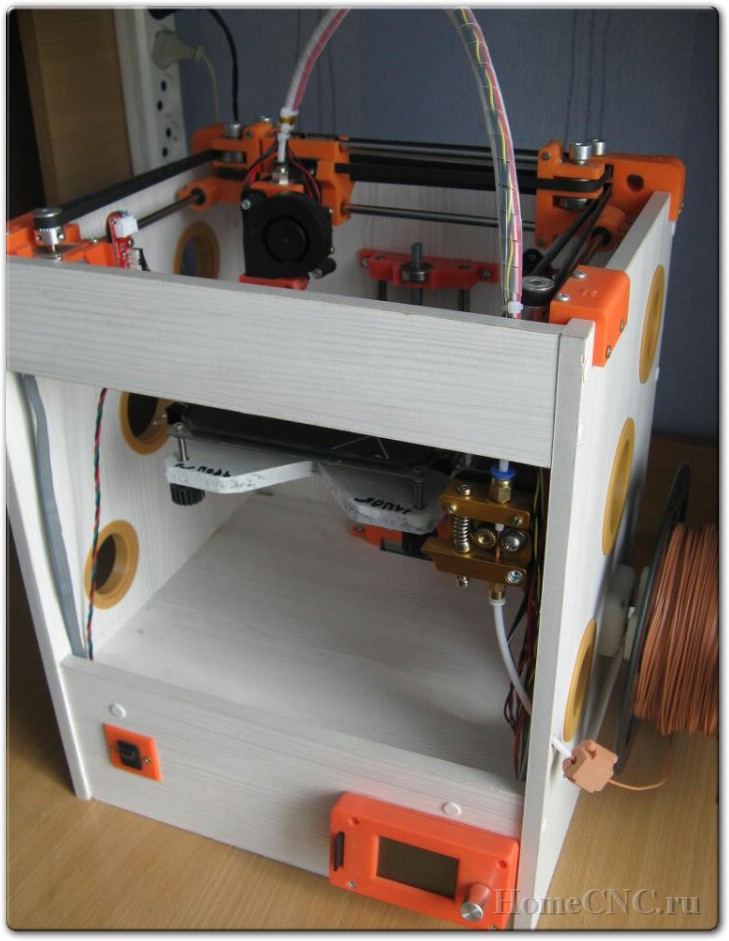

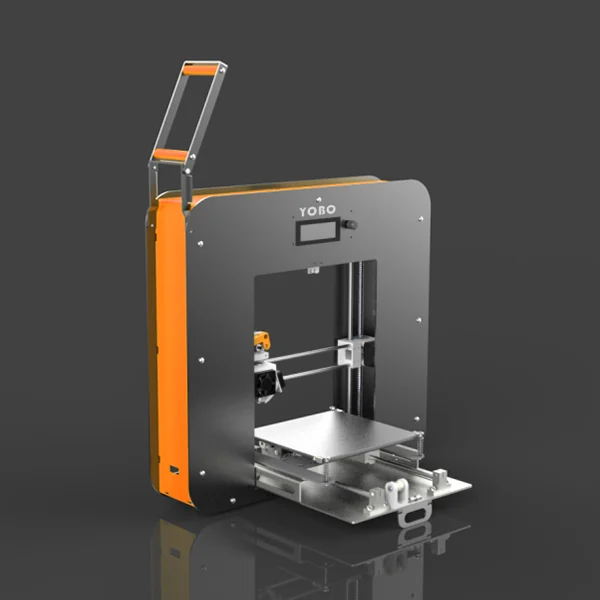

Mini fabricator 3d printer

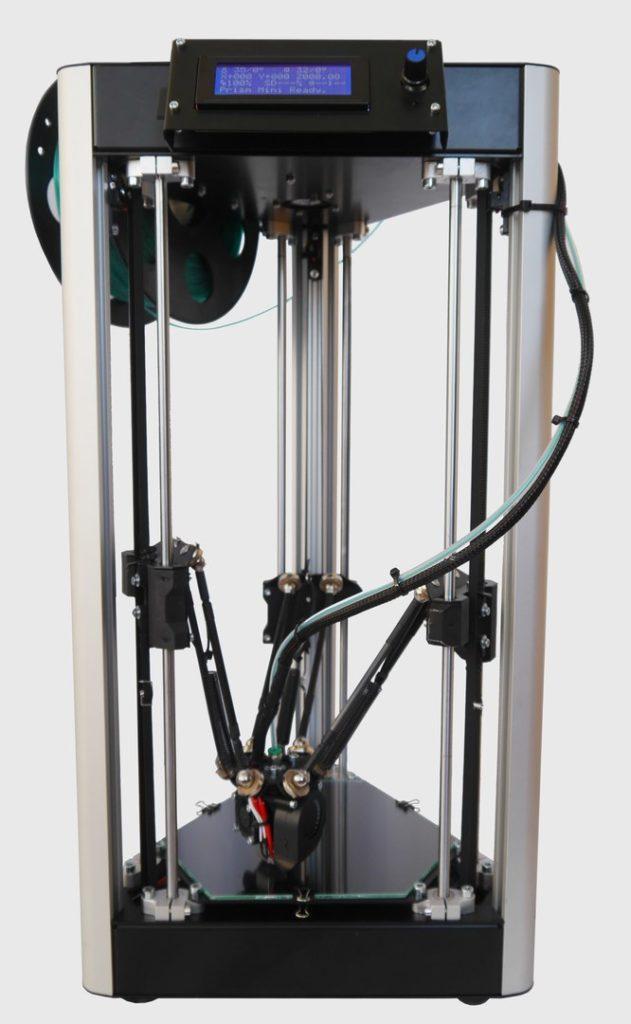

Mini Fabrikator V2 (US Plug)

JavaScript seems to be disabled in your browser.

