Nike 3d print

How Nike Is Leveraging 3D Printing In The Footwear Industry

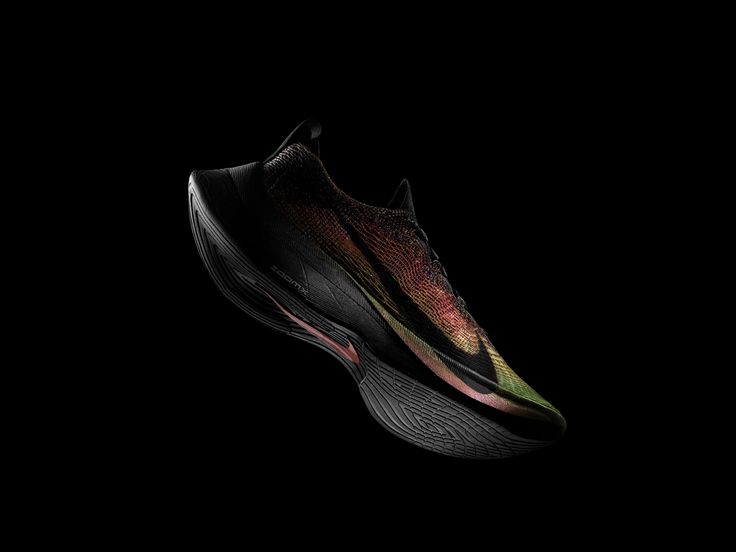

Above: Nike started experimenting with 3D printing as early as 2013/Image Source: NikeNike incorporated 3D printing in the footwear industry as early as 2013. Initially it went through an experimental phase to find a suitable fit for its products. As the years went by backed with a strong corporate push the company benefited from its commitment to the technology by launching back-to-back successful 3D printed shoes.

Nike Inc. is an American multinational corporation that is engaged in the design, development, manufacturing, and worldwide marketing and sales of footwear, apparel, equipment, accessories, and services. The Oregon-based company is the world’s largest supplier of athletic shoes and apparel and a major manufacturer of sports equipment globally.

We explore how Nike transformed the footwear market by using 3D printing technology.

Table of Contents

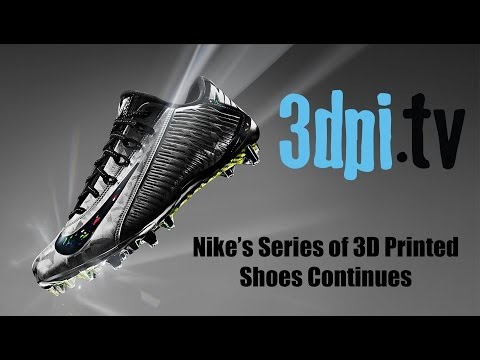

Early ExperimentsAbove: Nike Vapor Laser Talon/Image Source: NikeNike decided to bring 3D printing in the footwear industry and it first began experimenting with the technology in 2013. It was during this time that it developed and released the Nike Vapor Laser Talon – the ‘first-ever football cleat built using 3D printing technology’. The company used Selective Laser Sintering (SLS) 3D printing technology to manufacture the plate of the cleat by using a proprietary material. Interestingly, the Nike Vapor Laser Talon weighed a mere 156 grams and designed to provide optimal traction on football turf and to help athletes maintain their “drive stance” longer.

This was a successful product, however, the company did not fully invest in additive manufacturing until 2016 through a partnership with HP, the developer of the highly celebrated MultiJet Fusion technology.

At that time, Nike’s President of Innovation, Tom Clarke said, “We are excited to partner with HP to accelerate and scale our existing capabilities as we continue to explore new ways to manufacture performance products to help athletes reach their full potential.”

Early Collaborations2016 was the year when Nike focussed its energy to leverage the potential of 3D printing in the footwear industry. By partnering with HP, Nike developed a 3D printed track spike, the Nike Zoom Superfly Flyknit. On the developmental side, Nike collaborated with the American sprinter Allyson Felix before the Rio 2016 Olympics. Such collaborations with high-profile professional athletes are at the heart of Nike’s product development philosophy.

