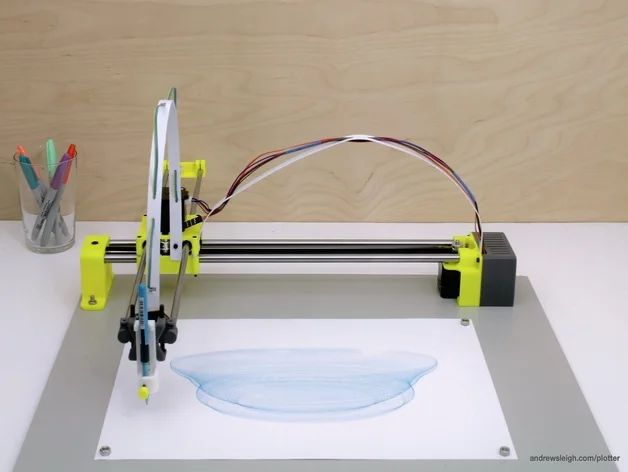

3D printer tube connector

Quick Connector & Teflon Tube & Fan

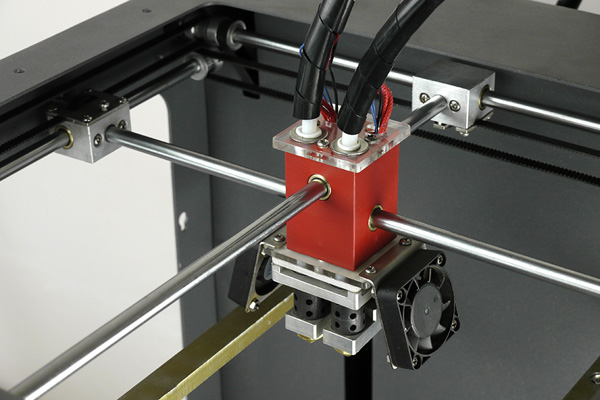

3D Printer

New

Control Board

Hot

Extruder Kit

Hot

LCD Display

Driver Board

Module Board

Filament

Upgrade Kit

Sort + FilterShow12243648

FeaturedBest Selling$ → $$$$$$$$ → $A → ZZ → AOld → NewNew → Old

Quick Connector & Teflon Tube & Fan

1M 2*4mm PTFE Tube Teflon PiPe to J-head hotend RepRap Rostock Bowden Extruder for 1.75/3.0mm For V5

From

$2.51

View

Diameter 6mm 33Ft.(10M) Spiral Cable Wire Wrap Tube PC Manage Cord 10m Black for 3D printer

$3.

View

BIGTREETECH 5015 12V/24V Blower Cooling Fan For V6 J-head Bowden Extruder

$3.15

View

BIGTREETECH 3010 4010 Fan LED Cooling Fan 30MM 12V 5V 2Pin DC Cooler Small Cooling Fan lights 3D Pinter Parts For j-head hotend

From

$4.52

View

BIGTREETECH 4010&3010 24V Cooling Turbo Fan 40*40*10mm 2Pin Quiet 100mm Brushless Blower Mini Fans 3D Printer Parts For B1 3D Printer Extruder

From

$5.83 |

View

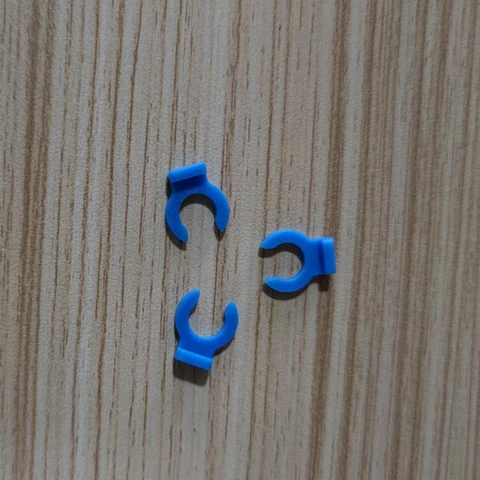

3D Printer Pneumatic Connectors PC4-01 1.75mm PTFE Tube quick coupler j-head Fittings Reprap Hotend Fit

From

$3.19 |

View

DC 5V 12V 24V 3010 Fan Cooling Brushless Mini Fan 30*30*10MM Cable 17CM 2Pin Radiator Black For 3D Printer Parts Reprap

$2.27

View

2/Lots 3D printer accessory for Reprap Bowden Extruder Connector One-touch fittings 4*2 mm M6 threaded for 1.

