Jay leno 3d printer video

Jay Leno partners with Stratasys to 3D print custom parts for classic vehicle and supercar collection

0Shares

Stratasys has announced it is collaborating with Big Dog Productions, the media production firm headed by North American comedian Jay Leno. The new partnership is an extension of Stratasys’ Performance Partner Program.

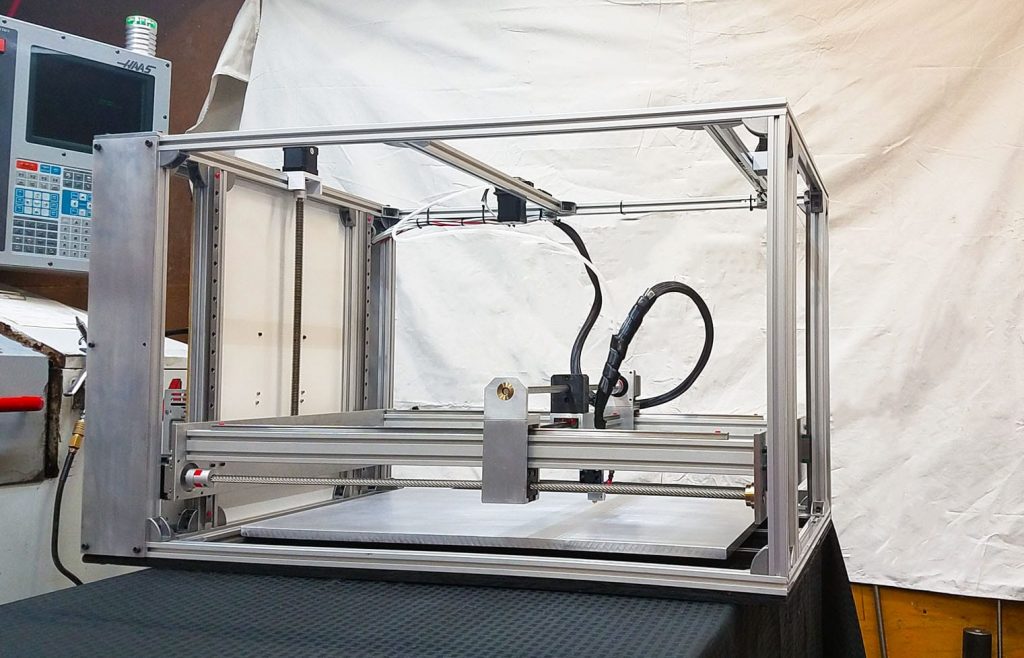

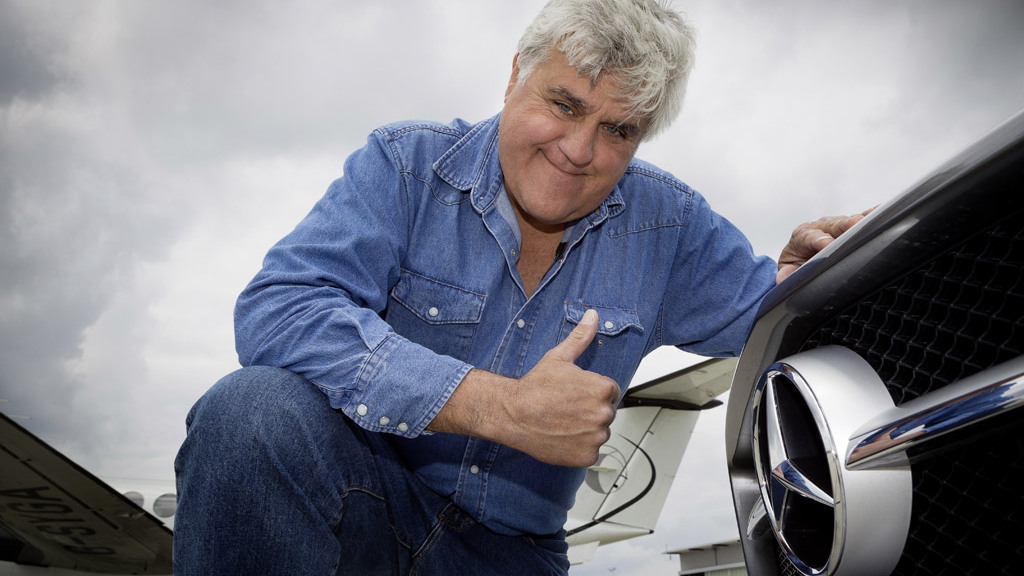

As part of the program, Stratasys will be providing the company with access to its FDM 3D printers to support the motor vehicle television series “Jay Leno’s Garage”, in which the former “Tonight Show” host conducts reviews on a wide range of vehicles, including vintage and restored cars. With access to Stratasys 3D printers, Leno intends to service his large collection of vehicles, located at his Big Dog Garage in Burbank, California, with 3D printed custom parts.

“Jay has long been one of the pioneers and adopters of 3D printing. He realized the technology’s potential for on-demand, custom parts early on – claiming it as a critical component to fueling a passion for classic vehicles,” commented Pat Carey, Senior Vice President of Strategic Growth Americas at Stratasys.

Jay Leno next to Stratasys Fortus 450mc 3D printer. Photo via Stratasys.“We cannot wait to see what uses of 3D printing they come up with next, because if they can dream it, we can 3D print it.”

Performance Partner Program

