3D printing mass unemployment

3D Printing: Employment Boom or Employment Swoon? - 3DPrint.com

We have already seen intense debates concerning what the outcome of a 3D printing economy may be. Traditionally technology has created more jobs than it has destroyed. When computers began to emerge on the scene in the 1970’s, talks of job losses were nearly as intense as they are today, surrounding 3D printing. What happened? The majority of people were wrong. Just think about how many jobs the Googles, Apples, and Microsofts of the world have created over the past decade alone.

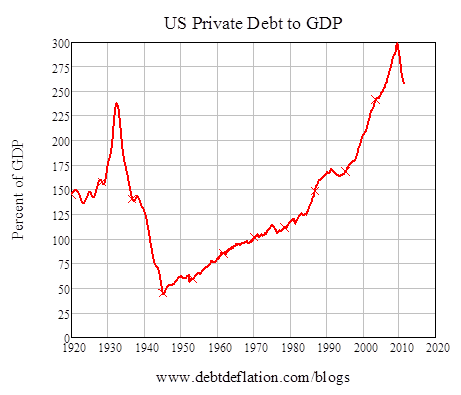

The basic pessimistic view on 3D printing is that the jobs market will be decimated, with losses in the tens of millions. Combined with robotics and intelligent machines, automation within manufacturing will certainly intensify. The question is, will 3D printing and these other technologies ultimately lead to a net decline in total jobs?

Manufacturing Job Losses:

