Micro center 3d printing

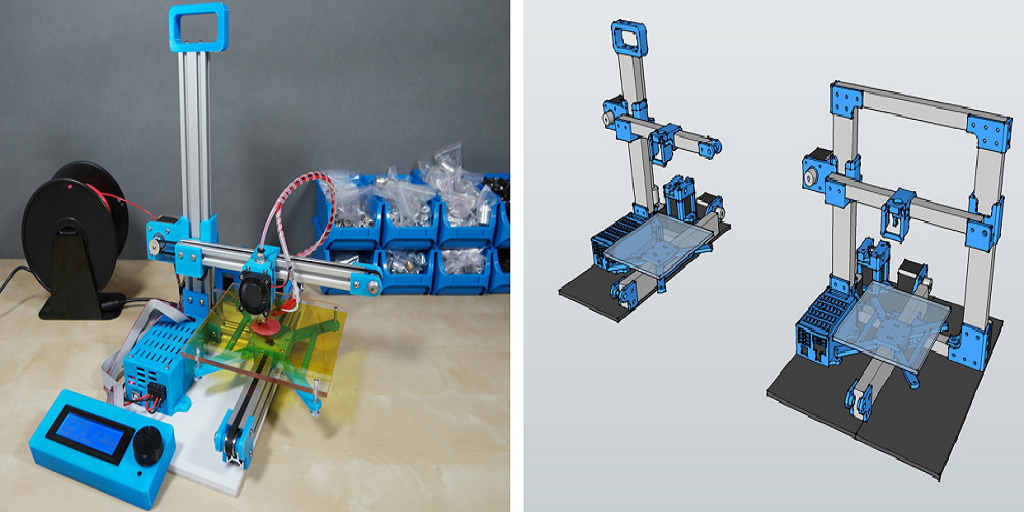

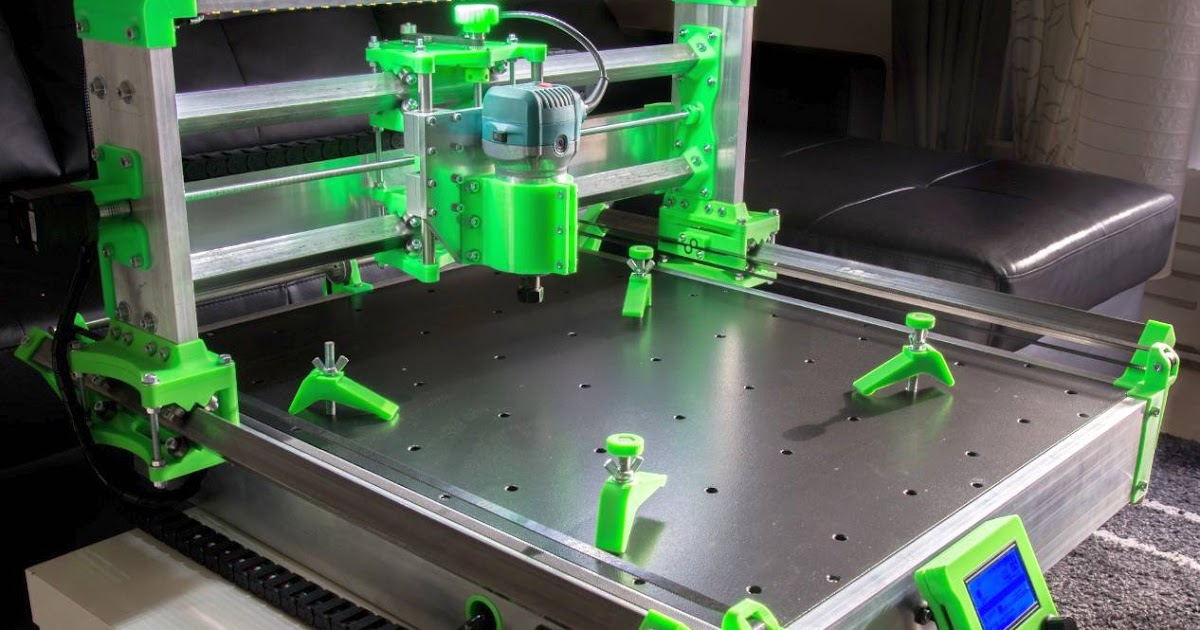

Creality Ender 3 Pro 3D Printer

Sorry, this deal has expired. Get notified of deals like this in the future. Add Deal Alert for this Item

Frontpage Deal

Micro Center Stores [store locator] offer New Customers: Creality Ender 3 Pro 3D Printer for $199.99 - $100 off in-store text coupon = $99.99 when you follow the steps below. Offer valid in-store only.

