Nasa 3d printed mars habitat

ICON 3D Prints the First Simulated Mars Surface Habitat for NASA Designed by Renowned Architecture Firm BIG-Bjarke Ingels Group

Mars Dune Alpha, the 3D-printed Habitat Located at Johnson Space Center in Houston, Texas, Will Aid in Long-duration Science Missions

AUSTIN, TX, AUGUST 6, 2021 – ICON, developer of advanced construction technologies including robotics, software, and building materials, today announced it has been awarded a subcontract through Jacobs supporting NASA’s The Crew Health and Performance Exploration Analog (CHAPEA) to deliver a 3D-printed habitat, known as Mars Dune Alpha, at NASA’s Johnson Space Center. ICON’s next-gen Vulcan construction system will complete a 1,700 square-foot structure, designed by world-renowned architecture firm BIG-Bjarke Ingels Group, that will simulate a realistic Mars habitat to support long-duration, exploration-class space missions.

CHAPEA, is a sequence of three one-year Mars surface mission simulations at the NASA Johnson Space Center in Houston. The analog missions will provide valuable insights and information to assess NASA’s space food system, as well as physical and behavioral health and performance outcomes for future space missions. NASA will use research from the Mars Dune Alpha simulations to inform risk and resource trades to support crew health and performance for future missions to Mars when astronauts would live and work on the Red planet for long periods of time.

Future space exploration habitats have the potential to be 3D printed with additive construction technology to eliminate the need to launch large quantities of building materials on multiple flights, which is cost prohibitive.

“This is the highest-fidelity simulated habitat ever constructed by humans,” said Jason Ballard, co-founder and CEO, ICON. “Mars Dune Alpha is intended to serve a very specific purpose--to prepare humans to live on another planet. We wanted to develop the most faithful analog possible to aid in humanity's dream to expand into the stars. 3D printing the habitat has further illustrated to us that construction-scale 3D printing is an essential part of humanity's toolkit on Earth and to go to the Moon and Mars to stay. ”

We wanted to develop the most faithful analog possible to aid in humanity's dream to expand into the stars. 3D printing the habitat has further illustrated to us that construction-scale 3D printing is an essential part of humanity's toolkit on Earth and to go to the Moon and Mars to stay. ”

