Minimaker 3d printer

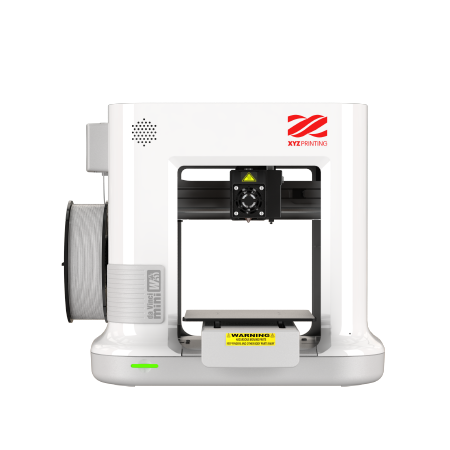

XYZPrinting Da Vinci Mini Review 2022

Heard about XYZPrinting Da Vinci Mini 3D printer? We did as well and decided to test one of them to see if they're worth it. Here are our findings!

By Justin Evans

4

See Price

So you’ve decided to get into the world of 3D printing. Where do you begin? There are printers for every possible requirement, and there’s a lot of jargon floating around that makes it hard to accurately compare different models. Relax – we’re here to help.

XYZPrinting is known for creating some of the best entry-level 3D printers around. Today, we’ll be looking for any strengths or weaknesses that the Da Vinci Mini might have– it’s a small printer, but it’s certainly capable. However, is it right for you and your needs? You’ll have to read on to find out.

| Filament Diameter | 1. |

| Extruders | 1 |

| Supported Materials | PLA |

| Connectivity | USB, WiFi |

| Printing Speed | 100mm/s |

| Build Volume | 5.91 x 5.91 x 5.91” |

Table of ContentsShow

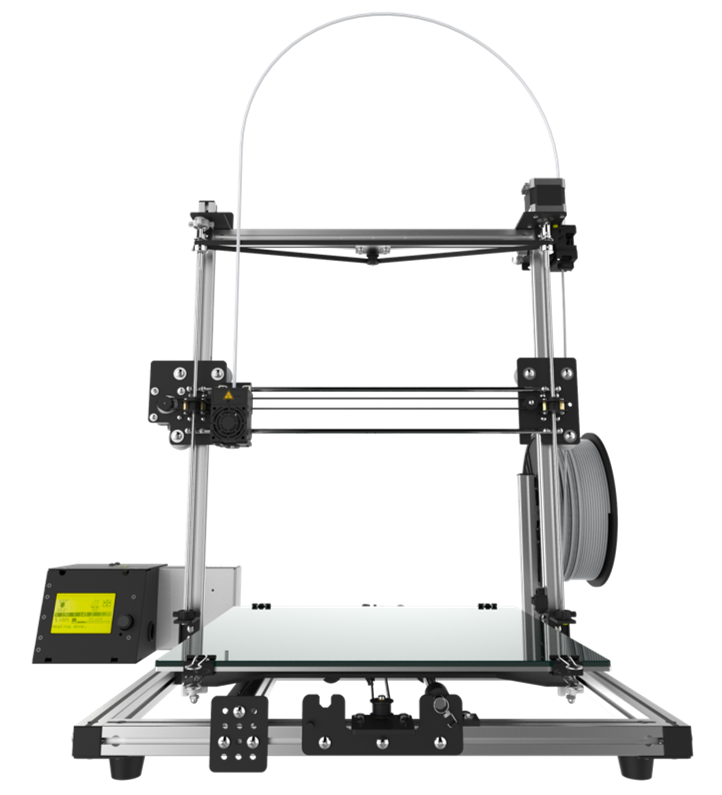

Design

The XYZPrinting Mini comes pre-assembled, so there’s no need to factor in build time. It’s a small-sized unit, perfect for sitting on your desktop, but this does mean that the build area is similarly restricted. Don’t get us wrong – you’ll be able to print decent-sized models, but nothing too huge.

Notice how there’s no enclosure? This means that it’ll be a little louder when you print, but all things considered, it’s still fairly quiet since the mechanical parts are mostly covered by the plastic frame. There are also implications for heat retention, but that’s not an issue, as we’ll explain later.

You get exactly what you’d expect from a low-end printer: there’s a single extruder and a maximum speed of 100mm/s. This is fairly standard and just means that you’ll take slightly longer to print. However, as the build area is only around 6” in each direction, you won’t be waiting hours unless you’re trying to print a large, solid cube.