By partnering with HP, Nike developed a 3D printed track spike, the Nike Zoom Superfly Flyknit. On the developmental side, Nike collaborated with the American sprinter Allyson Felix before the Rio 2016 Olympics. Such collaborations with high-profile professional athletes are at the heart of Nike’s product development philosophy.

According to Mark Parker, the then CEO of Nike, “Always, always, the elite athlete still leads our design. What we learn from them is who we are. 3D printing will define product development for the next generation of elite Nike products.”

Corporate Push for 3D Printing in the Footwear IndustryAbove: NIKE, Inc. Chairman, President and CEO Mark Parker, shared Nike’s new corporate strategy titled the Consumer Direct Offense/Image Source: Nike2017 was an important year for Nike when after a considerable period of stagnant revenues, the brand decided to unveil a new corporate strategy to lead them to the next stage of growth.

The new corporate strategy titled the Consumer Direct Offense, is meant to generate the next wave of long-term company growth and profitability. The core of the strategy is Nike’s Triple Double strategy, which focuses on three pillars to generate 2X revenues. The three pillars being 2X Innovation, 2X Speed, and 2X Direct, which means to double the cadence and impact of innovation, doubling the speed to market, and doubling the direct connections with customers. Additive manufacturing / 3D printing is at the core of the first two pillars of this strategy.

The core of the strategy is Nike’s Triple Double strategy, which focuses on three pillars to generate 2X revenues. The three pillars being 2X Innovation, 2X Speed, and 2X Direct, which means to double the cadence and impact of innovation, doubling the speed to market, and doubling the direct connections with customers. Additive manufacturing / 3D printing is at the core of the first two pillars of this strategy.

Thus the corporate initiative led to huge investments in 3D printing technology and the focus shifted from traditional manufacturing to explore and deliver products through additive manufacturing.

Professional CollaborationsAbove: Eliud Kipchoge shows the 3D printed shoes he used to run the INEOS 1:59 Challenge/Image Source: NikeWith successive successes with 3D printing and the corporate push in 2017, Nike saw expansion in investments for full-time focus on capitalising 3D printing in the footwear industry. In 2017, Nike collaborated with the world’s fastest marathoner, Eliud Kipchoge to develop the Nike Zoom Vaporfly Elite. Eliud wore the 3D printed shoe to run in the Berlin Marathon in 2017. Even though the 3D printed shoes were super lightweight but they had some minor issues which Kipchoge pointed out.

Eliud wore the 3D printed shoe to run in the Berlin Marathon in 2017. Even though the 3D printed shoes were super lightweight but they had some minor issues which Kipchoge pointed out.

The Nike designers reworked the design and produced a new version of the shoe named the Nike Flyprint – the first shoe in performance footwear with a 3D-printed textile upper. The tests started in early 2018 with Kipchoge and in spring 2018, Kipchoge wore it to run the London Marathon 2018.

With further modifications, Kipchoge again wore the Nike Flyprint to the Berlin 2018 Marathon to set a world record time and become the fastest marathoner. Following this, Kipchoge again used the Flyprint to run the INEOS 1:59 Challenge to break one of the final running barriers – the sub-two-hour marathon. Though not officially considered Kipchoge managed to break the barrier wearing the Nike Flyprint.

Rapid DevelopmentsAbove: Marathoner Eliud Kipchoge noted observations and passed them onto Nike/Image Credit: NikeThe development of Nike Flyprint saw the translation of complex athlete performance data from the Nike Sports Research Lab into prototype iterations with unprecedented speed and precision.

As recent as last year, Eliud Kipchoge was sponsored by INEOS for INEOS 1:59 Challenge to break one of the premier barriers in running – the sub-two-hour marathon. Kipchoge took the challenge to run the race with a modified version of the Nike Flyprint.

The rapid pace of new developments at Nike shows the speed of innovation 3D printing can provide. This pace is hard to match by any other existing manufacturing process.

