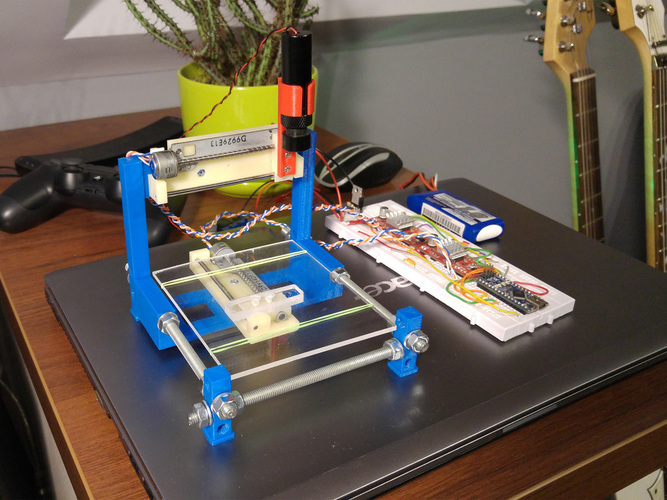

Cnc mounted 3d scanner

3D Scanning for CNC - CAD / CAM Services Inc. -

Scanning for Engineering and CNC

The world is a better place in the one-off part business. With new technologies, better scanners (both arms and 3D scanners), and smarter software – we now have an efficient and cost-effective way to scan items directly into CNC machines for engineering.

Consider this Scanning for CNC Issue:

Discontinued parts for 3D scanning and CNC

How do you take a discontinued part and create a duplicate of it?

Or, how do you create several copies of that same part?

Think of the first step in the Reverse Engineering process.

In the past, this has been an expensive, slow, and inaccurate process.

CAD / CAM Services Scans for CNC Engineering

Today’s Solution: Scanning for Engineering & CNC

Hexagon TIGO SF CMM 3D Scanning Station

Step 1: Generate a Point Cloud

of the Part or Object

There are two main approaches:

1) Arms with sensors attached, that can touch or scan any position on that part that you can see

2) 3D scanning.

Mitutoyo CMM machine 3D Scan Station

Types of CMM Machines

CMM machines start at $ 5-10,000 and can easily hit $ 130,000 or more depending upon the size and accuracy requirements.

Vendors like Mitutoyo, Hexagon and Zeiss are serious vendors in the CMM marketplace.

At best CMM machines can capture about 500mm per second.

Zeiss MMZ G CMM 3D Scanner

zCat Portable 3D Scanner

The zCAT 3D scanner is targeted at shop-floor measurement. it costs about $40,000.

Most significant shop-floor measurement innovations have been either portable, or probing systems built into CNC machine tools—also known as on-machine verification or OMV.

The zCAT advances the technology of portable measuring arms by automating repetitive part measurement with significantly better accuracy.

zCAT comes with a five-hour lithium-ion battery. It needs no electrical connection, therefor has no cables to stumble over. Another benefit is that zCAT doesn’t use air bearings, so there are no air hoses underfoot.

Another benefit is that zCAT doesn’t use air bearings, so there are no air hoses underfoot.

Arm Scanning with CMM

Arms with CMM have been the industry standard for years. They are mostly accurate and stable.

One advantage of arm scanners is that you can be very selective as to what section you wish to have tooled.

Think of a specific fitting / opening you need to mimic or fit to.

3D Scanning with Faro Scanner

With these types of scanners, you have the ability to capture specific sections.

Faro arm scanners are the industry standard and market leader here.

Handheld 3D Scanners

This category of scanners is much more affordable, quick and accurate.

With the passing of a laser scan, we can quickly and accurately capture the surface data of that part or object.

It might take several swipes/scans of that object to capture it in its entirety, but this scan will be worth its weight in gold.

artec-leo-2

Good industry handheld 3D scanners are are priced approximately $10-30,000.

We sell and use Artec hand helds, but Creoform are also excellent in this class.

The new Artec Leo can capture millions of points a second, which is rated at 80 frames per second.

Another huge benefit of the newer class of hand held scanners is portability. These hand held scanners can be run from a laptop.

Creoform White Light Hand Held 3D Scanner

Step 2- Point Cloud Data Assembly Required

3D Scanning with Point Cloud Generation and Assembly

What most suppliers tend to gloss over is the assembly of these new point clouds.

A point cloud is nothing more than a zillion 3D points in space that look like your part.

The wonderful news about this process is, software is now smart enough to greatly assist us in this automated assembly.

Point Cloud Density and Sub Density Map Piping

This results in a huge increase in productivity than the past.

In the past we had to use markers – targets, so a scanner knew when the next scan section starts and stops; along with knowing what to assemble to.

With small parts you can assemble the scan sections in just a few minutes, but on large buildings it can take 10-20 hours of computer processing.

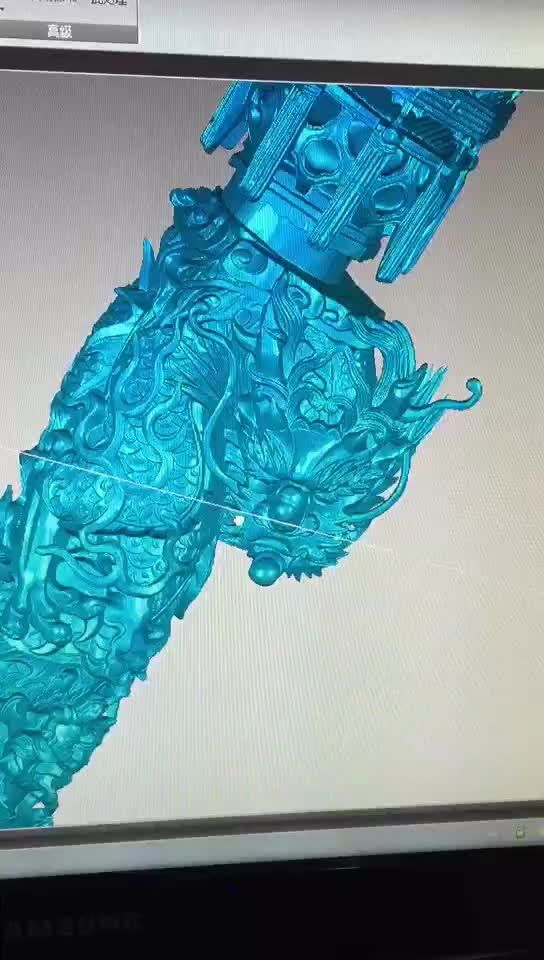

Step 3- Turn Point Cloud into a Mesh

CAD Mesh of a Part

Now that we have an assembled and clean point cloud. It is almost ready to turn it over to the CNC machine.

But we must now turn that clean and assembled point cloud into a mesh – a surface.

Some 3D scanning vendors include this feature, but most production houses use a higher end version called GeoMagic Wrap for this task.

Here we can smooth out surfaces, define how tight we want the mesh to be, check for hot-spots and inconsistencies, and even provide quality control across multiple parts to make sure they are within the production specifications.

geomagic turbine design

Here we generally output to a generic *.stl file, but HOPS files are also suitable for most NC machines.

At this stage, these are not CAD Files yet, but clean, mesh point cloud files.

Except for cleaning up a mesh, you really don’t edit these mesh files very much.

Within reason, it is a WYSWIG type file.

the good the bad and the ugly

The Good, The Bad and The Ugly

Further down the page we will discuss building a full CAD model. CAD modeling is useful if you are going to modify or edit a part.

For a straight forward scan to print or CNC approach, you don’t need that. You just need to make a copy of something.

At this point we can now simply drop the *.stl file into https://www.cadcam.org/3d-cad-services/3d-printing-2/, get an instant quote, and directly print this for you in a day or two.

Or, you are now ready for your CNC machine and MasterCAM software.

Don’t underestimate the fact, that some assembly will be required for your part.

You would be amazed how often we see missing sections of your part / object that where missed during the actual scan.

How can your CNC machine, even try to machine something that is undefined?

On a recent project– we cleaned up a huge mesh file on a very large building. The point cloud contained ½ billion points.

The point cloud contained ½ billion points.

Taking all of this into account, you truly get what you pay for.

Don’t expect a $ 3,000 approach to create Aerospace accurate parts. It won’t happen.

Industrial quality 3D scanners with good quality software are a $ 30-50,000 investment.