75 mm filament

75 mm filamentFrom

$2.34

View

BIQU 1M 3D printer PTFE tube 2*4MM black for 3D printer BIQU B1

$5.94 |

View

BIQU 3510 24V Ball Bearing Fan 3D Printer Parts For h3 Extruder

$4.50

View

Capricorn Bowden PTFE Tubing XS Series 1M+1Pcs Quick Fitting + 1Pcs Straight Pneumatic Fitting Push to Connect for 3D Printer

$18.68

View

1M ID 2mm OD 4mm Teflon PTFE Bawden Pipe +2/3pcs Quick Fit Couping 1.75mm Filament for E3D V5 E3D V6 J-head

From

$3.35 |

View

CR10 Extruder Bowden Extruder Capricorn PTFE Tube 1.75mm Filament 3D Printer Parts For CREALITY CR10 CR Ender 3 upgrade Printer

From

$15.25

View

1M 2*4mm Bowden PTFE Tube Teflon Pipe with Connectors for Ender 3 CR 10

$8.

50

50View

Control Board h3 Series Extruder Hot Deals New Arrival US Warehouse

BIGTREETECH PI4B Adapter V1.0 for CM4 or CB1

From

$5.90 |

View

BIGTREETECH Manta M4P/M8P/M5P Control Board running Klipper with CB1/CM4

From

$5.90 |

View

BIGTREETECH BTT SKR 3 EZ Control Board Mainboard for 3D printer

From

$7.28 |

View

BIGTREETECH BTT SKR 3 Control Board for 3D printer

From

$4.

98 |

98 | View

BIGTREETECH Manta E3EZ V1.0 for Ender 3/Ender 3Pro/Ender 5

From

$8.99 |

View

BIGTREETECH SKR MINI E3 V3.0 32 Bit Control Board for Ender 3/Ender 3 Pro/Ender 5/Ender 5 plus/CR-10

From

$3.79 |

View

BIGTREETECH SKR MINI E3 V2.0 32 Bit Control Board Integrated TMC2209 UART For Ender 3

From

$31.56 |

View

BTT SKR Pico V1.0 Control Board Compatible with Raspberry PI for Voron V0

From

$29.98 |

View

BIGTREETECH BTT Octopus Pro V1.0 for 3D Printer

From

$53.28 |

View

BIGTREETECH BTT Octopus Max EZ for 3D Printer

From

$8.99 |

31

31View

13 MoreShop All

Choosing Fittings

Choosing FittingsFrequently Asked Questions How To Install Choosing Your Tubing Measuring Your Filament

Fittings tend to wear out and loose teeth, so its never a bad idea to swap in new ones when you change your Bowden tube.

What are the differences between them?

First, the size of the tubing it accepts. Bowden tubes for 1.75mm filament are 4mm outer diameter. Part numbers beginning with PC4 indicate "Push Connector 4mm"

The next difference is threading. Most Bowden systems use either an M6 ("Metric 6mm"), M5, or M10 thread. 01 Threading is also common, which is a 1/8 inch NPT thread. The distance between the threads is called the pitch.

The third thing to look for is whether the fitting allows the tube to pass all the way through. We now carry 01NPT and M10 threaded fittings in both styles. Note that some fittings can be modified to allow the tube to go all the way through by careful drilling. For 1.75 tubing, use a #19 (4mm) drill bit. For 2.85 tubing, use a 1/4" drill bit.

We now carry 01NPT and M10 threaded fittings in both styles. Note that some fittings can be modified to allow the tube to go all the way through by careful drilling. For 1.75 tubing, use a #19 (4mm) drill bit. For 2.85 tubing, use a 1/4" drill bit.