Printing

There are three different speeds to choose from. As expected, the faster you print, the rougher the final quality. We found that the fastest setting resulting in significant stepping on curved surfaces, while if you allow it to take its time, your models look far better, but still not professional-level.

In an attempt to keep things as simple as possible for new users, XYZPrinting has limited the Mini to using PLA filaments. This removes the need for an enclosure but does restrict you somewhat in terms of the things you can build. Still, for beginners, PLA is more than enough to get you started.

The overall quality of the prints is too low for manufacturing, and the build volume too small for mass-production. However, it’s perfect for people looking to print things for their home or office. Better still, it takes any 1.75mm PLA filament – not just those made by XYZPrinting.

However, it’s perfect for people looking to print things for their home or office. Better still, it takes any 1.75mm PLA filament – not just those made by XYZPrinting.

Features

So what other features does the Mini have to make things easier for beginners? Well, instead of adding things, XYZPrinting has removed components. There’s no heated bed, for instance, and no built-in screen. You do have a USB connection, though, and WiFi functionality, which is almost unheard of in low-budget printers.

We were pleased to see that drivers are available for both Windows and Mac computers. On the other hand, there’s no Linux support. It supports four different file types, though, so you’re not really limited to using a particular modeling program, which is great.

Even the interface is simplistic. There’s a single button for starting a print and a status LED that lets you know how your print is going. All in all, it’s easy to use even if you’re not particularly tech literate. Let’s be honest – that’s never a bad thing.

Let’s be honest – that’s never a bad thing.

Cost

Here’s the thing: the Da Vinci Mini isn’t available in the United States. You can buy it from several European locations, though. It costs around $700, which makes it among the cheapest, most robust 3D printers we’ve covered. Of course, you’ll have to find a company to ship it over if you’re in the US.

Running costs are minimal. PLA is among the least expensive materials you can use, and since while third-party filaments aren’t supported, you can easily mod it to accept them. Large spools of PLA often cost less than $20 so really, your monthly material costs will depend on how often you print.

We think that this 3D printer is appropriately priced. It’s clearly intended for novice users, and the price point helps it stay affordable, unlike more advanced printers that offer user-friendly features. You’ll likely outgrow it in a year or two, but until then, it’ll serve you well.

Support

XYZPrinting’s support section provides customer help telephone numbers for 11 different countries. Best of all, each of these can talk to you in the native language or English. This is almost unheard of, and we’re genuinely delighted to see this level of help being offered for free.

Best of all, each of these can talk to you in the native language or English. This is almost unheard of, and we’re genuinely delighted to see this level of help being offered for free.

The limited warranty period is similarly outstanding. You’re covered from factory defects for up to two years at no extra cost, presuming you bought the printer from one of XYZPrinting’s recommended sellers. There’s no option to extend this warranty, though, which is a bit of a shame.

Customers can consult model-specific FAQs and tutorials in case they need any technical help. There are also different versions of the software, as well as documentation for each printer model here. All in all, it’s one of the most comprehensive support packages offered by any major 3D printing manufacturer.

HP Jet Fusion 3D 4200 Review

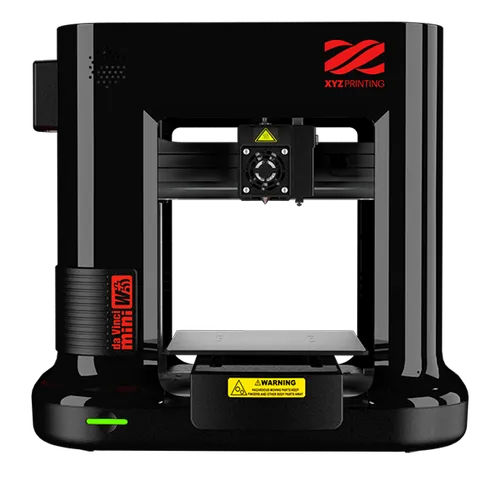

da Vinci miniMaker 3D Printer Review

7.0 Okay

Today's da Vinci miniMaker 3D printer review looks at one of the only printers made for kids. This colorful machine sure looks the part, but is it more than just a toy? Keep reading to find out if the da Vinci miniMaker makes the grade or comes up short.

This colorful machine sure looks the part, but is it more than just a toy? Keep reading to find out if the da Vinci miniMaker makes the grade or comes up short.