The industry leader RX Solutions DeskTom/EasyTom/EasyTom XL and all the way up to the UltraTom range in price from $ 100,000 to $ 1m systems.

The better scanners give you a better product. We utilize two RX Solutions CT scanners for our 3D scanning.

The Solution

In our business, one size does not fit all. We have learned our lesson with cheaper, less production arms and scanners.

We have also developed a clean process to make sure we know how to scan all of your surfaces, without missing any data.

aluminum 3D scanning

On shinny parts like aluminum, we often have to spray them with an anti-glare (3D Scan Spray) to reduce the gloss.

Otherwise, the scanners laser light would reflect off the surface.

Don’t worry, it is temporary and only useful for about an hour!

Faro Focus 3D Measurement & Imaging

CAD/ CAM Services utilizes CMM, CMM arms, and high-end 3D laser scanners, including some with white or blue light.

Industrial CT Scanner

We also utilize two types of industrial CT scanners to capture your meteorology and surface data.

This even allows us to look inside of your objects for voids, and surfaces you cannot see from an outside appearance.

FARO-Focus-M70-Laser Scanner- Scanning Pipes

All of our software is current, with experienced staff who knows how to operate it for excellent results.

3D scanning can be a science. It is something you learn with practice.

Faro Focus Laser Scanner 1

Regardless of what the scanning sales people say, they are only as good as the operator.

That is why after 30 years in business, customers keep coming back to CAD/CAM Services.

CAD/CAM Services Provides:

- Artec 3D scanner sales and rentals

- High-end 3D scanning services

- Point cloud to mesh creation

- And full CAD model and assembly

V6 Twin Turbo Engine 3D CAD Model Assembly

We now have an efficient & cost effective way to scan items directly into CNC machines for engineering.

Click now or call us at 800-938-SCAN (7226)

Request a Quote

Simple3D -- 3D Scanners, Digitizers, and Software for 3D Models and Measurements

Simple3D -- 3D Scanners, Digitizers, and Software for 3D Models and MeasurementsSimple 3D is a site about technologies (3d scanners, digitizers) used to create 3D models, measure 3D dimensions, and track objects in 3D spaces.

Over the past few years a number of 3D Scanner / measurement / tracking devices and techniques have been developed.

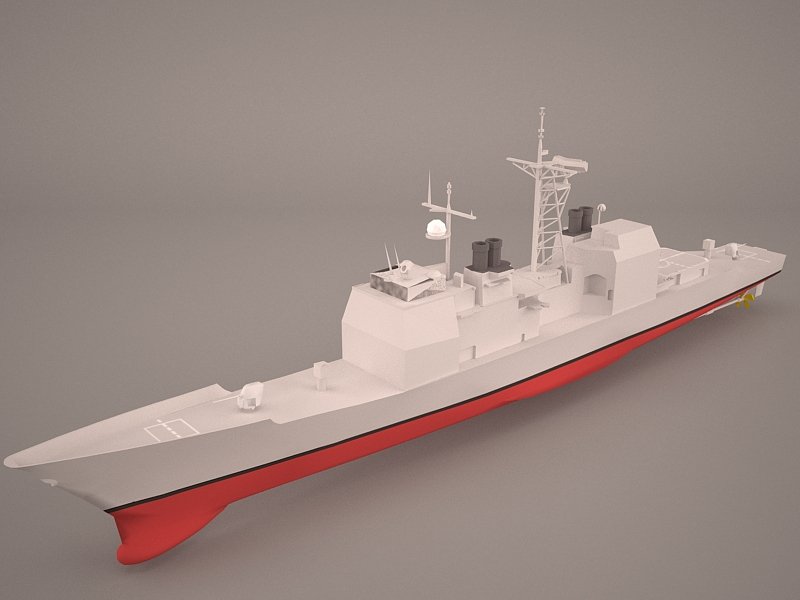

3D Models can be used in a large range of exciting applications areas: Animation, Archaeology, Architecture, Dentistry, Education, Fashion and Textiles, Foot Wear, Forensics, Games, Industrial Design, Manufacturing, Medical, Movies, Multimedia, Museums, As-built Plants Rapid Prototyping, Reverse Engineering, Sculpture, Toys, Mold Making, and Web Design.

Hopefully these pages will help you determine the best products for your applications (Frequently Asked Questions)

As an Amazon Associate I earn from qualifying purchases.

Table of Contents:

Acoustic Position Trackers

Books

Close Range Photogrammetry

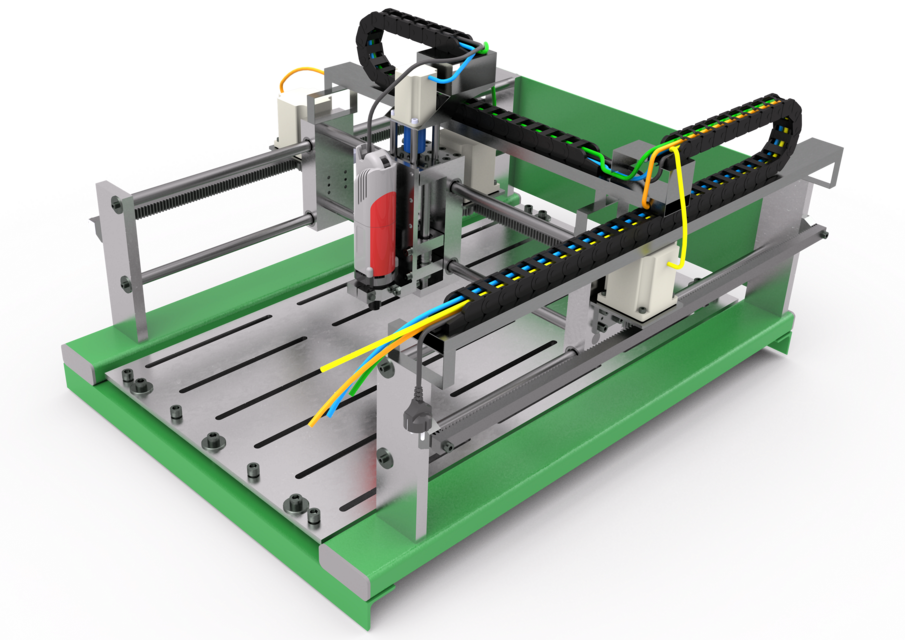

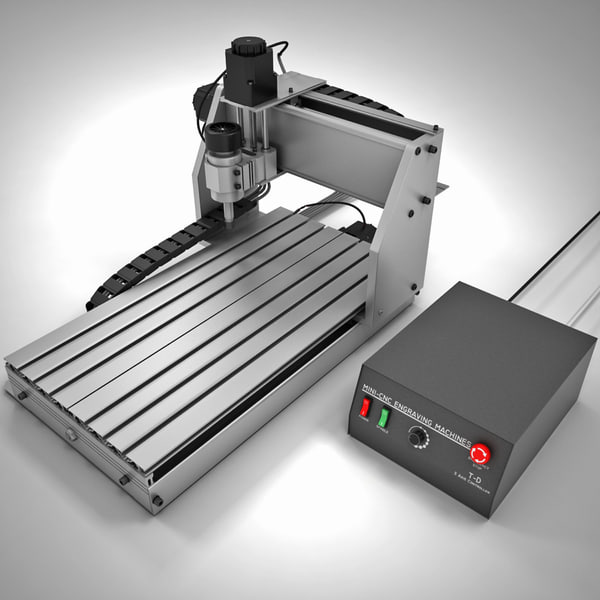

CNC Milling Machines and 3D Printers

Coordinate Measurement Machines

Dense Stereo Matching

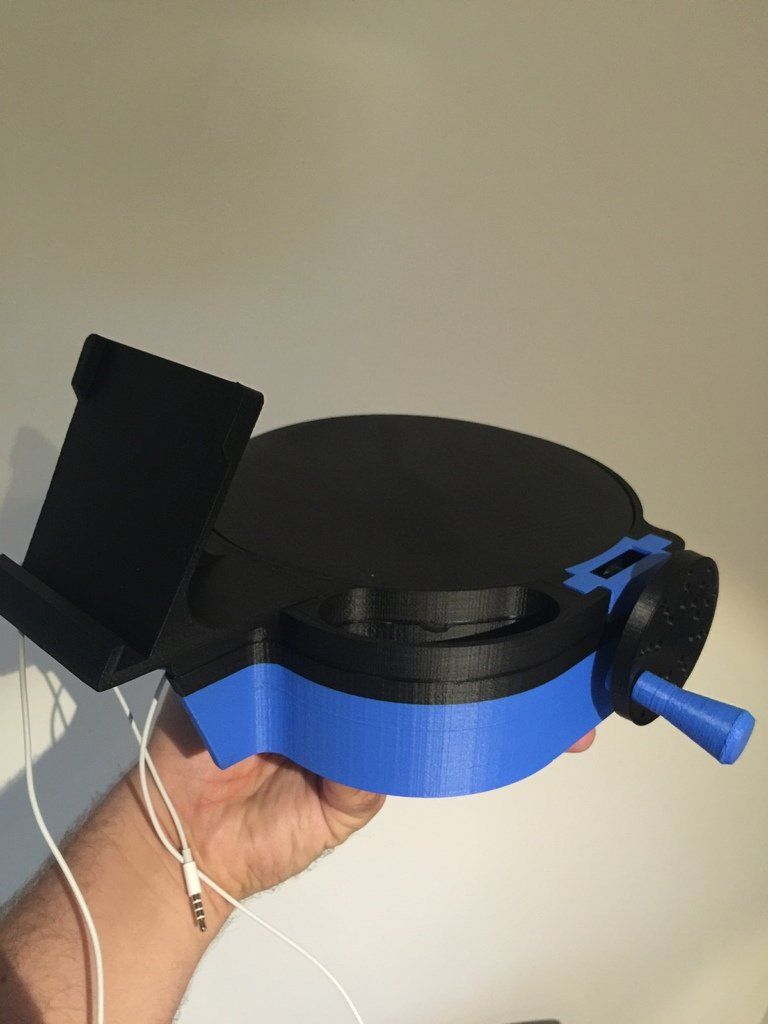

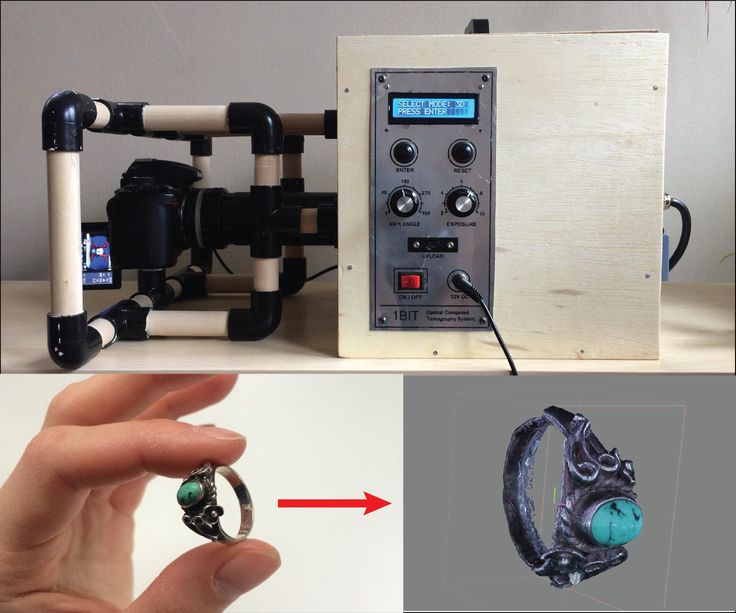

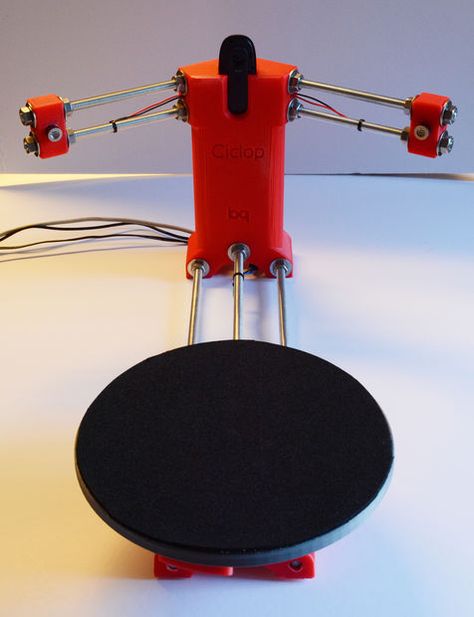

Homemade Scanners

Holography

Industry Magazines

Laser Radar Scanners

Laser Scanners

Laser Trackers

Magnetic Position Trackers

Measurement Service Companies

Optical Fiber

Optical Position Trackers

Professional Organizations

Profilers

Structured Light

Software

Time of Flight Laser Scanners

Total Stations and Theodolites

Touch Probes

Laser Scanners

- 3D Digital (now own rights to RealScan 3D... which was previously owned by Intel, and before that Lockheed Martin).

The Model 100 portable scanner has a USB interface for easy interfacing but no color texture. The Model 200 has color texture.

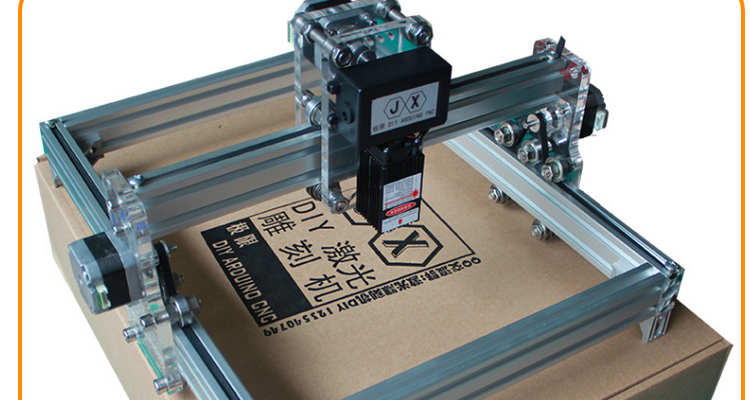

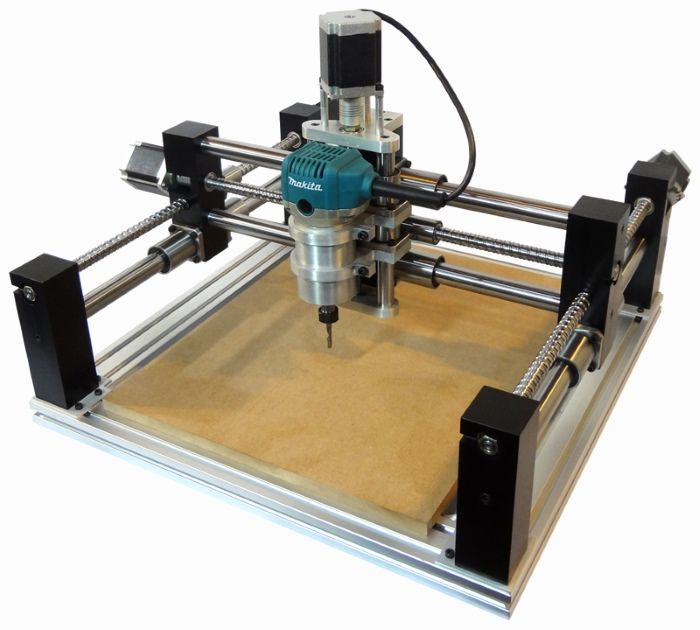

The Model 100 portable scanner has a USB interface for easy interfacing but no color texture. The Model 200 has color texture. - 3D Scanner has two different products. ModelMaker is a hand-held line scanner that fits on the end of an articulated arm (such as Faro). It comes in several different sensor configurations. The user can choose where to spend more time gathering dense data. The weight of the head and the rigidness of the articulated arm can make scanning a bit tiring. Replica/Reversa is a complete Computer Numerically Controlled (CNC) Machine.

- 3Shape 3D scanners for hearing aid and footwear applications

- DataPixel has sensors for CMMs, robot based inspection, and manufacturing in-line inspection.

- Axila G-scan is an integrated articulated arm and laser line scanner.

- Canadian National Research Council

- C-Map Systems LazrLyne projects a bright red vertical stripe into the video camera field of view.

This allows an operator to measure areas, distances, and angles on the screen. The device is typically used for remote controlled crawlers, undersea ROV's, borescopes, and video microscopes.