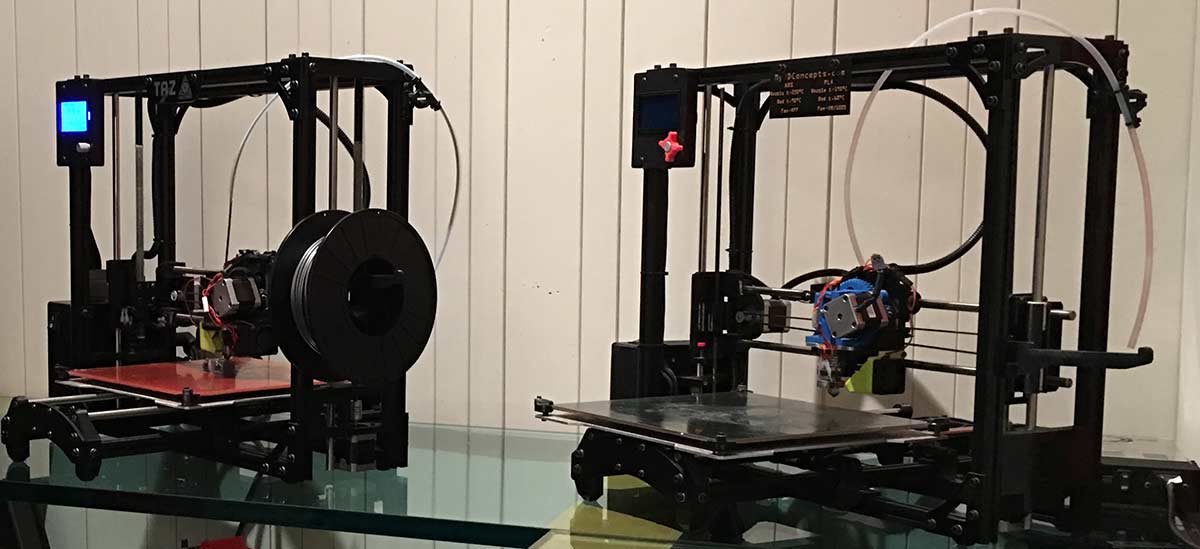

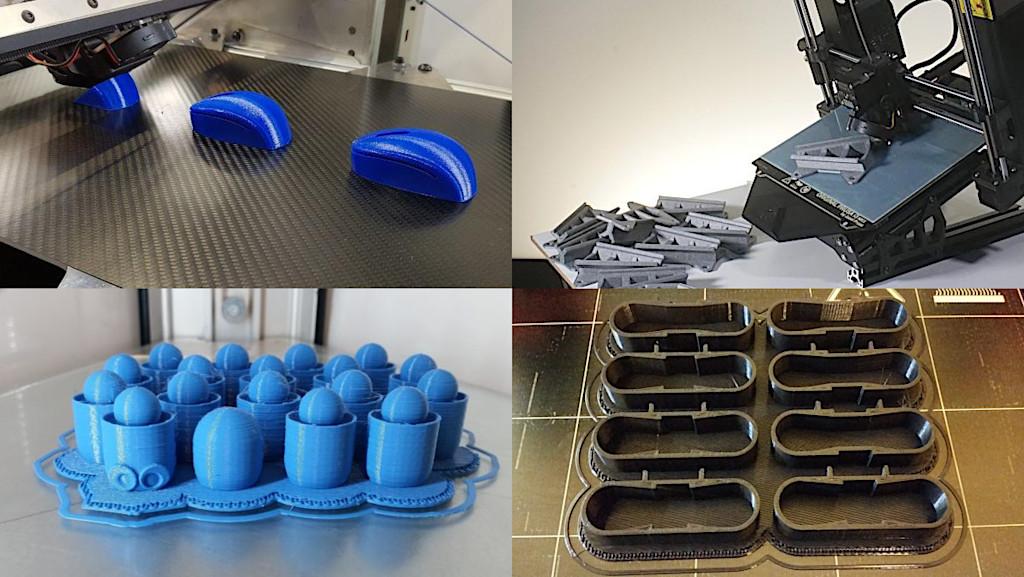

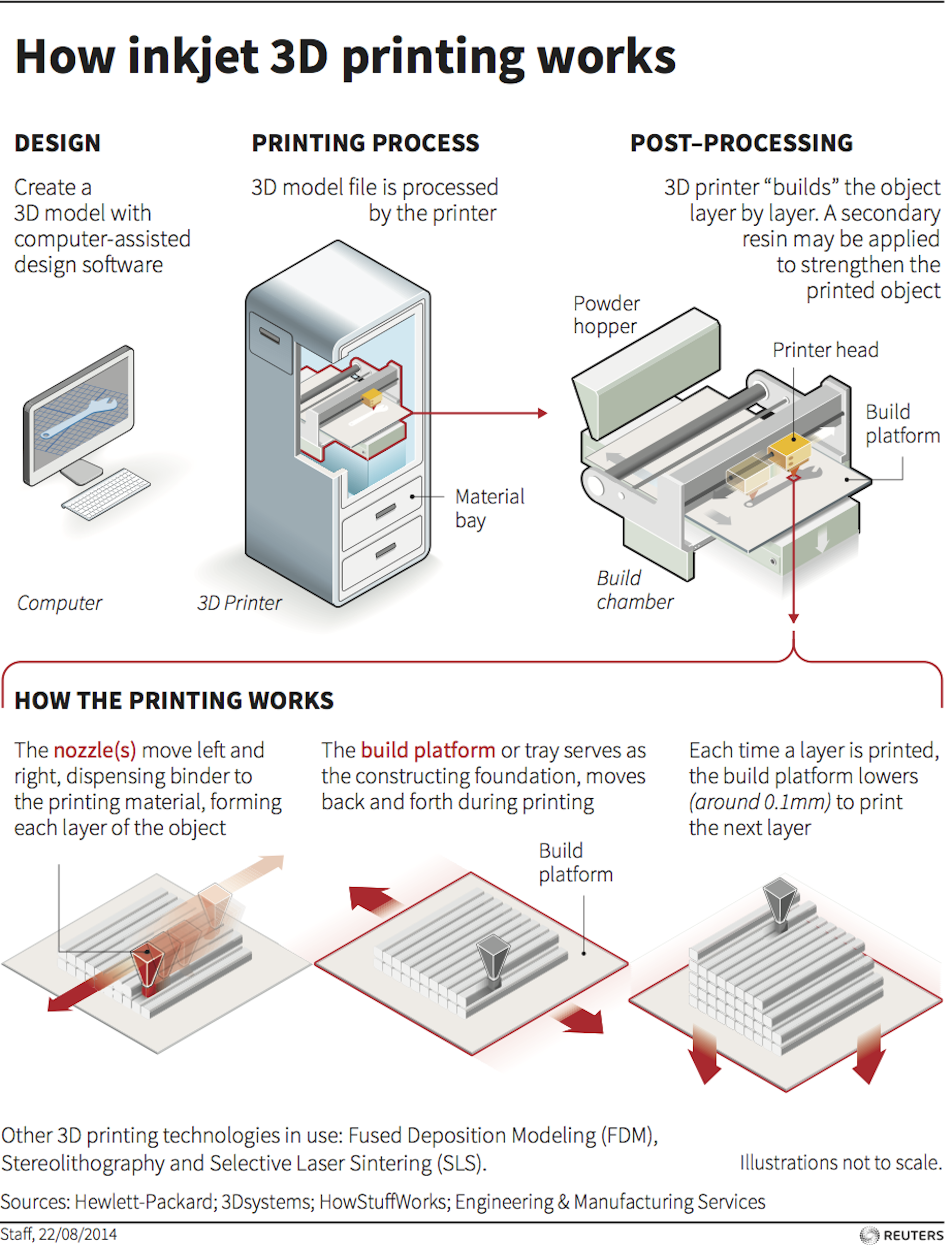

Without a doubt we will lose a significant number of jobs within the manufacturing sector. As 3D printing methods speed up, become more accurate, and new materials make their way into these machines, companies will begin increasing their capital expenditures to acquire automated machine labor. Why pay ten people on an assembly line to produce a product, when a 3D printer can print out the exact parts needed, and intelligent robotic arms can assemble those parts within minutes? This ends up leaving the company with variable costs no greater than that of the electricity and maintenance on the machines. There is little doubt that within 15 to 20 years the entire landscape of manufacturing will have changed in a drastic way.

Retail Job Losses:

Retail as well, will see major changes. Who will want to go out to a store to purchase the latest style of shoes, when they can download an open source design online, make the appropriate changes, and print them out in their own home for a fraction of the cost. We are still likely a decade, or even more, away from having the ability to print shoes with the same material and quality of those in retail outlets, but the time is coming. Jobs will be lost as retail outlets are forced to close shop, perhaps moving online where they can offer digital designs to customers, with only a fraction of the overhead.

Jobs will be lost as retail outlets are forced to close shop, perhaps moving online where they can offer digital designs to customers, with only a fraction of the overhead.