More Details ❯

-

Printing Speed 7

-

Build Size 6

-

Precision 6

-

Value 9

-

Design 7

-

User Experience 7

More Details ❯

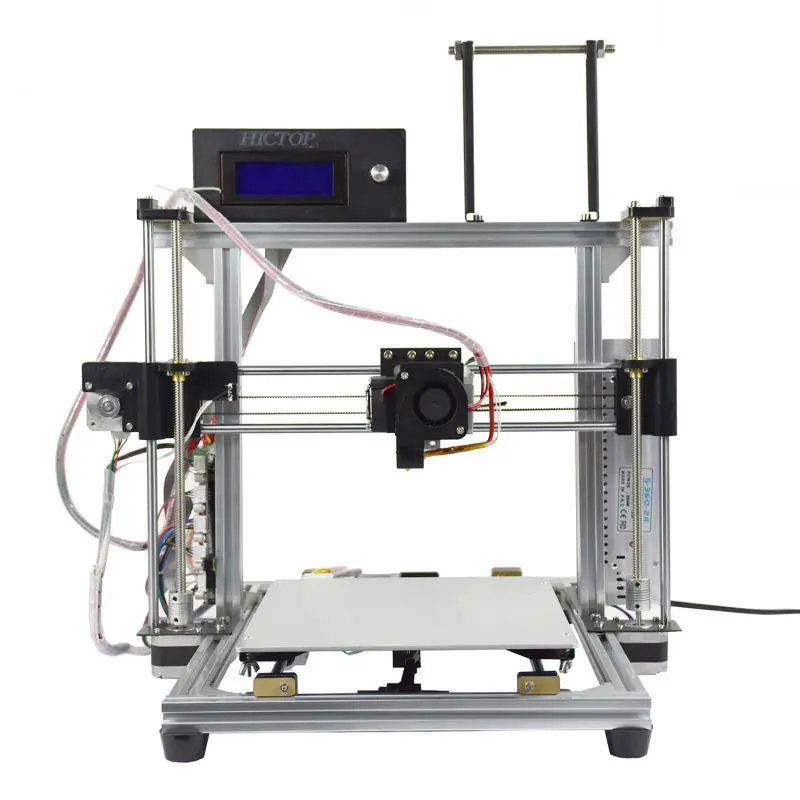

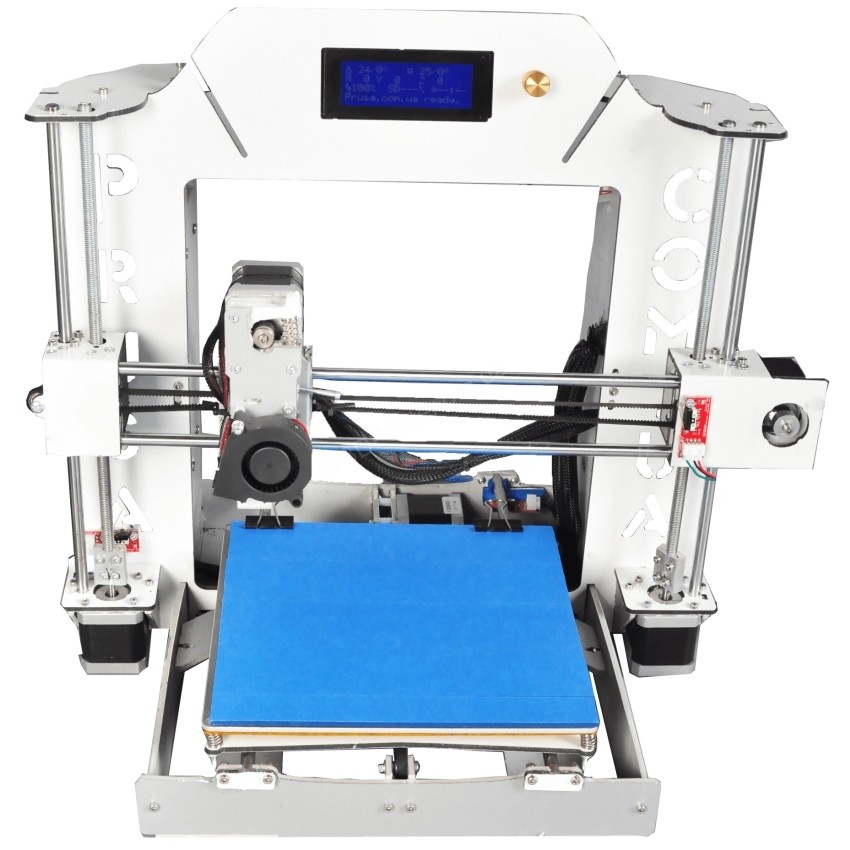

da Vinci miniMaker 3D Printer Review Basics

As you may expect, this affordable printer’s specs aren’t groundbreaking. In fact, it has similar specs to its XYZprinting brother, the da Vinci Mini. This includes a 6”x6”x6” print area and unheated aluminum print bed. Print at speeds up to 120mm/s, with realistic speeds running around 50mm/s. Resolution options are limited between 100-400 microns. The da Vinci miniMaker is also limited to PLA filaments offered by XYZprinting.

Resolution options are limited between 100-400 microns. The da Vinci miniMaker is also limited to PLA filaments offered by XYZprinting.

You need a USB connection to a computer in order to use the da Vinci miniMaker. This is a smart move which requires that children spend as little time as possible touching the actual printer, keeping both the children and the printer safe.

More Details ❯

da Vinci miniMaker 3D Printer Review Pros

Beginner Friendly

The da Vinci miniMaker’s biggest selling point is its ease of use. Designed for school-aged children to learn and experiment with this new technology, the da Vinci miniMaker has several user-friendly features.