This allows an operator to measure areas, distances, and angles on the screen. The device is typically used for remote controlled crawlers, undersea ROV's, borescopes, and video microscopes. - Cyberware pioneered laser and video-based scanning technology. Their head and body scanners have been heavily used in the movie industry. The have scanners to address a full range of applications and they build custom scanners for special applications. The scanners color texture inaddition to geometry data.

- DCS incubator project uses projection of multiple laser lines to create 3D profiles.

- Diff Scan handheld 3D scanner uses a laser, camera, and diffraction to obtain range information

- Digibotics has several different size models that use a single laser dot to scan an entire object. The systems automatically scan an entire object in an intelligent fashion. Because of the order it scans the object, the point cloud is very easy to convert to a NURB model usings tools like Surfacer.

The scanning is some what slow, but accurate.

The scanning is some what slow, but accurate. - Hamar laser alignment systems

- Hymarc Hyscan 45C laser digitizer is designed to fit to any Coordinate Measuring Machine (CMM), Computer Numerically Controlled (CNC) Machine, or other translation device.

- Industrial Technology Research Institute has a 4-axis scanner, a portable 3D scanner, and a body scanner.

- 4DI (bought by Brooks Automation) system projects multiple laser lines to scan an object. It has two video cameras to calculate the 3D points and one camera to keep track of the multiple lines.

- INO has a line of high speed 3D laser profiling sensors

- IVP high speed 3D machine vision sensor calculates range information directly in the camera (10,000 profiles / sec). Combined with the Ranger software, it makes creating 3D profiling applications easy.

- Kreon3D has two different models. The laser line is projected from the center of the sensor.

Two cameras are used on either side of the line projector. This allows data capture even if one of the cameras is obscured.

Two cameras are used on either side of the line projector. This allows data capture even if one of the cameras is obscured. - Laser Design makes both portable and CMM based scanners for large and small applications.

- LMI Technologies Inc. has single point, multi-point, single-line and multi-line laser sensors

- Mensi offers two different models, one for long distances (2.5 - 25 Meters), and one for shorter distances (0.8 - 10 meters).

- Metris has several CMM non-contact scanners.

- Metron Systems MSG2 3D Scanning System is for reverse engineering, rapid prototyping, first article inspection, quality and process control or simply scanning services

- Konica Minolta Vivid (USA) (Europe) (Japan) has three models (Vivid 330, 700, 900) to provide different accuracies and working volumes. These systems operate like a conventional camera and are portable, fast, and reliable. The systems product color texture and geometry data.

- Nagoya Institute of Technology Handy 3-D Cam

- Nextec has the Wiz laser point probe that can be mounted on a CMM or they have the Hawk integrated scanning system

- New Features Measurement sells the M2D line of laser line scanner

- NextEngine Desktop 3D Scanner uses multi-stripe laser triangulation and sells for around $2500.

- OGIScanner laser line scanner for measuring rough diamonds for use in diamond planning and cutting.

- Origin Technology captures a two-dimensional digital profile of a surface.

- Perceptron provides laser line scanner and software for integrating with articulated arms

- Polhemus has come out with a new model of the FastScan handheld laser scanner. The FastScan Cobra is a single camera laser line scanner. It is much lighter and easier to handle than the original FastScan. The user "paints" the object of interest. The point cloud is displayed on the screen as the scan is being done.

It uses a built-in magnetic tracker to obtain the position and orientation of the scanner. This puts the scanned points in the same coordinate system. The overlapping scans are processed into a single surface model. Optional software provides automatic hole filling and generates water tight meshes. The list price is around $20K and the accuracy is around 0.5mm. This product is not suited for working around metal because of the tracker. The scanner and FastRBF software are developed by Applied Research Associates NZ Ltd. and FarField Technology

It uses a built-in magnetic tracker to obtain the position and orientation of the scanner. This puts the scanned points in the same coordinate system. The overlapping scans are processed into a single surface model. Optional software provides automatic hole filling and generates water tight meshes. The list price is around $20K and the accuracy is around 0.5mm. This product is not suited for working around metal because of the tracker. The scanner and FastRBF software are developed by Applied Research Associates NZ Ltd. and FarField Technology - Roland Model LPX-250 Laser Scanner is a $10K laser dot scanner that has rotation and linear stages. The operating volume is 10" diameter, 16" height. The scanning resolution can be as small as 0.008". The unit is very nicely package, but large complex parts can take quite a bit of time to scan.

- Scantech produces 3D laser scanners and CAD/CAM for efficient and fast copy milling. They have a portable scanner and stationary 3D laser scanners for mounting on any CNC-controlled milling machine or CNC-turning lathe.

- ScanWorks from Perceptron can be mounted on an articulated arm

- Shapegrabber has tabletop, portable, and gantry scanning platforms.

- Steinbichler Comet T-scan hand-held laser scanner for 3D-digitizing of freeform surfaces

- Scantech portable or CNC mounted scanner for stone, wood, and metal industry

- Surphaser 3D Laser Scanner ($30k) scans 200,000/sec with an operating volume of 6' x 6' x 6' with 0.05mm RMS accuracy

- Wolf & Beck Optical Scanning sensors for CMMs

- Z+F UK Ltd LARA scanners and Light Form Modeller Software

Structured Light Scanners

- 3D Metrics

- 3D Shape GmbH

- BodySkanner models commercial patterns to a person's measurements within 1/16".

- Breuckmann Make a variety of scanners

- C 3D Imaging

- CalTech 3D photography

- Capture3D

- ComfORTAC acquires 360 degree trunk and limbs with +/- 1mm accuracy.

- Dimensional Photonics is back (new incarnation?). The have a nicely packaged accordian fringe system. Minolta now sells their system for high-end applications. The technology promises to be more tolerant of lighting and shinely parts.

- EOIS makes the mini-moire non-contact probe for portable measurement arms. They also have 'The Handy' handheld digitizer that uses a digital camera for data capture and storage. EOIS technology sold to Opton Co Ltd of Japan in 2001.

- Eyetronics sells the ShapeCam and the SnapeSnatcher Suite Software. ShapeCam consists of a digital camera and a specially designed flash device mounted on a lightweight frame. Photos captured with the portable ShapeCam are processed and assembled in 3D with the SnapeSnatcher Suite. The suite handles alignment and stitching of scans, polygon reduction, texturemapping, and surface extrusion.

- Genextech Rainbow

- GOM Atos working volume is 100 x 80 x 80 mm up to 350 x 280 x 280 mm, scan time is 8 seconds.

- Inspeck 3D Capturor ($13K) can be used alone or combined into large object scanners

- Intelligent Quality Systems moire system

- Minolta 3D1500 Camera

- MonTech

- Nub3D

- Opton Moire System

- RSI Digiscan 2000 use a combination of a standard LCD projector, video camera, and software to objects

- Solutionix

- Steinbichler Comet

- Vitronic

- VXTechnologies (formerly VX Optronics) StarCam Uses a pair of cameras to triangulate the dot pattern projected by an inexpensive LCD projector. The system is available with an internal optical reference to help with thermal calibration issues.

- Wicks and Wilson Triform have several different body scanners (full body, torso, head).

Holography

- Optimet point probe uses Conoscopic Holography

- Coherix uses a tunable laser with multiple wavelengths and phase shifting to make measurements in a 12x12x16" working volume.

The measurement time is 2-3 minutes. Works well on flat reflective surfaces. Applications have primarily been in the automotive (brake pads, pumps, engine blocks) and semiconductor areas (silicon wafers). Systems are high-end ($200K)

The measurement time is 2-3 minutes. Works well on flat reflective surfaces. Applications have primarily been in the automotive (brake pads, pumps, engine blocks) and semiconductor areas (silicon wafers). Systems are high-end ($200K)

Software

- 3D Reshaper

- Cortona VRML plugin can be used to view VRML files in your web browser

- CosmoPlayer VRML plugin can be used to view VRML files in your web browser

- Cyberware CySlice

- Delcam provides a free translator that converts Unigraphics, SolidWorks, Pro/E 2000i, Parasolid and CATIA files to IGES.

- Deskproto Converts STL files into machining paths for CNC machines

- Easy3DScan is a package for automating the scan process using Minolta VIVID scanners and a turntable

- FarField Technology provides advanced techniques for modeling scattered 2D and 3D data.

- Imageware Surfacer allows you to manipulate point clouds and convert them into useful objects such as points, lines, planes

- Innovmetric Polyworks accepts scan data from most scanner manufacturers and aligns them into one model.