You must have JavaScript enabled in your browser to utilize the functionality of this website.

Proceed to Checkout

Total Price

$0.00

Cart 0

want FREE shipping? Click here to find out more!

{{/findAutocomplete}}

SKU: {{sku}} {{#isFreeshipppingEnabled}} Free Shipping on Eligible Orders {{/isFreeshipppingEnabled}}

{{#isDiscountFlag1Enabled}}

{{/isDiscountFlag1Enabled}} {{#isDiscountFlag2Enabled}}

{{/isDiscountFlag2Enabled}} {{#isDiscountFlag3Enabled}}

{{/isDiscountFlag3Enabled}} {{#isDiscountFlag4Enabled}}

{{/isDiscountFlag4Enabled}} {{#isDiscountFlag5Enabled}}

{{/isDiscountFlag5Enabled}} {{#isDiscountFlag6Enabled}}

{{/isDiscountFlag6Enabled}} {{#isDiscountFlag7Enabled}}

{{/isDiscountFlag7Enabled}} {{#isDiscountFlag8Enabled}}

{{/isDiscountFlag8Enabled}} {{#isDiscountFlag9Enabled}}

{{/isDiscountFlag9Enabled}} {{#list_image_url}}{{/list_image_url}} {{^list_image_url}}{{/list_image_url}}

{{#isFreeshipppingEnabled}}

Free Shipping on Eligible Orders

{{/isFreeshipppingEnabled}} {{#isAddToCartEnabled}} {{#isWarehouseAddToCartEnabled}} {{^is_combo_product}}

QTY: {{#isAgerestrictionEnabled}} {{/isAgerestrictionEnabled}} {{^isAgerestrictionEnabled}} {{/isAgerestrictionEnabled}}{{/is_combo_product}} {{/isWarehouseAddToCartEnabled}} {{/isAddToCartEnabled}} {{#availableInOtherWarehouses}} {{{availableInOtherWarehouses}}} {{/availableInOtherWarehouses}} {{#is_combo_product}} {{^isProhibited}} View Details {{/isProhibited}} {{/is_combo_product}} {{#isProhibited}}

We are sorry, this product is not available in your country

{{/isProhibited}}

{{#hbk_price. stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_original_formated_label}} {{hbk_price.stock_2_group_0_original_formated}} {{/hbk_price.stock_2_group_0_original_formated}} {{#is_combo_product}} {{hbk_price.stock_2_group_0_combo_price_label}} {{/is_combo_product}} {{hbk_price.stock_2_group_0_formated}} {{#hbk_price.stock_2_group_0_original_formated}} {{hbk_price.stock_2_group_0_you_save_formated_label}} {{hbk_price.stock_2_group_0_you_save_formated}} {{/hbk_price.stock_2_group_0_original_formated}}

Turnigy Fabrikator Mini 3D Printer review! (TinyBoy) – Tom's 3D printing guides and reviews

It’s cheap. But is it good? The Fabrikator Mini tries to be the most affordable 3D printer out there, but i think it leaves out a few too many core features.

But is it good? The Fabrikator Mini tries to be the most affordable 3D printer out there, but i think it leaves out a few too many core features.

Last one that’s listed on Hobbyking

TinyBoy 2 campaign

TinyBoy 1 source files

How low can you go? Or actually, how low do you have to go to make a $175 3D printer? Well, stick around to find out as we take a deeper look at the Turnigy Fabrikator Mini from Hobbyking, which is exactly that.