(Note: The INEOS record set by Kipchoge was not official as standard competition rules of pacing and fluids were not followed and so the completion time of 1:59:40 is not considered as a world record but Kipchoge is still the fastest marathoner with his record-setting run in Berlin 2018 with a time of 2:01:39)

3D Printing in the Footwear Industry Combined with Athlete DataAbove: Nike started experimenting with 3D printing as early as 2013/Image Source: NikeTo manufacture the Flyprint upper, Nike used Solid Deposition Modelling (SDM) with a TPU filament, similar to a regular fused deposition modelling technology to develop the 3D printed shoe upper.

Using a proprietary variant of the popular FDM 3D printing technology named as Solid Deposition Modelling (SDM), Nike looks at normalizing 3D printing in the footwear industry. It is focusing its expertise on fabricating lightweight shoes by the use of flexible filament (TPU) to print the upper fabric.

The Nike Flyprint method starts with capturing the athlete data. This data records how the athlete runs and uses his feet. This data is then transported to computational designing software to appropriately design the material composition. This formulated data is then utilized by the SDM 3D printer to print the flexible upper fabric.

The fabric can be so structured that individual lines can be adjusted locally without affecting the global structure. This helps in location-specific rigidity & slackness. 3D printing the fabric also allows unique weaving designs to allow more breathing design at the same time being light in weight.

This process again establishes the fact that footwear manufacturing is changing. Footwear, popularly manufactured through the molding process, is now being additively manufactured. And most importantly the use of data in manufacturing is taking customization to a depth never envisaged before.

Footwear, popularly manufactured through the molding process, is now being additively manufactured. And most importantly the use of data in manufacturing is taking customization to a depth never envisaged before.

By concentrating serious efforts on leveraging 3D printing in the footwear industry, Nike has been able to develop new and innovative products. It has taken a unique approach to using the technology by producing only the 3D printed shoe uppers.

The current competition comes not only from industry veterans like Adidas, New Balance, Reebok, Under Armour but also from comparatively new Startups that also aim for a share in the footwear market.

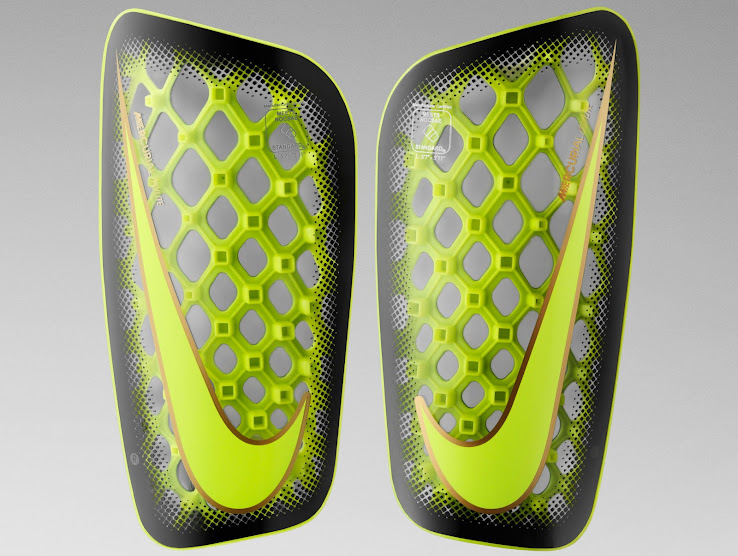

But while 3D printing in the footwear industry is fairly new, Nike might already be experimenting with other sporting equipment. The space is still ripe for other sports equipment like tennis rackets, soccer balls, and golf clubs.

About Manufactur3D Magazine: Manufactur3D is an online magazine on 3D printing. which publishes the latest 3D printing news, insights and analysis from all around the world. Visit our 3D Printing Education page to read more such informative articles. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn.

which publishes the latest 3D printing news, insights and analysis from all around the world. Visit our 3D Printing Education page to read more such informative articles. To stay up-to-date about the latest happenings in the 3D printing world, like us on Facebook or follow us on LinkedIn.

Acronym launches new 3D printable Nike trainer DLC, makers go wild

0Shares

German footwear firm Solebox and fashion designer Acronym have partnered with a team of Berlin-based creatives to come up with a novel range of downloadable content (DLC) for Nike trainers.