The included XYZware and XYZmaker software makes printing easy. Choose a model from the XYZprinting 3D Gallery, or even build your own models using these apps. This is also where you adjust print settings like layer resolution. Educators and parents will be interested in the included XYZprinting STEAM Educational Curriculum. This is a surprisingly comprehensive resource for 3D printing novices. All XYZprinting software is kid-friendly and simple to learn.

This is a surprisingly comprehensive resource for 3D printing novices. All XYZprinting software is kid-friendly and simple to learn.

The da Vinci miniMaker also comes with auto-calibration, filament detection, and automatic filament feeding. These are time saving features which leave less room for error and more time for 3D printing.

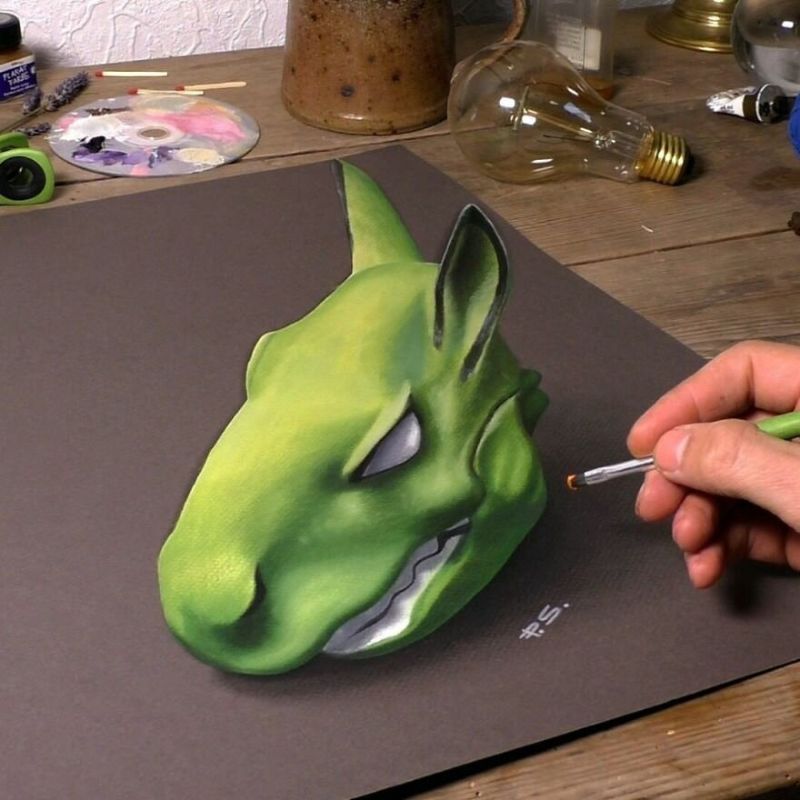

Good Print Quality

Obviously, results from the miniMaker aren’t as sharp as those from a more expensive printer. Layers are visible at any resolution and you shouldn’t use the miniMaker for models with tight tolerances (like nuts and screws). That said, fine details like those found in facial expressions, or in the Eiffel Tower’s lattice, are no problem for this hearty little 3D printer. Models with sharp points and smooth edges don’t pose a challenge for this printer, either. Considering the da Vinci miniMaker’s rock bottom price, its consistent print quality pleasantly surprised us.