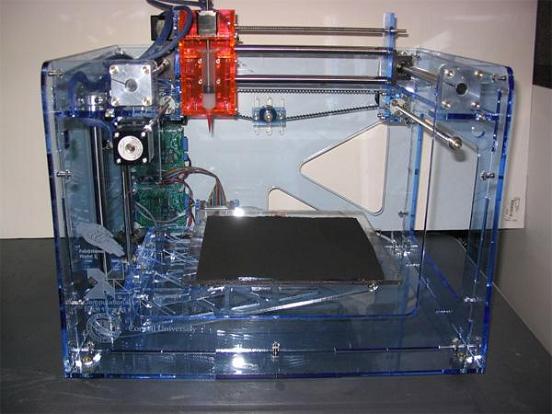

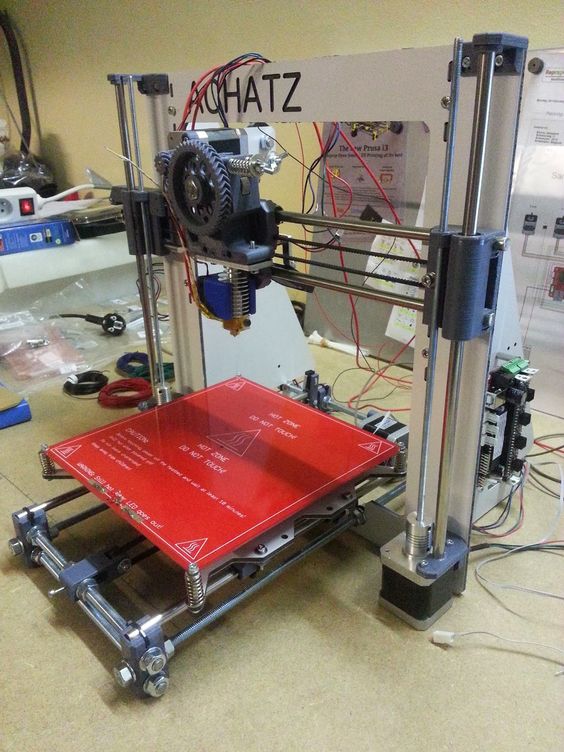

Now, surprisingly, this isn’t the only complete 3D printer you can buy for less than $200. In fact, for probably the same price once you factor in shipping, you can get a Prusa i3-esque machine with an LCD, a heated bed, and around 16 times the build volume of the Fabrikator Mini. But if you watch my review of the Malyan M150, a printer that is actually a good bit more expensive than that, you’ll get to see some of the flaws these rock-bottom 3D printers can come with. With something like the Fabrikator Mini, you will get the same experience anybody else is getting with it because you will receive the same hardware every single time – as opposed to simply buying the cheapest i3 from a random seller and getting a surprise package every single time. So what is the Mini Fabrikator all about? Well, let me show you its features! Actually, there’s not a lot to talk about since there are not noteworthy features per se. I guess the biggest “feature” would be its size, as it only takes up a 150mm square footprint on a desk. This is small enough to fit in the actual build area of most of my other 3D printers! Of course, you do sacrifice build area on the Fabrikator Mini that way, which leaves it with an 80mm cube build volume. Sure, that’s tiny, but i still think it’s a very usable size for its intended purpose, in fact, probably 95% of the things i print fit into this volume. The Fabrikator Mini is also surprisingly silent once you add the included feet, which come with a foam pad on their underside. These also lift up the bottom of the printer to allow for additional airflow, since some users complained about overheating of the motor drivers, which, in my case, didn’t seem to be a problem. But only after i retuned the driver’s current setting, which, out of the box, is set so high that not only the motor driver will shut down eventually, but it will actually heat up the smaller-than-usual NEMA14 motors so much that they will warp the thin acrylic frame.

So what is the Mini Fabrikator all about? Well, let me show you its features! Actually, there’s not a lot to talk about since there are not noteworthy features per se. I guess the biggest “feature” would be its size, as it only takes up a 150mm square footprint on a desk. This is small enough to fit in the actual build area of most of my other 3D printers! Of course, you do sacrifice build area on the Fabrikator Mini that way, which leaves it with an 80mm cube build volume. Sure, that’s tiny, but i still think it’s a very usable size for its intended purpose, in fact, probably 95% of the things i print fit into this volume. The Fabrikator Mini is also surprisingly silent once you add the included feet, which come with a foam pad on their underside. These also lift up the bottom of the printer to allow for additional airflow, since some users complained about overheating of the motor drivers, which, in my case, didn’t seem to be a problem. But only after i retuned the driver’s current setting, which, out of the box, is set so high that not only the motor driver will shut down eventually, but it will actually heat up the smaller-than-usual NEMA14 motors so much that they will warp the thin acrylic frame. On the other hand, if you tune down the stepper drivers too much, there are reports of these brass bushings starting to bind and causing the motors to skip steps, thus ruining your print. In my case, it printed perfectly fine after setting the driver’s reference voltage to about 0.7V. This is a bit higher than most viewers recommended in the live unboxing stream, but i had to add an external fan anyways, which in this case also cools the motors, but mostly serves as a part cooling fan. You see, this printer is made to work with PLA – it doesn’t have a heated bed, after all – and PLA needs a part cooling fan to print well, which the Fabrikator Mini does not have out of the box. These two prints were done from the exact same gcode, the left one without the fan, the right one with. Quite a big difference! Now, if you don’t want to just have a fan sitting on the table next to the printer, you can download and print one of the fan shrouds you can find online – again, an advantage of having a somewhat stable platform from a single vendor.

On the other hand, if you tune down the stepper drivers too much, there are reports of these brass bushings starting to bind and causing the motors to skip steps, thus ruining your print. In my case, it printed perfectly fine after setting the driver’s reference voltage to about 0.7V. This is a bit higher than most viewers recommended in the live unboxing stream, but i had to add an external fan anyways, which in this case also cools the motors, but mostly serves as a part cooling fan. You see, this printer is made to work with PLA – it doesn’t have a heated bed, after all – and PLA needs a part cooling fan to print well, which the Fabrikator Mini does not have out of the box. These two prints were done from the exact same gcode, the left one without the fan, the right one with. Quite a big difference! Now, if you don’t want to just have a fan sitting on the table next to the printer, you can download and print one of the fan shrouds you can find online – again, an advantage of having a somewhat stable platform from a single vendor.

