Object 500 3d printer

Stratasys Objet500 Connex3: World's First Full-Color Multi-Material 3D Printer

Stratasys Objet500 Connex3: World's First Full-Color Multi-Material 3D Printer - Stratasys Stratasys Invests in Axial3D to Make Patient-Specific 3D Solutions Available to All - Learn MoreUSA & Canada

Select your country and region

- Americas

- English

- Español (México)

- Português (Brasil)

- EMEA

- English (United Kingdom)

- Deutsch

- Español

- Français

- italiano

- APAC

- 中文(简体)

- 日本語 (日本)

- 한국어(대한민국)

- English (India)

USA & Canada

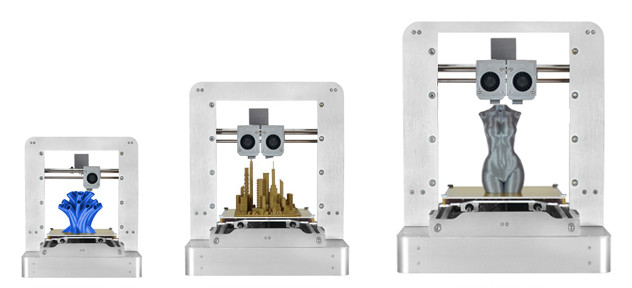

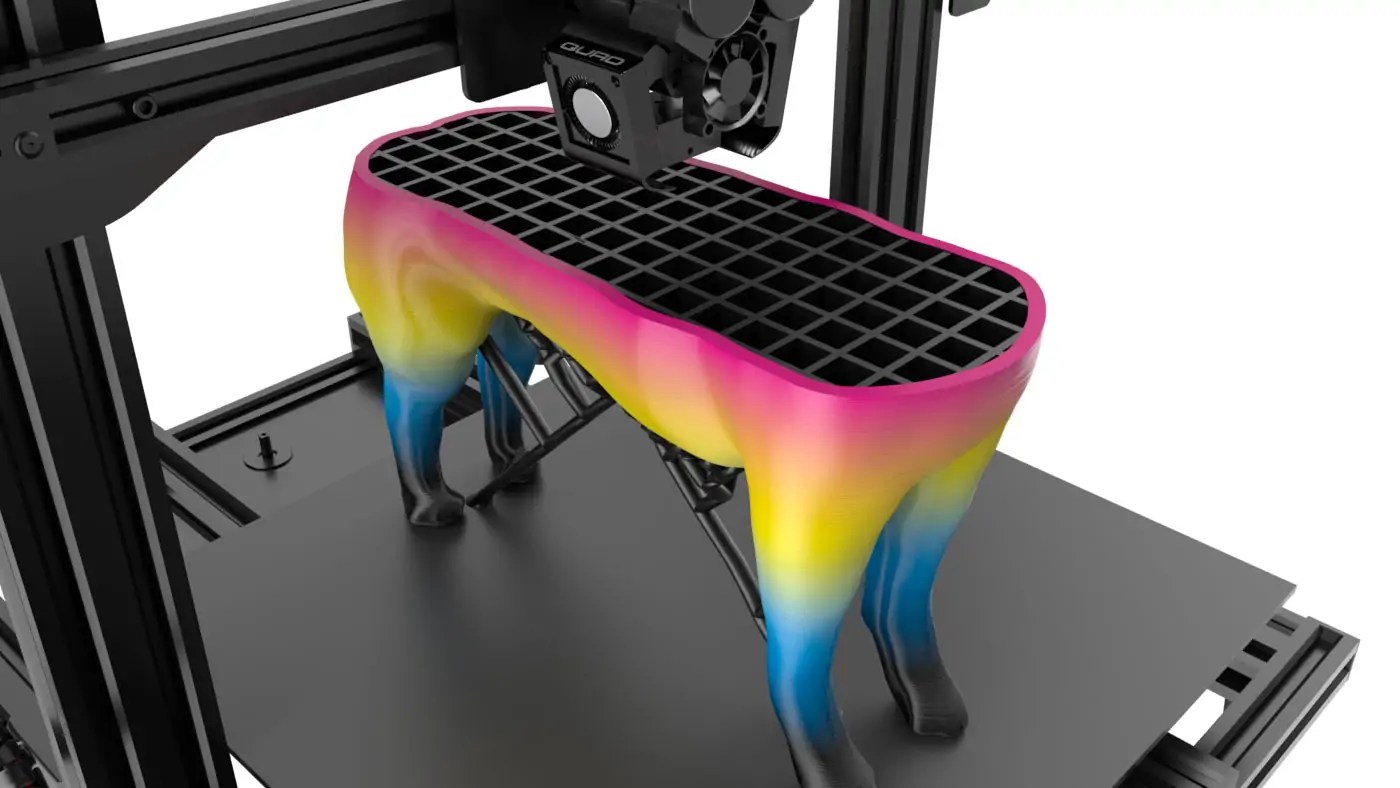

Stratasys 3D printing goes one step further by integrating multi-color, multi-material capabilities. Introducing Stratasys Objet500 Connex3 launch - the world's first color multi-material 3D printer. This printer optimizes design freedom, allows designers to create faster and smarter prototypes. The Objet500 Connex series offers vivid, accurate color and blend composite material capabilities give designers a boundless platform for creativity. Learn more: https://www.stratasys.com/3d-printers/objet-350-500-connex3

The Objet500 Connex 3 optimizes design freedom and allows designers to create faster and smarter prototypes.

Stratasys Objet500 Connex3 3D Printer

| Brand | Stratasys |

| Machine type | 3D Printer |

| Technology | PolyJet and PolyJetMatrix |

| Materials | ABS, Vero, Durable (PP-like) Resin, Tango (Rubber-like material), Digital ABS, Durus, Translucent Rigid |

| Website | http://www. stratasys.com/3d-printers/production-series/connex3-systems stratasys.com/3d-printers/production-series/connex3-systems |

| Average Price | Contact manufacturer |

Unmatched Design Freedom, Brilliant Color 3D Printing

The Objet500 Connex3 bring agility and aesthetics to every stage of your product development and production. The Connex3 system was the first 3D printer in the world to simultaneously 3D print multiple colors and materials. It continues to lead the field with an even broader range of printing capabilities so you can create parts with the precision, look and feel of real production parts. Connex3 delivers incredible efficiency with the power to serve your diverse needs with one system.

