Morpheus 3d printer

Morpheus 3D Printer - 3D Printers - Talk Manufacturing

jcamper

#1

Does anyone know anything about the Morpheus 3D Printer? I really like the Form Lab 2 but the build size is just so small

1 Like

Acorn3D

#2

I bought one of the original units through their kickstarter campaign. On the whole I am very pleased with it and it mostly does an outstanding job. The details and volume size are outstanding. It is generally easy to set up and use.

However, it is not perfect. 2 issues bother me the most. For large colored prints there is a high likelihood that for most resins the pigment will settle out leaving the print varied in color. You could avoid this by pausing the print occasionally stirring the resin. I usually avoid by using a clear resin. The clear resin tends to be easier to work with anyway.

The other issue is I sometimes have difficulty with getting the print to stick to the build plate, especially larger prints.

You do need to be cautious when handling the build tank film. It is fairly tough but carelessness would damage it.

I would recommend buying a spare tank and a spare build platform, if you plan on fairly high print volume. Cleaning the tank and platform between prints can be a bit tedious and if you are in a hurry to get the next print going then it is convenient to just swap the tank and plat form and then clean the previous one at your leisure while the print is going. Of course if you don’t clean it right away then the job can become more tedious.

Cheers,

jcamper

#3

If you don’t mind me asking how old is your unit? I wonder if those things have been improved.

Almost everything I would run would be a rubber like material that would run VERY SLOW

Acorn3D

#4

8 or 9 months,

Actually I had pretty decent results with the rubber type materials, although I mostly did flatter membrane and gasket type prints with those and those print pretty quickly but the rubber sticks to the plate nicely.

I forgot to mention that when large thin rigid materials stick to the plate, then the problem is often getting the print off the plate without breaking it. With rubber type of materials, the flexibility of the material makes it much easier to separate without breaking.

With rubber type of materials, the flexibility of the material makes it much easier to separate without breaking.

jcamper

#5

Do you have a direct contact with someone at Owl Works 3D (Morpheus)?

Acorn3D

#6

I believe SJ is their CEO.

Cheers!

jcamper

#7

thank you, you have been very helpful

Jory

#8

I’m curious about them too but reaching them has been a PITA and pointless up to now. Maybe they are so busy fulfilling Kickstarter orders that they are ignoring all potential future customers? I had received one response from SJ saying he would get back in touch and after 3 months…nothing.

Maybe they are so busy fulfilling Kickstarter orders that they are ignoring all potential future customers? I had received one response from SJ saying he would get back in touch and after 3 months…nothing.

jcamper

#9

yeah, I was very interested in the printer but after months of no reply or feedback I went and purchased a FormLabs Form 2. I’ve been very happy with it

It doesn’t have the build size of the Morpheus but I like it

The New Morpheus 3D Printer: Watching Closely as the Owl Works

0Shares

This week, I was especially lucky when I found out that the crew from Owl Works had to visit Busan on business, and moved quickly to schedule an up close and personal demonstration of their new printer, the Morpheus, which was just very successfully funded on Kickstarter after launching two weeks ago. And if that wasn’t enough, I also had the opportunity to speak with several of the team members about their product and company, and really pick their brains a bit.

And if that wasn’t enough, I also had the opportunity to speak with several of the team members about their product and company, and really pick their brains a bit.

