and produces enzymes of the human body).

Also, English doctors and scientists have created, with the help of a printer, a human ear that picks up radio waves and functions normally in a patient to whom it was transplanted;

Also, English doctors and scientists have created, with the help of a printer, a human ear that picks up radio waves and functions normally in a patient to whom it was transplanted; - surgery. 3D printers make it possible to simulate damage, reduce the time of surgery, reduce the possibility of a doctor's error to zero, and improve the patient's condition.

With 3D printers, medicine becomes more accurate, painless, able to give life even in the most difficult situations.

For this, for medical purposes, printers are used: Designer PRO 250, ConceptLaserMlab R, CeramCeramaker 3D printer.

The problem of organ transplants and their search may disappear, 3D technologies make it possible to create the necessary organ for the human body, and people with special needs will be able to find the missing organ.

3D printers in dentistry

3D printers are already widely used in dentistry, as they have greatly simplified and improved the quality of the process of treating the oral cavity.

One of the main assets of this 3D printer in dentistry is dental prosthetics. Previously, it was a very expensive and long process, which was accompanied by lengthy processes of fittings, improvements and other things.

The 3D printer allows an experienced prosthodontist to scan the oral cavity in 3D and create the perfect prosthesis or crown specifically for the patient's jawbone.

For the manufacture of dental prostheses using a 3D printer (in dentistry), methods are used: material melting (full or partial), sintering, melting. The choice of a printer for dental purposes should be approached very responsibly, because not every 3D equipment is suitable for the work of a dental orthopedist.

Recommended 3D printers for this purpose:

- CrownWorx;

- Objet Eden260VS DentalAdvantage;

- FrameWorx;

- Objet Eden350V and Objet Eden500V;

- Objet30 OrthoDesk.

The main advantages of 3D denture prosthetics are:

- rapid execution of prostheses, which eliminates the need to install temporary devices for the patient;

- performing the prosthetic procedure as accurately as possible, which guarantees a perfect fit of the model and the absence of any discomfort for the client;

- the ability to easily eliminate defects of any kind of teeth - chips, the consequences of caries treatment and others.

3D technologies in education

Even 20 years ago, the use of 3D printers in education was considered impossible. When printers hit the market 10 years ago, not all educational institutions had the opportunity to purchase them because of the high cost, but now they are used everywhere, just like a computer or a blackboard.

3D printers are most widely used in technical universities, where students implement their developments, design ideas that they need to write scientific papers, etc.

3D technologies are very popular in architectural and design educational institutions, where students can reproduce their creativity and diploma projects in reality.

Therefore, teaching students how to use 3D printers and practical work has long been introduced into the curriculum of the educational process in universities.

Now, in Russia, 3D technologies are being introduced into the school system so that students get used to working with new technologies, which will undoubtedly help them decide on the choice of their future specialty and gain the necessary skills in their future work.

The most popular models that are common in education are: Cube 3D printer, Cubex Trio, CubeProTrio and ShareBotKiwi 3D KIT.

Why do you need a 3D printer in everyday life?

