3D print map

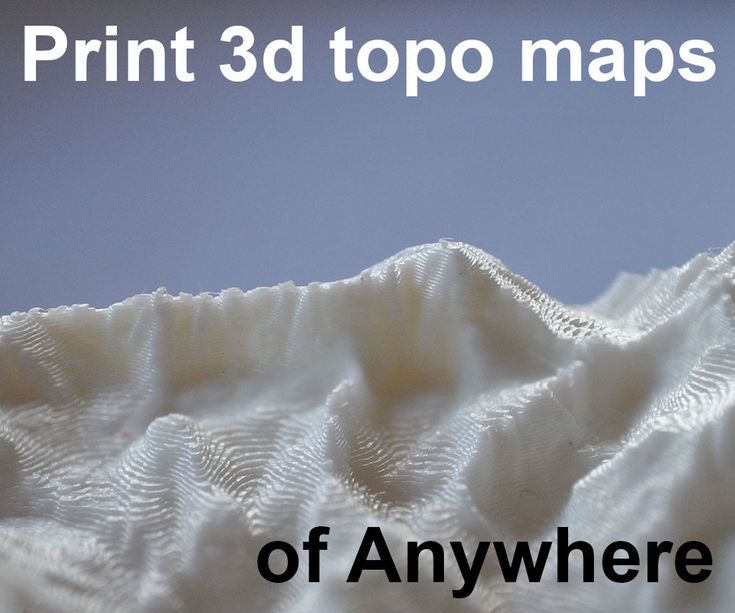

How to print maps, terrains and landscapes on a 3D printer

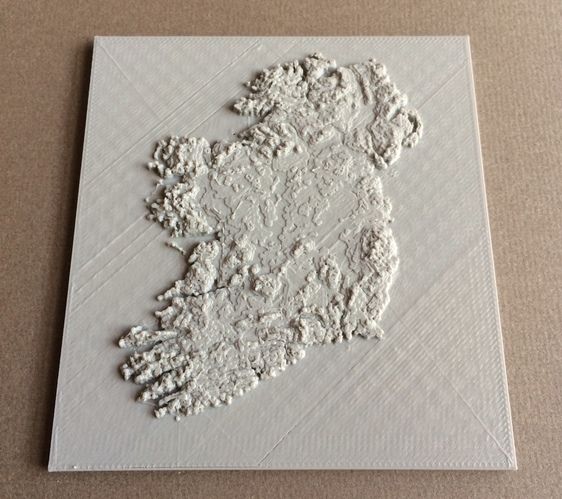

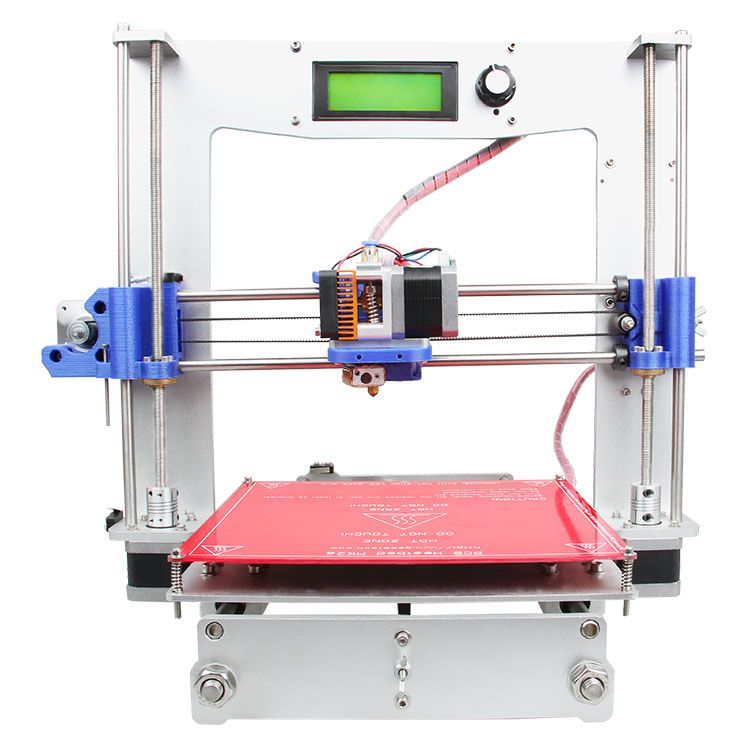

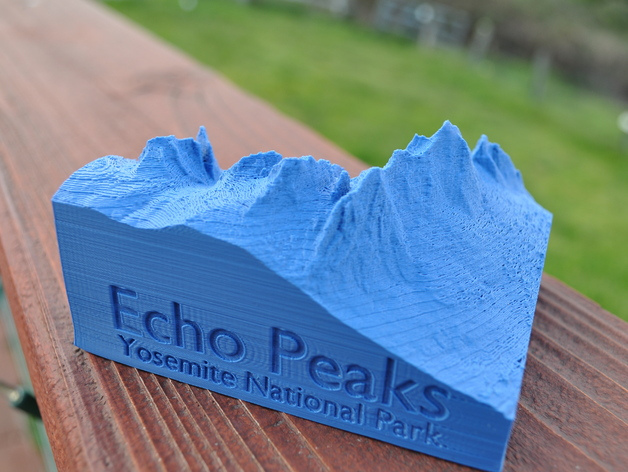

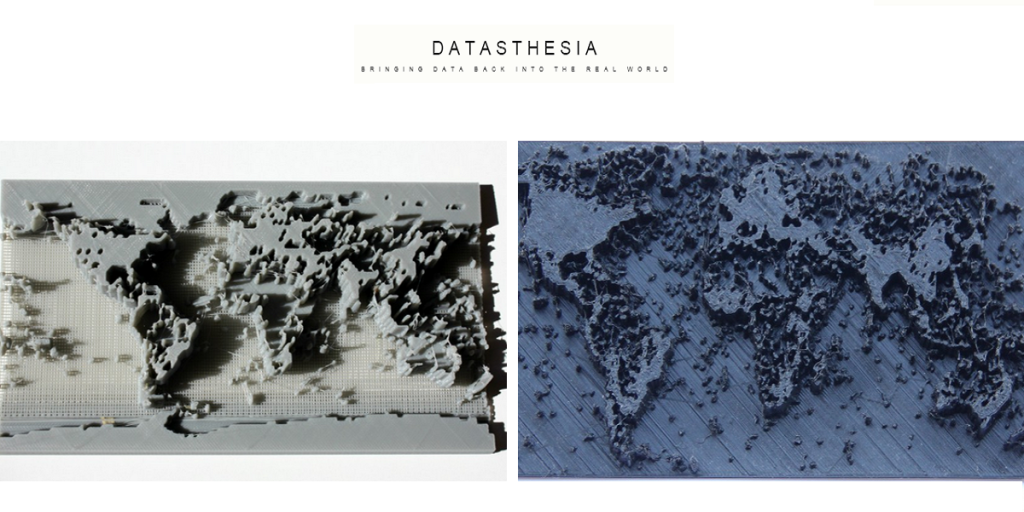

From time to time, every 3D printer owner is asked the same question: “Why is the printer really good and useful? I cannot imagine what would I use it for.” I did not find a satisfactory answer to this simple question at first, because I don’t consider printing figures and statues as the right example. That’s why every time the 3D printing technology is applied in practical use, I’m excited! Today, I’ll show you how to print a 3D map, that can serve in a number of situations not only using our Original Prusa i3 MK3 printer. How about a plastic model of terrain for school education, a small-scale version of a national park, a model that shows the overview of a real-world race track, or perhaps a tiny version of a mountain you climbed in the past. Thanks to these models, we can see the landscape from a bird’s eye view. Input data will be topographic maps that are most interesting for 3D printing purposes.

Models based on maps can be divided into two groups:

- Printing a terrain model – ideal for mountain ranges, volcanoes or abysses.

So where there are well-known elevations.

- Printing a terrain model including buildings – ideal for cities and areas with buildings.