It is very good at handling the extremely large datasets. It processes both the points and the texture. The point clouds and models can be exported or compared against CAD models.

It is very good at handling the extremely large datasets. It processes both the points and the texture. The point clouds and models can be exported or compared against CAD models. - MatchGraph integrates 3d scan data processing technology in one package. It handles the creation and modification of triangulated meshes, NURB curves, and surfaces with inspection and analysis

- MayaMetrix Real-time inspection and tool building help Link Digital CAD Models to Manufacturing

- Metris provides data preparation, registration, comparison, and reporting software for dimensional inspection.

- Okino Polytrans does a great job of converting 3D models between formats.

- Paraform surface reconstruction software

- PRISM 3D Software software for managing, sharing, and extracting information from as-built laser scan point clouds.

- Raindrop Geomagic has a product that converts point clouds into polygonal and NURB models.

The Qualify product aligns point cloud data to CAD models and inspects it.

The Qualify product aligns point cloud data to CAD models and inspects it. - RapidForm can create parametric models from point clouds. They also have software for inspecting products against their CAD definitions.

- Rhino3D Nurb modeling for Windows.

- RevWorks

- SpatialAnalyzer SpatialAnalyzer can simultaneously acquire data from any combination of metrology instruments - Theodolites, Total Station Theodolites, Laser Trackers, Laser Scanner, Coordinate Measurement Machines.

- UZR 3D Professional creates a 3D model from a series of object images.

- Visualization Toolkit (VTK) is an open source, freely available software system for 3D computer graphics, image processing, and visualization.

- Verisurf

Laser Radar Scanners

- Metricvision technology is based on Frequency Modulated Coherent Laser Radar, which gives it great precision (repeatability is in the sub-10 micron range at over 10m).

3. Approximate system pricing is $150K.

3. Approximate system pricing is $150K. - Quantapoint measures 125,000 points per second and covers a 70 degree by 360 degree field of view

- Riegl Laser Measurement Systems for 3D imaging of buildings and structures

Laser Trackers

- Automated Precision sells the Laser Tracker II system which is a lightweight, precise, compact and portable CMM tool designed for industrial applications.

- Faro (formerly SMX) produces a portable CMM system that precisely measure objects in the 0-100' range.

- Leica Geosystems sells a range of industrial measurements systems including laser trackers.

Touch Probes

- Axila claims to have invented the first six-axis portable CMM in 1986. The ORBITAL is their eight-axis arm.

- Faro Three families of digitizers (sterling, silver, and gold). Working volumes from 4-12', accuracies of 0.001" to 0.

007" 2 sigma.

007" 2 sigma. - Garda Inspector

- Immersion Microscribe Several different models with varying working volumes (50" - 66" sphere) and accuracy (0.009 - 0.015").

- Roland makes several small volume piezo scanners. The low price makes them great for scanning coins, jewelry, and other small parts.

- Romer Six axis articulation, 6 - 12' diameter measuring, accuracy to +/- 0.008"

- ZettMess Portable 6 Axes Measuring System

Optical Position Trackers

- 3rdTech HiBall-3100 Based on the UNC Wide-Area Tracking Research Project

- ArcSecond sells what they call an indoor GPS system. The system consist of 2-4 transmitters that are similar to rotating construction laser levels. Receivers are connected to wireless PDAs and display x,y,z location. The interesting part about this product is that you can many independent receivers. The systems are fairly accurate over a large working volume.

- Image Guided Technologies

- Krypton is a precalibrated mobile metrology system. There are no mechanical arms and the setup is fast and straight forward.

- Northern Digital makes the Polaris and Optotrak system. They track active and passive markers. ND focuses on the medical areas, and is common in image guided surgery.

- PhoeniX Technologies Real-Time 3D Motion Capture for research, biomechanics, VR, and gaming.

Magnetic Position Trackers

- Ascension Technology

- Polhemus developed the technology and sells the FasTrak and Liberty systems.

- Mednetix AG

- Northern Digital has a new Aurora system that uses small sensors. It has a measurement volume approximately 500mm x 500mm x500mm. The 1 sigma accuracies are 1-3mm and 1-2 degrees orientation. This product will help ND in the image guide surgery arena where optical systems can have their views blocked.

Acoustic Position Trackers

- GTCO CalComp Freepoint 3D Sonic" Several models listed, one with a large 16 x 8 x 8 ft working volume with a 0.

004" resolution.

004" resolution. - Pegasus Technologies Ltd

Optical Fiber

- Measurand

Dense Stereo Matching

- Geometrix FaceVision uses multiple low-cost digital cameras to create textured face models from ear to ear.

Profilers

- CamSys ShadowBox has 16" diameter, 16" high cylindrical working volume. Two models with different accuracy. Scan times range from 15 - 120 seconds.

- Solarius Development LaserScan is a 3D profilometer for laser measurement and analysis of surfaces

Coordinate Measurement Machines (CMMs)

- CMMtalk On-line Community for CMM Professionals

- Brown & Sharpe

- LK Metrology

- Mahr Federal Inc.

- Mitutoyo

- Renishaw

- Starrett

- Werth America Inc.

- Zeiss

Close-Range Photogrammetry

- Apollo Photo3D creates 3D textured models from photographs

- Australis is from the University of Melbourne.

Professor Clive Fraser has written many papers about using photogrammetry on industrial applications.

Professor Clive Fraser has written many papers about using photogrammetry on industrial applications. - DPA-Pro is from AICON 3D Systems. The software has a heritage from the older Rollei DPA-WIN software. Coded targets and automatic camera calibration greatly improve your productivity.

- Brunson Instrument Company sells Invar components and accessories useful for creating photogrammetry scale bars.

- Cognitens 3D vision measurement systems is targeted at the automotive and the aerospace applications.

- GSI Inca2 camera and V-Stars are top-of-the-line cameras and software. They are geared towards automatically measuring coded, circular retro-reflective targets, and scale bars. This is a true metric camera, not just a professional grade digital camera.

- Hubbs Machine and Manufacturing produce photogrammetry targets and tooling.

- Imetric produces very high resolution cameras (6 and 28 Megapixel).

Their software can read coded targets and can integrate their structured light sensor.

Their software can read coded targets and can integrate their structured light sensor. - Kodak sells several professional digital cameras that are good for medium to high accuracy photogrammetry projects. The cameras are available in monochrome versions which are typically better for photogrammetry. The current model is the DCS 760M, past models have been the DCS 420M and DCS 660M.

- Leica Geosystems also sells the V-Stars videogrammetry system produced by GSI.

- LensDoc is a Photoshop plugin to correct lens distortion

- Metronor

- Microsoft Live Labs Photosynth finds autocorrespondences and camera positions from a set of images

- Photometrix has the Australis suite for automated close-range phototgrammetric measurements and iWitness system for accident reconstruction and forensic photogrammetry.

- PhotoModeler is a great package for calibrating cameras, making measurements from photos, and creating 3D models from photos.

It has a lot of functionality for the price (<$1000).

It has a lot of functionality for the price (<$1000). - Renoir for 3D reconstruction from photos

- ShapeQuest ShapeCapture works with projected targets

- SPG Data 3D uses a projected pattern and multiple cameras to inspect large objects.

- TCTI (3DMD) uses random light patterns with up to 144 synchronized digital cameras to geometry and texture of human subjects

- TriTop is a photogrammetry package from Capture3D. It is usually sold and integrated with the ATOS structured light sensor that they sell. It allows the point cloud scans to be automatically placed using coded and uncoded retroreflective targets.

- Visual Interface

- Vexcel FotoG Automatic edge detection for targeting helps this software create as-built models of plants.

- W.N.B.C. in L.A. produces retroreflective targets for use in photogrammetry applications.