Thanks to community member tegz for finding this deal.

Note: Site may take some time to load or may take a few tries to get the coupon to work.

Offer valid while supplies last:

- Creality Ender 3 Pro 3D Printer

Steps:

- Visit the Sign-up Page here and fill out your info

- Fill out the Captcha if needed

- Click on the Send My Coupon button

- Wait for the page to load, this can take some time

- Note: If it errors-out, reload the page and try again

- Once completed you will get a 'Thank you, your coupon code has been sent.

' message on the page

- Check your Text Messages and reply Y to the text that was sent

- You should receive a link to your Coupon shortly after

- Coupon is valid through Sept 7th 2021

Product Info:

- 3.25 Inch LCD Screen with Dial Button

- Magnetic Removable Build Surface Plate

- UL Certified Power Supply

- 220 x 220 x 250mm Print Size

- About this deal:

- This offer is $200 lower (~66% savings) than the $299.99 list price.

- Offer terms:

- US customers only. By signing up and clicking "Send My Coupon", you are agreeing to receive up to 5 SMS messages per month and marketing emails from Micro Center to the information that you provided at the time of signing up. You will receive premier access to our best offers, exclusive deals, alerts about new products, and more. Carrier message and data rates may apply. For help, text HELP to 41091. To opt-out, text STOP to 41091.

To unsubscribe from email, see our Privacy Policy and Micro Center's Mobile T&C.

To unsubscribe from email, see our Privacy Policy and Micro Center's Mobile T&C. - Offer only valid at Micro Center retail locations. Coupon cannot be used with other coupons. No coupons available at the store. Coupon is serialized / one-time use only. Coupon not redeemable for cash. New customers only. Limit one coupon per customer. While supplies last. Coupon valid only for SKU 950725.

- US customers only. By signing up and clicking "Send My Coupon", you are agreeing to receive up to 5 SMS messages per month and marketing emails from Micro Center to the information that you provided at the time of signing up. You will receive premier access to our best offers, exclusive deals, alerts about new products, and more. Carrier message and data rates may apply. For help, text HELP to 41091. To opt-out, text STOP to 41091.

See Deal

Good deal?

You gave thanks to tegz for this post.

Thank you!

tegz posted this deal. Say thanks!

Original Post

Written by Edited August 25, 2021 at 06:55 AM by

Back in-stock at several locations - YMMV

In-store only - Micro Center [microcenter.com] is offering New Customers: $100 off Creality Ender 3 Pro 3D Printer [microcenter. com] (currently on sale for $199.99) for a final price of $99.99 before taxes. Coupon valid until 9/7/2021 while supplies last.

com] (currently on sale for $199.99) for a final price of $99.99 before taxes. Coupon valid until 9/7/2021 while supplies last.

Steps:

Browse to the Sign-up Page [microcenter.com] and fill out the form

Click 'Send My Coupon' button

You may need to retry several times if you receive errors

When successful you will see a message above the form 'Thank you, your coupon code has been sent.'

Reply Y to the text that was sent to the number provided

A link to the coupon should follow shortly after

https://www.microcenter

in 3D Printers (4)

Get Micro Center Coupons

If you purchase something through a post on our site, Slickdeals may get a small share of the sale.

Joined May 2017 L1: Learner

PurpleBoundary6462 asked this question on 08-20-2021 at 09:56 PM

drpepper84 asked this question on 08-23-2021 at 11:33 AM

erictom asked this question on 08-23-2021 at 11:55 AM

neil1492 asked this question on 08-23-2021 at 11:56 AM

gealguy asked this question on 08-25-2021 at 11:30 AM

PurpleBoundary6462 asked this question on 08-20-2021 at 10:11 PM

Micro Center Ender 3 3D Printer deal - $99 - Manufacturing

Chief Delphibobbysq

#1

Recently found this deal for an Ender 3 for only $99, you need to register for this coupon and it’ll compound with their current sale, allowing you to pick one up for $99. YMMV, it got posted on a computer deal page so it might be out of stock for a while.