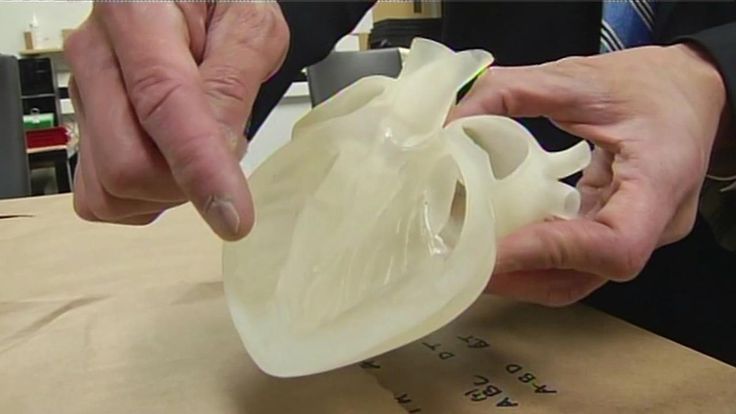

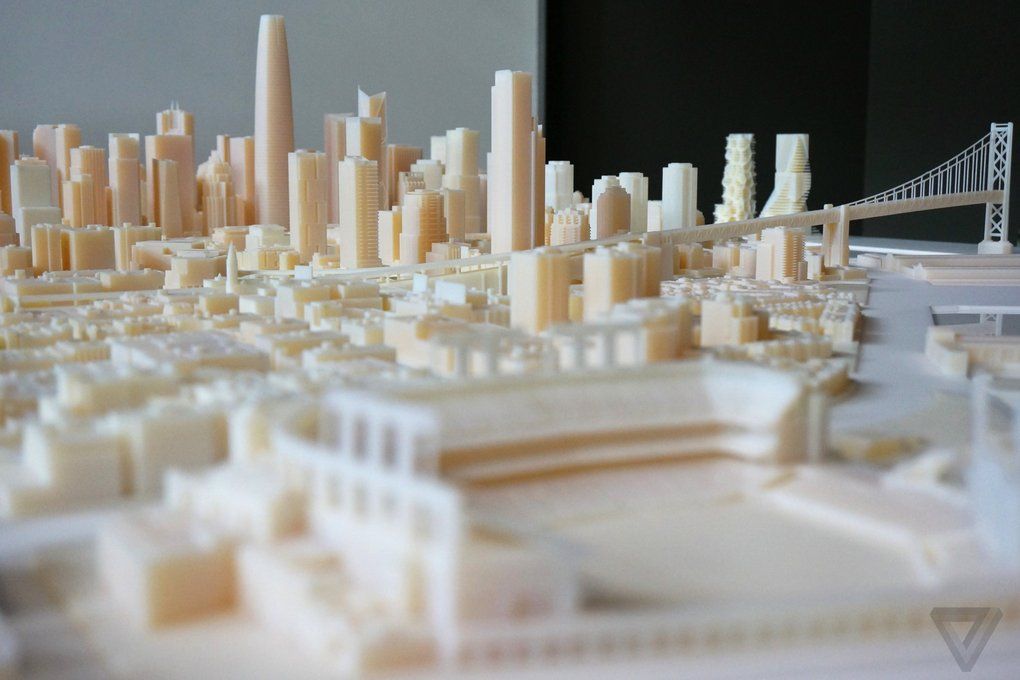

For those who don’t yet know, Owl Works’ new printer, the Morpheus, is a liquid resin printer that uses a combination of ultraviolet LED illumination and LCD masking to produce spectacular (and large) prints in a fraction of the time it takes traditional SLA or DLP machines to work. The Morpheus was the brainchild of SJ Park (aka: LabC) and Lee HongJoo, who came up with the concept a little over two years ago and first demonstrated it publicly just this year.