Total Stations / Theodolites

- Leica Geosystems sells a range of industrial measurement systems include theodolites and total stations

- Sokkia

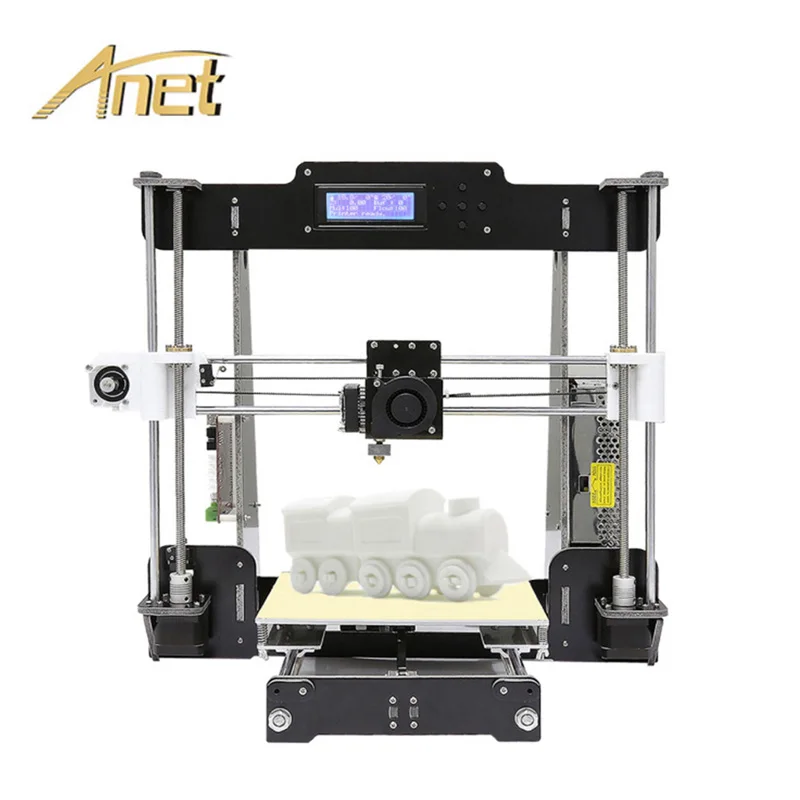

CNC Milling Machines and 3D Printers

- 3D Systems has SLA Stereolithography systems and solid imaging printers

- Fourth-axis makes rotary micromachines attachments for the Roland CNC machines.

It converts them into rotary mills for jewelry applications

It converts them into rotary mills for jewelry applications - Minitech

- MultiCam makes CNC routers, laser cutters and plasma cutters

- Roland CNC Milling Machines

- Zcorp has two different model 3D printers. The Z406 ($67.5K) uses a plaster-based powder. The Z400 ($49K) uses a starch-based powder. The loose powder acts as a supporting structure which can be removed and reused.

Professional Organizations

- ACM SIGGRAPH

- Coordinate Measurement Systems Committee

- Metrology Automation Association

- The Imaging & Geospatial Information Society

Measurement Service Companies

- DeChant Consulting Services sells the iWitness accident reconstruction software. They provide training and consulting services.

- Conservation Technologies Provides laser cleaning and scanning technology combined with traditional conversation skills to provide a range of conservation services

- Direct Dimensions provides 3D scanning, reverse engineering and inspection services utilizing a variety of tools from portable CMM's to laser scanners and laser trackers

- Solarius Development rent their equipment

- Arius3D

- 3Space

- Imtec

- Brunson

- Automated Precision

- ATT Metrology

- Archaeoptics Specialize in high-accuracy, low-cost 3D laser scanning most commonly in the fields of heritage management and archaeology.

- Streamline Automation

- 3Shape Consulting and Services

- 3DScanCo sell Konica Minolta range cameras, Faro equipment, and several software packages (Geomagic, rapidform, and Metris). They provide 3D scanning , reverse engineering, and quality inspection services.

- QPlus CMM Dimensional Measurement, Reverse Engineering, First Article Inspection 2D/3D Digitizing

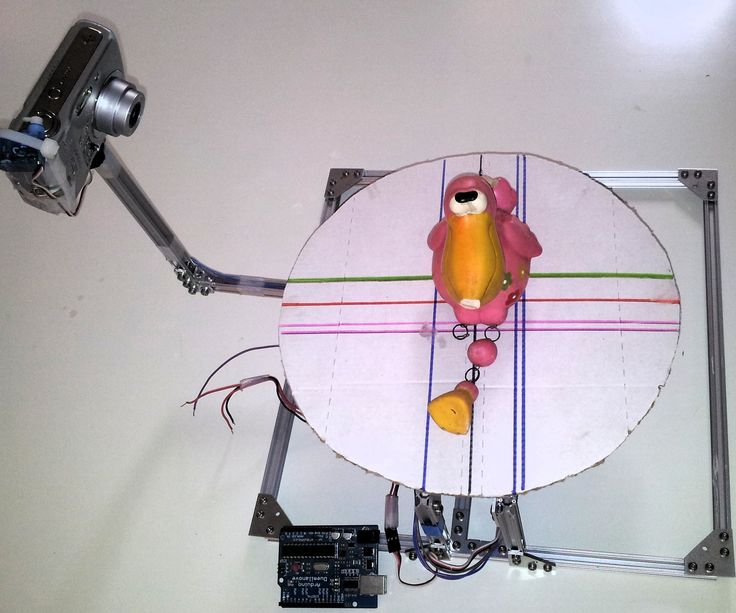

Homemade Scanners

- Building a Homemade Laser Line Scanner By Ethan Gold

- Home-Brew 3-D Photography by Jay Kubicky

- Development of a Four-Head Color Laser Range Scanner

- Public domain 3-dimensional data acquisition design and software by Laurence G. Hassebrook

- 3D Touch Probe Scanner by Roger Mueller

- 3D laser scanner by Roger Mueller uses a inexpensive quickcam pro 4000, a single laser line, and a turn table. Nice description of method, hardware, and software.

Industry Magazines

- Quality Online Magazine

- VisionSystems Design

- Advanced Imaging

- Photonics Spectra

- Time-Compression Technologies

Books

Computer Graphics and Visualization

Photogrammetry

- Close Range Photogrammetry and Machine Vision Edited by K.

B. Atkinson, Department of Geomatic Engineering, University College London

B. Atkinson, Department of Geomatic Engineering, University College London - 3D Modeling from Photos : Build 3d Models Fast Using Desktop Photogrammetry by Lyn Merritt

- Elements of Photogrammetry(with Applications in GIS) by Paul R. Wolf, Bon A. Dewitt

- Introduction to Modern Photogrammetry by Edward M. Mikhail, James S. Bethel, J. Chris McGlone, Chris McGlone

- Digital Photogrammetry by Michel Kasser and Yves Egels

Computer Vision

- Computer Vision : Three-Dimensional Data from Images by Reinhard Klette, Karsten Schluns, Andreas Koschan This is a great practical book for people that want to learn about creating 3D data from images.

- Computer Vision: A Modern Approach by David Forsyth, Jean Ponce

- Multiple View Geometry in Computer Vision by Richard Hartley, Andrew Zisserman

- Introductory Techniques for 3-D Computer Vision by Emanuele Trucco, Alessandro Verri Good classroom book for introduction to computer vision.

- The Geometry of Multiple Images: The Laws That Govern the Formation of Multiple Images of a Scene and Some of Their Applications by Olivier Faugeras, Quang-Tuan Luong, T. Papadopoulo

- 3D Structures from Images - Smile 2000

- Computer Vision by Linda G. Shapiro, George C. Stockman, George Stockman

- Computer Vision and Fuzzy Neural Systems (With CD-ROM) by Arun D. Kulkarni

- Active Contours : The Application of Techniques from Graphics, Vision, Control Theory and Statistics to Visual Tracking of Shapes in Motion by Andrew Blake, Michael Isard

- Handbook of Computer Vision Algorithms in Image Algebra by Gerhard X. Ritter, Joseph N. Wilson

- Calibration and 3D Reconstruction for Multicamera Marker Based Motion Measurement by J.C. Sabel

Image Processing

- Computer Vision and Image Processing: A Practical Approach Using CVIPTools (BK/CD-ROM) by Scott E.

Umbaugh

Umbaugh - The Image Processing Handbook, Third Edition by John C. Russ

- Algorithms for Image Processing and Computer Vision by James R. Parker

- Practical Algorithms for Image Analysis: Descriptions, Examples, and Code by Michael Seul, Lawrence O'Gorman, Michael J. Sammon

- Feature Extraction in Computer Vision and Image Processing by Mark S. Nixon, Alberto Aguado

- Contemporary Optical Image Processing With Matlab by Ting-Chung Poon, Partha P. Banerjee

- 3-D Image Processing Algorithms by I. Pitas, Nikos Nikolaidis

- Practical Algorithms for Image Analysis: Descriptions, Examples, and Code by Michael Seul, Lawrence O'Gorman, Michael J. Sammon

Contact us to add or update information

Copyright � 1999-2018 Simple3D, All rights reserved.