It is very likely that many of these people losing their jobs will not be able to simply jump into another career. More than likely the jobs being lost will be for relatively unskilled labor, while any jobs being created by new technology will be for managing and skilled labor. This will create a further gap of income inequality in America. Having said this, within the next decade the cost of a higher education will likely drop substantially. There are already a tremendous number of resources available online like KhanAcademy, as well as free courses offered by respected universities and colleges. This will mean that those who want to further their education can do so with little or no financial resources. Now that we got the negative aspects out of the way, let’s take a look at why we may actually be in for a major economic boom, here in the U. S.

S.

Job Creation

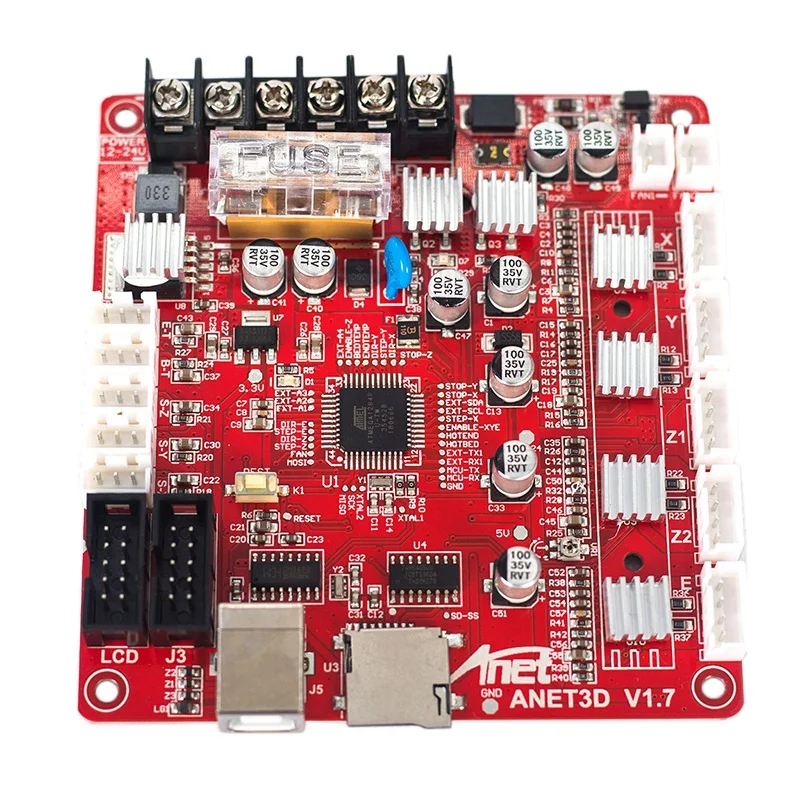

Yes, many millions of jobs will be lost, but for every job lost there is a fairly good possibility that more than one job will be created. As employees are laid off by retailers and manufacturers, actual costs to the companies are decreasing substantially. This can then be passed on to the consumer, allowing for a lower cost of living nationwide. This may lead to a stronger economy as more money is available to spark new business, new innovation, and eventually millions of new jobs. While the jobs to GDP ratio will decrease, the overall economy and thus GDP may increase substantially. This means that the actual employment numbers will also rise. We have already seen thousands of new jobs created around the 3D printing industry. This number will grow for years, and even decades to come. We need people to fix the machines, make the machines, sell the machines, and manage the companies that do all this. In addition, entirely new job categories will be created. 3D printing has brought on a new wave of innovation which we have not seen in many years. There are new types of artists who rely on 3D modeling, and the CAD software market is heating up, meaning we need more programmers to write the scripts. Those who can learn new fields the fastest will be the individuals who stay employed, and likely prosper.