YMMV, it got posted on a computer deal page so it might be out of stock for a while.

Regardless, I’ve heard good things about the Ender 3 as an entry-level 3D printer, so this seems like a good pickup for any team near a Micro Center.

7 Likes

troy_dietz

#2

< old man rant >

Back in my day we had to scrap and save for a $400 Wanhao Duplicator i3!

< /old man rant >

7 Likes

marshall

#3

Yeah, I remember the before times too. I miss them so.

1 Like

sanddrag

#4

This is a great deal, but I can’t pass the reCAPTCHA. It just sits there and spins. Anyone else have this problem?

It just sits there and spins. Anyone else have this problem?

Peyton_Yeung

#5

I purchased a Solidoodle 2 for $400 my freshman year of college. I thought it was a steal to get a 6x6x6 inch build volume printer for that price. Still don’t think I ever got a good print off of it.

Andrew_L

#6

cries in in-person pickup only

6 Likes

Stuart

#7

Guess I’ll be picking one up tommorow before the new member meeting

1 Like

bobbysq

#8

I feel that - the closest one to me is 3 hours away. I was just there this weekend, too… At least I got a free SSD out of it.

I was just there this weekend, too… At least I got a free SSD out of it.

UnofficialForth

#9

Does anyone know how to check the hours they are open? I’m willing to take a road trip to get one, presuming the are actually open when I get there.

GeeTwo

#10

Both Chicago and Cincinnatti show 9pm on Google Maps.

Closest to me is Houston…nope.

mdurrani834

#11

Hmm…only a 50 minute drive…

Stuart

#12

And 1745 now has a print farm.

Or atleast a print farm assembly project on the Todo list

4 Likes

BrianAtlanta

#13

Check store inventory where ever you go. Use the link in the original post. The Chicago store out of stock, FYI.

2 Likes

troy_dietz

#14

Yap.

Tustin store was out the moment it was posted on r/bapcs

scottgoering

#15

There were at least 20 on the floor in the Overland Park, KS store at about 3:30pm this afternoon.

Thanks to OP for the coupon and link! Starting my 3D printing journey now.

8 Likes

DonRotolo

#16

Yup, same here. Firefox. Try another browser.

Or not: completely sold out nationwide.

FrankJ

#17

Same on Firefox. It worked on chrome, but it said new customers only.

DonRotolo

#18

Well, I got my coupon but with none available it’s kinda pointless.

“New Customers” means new to this version of their loyalty program. Living between Marietta and Duluth gives me unusually good MicroCenter access, I already get their weekly emails and such. For this particular thing, I opted back out of texts and emails right quick.

scottgoering

#19

You might try to call and see if they can check the store stock; or just head to the store. Yesterday the website said it was sold out in Overland Park, but there were 20+ on the floor.

The website now says there are 25+ available, but my brother just picked his up and said there were maybe 15-20 left.

Long story short: the stock on the website may not be completely accurate.

1 Like

DonRotolo

#20

I’ll head there tomorrow morning. Thanks!

Thanks!

next page →

(There is a solution) What is PLA+? How is it different from PLA?

pla filament filament-choice pla+

Question

What is PLA+? How is it different from PLA? I'm looking for science, composition, formula, safety issues (or lack thereof), etc.

