3D clothes printing machine

3D Knitwear: How 3D Printing is Revolutionizing Fashion

Published on December 6, 2022 by Mikahila L.

In recent years, 3D printing has become growingly everpresent. From medicine, aerospace, to design, and construction — every day there’s news about breakthroughs, innovations, and developments in the additive manufacturing industry. However, in one particular industry, it’s still pretty quiet regarding developments around 3D printing. We’re talking about the fashion industry. It cannot be denied that the first experiments and advances in 3D printed clothing have only been recorded relatively recently. Yet, if you have followed these developments in fashion a little more closely, you may have noticed that these are high-end fashion, i.e. clothing created for the runways and red carpet and not for everyday wear. The reason why the combination of 3D printing and clothing seems so difficult is quite simple: The materials used in 3D printing, mostly plastic, and metal, are not flexible enough. To counteract this problem, some fashion and 3D enthusiasts have been looking into suitable options and ultimately honed in on one solution: 3D knitwear. But, what exactly is 3D knitwear? How does its production method differ from additive manufacturing and conventional textile production? Will 3D knitwear be available as ready-to-wear for ordinary consumers in the near future? We got to the bottom of this topic in more detail and we clarify all of these questions with the help of various expert opinions from the industry.

In order to understand the principle of 3D knitwear and its differences and similarities to 3D printing, it is first necessary to take a look at the definitions. Gihan Amarasiriwardena, co-founder and CEO of the Ministry of Supply, defines 3D printing as follows: “In 3D printing, molded products (such as plastics) are produced by adding a layer of material (often plastic or synthetic) according to a given digital Design is ‘printed’.” Rosanne van der Meer, designer and founder of New Industrial Order, offers a broader definition: “3D printing is the production of a three-dimensional shape on the basis of a filament that is formed by a machine. “ In fact, 3D printing is all about computer-controlled machines creating three-dimensional objects and building them up layer by layer. The question now remains whether 3D knitwear is made according to the same principle.

“ In fact, 3D printing is all about computer-controlled machines creating three-dimensional objects and building them up layer by layer. The question now remains whether 3D knitwear is made according to the same principle.

In 3D printing, the object is additively manufactured layer by layer.

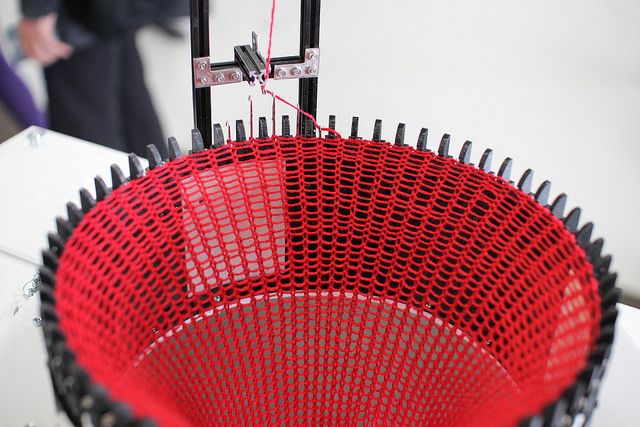

Production of 3D Knitwear

The manufacturing process of 3D knitted fabrics is quite similar to other 3D objects. Both begin on a computer: CAD software is used to create the design and ultimately to obtain a programming language. The digital codes are then forwarded to the machine, which then begins the manufacturing process. However, the machine used is where knitwear and traditional 3D printing diverge. The primary difference from additive manufacturing is that the machine is not a 3D printer that processes filament or powder through extruders, rather, a knitting machine that can produce a three-dimensional garment in a single pass by uniting it thread by thread. Consequently, it should be noted that the principle is essentially the same both are based on software and are additively manufactured, but the material creates a big difference between the two methods.

Therefore, it is hardly surprising that industry experts agree in saying that 3D knitted goods are not manufactured using 3D printing, but rather, 3D knitting is a technology in its own right. Gerard Rubio, co-founder, and CEO of Kniterate, a company that sells 3D digital knitting machines, adds the following about his company’s machines and the use of the word 3D in connection with the production method: “These machines are capable of 3D knitting. But these machines are not necessarily 3D knitting machines.” This is because flat, single-layer garments like scarves can also be printed with a Kniterate machine, which eliminates the additive manufacturing aspect. Rosanne van der Meer adds that she deliberately uses the term ‘3D printed knitwear‘ for her products in order to make a clear distinction between 3D knitwear and conventionally produced knitwear.

Compared to Conventional Textile Production

Now that the differences and similarities between 3D knitwear and 3D printing have been outlined, the question remains whether and, if so, why 3D knitwear should be preferred to traditionally manufactured clothing. In order to provide a reasonable answer to this, conventional textile production must first be examined more closely.

In order to provide a reasonable answer to this, conventional textile production must first be examined more closely.

This is still a touchy subject, with so few companies keeping their value chains and production methods transparent. Obvious and ongoing issues such as child labor, low wages, and inadequate protective measures in low-cost manufacturing countries are joined by the astronomically negative impact the industry has on the environment. From the cultivation of cotton, whereby both the use of pesticides and an enormous waste of water are recorded, to transit once the material has been broken down, and shipped to be processed into yarn and ultimately fabric in another country — this phase alone requires much examination for improvement.

Then, we have the woven fabric being sent back to be bleached or dyed at another factory. The harmful substances used in this process mostly end up in the wastewater, which in turn leads to the pollution of rivers and oceans. Lastly, the garment is sewn, knitted, and finished again in a different facility, with a large amount of material being wasted in the manufacturing process. The finished products are sent to the various branches around the world. The unbelievably long transport routes, which significantly increase Co2 emissions, rounds out the disadvantages of conventionally produced clothing. Although there are of course also smaller manufacturers who pay attention to sustainable, fair, and regional production, large-scale fashion producers that use traditional production channels still dominate the clothing market.

The finished products are sent to the various branches around the world. The unbelievably long transport routes, which significantly increase Co2 emissions, rounds out the disadvantages of conventionally produced clothing. Although there are of course also smaller manufacturers who pay attention to sustainable, fair, and regional production, large-scale fashion producers that use traditional production channels still dominate the clothing market.

