New school 3d printing

3D Print Lab - Parsons Making Center

Previous

Previous:

Laser Lab

Open to: all students who have taken the mandatory orientation

Sheila C. Johnson Design Center, 2 W 13th St, 2nd Floor • Mon-Friday 10-6pm // Sat-Sun 11-7pm

Academic Year 2022-23 Update

The 3D Lab will be open until Dec 18th. From Dec 19 – Jan 2nd the lab will be closed for maintenance and xmas break. Open hours in January will be updated soon.

Welcome to the 3D Lab. To use the lab you must:

- Complete a Mandatory Orientation, located in Canvas, pleas locate the red button below title Take the Orientation. (Do this once, before you ever use the lab)

- Book a Technician Consultation (Do this every time you need to use the lab)

If you have questions about 3DLab access email 3dlab@newschool. edu

Mandatory Orientation

Students and faculty are required to complete an orientation before using the lab. Working knowledge of CAD is necessary.

The 3D Lab is now offering online orientations via the Canvas platform (sign into the “Making Center Trainings and Authorization” course in Canvas using your NetID/password, go to the Modules section, and complete the “3D Lab (Digital Tools)” module.)

Once you have completed the quiz and filled in the form at the end you have immediate access to the lab. Remember, you must still book a consultation every time you want to use the lab.

Faculty:

- interested in class orientations: The lab does not offer class orientation however we do offer a limited amount of lab introductions, which take about thirty minutes. During the introduction we briefly go over all aspects of the lab, this is not a training period.

Because the lab is busy we cannot guarantee every class this accommodation. Faculty are expected to attend the introduction. Please give us one to two weeks advance notice so we can clear the calendar. To request a lab introduction email the lab at [email protected].

Because the lab is busy we cannot guarantee every class this accommodation. Faculty are expected to attend the introduction. Please give us one to two weeks advance notice so we can clear the calendar. To request a lab introduction email the lab at [email protected]. - interested in mobile 3D printing class cart: We now have a mobile cart with a Pursa 3D printer on it that you can bring to your class to use for a demo. Please email the lab at [email protected] to learn more.

Technician Consultation

After you have completed the orientation you must schedule a consultation each time you want to print. You must have a finished 3D model (.stl or .obj) before making a consultation. Creating, editing, or repairing of 3D models is the responsibility of the student. A consultation is a 30 minute meeting where we will:

- Check over your 3D model

- Discuss material/printer options

- Pay for the material (if you are bringing your own material, please read this document)

- Export your file ready to be printed

- Add you to the printing waitlist if there is not a printer immediately available

Note: Consultations do not guarantee immediate use of the 3D printer. You may have to wait until a machine is free or be put on a waitlist to print as soon as one becomes available.

You may have to wait until a machine is free or be put on a waitlist to print as soon as one becomes available.

Please also make a consultation if you are interested in using one of the 3D scanners.

Project Submission Queue

Projects are processed in the order they are received. Please check the log below for current status.