Other than the printer itself, a power supply, a few extra sheets of blue painter’s tape for the bed and the feet, you don’t get a whole lot in the package. I guess the PLA sample isn’t really worth mentioning since it’s literally just enough for, like half a test print. The initial unboxing experience is really simple – you load the print profile into Repetier host – if you want to use Cura or any other slicer, you will need to type them in manually – adjust the bed height with this little screw on the back, plug in the bowden tube and you’re ready to print.

Now, the print quality in general is pretty ok – especially for the money. Of course, grey PLA does amplify any quality issues on camera, but except for some slight layer inconsistencies, it’s really ok. Which was expected, given that the default print speed is a whopping 15mm/s – for comparison, i run most of my other printers at 60mm/s, which is, i guess, a normal speed. But on the Fabrikator Mini, anything faster will start showing some artifacts from the extremely weak linear guide system. The first print i started actually used the wrong slicing profile and had it printing at 40mm/s, which worked, but it also only had smooth surfaces, so there wasn’t any risk of ending up with ringing artifacts. It’s also set up for quite low accelerations and uses a bowden system, so the forces on this motion system are fairly low. Still, XXmm unsupported linear rails and this tiny M4 Z-axis spindle, which has a ton of backlash, all in combination with the 4mm thin acrylic frame are anything but trust-inspiring. But in the end, it works! So i had the Fabrikator Mini set up for a full day of printing, and printed off 8 of these clamps that i’ll be using in an upcoming project. Except for some slight variations of the first layer bed height, these all came out very consistently and reliably. Pop one off, start the next one, rinse and repeat, all day long.

The first print i started actually used the wrong slicing profile and had it printing at 40mm/s, which worked, but it also only had smooth surfaces, so there wasn’t any risk of ending up with ringing artifacts. It’s also set up for quite low accelerations and uses a bowden system, so the forces on this motion system are fairly low. Still, XXmm unsupported linear rails and this tiny M4 Z-axis spindle, which has a ton of backlash, all in combination with the 4mm thin acrylic frame are anything but trust-inspiring. But in the end, it works! So i had the Fabrikator Mini set up for a full day of printing, and printed off 8 of these clamps that i’ll be using in an upcoming project. Except for some slight variations of the first layer bed height, these all came out very consistently and reliably. Pop one off, start the next one, rinse and repeat, all day long.

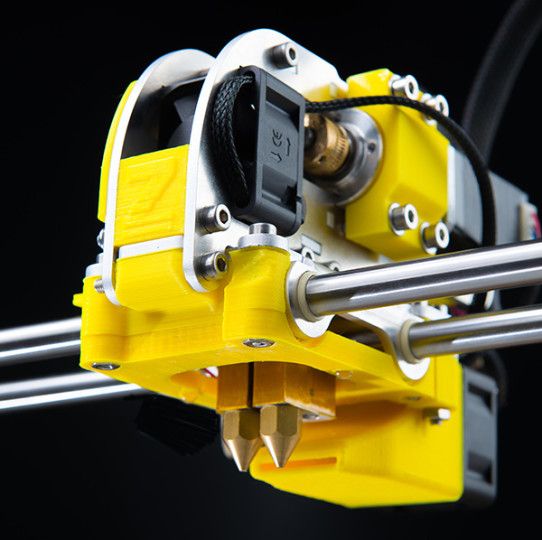

So there are actually a few nice features in here that you wouldn’t expect in an “as cheap as possible” 3D printer. On is the E3D v6 imitation, which, i mean, doesn’t add a whole lot of value as-is, as, as usual it’s not particularly well-made and uses a heatbreak that is much too thick, wastes a bunch of power, but also heats up the heatsink so much that it’s incredibly easily to jam the hotend if you pull out the filament too slowly when swapping filament. What will happen is that the filament will stick to the warm, but not hot metal sides and form a pretty solid plug, something the genuine one avoids by not heating up the heatsink so far and by putting a bit extra effort into making the heatbreak smooth inside.

What will happen is that the filament will stick to the warm, but not hot metal sides and form a pretty solid plug, something the genuine one avoids by not heating up the heatsink so far and by putting a bit extra effort into making the heatbreak smooth inside.

Also surprising to see here is the fully featured MKS base mainboard. Five stepper drivers, three power outputs, a heated bed output, and as expected for a cheap-ish board, standard Allegro stepper motor drivers and zero consideration for component current limits or any sort of failsafes. Ironically, though, now my smallest and my largest cartesian 3D printers use the exact same boards.

And the way the belts are set up here is pretty ingenious. Instead of just using a single loop, it uses this hoist-like system, which reduces the torque needed from the motor and also increases positioning accuracy.