Terrain models

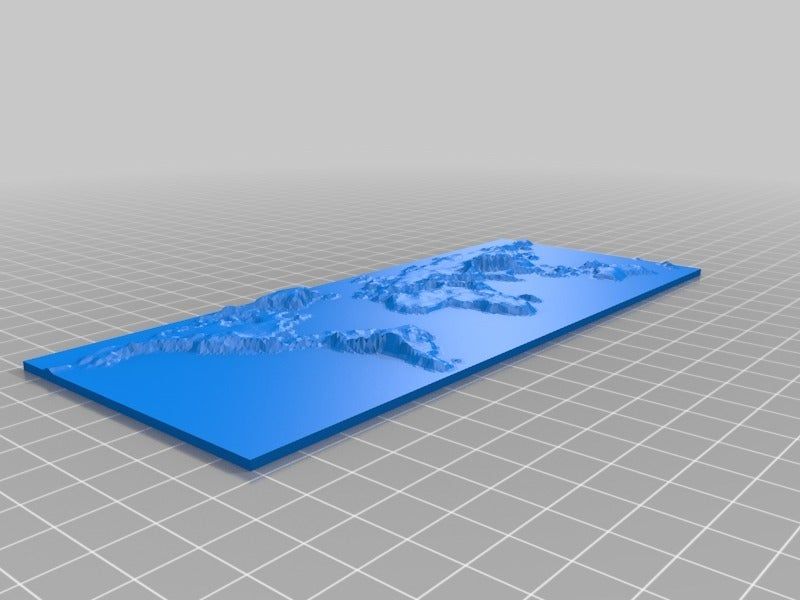

A 3D terrain model (without buildings) can be obtained simply and for free with the Terrain2STL web application.

- Find a place on the map. Rugged terrain works the best.

- On the Location tab, press Center to View. This will show a selection rectangle on the map.

- On the Model Details tab, adjust the size of the selected area by moving the Box Size slider. The selection can be moved in the map. If the resulting model is very flat, it is possible to scale it on the Z axis. This is done in the Model Details by using the Vertical Scaling slider. However, keep in mind that the resulting model will differ from reality.

- On the Water and Base Settings tab, set the desired model base height.

- Press the Generate Model button. Then click the Download button and download the model.

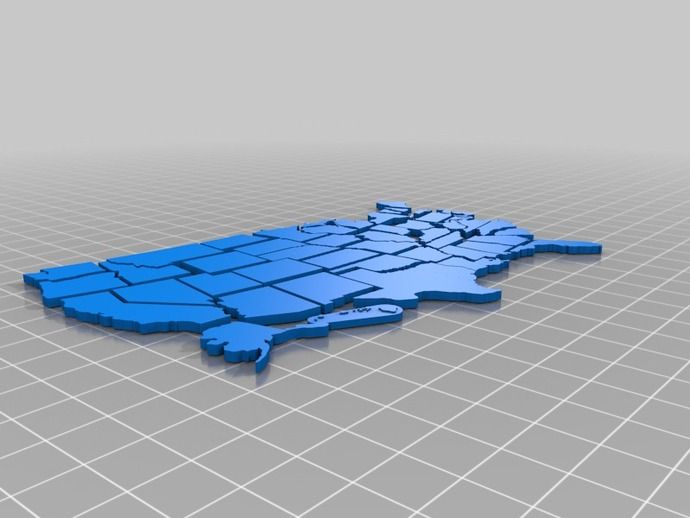

Does a square or rectangular shape feel way too ordinary? Let’s take a look at how to work with some more complex shapes. Naturally, one of the basic ideas is to use borders of existing countries. For the sample print, I chose the Czech Republic – the home of Prusa Research. A good start is to successfully obtain the STL terrain model from the previous step. However, the disadvantage of the Terrain2STL application is that it is not possible to change the shape of the selection. So, if you want to work with a larger area, you will need to cut the STL model first using a 3D editor and then work with it. This is because the Tinkercad software we want to use limits the size of the imported file to 25MB. A better solution is to use a similar tool like Terrain2STL. The TouchTerrain project allows you to select any aspect ratio on the map. I recommend aligning the map, for example, in the upper left corner for a simpler placement of the shape for the cutout.

I recommend aligning the map, for example, in the upper left corner for a simpler placement of the shape for the cutout.

How to do it:

- Find and download the desired shape in .SVG format. Ideally, it should be on a white or transparent background. To make searching easier, I recommend adding the keyword “silhouette“.

- In a web browser, open the Tinkercad tool and sign in (or create a free account).

- Create a new design by pressing the Create new design button.

- Create a block (use the “Box” tool on the right) and change the dimensions so it stretches across the entire Workplane.

- Import the downloaded .SVG file with the shape using the Import button in the top right corner. When the import is complete, the image is automatically converted to a 3D object. Change the shape type to “Hole“.

- Click the object with the right mouse button and first adjust its height in the Z-axis so that it is higher than the block.

Then, adjust the size of the model by dragging any corner to fit the block. To keep the aspect ratio hold the Shift key.

Then, adjust the size of the model by dragging any corner to fit the block. To keep the aspect ratio hold the Shift key. - Now select both objects (Ctrl + A), group them with the Group button (Ctrl + G) and change to the “Hole” type. This creates a negative shape, which then cuts the terrain.

- Import the terrain model using the Import button in the top right corner and wait for it to finish.

- Adjust the size of the terrain model and place it in the right place in relation to the carved shape.

- Deselect the selection of objects by pressing the mouse outside the print area.

- Export the object using the Export button in the top right corner of the .STL format.

- The model is ready to be sliced, for example, in Slic3r, where it can be scaled in the Z-axis if needed for better terrain visualization.