There are many problems with the conventional textile methods of large-scale fashion producers. These include the exploitation of workers in low-wage countries and the negative impact on the environment.

These social and environmental problems are primary focuses for CEOs Gerard Rubio, Gihan Amarasiriwardena, and Rosanne van der Meer, which is why they all pay attention to sustainability in the development of their companies and in the manufacture of their products. Awareness begins with the procurement of materials: While more than half of all clothing is produced using man-made fibers, mainly polyester, but also nylon, elastane, and acrylic, which are obtained from fossil fuels and therefore have a negative environmental impact; new industrial methods use merino wool which is obtained sustainably and as a natural fiber which generally has a smaller footprint compared to synthetic fibers.

Rosanne van der Meer also adds that she relies on high-quality yarn in order to achieve the best possible results and in order to not run the risk of the thread breaking in the middle of the knitting process and thus having to restart production. A special feature here: even if the thread were to break, the half-finished knitted part could be recycled since the knitwear is designed in such a way that it can be separated again. This means that the material used can be recovered — another sustainability factor. As far as the material is concerned, large savings can be made using 3D knitwear, as the machines produce additively In just one pass and therefore only requires the threads that will be used, thereby eliminating numerous production steps and saving a lot of time and costs. Gihan Amarasiriwardena confirms this statement: “With 3D-printed knitwear, only the required fabric is used. This results in approximately 30% less material waste”. Sustainability also plays a role at Kniterate. Gerard Rubio relies on plant-based yarns, which can be recycled, so items of clothing that are no longer wanted can be disposed of properly and not end up in a landfill.

Gerard Rubio relies on plant-based yarns, which can be recycled, so items of clothing that are no longer wanted can be disposed of properly and not end up in a landfill.

The material plays a huge role in the manufacture of 3D knitted fabrics. (Photo Credit: Kniterate)

Since 3D knitwear is on-demand production, problems such as overproduction and inventory waste can also be avoided. Large-scale fashion producers are not able to react flexibly and quickly to changes in the market mainly due to long supply chains, which results in overproduction and overstocking. This is a fatal flaw in today’s fast fashion industry, where new collections and goods hit stores nearly every week. And where should the “old” items of clothing go that have not been bought? These resource and energy-intensive manufactured textiles mostly end up in the garbage or are partially incinerated. On-demand production that takes place on-site/in-house could be a solution here. Not only are transport costs and emissions saved as a result, but practically significantly less waste is produced.

This goes hand in hand with Rosanne van der Meer’s motto: “The starting point for a better climate balance in the fashion industry is less consumption. If you have timeless clothing that fits you really well, you will also consume less.” Thanks to 3D technologies, it is also possible to personalize 3D knitwear. Since the designs are created digitally and every needle stitch is equivalent to a pixel, patterns can easily be modified and adapted to customer requirements, which allows a lot of freedom. A special program from the start-up Shavatar also helped New Industrial Order to improve the accuracy of fit of their 3D knitwear without a 3D scanner – an essential aspect when it comes to buying clothes. With the help of the open-source system and the knitting machine from Kniterate, users are obviously also open to all creations and personalizations. Last but not least, the typical problems such as the exploitation of workers through in-house, regional productions are also eliminated.

Challenges of 3D Printed Clothing and Predictions for The Future

After explaining the numerous advantages offered by 3D knitwear, the question now remains as to why it is not yet increasingly available in stores. What are the current challenges and what improvements may still need to be made? Will 3D printed clothing and especially 3D knitwear be the future of the fashion industry?