And that’s why i kinda like the Turnigy Mini Fabrikator – yeah, sure, it’s super cheap and barely any features to write home about, but it’s got that vibe to it where it tries to do more with less and is mostly successful with it.

Now, this machine is not designed by Turnigy aka Hobbyking, it’s a project from TinyBoy aiming to provide affordable 3D printer for education – for that job, i think the way the Turnigy version is put together with the lack of a part cooling fan and the overheating issues, it’s just barely not enough to fit that bill. Educators are notoriously short on time and typically don’t want to spend it on getting a machine like this to work well. But – and here’s the kicker – there is a new version coming up, the TinyBoy 2, which was launched on Indiegogo a good year ago and should have been shipping by now, but TinyBoy’s CEO dropped out for a while due to medical issue and it looks like, they now are actually producing the new machines. I fully expect the new version to become available at Hobbyking again, seeing that the original one has been quite popular. As of right now, this exact machine here is on backorder and it looks like none have been shipped out for a while, so i can’t really recommend ordering it it right now. But it is a promising base for that next model.

But it is a promising base for that next model.

With this exact setup, you could make it work really well if you can and want to do a bit of tinkering, and with things like the fake v6, the big bowden extruder and the MKS board in there, you do even have the option of taking this entire thing apart and using those components to build something bigger if you feel like you need the extra space.

So those were my impressions on the Hobbyking Turnigy Fabrikator Mini aka TinyBoy v1.5 – if you’re looking for a similar machine, but, like, want it right now, check out my review of the Printrbot Play right up here. Now, for this video, if you enjoyed it, leave it a thumbs up, if not, a thumbs down, if you want to stay up to date as new videos come out, get subscribed, and if you’re really into what i’m doing here, drop me a dollar or two on Patreon. And that’s about it, see you in the next one or in this weekend’s livestream right here on Youtube.

This video is licensed as Creative Commons Attribution Share-alike thanks to my supporters on Patreon!

Music is Jahzzar – Halley, licensed CC-BY-SA

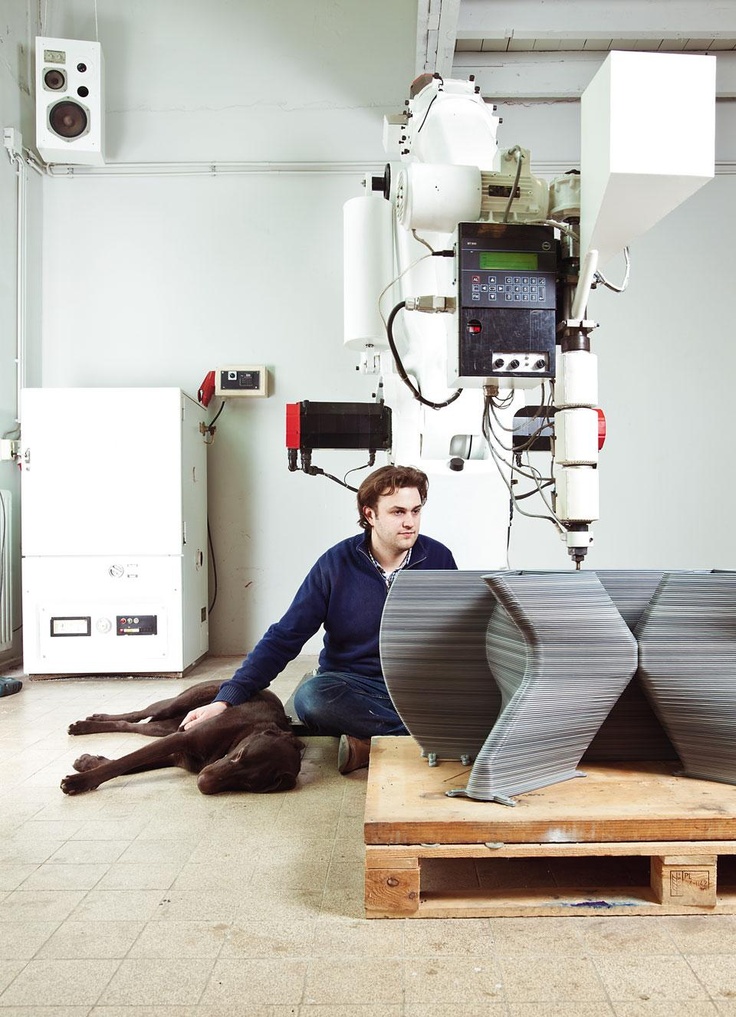

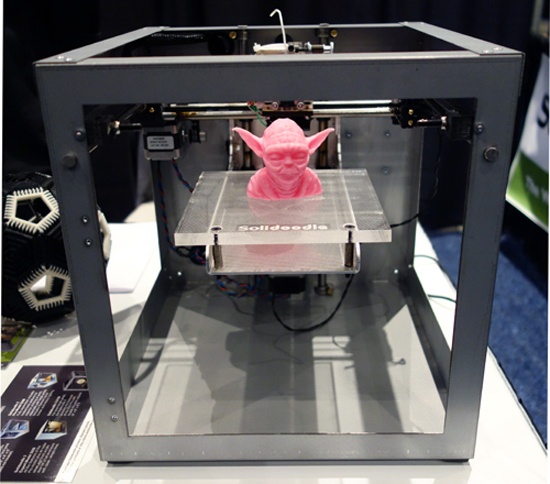

Overview of the budget 3D printer Monoprice Select Mini

3DPrintStory Reviews Overview of the budget 3D printer Monoprice Select Mini

Prices for desktop 3D printers continue to fall. There were times when a $600 3D printer was a delight and a desire to order it as soon as possible, but technology does not stand still, and developers and manufacturers are looking for new options to lower the price even lower. This review is dedicated to one of the budget 3D printers costing about $200 - Monoprice Select Mini.