3D printing has brought on a new wave of innovation which we have not seen in many years. There are new types of artists who rely on 3D modeling, and the CAD software market is heating up, meaning we need more programmers to write the scripts. Those who can learn new fields the fastest will be the individuals who stay employed, and likely prosper.

Jobs Return to American Soil

Some of the largest number of job losses will be within mass manufacturing companies like Foxconn, a Chinese manufacturer who is known for building tech gadgets like the iPhone. As manufacturing costs rise in China, and drop in the United States, due to the fact that machines can provide around the clock production for a fraction of the cost, we will see more and more jobs moving back onshore. In fact, we have already seen this beginning to happen with Apple and Google. Sure, many of these jobs will be suited best for machines, but someone has to maintain these machines, manage the supply chains, and oversee production.

You could ask a hundred economists what they think will eventually happen once the 3D printing and robotics markets mature, and you will likely get a hundred different answers. We have seen what technology has done in the past, destroying millions of jobs, but in the process creating tens of millions of new jobs. There is little reason to believe that this wave of progress will be any different. What are your thoughts? Discuss the possible economic impacts of 3D Printing with us at 3DPB.com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printing employment • 3d printing jobs • employment • job loss 3d printing • job losses • technology affects on jobs • unemploymnt

Please enable JavaScript to view the comments powered by Disqus.

3D Printing Could Disrupt Labor Markets and National Security

For Release

Wednesday

May 9, 2018

While advances in additive manufacturing offer potential breakthroughs in prosthetic arms, jet engine parts, and a host of other products, 3D printing, as it is known, may also disrupt traditional labor markets and exacerbate existing security threats from violent actors.

A new RAND Corporation paper suggests additive manufacturing could benefit military adversaries, violent extremists and even street criminals, who could produce their own weapons for use and sale. As this technology further develops, and without proper controls, violent actors might be able to replicate more sophisticated weapons systems, print lethal drones, and even produce jamming devices or cheap decoys that disrupt intelligence collection.

3D printing technology is also susceptible to sabotage by hackers who could develop the means to instruct 3D printers to introduce flawed instructions or algorithms into mission-critical parts of airplanes, according to the paper.

“Lone-wolf attacks may become more lethal when individuals have ready access to 3D printers,” said Trevor Johnston, lead author and an associate political scientist at RAND, a nonpartisan research organization.

Additive manufacturing may also indirectly allow countries under international sanctions, like North Korea and Iran, to produce complex items domestically, mitigating the economic impact of sanctions.

From an economic perspective, by decentralizing manufacturing, individuals and firms may choose to produce more products locally rather than importing them. 3D printing could therefore weaken international connections currently sustained by complex, multi-country supply chains, the authors conclude. That in turn may create upheaval in labor markets—and potentially intensify social conflict.

“Unemployment, isolation and alienation of middle and low-skilled laborers may be exacerbated by additive manufacturing together with automation and artificial intelligence,” said Troy Smith, an author on the paper and an associate economist at RAND.

The paper finds the relative risk and cost of future threats will depend in part on the evolution and regulation of additive manufacturing hardware (printers), raw materials and software (intellectual property). Threat prevention will be more effective if focused on material controls.

By limiting supplies of rare or dangerous raw materials, regulators can at least ensure that some of the most destructive weapons (e. g., nuclear dual use technologies) do not become readily accessible. By monitoring online communities, law enforcement may be able to curtail digital exchanges of prohibited technologies but these measures can only contain the spread of such technologies for so long. Alternatively, law enforcement may themselves hack additive manufacturing software to disrupt potential attacks or limit their destruction.

g., nuclear dual use technologies) do not become readily accessible. By monitoring online communities, law enforcement may be able to curtail digital exchanges of prohibited technologies but these measures can only contain the spread of such technologies for so long. Alternatively, law enforcement may themselves hack additive manufacturing software to disrupt potential attacks or limit their destruction.

The paper, “Additive Manufacturing in 2040: Powerful Enabler, Disruptive Threat,” is part of a broader effort to envision critical security challenges in the world of 2040, considering the effects of political, technological, social and demographic trends that will shape those security challenges in the coming decades.