Which fitting is right for me?

The easiest way it to look closely at the pictures, paying close attention to the measurements. We are working to build a list of printers for each fitting size, but it isn't complete yet. Please help us out by emailing or tweeting at us, and let us know what printer you're running, and what fittings it uses.

Don't see your printer listed here? Help us build our database by emailing [email protected] or tweeting @CapTubes with pictures and measurements of your fittings.PC4-M6PC4-M6 fittings feature a 4mm opening, and M6 threading with a 1.0mm pitch. This is our most popular fitting, used by the Creality CR-10 (extruder end), and many of the newer RepRap printers. Note that this fitting does not allow the tube to pass all the way through. We also carry a PC4-M6-C, which is a more compact, lightweight version. Note that this fitting does not allow the tube to pass all the way through. We also carry a PC4-M6-C, which is a more compact, lightweight version. | |

PC4-M6-CThis is the Compact, lighter weight version of the PC4-M6.They feature a 4mm opening, and M6 threading with a 1.0mm pitch. Packed into a sleek housing measuring only 8 mm in diameter and 16 mm long (compared to 10x20mm for the full size version.) | |

PC4-M10x0.9-4.1*New in stock 8/2018* The M10 threaded fitting with 0.9mm pitch is used by the Creality CR-10 at the Hot End side. It has a 4.1mm opening at the back end that allows the tube to pass all the way through to the hotend. | |

PC4-M10x1.0 and PC4-M10x0.9M10 threaded fittings available with 0.9 and 1.0mm pitch, for 4mm tubing. This is used in some of E3D's hot ends, and TEVO printers. Note that there are several versions of the M10 fittings. Be sure to check the pitch of the threads for the best fit.. Be sure to check the pitch of the threads for the best fit.. These do NOT allow the tube to pass all the way through, like the CR-10. (those are above) M10x0.9 fittings can also be used on the CR-10 by cutting an additional piece of PTFE to go on the other side of the fitting, down into the hot-end for a 'quick disconnect' style set-up similar to the Monstah adapter. | |

PC4-M5This is another common size for RepRaps, and is utilized in the Monstah Adaptor for the popular HE280 hotend.It has a 0.9mm pitch M5 thread, and does not allow the tubing to pass all the way through. | |

PC4-01 NPTThis fitting has an 1/8 inch NPT thread. This is similar to an M10 except with a slight taper. 01 and M10 threads are so close that they can often be used interchangeably.Note that these do not allow the tube to pass all the way through. ) | |

PC4-01 NPT-4. 1This fitting has an 1/8 inch NPT thread. This is similar to an M10 except with a slight taper. 01 and M10 threads are so close that they can often be used interchangeably. 1This fitting has an 1/8 inch NPT thread. This is similar to an M10 except with a slight taper. 01 and M10 threads are so close that they can often be used interchangeably. This version has a 4.1mm back end that allows the tube to pass all the way through to the hotend. These are used in the Stacker S4 printer. ) | |

PC6-M10This is an M10 threaded fitting for our 6.35mm tubing, for 2.85mm filaments.Note that these do not allow the tubing to pass all the way through. | |

PC6-M10-6.2This is an M10 threaded fitting for our 6.35mm tubing, for 2.85mm filaments.Pre-drilled to allow the tubing to pass all the way through. Please Note: we have marked these out-of-stock as of 2019. | |

Monstah AdapterDirect from Mastermind Sarah from New Zealand; we introduce you to the Official Monstah Adapter. Working with Sarah, Capricorn is your Premiere North American distributor. Only seems “fitting” we pair the adapter with our premium XS tubing to provide the best defense against the infamous HE280 puck! Only seems “fitting” we pair the adapter with our premium XS tubing to provide the best defense against the infamous HE280 puck! What is the HE280 puck? If you’re unfamiliar with the HE280, it’s a hotend offered by another wonderful Hoosier company, SeeMeCNC; unfortunately, it can be a challenge to get the PTFE tube seated properly against the heat break to prevent pooling of plastic from forming, aka the dreaded puck! The puck leads to feeding inconsistencies, jamming, and loads of colorful words shouted over another failed print. Time to “Scare the Puck Out!” and outfit your HE280 with an Official, Capricorn XS enhanced, Monstah Adapter! |

What if I accidently purchase the wrong fittings?