There were times when a $600 3D printer was a delight and a desire to order it as soon as possible, but technology does not stand still, and developers and manufacturers are looking for new options to lower the price even lower. This review is dedicated to one of the budget 3D printers costing about $200 - Monoprice Select Mini.

It is worth noting that this inexpensive model breaks established traditions and did not start with Kickstarter, unlike others like M3D Micro, Tiko, OLO / ONO and Trinus, which attracted the attention of consumers and investors thanks to crowdfunding platforms (by the way, this is really an effective development strategy for small startups, but there is often a mismatch between expectations and the final product).

Monoprice is different. This is an American company that did not particularly bother with the development and production of its own 3D printer, but simply imported the Malyan M200 from China, hung its logo on it and put an attractive price of $199. What if you got a defective 3D printer? No problem, send it back and they will replace it for you.

What if you got a defective 3D printer? No problem, send it back and they will replace it for you.

A reasonable question arises: can such a cheap 3D printer compete with Ultimakers or Printrbots? And is it even worth comparing? We will try to answer these and other questions in the review below.

Features Monoprice Select Mini

- Available;

- Robust design;

- Easy to use;

- Predictable 3D printing at low speed;

- Works with any slicing software and standard 3D printing materials;

- Amenable to improvements and upgrades;

- I think we already mentioned the price?

Disadvantages Monoprice Select Mini

- Difficult to calibrate;

- Prints poorly at high speeds;

- Print table not protected;

- Faulty power supply;

- WiFi module not active;

- Unstable nozzle temperature;

- Strange quirks...

Short Verdict

The Monoprice Select Mini is a great 3D printer for the price. There is a heated table, easy to operate if you do not use high speeds, stable 3D printing quality.

There is a heated table, easy to operate if you do not use high speeds, stable 3D printing quality.

Naturally, there are disadvantages. During operation, the temperature of the nozzle may change, and at high speeds, 3D printing errors occur. The calibration process takes a lot of time and the first time you have to tinker. Well, the most interesting thing is that the power supply burned out after 12 hours. But the latter, incorrect, can be attributed to an accidental marriage.

Despite all the shortcomings, the Monoprice Select Mini is a wonderful little 3D printer with many great features. In general, it performs in accordance with the information in the technical specifications, and the quality of the 3D printing even exceeded our expectations.

If you are not afraid to take it apart / put it back together, then you can do a few upgrades. The first thing to do is to replace the hotend and update the firmware to activate the WiFi module ( be careful! These upgrades have not been tested as part of this review and may damage your 3D printer! ). You can install the glass on the print table. Even with these upgrades, the price will still remain acceptable.

You can install the glass on the print table. Even with these upgrades, the price will still remain acceptable.

Would you recommend the Monoprice Select Mini as your first 3D printer? Yes, definitely.

Specifications and features Monoprice Select Mini

Monoprice Select Mini workspace 120 x 120 x 120 mm. The maximum resolution of 3D printing is 100 microns. Heated table. The 3D printing speed is 55 mm/s.

You can upload your 3D model via micro SD card or USB. The manual states that compatible slicing programs are Cura, Repetier-Host, ReplicatorG, and Simplify3D. This means that the Monoprice Select Mini recognizes the standard G-code, and this 3D printer is not tied to any particular software. Cura was used during testing for this review.

Monoprice Select Mini doesn't limit your media usage. You can print with any standard 1.75 filament using PLA or ABS thermoplastics. In our case, PLA plastic from ColorFabb was used.

These two points - the freedom to choose software and filament - are very important in this price range, because manufacturers such as M3D Micro and XYZprinting, which are Monoprice's main competitors in this niche, tend to use proprietary software and their own materials for 3D printing .

Unpacking and installation of the Monoprice Select Mini

Installation of the Monoprice Select Mini is quite simple. You can start typing within 20 minutes.

Inside the box you will find a 3D printer, a power supply, an imbus wrench for calibrating the table, a plastic spatula to scrape off the rest of the material from the table after printing, a 256 MB micro SD card and a micro USB cable.

One piece of paper contains a basic instruction and a link to a website where you can download the full version.

You will also find a rectangular steel sheet, the purpose of which is not clear at first. It turns out that this is a coil holder that is attached to the side of the main unit.

It is important to note that the Monoprice Select Mini kit does not include media test samples. So stock up on filament with a diameter of 1.75 mm.

You can use the wheel to adjust. The menu is well structured and easy to understand. You can start the calibration process, preheat the extruder and feed the filament.