Funding for the Security 2040 initiative was provided by gifts from RAND supporters and income from operations.

The research was conducted within the RAND Center for Global Risk and Security, which works across RAND to develop multi-disciplinary research and policy analysis dealing with systemic risks to global security. The center draws on RAND's expertise to complement and expand RAND research in many fields, including security, economics, health and technology.

The center draws on RAND's expertise to complement and expand RAND research in many fields, including security, economics, health and technology.

About the RAND Corporation

The RAND Corporation is a research organization that develops solutions to public policy challenges to help make communities throughout the world safer and more secure, healthier and more prosperous.

RAND Office of Media Relations

(703) 414-4795

(310) 451-6913

[email protected]

Researcher Spotlight

-

Troy D. Smith

Associate Economist

Troy Smith is an economist at the RAND Corporation and professor of policy analysis at the Pardee RAND Graduate School. His research is in applied microeconomics focusing on education, entrepreneurship, development, and labor.

Explore

All News Releases

- By Date

Related Topics

Research Conducted By

Explore All Topics »

Satisfy My Printing - Sekret Firmy - Kommersant

Autodesk futurist Jordan Brandt predicts that 3D printing will revolutionize the industry. In an interview with Firm Secret, he told how companies like Apple and Google will in the future be able to produce gadgets without factories, right in the apartments of their customers.

In an interview with Firm Secret, he told how companies like Apple and Google will in the future be able to produce gadgets without factories, right in the apartments of their customers.

3D alarm. Jordan Brandt believes that despite the prospects that 3D printing opens up for humanity, it also carries the threat of mass unemployment

Photo: Autodesk

Text: Andrey Lapshin

You have been closely following the development of 3D printing for several years now and believe that it can change our lives. But how? So far, the passion for 3D printing is more like the fun of adult children: toys, parts, disposable pistols. Is there something new and interesting coming soon?

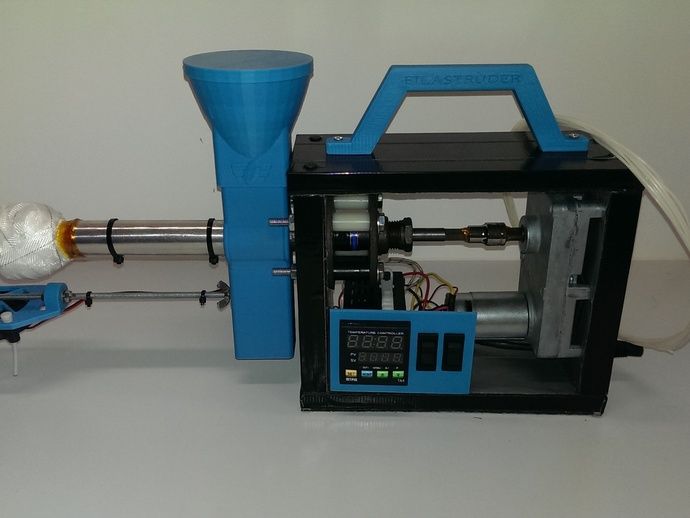

All the fun with 3D printing is starting to happen right now. Already today, manufacturers can make a significant part of the parts for their products using 3D printers. Traditional methods of manufacturing these parts, which were previously used in factories, are no longer needed. Moreover, they become economically inefficient. nine0003

Moreover, they become economically inefficient. nine0003

But this is still an internal kitchen. The user does not care how this or that detail is made. I don't see this.

Something users can already see. This year, the American delivery service UPS announced the start of an interesting experiment. She installed 3D printers in 10 of her offices and now not only delivers goods, but also offers her customers to make them right on the spot, in front of their eyes. Yes, for the most part, UPS only produces plastic parts for gadgets and toys in this way, but this is only the very beginning of the grandiose transformations that await us. Very soon you will be able to not only see the process of creating a product, but also take part in it yourself. Everything is going to the fact that in 20 years Apple will not be producing consumer electronics in factories, but you yourself will be able to do it at home. nine0003

How? Will I have a construction set made of parts produced on a 3D printer, from which I will assemble the iPhone myself?