About the 3D Print Lab

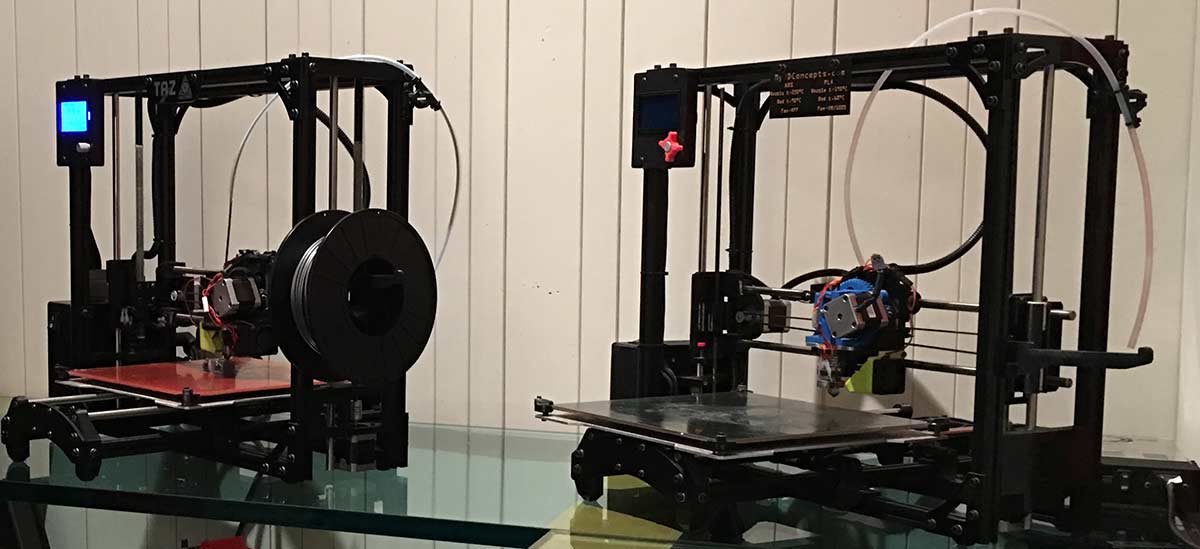

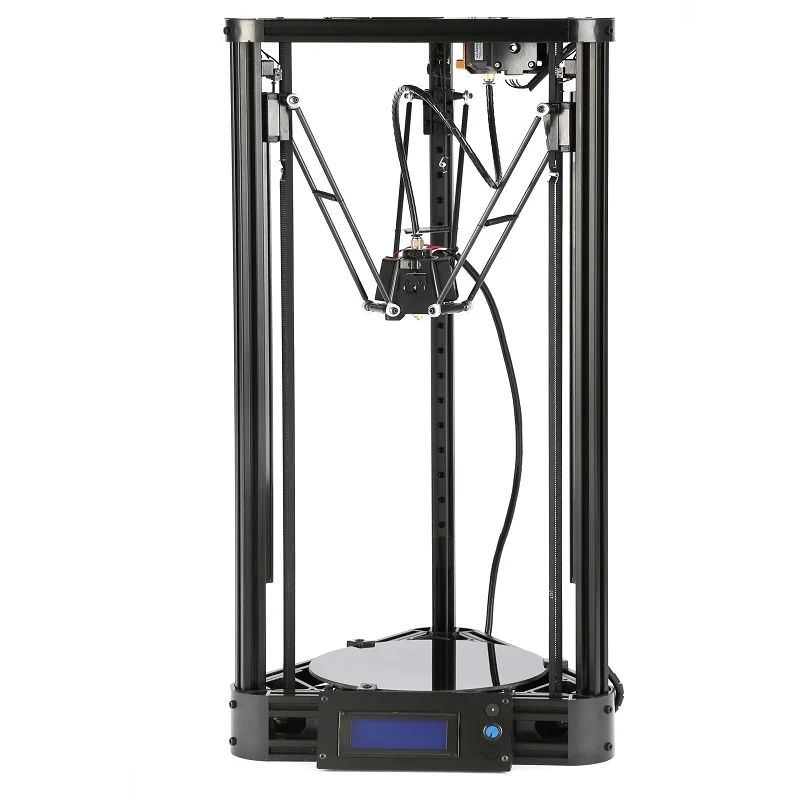

The 3D Print Lab is a Making Center workspace dedicated to creative exploration using various 3D technologies. The lab consists of a range of technological equipment including; 3D scanners, haptic modeling devices, and 3D printers.

We DO NOT accept prints that exceed 24 hours in print time.

We are NOT a self service lab.

Do not start your print after hours.

You will be banned for the semester!

Featured Equipment and Tools

- Ultimaker 2+ Extended

- Markforged Mark Two

- Structure 3D Scanner

- Form 3

- Ultimaker S5

- Prusa i3 MK3S+

Contact

- 3D Print Lab Staff

212-229-8990 x4256

3dlab@newschool. edu

edu - Ryan Haselman, Assistant Manager Digital Tools

[email protected]