Multiple materials can be loaded at one time in the Connex3, enabling you to print parts that require a range of mechanical, optical or thermal properties like non-slip grips, transparent windows or flexible hinges.

Fast, flexible colors can be printed directly from the color information in your original CAD file. Produce smooth three-color gradients, vivid multi-color textures, sleek transparencies or milky opaque colors.

No assembly required for parts 3D printed with multiple materials, so you can create custom jigs, assembly fixtures and tools with ultra-fine accuracy and smooth surfaces.

The point-and-click Objet Studio software makes it simple for anyone to build high-quality accurate 3D models with the Connex3 systems.

Versatile Material Options

Over 1,000 material options are available on the Connex3, enabling you to print both complex and delicate features on your models, re-creating astonishingly realistic production parts. Delivering special material properties such as transparency, flexibility and even bio-compatibility, the PolyJet technology built in to the Connex3 systems offers you a competitive edge in consumer products prototyping, precision tooling and specialized production parts.

SINGLE MATERIALS:

VeroWhitePlus (RGD835), VeroGray (RGD850), VeroBlue (RGD840), VeroBlackPlus (RGD875), VeroCyan VeroMagenta, VeroYellow, VeroBlack, VeroWhitePlus, Vero PureWhite, a brilliant white 20 percent brighter than VeroWhitePlus with twice the opacity

MODEL MATERIALS:

Vero family of opaque materials, including various neutral shades and vibrant colors, Tango family rubber-like flexible materials, Medical: MED610, Digital ABS Plus and Digital ABS2 Plus in ivory and green, DurusWhite RGD430, High Temperature RGD525 white, Transparent: VeroClear and RGD720

DIGITAL MODEL MATERIALS:

Digital ABS Plus, Rubber-like materials in a variety of Shore A values, Vibrant blended colors in rigid opaque, Translucent colored tints, Polypropylene-like materials with improved thermal resistance

Reviews 4.