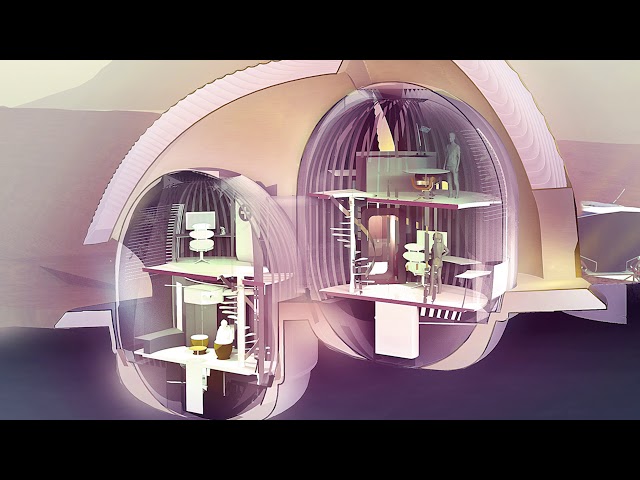

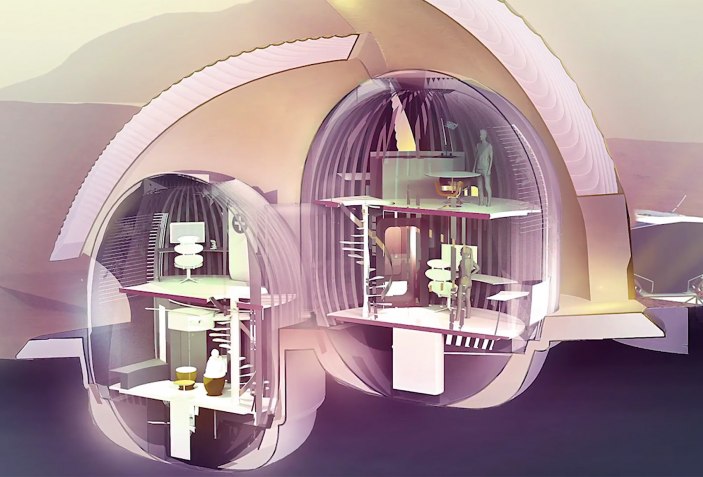

Life in Mars Dune Alpha will resemble the expected experience for those living in a future Mars surface habitat. Designed by BIG-Bjarke Ingels Group, the layout of the innovative structure is organized in a gradient of privacy. Four private crew quarters will be located on one end of the habitat; dedicated workstations, medical stations and food-growing stations are located on the opposite end, with shared living spaces found in between. Varying ceiling heights vertically segmented by an arching shell structure accentuate the unique experience of each area to avoid spatial monotony and crew member fatigue. A mix of fixed and movable furniture will allow crew members to reorganize the habitat according to their daily needs, as will the customizable lighting, temperature, and sound control – helping regulate the daily routine, circadian rhythm, and overall well being of the crew.

“Together with NASA and ICON, we are investigating what humanity’s home on another planet will entail from the human experience,” says Bjarke Ingels, Founder and Creative Director, BIG-Bjarke Ingels Group. “The data gained from this habitat research will directly inform NASA’s standards for long-duration exploration missions, and as such will potentially lay the foundation for a new Martian vernacular. Mars Dune Alpha will take us one step closer to becoming a multiplanetary species.”

Ballard continued, “Bjarke Ingels and the team at BIG are incredible thought leaders in the architecture space. It was important to have a partner who believed in this transformative role of the future of construction and who could help us imagine pioneering new frontiers -- both materially, technologically and environmentally. ”

”

Today, NASA has begun its recruitment for the long-duration Mars mission analog study inside the 3D-printed habitat. Applications to participate as crew are being accepted through mid-September 2021 for the one-year analog mission that starts in Fall 2022. To learn more or to apply, visit www.nasa.gov/chapea/participate.

ICON also received funding from NASA and launched “Project Olympus” to begin research and development of a space-based construction system to support future exploration of the Moon. As part of a government Small Business Innovation Research (SBIR) contract, “Project Olympus” brought ICON and BIG together again to imagine humanity’s first home on another world.

Known for its advanced 3D printing technology for homebuilding on Earth, ICON delivered the first, permitted 3D-printed home in the U.S. in 2018. Since then, the team delivered the world’s first 3D-printed community of homes in Mexico in partnership with housing nonprofit New Story (as seen on Apple TV+ docuseries, “HOME”), completed a series of homes serving the chronically homeless in Austin, TX with nonprofit Mobile Loaves & Fishes at Community First! Village and forged a partnership with the Defense Innovation Unit and United States Marine Corps. In 2021, ICON entered mainstream American housing by printing the first 3D-printed homes sold in the U.S. and launched its Exploration Series of homes pushing the boundaries of architecture and design in 3D-printed home construction. The Austin-based technology company continues to break ground on additional projects spanning mainstream developments, social/affordable housing, disaster-relief housing along with continued work with the Department of Defense and military forces.

In 2021, ICON entered mainstream American housing by printing the first 3D-printed homes sold in the U.S. and launched its Exploration Series of homes pushing the boundaries of architecture and design in 3D-printed home construction. The Austin-based technology company continues to break ground on additional projects spanning mainstream developments, social/affordable housing, disaster-relief housing along with continued work with the Department of Defense and military forces.

For more information visit www.iconbuild.com.

About ICON

ICON develops advanced construction technologies that advance humanity. Using proprietary 3D printing robotics, software and advanced materials, ICON is shifting the paradigm of homebuilding on Earth and beyond. For more information visit www.iconbuild.com or follow the conversation on Instagram, Twitter, Facebook, YouTube (@ICON3DTech).