Staff

-

Ryan Haselman

Facilities Manager, Digital Tools

-

Huy Nguyen

Technician, Digital Tools

-

Jason Rabie

Assistant Manager, Digital Tools

-

Sarah Lam

Technician, Digital Tools

-

Echo Yuan

Technician, Digital Tools

-

Deanna Siguenza

Technician, Digital Tools

-

Kelly Chang

Technician, Digital Tools

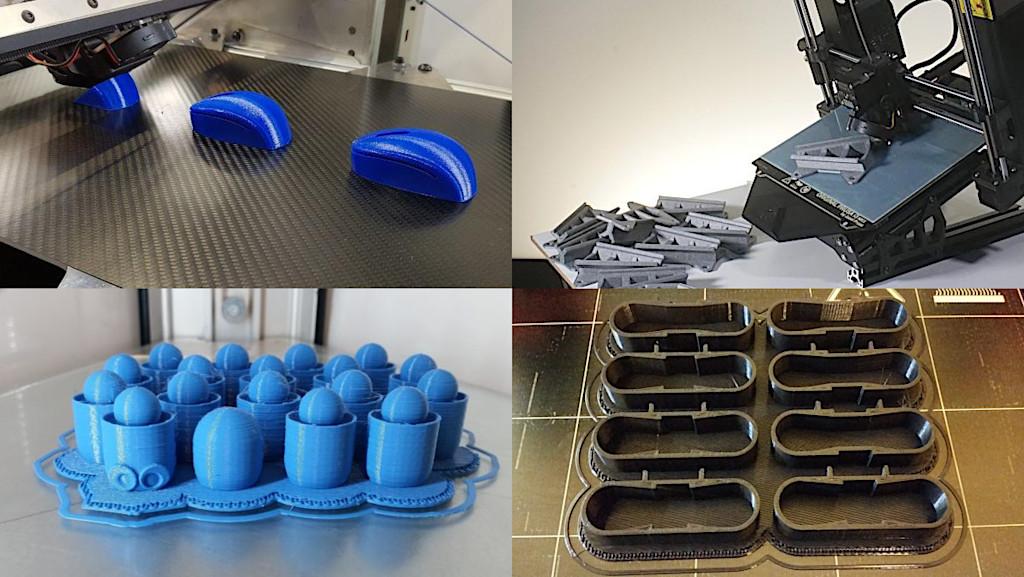

Gallery

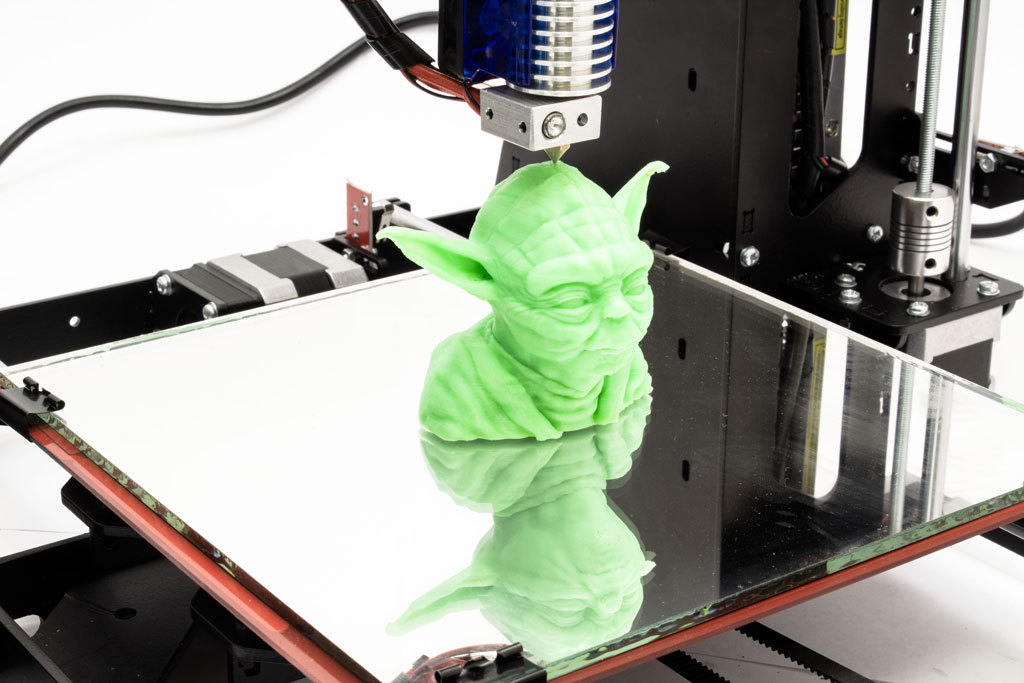

3D printing

Prusa i3 mk3s

3D printing lab, 3D scanning

Form 3, Resin printer

The 3D printing area in the Making Center

Markforged

The newly created Making Center hub, a spacious studio bringing together creative tools from around The New School, will offer students unprecedented opportunities to acquire industry-ready skills, transform how products are made, and upend conventional notions of supply chains, local production, mass customization, and craft. The hub is located on the basement, second, and third floors of Parsons' building at the corner of Fifth Avenue and 13th Street (Sheila C. Johnson Design Center).