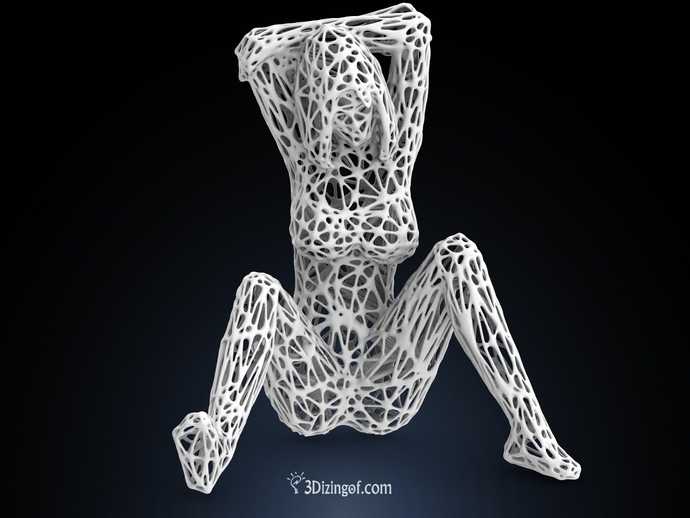

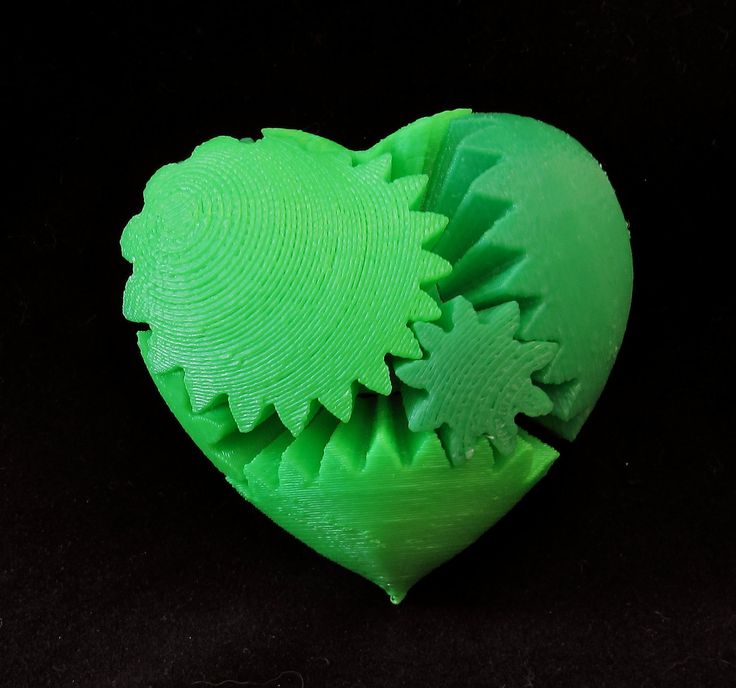

Indeed, additive manufacturing of apparel faces a number of challenges. As mentioned earlier, the material is probably the biggest obstacle – which is why 3D knitwear is being resorted to. When a closer look is taken at previous projects involving 3D-printed clothing, such as products by fashion designer Danit Peleg, it quickly becomes apparent that the options are limited: The materials compatible with a 3D printer are mostly plastics such as ABS, PLA or the currently very popular and very flexible TPU. Although the latter can be used to create stretchy, movable 3D objects, it doesn’t begin to compare to the soft, comfortable texture of fabric. Although it could now be argued that the majority of conventionally produced clothing is also made of synthetic polymers, i.e. plastic, the problem lies with the texture. It makes a big difference what form the material is in: Fibers and threads have a filigree, elastic and flowing state, whereas filament has a comparatively thick, hard and rigid state.

Although the latter can be used to create stretchy, movable 3D objects, it doesn’t begin to compare to the soft, comfortable texture of fabric. Although it could now be argued that the majority of conventionally produced clothing is also made of synthetic polymers, i.e. plastic, the problem lies with the texture. It makes a big difference what form the material is in: Fibers and threads have a filigree, elastic and flowing state, whereas filament has a comparatively thick, hard and rigid state.

3D-printed clothing differs in texture from conventionally produced goods. (Photo credit: Danit Peleg)

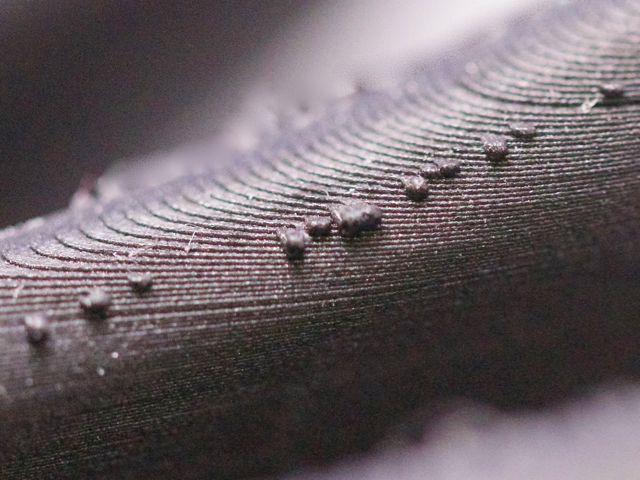

Furthermore, most 3D printers cannot produce fine enough details. Unlike 3D knitting, where the moving threads are processed by many small needles, the extruders of a 3D printer cannot produce anything comparable. The structure and texture of 3D-printed clothing is heavy and pitted, and the surface texture is likely to be quite cold and unpleasant. Gerard Rubio agrees, saying, “At this point, the materials are not developed enough. However, I strongly believe that 3D-printed clothing will be the future.”

However, I strongly believe that 3D-printed clothing will be the future.”

With regard to 3D knitwear, other problems are encountered. Rosanne van der Meer particularly emphasized here the difficulty of creating the digital codes for the knitting machine. That is why she relies on extensive databases, suitable non-fiction books and an open-source system. The latter should support New Industrial Order’s goal of creating a workflow that makes the codes for 3D knitwear accessible to all those who show interest. Gerard Rubio echoes this sentiment. He, too, describes developing the right parameters as a major challenge. The road from the prototype to the final, commercializable Kniterate machine, which is very complex, was long and difficult, according to him. Referring to the future, however, Rosanne van der Meer sees no problem in this regard: “The technology is already established and ready to function, but the current system works completely differently.”

The biggest difference between 3D printed objects and 3D knitwear is the material. It is easy to see that much finer structures can be created with threads.

It is easy to see that much finer structures can be created with threads.

This is because on-demand production, which is the principle of most current 3D knitwear manufacturers, completely contradicts the market flow. The current fashion market is based on mass production and mass consumption. Changing long-established systems and breaking habits is extremely difficult, which is why more sustainable companies specializing in on-demand production and customization face a major hurdle in entering the market. Also, in terms of production costs, 3D knitwear cannot compete with conventional clothing due to low market compatibility. Therefore, the current products from New Industrial Order and Ministry of Supply are still rather in the luxury segment in terms of price, within the framework of which customers are willing and able to spend a lot for personalization, sustainability and quality.

However, the experts are confident that 3D printing will play a greater role in the fashion sector in the future and firmly believe that novel technologies will revolutionize it. Rosanne van der Meer summarizes: “Changes in the textile industry are slow. Yes: in the future we will find more additively manufactured clothing, but how far this progress is in the future cannot be said.”

Rosanne van der Meer summarizes: “Changes in the textile industry are slow. Yes: in the future we will find more additively manufactured clothing, but how far this progress is in the future cannot be said.”

Ministry of Supply offers, among other things, 3D-printed blazers and masks. (Photo Credit: Ministry of Supply)

What do you think of 3D printed knitwear? Let us know in a comment below or on our Facebook and Twitter pages. Don’t forget to sign up for our free weekly newsletter, with all the latest news in 3D printing delivered straight to your inbox!