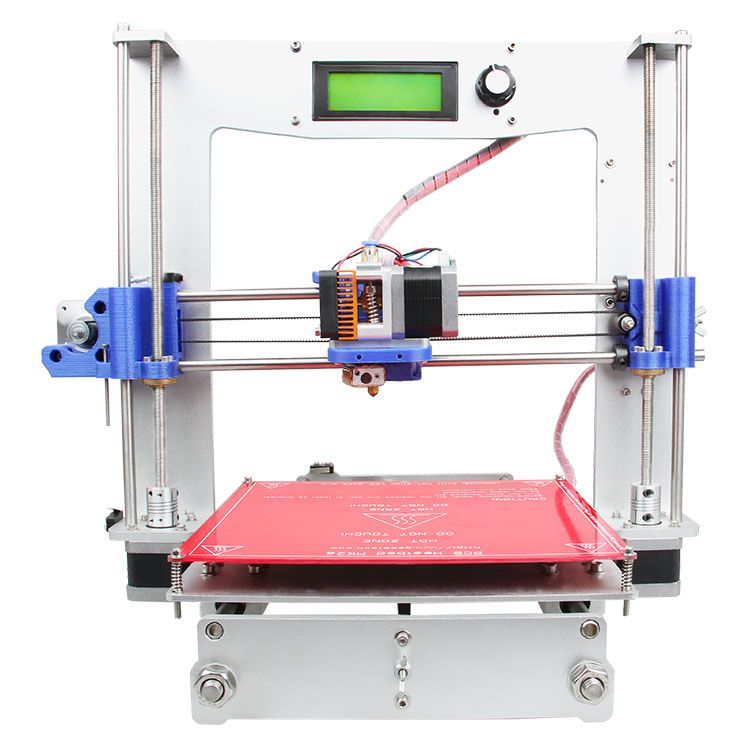

The Owl Works crew – including SJ Park, Lee HongJoo, Cho KyuBuk, and Hwang BoSeong – arrived with their machine and began to set it up. At the time, they had it mostly disassembled, so I got to see it being put back together, which was fascinating. The Morpheus isn’t an overly complex piece of hardware, from a design point of view. But looks can be deceiving, as SJ Park explained the engineering troubles that they had to overcome to make the whole thing work as well as it does. Not being an electrical engineer, most of what he explained sailed over my head with ease, but he did manage to help me to understand the most salient points.

Not being an electrical engineer, most of what he explained sailed over my head with ease, but he did manage to help me to understand the most salient points.

The early models had several problems, most notably that LCD screens were not suitable for UV masking, and, of course, finding supporters who believed in the idea. “We started out with no investors at all, just us. And, for two years, we had no income at all and we were exhausted,” said SJ, “But that first huge step is over, and now we can attract people with more technical skills and abilities.” He went on to explain how the early LCD screen (which was originaly made for displays) allowed the UV light to pass through and didn’t really work well. “We had to find the peak frequency of our light source(s) and match it to the proper LCD screen, which took a bit of searching.”

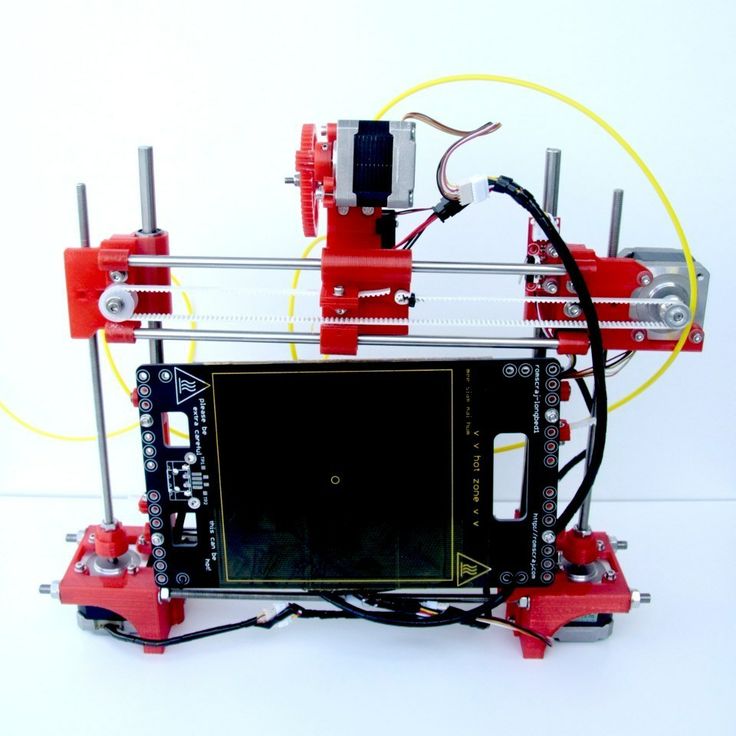

As he spoke, the machine began to hum and glow a beautiful pale purple, the LED lights switching on. I looked over the still only partially-assembled machine, with its wires and circuit boards spilled out all over the workbench, and noted that it looked like it had been violently disemboweled. HongJoo assured me that it was fine, and that everything fit neatly into the machine’s casing. It just made working and adjusting things while they were still experimenting a bit easier.

I looked over the still only partially-assembled machine, with its wires and circuit boards spilled out all over the workbench, and noted that it looked like it had been violently disemboweled. HongJoo assured me that it was fine, and that everything fit neatly into the machine’s casing. It just made working and adjusting things while they were still experimenting a bit easier.

HongJoo told me that, as an engineer, he enjoys his work, but what he is really working for is the economic freedom for his children. “3D printers are still very young, but as we build better and better ones, I think they will help bring about more economic equity in the world, allowing people to create what they really need to make their individual lives easier. At least, that is my hope.”

While we talked, both KyuBuk and BoSeong were busy changing the flexible, clear plastic sheet that serves as the bottom of the printer’s resin tank. This was one of those little things that, when you see it, you think, “Why didn’t anyone else think of that?” The tank itself is made of a welded steel frame, over which the plastic sheet is stretched and bolted into place.