The hub is located on the basement, second, and third floors of Parsons' building at the corner of Fifth Avenue and 13th Street (Sheila C. Johnson Design Center).

The first 3D-printed school in the world created in a warzone to be built in Ukraine

Amid the war-scarred streets of the Ukrainian city of Lviv, which has been heavily bombed by the Russians, the foundations of the world’s first 3D-printed school to be built in a war zone have been laid this week.

The ambitious project - which has never been undertaken before on the ground amid an ongoing conflict - was initiated and funded by the non-profit tech and humanitarian start-up TEAM4UA in cooperation with the city authorities and other companies who are putting 3D technology at the service of those displaced by the war in Ukraine.

Over 2,000 schools have been damaged or destroyed in Ukraine since the beginning of the Russian invasion on February 24, according to the country’s defence ministry and "Save Schools," a Ukrainian project which keeps track of all damaged and ruined schools in the country by compiling images of the destroyed buildings and the dates they were hit by shelling.

As a result of the invasion, which is still unfolding over seven months later, some 3.6 million children are at risk of missing classes, while 1.5 million are at risk of suffering mental health issues, according to international aid organisation World Vision.

Many charities and international non-profit organisations have been raising alarm over the plight of school children in Ukraine.

"The conflict is jeopardising the future for an entire generation of Ukrainian children," said Jennifer Neelsen, World Vision Ukraine Crisis Response Director.

"With each day that passes in this war, children’s lives and futures are put at greater risk," Onno van Manen, Save the Children’s acting Country Director in Ukraine, said.

75,000 displaced children

In the Lviv region, where the school will be built, there are 250,000 officially registered internally displaced people, over 75,000 of which are children.

This is perhaps why, when TEAM4UA offered its service to the city, Lviv asked first for a school to be printed.

Building the school’s walls with a 3D printer will be faster and cheaper than constructing a new building in concrete from scratch, according to the tech start-up, which it says could take up to two years.

What’s more, the project is much more sustainable than traditional construction techniques, it says.

"It saves time. It's efficient as far as it concerns energy costs, and it's going to be quick," Charles Tiné, member of TEAM4UA’s strategic committee, told Euronews Next.

"And the buildings produced are very long-term, they last for a long time. The insulation is done very efficiently, it's not like putting refugees into buildings that would last two weeks.

"It's long-term, and when it's finished, you can pack up your printer, put it on a truck and move somewhere else".

The success of this initiative could see an upsurge in the use of 3D technology for reconstructing destroyed buildings in Ukraine, including homes.

According to TEAM4UA, some 10,000 homes need to be rebuilt across the country.

The final goal, said Tiné, is to bring a total of 15 3D printers to Ukraine, train Ukrainians to use them, take the debris of buildings destroyed by the war and recycle that concrete to print new buildings.

Rebuilding Ukraine with 3D printing

Tiné is confident that the school will be just the beginning of the use of 3D printing in the country and in other places in the world that might need it.

"We can print bridges, warehouses [after the school]," Tiné said. "And once the war is over in Ukraine, the idea is to move these printers to other places where it’s needed, after an earthquake or after similar disasters".

The recent Russian strikes against civilian targets, launched by Moscow in retaliation for the destruction of a key supply bridge between Russia and Crimea, have put Lviv once again under fire.

On Tuesday, a Russian missile hit critical infrastructure in the city.

Tiné said that the strikes won’t stop the construction of the 3D-printed school - but the blackout the city has experienced after Russian strikes hit an electricity supply in the Lviv region on Monday is likely to hinder efforts to build it.

Construction may be delayed, but Tiné is positive the school will be built - as soon as it’s safe for the crew to get into Ukraine.

"This will absolutely not divert us one centimetre off the target, which is to help people reconstruct what has been destroyed and to receive long-term education," he said.