Background

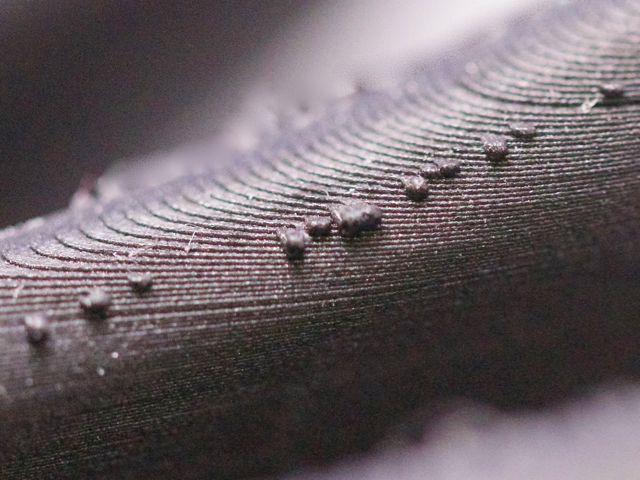

I picked up a roll of PLA+ at Microcenter (their own in-house brand) because it was in customs. I didn't even notice the "+" until I decided to try this color and then noticed it on a sticker. It prints well, feels like ABS, smells like PLA when printed, and I can use the PLA temperature on my printer. It was better than PLA, and if I didn't notice the PLA+ stickers and the smell, would have thought it was ABS . It will break its line in my printer like PLA does; ABS won't break if left alone. However, PLA+ lasts longer than regular PLA before breaking down.

Getting information from the Internet

Other than a few reddit discussions (review, commercial introduction), I can't find anything about it.

Obtaining information from the Manufacturer

I went back to the Microcenter and the guy who worked there in the 3D printing section didn't know what I was talking about. nine0003

I went to the Microcentre another time and the guy in the filament area said that all their PLA filament is now PLA+ and that the + means it should be used at a higher temperature. Boxes are marked with 205 - 225°C. It seems that all the internal brand of PLA I have is PLA+, with the exception of the first roll I bought. There are no temperature marks on it.

Flash ahead 1.5+ years from the original question

This question has received some recent attention, so I've been looking for an answer again. I found this article, which is a hot bunch of !usefulness, giving no data, lots of opinions, and probably some direct ideas from someone's marketing department. nine0003

These guys say it's good stuff, but nothing about the chemical or compositional difference between the two. When I find people talking about the difference (on reddit for example), it's the commonly mentioned details that are vague, anecdotal and opinionated and could be smart marketing (maybe not necessary). For example, the shine of one person is the matte color of another.

When I find people talking about the difference (on reddit for example), it's the commonly mentioned details that are vague, anecdotal and opinionated and could be smart marketing (maybe not necessary). For example, the shine of one person is the matte color of another.

Monoprice confirmed what I had already done by reading the label and printing it but mentioned TPU which could be TPU. No quantity, no proportion, nothing, and since they are the only manufacturer/seller to officially state this, I consider it unconfirmed. One of the answers below says that PLA+ probably includes TPU or something, but that's speculation or opinion by their own admission. nine0003

PLA+ is a variation of PLA that added material to make the thread is less brittle, has a smoother surface and less likely to absorb moisture. Generally, TPU is added to the filament to achieve this property. PLA+ will have a feel and odorless ABS functionality. If you didn't know better, you I would think it's ABS.

We offer printing with PLA+ at temperatures from 205 to 210 degrees Celsius and with a table temperature of 45 degrees Celsius. PLA+ responds very well to blue duct tape and duct stick to properly hold and not peel off when printing. nine0003

These people also ask what it is, but they are doing science about it around 2014 to try to understand it.

I'm not sure what to think of this manufacturer/seller's description. They seem to imply that PLA has a branding issue, so they added a plus to it for a new formula to fix their branding.

PLA Plus is an upgraded version of our PLA that is less brittle and more durable. ‘Improved’ PLAs have a bad reputation, some don’t better than PLA, some work worse in some conditions. We took different approach: our "regular" PLA is considered the strongest pure PLA in the industry, it is difficult to improve the best. But sometimes you need something more durable. Enter our specially designed PLA Plus. Prints like PLA but with better strength.

It is available with their more vibrant color options! nine0003

Closing Thoughts

I find many articles/posts talking about "eSUN PLA+" specifically. I'm starting to think it might be an OEM and that other companies are selling it with their own brand, but that all PLA+ comes from the same place. I found their product page and it says this but nothing about the formula:

Features:

- corn extracted and cleaned;

- high rigidity, good glossiness and transparency; nine0053

- is suitable for printing large models;

- strength is 2 times that of PLA on the market;

- no problem with wire drawing, print surface will be more smooth and delicate;

- no cracking problems.