6 1 reviews

6 1 reviews Print Quality

Reliability

Ease Of Use

Failure Rate

Running Expenses

Software

Build Quality

Customer Service

Community

Show reviews Hide reviews

Mar 21, 2022

Prototyping parts in different colours and materials. Rigid, white, black, transparent, rubber-like.

Omni500 LITE

3D Printer Review Growing industries continue to need innovation. It is a search for new solutions, revolutionary technologies and innovative ideas. Industrial 3D printing has become the solution to these needs. The Omni500 LITE industrial 3D printers are built to print durable, precise, and mechanically, thermally and chemically resistant large-scale models. This is exactly what modern industry needs. Find out what the Omni3D features, where it is used, what materials are used, and how to properly set it up.

It is a search for new solutions, revolutionary technologies and innovative ideas. Industrial 3D printing has become the solution to these needs. The Omni500 LITE industrial 3D printers are built to print durable, precise, and mechanically, thermally and chemically resistant large-scale models. This is exactly what modern industry needs. Find out what the Omni3D features, where it is used, what materials are used, and how to properly set it up.

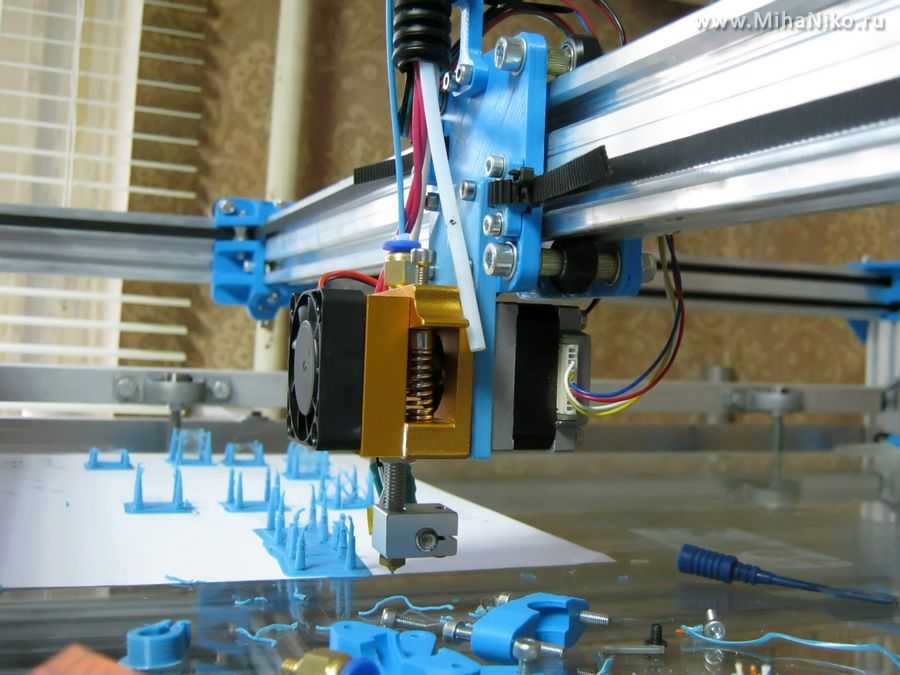

Omni500 LITE 3D Printer Overview

The Omni500 LITE industrial 3D printers are designed for advanced, fully functional prototypes as well as final products. Items can be printed as separate models. At the same time, technologies can be personalized according to individual customer needs. Industrial 3D printing allows the production of interchangeable elements, often with properties that exceed the physical characteristics of the final parts created in the traditional way. The Omni500 LITE can also print test items to help you develop new solutions.

Printer description

The Omni500 LITE 3D Printer is ideal for demanding customers who want a quick and easy tool to work to industry standards.

46 x 46 x 60 cm build volume allows you to print small 3D models and large objects at the same time. The printer is equipped with two high-precision heads with a filament sensor, which allows you to print on two different materials during one print session. The machine can be managed through a dedicated website, making it easy to start printing and manage it remotely.