The Performance Partner Program from Stratasys was announced recently, in September 2019, and it aims to connect auto racing, competitive sailing and supersonic travel teams leveraging additive manufacturing. “Never before has there been a focused, collaborative group of the who’s who of these industries – dedicated to advancing the use of additive manufacturing across these high-performance environments,” explained Pat Carey, Senior Vice President of Strategic Growth at Stratasys.

At launch, the Performance Partner Program consisted of 11 partners. This includes Colorado-based aerospace company Boom Supersonic, which recently extended its partnership with Stratasys to further accelerate the adoption of additive manufacturing for flight hardware. NTT IndyCar Series racing team Arrow Schmidt Peterson Motorsports (Arrow SPM) is also a part of the program. The racing team has integrated the Fortus 450mc and F370 3D printers from Stratasys to accelerate design iterations, workflows, and final part production.

NTT IndyCar Series racing team Arrow Schmidt Peterson Motorsports (Arrow SPM) is also a part of the program. The racing team has integrated the Fortus 450mc and F370 3D printers from Stratasys to accelerate design iterations, workflows, and final part production.

Harnessing 3D printing for automotive digital inventory

As an extension of Stratasys’ Performance Partner Program, Jay Leno’s Garage/Big Dog Productions will leverage 3D printing to build a digital inventory that helps road test, refurbish and retrofit classic vehicles and supercars in Leno’s collection. Located within the Big Dog Garage are 169 cars and 117 motorcycles. Previously, Big Dog had already been collaborating with Stratasys Direct, the company’s on-demand manufacturing service, for nearly 10 years.