@yetanometerrandomuser, ●27

Discussion

7 answers

Best answer:

▲ 12

Refusal: I am not associated with any related brand or company, I simply refer to them for suggested print settings. nine0003

nine0003

PLA, by definition, is a polylactic acid, a polymer interwoven with lactic acids. It is usually made from fermented starch - not by type I (alcohol) fermentation, but type II (lactic acid) fermentation user77232, Wikipedia . Chemically, it looks like this:

These are the corresponding physical data for a pure material - a density of 1.210–1.430 g cm −3 and a melting point of 150 to 160 ° C. Wikipedia .

Usually PLA, sold only under the name PLA, contains, in addition to PLA, additives to change the color from transparent to any color that is printed. This may change the standard print temperature depending on the amount, size and shape of pigments applied (see below).

General print temperatures are specified by manufacturers as 185 to 210°C. Color can affect print temperature, especially when there is a difference between transparent and opaque filaments. While a heated table is not strictly necessary, the temperature of the work table is usually stated at 60°C. nine0003

nine0003

I print most PLA filaments myself at 200°C and 60°C on the bench, but for colored clear filaments I have had the best results at 190°C.

Please note that not all PLA is just PLA! It is very likely that some brands of PLA contain fillers and additives from home without claiming +-filament, in fact additives predate the idea of PLA+, as will be shown in the case of PP3DP multilevel filaments.

Special Tier Mix

Starting in 2012 or earlier, ABS made by Tiertime includes some unknown compound (probably PC) that changes the print temperature from a "normal" 220-240°C to a much higher but narrower 260- 270 °C stripes. Why this is done remains a mystery to 3d printing enthusiasts, but it could either be to get rid of any color dependency of print results, or to make conventional ABS more difficult to use. The fact is that this temperature corresponded to what was established as the (then unchangeable) standard temperature at software Up 1.1.7 of that time. Angus aka MakersMuse and Tiertime forums . The higher temperature has not changed over the years. * Indeed, PLA Tiertime, introduced in March 2014 by , is also cited for printing at higher temperatures than regular PLA, and had a similarly higher default temperature in the then updated Forums on Tiered Software. although I found lists from 200 here and here up to 215 °C here under Technical date .

Angus aka MakersMuse and Tiertime forums . The higher temperature has not changed over the years. * Indeed, PLA Tiertime, introduced in March 2014 by , is also cited for printing at higher temperatures than regular PLA, and had a similarly higher default temperature in the then updated Forums on Tiered Software. although I found lists from 200 here and here up to 215 °C here under Technical date .

Modern UP-Studio software allows you to freely set the temperature aka MakersMuse .

So what is the difference between PLA and PLA+? Well, PLA+ is modified PLA, which means that it contains additives that change its properties. What exactly is added is highly dependent on the manufacturer, and no two PLA+ are the same. nine0083 all3dp .

PLA+ has - but by a few degrees - the same print temperature as standard PLA. In fact, the difference in print temperature between standard PLA from different brands is often greater than the difference between PLA and PLA+.

All3dp states that most PLA+ would have a better surface finish than PLA of the same brand. Because of the additives, they also usually print best at elevated temperatures compared to PLA. Among various manufacturers I have seen 210-240 °C Kodak PLA+ , 190-220°C SUNLU PLA+ and 190-210°C eSUN PLA+ .

However, there is no uniformity in other effects on the filament. Some yarns will have less water absorption, different stiffness or compressibility, while others may have higher tensile strength and an extremely glossy finish.

The most commonly claimed benefits are the strength of the filament, the texture and glossiness of the surface, and the ability to print projections. nine0003

PLA+ is not a single product as such, but is a family of modified PLA . While you can print PLA+ with the same settings as regular PLA, the resulting benefits between different brands are much more varied than with regular PLA.

- Switching between different grades of regular PLA of the same quality usually has little to no effect on overall print properties.

- Transition between different brands PLA+ of similar quality can significantly change print properties

Because no two brands of PLA+ are the same (and manufacturers don't say which additives they use to modify properties), don't rely on the same effects when switching between brands.

, @ Trish

▲ 6

There is not much difference between the two. Print settings such as temperature and print speed are almost the same. But PLA+ has a much better surface quality and is slightly brighter than regular PLA. Another difference is that PLA+ is more effective in bridges than PLA. nine0003

If you want to compare PLA and PLA+, go right here, PLA vs PLA+ (at a glance). This post is an awesome experiment with both materials.