Security by Mike Evanshow to install, characteristics, operation features

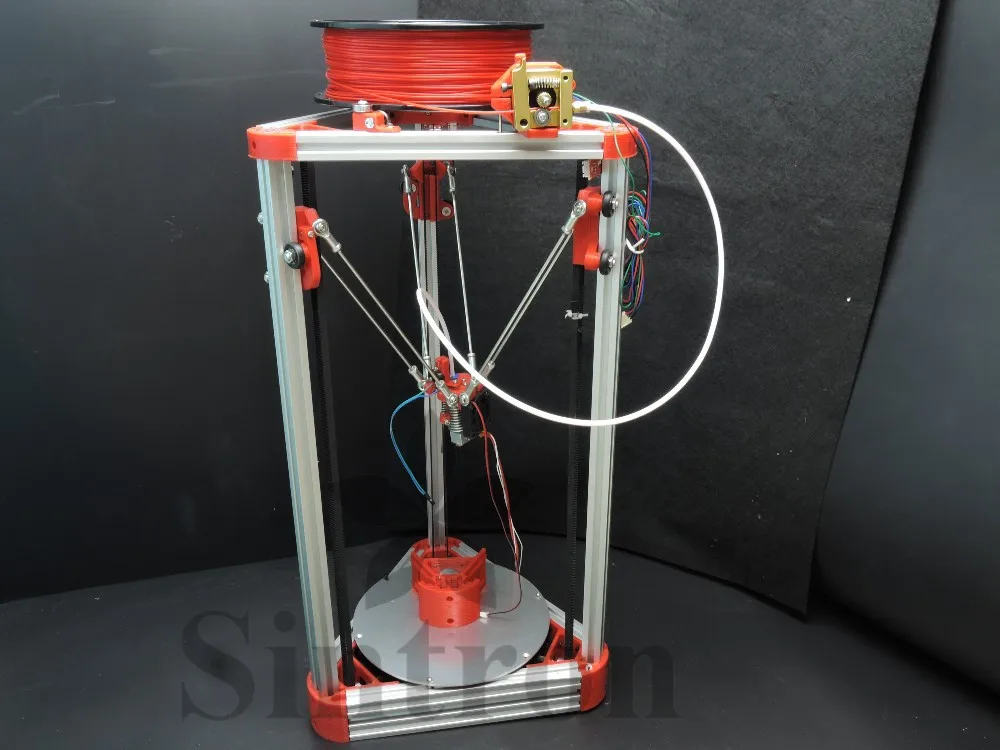

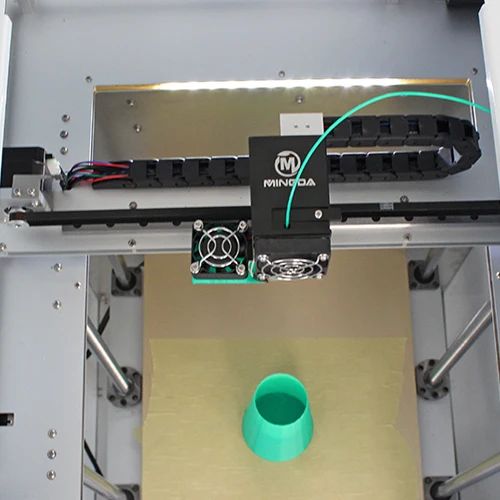

3D scanner for CNC provides a wide range of functions that are performed by numerical control. Used in many industries, from medicine to reverse engineering. With its help, you can build a three-dimensional model of a wide variety of parts as accurately as possible.

Used in many industries, from medicine to reverse engineering. With its help, you can build a three-dimensional model of a wide variety of parts as accurately as possible.

Contents:

- 1 What is a 3D CNC Scanner?

- 2 TTX

- 3 Construction

- 4 Applications

- 5 Step by step installation instructions

- 6 Pros and cons

What is a 3D CNC Scanner?

Scanners of this type allow you to recreate the correctness of the digitized part, which occurs by measuring the geometry of specific parts. It immediately provides an answer to the question: "Does the new component correspond to the original parameters of the product?". Such control of the manufactured goods reduces the risk of defective items. And also to minimize inaccuracies in the sizes.

The device helps to reproduce complex details. Even if they are sold manually from soft raw materials (plasticine is a good example). A similar method is actively used in the production of various decor. More responsible tasks lie ahead for industrial 3D scanners for CNC. Models of this configuration are distinguished by the accuracy and speed of their scanning.

More responsible tasks lie ahead for industrial 3D scanners for CNC. Models of this configuration are distinguished by the accuracy and speed of their scanning.

performance characteristics

Sensors built into CNC scanners have the following performance characteristics:

- measurement from 5 to 1200 millimeters;

- maximum value measurement frequency 16150 Hz.

Digital interfaces are:

- Virtual COM port.

- Ethernet 100 Mb.

- RS232 and RS485.

- CAN 2.0A, 2.0B.

Analog inputs for programming:

- .5mA (load ≤ 2800Ω)

- .10mA (Load ≤ 1400Ω)

- .20mA (Load ≤ 700Ω)

- .20mA (Load ≤ 700Ω)

And the following characteristics are also provided:

- several modes of data buffering, namely by synchronizing signal or time;

- built-in buffer for storing up to 40 thousand measurements;

- it is possible to connect positioning signals for up to two axes;

- has four galvanic inputs and two outputs;

- many models are IP67 rated;

- supply voltage is five volts;

- stepper motor signal buffering is present.

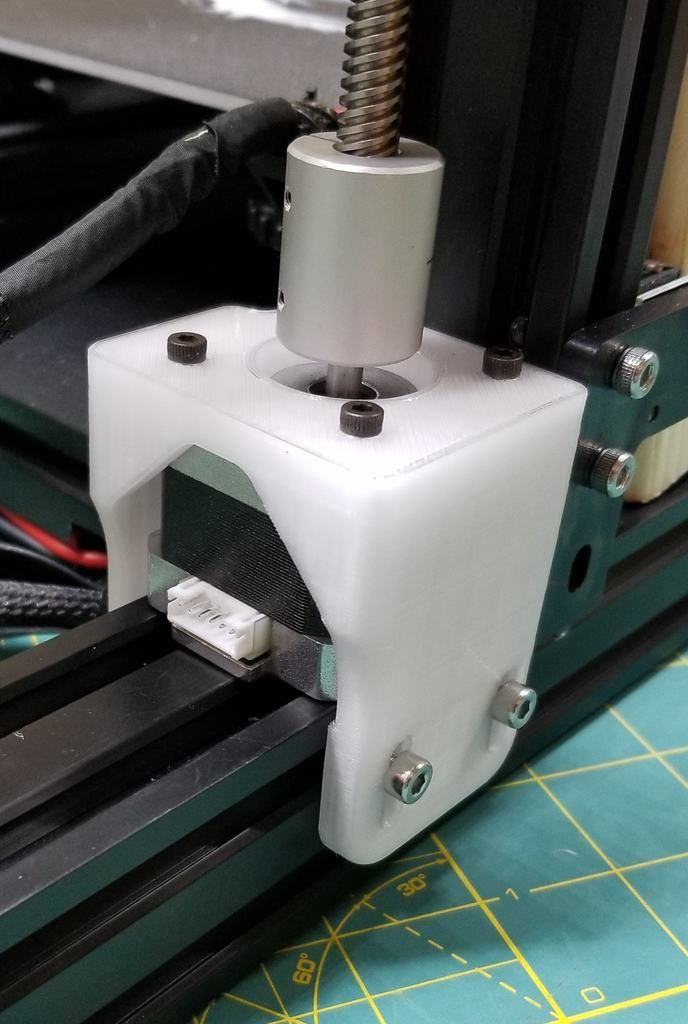

Construction

With regard to construction, this device is divided into three subsections. They differ in the specifics of the mechanism and are expressed in the following forms:

- System with fixed components. And also with high precision angle type sensor. The measuring arm is positioned at the end, providing mathematical calculations that are directly related to the rotation of the wrist. Suitable for probing interior or recessed spaces with several small inlets.

- Inside the carriage is a perpendicular measuring arm. During the sliding of the hand on the carriage, axial displacement occurs. The optimal system is used for convex curves or flat surfaces.