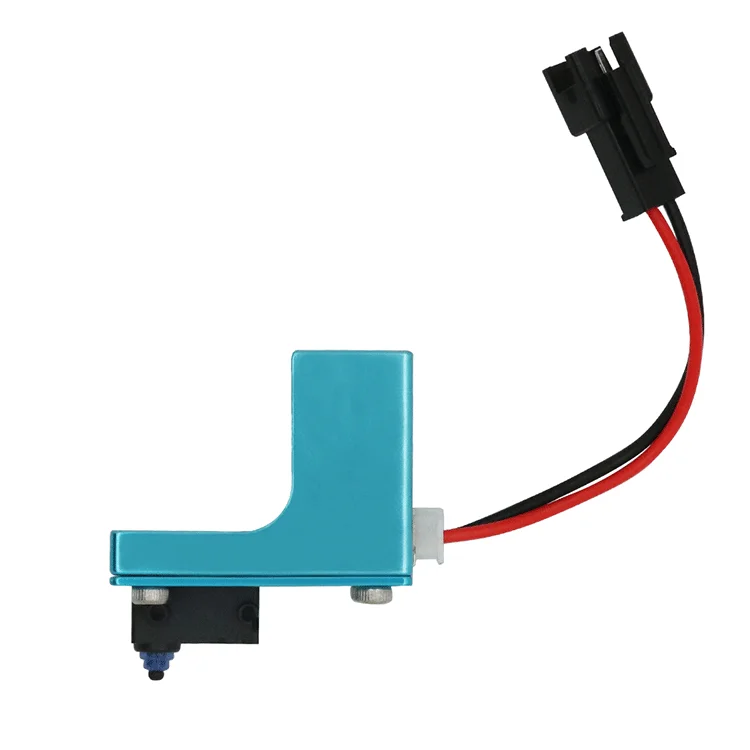

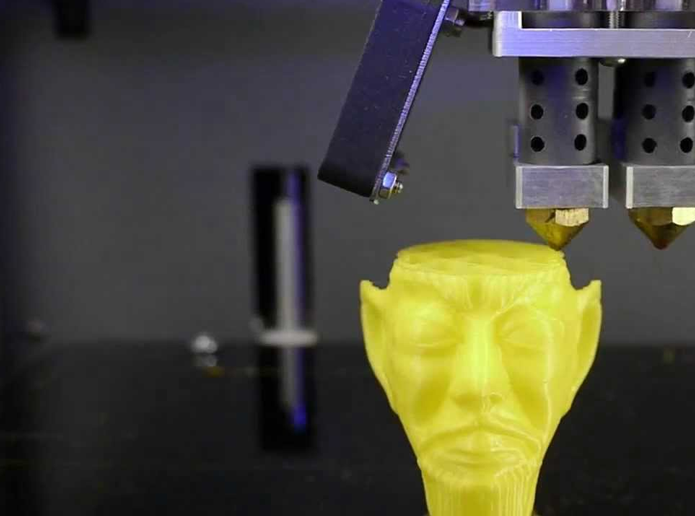

Jay Leno and Big Dog Garage will henceforth have access to core Stratasys additive manufacturing solutions, which includes the Fortus 450mc 3D printer and FDM Nylon 12 Carbon Fiber. Thus far, Leno has worked with the extended Stratasys team to produce high performing 3D printed prototypes and custom parts for the automotive collection. The technology has provided a significant advantage in facilitating the re-creation of parts no longer on the market or components that would prove too time-consuming to manufacture using traditional methods.

Thus far, Leno has worked with the extended Stratasys team to produce high performing 3D printed prototypes and custom parts for the automotive collection. The technology has provided a significant advantage in facilitating the re-creation of parts no longer on the market or components that would prove too time-consuming to manufacture using traditional methods.

“As a lover of classic cars, I’m always looking to push the boundaries of what’s possible in creation and re-creation of these vehicles – and 3D printing is integral to this process,” explained Jay Leno. “After working with Stratasys and Stratasys Direct for years to drive the ultimate in 3D printing innovation, I’m really excited about this new Fortus machine and where it takes us next.”

Subscribe to the 3D Printing Industry newsletter for the latest news in additive manufacturing. You can also stay connected by following us on Twitter and liking us on Facebook.

Looking for a career in additive manufacturing? Visit 3D Printing Jobs for a selection of roles in the industry.

Featured image shows Jay Leno’s Garage. Photo via Walker Dalton/CNBC.

Tags Big Dog Garage Big Dog Productions FDM Nylon 12CF Jay Leno Jay Leno’s Garage Pat Carey Performance Partner Program Stratasys Stratasys Fortus 450mc

Anas Essop

Anas Essop is an English and Film graduate, who loves writing about the advancement of technology.

Jay Leno Reveals What He Thinks Of The Czinger 3D-Printed Hypercar

By Cody Colella

The 1250 horsepower car has a top speed of over 250 mph and gives a glimpse into the future of automotive manufacturing.

Via: YouTube via Jay Leno's GarageJay Leno's Garage on YouTube takes a trip to the headquarters of Divergent Technologies in California where Jay checks out the 2023 Czinger 21C, a hypercar made through a 3D printing process.

Jay talks through the digital manufacturing technology with founder Kevin Czinger and his son Lukas before taking the car for a test drive on the track.

Check out the video to see this innovative approach to car manufacturing in action.

The 2023 Czinger 21C On Jay Leno's Garage

As Jay Leno puts it, the 2023 Czinger 21C "marks a new era in the car business" as it allows for an even more efficient, simple approach to manufacturing automobiles than what exists already.

The car has a dual turbo and 7-speed manual transmission as well as a carbon fiber body and hybrid powertrain - the result of this car, due to the manufacturing, is a light, precise and extremely strong vehicle.