No, you may not even know how the iPhone works. But it will know your printer. You simply upload a special form and powder into it, select the desired file and get the whole new gadget. The mold and powder will be very cheap. They will be delivered directly to your home in the quantities you order. Remember how Lilu in the movie "The Fifth Element" put an empty plate into the microwave and took out a huge chicken in a few seconds? Approximately the same way, users will receive new gadgets: a smartphone, augmented reality glasses or something else. First, this technology will be tested in the factory, and then it will migrate to your house. Factories will only produce large items or things that, for safety reasons, must be produced under strict control, such as cars, aircraft or missiles. But they will be printed out in the same way as smartphones. nine0003

But it will know your printer. You simply upload a special form and powder into it, select the desired file and get the whole new gadget. The mold and powder will be very cheap. They will be delivered directly to your home in the quantities you order. Remember how Lilu in the movie "The Fifth Element" put an empty plate into the microwave and took out a huge chicken in a few seconds? Approximately the same way, users will receive new gadgets: a smartphone, augmented reality glasses or something else. First, this technology will be tested in the factory, and then it will migrate to your house. Factories will only produce large items or things that, for safety reasons, must be produced under strict control, such as cars, aircraft or missiles. But they will be printed out in the same way as smartphones. nine0003

Which companies do you think will succeed with 3D printing? And will the structure of income from the sale of goods change, because it turns out that electronics retailers simply won’t be needed in 20 years?

Many tech companies are gearing up to make their money from the distribution of digital data rather than physical goods. Apple, for example, has recently patented several technologies related to 3D printing. One of Elon Musk's companies, Space X, is already using 3D printing to produce individual parts for its rockets. A very interesting project is being prepared by Google, which promises to release the Ara smartphone in early 2015: it can change failed modules and print some of them on a 3D printer. nine0003

Apple, for example, has recently patented several technologies related to 3D printing. One of Elon Musk's companies, Space X, is already using 3D printing to produce individual parts for its rockets. A very interesting project is being prepared by Google, which promises to release the Ara smartphone in early 2015: it can change failed modules and print some of them on a 3D printer. nine0003

If we talk about income, then their distribution system will become similar to the model used by the same Google and Apple in the GooglePlay and AppStore app stores. Apps that allow you to print specific products will be sold in these app stores. Users will pay some amount to the developer for downloading, and the app store owner will keep his commission. Of course, offline hardware stores in such situations will lose their meaning.

An important point is the price of such applications and the price of the printers themselves. Will they be more accessible than now? nine0013

Within 5-10 years, printers that can completely create, for example, a smartphone, will still be too expensive for the average consumer. But in 20 years they will be available to everyone. The cost of applications that allow you to print different items, I think, will also please many. But this cheapness has a downside - many items will become less durable. You will need to print them often and pay each time you use print apps. True, there is good news here. You can grind broken parts into powder, fill it into a 3D printer, and use the resulting mass to remake what you have broken. nine0003

But in 20 years they will be available to everyone. The cost of applications that allow you to print different items, I think, will also please many. But this cheapness has a downside - many items will become less durable. You will need to print them often and pay each time you use print apps. True, there is good news here. You can grind broken parts into powder, fill it into a 3D printer, and use the resulting mass to remake what you have broken. nine0003

Is there something that poses a threat in this exciting future, where you can print new items every day from the comfort of your home? What about those who want to print Kalashnikov assault rifles at home?

The technology to illegally produce weapons will indeed become available, but you just can't print them. The artificial intelligence of the 3D printer will not allow you to do this. However, hackers will eventually defeat any artificial intelligence, so the state will have to control their actions even more tightly. But it seems to me that it will cope with this function. nine0003