Photo Credit: New Industrial Order

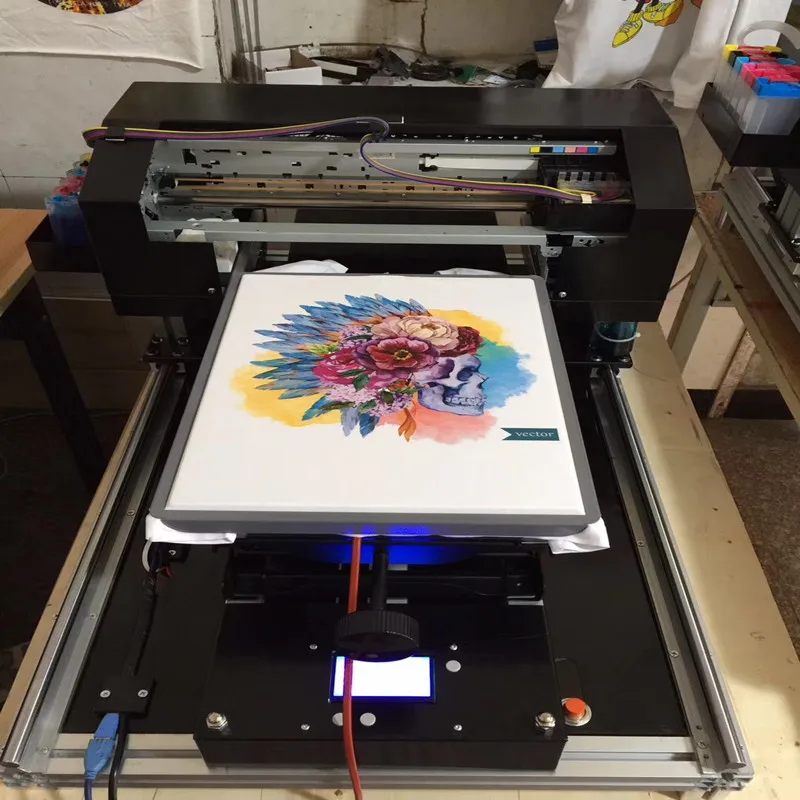

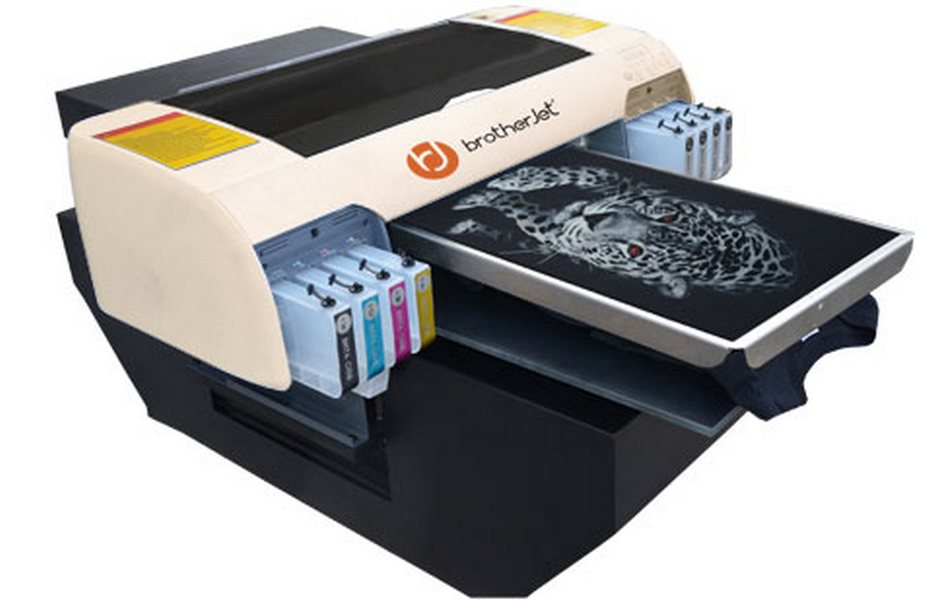

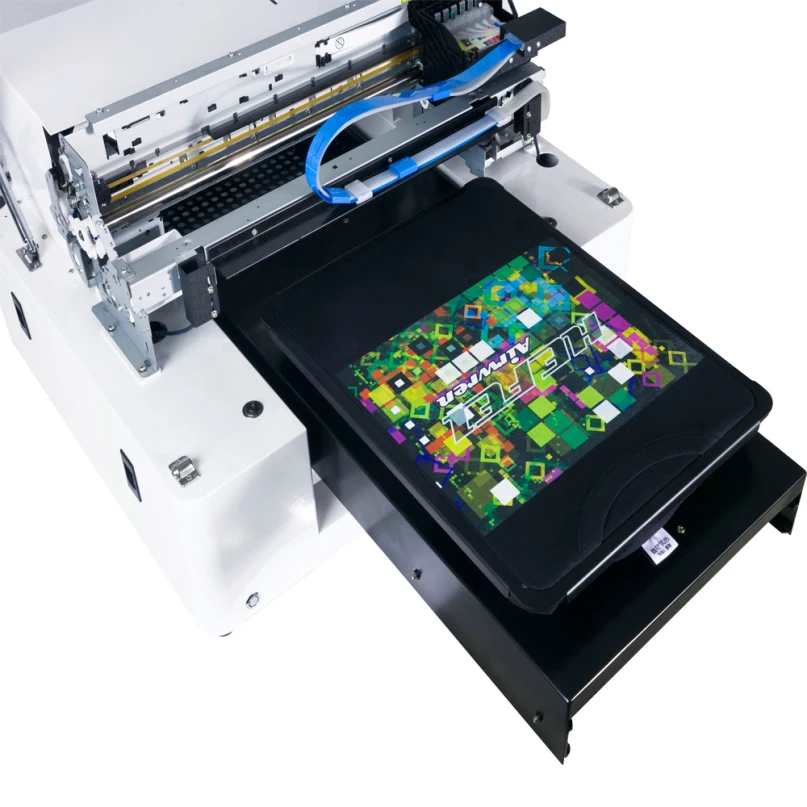

The Top 5 T-Shirt Printing Machines of 2020 [w/ Comparison Table]

Your choices for garment decoration are ever-expanding. Today’s options include traditional screen prints, embroidery, applique, transfers and the increasingly popular digital direct-to-garment (DTG) printing.

Since its inception, the number of manufacturers and models in the DTG market space has been in constant flux. Many well-marketed machines, once prevalent in discussions and trade show halls, have now nearly vanished.

Many well-marketed machines, once prevalent in discussions and trade show halls, have now nearly vanished.

However, over the last several years there have consistently been a handful of manufacturers leading the pack. Below, we’ve compared 2019’s top five DTG t-shirt printing machine models:

- Epson F2100

- Brother GTX

- Col-Desi (DTG Digital) M2

- Kornit Breeze

- M&R M-Link-X

Epson F2100

EpsonAt roughly 3’ by 5’, the Epson F2100’s footprint is more rectangular than the GTX from Brother. And at just over 1.5’ high, it’s certainly smaller. This is a table or bench top design and is not free standing, so you’ll need to plan on where it will be setup. Overall, the F2100 is a very quiet operating machine with a polished, put-together profile that works as easily in a home-based business as it does in a full production environment.