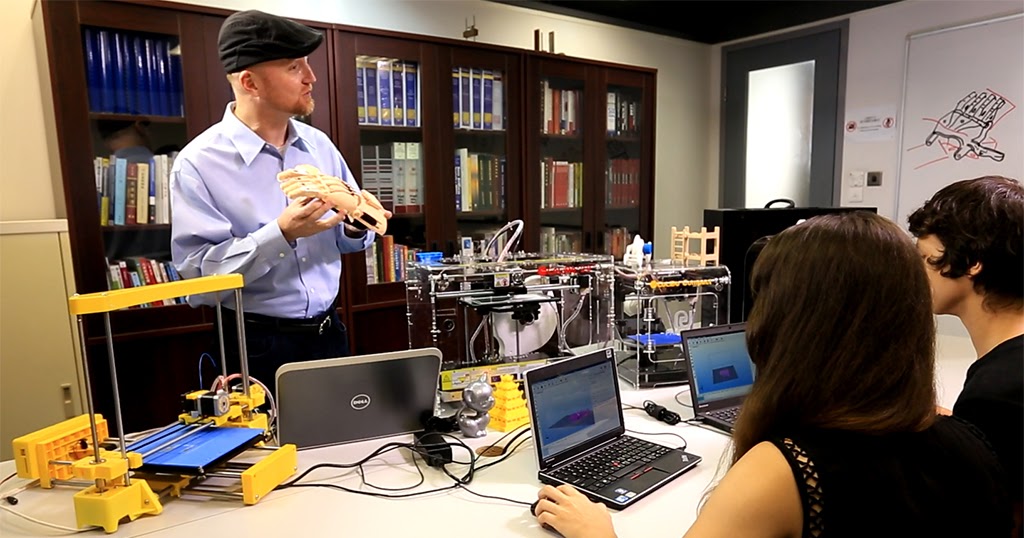

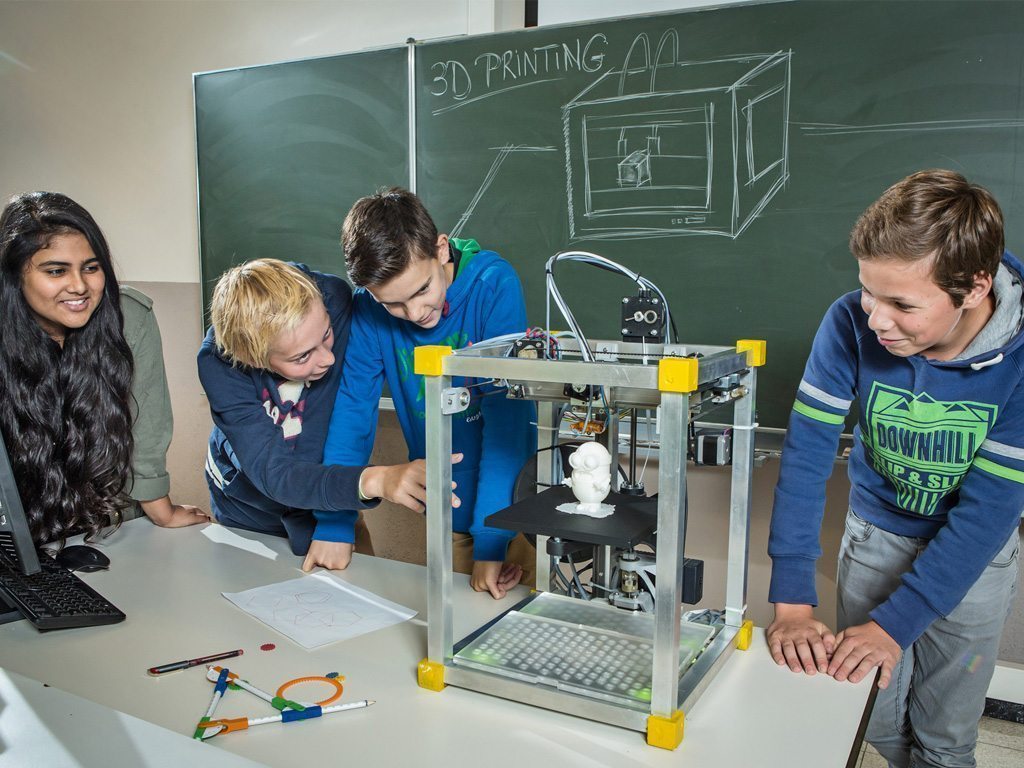

Read the article - 3D printing in secondary schools on the example of the New Chernogolovskaya school

In the modern world, additive technologies make it possible to facilitate the solution of many problems and reduce costs in almost all areas of activity. And, of course, the introduction of 3D equipment into the educational process is taking place by leaps and bounds, not only in higher educational institutions, specialized colleges, but also in secondary schools.