But it seems to me that it will cope with this function. nine0003

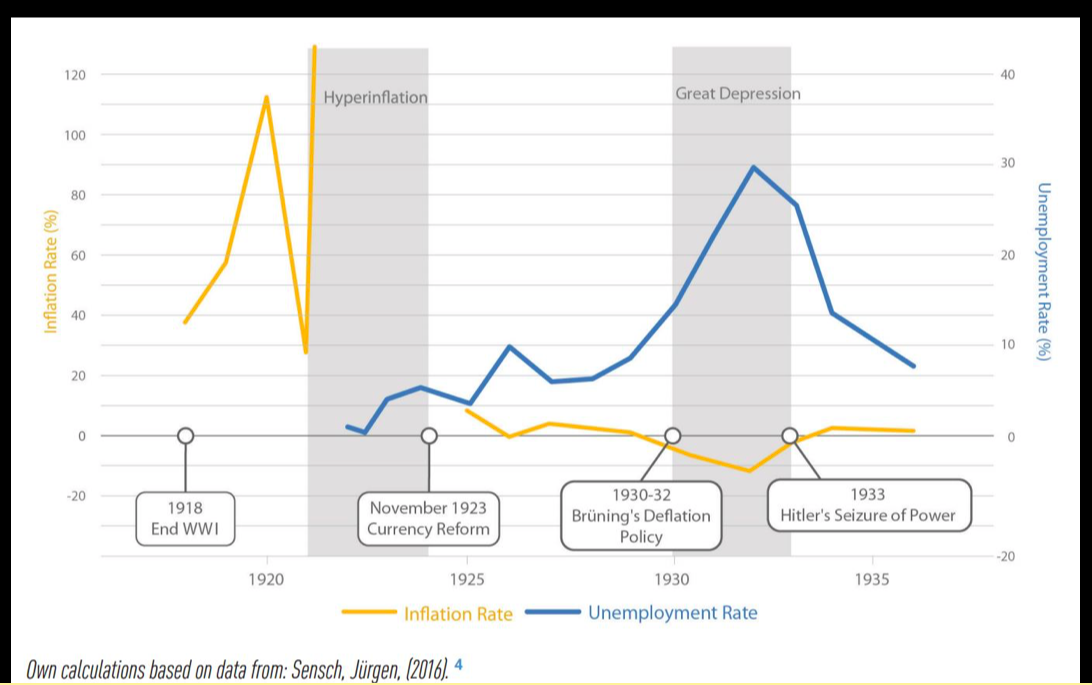

The most important question to be answered now is what will the hundreds of millions of people around the world who now work in factories do? Their skills will soon be of no use to anyone, because the factories will close. Yesterday's workers will have to receive a special technical education, otherwise they will lose their relevance to the economy, and the economy itself will be shaken by hundreds of millions of unemployed.

Let's hope that humanity will save the Internet and the knowledge that can be gleaned from it. It is already obvious that there is no other way to train such a large number of people in a short time. nine0003

Evil aliens or good friends?

The production of our own 3D printers was opened in Russia for the first time. This allows us to hope that we will not fall behind the most promising technology of the millennium in the same way that we lagged behind computers in our time. Because whoever owns 3D printing owns the economy

Because whoever owns 3D printing owns the economy

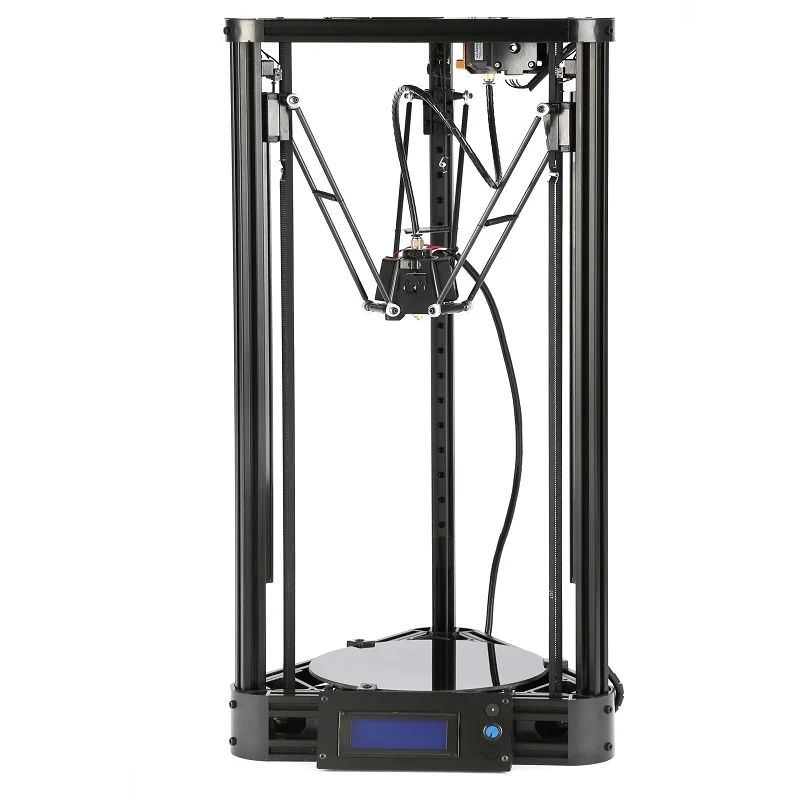

Household 3D printers that work with plastic have long been available in retail, but absolutely all of them are foreign-made. At the United Engine Corporation, we have our own installation for printing large-sized parts for industrial gas turbine engines, but this is a single copy. But the private company "Laser Systems", operating in the Special Economic Zone "St. Petersburg", is starting to mass-produce small (the length of the side of the model is no more than 25 cm) metal-oriented printers. They do not count on the retail market there - we are talking about cooperation with industrial enterprises, primarily those that are part of the Rostec system. 3D printing significantly speeds up and reduces the cost of producing the most complex parts, and the more complex the part, the greater the savings. nine0003

But won't all this lead to the displacement of man by the machine, and hence to a surge in unemployment?