Pricing:

- MSRP: $17,995

- Est. Street Price: $15,995

Brother GTX

At 4. 5’ by 4.25,’ the GTX is a little boxier and immediately conveys an industrial look with its predominately metal exterior. The GTX is a table or bench top unit, but with a custom stand available. This stand is recommended, as it allows users to take advantage of the open bottom design of the printer for humidification, which is often necessary for consistent operation.

5’ by 4.25,’ the GTX is a little boxier and immediately conveys an industrial look with its predominately metal exterior. The GTX is a table or bench top unit, but with a custom stand available. This stand is recommended, as it allows users to take advantage of the open bottom design of the printer for humidification, which is often necessary for consistent operation.

Pricing:

- MSRP: $22,500

- Est. Street Price: $22,500

Col-Desi (DTG Digital) M2

Being the only dual platen printer of this group — meaning there are two platens to load t-shirts instead of just one — the natural thought would be that it has a much larger footprint. At about 4’ x 3,’ it occupies a similar space as the Brother, but with a much larger shadow as it’s nearly a complete rectangle.

A tabletop/bench top unit as well, the M2 will require proper arrangements. Quieter than the Brother GTX but not to the level of the Epson F2100, this unit can be an option for users that need an extra-large imaging area.

Pricing:

- MSRP: $19,995

- Est. Street Price: $19,995

Kornit Breeze

As the introductory machine from Kornit, the Breeze is the smallest in their line-up but one of the largest in this group. The 4’ x 5’ framework is the most modern looking by far. As the only machine in the group with an integrated pre-treatment system, the overall footprint may be smaller. Kornit’s inks are typically cured with a gas dryer, which can serve as the base table for this printer.

Pricing:

- MSRP: $65,000

- Est. Street Price: $62,000

M&R M-Link-X

As the only free-standing unit in this group, the M-Link-X also has the distinction of being the largest at 4.5’ x 5.5.’ With a rugged steel frame and squared-off edging, the M-Link has the most industrial look and feel. Not the best option for home-based businesses, this unit is better suited for a production environment.

Pricing:

- MSRP: $74,995

- Est.

Street Price: $70,995

Street Price: $70,995

See all pricing in the printer comparison table below

Target Audience

In comparing these models, it’s best to start with their intended target audience.

M&R and Kornit’s focus has always been toward production shops while Epson, Brother and Col-Desi have tried to broaden their audiences to include smaller garment shops and even sign and graphics shops, where t-shirts are often a complementary workflow.

In the cases of Epson and Brother, they’ve taken that a step further by targeting home-based businesses with their ease of use as well. That’s not to say that the F2100 and GTX can’t handle production, because they are both capable of running regular shifts in production shops. (Note the production volumes in the chart below.)

Unsure What Direct to Garment Printer is Right for You?

Try our Printer Finder Tool >>

Maintenance

Maintenance is usually one of the first questions from potential users of t-shirt printing machines. In this regard, the Epson and Brother receive the highest marks with their low costs (~$30 a month) and minimal manual maintenance time <5 minutes – especially when compared to the outputs. Both units feature daily automated cleaning capabilities that reduces hands-on time for the operator.

In this regard, the Epson and Brother receive the highest marks with their low costs (~$30 a month) and minimal manual maintenance time <5 minutes – especially when compared to the outputs. Both units feature daily automated cleaning capabilities that reduces hands-on time for the operator.

Col-Desi’s M2 uses older Epson photo print heads. And even though it doesn’t purge ink in the line to the extent of the Kornit, the maintenance cost is still a factor — both in time and material. Kornit’s Breeze pre-treats (binding agent) garments inside the t-shirt printing machine, which will add to the manual cleaning times that typically run well over an hour or two per week for maintenance.

Service & Training

For t-shirt printing machines, service and training typically fall in line right after maintenance questions. We always encourage on-site installation/training by a professional service technician. This way, you will know that your machine is functioning properly and you’re operating it correctly.

In this area, Col-Desi receives a poor grade since they only offer remote training or on-site training at their corporate offices in Florida. When it comes to getting a technician on-site, Epson and Brother come out the winners, as they have national networks of service technicians. Epson also has a 48-hour on-site guarantee built right into their warranty.

Service when you need it is always important for any DTG printer, and it’s going to start with your distributor. Some are going to be much more adept than others when it comes to addressing smaller service questions and getting you back up and running quickly.

Material Costs

There is always extensive discussion on ink costs and t-shirt costs. Far more important is the actual operation costs of any particular t-shirt printer. This is going to give you real-world costs on what producing an actual garment is, not just the cost of the ink on the shirt. Shirt cost analysis done with only the ink cost on a shirt is misleading at best and often includes numbers that get flaunted by manufacturers to one up a competitor.

Every shop is going to have different operation costs so an individual analysis should be done with your distributor to understand your overall costs. But from an equipment standpoint, Epson and Brother are the most transparent in their operation costs with easy-to-calculate shirt costs as well as expected maintenance material and time costs. Ink cost alone can be a small fraction of the overall operation, so don’t be lured in by this figure alone.

T-shirt Printer Comparison Chart

We’ve created the chart below for a side-by-side comparison of these leading printer models.

However, if you’re in the market for a DTG printer, we always recommend a consultative analysis and to demo the equipment you’re looking to bring in-house.