Calibration can be somewhat difficult. In theory, it should be carried out even before shipment, in production, and you should have a piece of paper between the nozzle and the printing table. If it doesn’t work, then hex keys will come in handy here. It will be necessary to try and tighten the screws at the corners of the table so that the sheet still passes.

At this stage, the first important shortcoming of this model becomes clear. The printing table is made of aluminum and does not have a special protective film or coating on it. So stock up on blue 3D printing tape or install glass right away. Otherwise, the table will wear out very quickly and you will have to change it.

Well, one more bug that got out in our particular case. The power supply burned out after 12 hours of use. Foaming it was not difficult, but it was very unpleasant. You can probably throw it off for marriage, but in any case, be prepared for a similar turn of events.

Design and build quality of the Monoprice Select Mini

Very pleased with the build quality of the Monoprice Select Mini. The construction is strong, reliable, with a steel sheet metal case that hides all the electronics. So don't worry about shipping damage.

The construction is strong, reliable, with a steel sheet metal case that hides all the electronics. So don't worry about shipping damage.

This 3D printer uses deposition modeling technology. The classical Cartesian coordinate system is used. The design is similar to Printrbot Simple. One cooler is used to cool the nozzle. It is likely that problems may arise during 3D printing with unusual materials.

The extruder has a diameter of 0.4 mm and can be heated up to 230°C. We have not been able to test how easy it is to change, but in the long run this is an important factor as the nozzle will still need to be changed over time.

Monoprice Select Mini Print Quality

Pre-loaded models will already be on the micro SD card. They are supposed to be optimized for 3D printing on the Monoprice Select Mini. So before uploading our own models, we printed test ones.

The cat was printed first. The resolution was 200 microns. Everything went well until the last layers. The upper part of the paw and ears could not be printed even once. There were 3 attempts in total.

The upper part of the paw and ears could not be printed even once. There were 3 attempts in total.

G-code analysis in Simlify3D showed that the table accelerated up to 55 mm/s during the printing of the last layers. That is why the error was repeated. Quite a strange decision of the company - to provide a test model, which a priori will be printed with errors...

The second model that we printed is a test elephant. The resolution was also 200 microns and 10% infill. There were no problems! The result is excellent and you can see it in the photo below.

Next we moved on to our own models. We used Cura for slicing. This article reveals the excellent Cura settings for 3D printing on the Monoprice Select Mini and we used them.

We printed a classic 3DBenchy and Graphica model: a MEGA Ghost with 200 micron resolution and 10% infill, a V29 whistle with 200 micron resolution and 100% infill, and another 3DBenchy model with 100 micron resolution and 10% infill.

The simple 200 micron models worked well. There are no special problems with small protrusions and holes, although there are sagging. The layers are laid evenly along the X and Y axes.

The V29 whistle sounds as loud as intended, which means the partitions were printed correctly. The Graphica Mega Ghost with its long tongue also printed correctly. The hinge glided smoothly. The

3DBenchy at 100 microns worked well too. When you look at the photo, don't forget that this is a $19 3D printer.9.

We have noticed that most errors in 3D printing occur when the spool of filament clings or there is not enough adhesive coating on the printing table. This cannot be attributed to the shortcomings of the Monoprice Select Mini itself, since this is a global problem for all FFF printers.

During operation, the print table may block access to the control wheel. This point is implemented in the design is not very ergonomic.

Another disadvantage is that the nozzle temperature has an error in the region of 5°C. For example, when the 3D printing temperature is set to 215°C, it jumps between 213°C and 217°C on the control panel.

For example, when the 3D printing temperature is set to 215°C, it jumps between 213°C and 217°C on the control panel.

This does not particularly affect printing with PLA plastics, but may have a negative effect during 3D printing with materials that are more sensitive to temperature changes.

Finally, we printed a Low Poly Moai bust. We scaled the model by 50% and printed with 100 micron settings and 30% infill. It turned out well on the whole, the only small marriage is the influx of material on the chin. By the way, we observed the same effect when printing 3DBenchy with resolution settings of 100 microns.

Life hacks and upgrades Monoprice Select Mini

A few words about upgrading the Monoprice Select Mini 3D printer. There are no official upgrades! But here are a few options that you can try to implement on your own.

In our opinion, it is necessary to deal with the temperature of the extruder, make it more stable. For example, you can implement a PID temperature controller.

You can activate the WiFi connection by downloading the original Malyan M200 firmware. But be careful! This option has not been tested and there is a possibility that you may damage your 3D printer!

Monoprice Select Mini Summary

After testing the Monoprice Select Mini, this is one of the best 3D printers you can buy for $200.

But it's important to realize that the print quality can't be compared to the Original Prusa i3 MK2 or LulzBot Mini. Not to mention the more expensive models.

If you're looking for a small business 3D printer or just high-quality 3D without bugs, then the Monoprice Select Mini is not for you. In addition to the print quality, you will obviously not be satisfied with periodic bugs and a small workspace.

But if you are just starting to explore the world of 3D printing, then this is a great choice and a good alternative to the Chinese Anet A8 3D printer.