Please contact [email protected] and we will provide instructions to return the un-used fittings for an exchange or refund.

What if you don't carry the fitting I need?

We are constantly expanding our selection to meet the needs of the community. Please tweet us @CapTubes or email [email protected] with your printer or hotend, and the specs of the fittings you need.

Please tweet us @CapTubes or email [email protected] with your printer or hotend, and the specs of the fittings you need.

Frequently Asked Questions How To Install Choosing Your Tubing Measuring Your Filament

All fittings are evil. But there is a solution!

Technical

Subscribe to the author

Subscribe

Don't want

41

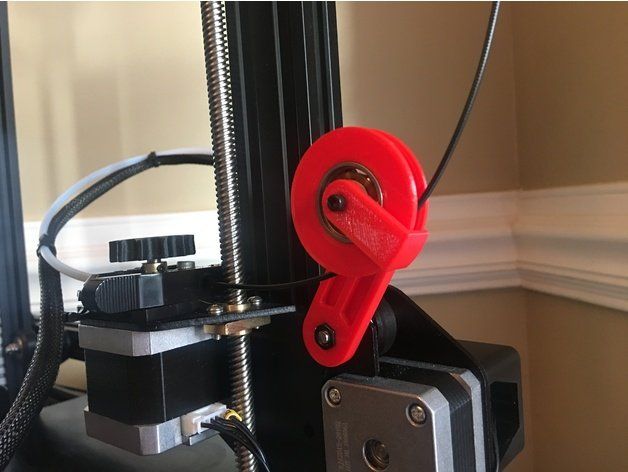

It so happened that pneumatic connectors for bowden tubes (bowden) for 3d printers, such as PC6 / 4, became the gold standard. In general, the solution looks quite convenient. You just need to insert the tube and you're done! You can also attach a tie to secure the connection more firmly.

But not everything is so smooth. Inside such a fitting is a serrated ring that cuts into the tube in a circle and eventually gnaws deeper until it cuts a groove for itself. Which in the future not only prevents the removal of the tube, but also adds backlash, in some cases it can even bite the tube. nine0003

nine0003

The most unpleasant thing is backlash. Pneumatic connectors do not imply backlash-free fastening. Of course, you can first insert the tube, and then screw the fitting back on. This will push the tube against the gap between the throat/nozzle and the retaining ring inside the fitting. But there are pitfalls here too. Without calculating the force, you can jam the end of the tube and it will be difficult for the filament to pass. And the fitting will bite even harder into the tube and it will be almost impossible to pull it out. In hard conditions, for example, on high-feed flying extruders, backlash appears quickly enough. nine0003

And on hot ends with a through neck, micro backlash inevitably causes gaps with melted plastic or even plugs.

In general, despite the apparent simplicity, pneumatic connectors are a real evil.

Many enthusiasts came up with different ways to solve this problem with the help of "crutches". but I didn't like any of it.

I also know that for example tringllab and others sell their fittings (expensive infection) and if you go through the reviews, you can see that they do not solve the problem. nine0003

There are also printed variations, where the tube is clamped with a printing collet. It looks bulky, and since Teflon is soft and slippery, it can either slip out or pinch the tube (for a long time I could not understand why the filament is pushed through so badly). Also, the prusa mini was sold with a collet clamp, although judging by the forums they encountered the same problems and now they are trying to install hydraulic fittings. Also, the collets do not allow the tube to rotate freely, and this can add other loads when moving the print head, since the tube is constantly subjected to twisting forces. nine0003

For a long time the brain could not calm down in search of a solution. I set myself the following requirements for fixing the tube:

1) Do not give backlash

2) Free to rotate

3) Do not damage the tube during prolonged use

4) Easy to manufacture without complicated tools

5) Low cost

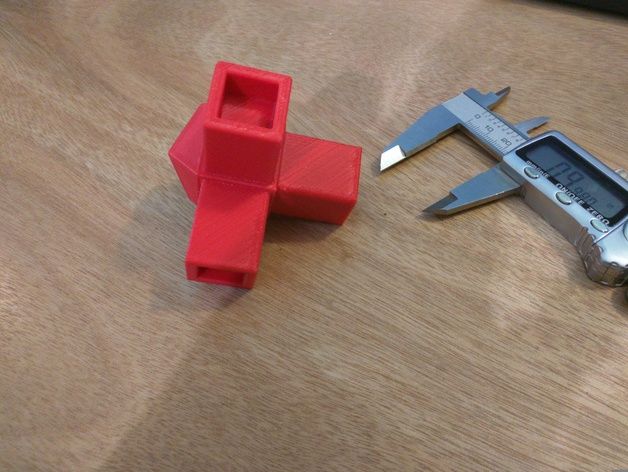

And here's what I came up with:

The first thing to do is print out of PETG or PLA this cylinder, the outer radius of which will be about 6. 45mm, and the inner radius of 3.8mm, the height is about 7mm. if the printer/nozzle allows, you can print very slowly in the "vase" mode. nine0003

45mm, and the inner radius of 3.8mm, the height is about 7mm. if the printer/nozzle allows, you can print very slowly in the "vase" mode. nine0003

Next, you will need to push the threads inside this cylinder with an m4 screw. Tapers cannot be used. Dimensions may vary slightly, it will be clear later why.

Preparing the tube. It is necessary to slightly grind the end of the tube into a cone on which we will "cut" the thread. This can be done in any way, for example with a knife.

Next, we take our tube and scroll with force, forcing the thread with our printing cylinder. Next is the next most important moment without which nothing will work. We take an L-shaped hexagon (2mm) with a ball end and insert it to the depth we need. We scroll our cylinder to the end, after which we pull out the key. Manipulations with the key are needed not only to correctly push the threads on the tube, but also to maintain the internal diameter. And it will also be convenient to hold on to it when pushing the thread (we will not deform the tube once again). Kills three birds with one stone. nine0003

Kills three birds with one stone. nine0003

The next step is to make a mating piece from a waste PC-6 fitting. To do this, you need to pull out all the offal from it with wire cutters. Only a sealing rubber insert will remain inside.

The cylinder must fit snugly under the fitting, but still rotate freely in it.

You can also print another cylinder that will relieve bending loads. It should fit as tightly as possible both into the fitting and tightly put on the tube itself (here without a thread). Dimensions will have to be selected empirically, since all fittings are slightly different. nine0003

It will also be useful to seal the thread of the fitting in any way, in this case I glued one turn of electrical tape.

The final meaning of this method is as follows. One end of the tube will rest against a thermal barrier or, if you are using a through throat, against a nozzle. And the other part will slide on the inside of the fitting. Slightly twist the impression cylinder, you can completely select the play. Teflon over time will try to return to its original state and the impression cylinder will sit very firmly on the tube and will not rotate without effort. nine0003

Slightly twist the impression cylinder, you can completely select the play. Teflon over time will try to return to its original state and the impression cylinder will sit very firmly on the tube and will not rotate without effort. nine0003

It is also possible to attach the back part to the extruder itself. On this tube, it was a flying extruder, I printed 4 kg of plastic and the backlash did not appear. And I forgot, like a nightmare, all these ordeals with fittings.

If it is not clear from the photos, you can watch a short video version.

https://www.youtube.com/watch?v=bnRLHkP3iC8

Prusa bowden Bowden Fitting ender PC-6 PC-4

Follow Author

Follow

Don't Want

41

3D Printer Parts - Page 9 of 11

Showing 201-225 of 258

Initial SortBy PopularityBy RatingSort By Latest Price: Ascending Price: DescendingCombined power block 3D printer

76 UAHTriple socket for 3D printer power cable connection.

Universal triple block contains:

- socket for connecting the power cable,

- fuse,

- power button.