Trade show demonstrations can be a good step in initial review but spending some hands-on time thoroughly testing the entire workflow and production is the best way to understand all the caveats of operation.

| Manufacturer | Description | Epson | Brother | DTG Digital | Kornit | M&R |

| Model | F2100 | GTX | M2 | Breeze | M link X | |

| MSRP | Manufacturer Suggested Retail Price. | $17,995 | $22,500 | $19,995 | $65,000 | $74,995 |

| Est. Street Price | Actual retail price. | $16,995 | $22,500 | $19,995 | $65,000 | $70,995 |

| Ink Configuration | Compatible ink colors. | cmykwwCl | cmykwwCl | cmykw | cmykww | cmykw |

| Ink Delivery | The size of the cartridges/bottles. | 600ml Cart | 200cc/500cc/700cc | 250cc | 150cc / 1500cc | 1 L Bulk |

| Ink Cost | The price for the cartridges/bottle size listed in ink delivery. | $207 | $103/$183/$218 | $42 | $180 / $280 | W – $262; Color – $241 |

| Ink Cost Per CC | The cost of ink per cubic centimeter. | $0.34 | $0.52/$0.37/$0.32 | $0.17 | $0. | $0.26 / $0.24 |

| Ink Circulation System | The internal system that circulates the white ink inside the machine. | Yes | Yes | Yes | No | Yes |

| OEKO-TEX® 100 Certified | An independent testing and certification system for finished textile products. | Yes | Yes | No | Yes | No |

| AATCC Wash Test Rating | American Association of Textile Chemists and Colorists (AATCC). On a scale of 1-5, this test determines wash fastness and durability of the ink. |

5 |

4.1 |

Unknown |

5 |

Unknown |

| Max Print Area | Dimensions of appropriate media size. | 16″x20″ | 16″x18″ with White 16″x21″ Color Only | 17.7″x24″ | 14″x18″ | 16″x20″ |

| Production Volume on Dark | How many prints you can produce when printing with white ink. | 35-45 | 40 | 20-25 | 25 | 55 |

| Production Volume on Light | How many prints you can produce when printing with color ink. | 50-60 | 45-55 | 45 | 32 | 75 |

| Print Head | The number of and type of print head included. | 1- Epson TFP | 2-brother | 1-Epson DXS | 6-Spectra | 2- Ricoh Gen 5 |

| Max Print Head Resolution | Measured in DPI (dots per inch). | 14400 | 1200 | 2880 | 1200 | 1200 |

| Software | Image processing software included with purchase. | Garment Creator | Printer Driver | RIP | RIP | RIP |

| Warranty | Type and length of warranty and coverage with purchase. | 1 Yr – Full | 1Yr Full – 2nd Yr Limited | 2 Yr Parts & Labor | 1 Yr Full Warranty | 1Yr |

| Training | Type of product training included with purchase. | On-Site | On-Site | Remote | On-Site | On-Site |

| Daily Maintenance | Is maintenance required? | Automated | Automated | Yes | Yes | Yes |

| Pre-Treatment | Type of pre-treatment necessary. | Offline | Offline | Offline | Integrated | Offline |

Pre-Treatment Machines & Heat Presses

Your t-shirt printing machine may require some additional pieces of equipment.

Pre-Treatment Machines

Printing with white ink requires preparation. Pre-treatment machines prepare your garments by applying a consistent amount of solution before you print. They can also apply anti-migrants for printing on synthetic and wicking garments.

The Kornit model has an integrated pre-treatment process but the others require offline treatment.

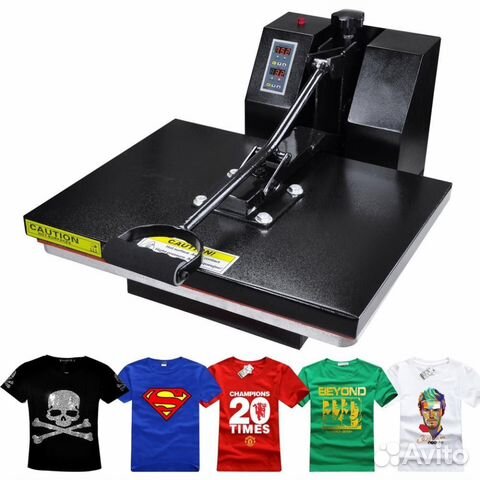

Heat Presses

As an integral part of the garment decorating process, a heat press is often necessary for some DTG and dye sublimation workflows — it will depend on the type of ink you’re using. Additionally, with a heat press, you can also easily transfer custom, unique designs to various substrates via transfer papers, heat applied films, digital transfers, screen printed transfers and more.

If you have any questions about the best t-shirt printing machine for your needs, don’t hesitate to reach out to our team for advice!

10 Questions to Ask Before Buying Your Next Inkjet Printer

The first question to ask when considering a new inkjet printer, especially if it would be your first one, is: Does

my business need a commercial inkjet printer?

3D printed clothes: 3D printed clothes and dresses

The idea of printing rather than sewing clothes has been on the minds of minds for many years. And for good reason: 3D printing has many advantages over traditional manufacturing. The lack of suitable materials slows down the process. Often printed clothes are inconvenient in everyday use. But over the past 10 years, a big step forward has been made.

And for good reason: 3D printing has many advantages over traditional manufacturing. The lack of suitable materials slows down the process. Often printed clothes are inconvenient in everyday use. But over the past 10 years, a big step forward has been made.

Application history

3D printing is what almost everyone is talking about today. We hear about 3D printed houses, food, and even human organs. So the fashion industry could not stay away from the opportunities that 3D printing technology promises. nine0003

2010

Dutch designer Iris van Herpen is the first to use a 3D printer to create clothes. In 2010, van Herpen presented her first creation using additive technologies at the International Fashion Week in Amsterdam. It was a white "Crystallization" polyamide top.

The process of turning liquid into crystals - that same crystallization - inspired Iris to create such an unusual shape. The model caused a sensation, and other creative designers turned their attention towards 3D printing. nine0003

nine0003

2011

A year later, the innovative brand Continuum Fashion tried to take 3D printing beyond the haute couture world by creating a prototype bikini that can be worn not only on the catwalk, but also for its intended purpose. The model is made of nylon, ideal for this piece of clothing. All details of the swimsuit, including the clasp, are 3D printed and have no seams. You can’t find this model in offline stores, but you can order it on the company’s website. It is worth noting that the price will unpleasantly surprise you. Pleasure is not cheap. But this is kind of the first step towards using 3D printing for mass production of clothing. nine0003

2013

Additive technologies have made it possible to embody the most daring fantasies of designers. In February 2013, the famous dancer Dita Von Teese appeared at a conference held in New York at the Ace Hotel. The chic dress she wore was 3D printed and embellished with Swarovski crystals. This outfit differed from its predecessors in that it was quite flexible with 3,000 moving joints. It could be taken off and put on like a normal dress sewn in the traditional way. nine0003

It could be taken off and put on like a normal dress sewn in the traditional way. nine0003

Designers - Francis Bitonti (Francis Bitonti) and Michael Schmidt (Michael Schmidt), who created this futuristic attire, managed to completely surprise the audience. The drawings of the 12 pieces of the dress were computer generated and subsequently printed by New York-based Shapeways. In production, the method of selective laser sintering (SLS) was used.