About BIG

BIG-Bjarke Ingels Group is a Copenhagen, New York, London and Barcelona based group of architects, designers, urbanists, landscape professionals, interior and product designers, researchers and inventors. The office is currently involved in a large number of projects throughout Europe, North America, Asia and the Middle East. BIG’s architecture emerges out of a careful analysis of how contemporary life constantly evolves and changes. By hitting the fertile overlap between pragmatic and utopia, we architects once again find the freedom to change the surface of our planet, to better fit contemporary life forms.

The office is currently involved in a large number of projects throughout Europe, North America, Asia and the Middle East. BIG’s architecture emerges out of a careful analysis of how contemporary life constantly evolves and changes. By hitting the fertile overlap between pragmatic and utopia, we architects once again find the freedom to change the surface of our planet, to better fit contemporary life forms.

This 3D-printed Mars habitat could be your new home in space

Made the months-long journey to Mars but got nowhere to live? One company's vision for a Martian habitat hopes to bring the familiar touches of home to the red planet.

Claire Reilly

See full bio

1 of 20 AI SpaceFactory

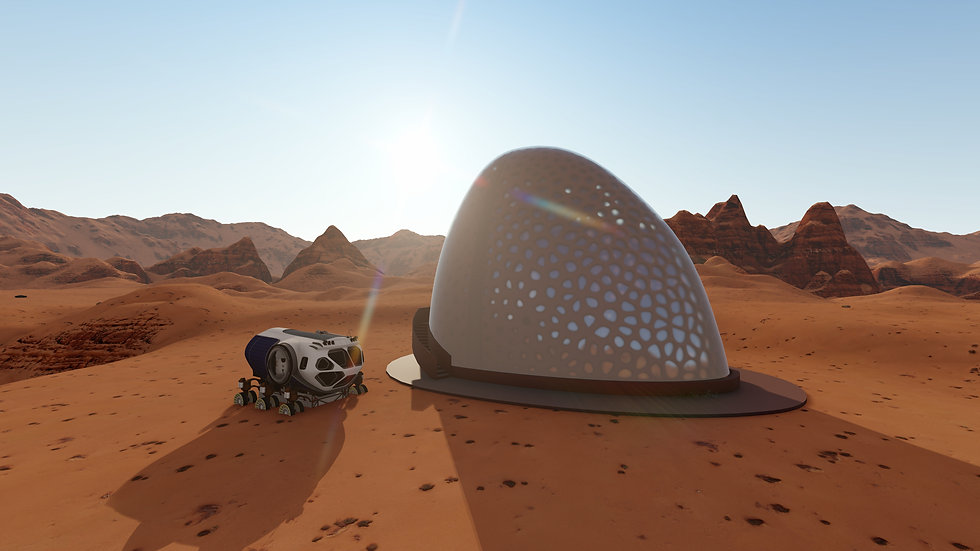

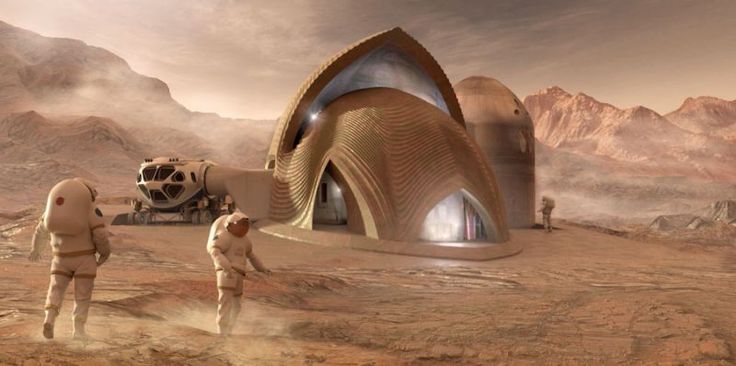

When life on Earth starts to feel particularly apocalyptic, it's tempting to imagine that humans may one day leave this planet and become an interplanetary species. But though SpaceX and NASA might want to put humans on Mars, what would life look like there long-term? One company has built its vision for the future of life on Mars, designing a habitat called Marsha. The egg-shaped design was created by New York-based architecture firm AI SpaceFactory, in response to NASA's 3D-Printed Habitat Challenge. The company built a one-third scale replica of the habitat here on Earth and took the top prize in NASA's challenge.