, @ Juan Pablo Rodas Martínez

▲ 3

PLA+, depending on the brand, is likely a blend of other plastics (e.g. TPU 1 ) that helps overcome the disadvantages of conventional PLA such as brittleness and moisture absorption. Or they just used a higher quality PLA blend to create the filament. nine0003

I have no specific source other than collaborations with various material experts such as Essentium Materials. TPU is a flexible plastic that can have different levels of "hardness".

1 Thermoplastic Polyurethane. It is a flexible thermoplastic.

, @ Adam Starbuck

▲ 1

PLA+ is brand . Where PLA and ABS have specific chemical meanings (more or less... manufacturers will already have different additives or processes), the only real requirement for PLA+ is to use some unknown amount of PLA as a base. nine0003

Look at coffee beans as an example: we have Arabica versus Robusta. Arabica is generally considered the best, for some definition of "better". (By the way: Starbucks serves cheaper Robusta.) It is important to note that in many places you only need 10% Arabica content to label and sell coffee as Arabica. The rest of the product could be... well, whatever the creator wants to include.

PLA+ is similar. There is no real ultimate point to this other than some measure of original PLA content and the hope that you will believe it is "better" and therefore perhaps pay a little more. nine0003

The good news is that PLA+ is usually better... at least for now. But as more people start to see this as a real step up from regular PLA, it's likely that we'll also start to see some shady businessmen transfer inferior product to PLA+. It is likely that this is already happening.

Moral of the story: Read the label carefully. And unlike coffee, which is a food and therefore better regulated, threads have little to no labeling rules; you may not need to read the label at all, so be especially careful with what you buy. nine0003

, @ Joel Coehoorn

▲ 4

Some of these questions could be answered by asking the manufacturers for the MSDS (Material Safety Data Sheets), a.k.a. SDS (Safety Data Sheets).

In accordance with EU legislation in force since 2008, any substance supplied to the EEA (European Economic Area) in quantities of more than 1 ton per year, the composition of which contains more than 0.1% by weight of a compound identified in the article 57 database , shall provide the MSDS upon request, including a breakdown of its content. nine0003

If you look at the SDS for PLA+ eSUN, for example, you will see:

═══╦═══════════╦═════════════╗ ║ Ingredient Name ║ CAS No. ║ EC No. ║ Content (%) ║ —The ═══════════╣ ║ Polylactide resin ║ 9051-89-2 ║ 618-575-7 ║ 98 ║ ║ Calcium carbonate ║ 471-34-1 ║ 207-439-9 ║ 2 ║ “It is possible to have a matter of ═══════════╝

, @ nine0166 FooMonkey

▲ 2

I know this is an old question, but CNC Kitchen just did a review of PLA+ and the mechanical properties of one brand and found it to be much weaker than regular PLA, but with failure modes that can be more elegant/preferred for some applications. In short, it stretched and tore rather than broke.

, @ R.. GitHub STOP HELPING ICE

▲ 0

Adding this as a new answer as it doesn't seem to be covered by the existing answers:

Despite "PLA+" being a marketing term with no specific definition, I have found that many (most?) filament vendors don't seem to make their own secret sauce mix to do so, and most premium filament vendors who document< /em> the original polymers they use use roughly the same thing - most often one from Natureworks Ingeo. A three-dimensional series of polymers obtained as raw pellets, often 3D850 or 3D870. So, if you can be sure it's the filament you're selling as "PLA+" made from (or just find one that's well documented), you can use the polymer data sheets to learn more about its composition. nine0122

, @ R. . GitHub STOP HELPING ICE

Resin FAQ page 2

- 3D print safety/high temperature parts ESD I am trying to develop a process for printing fixtures/fixtures that can withstand the temperature of a convection oven of 165°C. The trick is that these parts should be considered safe for…

- How long should the UV lamp take to cure the resin? nine0274 I recently bought this UV lamp to cure my SLA prints: But I don't seem to be able to make this work. I have a few leftover coasters and wanted to throw them in the trash...