2015

After that, fashion designers were unstoppable. Three-dimensional technologies have firmly entered the world of fashion, which is still only high. In 2015, Dutch designer Anouk Wipprecht introduced the amazing Spider Dress. It is easy to guess by the name that the image of a spider (from the English spider - a spider) became the source of inspiration. The dress is an exoskeleton equipped with 20 sensors. "Spider legs" will rise and "protect" the owner's personal space if the sensors detect an increase in stress. nine0003

nine0003

Present

But some designers have not abandoned the idea of using 3D printing for more than extravagant haute couture models. Among them is Danit Peleg, who has been professionally engaged in 3D printing of clothes for everyday life for many years. Despite the fact that the cost of models from her collections is still quite high for the average buyer, the clothes are comfortable to wear, practical and look spectacular.

Modern clothing designers use additive technologies not only for self-expression, but also as a means to make this world a better place, and clothes more practical. Julia Daviy is a designer and environmental technologist who lives by the idea of biodegradable materials. 3D printing for her is primarily an opportunity to reduce production costs and waste.

How are clothes made with a 3D printer?

Printing clothes on a 3D printer can be divided into three stages:

- Create a sketch. It can be done both on paper with subsequent transfer to a special program for 3D modeling, or immediately in this program.

Rarely is the entire article printed. Therefore, the outfit will be divided into several elements, which then will need to be connected.

Rarely is the entire article printed. Therefore, the outfit will be divided into several elements, which then will need to be connected. - Print file or files.

Important: material selection is key to ensure that the finished product is not too stiff and uncomfortable to wear. Soft, stretchy materials based on polyamide are well suited for these purposes. nine0003

- Final assembly and other finishing work.

Advantages of 3D printed clothing

Production of clothing using additive technologies has a number of advantages over traditional ones.

Reducing production waste

The large amount of waste generated in the production of clothing is a huge global problem. And we are talking not only about production costs, but also about environmental pollution. Therefore, many elements of the production process require rethinking. nine0003

Reference: 2700 liters of water are required to produce one cotton T-shirt.

This is how much one person will drink in 900 days.

The production and dyeing of fabrics uses a huge amount of water. Along with this, the cutting process itself is impossible without scraps that replenish landfills. The use of 3D printing will reduce the amount of waste: only the amount of material that is needed to create a project will be used.

Easy disposal of finished products

Ability to recycle unwanted clothing for reuse in the production process. Already, Adidas is using recycled plastic found in the ocean to produce the midsole of its sneakers. Creating new materials from old ones and using plastic more responsibly is a big advantage of 3D printing over traditional production.

Availability of individual designs

3D printing will give everyone the opportunity to get a dress like a catwalk model, which, in turn, will fit perfectly on the figure. Moreover, with the development and widespread use of 3D printing, anyone can feel like a designer by developing their own model. nine0003

nine0003

Reduced logistics costs

With the development of 3D printed clothing, there will be no need for complex logistics chains when fabric is produced in one country, models are made in another, which are then sent around the world.

Applied 3D printing technologies for clothing

Although printed clothing is a relatively new phenomenon, 3D printing technology itself has been used for many years to make accessories: bags, shoes, jewelry. The main problem is that the materials used for 3D printing are more rigid than regular fabric. We have to find a compromise between rigidity and strength. Therefore, this direction is not developing as fast as others. nine0003

The most commonly used technologies for garments are:

- FDM (Fusion Fused Modeling). Low print resolution, possible defects. Materials: thermoplastics (nylon, polycarbonate (PC), polyethylene, PLA, ABS, PET, TPU).

- SLS (selective laser sintering). This method allows you to create intricate designs with a high level of detail.

Materials: powdered thermoplastics (Nylon 6, Nylon 11, Nylon 12).

Materials: powdered thermoplastics (Nylon 6, Nylon 11, Nylon 12). - SLA (Laser Stereolithography). Very high print resolution. Materials: photopolymer resins (standard, casting, transparent, high temperature). nine0052

Application examples

Transformer dresses

In 2016, the University of Herfordshire in the UK created a collection of transformable dresses based on Modeclix technology. They differ from other models in that their design allows you to change the style and size both before and after printing.

The use of 3D printing by fashion designers

Noa Raviv

The work of a young talented fashion designer from Israel is a synthesis of geometric lines and unusual shapes. The latest collection, printed on a Stratasys' Objet Connex 500 Multi-Material 3D printer, is black and white abstractions with bright orange lines added to effectively emphasize the simplicity of the dresses' shapes. nine0003

ThreeASFOUR

The threeASFOUR brand brings together three designers, Gabrielle Asfour, Angela Donhauser and Adi Gil, who skillfully combine cutting-edge technology with the traditional art of modelling.

The Pangolin dress presented at New York Fashion Week was printed with nano-enhanced elastomer, which is highly durable and flexible at the same time. This piece of art was created in collaboration with Travis Fitch and Stratasys. nine0003

10 printers spent 500 hours printing elements of the dress, which were then connected to each other. All parts are movable. They create this attractive three-dimensional effect.

Anouk Wipprecht

Dutch designer Anouk Wipprecht's dresses combine bold shapes, interesting ideas and modern technology, and the latter goes beyond the 3D printing with which they are created. "Smart" Anouk dresses interact with the environment and react to external influences: they move, change shape, glow, blink. nine0003

The Smoke Dress releases smoke when someone gets too close. The idea is to create a veil and alert the person that they are in the wearer's personal space. The Smoke dress was created as part of a collection for the Volkswagen Group.

Application in batch production

Viptie 3D

Albanian company Viptie 3D produces stylish 3D printed ties. Each model can be modified according to the wishes of the client. They managed to combine luxury and high technology. nine0003

Ministry of Supply

Boston-based Ministry of Supply has been making seamless 3D printed blazers and jackets since 2016. The production uses 3D Robotic Knitting technology. It takes only 90 minutes to print one product.