Download link: The Czech Republic 3D terrain model on PrusaPrinters

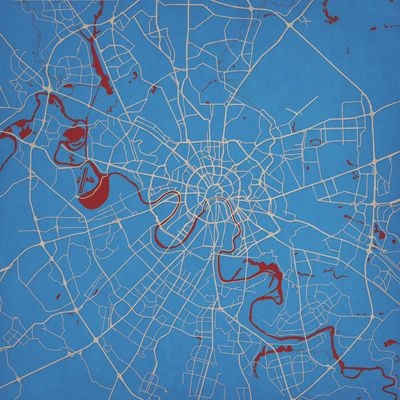

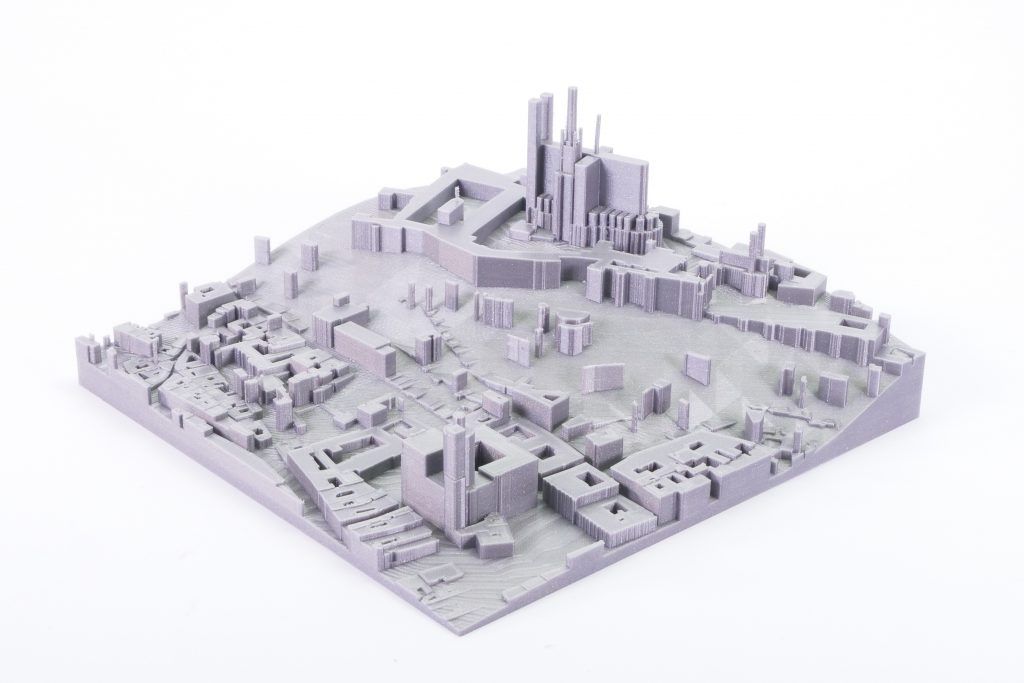

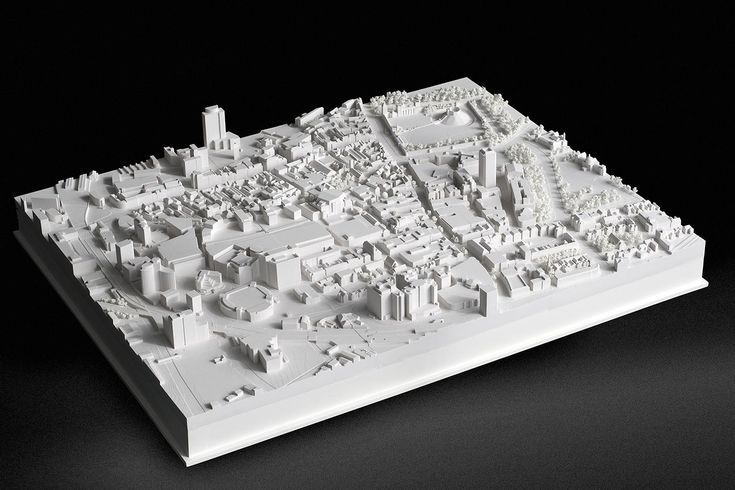

City model with terrainIn this case, the procedure is a little more complex than the terrain itself and more tools need to be used. To get the model, we use the CADMAPPER web tool, which uses freely available maps from OpenStreetMap as a source. The tool allows you to download a 3D model up to 1 km² area for free. Larger areas are paid. In most cases, 1 km² is perfectly fine. By covering the entire print area (25 x 21 cm), we get the ideal scale for the model (approximately 1: 4000 to 1: 5000).

To get the model, we use the CADMAPPER web tool, which uses freely available maps from OpenStreetMap as a source. The tool allows you to download a 3D model up to 1 km² area for free. Larger areas are paid. In most cases, 1 km² is perfectly fine. By covering the entire print area (25 x 21 cm), we get the ideal scale for the model (approximately 1: 4000 to 1: 5000).

- Open CADMAPPER tool in the browser and click Create a map.

- Select the desired area up to 1 km² (or larger and buy the model).

- Select the output format for SketchUp 2015+.

- Include Topography and 3D Buildings in the output model and choose the height of buildings for which the height in the map is not defined.

- Press the Create button to start generating.

- Press the Download button to download a generated zip file that contains the .SKP file.

The downloaded file is not yet fully prepared for slicing. What we need to do is to create an object under the terrain. In addition, we can simply change the height of buildings in this tool, especially those that have a default value from CADMAPPER. We will use SketchUp Pro for editing, which is free to download in the trial version.

What we need to do is to create an object under the terrain. In addition, we can simply change the height of buildings in this tool, especially those that have a default value from CADMAPPER. We will use SketchUp Pro for editing, which is free to download in the trial version.

Eneroth Terrain Volume extension is useful when you want to create a solid object under the terrain easily. Download this extension as well.

Add extensions using the Window -> Extension Manager. Press the Install Extension button and select the downloaded file from the previous step.

Now we have everything ready and we can start editing the model.

- Run SketchUp, open the downloaded file from CADMAPPER (File -> Open).

- On the right side of the application window, expand the Layers section and remove all layers except buildings, topography and Layer0. Press the “Delete content” icon. The content of the deleted layers is not easily printable, that’s why we’re deleting them.

However, you can play around with the content of deleted layers and see if something interesting comes out of it – we won’t be using them in our guide, though.

However, you can play around with the content of deleted layers and see if something interesting comes out of it – we won’t be using them in our guide, though. - Click anywhere on the terrain to select it. In the top menu of the app select Extensions menu -> Eneroth Terrain Volume. This creates a solid object under the terrain.

- If you want to change the height of the base or buildings, you must explode the model (select the whole model, right mouse button, Explode option), and then the Push / Pull tool to increase or decrease the height of the buildings or the base under the model.

- Export the model using File -> Export -> 3D Model.

The file is now ready for 3D printing. Open it in the Slic3r PE and adjust the size to fit the print area. For an area of 1 km², the approximately square shape of the model is reduced to about 20% of the original size. So we get the model on a scale of cca 1: 5000. We recommend a PLA material and a layer height 0. 15mm.

15mm.

1:5000

1:2500

1:1000

Download link: Prague Castle area on PrusaPrinters

Preparing the model for printing and correct orientationUse Slic3r PE or your favorite slicer tool to generate the gcode file.

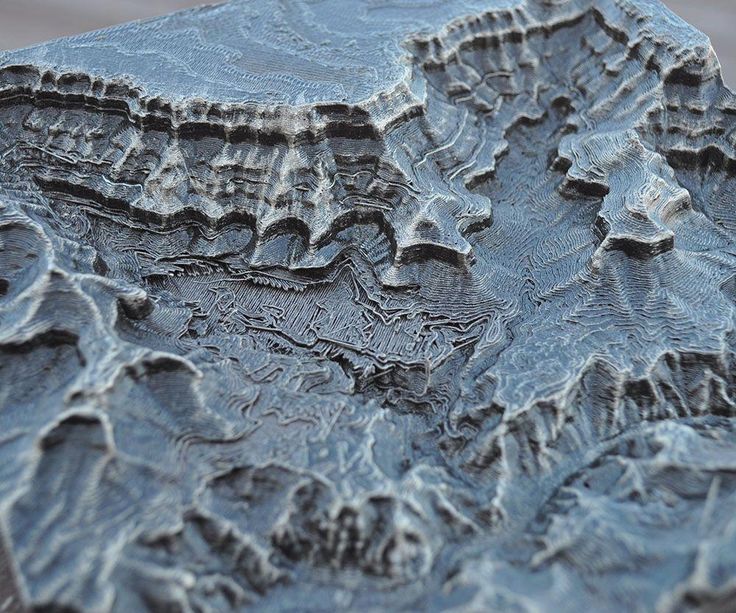

Terrain models with at least one straight edge can be printed in two ways, either horizontally or vertically. Each of these orientations has its pros and cons and for each model, it is necessary to decide which orientation to choose. Let’s look at the main differences.

The horizontal positionThis position is natural in the real world. In this position, we are able to print almost any model. In the Z-axis, however, we are limited by the height of the layer. The lowest height of the extruded material is about 0.05mm and the most commonly used nozzle diameter is 0.4mm. The relatively large diameter of the nozzle alone causes “drops” on the peaks. The nozzle diameter also affects edge sharpness.

We recommend selecting a layer height of 0.15mm and a 15% to 20% infill.

Pros:

- you can print almost any model

- there are horizontal lines on the model that represent contour lines (some may consider this a con)

Cons:

- infill is necessary (longer printing time)

- drops on peaks

- there may be strings between the peaks/buildings

In the vertical position, the biggest advantage is that no “drops” of material on the peaks will be created, and the peaks will be smoother. This makes the surface more detailed and looks much better. The vertical orientation is suitable for models where there are no areas that make an angle with the print area less than about 45°. Supports for such models is not a solution we would recommend.

Vertical orientation is also not suitable for printing city-building models, because almost every building would have a perimeter wall parallel to the print surface and therefore the model would be non-printable without supports.

With vertical orientation, it is advisable to choose the most suitable area on which the model will be placed. Choose the one that will touch the bed with the largest possible area. Use the Place on the face button to rotate the model.

We recommend selecting a layer height of 0.15mm and a 0% infill. Infill is not needed in most cases. The printing time will be almost half and you save some material. For best results, use PLA filament.

Pros:

- print without support and infill

- there is no stringing between peaks

- the terrain looks smoother than the horizontal print position

Cons:

- can not be used to print city models

- there’s a chance that it will become loose and that the print will fail

The difference of print in horizontal and vertical orientation is shown in the pictures below.