There is a point of view according to which we are practically facing the end of an era. Indeed, printers reduce the cost of production primarily by eliminating or minimizing manual labor. They are already being printed on, for example, human organs, residential buildings and small arms. And it is reasonable to assume that people with working specialties will simply lose their jobs - say, builders, of which there are about 12 million people in the European Union, 5 million in Russia, and even the Chinese themselves are afraid to count how many in China. nine0003

Indeed, printers reduce the cost of production primarily by eliminating or minimizing manual labor. They are already being printed on, for example, human organs, residential buildings and small arms. And it is reasonable to assume that people with working specialties will simply lose their jobs - say, builders, of which there are about 12 million people in the European Union, 5 million in Russia, and even the Chinese themselves are afraid to count how many in China. nine0003

The proletariat dearly loved by Karl Marx will be supplanted by the infernal machine invented by the eggheads. The communist idea will simultaneously perish as proletarian-oriented and triumph as idealizing the classless society that 3D printers can bring us closer to.

Photo: www.globallookpress.com

In fact, what we have before us is not a revolution, but an evolution. "3D printer" is just a relatively new word, and these cute devices didn't come out of nowhere. Machine tools with numerical control have been known for a long time, and they, in fact, are the same printer, except that it works with a solid workpiece, while modern devices “sculpt” parts from molten materials. So now we are talking more about the popularization of technology, about the application of "additive selective laser fusion installations", as they are called according to the official Russian classification, to an ever wider range of tasks. nine0003

So now we are talking more about the popularization of technology, about the application of "additive selective laser fusion installations", as they are called according to the official Russian classification, to an ever wider range of tasks. nine0003

As for the builders, everything is simple. A 3D-printed multi-storey building is now the same do-it-yourself constructor as traditional block and panel buildings. The installation process, for which builders are needed, does not change significantly, although it is noticeably simplified. But small buildings really no longer require the participation of heroes of physical labor - for example, in 2017 in the city of Stupino, Moscow Region, a 3D printer built a house in the truest sense of the word around itself. nine0003

Weapons are now available to everyone - that's a fact. In 2013, a simple Liberator pistol was created from just 16 plastic parts and one striker nail - not the first, but the most popular such device due to its extreme simplicity. There was a lot of controversy regarding the legality of such experiments, and there were demands to ban the technology as such. But we do not ban no less deadly kitchen knives. The supporters of freedom have won: since 2018, in the United States it has been allowed to distribute 3D models of non-automatic weapons via the Internet, with the only restriction - they must contain metal parts so as not to become invisible to detectors. We add that such a weapon looks rather ridiculous, so it is easy to confuse it with a child's toy. And yes, in Russia the printing of weapons is strictly prohibited. nine0003

There was a lot of controversy regarding the legality of such experiments, and there were demands to ban the technology as such. But we do not ban no less deadly kitchen knives. The supporters of freedom have won: since 2018, in the United States it has been allowed to distribute 3D models of non-automatic weapons via the Internet, with the only restriction - they must contain metal parts so as not to become invisible to detectors. We add that such a weapon looks rather ridiculous, so it is easy to confuse it with a child's toy. And yes, in Russia the printing of weapons is strictly prohibited. nine0003

Skull with 3D printed metal facial implant. Photo: www.globallookpress.com

Bioprinting makes artificial organs far more affordable than just a decade ago. With this fantastic technology, the viability of cells is preserved, that is, to some extent, people have learned to print life on a printer. Unfortunately, the main successes so far have been with the Americans and the Japanese, but the thyroid gland has already been successfully printed in Russia; Moreover, Russian scientists managed to create organs in zero gravity on the ISS. nine0003

nine0003

And these are just three of the hundreds of very different, but equally interesting ways to use the technology of physical embodiment of computer 3D models. It is clear that there can be no talk of any surge in unemployment with such an abundance of human effort. Yes, with the inevitable flourishing of 3D printing, there will be fewer workers, but they will not disappear anywhere. It is interesting that highly qualified specialists will suffer first of all - no matter how good they are, the printer will make the same part faster and more accurately. But handymen will find application in almost any, the most technologically advanced production. nine0003

3D printed outsole. Photo: www.globallookpress.com

But there is a real flourishing of chemistry ahead - an explosive growth in demand for a variety of polymers and alloys for 3D printing is expected. A sea of work for designers and engineers. Of course, one cannot do without programmers, and without representatives of several dozen other professions.