Debuted at the Solebox-hosted ACRONYM Dynamics Lab event, these removable heel clips are designed to be 3D printed and fitted to special edition Nike Blazer Lows, as a means of providing them with a personalized visual flourish.

Since the firm’s ten original DLC models were showcased last month, makers have gone on to come up with a range of other distinctive designs, with many taking inspiration from cultural touchstones such as Evangelion and Death Stranding.

Introducing ‘DLC’ for trainers

Held in early February, ACRONYM’s Dynamics Lab workshop was organized by its Founder Errolson Hugh, who, having struck a deal with Nike to collaborate on a footwear collection, was seeking out ways of customizing their new collection.

At the event, a group of ten creatives managed to dream up several unique heel clip designs for Hugh’s NIKE X ACRONYM range, which were then 3D printed in TPU and showcased at a special exhibit on February 10, 2022. Designed to be a ‘reinterpretation’ of Nike’s Blazer Lows, the sneakers’ swappable accessories are said to be inspired by ‘Bōsōzoku,’ a Japanese motorcycle-customizing subculture.

As a result, each NIKE X ACRONYM shoe doesn’t just feature custom logos across their tongue, liner and heel, but a range of rear-mounted add-ons. Marketed as sneaker ‘DLC,’ that offers “a futuristic take on one of Nike’s esteemed heritage looks,” these fresh heel prints have now been made free to download, but predictably, the maker community has also added to these with designs of their own.

Sneaker DLC: the makers respond

Typically of the 3D printing community, makers have taken Acronym’s idea and ran with it, in a way that has yielded a variety of conceptual designs that are bound to draw some attention to whoever’s wearing them. Take Art Director les83machines’ Evangelion-inspired designs, for instance. The creative’s models feature bold, complex, sharply-pointed layouts, that are reminiscent of the show’s characters.

les83machines’ Evangelion-inspired NIKE X ACRONYM design. Image via les83machines, Twitter.Elsewhere, toy designer nixon has also managed to create a design featuring a ‘bridge baby’ from the popular video game Death Stranding. In the game, the seven-month-old foetuses are used as a connection between the world of the living and the dead, and they’ve become a popular icon among fans, even making a cameo in Cyberpunk 2077.

nixon’s Death Stranding ‘bridge baby’ heel attachment design. Photo via nixon.

Photo via nixon. Hugh himself has also popped up on Instagram to share images from the launch of his new footwear range, which he calls “DLC for your Blazers, DLC for your brain.” Thankfully, the creative has already promised that the project “won’t be the last” of its kind that he takes part in, so it could well be the case that we see further iterations from Acronym as well.

Can I buy a pair of NIKE X ACRONYMs?

According to Youtuber This Is Antwon, who has already got his hands on a pair of the new sneakers, they can now be bought for around $140. In his review, the footwear and fashion vlogger complemented the upmarket look and feel of the shoes, particularly the contrast colored laces and heel blocks that came with them, although he suggested that wear and tear makes constant switching inadvisable.

Given the status enjoyed by the original Blazer Lows in the skating community, Antwon also took them on a ‘skate-test,’ in which he found that their relatively good value may come at the cost of sole durability. That being said, he was keen to point out that Acronym’s shoe has added utility to a sportswear classic in a way that “Nike would never do itself,” and its heel gives it “great long-term appeal.”

That being said, he was keen to point out that Acronym’s shoe has added utility to a sportswear classic in a way that “Nike would never do itself,” and its heel gives it “great long-term appeal.”

“We’ve already seen some really really cool iterations and ideas as to what you can do here, and that’s only going to increase with time,” said This is Antwon in his video. “I’m really looking forward to seeing what people manage to come up with, to modify and customize. I think it’s awesome that what Acronym has done here, is not just build a product you can buy, but a platform for your creativity.”

“The sky’s the limit, with what you could achieve with this.”

Those looking to get creative with a pair of NIKE X ACRONYMs, can either access one of the designs developed at the ACRONYM Dynamics Lab event here, download les83machines’ Evangelion-inspired design here or come up with a style entirely of their own.