More Details ❯

da Vinci miniMaker 3D Printer Review Cons

Filament Limitations

The most obvious and frustrating problem with the da Vinci miniMaker is its reliance on proprietary filament. XZYprinting sells the idea that their filaments are non-toxic and safe for children, but this is true of all PLA filament. In fact, PLA is always made from safe, plant-based materials.

XZYprinting sells the idea that their filaments are non-toxic and safe for children, but this is true of all PLA filament. In fact, PLA is always made from safe, plant-based materials.

Another problem is that this printer only prints in PLA filaments. This isn’t necessarily a problem for children or educators, but it does mean that this printer isn’t suitable for adult hobbiests who want to experiment with different materials.

da Vinci miniMaker 3D Printer Review Verdict

The da Vinci miniMaker is a safe choice for parents and educators who want to encourage their children’s curiosity and creativity. The included software is specially designed for young learners of any age. Older kids get the freedom to build their own 3D models and learn advanced techniques, while younger children are guided with easy steps to print pre-built models.

For its price, the da Vinci Mini also comes with an awesome variety of features that help make 3D printing easier. That makes this printer a great value on top of everything else. For these reasons, we can overlook the fact that XYZprinting forces users to buy their filament replacements.

For these reasons, we can overlook the fact that XYZprinting forces users to buy their filament replacements.

More Details ❯

Share. Twitter Facebook Google+ Pinterest LinkedIn Tumblr Email

Modular Mini Circular (3D printer)

Ruvim

Loading

15.06.2020

15276

Miscellaneous

Subscribe to the author

Subscribe

I do not want

40

Good day all!

I finally finished the biggest and longest project in my career. It took me more than three weeks from idea to implementation, considering that I spent all day doing just that. But although various difficulties constantly arose, I was very pleased with the end result.

Model and links here: https://www. thingiverse.com/thing:4458304

thingiverse.com/thing:4458304

Demo and assembly video is also available: https://youtu.be/Yq_Sa27NV18

But let's get started.

- I came up with the idea of creating a "Mini Circular" with the possibility of transformation (moreover, fast and easy to use). In general, I am a supporter of ideology, each tool is strictly sharpened for its task. But then I realized that I do not have a factory. The place in the apartment is limited and of course it is much cheaper than making three machines. It turned out a machine that will cover most of the tasks of a 3D maker. This is how this project was born.

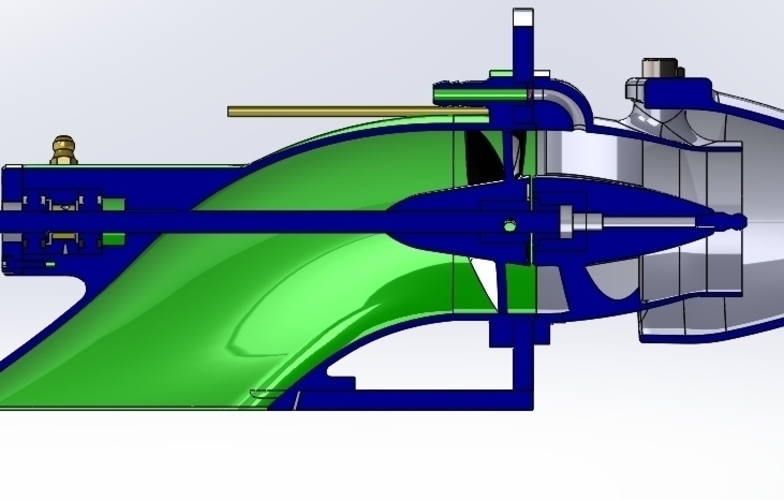

- The first thing I will face is the dimensions of the table on the 3D printer. It turns out that the circular of my dreams is larger than the table on the printer. And I had to break the machine into two parts (which served as the idea for modularity). The result was a part where the motor is located and all the electronics and a changeable table that can be changed depending on the tasks.

For example, you need a circular installed a large countertop. Need a grinder? With a slight movement of the hand, we remove the table, the flange with the disc and install the disc with Velcro for the abrasive. Accordingly, for grinding there will be another table with which it is convenient to work. In general, the project will be finalized and various tables and bells and whistles will be added in the future. It all depends on your response and interest.