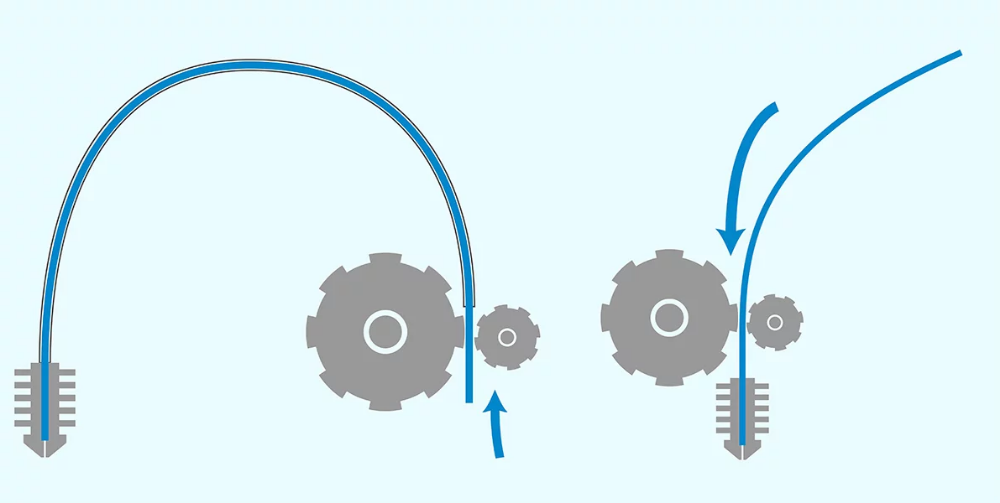

In addition to being economical, as you do not have to replace the entire tank as on other SLA/DLP machines, the flexibility of the sheet allows the machine to detach the 3D model being built from the tank floor simply by pulling it up slightly, without the need for the “tip and peel” process seen in other printers. This also helps to speed up the entire printing process, as unnecessary movements (and the more complex mechanisms needed to perform those movements) are eliminated. What you end up with is a lighter, simpler, more robust machine that has even better capabilities than its competitors.

As KyuBuk told me, “This machine is something new and I find it very fascinating. Literally we created something out of nothing. I know that our contribution to 3D printing will help a lot of people, and knowing that people will be using something I helped create is very exciting.”

BoSeong expressed similar feelings, but added that he found that as a Maker, “The work is just fun…like falling in love. It is hard to accurately express my feelings as the potential results of our work is not really limited by anything. We are creating our own futures.”

It is hard to accurately express my feelings as the potential results of our work is not really limited by anything. We are creating our own futures.”

Mark Lee

Mark teaches at a national university in Busan, South Korea and he conducts a variety of courses, including classes on transhumanism and additive manufacturing. He also supervises several student organizations and is currently organizing a student 3D design and printing users group to help further awareness about this exciting technology.

Team Owl Offers Morpheus Delta

Budget Resin 3D Printer News

The Korean team Team Owl offers a photopolymer 3D printer with an LCD mask - Morpheus Delta. The new evolution of the Morpheus line is positioned as a budget option under $1000.

LCD stereolithography mask technology is gradually gaining popularity. The main reasons for this are the low cost of LCD masks compared to DLP projectors and laser systems, as well as the ability to scale the working volume to quite impressive proportions - for example, the size of the construction area of the original Morpheus, launched in 2015, reaches 330x180x300 mm. The characteristics of the new Morpheus Delta are more modest, but for the sake of improved affordability. nine0003

The characteristics of the new Morpheus Delta are more modest, but for the sake of improved affordability. nine0003