Attention! It is possible to create and manage a set of printers online.

Highlights

Omni500 LITE is the ideal solution for users who need to combine industry standard with speed and ease of production. Among the main features are the following:

- Ability to connect to a local network and Wi-Fi. The device can be connected to the Internet to start/stop printing and manage it remotely.

- Large objects or several smaller 3D models can be created on the same table at the same time.

- Closed and insulated chamber allows the use of customized materials that are difficult to produce ABS.

- Automatic calibration optimizes operator work for fast and efficient 3D printing.

- Uses Fused Fiber Technology (FFF) for printing.

- The cooking plate is heated and has a glass surface.

- Production accuracy +/- 0.2% is ensured by the presence of screw gears in all axes.

- The maximum print speed reaches 86 cm³/s, which allows you to quickly print a high quality product.

- You can use SD cards, Internet, Wi-Fi to transfer data for printing.

- Compatible file extensions are *.stl, *.3mf, *.gcode, *.obj, *.factory.

- The Omni500 LITE model 3D printer consumes a maximum of 2.0 kW, which is quite low for similar devices.

- The equipment comes with a 12 month warranty and an option to extend the warranty period up to 24 months.

Important! Also among the advantages of the printer are lighter weight compared to analogues, air filtration inside the camera, as well as the presence of a webcam inside the device.

The device works not only with plastic filaments from Omni3D, but also with filaments from other manufacturers.

Equipment

When purchasing a 3D printer model Omni500 LITE, the user receives all the necessary support package:

- the ability to check before use;

- sample sheet for printing a test model and checking the print quality;

- a complete set of tools for working with the device;

- high-strength industrial printing materials;

- Power supply 230V/50Hz (optional 110V/60Hz).

The Omni500 LITE comes fully assembled and ready to print on delivery. The device is completed with packaging, a substrate, a detailed operation manual and a warranty card.

Omni500 Lite 3D Printer

- Control connection interfaces SD card; Ethernet; WiFi

- Maximum platform temperature for printing 130 °C

- Max extruder temperature 360°C

- Chamber temperature 50 °C

- Print Accuracy +/- 0.

2%

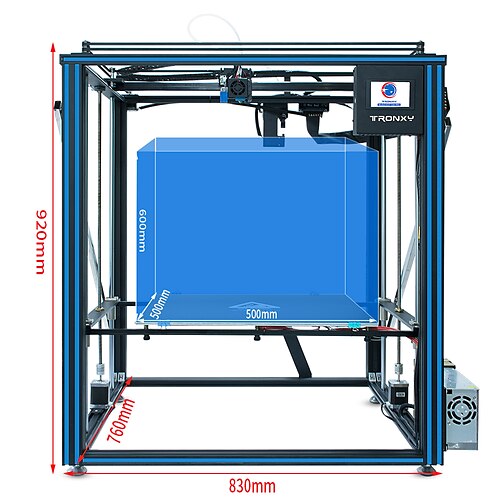

2% - Working chamber area 460x460x600 mm

- Speed 86 cm³ / h

- Layer thickness from 50 µm

- Thread diameter 1.75 mm

- Nozzle diameter, mm 0.4

- Display LCD touch control panel 7"

- Print technology FFF

- Weight, kg 150

- Supported Software Simplify3D

Go to product

Print quality and product examples

The device can create first-level prototypes and high-quality accurate functional models, which optimizes testing time and reduces costs.

Compact and easy to operate, the Omni500 LITE 3D printer uses FFF technology to produce large models from the toughest resins.

Automotive:

Aircraft:

Medical industry:

Other industries:

Who will use the devices: Applications

The Omni500 LITE 3D printer allows you to make a visual layout, produce spare parts and specialized parts for various industries.

The device is actively used in the following industries:

- automotive industry;

- civil, military and space industry;

- medical field;

- 3D printed molds in casting.

Automotive

Parts manufacturing has a long history in the automotive industry at all stages of production, from prototyping to the production of parts and final automotive components. The affordable materials used to print the Omni500 LITE 3D printer make it possible to print not only lightweight, but also extremely durable automotive components.