But though SpaceX and NASA might want to put humans on Mars, what would life look like there long-term? One company has built its vision for the future of life on Mars, designing a habitat called Marsha. The egg-shaped design was created by New York-based architecture firm AI SpaceFactory, in response to NASA's 3D-Printed Habitat Challenge. The company built a one-third scale replica of the habitat here on Earth and took the top prize in NASA's challenge.

2 of 20 AI SpaceFactory

AI SpaceFactory set out to design a habitat that could be built by robots, with little human intervention, and that could be constructed from materials that are easily accessible on Mars. Marsha is designed to be 3D-printed using a mixture of ground-up Martian rocks and plant-based polymer. This reliance on "locally sourced" materials means taking less building materials as cargo on the expensive journey from Earth.

3 of 20 AI SpaceFactory

Sci-fi movies like The Martian often show dome-shaped structures in space, but AI SpaceFactory used an egg shape for its design. According to the company, this shape is the most structurally efficient form for a build, particularly when you want to minimize the materials needed for construction.

According to the company, this shape is the most structurally efficient form for a build, particularly when you want to minimize the materials needed for construction.

4 of 20 AI SpaceFactory

AI SpaceFactory conducted a practice build for Marsha at the Autodesk Technology Center in Boston. There, the team was able to work on aspects of the design and to build using 3D-printing processes similar to what might one day be used on Mars.

5 of 20 AI SpaceFactory

One of AI SpaceFactory's employees looks on during a practice build of a scale model of Marsha.

6 of 20 AI SpaceFactory

Marsha features a double-walled design with a skylight at the top, which allows natural light to filter down between the shells and light up all four levels.

7 of 20 AI SpaceFactory

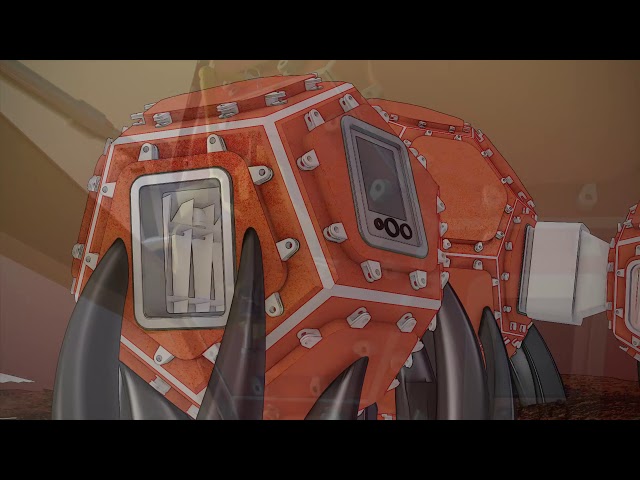

Marsha's double-walled structure also helps the habitat withstand the pressures of being in space. The Martian atmosphere outside is much thinner than the Earth-like atmosphere inside, so AI SpaceFactory had to design for internal air pressure. That double-walled design stops the habitat from expanding out like a balloon.

That double-walled design stops the habitat from expanding out like a balloon.

8 of 20 AI SpaceFactory

The design features stairways built into the curved structure that allow residents to move easily between levels.