Innovative 3D printed footwear

Where 3D printing has been used to realize various innovative footwear designs in the past, it tends to have been deployed by manufacturers rather than makers themselves. German sportswear giant Adidas, for instance, continues to work with Carbon to innovate upon its 3D printed ‘4DFWD’ midsole, which in turn, was incorporated into the shoes worn by many athletes at the Tokyo Olympic Games.

Likewise, CRP Technology has deployed its 3D printing capabilities and Windform SP carbon fiber material to create a unique athletics track shoe. Working with Venetian middle-distance runner Miro Buroni in October 2021, the firm was able to LPBF 3D print the ‘Pleko’ spike shoe in a single-piece, including its outsole, midsole and pins.

Last summer, in a similar, albeit less sporty application, Hush Puppies also agreed to incorporate Voxel8 3D printed insoles into its upcoming designer footwear range. By adopting additive manufacturing, the firm anticipated at the time being able to not only simplify its production workflow, but accelerate the products’ time to market.

To stay up to date with the latest 3D printing news, don’t forget to subscribe to the 3D Printing Industry newsletter or follow us on Twitter or liking our page on Facebook.

For a deeper dive into additive manufacturing, you can now subscribe to our Youtube channel, featuring discussion, debriefs, and shots of 3D printing in-action.

Are you looking for a job in the additive manufacturing industry? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows one of the ten original 3D printed heel designs for the Nike Blazer Low trainer. Photo via Nike.

Photo via Nike.

Tags Acronym adidas Carbon CRP Technology Errolson Hugh Hush Puppies les83machines Miro Buroni Nike Nike x Acronym nixon Solebox This is Antwon Voxel8

Paul Hanaphy

Paul is a history and journalism graduate with a passion for finding the latest scoop in technology news.

Best Nike・Cults

3D Printing STL FilesMuscular Cai Shen / God of Wealth

20 €

NIKE PEN HOLDER / VASE / FLOWER POT

€1.50 -10% 1.35 €

Jordan Nike 9 logo cookie cutter0003

0.61 €

Nike Jordan sneakers cut out of cookies

0.61 €

shoes Nike

0,50 €

Air Jordan 1

1 € -20% 0. 80 €

NIKE CLIP (width 20 mm)

Free

NAME BRIAN WITH NIKE LOGO - LED LAMP WITH NAME

6 €

flower pot correctly sneakers nike air jordan

1,50 €

"Chicago" replica inspired by Shoeuzi

6.43 €

nike air jordan 4 right and left shoes

8€ -69% 2.48 €

nike air jordan 4 left shoes

5 € -70% 1.50 €

nike air jordan 4 correct shoes

5 € -70% 1. 50 €

NIKE AIR JORDAN CHICAGO LAMP black top

3 €

nike air jordan 4

5 € -70% 1.50 €

JORDAN CANDLE MOLD 1

1.75 €

Nike Air Logo

0,50 €

Jordan 1 - Nike

Free

Astro Boy boots (boots, mschf)