- AnyCubic default printer settings? Does anyone know where I can find a list of recommended settings for different types of resin/print objects for Anycubic printers? I understand that some details need to be changed in every…

- When changing the FEP, do I have to pierce it first or just screw through it? nine0274 I am about to do my first FEP change on my Elegoo Saturn. The manufacturer has a video on how to replace it showing how they put the FEP into the spacer frame and then just screw it in.

..

.. - How to print Lego bricks? How can I print Lego bricks to attach them? I need them to be separate parts. I use resin for printing. My model is Elegoo Mars 3. What resolution should I…

- DLP build plate adhesion Does anyone have any tips to improve build plate adhesion in DLP printers? I heard that a thin layer of resin or UV glue applied to the plate would help, but we are not sure if we will leave…

- Fragile resin prints I don't have a clear understanding of what causes resin prints to become brittle. First, it seems that extreme cold (in the 40's or even 30's I'm in New England) can be... ? From what I understand, there is some kind of resin transfer process, but I'm not entirely sure if this works for…

- SLA 3D Printer Resin Curing LCD Display I'm doing some research on what types of LCDs can be used to filter and let UV light through to cure resin - especially in the context of… ? I've seen that you can deresin a used IPA by putting it in the sun for a while, making the resin dissolve during the IPA's curing process.

Can I do the same, just…

Can I do the same, just… - Aggressive Resin Remover For cleaning, I need an aggressive cured or partially cured resin solvent that breaks down the resin to its liquid state. I'm looking for one that will eat specifically a resin (I...

- UV degradation UV curing resins I needed to know if typical UV curing resins like Anycubic could withstand solar radiation for long periods of time with little to no degradation. It was pretty…

- Making an office-made UV-curing resin I have relevant chemical experience from the university. Making a UV curable DLP 3D printer resin seems doable with a decent chemistry…

- Delamination in the middle area of a photonic printer I had delamination and other problems in the middle area of my Anycubic photonic printer. Sometimes the print does not stick to the platen, and sometimes it delaminates, as in the images below, but…

- Why is cupping bad in SLA prints? Why is cupping bad? (I don't mean hollow parts) Example: Let's say I want to print a simple cup without a handle.

There are two obvious orientations: In one orientation it won't require...

There are two obvious orientations: In one orientation it won't require... - Resin LCD prints end up with random holes in them Context: I am trying to print this Voronoi pattern container. The actual object itself was created using a combination of this online tool and Fusion 360. It was then imported into…0275

- Pros of UV printing This is due to the disadvantages of UV printing and is centered on Ryan Carlyle's answer, mentioning: "...resin cured SLA/DLP printers are industrial or commercial tools…

- UV Printing Cons I was curious about the various UV/Laser printers on the market (or coming up) using liquid resin. I seen samples of Pegasus Touch, Form1 and Carbon3D as examples.…

- Resin printing on Voxelab Polaris I recently got an Elegoo Mars-like polymer printer called Voxelab Polaris. So far, I've had a lot of success with it, but one piece turned out really...

- Does resin differ from printer to printer? I'm using clear resin to print parts with a Formlabs printer.

At the moment I'm using resin from Formlab, which comes in a cartridge that fits into the printer. However, I…

At the moment I'm using resin from Formlab, which comes in a cartridge that fits into the printer. However, I… - Accidental over-curing of 3D printing I am relatively new to SLA 3D printing and 3D printing in general. I have a budget SLA resin printer that I've been fiddling with for a few months now. So I had some soft...

- How to block UV light (transparent material)? I want to build my own curing station for my printed resin parts. I know that there are many ready-made machines, but they do not fully meet my needs. Now I want...

- Use SLA 3D printing to make a flexible mold I've seen some videos like this that use 3D printing to make a part that will be used to make a silicone mold and then used…

- Why LCD printers don't use subpixels in color panels? The LCD printers I've looked at are pretty standard resolution for a smartphone and I understand they use the same technology. However, color liquid crystal displays have three.

..

.. - Clear Resin Prints 3D Coatings I want to apply a clear UV blocking coating to some of my resin 3D prints. I have tried Clear krylon UV resistant...

- Delamination in resin prints I have observed some random delamination in the horizontal layers of my resin prints - see two examples: What is the reason, and how can it be minimized?