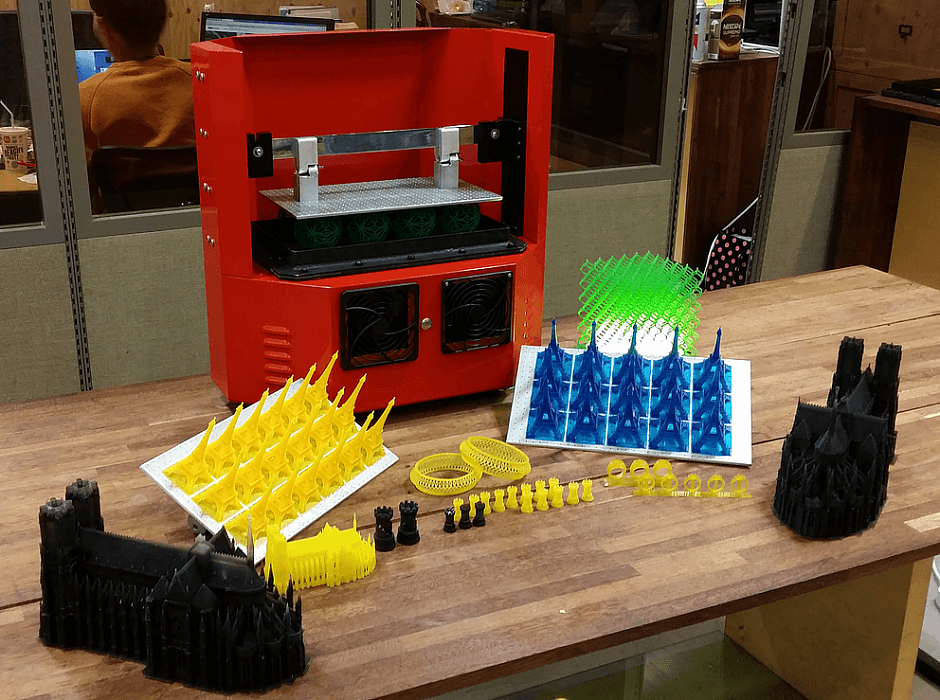

Morpheus Delta allows you to print objects up to 150x80x150 mm in size at a fairly high speed: with a ten-second exposure to 100 micron layers, the build-up rate is about 36 mm/h, although much depends on the material used. The X/Y resolution is 190 microns and the layer thickness can be varied between 25-200 microns.

The resin is cured using an LED panel with an LCD mask and lenses, but unlike similar Uniz Slash and Photocentric LC 3D printers, the illumination is in the UV range. In this case, one can only guess about the survivability of the mask, but the range of available consumables is significantly expanding. nine0003

The company offers a proprietary general purpose photopolymer resin in four colors - white, black, red and blue - for $69 per kilogram. At the same time, the developers promise to test resins from other manufacturers and share recommendations. 3DM and Fun-To-Do photopolymers have already been approved. Transparent, elastic and burnable options are currently being tested for compatibility.

3DM and Fun-To-Do photopolymers have already been approved. Transparent, elastic and burnable options are currently being tested for compatibility.

Software consists of Trinity proprietary slicer with nanoDLP capability for Raspberry Pi. Over time, the company plans to expand the lineup to include a compact version with high horizontal resolution (50-70 microns), a model with a larger build area, and perhaps even a color photopolymer option. nine0003

The Kickstarter fundraiser has already passed the minimum threshold with three weeks to spare. Pre-orders are still available for $579 before shipping and customs fees. The start of deliveries is scheduled for May next year, but the prototype (Morpheus E7) can be obtained as early as January for $750. Additional information is available at this link.

Do you have interesting news? Share your developments with us, and we will tell the whole world about them! We are waiting for your ideas at news@3Dtoday. ru. nine0029

ru. nine0029

Follow author

Follow

Don't want

7

Morpheus・Cults 3D Printable Best Files

Sandman helmet

Free

Morpheus Helmet - Sandman

15 €

Morpheus - Sandman

26.69 €

nine0004 Sandman Helmet ARTICULATED Dream Helmet Dream Helmet4,80 €

Sandman

€10.30

Dream stone necklace Ruby Sandman

1.49 €

Dreamstone Ruby Gudgeon

0,99 €

Funko Pop The Sandman Netflix Tridy Neil Gaiman

€15.53

Sandman

5 €

Dream helmet/mask (Sandman/Morpheus)

18 € -thirty% 12. 60 €

60 €

Sandman head

2 €

nine0004 Flexi Sandman helmet ARTICULATED The Helmet of Dreams2,80 €

SANDMAN helmet scale 1:1

3,75 €

FLOPPY MORPHEUS SANDMAN COLLECTION

2 €

Sandman steering wheel

19 €

MORPHEUS - SANDMAN

€15.13 -10% 13.61 €

The Sandman sogno morpheus

5 €

Sandman Dream of Morpheus Sogno

6 €

Dream // Sandman

0.