2,05 €

Jordan Potty Shoe

Free

Performance running shoe

Free

PACK Sports branded keyrings

0.50 €

jordan 1 travis scott

Free

Jordan 4

Free

nike dunk

Free

NIKE AIR JORDAN BOX 1

1. 75 €

F*ck You Shoe Lave - Lace Lock

2,50 €

NIKE JORDAN AIR FORCE ONE - 4 COLORS, FULLY PAINTED IN STUDIO PS & BAMBU

1,99 €

shoes Nike

2.81 €

Grinding machine NIKE

1.30 €

Air Pipen

12.72 €

nike air max

12.72 €

nike jordan

2 €

Nike lace lock

€9.99 -50% 4.99 €

NIKE X BIGFOOT JORDAN 1

€3.50

YEEZY BOOST 350

3,50 €

key rings with trainers' logos

1. 94 €

Jordanian neon lamp

1.49 €

Mickey Mouse Beast

Free

jordan air 1 low keychain multicolor

€0.84 -20% 0.67 €

nike AF1 tennis buckle large

1.08 €

Buckle with NIKE symbol large

1.08 €

Nike Air Jordan 1

1.75 €

Nike Air Jordan 1 Retro

10.25 €

Nike Logo

Free

Buckle with NIKE symbol small

1.08 €

NIKE DUNK CUSTOMIZED KEYRING

€1. -40% 0.63 € 05

Signature key rings

0.58 €

Adidas and Nike will print shoes on a 3D printer in the presence of a client

Fresh number

RG-week

Rodina

thematic applications

Fresh number

9026 Technologies 900012.10.2015 13 13 13 :50

Denis Kuznetsov

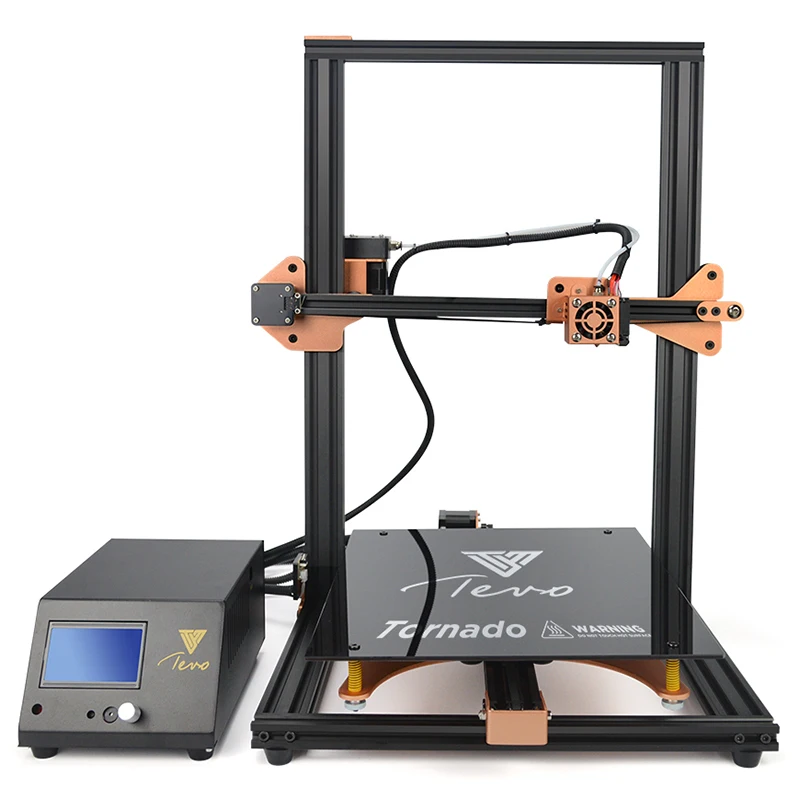

Global corporations that produce sports shoes have made great strides in the development of 3D printing (replication) of sneakers in recent years. And according to the latest industry news, they are now looking for ways to "print" shoes in accordance with the individual characteristics of the foot of the buyer and in his presence.

Adidas Group recently unveiled the concept of the Futurecraft 3D running shoe, with a custom-made outsole created using a 3D printer.

"Adidas is committed to the fact that the buyer can walk into the store and, after spending only a few minutes on the treadmill, receive a 3D-printed pair right on the spot," says the release received by RG. A cast of the foot that accurately follows the contours of the foot and clearly shows the pressure points while running, will help you choose shoes that make every run truly exceptional.

Futurecraft 3D, co-created with 3D printing pioneer Materialize, is just the first part of Adidas's Futurecraft series, and the alliance's goal is to innovate throughout the production cycle, the announcement goes on to say.

In the next six months, Adidas has promised to introduce other design innovations.

In parallel with Adidas, another global footwear giant, Nike Corporation, which, according to its website, has been introducing 3D printing since 2012, is moving in parallel. In terms of marketing, she went even further and is ready to start the production of shoes right at the consumer's home.

This became known during the summit, organized by the specialized American Internet publication GeekWire.

"Imagine this scenario: you logged into the Internet through your home computer, bought a file on the Nike website that contains all the necessary data: type of shoe, individual characteristics of your foot, design and color, the publication writes.