Czingers' 21C outputs 950 horsepower from the ICE engine alone and comes with a value of $2,000,000.

RELATED: 10 Current Hypercars Every Gearhead Should Know About

Divergent Technologies is already collaborating with multiple OEMs given the flexibility and adaptability of the manufacturing process.

The structure pieces of the car are both hollow and with internal structure support which combines lightness but also strength - the manufacturing process of the components of the car involve a succession of layers built on top of one another that is about 90% aluminum and 10% "secret sauce" the specifics of which they do not reveal.

Jay Leno Test Driving The Czinger 21C Hypercar

Via: YouTube via Jay Leno's GarageJay examines a brake caliper which is unlike any you have seen before given that it is a braking system and a suspension system built into a single unit labeled "functional integration."

With a thorough review of how the car works, it is time for Jay to take the car for a test drive; he will be the first person outside the company to drive the car.

The design of the 21C drew inspiration from the United States Air Force SR-71 Blackbird.

RELATED: Everything We Know About The Viritech Apricale, A Hydrogen-Powered Hypercar

Out on the track in the desert, Jay enjoys the driving dynamics of the car that has two seats behind each other like a fighter plane.

The center driving position allows for great visibility and overall control of the car which has a top speed of 253 mph, with Jay commenting that even when you think you've reached the limits, you can tell the car will go faster.

The car utilizes regenerative braking and torque vectoring and the parts, given the engineering and build process can be re-designed and manufactured in a matter of hours.

Jay Leno restores EcoJet and other rare cars with

3D printing technology12/14/2015

We all know Jay Leno as a stand-up comedian and host of 's The Tonight Show. He is also widely known to car enthusiasts: his collection includes more than 286 cars and motorcycles. But today, Leno has shown himself in a new light: as the star face of 3D printing technology.

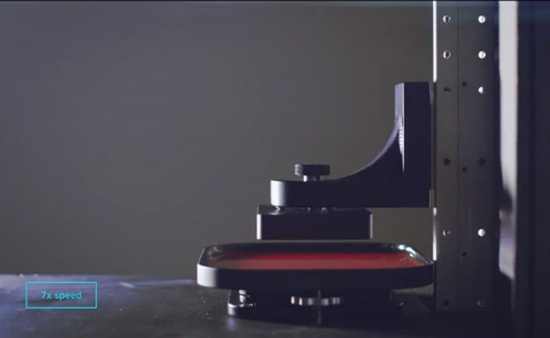

Recently on CNBC's Jay Leno's Garage, Leno talked about Local Motors, the creators of the first 3D printed car model. He also tested the materials used in Sphere 9 for durability in front of cameras.0005 3D technology from and even drove a Strati, a car completely created on a 3D printer. Just recently, industry giant 3D Systems, revealed that the screen star turned to them to create the necessary parts to restore a homemade car, a one-of-a-kind EcoJet Car.

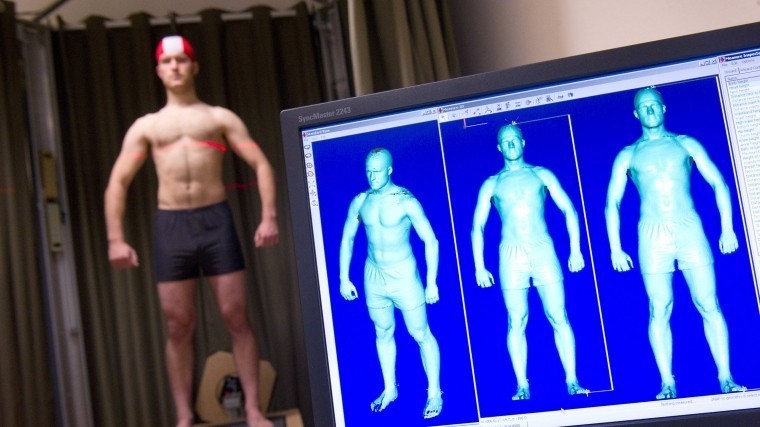

This is a ventilation grill for a car designed by Leno with General Motors; its body is made of carbon fiber, and the power of the Honeywell LTS-101 turbine engine is 650 horsepower and is often used for helicopters. The ventilation grille is an important component to ensure sufficient air access to the engine, but the existing models were too fragile and broke during transport from the workshop. Leno turned to 3D Systems to resolve the issue.