One of these modern schools is the New Chernogolovskaya School (NChSH) with in-depth study of subjects in the city of Chernogolovka near Moscow. nine0003

In addition to the implementation of the general education program with fundamental academic knowledge, the School of Economics pays great attention to building an individual educational trajectory for each student with the possibility of research and application of the knowledge gained, the development of initiative, creativity and independence of children.

Mikhail Sergeevich Gavrilov, head of the Engineering Center and part-time technology teacher, told us how the educational process is built. nine0003

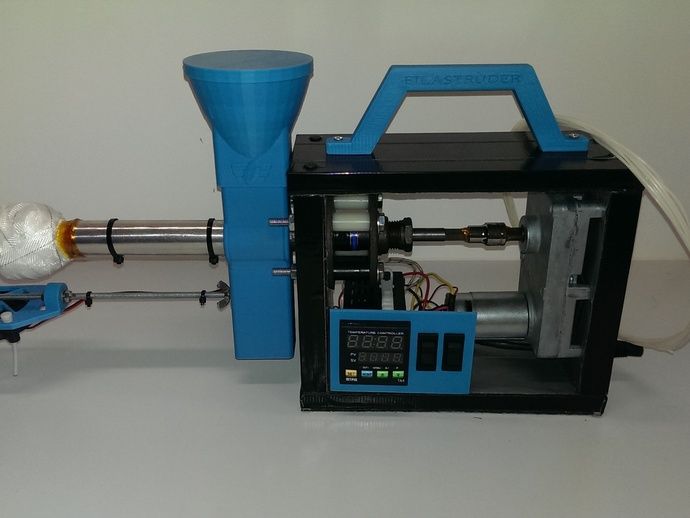

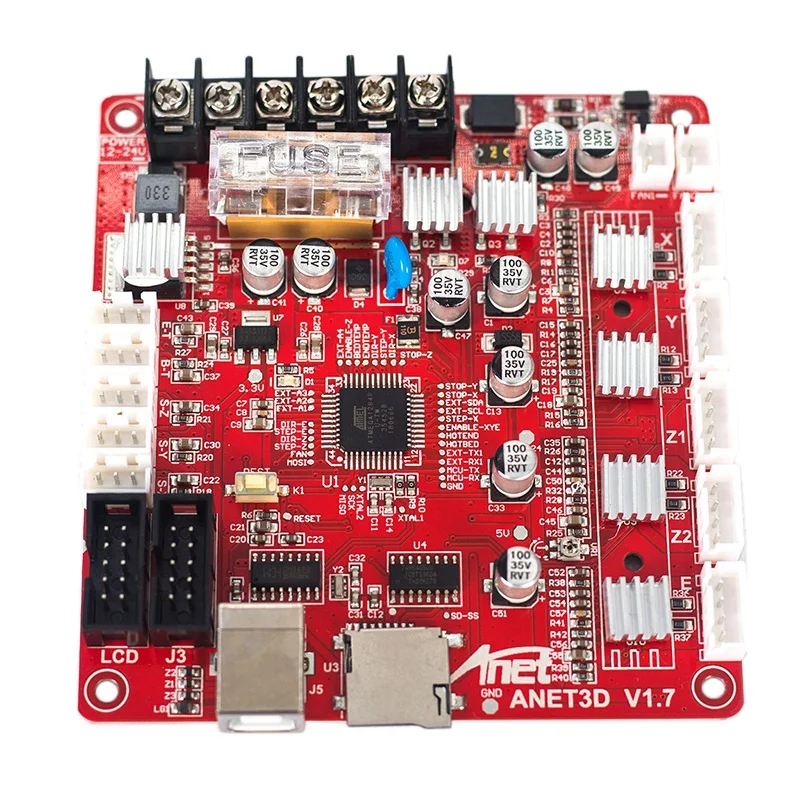

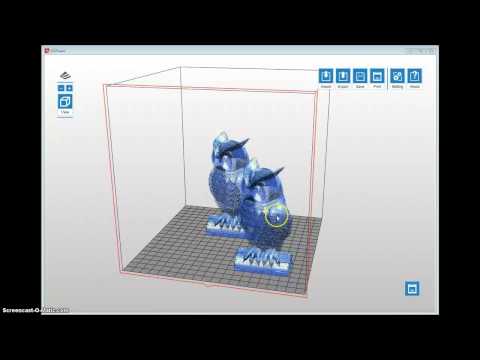

The engineering center located at the school is equipped with Raise3D Pro2, PICASO3D FDM 3D printers, Phrozen Sonic Mighty 4K photopolymer printer and Granbo and Phrozen accessories, 3D scanner and CNC milling machine, as well as turning and drilling machines and various hand tools.