The use of 3D printing in the automotive industry makes it possible to optimize the time and cost of manufacturing parts, as well as identify problem areas in projects at an early stage of design. This allows you to quickly eliminate all the shortcomings and reduce the loss of materials. The use of 3D models makes it possible to reduce the final weight of a car or part of it.

3D printing in the automotive industry is important for efficiency in manufacturing and design:

- design check;

- assembly and testing of equipment;

- creation of end pieces and spare parts for machines;

- efficient prototyping required for design verification;

- reducing the time and cost of project development;

- light post-processing.

Reference. Small-scale production makes it possible to produce equipment for special purpose vehicles, such as ambulances or police cars. It is possible to produce finished parts to facilitate racing cars.

Civil, military and aerospace

The ever-changing transport conditions used in aviation must constantly adapt. With the Omni500 LITE, this is very easy to do and at a significant cost reduction. 3D printing has significantly expanded the capabilities of the aircraft industry, making the process of designing and then manufacturing parts more flexible, creative and cheaper.

Some of the benefits of using the Omni500 LITE in aviation include:

- low production cost;

- reduction of time to obtain the final product;

- the opportunity to expand the boundaries of creativity.

The manufacturer's high resolution Omni3D printer makes it easy to print aircraft models, aircraft parts and other designs. For the manufacture of 3D models, modern high-strength materials are used, which makes it possible to improve and reduce the cost of production in the aircraft industry.

Medical industry

3D printing helps support the medical industry and take it to the next level. Omni500 LITE is used at the stage of preparation for surgery. Allows you to print high-precision models, for example, of the spine, to make surgical analysis and reduce the risk of errors during the operation.

Omni500 LITE is used at the stage of preparation for surgery. Allows you to print high-precision models, for example, of the spine, to make surgical analysis and reduce the risk of errors during the operation.

Reference. 3D models are actively used to create school and academic textbooks. The printer can print models of organs, which were economically unprofitable to manufacture in small-scale production.

The use of the Omni500 LITE in the medical industry allows you to tailor conditions to the individual needs of patients, reduce risk through the analysis of anatomical models, and carry out high-quality preoperative planning.

Among the advantages of using this printer in the medical field are:

- individual and fast printing;

- creation of anatomical models;

- saving time;

- cheaper production.

Using the device from the manufacturer Omni3D allows you to print neuroanatomical models that are useful in the work of neurosurgeons. Such models provide a representation of the most complex structures of the human body, which allows you to make the correct diagnosis and prepare for surgery.

Such models provide a representation of the most complex structures of the human body, which allows you to make the correct diagnosis and prepare for surgery.

Application of 3D printing in casting

The main element of modeling is the model. It is surrounded by molding material, silicone or ceramics - on this basis, a mold is created that will be needed in the further process.

Preparation of equipment for the production of molds using traditional CNC machines is a series of complex activities, including design of the processing process, preparation of machine tools and tooling equipment. This is time consuming and requires a lot of employee input, and often the resulting model requires further processing.

3D printing technology can significantly reduce the cost and time spent on a project, while maintaining the accuracy of the final form. 3D printing also eliminates the disadvantages that result from incorrect filling of the mold with material. The Omni500 LITE allows you to achieve flexibility in operation, as well as reduce processing time.

Attention! The machine can be used for mold prototyping before mass production, wax patterns for casting molds, parts in the small-scale production industry, as well as in jewelry.

Among the main advantages of using the device are the following:

- shortening of production processes;

- production of small series without increasing costs;

- limitation of labor participation in the production process.

Casting patterns created with this printer enable the production of individual items and short series production. The result is an exact copy of the product printed on the printer.

What materials are used?

The printer uses high-quality materials that have different purposes:

- ASB -42. Standard thread for universal use. Differs in high mechanical durability and is easily exposed to post-processing.

- ASB-20C. Modified material with increased flexibility.

Solid and impact resistant, ideal for industrial model building.

Solid and impact resistant, ideal for industrial model building. - ASA-39. It is used to create products that are resistant to atmospheric conditions, especially UV radiation. Possesses the increased durability.