Reinforced spring 13mm

4 UAH

This reinforced spring can be used for a heavy 3D printer platform, as well as for adjusting the backlash of a trapezoidal screw pair.

Add to cart

Black flexible cable channel (mesh)

35 UAHBlack nylon mesh for cable management. nine0005

3D printer wiring is an intricate tangle of many cables.

It is best to use specialized cable channels for laying the array of cables. An affordable alternative to flexible cable duct is flexible nylon mesh.

The price is for 1 meter of mesh.

Add to cart

Wide spring for 3D printer 10 mm - 1 pc

6 UAHSpring can be used for 3D printer platform.

Such springs are often used in Makerbot and its copies with thin aluminum platforms. This is a good option for 3D printers with a small printable area

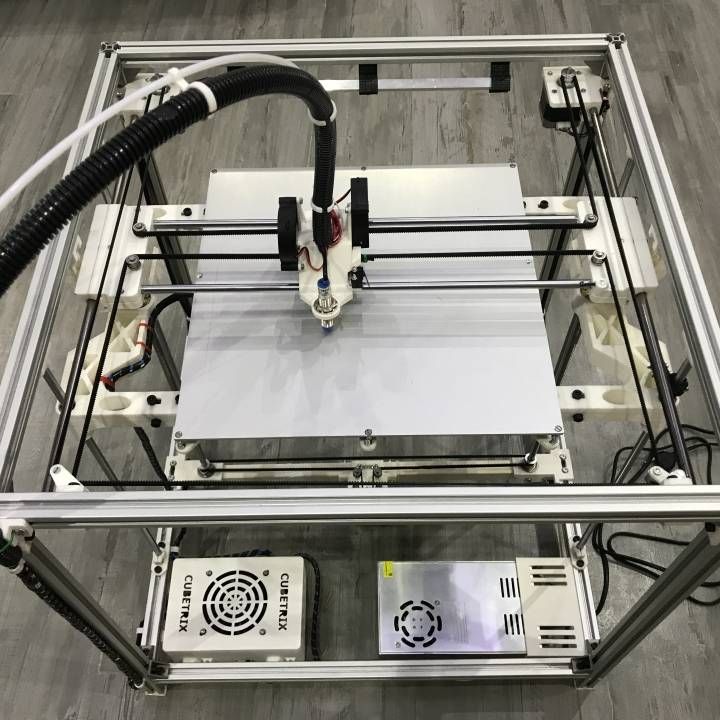

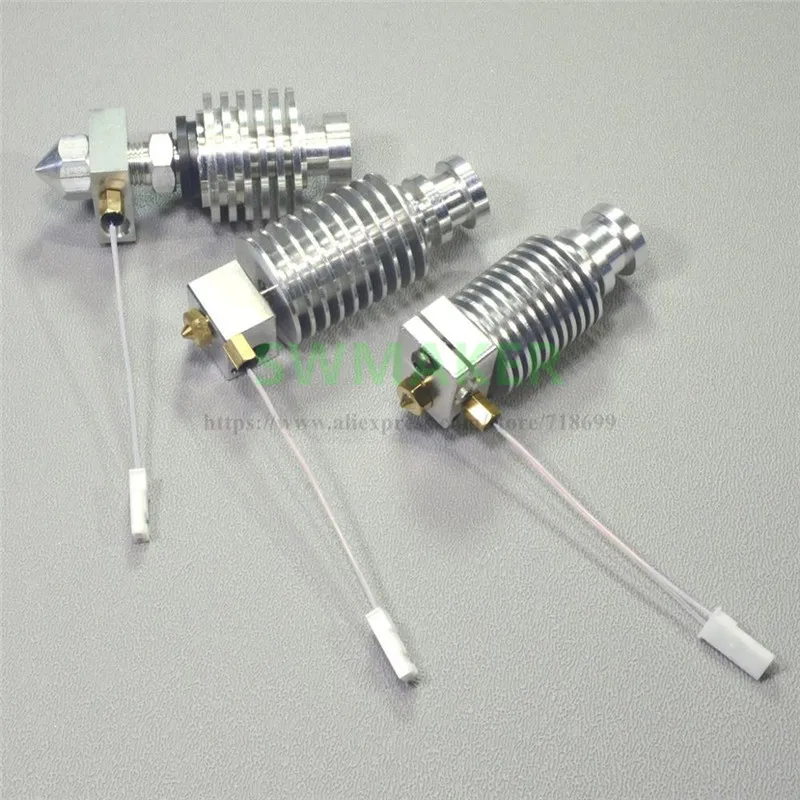

Diamond E3D Color 3D Printing Extruder

430 UAHExtruder for mixing 3 colors of plastic for color 3D printing.

Diamond extruders allow you to print with 3 filaments using only one nozzle and one heating element. This solution avoids problems with randomly flowing plastic from an unused nozzle. nine0003

Structurally, this extruder consists of:

- one copper nozzle,

- three Teflon core steel studs,

- three fittings

- and three heatsinks E3D v6.

These extruders can be equipped with a Trident 3D printer in the older configuration.

Add to cart

Bluetooth module for 3D printer nine0107 96 UAH

Wireless module for 3D printer.

Wireless printing is available to you today. You don't need to spend huge money on wireless 3D printing.

3D print from your phone without any hassle or limitations.

Flexible coupling for stepper motor

35 UAH – 169 UAHFlexible Coupling is a simple and inexpensive solution for transferring torque from a 3D printer motor to a shaft.

The flexible coupling allows you to use a toujon to connect the stepper motor to the shaft. nine0003

Cable 4 cores 22awg

30 UAH

Universal cable for wiring your 3D printer.

Such cables will become indispensable assistants when switching Ramps, limit switches and stepper motors.

The price is for 1 m.

Add to cart

Cable 2-Pin female/male – JST-XHD 2.5mm

17 UAHThe connector is designed to connect low current electronics. nine0137