Mikhail said that the choice of printers was based on personal experience in using various printers and machines. I had experience with Anet, Printbox, Hercules, Anycubic devices. The Raise3D printers proved to be very reliable in operation, they had much less problems with operation compared to others, and they also have a lot of useful features. The ideamaker software that comes with the printers allows you to quickly prepare a file for printing, has many settings, and provides a good print result. nine0003

nine0003

After purchasing the printers, they were immediately put into operation, thanks to a mentor with rich experience in working with CNC machines and 3D printers.

Students begin their acquaintance with 3D printing technology from the 5th grade, and students from 7th to 9th grade are already making various design works, moving mechanisms, souvenirs and much more using 3D printers. Parts of projects or the entire creation are printed on printers. These are not only school work and assignments, often students defend projects within the framework of the session of the Minor Academy of Sciences and present their work at the All-Russian Olympiad for School Students in Technology and at the Moscow Olympiad for School Students. nine0003

Along with 3D printing and scanning, of course, children learn 3D modeling in Compass 3D and Fusion 360. They develop 3D models on their own with tips and advice from a mentor. The teacher also comes up with various practical tasks designed to practice certain techniques for building 3D models.

A few words about the work "Chess"

To create a chess table, a CNC milling machine was used. The chessboard itself is made of a mirror engraved on a laser machine. nine0003

With chess pieces it's still more interesting. First, the authors of the project prepared 3D models of themselves and their classmates using a 3D scanner, then printed them on a 3D printer and, after a little processing, covered them with paint.

In the near future, it is planned to use 3D printers for the manufacture of architectural models, as well as the creation of robots.

According to Mikhail, the introduction of 3D printing into the educational process is very important for modern schoolchildren. This allows you to develop spatial thinking, creativity, technical skills, reveals the ability to project activities. When making their projects, students develop an engineering culture, a desire for their own discoveries and self-development. And also students get an idea about modern production, and someone is already deciding on their future profession. nine0003

And also students get an idea about modern production, and someone is already deciding on their future profession. nine0003

First 3D printed school

The Danish company COBOD International A/S, which manufactures construction 3D printers that were behind the first one-, two- and three-story buildings in Europe, among other things, is now also responsible for supplying the printer, which created the world's first school using 3D printing.

A school in Malawi was printed on COBOD's BOD2 model 4-4-2 3D printer, which is capable of printing concrete structures up to 10 meters long and wide and 3 meters high, by 14Trees, a joint venture between Lafargeholcim and CDC. The use of the COBOD BOD2 printer in Malawi follows many other successful projects started with this technology, such as the first 3D printed concrete wind turbine tower made for GE. Henrik Lund-Nielsen, Founder and CEO of COBOD, said: “These projects show that using our printers for small private homes was just the beginning and that many more applications can be done with our versatile printers. We look forward to working with 14Trees to help address the shortage of schools in Africa." nine0013 The innovative application of 3D printing technology has reduced the cost, time and materials traditionally used to build schools and homes. In addition, the construction also had an environmental impact that was over 50% less than traditional construction methods.

We look forward to working with 14Trees to help address the shortage of schools in Africa." nine0013 The innovative application of 3D printing technology has reduced the cost, time and materials traditionally used to build schools and homes. In addition, the construction also had an environmental impact that was over 50% less than traditional construction methods.

There is a huge shortage of schools in Africa. UNICEF estimates that Malawi alone is short of 36,000 classrooms that would take 70 years to build using conventional methods and speed. According to 14Trees, this infrastructure gap could be bridged in just 10 years with 3D printing technology, and this new technology has been well received in the country. Representative of Malawi's Director of Education, Youth and Sports, Juliana Kuphanga Chikandila, Primary Education Advisor, said: “I'm very impressed with the new building - its durability and design provide space and amenities that students didn't have before.