9 of 20 AI SpaceFactory

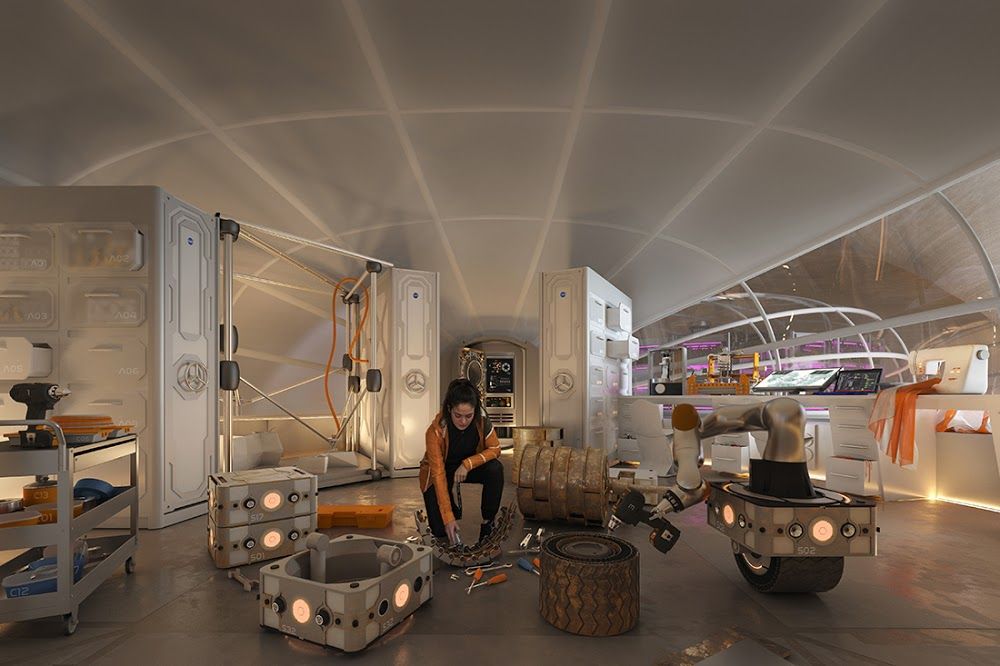

On the ground level, Marsha features a garage and wet lab with space for inhabitants to work.

10 of 20 AI SpaceFactory

Even on the ground floor, light filters down from the above skylight, allowing the crew to work comfortably as they would back home.

11 of 20 AI SpaceFactory

The ground floor also features a space for EVA prep, where astronauts can prepare for "extravehicular activities" that'll take them outside into the Martian environment.

12 of 20 AI SpaceFactory

The second floor features more communal space, with a kitchen and dry lab.

13 of 20 AI SpaceFactory

The office space sits alongside the kitchen area on the second floor. Though you wouldn't expect to be eating many gourmet, three-course meals, you might still prepare food grown on Mars (like potatoes, served a la "The Martian").

14 of 20 AI SpaceFactory

The curves of the 3D-printed structure give Marsha a more organic feel, despite the highly technical nature of the space.

15 of 20 AI SpaceFactory

The third floor features a garden and sanitation pod as well as personal spaces for the inhabitants. One of the key design considerations for AI SpaceFactory was creating a space that felt natural and human-centric, with private space to recharge.

16 of 20 AI SpaceFactory

Inside one of the personal pods in Marsha. Even on Mars, AI SpaceFactory likes to think, there'll still be time to video chat with your friends.

17 of 20 AI SpaceFactory

On the fourth floor of Marsha, a communal recreation and exercise space takes advantage of the light from the skylight above.

18 of 20 AI SpaceFactory

Isolation will be a big factor for travelers to Mars. AI SpaceFactory wanted to create a space where inhabitants could still enjoy some down time.

19 of 20 AI SpaceFactory

AI SpaceFactory's vision for the future of Martian habitation may be a long way off, but the company hopes that one day life on Mars will be within reach of humans on Earth.