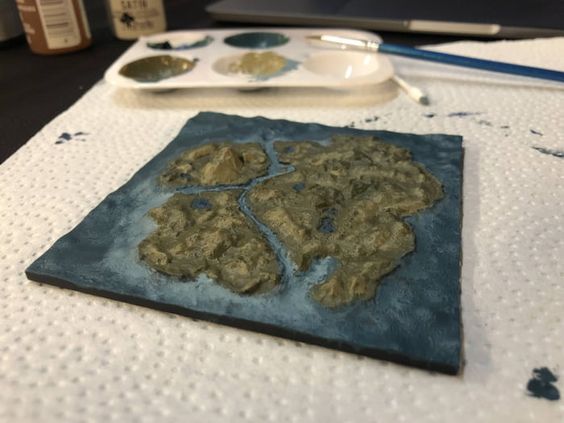

Our tips for color models:

- Use ColorPrint to change the color of the filament depending on the altitude.

Learn how to use ColorPrint in this article.

- Print the model with a single filament and paint it afterward. It depends only on your imagination.

- If you already have Original Prusa Multi Material Upgrade 2.0, you can try to create a color model to distinguish terrain, buildings, waterways and roads.

Feel free to experiment, try various changes and edits, and don’t forget to share the results in our forum.

3d Print Map - Etsy.de

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

GERMANY Find unique items from around the globe that ship to Germany

(1,000+ relevant results)

3D Services Sitemap

Loading

Pages

Posts by category

- Category: Uncategorized

Projects

- 3D printed dental model

- 3D printed plaster figurine

- 3D printing house layout

- 3D printed glasses

- 3D printed bearing

- 3D printed housing

- 3D scan of column

- 3D printed model

- 3D printed transparent body

- 3D scan of body

- 3D modeling figurine

- 3D printing with polyjet photopolymer

- 3D printing parts kit

- 3D printed part

- Boar 3D Modeling

- Panther 3D Modeling

3D Print

- 3D Print

- 3D printing of PET-G plastic using FDM technology

- SBS 3D printing with FDM technology

- 3D printed Nylon with FDM plastic

- 3D printing FLEX plastic using FDM technology

- Printing with metals using SLM technology

- Printing with polyamide using SLS technology

- Printing with gypsum resin using CJP technology

- PolyJet Resin Printing

- SLA photopolymer printing

- ABS PLA printing with FDM technology

- Food industry

- Fashion and design

- Jewelery

- Medicine

- Architecture

- Engineering

- Dentistry

3D Modeling

- 3D Modeling

- Refinement of 3D scans

- Artistic Modeling

- CAD Modeling

- Industry

- Fashion and design

- Jewelery

- Medicine

- Architecture

- Dentistry

3D Scan

- 3D Scan

- 3D Geometry Check

- 3D scanning of large objects

- 3D scanning of medium objects

- 3D scanning of small objects

- Industry

- Fashion and design

- Jewelery

- Medicine

- Architecture

- Engineering

- Dentistry

Applications

- 3D scanning for copying parts

- Aircraft 3D printing

- 3D printed Christmas decorations

- 3D printed wedding props

- 3D printing and climbing

- 3D printing of large models on a 3D printer

- Composite 3D printing

- Military 3D printing applications

- 3D printed conductors

- Agricultural 3D printing

- 3D printing and 3D scanning for home appliance repair

- 3D printed life figures and park sculptures

- 3D printing of three-dimensional paintings

- Creation of 3D models of implants

- Post-processing of products after 3D printing with photopolymer

- Free libraries of 3D models and STL files

- 3D printing of exhibition layouts

- 3D printed buttons

- Food grade plastic for 3D printer

- PEEK, PEKK & ULTEM: 3D printing with high performance plastics

- Jewelry casting with 3D printed models

- 3D printed box molds

- 3D scanning of dental plaster casts

- 3D car scan

- Materials we work with

- 3D scanning of goods for website

- 3D printing of models of churches, church cathedrals

- 3D printing models from Minecraft

- 3D printed end caps for profiles

- 3D printed cosplay elements

- SLS - Selective Laser Powder Sintering

- Orthodontic aligners at Formlabs

- 3D printing of medical equipment components

- 3D Printed Protective Visers

- Virus protection mask

- Create a 3D model from a photo

- Graduation project on a 3D printer

- 3D printed arm splint

- Sculpture scanning

- 3D printing based on CT and MRI

- Store design

- Packaging design

- 3D printed human figurines

- 3D printing in education

- 3D printing of interior items

- 3D printing layouts

- Small batch production

- Applications

Coupons

- Coupons 1

- Coupon 2

- Coupon 3

- Coupon 4

Products

- Photopolymer HARZ Labs Model SLA 1 l gray

- Photopolymer HARZ Labs Model SLA 1 l white

- Photopolymer HARZ Labs Model LCD/DLP 1 l black

- Photopolymer HARZ Labs Model LCD/DLP 1 L blue

- Photopolymer HARZ Labs Model LCD/DLP 1 l gray

- Photopolymer HARZ Labs Model LCD/DLP 1 L transparent

- Photopolymer HARZ Labs Model LCD/DLP 1 l natural

- Photopolymer HARZ Labs Model LCD/DLP 1 L cherry

- Photopolymer HARZ Labs Model LCD/DLP 1 l white

- Photopolymer HARZ Labs Model SLA 1 1 l transparent

- Photopolymer HARZ Labs Dental Sand Form2 1 kg nine0017 Photopolymer HARZ Labs Dental Sand LCD/DLP 1 kg

- Photopolymer HARZ Labs Dental Pink LCD/DLP 1L

- Photopolymer HARZ Labs Dental Peach Form2 1 kg

- Photopolymer HARZ Labs Dental Peach LCD/DLP 1 kg

- Photopolymer HARZ Labs Dental Clear SLA 1L

- Photopolymer HARZ Labs Dental Clear LCD/DLP 1L

- Photopolymer HARZ Labs Dental Cast LCD/DLP 1 l red

- Photopolymer HARZ Labs Basic LCD/DLP 1 l red

- Formlabs Form 3 Print Bath

- PC plastic 1.

75 PrintProduct

75 PrintProduct - NYLON plastic PrintProduct natural

- NYLON plastic PrintProduct

- NYLON MOD plastic PrintProduct natural

- FLEX SOFT plastic PrintProduct transparent

- FLEX SPRING plastic PrintProduct black

- FLEX HARD plastic PrintProduct black

- FLEX HARD plastic PrintProduct white

- FLEX HARD plastic PrintProduct natural

- TITI FLEX MEDIUM plastic PrintProduct transparent

- TITI FLEX MEDIUM plastic PrintProduct black

- TITI FLEX MEDIUM plastic PrintProduct white

- TITI FLEX MEDIUM plastic PrintProduct green

- TiTi FLEX SPRING plastic PrintProduct black

- PET-Gun plastic PrintProduct transparent

- PET-Gun plastic PrintProduct black

- eSUN 3D FILAMENT ABS BLACK 1.75 mm

- eSUN 3D FILAMENT ABS YELLOW 1.75 mm

- eSUN 3D FILAMENT ABS BLUE 1.75 mm

- eSUN 3D FILAMENT ABS GOLD 1.75 mm

- eSUN 3D FILAMENT ABS GREEN 1.