- Resin holding time determination When the resin is shipped without a proper data sheet (!) Or more likely when the exposure time of the first layer and the default layer does not match your LED resin printer, how do you…

- Book recommendation for 3D resin printer I want to learn 3D -printer to work with resin. Are there books, e-books, tutorials or webinars, etc. to learn resin 3D printing? I am using DLP machine for clear aligner. I…

- remaining photopolymer resins Do not store leftover resin back with intact resin in original packaging, seems to be a general recommendation.

What is the best practice here? Store in a separate…

What is the best practice here? Store in a separate… - How to Remove a Stuck Resin Print I stuck a resin print that won't come off the table of my Creality LD-002R LCD printer. I think I could break the print piece by piece, but it won't budge with pressure pulling...

- Clear Resin Print Finish I am printing some resin models in clear resin. They look pretty good when they come out of the printer, but later they get this white hazy look that even when removed with...

- Different shutter speeds for black resin? I'm running test prints on the new Sainsmart Kumitsu KL-9, a large resin printer for the hobby market that's hard to beat in terms of price and volume. I ordered two test prints to peel off...

- How to remove resin print stuck to the bottom of the FEP 9 tray0274 When using a resin printer, the print sometimes sticks to the bottom sheet of the resin tray (FEP transparent sheet) and not to the stainless steel print plate.

How to remove bad print from…

How to remove bad print from… - Resin prints peel off build platform My prints start out fine but seem to warp or peel off build platform later. Should I separate my support bases so they are not one big base? Should I…

- How to fix WoW models in Photon Workshop I am using AnyCubic Photonic Resin Printer. I used ( WoW model viewer to export a thumbnail that I hope to 3D print. However, when I look at the model in the photonic workshop,…

- Can I mix the colors of photopolymer resins? Can different resin colors be mixed to create new colors? I use eSUN water washable resins, but I'm happy to switch if that's another supplier's option.

- Installing multiple versions of ChiTu side by side I use two resin printers based on ChiTu software (Creality LD-002R and SainSmart Kumitsu KL9) and the first one uses ChiTu 1.6.2 while the last one comes with 1.6.1.…

- resin printer calibration I bought a Creality LD-002R resin printer.

It's solid equipment, with a good experience and excellent value for money, but it comes with very little documentation. I…

It's solid equipment, with a good experience and excellent value for money, but it comes with very little documentation. I… - Each print falls off plate I am new to 3D printing and just bought an Elegoo Mars Pro. It's been a few days now where I'm desperately trying to print something, but every print (including the test file) after a while...

- SLA printers: food-safe resin parts Actually I read that resin printed parts not food safe in Reddit and Formlabs guide. However, it also states that food safety can…

- SLA Printers: Safe Disposal of Resin Contaminated Waste I recently bought an Elegoo Mars Pro and I've watched hundreds of videos of all kinds of processes and everyone says the same thing: Resin is toxic so you should cure it before throwing it in the trash otherwise it is…

- Curated Resin Size Shrinkage (and Methods to Reduce It) I recently bought an Elegoo Mars Pro 3D printer.

I've read that the percentage of resin molds is getting smaller and I understand that. But do slicers (or software that helps with…

I've read that the percentage of resin molds is getting smaller and I understand that. But do slicers (or software that helps with… - Safe disposal of resin I have some leftover resin (100 ml) that I don't plan to use anymore. What is the safe way to get rid of it without requiring treatment?

- Resin Imprint Curing After resin printing is completed, what is the expected process for printing completion? Is there any cleaning expected? I also sell some UV camera manufacturers for surface treatment printing…

- Resin types: Water Soluble vs. PLA With resin (not filament!) LCD printers, what considerations to choose between PLA and "water soluble"? The micro center carries resins from esun in these two types and their specs show that…

- resin printer build plate scratch/damage I have an Anycubic photon and sometimes I have trouble removing prints from the build plate. In trying to remove the prints, I put a few scratches on the surface as I think…

- LCD/DLP 9 Resin Curing System0274 I am trying to design a device to burn a glass slide surface with a specific pattern of ultraviolet light (from 300nm to 360nm) on a surface of 5cm.

Learn more

.jpg)