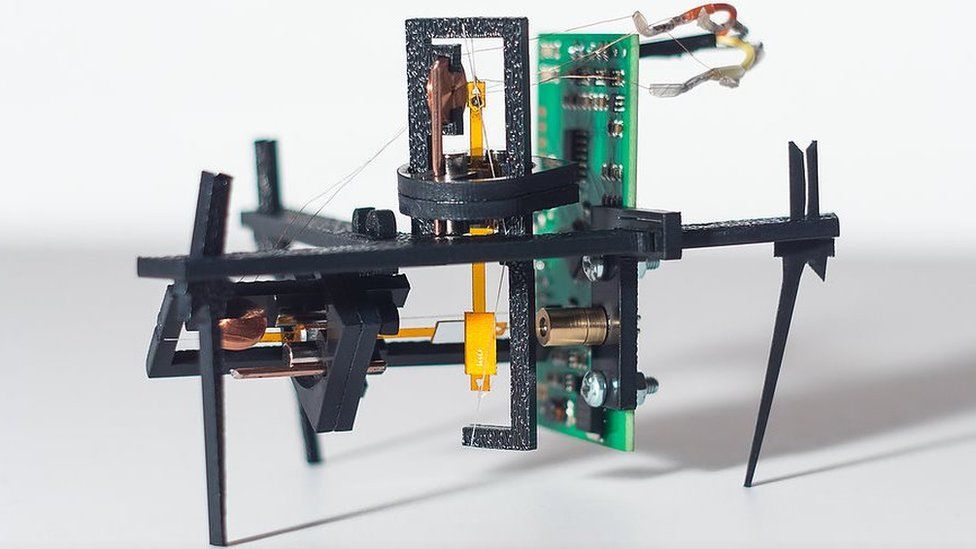

Every family needs a 3D printer at home. On it you can do everything you need: ordinary household containers, toys for your children (or their repair), a quadcopter (homemade), any necessary parts, etc. With a 3D printer, you can unleash your creativity at home. In addition, 3D technologies will allow you to develop your child's creative abilities, and the result of your games with your child can be realized using 3D.

With a 3D printer, you can unleash your creativity at home. In addition, 3D technologies will allow you to develop your child's creative abilities, and the result of your games with your child can be realized using 3D.

To use a 3D printer at home, you do not need to buy too powerful equipment. Printer type will suffice:

- 3d printer model Mbot. There are models in a steel and wooden case, equipped with a liquid crystal screen, power supplies. USB cable and SD card included. It is possible to print in two colors at the same time;

- 3d printer - Up! Plus. Ability to print multiple colors, USB, has a small size and weight. Quality assurance. Ideal for beginners;

- MiRiwell 3d printer. Chinese 3D printer. Has bright colors. Suitable for home use;

- WanhaoDuplicator 3D printer. Body material: wood, metal, plastic. Great software, quality home printer.

In our online shop you will find exactly the printer that will allow you to realize your goals. We offer competitive prices for 3D printers and help you choose the perfect model based on your goals and needs. 3D printers will help make your life more comfortable!

We offer competitive prices for 3D printers and help you choose the perfect model based on your goals and needs. 3D printers will help make your life more comfortable!

Russian scientists have developed a 3D printer to create meat — 07/28/2022 — In Russia on REN TV

One of the advantages of food products created on a 3D printer is the solution to the problem of the so-called "hidden hunger".

Photo: © Global Look Press/Bernd Weißbrod/dpaRussian scientists have developed a 3D printer for creating meat and other food products. The new technology will make it possible to produce not only meat products, but also chocolate, cakes and dough. Scientists of the Moscow State University of Food Production (MGUPP) told "Izvestia" nuances of printed food production.

To make a meat product on a 3D printer, a biopsy is taken from an animal – tissue is plucked off, the cells of which are later multiplied in special bioreactors. However, the process of growing cells takes several months. The second stage is the preparation of raw materials.

However, the process of growing cells takes several months. The second stage is the preparation of raw materials.

"A special plant-based substrate is printed on which live cells are applied. Layers of animal and plant materials alternate", – Alexey Kuchumov, Vice-Rector for Research and Development, told.

One of the advantages of 3D printed food products is the solution to the problem of so-called "hidden hunger". As Kuchumov explained, a person often receives less vitamins, microelements and antioxidants from ordinary foods. It will be possible to add exactly those micronutrients that the human body lacks in printed products.

"We are currently working on a database of smart recipes that will be like instructions for a printer, like a costing card for a chef", - said Alexey Kuchumov.

In the near future, scientists plan to improve the already developed device so that it can print more complex products - sausage, cutlets and even steak. Now the printer is able to create food from relatively simple ingredients: chocolate, dough, puree masses.

Now the printer is able to create food from relatively simple ingredients: chocolate, dough, puree masses.

One of the problems with making and distributing printed food is the cost. The price of such products is many times higher. For example, 3D printed beef is a thousand times more expensive. How to reduce the price, scientists at SCiFi Foods (California, USA) came up with the help of gene editing of a cell line using CRISPR technology.

Russian experts are sure that as soon as technological products become available, the demand for them will increase.

"Bioprinting has a special application value in specialized nutrition. With the help of a 3D printer, it will be possible to create a product that a person needs for health reasons. "Printed" food will not just not be a protein enriched mixture, but food very similar to traditional food" , - told the director of the Federal Scientific Center for Food Systems. V. M. Gorbatova Oksana Kuznetsova.

0006 in]

0006 in]