First of all, 3D Systems Geomagic Design X software was used to create a single model for printing, after processing the 3D laser scan data of the broken part. When the digital 3D model was ready (the process took less than 30 minutes), the part was printed on the production SLS printer. The material chosen was DuraForm HST, a lightweight material based on nylon fibers. Thus, Leno was able not only to recreate the original model, but also to make it stronger and more reliable.

“Simply amazing! We took the results of a 3D scan - and now I have a finished, perfectly fitting part in my hands.

With the help of 3D printing technology, the automotive industry will be able to develop by leaps and bounds,” says Leno.

“This is a huge opportunity: we can recreate any part, no matter how rare or complex, in almost a day. It will cost less and be created faster than ever before. I think this is the future of the automotive industry,” Leno shares his impressions.

However, as it turns out, this isn't the first time the TV presenter has turned to 's 3D printing technologies to create rare parts for his rarest and oldest collectible cars.

Whether Jay Leno likes it or not, he could soon be the face of technology.

Source: 3ders.org Please rate the news: Share: ago to news News Subscribe I do not want 5 In this episode, we'll cover ViscoTec's two-component viscous extruders, British 3D laser powder printer manufacturer Renishaw's participation in Spain's next-generation gas turbine engine program, and show a full disassembly and run-in view of the Divergent Blade 3D printed supercar. Viscosity Printing Extruders ViscoTec develops screw extruders with a focus on 3D printing with viscosities. The newest offer, ViscoDUO-FDD, provides printing with two-component compositions - silicones, epoxy resins, polyurethane, acrylates and polyesters. The design of the extruder is based on a split feed with mixing in a replaceable tube. Such a campaign avoids clogging the head with hardening material. The use of auger feed makes it possible to accurately control the retract. The company hopes that the new extruders will provide a strong alternative to the standard heads used in FDM printing and expand the range of materials used. The design of the extruders makes it easy to install new heads on familiar desktop bar 3D printers. Additional information is available on the manufacturer's website. Renishaw industrial 3D printers in the Spanish engine industry Demand for additive manufacturing technology in the aircraft industry continues to grow. Funded by the Spanish Ministry of Economy, the project will be directly involved in the ninth-ranked engine company ITP in the world in terms of annual revenue, and the national research organization IMDEA, which brings together a number of specialized institutes. Renishaw's mission is to 3D print high-performance, lightweight components using RenAM 500M 3D printers. Road test of a 3D printed supercar The famous American showman Jay Leno, longtime host of The Tonight Show, has been working on a not-quite-professional amateur project for several years - car reviews called Jay Leno's Garage. Most recently, the star of American television and a notorious car enthusiast had a chance to break in the Divergent Blade supercar. We have written about Divergent more than once. The production model of the company is based on the wide use of additive technologies. So, the Blade supercar is built on a chassis consisting of an ultra-light composite frame - carbon fiber pipes connected by 3D-printed metal fasteners. In addition to the frame, body elements are also printed. The car, weighing only 635 kg, is driven by a Mitsubishi engine with a power of 700 hp. From zero to one hundred kilometers per hour, the 3D printed rocket on wheels accelerates in just two and a half seconds, reaching a top speed of 320 km/h. On the next episode of his show, Jay spoke with Divergent CEO and designer Kevin Zinger, and at the same time tested the 3D printed supercar on the roads. Will it take off? Fall apart? See for yourself: Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at news@3Dtoday.

Subscribe to receive relevant news

90,000 extruders for printing with viscous materials, industrial 3D printer Renishaw and road tests of the 3D-print supercar Sign up for the author

The British company Renishaw, a manufacturer of industrial 3D printers using selective laser fusion technology (SLM), will take part in the Spanish Futuralve initiative. The project is aimed at developing a new generation of gas turbine units, including aircraft turbojet engines.

The British company Renishaw, a manufacturer of industrial 3D printers using selective laser fusion technology (SLM), will take part in the Spanish Futuralve initiative. The project is aimed at developing a new generation of gas turbine units, including aircraft turbojet engines.

Learn more