Danit Peleg

Fashion designer known for her work in the field of 3D printing. She designs her own textiles and experiments with various technologies such as laser cutting, screen printing and 3D printing. On her website, you can buy a fully customized jacket. Printing and assembly takes over 100 hours. Thanks to this revolutionary technology, each piece is unique, made according to the individual requirements of the customer. nine0003

Hercules 2018 Clothing 3D Printer

Hercules 2018 Closed Camera Desktop 3D Printer from Russian manufacturer IMPRINTA uses FDM/FFM printing technology. Productivity of the device for flexible materials is up to 34 cm 3 /hour. The size of the working chamber is 200 × 200 × 210 mm. The model has high print quality without visible layers, which is achieved by reducing the layer thickness value. For the Hercules 2018 model, this value is 15 microns. nine0003

Productivity of the device for flexible materials is up to 34 cm 3 /hour. The size of the working chamber is 200 × 200 × 210 mm. The model has high print quality without visible layers, which is achieved by reducing the layer thickness value. For the Hercules 2018 model, this value is 15 microns. nine0003

3D printer Hercules Original

- Guarantee 1 year

- Performance 34-50 cm3/h

- File formats STL, OBJ

- Dimensions, mm 391x380x496

- Housing material Steel

- Software Slic3r

- The country of manufacture Russia

- Weight, kg 18.

9

9

- closed case no

- Table top calibration mechanical

- Maximum platform temperature for printing 125°C

- Max extruder temperature 260°C

- Seal FDM

- Table heating yes, removable glass

- Travel speed up to 150 mm/s

- Noise level 48 dB

- Working chamber area 200x200x210 mm

- Speed 100 mm/s

- Number of print heads 1

- Layer thickness from 20 µm

- Thread diameter 1.

75

75 - Nozzle diameter, mm 0.2, 0.3, 0.5, 0.8, 1

- Interfaces USB;SD card

Go to product

Another feature of the Hercules 2018 printer is its low noise level of only 48 dB, which makes it suitable for home use. nine0003

Although the use of 3D printing in the fashion industry is severely limited by the materials used, a number of fashion designers continue to experiment hard, gradually turning the idea of printing clothes into reality.

- May 24, 2020

- 6598

Get a consultation nine0002 April 26, 2022

Recently, there has been a growing demand from shoe manufacturers for 3D printing technology. What awaits us in the future and how will the 3D format change the entire industry of production and consumption?

What awaits us in the future and how will the 3D format change the entire industry of production and consumption?

The world's first 100% 3D printed sneaker was designed by Virginia Tech graduate Calan Kerner. The raw material for the manufacture was a completely recyclable material. The shape of the shoes looks like a monolithic product, from a distance reminiscent of traditional Dutch shoes (klomps), but has a more futuristic design and is made in a modern way. nine0003

To be honest, shoe manufacturers have been using a 3D printer for a long time, although they are experimenting only with decorative elements and soles. This is due not to the ability of 3D technologies to work with leather or textiles. To date, the main material used for the manufacture of three-dimensional products is plastic.

3D printing technology does not stand still, progress in this area is actively gaining momentum - printers can work with liquid concrete, dough, print artificial organs, etc. , so the ability to use these machines to print something similar to textiles is just around the corner . Time will pass, and we will see really unique things. nine0003

, so the ability to use these machines to print something similar to textiles is just around the corner . Time will pass, and we will see really unique things. nine0003

Looking back, it took about 50 years for the computer to go from a massive model to a personal one, and now no industry can exist without it. Now imagine what will happen when every home has a 3D printer and will be able to make products from different materials. The first thing people start churning out is shoes, clothes, and possibly food.

Development will lead to the disappearance of the usual tables indicating sizes and measurements, as clothing will be made to fit a specific person. All shoe factories will begin to massively rebuild to meet new realities: the production of files that are accepted by 3D printers will begin, and sneakers and shirts will become a thing of the past. nine0003

It seems that in the future the scheme of interaction between the buyer and the manufacturer will be as follows: go to the site, choose the color and style, pay for the purchase and send the finished prototype to print. The phrase “I bought myself new jeans” is transformed into “I downloaded new jeans for myself.” All this will become commonplace and familiar, plus a “black market” of files will appear - similar to the current one (production of fake Nike, Puma, etc.). There will be an active fight against piracy, but this will not lead to success - replicas have always existed and it is unlikely that anything will change. nine0003

The phrase “I bought myself new jeans” is transformed into “I downloaded new jeans for myself.” All this will become commonplace and familiar, plus a “black market” of files will appear - similar to the current one (production of fake Nike, Puma, etc.). There will be an active fight against piracy, but this will not lead to success - replicas have always existed and it is unlikely that anything will change. nine0003

New technologies will give a new flowering of self-expression and creativity. Making clothes, shoes at home, you can always print unique design models, experimenting as much as you like. For example, today everyone can create a presentable website with their own content and design using an online designer, and in the future it will be possible to create sneakers or a dress in a personalized color and style.

There may be programs for smartphones (if they do not disappear by then) that allow you to instantly create a design, shape, size of a future product, and then send it to print or share with friends for joint editing. Every day it will be possible to try on a new fashionable “bow”. Undoubtedly, most of the "homemade" will look ridiculous and even terrible, but there will also be successful models that will squeeze out professional designers. nine0003

Every day it will be possible to try on a new fashionable “bow”. Undoubtedly, most of the "homemade" will look ridiculous and even terrible, but there will also be successful models that will squeeze out professional designers. nine0003

Retail stores will go out of business and disappear, and the textile industry will have to seriously reorganize in order not to cease to exist. Warehouses, supplies, buildings, etc. will lose their purpose and sink into oblivion - everything from boots to caps can be downloaded from the Internet and printed at home using equipment the size of a washing machine.

In the future, there will be a complete recycling that will replace washing machines. Of course, a new future is still far away, but the presented monolithic sneakers are the first call of the coming technological revolution, which will cause the disappearance of mass production. I suppose that all this awaits us in 40-50 years. Although the current rate of progress can significantly reduce this period.

.jpg)