75 mm

75 mm - eSUN 3D FILAMENT ABS GRAY 1.75 mm

- eSUN 3D FILAMENT ABS NATURAL 1.75 mm

- eSUN 3D FILAMENT ABS ORANGE 1.75 mm

- eSUN 3D FILAMENT ABS PEAK GREEN 1.75 mm

- eSUN 3D FILAMENT ABS PINK 1.75 mm

- eSUN 3D FILAMENT ABS PURPLE 1.75 mm

- eSUN 3D FILAMENT ABS RED 1.75 mm

- eSUN 3D FILAMENT ABS SILVER 1.75 mm

- eSUN 3D FILAMENT ABS WHITE 1.75 mm nine0017 eSUN 3D FILAMENT ABS LUMINOUS RED 1.75 mm

- eSUN 3D FILAMENT ABS LUMINOUS BLUE 1.75 mm

- eSUN 3D FILAMENT PLA Glass Purple 1.75 mm

- eSUN 3D FILAMENT PLA Glass Light Blue 1.75 mm

- eSUN 3D FILAMENT PLA Glass Lemon Yellow 1.75 mm

- eSUN 3D FILAMENT PLA Glass Watermelon Red 1.75 mm

- eSUN 3D FILAMENT PLA Glass Orange 1.75 mm

- eSUN 3D FILAMENT PLA GOLD 1.75 mm

- eSUN 3D FILAMENT PLA BLACK 1.75 mm nine0017 eSUN 3D FILAMENT PLA GREEN 1.75 mm

- eSUN 3D FILAMENT PLA GRAY 1.

75 mm

75 mm - eSUN 3D FILAMENT PLA NATURAL 1.75 mm

- eSUN 3D FILAMENT PLA WHITE 1.75 mm

- eSUN 3D FILAMENT PLA YELLOW 1.75 mm

- eSUN 3D FILAMENT PLA RED 1.75 mm

- eSUN 3D FILAMENT PLA PINK 1.75 mm

- eSUN 3D FILAMENT PLA SILVER 1.75 mm

- eSUN 3D FILAMENT PLA ORANGE 1.75 mm

- eSUN 3D FILAMENT PLA PURPLE 1.75 mm

- eSUN 3D FILAMENT PLA PEAK GREEN 1.75 mm

- eSUN 3D FILAMENT PLA LIGHT BLUE 1.75 mm

- eSUN 3D FILAMENT PLA BLUE 1.75 mm

- PROTOTYPER T-SOFT (CLEAR) 1.75 mm Clear

- PROTOTYPER T-SOFT (CLEAR) 1.75 mm Yellow

- PROTOTYPER T-SOFT (CLEAR) 1.75 mm Orange

- PROTOTYPER T-SOFT (CLEAR) 1.75 mm Red

- PROTOTYPER T-SOFT (CLEAR) 1.75 mm Bottle Brown

- PROTOTYPER T-SOFT (CLEAR) 1.75 mm Bottle Green nine0017 PROTOTYPER T-SOFT (CLEAR) 1.75 mm Bottle Olive

- PROTOTYPER T-SOFT (CLEAR) 1.75 mm Lime

- PROTOTYPER T-SOFT (CLEAR) 1.

75 mm Emerald

75 mm Emerald - PROTOTYPER T-SOFT (CLEAR) 1.75 mm Aquamarine

- PROTOTYPER T-SOFT (CLEAR) 1.75 mm Blue

- PROTOTYPER T-SOFT (CLEAR) 1.75 mm Violet

- PROTOTYPER S-SOFT (SOLID) 1.75 mm Black

- PROTOTYPER S-SOFT (SOLID) 1.75 mm White

- PROTOTYPER S-SOFT (SOLID) 1.75 mm Gray

- PROTOTYPER S-SOFT (SOLID) 1.75 mm Ivory

- PROTOTYPER S-SOFT (SOLID) 1.75 mm Blue

- PROTOTYPER S-SOFT (SOLID) 1.75 mm Yellow

- PROTOTYPER S-SOFT (SOLID) 1.75 mm Violet

- PROTOTYPER S-SOFT (SOLID) 1.75 mm Orange

- PROTOTYPER S-SOFT (SOLID) 1.75 mm Green

- PROTOTYPER S-SOFT (SOLID) 1.75 mm Magenta

- Formlabs Gray Pro Photopolymer 1L Cartridge

- PC polycarbonate 3DMall 1.75 mm

- PLA plastic 3DMall 1.75 mm metallic gray

- PLA plastic 3DMall 1.75 mm white

- PLA plastic 3DMall 1.75 mm black

- PLA plastic 3DMall 1.75 mm brown

- PLA plastic 3DMall 1.

75 mm gray

75 mm gray - PLA plastic 3DMall 1.75 mm metallic bronze

- PLA plastic 3DMall 1.75 mm metallic gold

- PLA plastic 3DMall 1.75 mm metallic blue

- PLA plastic 3DMall 1.75 mm metallic green

- PLA plastic 3DMall 1.75 mm blue

- PLA plastic 3DMall 1.75 mm green

- PLA plastic 3DMall 1.75 mm purple

- PLA plastic 3DMall 1.75 mm red

- PLA plastic 3DMall 1.75 mm orange

- PLA plastic 3DMall 1.75 mm yellow

- PLA plastic 3DMall 1.75 mm burgundy

- PLA plastic 3DMall 1.75 mm blue

- ABS plastic 3DMall 1.75 mm metallic gray

- ABS plastic 3DMall 1.75 mm white

- ABS plastic 3DMall 1.75 mm black nine0017 ABS plastic 3DMall 1.75 mm brown

- ABS plastic 3DMall 1.75 mm gray

- ABS plastic 3DMall 1.75 mm metallic bronze

- ABS plastic 3DMall 1.75 mm metallic gold

- ABS plastic 3DMall 1.75 mm metallic blue

- ABS plastic 3DMall 1.

75 mm metallic green

75 mm metallic green - ABS plastic 3DMall 1.75 mm blue

- ABS plastic 3DMall 1.75 mm green

- ABS plastic 3DMall 1.75 mm purple

- ABS plastic 3DMall 1.75 mm red

- ABS plastic 3DMall 1.75 mm orange

- ABS plastic 3DMall 1.75 mm yellow

- ABS plastic 3DMall 1.75 mm burgundy

- ABS plastic 3DMall 1.75 mm fluorescent pink

- ABS plastic 3DMall 1.75 mm blue

- ABS plastic 3DMall 1.75 mm fluorescent green

- ABS plastic 3DMall 1.75 mm fluorescent lemon

- 3M adhesive tape blue

- PLA plastic SEM 1.75 mm orange

- PLA plastic SEM 1.75 mm white

- PLA plastic SEM 1.75 mm black

- PLA plastic SEM 1.75 mm red

- PLA plastic SEM 1.75 mm yellow

- PLA plastic SEM 1.75 mm green

- PLA plastic SEM 1.75 mm natural

- PLA plastic SEM 1.75 mm blue

- PLA plastic SEM 1.75 mm purple

- ABS plastic SEM 1.75 mm marble

- ABS plastic SEM 1.

75 mm pink marble

- ABS plastic SEM 1.75 mm metallic bronze

- ABS plastic SEM 1.75 mm metallic blue

- ABS plastic SEM 1.75 mm metallic gold

- ABS plastic SEM 1.75 mm metallic green

- ABS plastic SEM 1.75 mm fluorescent green

- ABS plastic SEM 1.75 mm fluorescent lemon

- ABS plastic SEM 1.75 mm fluorescent pink

- ABS plastic SEM 1.75 mm blue

- ABS plastic SEM 1.75 mm burgundy

- ABS plastic SEM 1.75 mm white

- ABS plastic SEM 1.75 mm yellow

- ABS plastic SEM 1.75 mm brown

- ABS plastic SEM 1.75 mm green

- ABS plastic SEM 1.75 mm gray

- ABS plastic SEM 1.75 mm blue

- ABS plastic SEM 1.75 mm natural

- ABS plastic SEM 1.75 mm orange

- ABS plastic SEM 1.75 mm red

- ABS plastic SEM 1.75 mm transparent

- ABS plastic SEM 1.75 mm black

- PC polycarbonate SEM 1.75 mm

- ABS plastic SEM 1.