A similar connector is actively used to connect 3D printer fans.

The connector is actively used by the MKS motherboard developer.

Cable JST-XHD 2.5mm 3-Pin female/male

18 UAHThe connector is designed to connect low current electronics.

These cable kits make it easy to extend or repair any standard 3-core cable.

The connector is actively used by the MKS motherboard developer. nine0003

nine0003

Add to cart

Cable set JST-XHD 2.5mm 4-Pin female/male

21 UAHThe connector is designed to connect low current electronics.

With these cable sets, it is very easy to extend or repair any standard 4-core cable.

The connector is actively used by the MKS motherboard developer, as well as by other developers for switching stepper motors.

Kit Xh3.54 3P female/male (cable and connector) nine0107 18 UAH

The connector is designed to connect low current electronics.

kit can be used to repair or extend trailer cables.

The connector is actively used by the MKS motherboard developer.

The use of connectors in 3D printer electronics allows for quick and easy replacement of elements in the future.

Add to cart

Connector JST-XHD 2.5mm 2-Pin female

5 UAHThe connector is designed to connect low current electronics. nine0137

A similar connector is actively used to connect 3D printer fans.

The connector is actively used by the MKS motherboard developer.

The use of connectors in 3D printer electronics allows for quick and easy replacement of elements in the future.

Add to cart

Connecting cables female-male 4 Pin JST SM

28 UAHThe 4-pin connector is universal for 3D printers, since most of its elements have 4 wires. nine0005

Multi-colour markings are easy to use.

The cable is great for extending the standard wiring of 3D printer motors.

Connecting cables female-male DC5.5

20 UAHThis popular connector standard is widely used for DC voltage transmission.

The connector is actively used by the motherboard designer MKS.

Connecting cables female-male JST 2P (set) nine0107 15 UAH

Tuning, assembly, as well as repair of a 3D printer involves working with cables. As a rule, the standard length of limit switches or stepper motors is not enough for neat laying of all wiring.