For example, you need a circular installed a large countertop. Need a grinder? With a slight movement of the hand, we remove the table, the flange with the disc and install the disc with Velcro for the abrasive. Accordingly, for grinding there will be another table with which it is convenient to work. In general, the project will be finalized and various tables and bells and whistles will be added in the future. It all depends on your response and interest.

- The design has been designed so that all walls can be printed individually. So it is easier to print with ABS plastic and the printing time is also not so huge. It is easier to print in small runs than one part for two days.

So, I started typing the whole thing. The walls, bottom and everything that was printed flat did not cause any problems. But the second table that I originally printed with the legs caused a lot of problems. As you already know, ABS shrinks. Yes, such that cooling down broke the glass in several places. Therefore, I broke this large part into several parts and then you can simply connect it with M3 bolts.

Therefore, I broke this large part into several parts and then you can simply connect it with M3 bolts.

The heart of this miracle is the 775 engine. There is also a PWM regulator, it is very necessary for grinding and also saves from the starting current.

Write your ideas for the continuation of the project. What modules to make and what do you think about such a unit?

Well, according to the established tradition, a few photos for a good example.

Article comments

More interesting articles

ski

Loading

10/14/2022

951

5

Subscribe to the author

Subscribe

Don't want

A video post about how, taking the right idea and implementation, you can bring the whole concept to mind. ..

..

Read more

one

Subscribe to the author

Subscribe

Don't want

Dear friends! Formlabs User Summit 2022 will take place on October 26 and 27

Last year...

Read more

CEPKO777

Loading

02/08/2018

139362

273

Subscribe to the author

Subscribe

Don't want

Hello everyone. After buying a printer and understanding the principle of operation of CNC machines, I began to look at others ...

Read more

Mini Double Sided Sander For 3D makers.

Miscellaneous

Subscribe to the author

Subscribe

Don't want

61

Hello everyone! Due to numerous requests from subscribers and friends, I made a Mini Sander for two discs 75mm and 50mm

A lot of effort, days and plastic were spent, but the result exceeded all expectations. It turned out to be a very powerful grinder for all occasions. Personally, I made it for processing printed models from ABS plastic. With what she copes with a bang. The heart of the whole movement is the 775 Motor. It works up to 36V and is capable of delivering about 15t rpm. Given the pulleys, the speed will be slightly less. For the first, rough plastic grout, this is an excess speed and the ABS will melt. Therefore, I installed Shim speed control and with it you can already set any speed. But for the final polishing with felt, which makes the model shine, high speed is just right! She can also easily sharpen knives, remove burrs from metal, and in general it all depends on the set circle, she has a lot of power. The price was not expensive, at first I ordered a motor with delivery from China for 480 rubles, waited 3 months, opened a dispute and ordered from the Russian warehouse, for 600 rubles, the next day the motor was brought home, despite the quarantine). I took an 8mm shaft from an old laser printer, bearings, a belt and pulleys are not expensive.

It turned out to be a very powerful grinder for all occasions. Personally, I made it for processing printed models from ABS plastic. With what she copes with a bang. The heart of the whole movement is the 775 Motor. It works up to 36V and is capable of delivering about 15t rpm. Given the pulleys, the speed will be slightly less. For the first, rough plastic grout, this is an excess speed and the ABS will melt. Therefore, I installed Shim speed control and with it you can already set any speed. But for the final polishing with felt, which makes the model shine, high speed is just right! She can also easily sharpen knives, remove burrs from metal, and in general it all depends on the set circle, she has a lot of power. The price was not expensive, at first I ordered a motor with delivery from China for 480 rubles, waited 3 months, opened a dispute and ordered from the Russian warehouse, for 600 rubles, the next day the motor was brought home, despite the quarantine). I took an 8mm shaft from an old laser printer, bearings, a belt and pulleys are not expensive.

At first I thought that this was an overly complex mechanism, there is a powerful motor, and two discs 50mm, 75mm. But upon completion of the project, I worked on it for several days and realized that this is an awesome tool, as versatile as possible and easy to manufacture. The table can be removed, or at any time printed at a different angle or wider. In general, it all depends on the tasks.

If you have any questions, write, I will be happy to answer. In the comments on YouTube, I answer faster. If not urgently, you can write people. Have a nice day, everyone!

As always a link to all models and components

Detailed assembly video.

More interesting articles

ski

Loading

10/14/2022

951

5

Subscribe to the author

Subscribe

Don't want to

Video post about how taking the right idea and implementation, you can bring to mind the whole concept.