75 mm purple

75 mm purple - HIPS plastic SEM 1.75 mm white

- PLA plastic SEM 1.75 mm bronze metallic

- PLA plastic SEM 1.75 mm silver metallic

- ABS/PC plastic SEM 1.75 mm natural

- Photopolymer Fun To Do Standard Blend 1l red

- Photopolymer Fun To Do Standard Blend 1l black

- Photopolymer Fun To Do Standard Blend 1l natural

- Photopolymer Fun To Do Snow White 1l white

- Photopolymer Fun To Do Industrial Blend 1l, red

- Photopolymer Fun To Do Industrial Blend 1l, black

- Photopolymer Fun To Do Industrial Blend 1l, natural

- Photopolymer Fun To Do Deep Black 1l black

- Photopolymer Fun To Do Castable Blend cast 1l red

- Photopolymer Fun To Do F1+ 1l white

- Photopolymer Fun To Do F1+ 1l transparent

- Photopolymer Fun To Do F1+ 1l gray

- Photopolymer Fun To Do F1+ 1l black

- Photopolymer Fun To Do Dentifix-3D Modeling HR 1L

- Photopolymer Fun To Do Dentifix-3D Modeling LR 1l

- Formlabs Dental Model Resin in 1L Cartridge

- Formlabs Black Resin 1L Cartridge

- Formlabs White Resin 1L Cartridge

- Formlabs Clear Resin 1L Cartridge

- Formlabs Gray Resin 1L Cartridge

- Formlabs Castable Resin 1L Cartridge

- Formlabs Dental LT Clear Resin 1L Cartridge

- Formlabs High Temp Resin 1L Cartridge

- Formlabs Durable Resin 1L Cartridge

- Formlabs Castable Wax Resin 1L Cartridge

- Formlabs Tough 2000 Resin 1L Cartridge

- Formlabs Flexible Resin 1L Cartridge

- Formlabs Rigid Resin 1L Cartridge

- Wanhao photopolymer resin 1 l white

- Wanhao photopolymer resin 1 l orange

- Wanhao photopolymer resin 1 l green

- Wanhao photopolymer resin 1 l black

- Wanhao photopolymer resin 1 l gray

- Wanhao photopolymer resin 1 l yellow

- Wanhao photopolymer resin 1 l red

- Wanhao photopolymer resin 1 l transparent

- Cleaning needle for 3D printer FDM

- Form 2 Long Term Print Bath

- Heat resistant glass for heated platform

- 3D Printing Adhesive Spray

- Intesa varnish for 3D printing

- 3D Model Cleaner Limonene

- Matting Spray Helling

- Nozzle for 3D printer PICASO Jet 0.

3

3 - Formlabs Form 2 Print Bath

- Dichloromethane (methylene chloride)