20 of 20 AI SpaceFactory

"Living on Mars is for the adventurous," says AI SpaceFactory CEO David Malott, one of the key people behind Marsha. "I think there's a certain romance of going to a place that no one has gone before."

NASA's 3D-printed Martian habitat could work on Earth

Back in August 2018, NASA's 3D-printing Mars competition was unveiled. One of them was "Marsha" from AI SpaceFactory, which received $500,000 in the competition.

Even though humans haven't reached Mars yet, the AI SpaceFactory hasn't stopped working on their habitat and has become quite technologically inventive and useful for research right here on Earth.

“In space architecture, every design decision is critical to success. Structures must be stable and fit for the mission,” says the Marsha website.

Structures must be stable and fit for the mission,” says the Marsha website.

"Marsha, AI SpaceFactory's Mars habitat design, shows that the outcome can be both forward-thinking and believable with an alien yet familiar environment."

Let's explore the technology behind this almost luxurious living environment.

1. 3D printed.

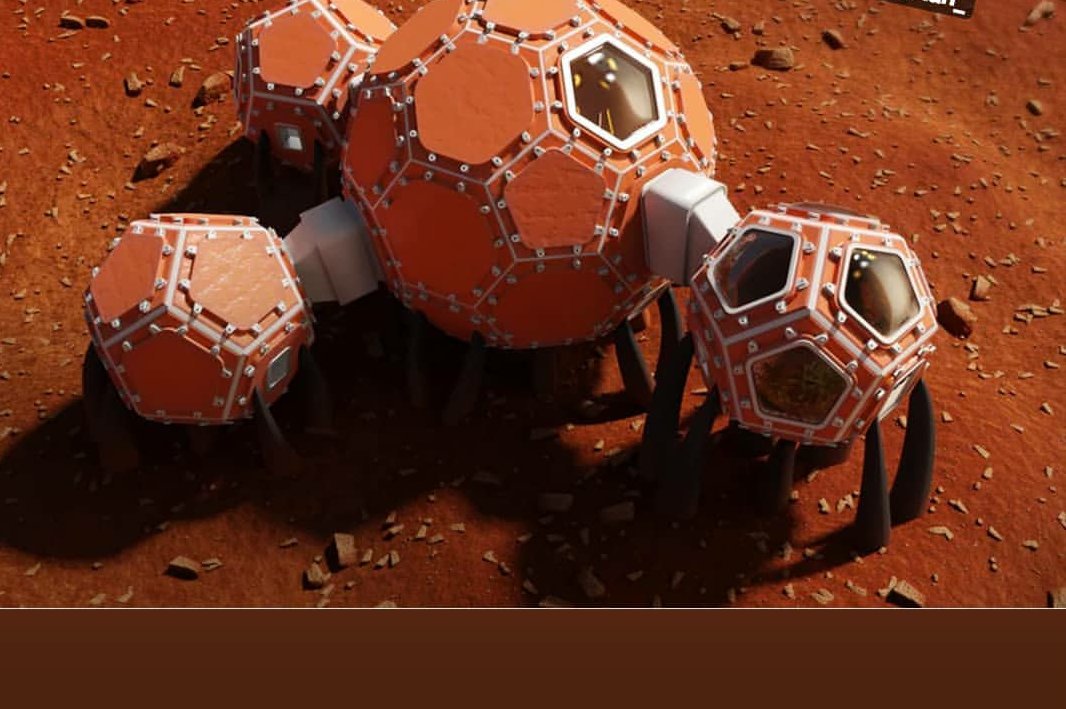

SpaceFactory combines innovations in robotics, control algorithms, materials and design to deliver a full-service 3D printing experience. This means printing on Marsha is cheaper, greener and safer. This also means that Marsha can be easily built on Mars with local materials. Which is especially important for future missions to Mars, since we won't be able to take all the materials we need to build housing with us.