- PAT-G-32. The material has low shrinkage. Used to create high-precision models in the medical industry.

- HIPS-20. Printed elements from this thread can be subjected to post-processing, such as gluing, sanding or painting. A safe material commonly used to produce packaging suitable for food contact.

- PLA-36. Biodegradable polymer. It is a versatile material for use in various industries.

All Omni3D materials are interchangeable with other manufacturers.

Initial setup and preparation instructions

The printer is shipped ready to use. To start using it is necessary:

- open the cover on the top and right side;

- insert material into the consumables compartment;

- hang the material spools in place;

- insert the end of the rod into the conductive tube;

- check that the media is securely loaded in both printheads;

- enable automatic calibration;

- send the sketch file for printing.

Important! The kit comes with a detailed instruction manual for the equipment, which should be read before starting work.

The Omni500 LITE is a great option for industrial users who want a quality, affordable and compact printer to bring their ideas to life, pre-design and print quality 3D models. The high speed and accuracy of printing allows the device to be used in various industries in order to reduce the cost of producing spare parts and large objects.

- October 03, 2020

- 401

Get expert advice

SLM Solutions SLM 500 Metal 3D Printer - Scientific Equipment

SLM 500 - Selective laser metal melting machine with a large working chamber (500 x 280 x 365 mm). It is used for single and small-scale production of complex products from special metal powders: stainless and tool steel, aluminum, titanium alloys, inconels, cobalt-chromium. The SLM 500 is the most productive selective laser melting machine among all SLM machine formats on the market. The process of building products is fully automated and does not require the presence of an operator after starting the machine.

The SLM 500 is the most productive selective laser melting machine among all SLM machine formats on the market. The process of building products is fully automated and does not require the presence of an operator after starting the machine.

Versatility and multitasking

Equipped with 2 or 4 lasers at once, the SLM 500 offers the best solution for any production need. The ability to adjust the laser spot makes it possible to choose between maximum accuracy or high speed building on simple areas. With a configuration of 4x400W or 4x700W lasers operating simultaneously, it is possible to increase productivity by up to 90% compared to a 2x400W or 2x700W system.

Large build area

The SLM 500 laser melter enables the creation of large objects. The dimensions of the construction chamber well (500x280x365 mm) make it possible to build large products not as separate units and components, but as a whole. It is also possible to build several “small” products, including those based on different 3D models, in one cycle.

High speed and precision printing

SLM 500 3D machine capable of producing up to 105 cm 3 metal products per hour. The unit is the flagship of the series and outperforms the nearest medium format model (SLM 280) by 2 times in efficiency. The minimum wall thickness is 150 µm. The laser spot is automatically adjusted from 80 to 115 microns, and the minimum layer thickness is only 20 microns!

Automatic powder cleaning system

The SLM 500 is equipped with a module for cleaning and sifting unused powder. After you remove the finished part, the system will automatically filter out the remaining powder and prepare it for further use. Thus, the loss of material during the cleaning of prototypes or the change of material is no more than 4-5%.

Wide range of materials

Stainless, tool steels, aluminium, titanium alloys, titanium, inconels, cobalt-chrome. The most reliable, proven and versatile materials are at your disposal. Also, the SLM 500 system can be made to work with the material or alloy you need.

Also, the SLM 500 system can be made to work with the material or alloy you need.

Customizable software

The SLM 500 3D laser melting system comes pre-installed with special software - Metal build processor (jointly developed by SLM Solutions and Materialize (Belgium). The software, thanks to the flexibility of customization, allows you to optimize manufacturing processes and reduce build time.

Wide range of applications

The SLM 500 is used to create complex geometries, often with thin walls and cavities. This 3D machine is widely used in mechanical engineering, heavy and light industry, defense and aerospace, science and research - wherever you need to quickly and accurately produce complex metal products.

Absolute safety

The unit is equipped with a fire and explosion safety system for building products, including from reactive powders of fire hazard class D. The process of building products takes place in an inert gas atmosphere nitrogen or argon (depending on the type of powder used).