Gallery

- 3D Scan Battery Blank 3

- 3D scan of a wooden interior element

- 3D scanning of shoes

- Printing models of plastic bottles

- 3D printed screed

- 3D printed dinosaur jaw

- 3D printed nylon 9 part0020

- 3D printed metal element

- 3D printed metal part

- 3D printed metal part

- 3D printed lock element

- 3D printed pump

- 3D printed metal filter

- 3D printing auto parts

- 3D printed turbine element

- 3D printed bas-relief

- 3D printed horse figurines

- 3D printed keychains

- 3D printed dog figurine

- 3D printed stand

- 3D printing scoop

- 3D printed astronaut figurine

- 3D printed eyeglass frames

- 3D printed badge

- 3D printed lock

- 3D printed pangolin

- 3D printed hero bust

- 3D printed filter

- 3D printed architectural model

- 3D printed engine model

- 3D printed figurine

- 3D printed dental template

- 3D printed sneaker

- 3D printed housing

- 3D printed part

- 3D printed door frame

- 3D printed souvenir

- 3D printed figurine

- 3D printing of building

- 3D printed glasses

- 3D printing parts

- 3D printed bearing

- 3D printed eyeglass frames

- 3D printed hand

- 3D printed pergola

- 3D printed parts

- 3D scan of gearbox

- 3D scan of car body nine0017 3D scan of ventilation detail

- 3D engine scan

- 3D scan of column

- 3D scan of bus

- 3D jaw scan

- 3D scan of body

- 3D scan of hull model

- 3D tube scan

- Dashboard 3D scan

- 3D scan of screw

- 3D car scan

- 3D scanning figurine

- Panther 9 3D scan0020

- 3D bust of Putin

- 3D modeling sneaker

- 3D hair modeling

- 3D face modeling

- ATV 3D Modeling

- 3D building modeling

- 3D modeling of column

- 3D tank modeling

- 3D modeling tiles

- 3D modeling of a hamburger

- 3D modeling of coin

- 3D modeling of auto suspension

- 3D robot simulation

- 3D modeling of atlanta

- Boar 3D Modeling

- 3D modeling chairs

- 3D modeling chair

- 3D printed photopolymer case

- 3D printed plastic parts kit

- 3D printing of electrical appliance case

- 3D printed toys

- 3D printed Resin Hirspattern Clear

- 3D printed lizard

- 3D printed nozzles

- 3D printed teeth template

- 3D printed mask

- 3D printing of a woman from plaster

- 3D printed small body

- 3D printed small body parts

- 3D printed gray housing 2

- 3D printed gray body 1

- 3D printed white case

- 3D printed doll heads

- 3D printed dental template

- 3D printed parts of the red body

- 3D modeling of watch strap part 2

- 3D modeling of watch strap part 3

- 3D modeling of watch strap part

- 3D printed large body

- 3D printing of machine elements

- 3D printed body parts

- 3D printed doll heads

- 3D printed diagnostic model

- 3D printing of preoperative models

- 3D printed rings

- 3D printed titanium rings

- 3D printed console case

- 3D printed bracelet part

- 3D printed gun stock

- 3D printed cowboy

- 3D printing Spartak

- 3D printed cover

- 3D printed console case

- 3D printed movie character

- 3D printing machine parts

- 3D printed polyamide parts

- Scanning decorative tiles from original

- Scanning the turbine nozzle and creating a 3d model

- Printing Toy Gun Parts Kit

- PLA bottle mockup printing

- Printing fixtures for instrument

- Printed enclosure for ABS boards

- PLA tile mold printing

- Plastic tile mold printing

- Scan tiles and create a 3d model

- Handmade bottle layout print

- Printing crowns on the Objet printer

- 1 liter plastic bottle mockup print

- Printing a sleeve on a 3D printer

- 3D printed ABS sleeve

- Printed white ABS sleeve

- Painted instrument housing

- Creation of a 3D skull model from CT

- Fan trim

- Model master for aligners

- PLA bottle mockup

- Printing ABS fasteners

- Printing photopolymer fittings on Formlabs

- Printing and painting of a large body

- Printing and painting of body parts

- 3D printed part of the skull

- Seal part for sporting weapons

- Transparent body

- Copy of sleeve

- Hookah model

- White PLA bottle printing

- 3D printed doll parts

- Scan an element and create a solid model

- 3D scan chess piece

- 3D scan of a horse figure

- 3D scan of cladding

- 3D print master head models

- 3D printing master teeth models

- 3D printed head models

- 3D printed chess pieces

- 3D printed kayak

- 3D printed cup

- 3D printed titanium rings

- 3D printed titanium jewelry

- 3D printing medal for direct casting

- 3D printed buttons for remote control

- 3D printed brake shoe model

- 3D printed octopus

- 3D printed doll head

- 3D printing spare parts

- 3D printed red case

- 3D printed teeth model

- 3D printed drone mount

- Printing caps on a 3D printer

- Printing a fish model on a 3D printer

- Bender head print

- Scanning of fastening part with scanner

- Scan fastening detail

- Star Wars Ship Seal

- Heart layout printing

- Scanning the cone figurine

- Bump scan

- Print kit nine0017 Mandibular and maxillary master prints

- Printing jaw master models

- Polyamide parts kit printing

- Printing of the head model in SLA photopolymer

- Custom 3D printing of PETG parts

- 3D printing of PETG parts

- 3D scan of motorcycle parts

- 3D scan parts from Harley-Davidson 3

- 3D scan parts from Harley-Davidson 2

- 3D scanning parts from Harley-Davidson 1

- 3D scan parts from Harley-Davidson

- 3D scan of boot

- 3D printed doll parts

- 3D head scan

- 3D ear scan

- Mold creation

- 3D scan of a wooden element

- Creation of a 3D model of the fastening mechanism

- 3D printed end caps

- 3D printed housing for device

- White PLA bottle prototype

- 3D printed temporary crowns

- 3D printing of children's toy parts

- Prototyping bottle

- Manufacture of instrument housing

- 3D printed diagnostic model for aligners

- 3D printed bottle prototype

- 3D printing car cap

- 3D printed reinforced ABS coupling

- Clear resin print

- 3D printed doll head

- 3D printed titanium products

- Gorilla Bust 3D Modeling

- 3D modeling of the human skull

- 3D bust modeling 2

- 3D bust modeling 1

- 3D modeling lion figurine 4

- 3D modeling lion figurine 3

- 3D modeling lion figurine 2

- 3D modeling lion figurine 1

- 3D modeling medal 3

- 3D modeling medal 2

- 3D modeling medal 1

- 3D modeling of the Olympic medal

- 3D printed gears 2

- 3D printed gears 1

- Formlabs 2 Clear and Gray Resin

- Formlabs Clear and Gray Resin 1

- SLA 2 3D resin printing

- SLA 3D Resin Printing 1

- 3D printed soldier model

- 3D printed polyamide with dyeing 4

- 3D printed polyamide with dyeing 3

- 3D printed polyamide with dyeing 2

- Polyamide 3D printed with dyeing 1

- 3D printed monster on a 3D printer 2

- 3D printed monster 1

- 3D printed PETG impeller

- 3D printed vape body 3

- 3D printed vape body 2

- 3D printed vape body 1

- ABS kit 2

- ABS kit 1

- Titanium rings on a 3D printer 5

- Titanium rings on a 3D printer 3

- Titanium rings on 3D printer 2 nine0017 Titanium rings on a 3D printer 1

- 3D printed reinforced ABS 3

- 3D printed reinforced ABS 2

- 3D printed reinforced ABS 1

- 3D scan of product body 4

- 3D scan of product body 3

- 3D scan of product body 2

- 3D scan of product body 1

- 3D model of knee sled 3

- 3D Modeling of the Knee Sled 2

- 3D Modeling of a lap sled

- 3D printed eyeglass frames 3

- 3D printed eyeglass frames 2

- 3D printed eyeglass frames 1

- Batman 3 mask 3D printing

- Batman 2 mask 3D printing

- 3D printed Batman mask 1

- 3D printing parts kit

- 3D printing of PLA plastic products 3

- 3D printing of PLA plastic products 2

- 3D printing of PLA plastic products 1

- 3D printing of ABS products 2

- ABS 3D printing 1

- 3D printed security visers 5

- 3D printed security visers 4

- 3D printed security visers 3

- 3D printed security visers 2

- 3D printed security visers 1

- 3D printed protective mask 2

- 3D printed protective mask 1

- 3D printed parts in red PLA plastic

- 3D printed temporary crowns 4

- 3D printed temporary crowns 3

- 3D printed temporary crowns 2

- 3D printed temporary crowns 1

- 3D printing of a bust from photopolymer Gray Resin 3

- 3D printing of a bust from photopolymer Gray Resin 2

- 3D printed bust in Gray Resin 1

- 3D printed bottle holders 3

- 3D printed bottle holders 2

- 3D printed watch holder 2

- 3D printed watch holder 1

- 3D printed bushings from photopolymer

- 3D scan of car rim cap 3

- 3D scan of car rim cap 2

- 3D scan of a cap for a car rim 1

- 3D scan of steering wheel controls 4

- 3D scan of steering wheel controls 3

- 3D scan of steering wheel controls 2

- 3D scan of steering wheel controls 1

- 3D scan angel figurine 6

- 3D scan angel figurine 5

- 3D scan angel figurine 4

- 3D scan angel figurine 3

- 3D scan angel figurine 2

- 3D scan angel figurine 1

- 3D scan chair 5

- 3D scan of chair 4

- 3D scan of chair 3

- 3D scan of chair 2

- 3D scan of chair 1

- 3D scanning plasticine sculpture 5

- 3D scanning plasticine sculpture 4

- 3D scanning plasticine sculpture 3

- 3D scanning plasticine sculpture 2

- 3D scanning plasticine sculpture 1

- 3D scanning of the car body 6

- 3D scanning of the car body 5

- 3D scanning of the car body 4

- 3D scanning of the car body 3

- 3D scan of the car body 2

- 3D scanning of the car body 1

- 3D scan of battery plug 5

- 3D scan of battery plug 4

- 3D scan of battery plug 2

- 3D scan of battery plug 1

- 3D scan gnome figurine 5

- 3D scan gnome figurine 4

- 3D scan gnome figurine 3

- 3D scan gnome figurine 2

- 3D scan gnome figurine 1

- 3D scan of the bust of Vladimir Mayakovsky 6

- 3D scan of the bust of Vladimir Mayakovsky 5

- 3D scan of the bust of Vladimir Mayakovsky 4

- 3D scan of the bust of Vladimir Mayakovsky 3

- 3D scan of the bust of Vladimir Mayakovsky 2

- 3D scan of the bust of Vladimir Mayakovsky 1

- 3D scan of bottle cap 3

- 3D scan of bottle cap 2

- 3D scan of bottle cap 1

- 3D scanning of bottle neck 2

- 3D scanning of bottle neck 1

- 3D printed titanium jewelry 6

- 3D printed titanium jewelry 5

- 3D printed titanium jewelry 4

- 3D printed titanium jewelry 3

- 3D printed titanium jewelry 2

- 3D printed titanium jewelry 1

- 3D printed human heads 2

- 3D printed human heads 1

- 3D printed Roman helmet 3

- 3D printed Roman helmet 2

- 3D printed Roman helmet 1

- 3D printed bottle prototype 5

- 3D printed bottle prototype 4

- 3D printed bottle prototype 3

- 3D printed bottle prototype 2

- 3D printed bottle prototype 1

- 3D printed PLA prototype

- 3D human scan

- 3D human scan 2

- 3D human scan 3

- 3D human scan 4

- 3D modeling gear 5

- 3D modeling gear 4

- 3D modeling gear 3

- 3D modeling gear 2

- 3D modeling gear 1

- 3D stone scan 4

- 3D stone scan 3

- 3D stone scan 2

- 3D stone scan 1

- 3D scan of attachment part 4

- 3D scan of attachment part 3

- 3D scan of attachment part 2

- 3D scan of attachment part 1

- 3D printed side plates 4

- 3D printed side moldings 3

- CT 3D printing of the spine 1

- 3D printed decoration item 1

- 3D scan cat figurine 3

- 3D scan cat figurine 2

- 3D printed cat figurine 1

- 3D printed ski mask 2

- 3D printed ski mask 1