Source: SpaceFactory

2. Construction robotics is used.

SpaceFactory's 3D printing technology uses telemetry/teleoperation, data analytics, machine learning and AI for greater offline capabilities. This means that habitats on Mars will be able to build themselves without much human oversight. This is very important since our first colonies on Mars will most likely not be very populated and will consist of a few key scientists needed to complete the mission.

This means that habitats on Mars will be able to build themselves without much human oversight. This is very important since our first colonies on Mars will most likely not be very populated and will consist of a few key scientists needed to complete the mission.

Source: SpaceFactory

3. Using high quality eco-friendly materials.

In space, SpaceFactory plans to use local materials, but right here on Earth, natural and recycled composite materials are used, which are stronger and more durable than concrete.

Source: SpaceFactory

The interiors of the habitat are filled with space. One could imagine that they belonged to some luxurious eco-project. Looking at this project from the inside, it becomes very clear why NASA chose it as a winning option back in 2018. But will it be he who will populate future colonies on Mars? Time will tell.

Image: AI SpaceFactory

interesting engineering

Tags: Additive technologies 3d printingComposite materialsRobotics

BIG and ICON to 3D print a "new Martian language" for NASA

Bjarke Ingels Studio BIG collaborates with building technology company ICON and NASA to create Mars Dune Alpha , a 3D printed structure designed to mimic life on Mars.

Under construction at the Johnson Space Center in Texas, USA, the 158 square meter "habitat" was designed by BIG and ICON to help prepare people for life on the Red Planet.

BIG unveils Mars Dune Alpha visuals

Mars Dune Alpha will keep four people occupied for extended periods of time and, by simulating the expected experience of life on Mars, will help NASA understand the physical and mental issues that can affect crew on a long-duration space mission .

"Together with NASA and ICON, BIG is exploring what humanity on another planet would entail from the human experience, potentially laying the groundwork for a new Martian language," BIG's Kai-Uwe Bergmann wrote in an Instagram post.

The structure will be 3D printed.

Mars Dune Alpha is being built using 3D printers as it is the technology of choice for building extraterrestrial habitats due to the lack of necessary building materials.

The specific technology that will be used is Vulcan, ICON's 3D printing system that uses the company's proprietary Portland cement-based mixture called Lavacrete.

It is under construction at the Johnson Space Center.

Once built, the structure will include four private crew quarters on one side, accessed through centrally located shared living quarters. On the other side there will be workers, medical and food stations.

According to ICON, ceiling heights will vary throughout to ensure each room is visually unique to "avoid spatial monotony and crew fatigue."

Each room will also have customizable lighting, temperature and sound adjustment, and fixed and movable furniture to allow users to reorganize and personalize the interior.

It will use ICON Vulcan technology.

"This is the highest quality habitat simulation ever created by humans," said ICON co-founder Jason Ballard.

“Mars Dune Alpha is meant to serve a very specific purpose, to prepare people for life on another planet. We wanted to develop the most accurate analog that could help humanity's dream of expanding to the stars."

"Habitat 3D printing has once again illustrated to us that construction scale 3D printing is an essential part of humanity's toolkit on Earth and for going to the Moon and Mars to stay," Ballard added.

“Together with NASA and ICON, we are exploring what humanity on another planet would entail from the human experience,” said BIG founder Bjarke Ingels.

“The data generated from this habitat study will directly feed into NASA standards for long-duration exploration missions and, as such, will potentially lay the groundwork for a new Martian jargon. Mars Dune Alpha will bring us one step closer to becoming a multi-planet species."

Researchers will determine the suitability of 3D printing for extraterrestrial habitat

Mars Dune Alpha is being built with the support of NASA's Office of Space Technology (STMD), which is part of The Crew Health and Performance Exploration Analog (CHAPEA).

CHAPEA is a series of three one-year simulation flights to the surface of Mars at NASA's Johnson Space Center in Houston to provide insight into future space missions.

NASA is currently recruiting a team for a long-term study of a mission to Mars inside a 3D-printed Mars Dune Alpha starting in the fall of 2022.