The Monoprice Select Mini has some drawbacks, but it's still a great option for learning and just having fun. It's easy to use and print quality rivals more expensive models.

It's easy to use and print quality rivals more expensive models.

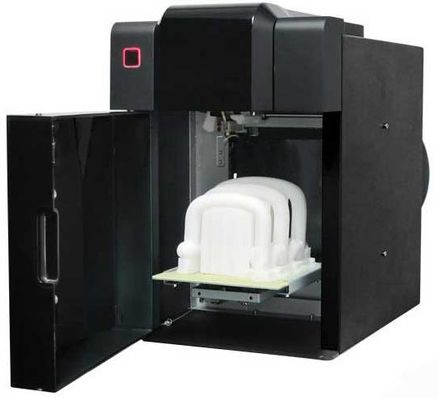

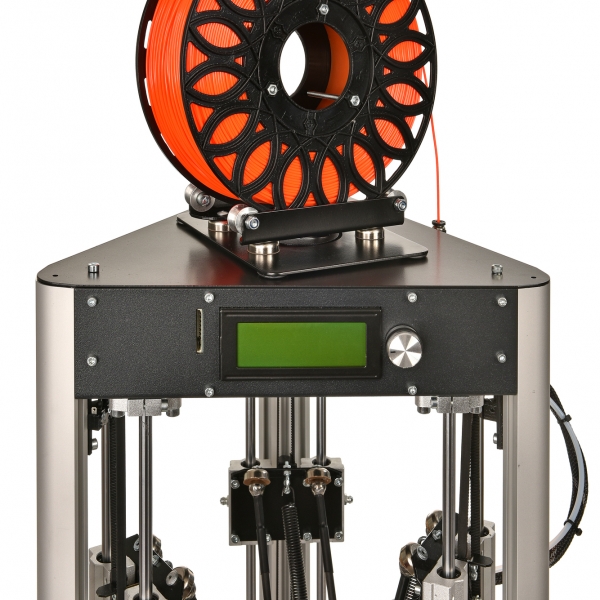

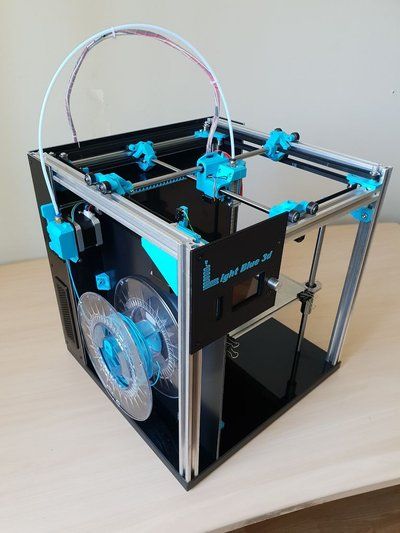

Createbot Mini I 3D printer (1 extruder)

| Specifications | |

| Trade-in | Yes |

| 10% promotion for plastic | Yes |

| Weight (unpackaged) | 11 kg |

| Warranty | 12 months |

| Filament diameter (printer) | 1.75 mm |

| Nozzle diameter (mm) | 0.4 |

| Display | LCD display |

| Connection interface | USB, SD |

| Number of extruders (print heads) | 1 |

| Housing material | Steel |

| Operating systems | Linux, Unix, Windows 8, Windows 7, Windows XP |

| Supported file formats | STL, OBJ, DAE, BMP, JPG |

| Software | CreateBot SoftWare |

| Manufacturer | Createbot |

| Extruder operating temperature | 230 (max. 260℃) 260℃) |

| Construction area size | 150×150×220 mm |

| Dimensions (without packaging) | 325×303×428 mm |

| Print speed | 80-150 (45 cm3/hour) |

| Country of origin | China |

| Print technology | FDM\FFF |

| Plastic type | PLA, ABS |

| Layer thickness | 0.1 - 0.3 |

| XY Positioning Accuracy | 0.01 |

| Z-axis positioning accuracy | 0.002 |

| Power supply | 220V, 50/60Hz, 4. 0A 0A |

| Equipment | |

| SD card | 1 pc. |

| USB cable | 1 pc. |

| Warranty card | 1 piece |

| Spool holder | 1 pc. |

| User manual in Russian | 1 pc. |

| Card reader | 1 pc. |

| Hexagon set | 4 pcs. |

| Tweezers | 1 pc. |

| plastic (1kg) | 1 pc. |

| Power cord | 1 pc. |

| Printing tape | 1 pc. |

| Spatula | 1 pc. |

Seeing the fruit stand model on the Thingiverse website (http://www.thingiverse.com/thing:724096) we were eager to print it on the CreateBot Mini I budget printer. The model is modular and can consist of a different number of elements , depending on the desire of the one who prints it. In our case, it consisted of 35 elements, the total weight was 352 grams, the total printing time was 48 hours, we printed the parts one by one. When printing, we used ESUN PLA in orange and light green. The printer proved to be very good, for all the time we had only a couple of failures associated with models coming off the table and this happened with printing leaves that are printed while standing and the area of \u200b\u200btheir contact with the platform is very small.