- Polyamide 5 3D printing

- Polyamide 4 3D printing

- Polyamide 3 3D printing

- Polyamide 2 3D printing

- 3D printed polyamide 1 nine0017 3D scan for car workshop 2

- 3D scan for car workshop 1

- 3D scanning of doll parts 1

- 3D scan of doll parts 2

- 3D scan tiger figurine 5

- 3D scan tiger figurine 4

- 3D scan tiger figurine 3

- 3D scan tiger figurine 2

- 3D scan tiger figurine 1

- 3D scan case for airpods 3

- 3D scan case for airpods 2

- 3D scan case for airpods 1

- 3D scanning sumo figure 1

- 3D scanning sumo figure 2

- 3D scanning sumo figure 3

- 3D scanning sumo figure 4

- Tennis player 3D scan 1

- Tennis player 3D scan 2

- Tennis player 3D scan 3

- Tennis player 3D scan 4

- Tennis player 3D scan 5

- Tennis player 3D scan 6 nine0017 3D scan of a wooden panel with texture 1

- 3D scan of textured wood panel 2

- 3D scan of textured wood panel 3

- 3D scan of textured wood panel 4

- 3D scan of a cross with a crucifix 1

- 3D scan of crucifixion cross 2

- 3D printed teddy bear model from photopolymer

- 3D printed photopolymer bear model 1

- 3D scanning of plaster cast 1 nine0017 3D scanning of plaster cast 2

- 3D scan of plaster cast 3

- 3D scan of plaster cast 4

- 3D scan of shoe heel 1

- 3D scan of shoe heel 2

- 3D scan of shoe heel 3

- 3D false nail scan 1

- 3D false nail scan 2

- 3D false nail scan 3

- 3D scan clip 1

- 3D clip clip 2

- 3D scan clip 3

- 3D printed washing machine handle 1

- 3D printed washing machine handle 2

- 3D scan of cat figurine 1

- 3D scanning cat figurine 2

- 3D scanning cat figurine 3

- 3D print mounting bolt

- 3D printing fasteners 1

- 3D printing fasteners 2

- 3D modeling panels from photo 1

- 3D modeling of a panel from a photo 2

- 3D printed copy of ABS product 1

- 3D printed copy of a product made of ABS plastic 2

- 3D scanning figurine 1

- 3D scanning figurine 2

- 3D scanning figurine 3

- 3D printed parts in Formlabs Tough 1500 Resin

- 3D printing of impellers using FDM technology

- 3D scan of doll head 1

- 3D scan of doll head 2

- 3D head scan doll 3 nine0017 3D scan of doll head 4

- 3D Modeling Disc for Toy Cars Photo 1

- 3D Modeling Disc for Toy Cars Photo 2

- 3D Modeling Disc for Toy Cars Photo 3

- 3D printing of device body 1

- 3D printing of device body 2

- 3D printed aircraft model made of PLA plastic 1

- 3D printable PLA airplane model 2

- 3D printed Tough Resin gears 1

- 3D printed Tough Resin 2 gears

- 3D printed layout for packaging fitting 1

- 3D printed layout for packaging fitting 2

- 3D printed layout for packaging fitting 3

Reviews

- Sergey, head of project department

- Ekaterina, interior designer

- Gennady, detail from the meat grinder

- Tatiana, 3D printed figurine

- Michael, tuning service

- Elena, architect

- San Sanych, engineer

- Marina

- Alexander, PR-specialist

- Pavel Alekseevich, collector

- Kirill, auto repair shop

- Danil, car mechanic

- Svetlana, restorer

- Alexander, engineer

- Sofia

- Michael

- Alexey

- Zemfira, jewelry store

- Sergey, entrepreneur

- Christina

- Demian

- Pavel

- Tamara, architect

- Sergey Sergeevich, engineer

project categories

- Default

Product categories

- Accessories

- Plastic threads

- Polymer resins

Gallery Categories

- 3D MODELING

- 3D PRINT

- 3D SCAN

How the 3D map will fit

Authorization Registration nine0010

Reset password

Subscribe to "SR-COURIER" Fast and small as an atom newspaper - we deliver the latest news from Rosatom, Russia and the world straight to your mailbox

Don't show again

Do you know more and are ready to tell?

Do you have an interesting story or know more about a topic that we have already covered. Share any idea with SR. We are waiting for your messages! nine0010

Share any idea with SR. We are waiting for your messages! nine0010

Attach file

Submit

Rosatom prepared and sent for approval to the government a roadmap for the development of additive technologies in Russia until 2030. "SR" found out why the map is needed, what its main goals are and what the nuclear scientists have to do with it.

For the first time, the general public was told about the roadmap at the leader forum “Additive Technologies. Expanding horizons”, which was organized by Rosatom at the Skolkovo Institute of Science and Technology. Representatives of the military-industrial complex, the Ministry of Science and Higher Education, universities, development institutions, major industrial corporations (Roscosmos, United Engine Corporation, etc.), as well as commercial companies developing industrial 3D printing technologies, were invited to the event. nine0010

“We have developed a roadmap for additive technologies as part of the implementation of an agreement with the government on the development of new materials and substances,” said Ivan Kamenskikh, First Deputy General Director of Rosatom, Head of the Directorate for the Nuclear Weapons Complex, opening the forum. - We need to create our own, domestic, and it is important that our products are better than foreign ones. The purpose of the roadmap is to coordinate the work of public and private enterprises in this area in order to clearly understand what needs to be done and how much to invest.” nine0010

Four goals

The map contains four main goals for the development of additive technologies in Russia. They are planned to be achieved by 2030. The first is to create and develop the infrastructure for introducing 3D printing into production, for which they will organize a network of additive printing centers and develop digital product design systems. It is also necessary to create conditions for rapid certification and attestation of products made by additive methods.

The second is to overcome the backlog from the world market leaders. This will require an extensive R&D program to create competitive printers, new materials and control systems. nine0010

The third goal is to provide the new industry with highly qualified personnel. To achieve it, it is necessary to launch educational programs, form a network of educational institutions for training specialists and provide this network with 3D printers.

To achieve it, it is necessary to launch educational programs, form a network of educational institutions for training specialists and provide this network with 3D printers.

And finally, the fourth goal is the development of the market and the creation of high-tech industries. Measures are proposed to stimulate Russian industrial enterprises to use additive technologies in production.

As a result of the implementation of the roadmap, Russia will enter the top 5 players in the global 3D printing market by 2030, according to TVEL.

Everyone needs a plan

Neither the authorities nor the developers doubt that such a map is needed. “The roadmap should become an interdepartmental coordination program that includes the whole range of work on additive technologies. The state must get involved, know who is doing what, so that there is no duplication of work,” said Yury Mikhailov, Deputy Chairman of the Military Industrial Commission under the Government of Russia. nine0010

nine0010

First Deputy Minister of Science and Higher Education Grigory Trubnikov told how the system of personnel training for work in the field of additive technologies is being formed. “We need engineers with 3D imagination and excellent knowledge of basic disciplines: mathematics, chemistry, physics, mechanics,” he emphasized. Educational programs for the training of such specialists are gradually being formed and implemented at the Moscow State Technical University. Bauman, St. Petersburg Polytechnic University, MISiSe, ITMO University, STANKIN. A roadmap is also needed in order to streamline this process. The Deputy Minister also noted that it is desirable to prescribe in the document the necessary growth rates for the use of additive technologies in various technological processes. nine0010

“My wish for the roadmap: let's not forget about the consumer,” said Deputy Minister of Industry and Trade Mikhail Ivanov. — Rosatom is ready to take on the function of coordinating those who can supply additive technologies and equipment. This is very correct, but interaction is also needed with those who will consume these technologies. It is with them that we need to negotiate, it is they who need to be explained what advantages the use of 3D printing in production provides.”

This is very correct, but interaction is also needed with those who will consume these technologies. It is with them that we need to negotiate, it is they who need to be explained what advantages the use of 3D printing in production provides.”

Roskosmos is ready to participate in the development of a plan for the development of additive technologies on the part of consumers, said Denis Pudkov, director of the department for working with suppliers and organizing production at the state corporation. “We need technology and we invite those who believe in the future and in science fiction to join the consortium. We are ready to start interacting today,” he said.

Why Rosatom

Why Rosatom took upon itself the preparation of the road map for the whole country and why the state trusts it, explained the president of TVEL (the fuel company oversees the direction of 3D printing in the state corporation) Natalya Nikipelova: “I think that Rosatom is one of the few organizations that can create new industries. When we build nuclear power plants in newcomer countries, we literally create a new industry there in five to seven years. In recent years, the state corporation has also taken on tasks not related to the nuclear business, and successfully fulfills them.” nine0010

When we build nuclear power plants in newcomer countries, we literally create a new industry there in five to seven years. In recent years, the state corporation has also taken on tasks not related to the nuclear business, and successfully fulfills them.” nine0010

According to Natalia Nikipelova, it is precisely such a large and experienced player as Rosatom that, with the assistance of the state, is able to form and coordinate a large consortium that will be able to quickly develop the additive industry.

Andrey Grigoriev, General Director of the Advanced Research Foundation, agrees that the development of additive technologies is necessary, but nuclear scientists must correctly understand their function in this process: Rosatom is not a leader in additive technologies, but an operator, a coordinator. If the state corporation realizes its role, then there will be a result. If the state corporation rushes ahead of everyone, then it will not gather anyone around it.” nine0010

Andrey Shevchenko, Deputy Head of the Directorate of the Nuclear Weapons Complex, Director of the Research and Production Base Development Department, assured that Rosatom is not going to put pressure on the consortium partners: “We are not taking anything from anyone, we want to help consolidate efforts to develop a new industry.