- The third form implies a combination of the two above. So the manipulator is combined with the carriage. Allows you to get more voluminous and large-scale objects that have internal planes.

Or overlap one another with a surface.

Or overlap one another with a surface.

Applications

The use of the 3D CNC scanner is spreading across multiple industries at the same time. Professional equipment belongs to different fields of activity: science, business, medicine, production and design. The following usage solutions are common:

- Automotive. Designing cars or motorcycles. Their repair and tuning.

- Architecture. Scanning entire buildings, facades or individual rooms.

- Media sphere, advertising and design. Allows you to produce the kind of material. Develop graphics for advertising or design.

- Dentistry, medicine. Precise scanning of various parts of the body. Preparation of prostheses and dental implants.

- Oil and gas industry. Monitoring the wear of a pipe system or scanning areas for their laying.

- Science and education. Solving various problems for educational purposes. Scientific measurements, preparation of constructors and designers to work with large design tasks.

- Industry. production tasks. Design development. Quality control of manufactured products. Precise control over the dimensions of components. More simplified assembly of overall equipment and mechanisms.

- Engineering. Accurate marking for further design and preparation of design documentation for production work.

Step by step installation instructions

- Sensor installation. On the machine, you need to install the sensor so that it has the ability to move simultaneously on two axes. They must be mutually perpendicular. More often this is the situation with the X and Y axes.

- Connecting the sensor to the machine. There are two options for this step. The first involves working with signals on the CNC controller. The second works with quadrature axes A and B.

- Power connection. Cheaper modifications are powered exclusively from the USB port.

Industrial sensors can be provided not only by this. But also the power supply. Moreover, power sensors have a voltage of up to five volts. It is also possible to consider the option of a galvanically isolated sensor power supply (9–36 volts).

Industrial sensors can be provided not only by this. But also the power supply. Moreover, power sensors have a voltage of up to five volts. It is also possible to consider the option of a galvanically isolated sensor power supply (9–36 volts). - Connect the sensor to the computer. To scan qualitatively, connect the sensor together with the USB virtual COM port. You can also use the Ethernet port. The latter option has the advantage of a higher exchange rate. For USB, the advantage is that there is no need for an external power supply. But the cable length will need at least five meters, according to the USB specification.

- Establish communication with the encoder. Run the installed program and confirm the connection with the "Connect" button. After that, you can go to the connection settings by selecting the "RS232/RS485/USB" tab. This is important for those wishing to work via aorta COM or USB. You can also select "Ethernet" if you plan to operate via Ethernet.

Pros and Cons

| Pros | Drawbacks |

|---|---|

| Good value for money. | Difficulty setting. |

| High precision. In the production of parts, every millimeter is controlled. Allows you to work with complex geometry. | Regular inspection required. |

| Fully autonomous operation can be configured. | |

| Easy to use once you understand the settings. Instructions are included with the models. |

There are many more key benefits. This can guarantee the popularity of application in all industries. From medicine to engineering.

From medicine to engineering.

Share on social networks

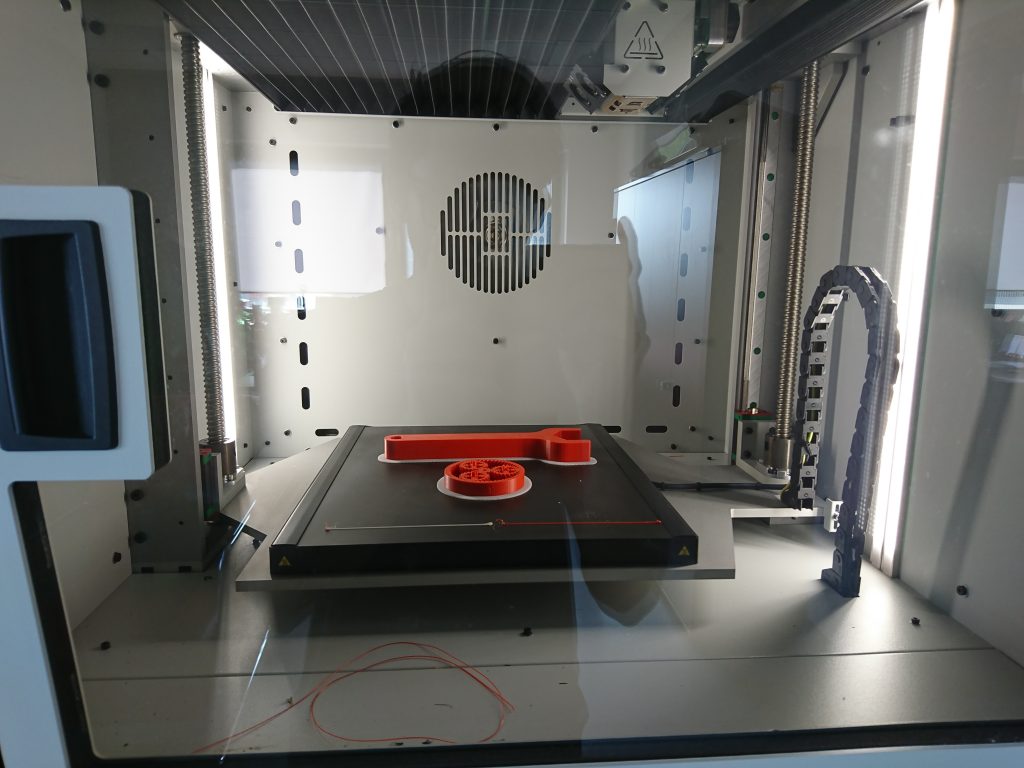

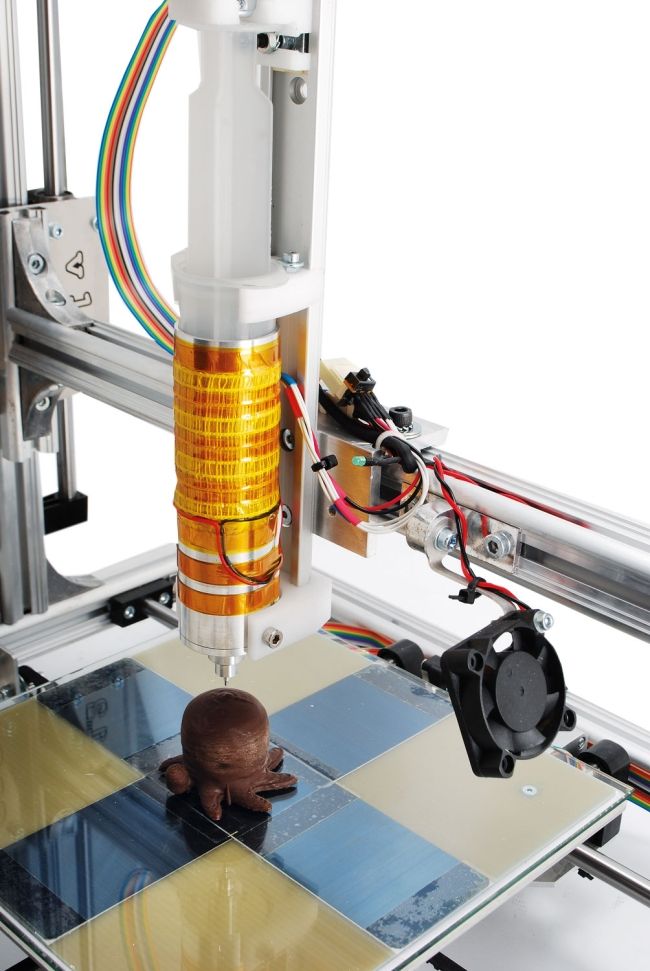

CNC furniture: Custom design with 3D scanning with EinScan

Throughout the history of mankind, the methods of creating and manufacturing things have constantly changed. Especially in the last 200 years, the way products are designed and manufactured has changed a lot and has had a major impact not only on the materials being processed, but also on the perception of the product by the customer. Today we are seeing a growing demand for product personalization, primarily in the area of consumables, but increasingly also in other areas, as we can learn from the following example of custom-made furniture:

With over 10 years experience in reverse engineering and metrology, Voxel 3D focuses on selling 3D digitizing equipment and offers scanning and manufacturing services. One of the important activities is the combination of 3D scanning and CNC wood carving in the furniture industry. Having successfully completed a wide range of such CNC furniture production projects, Voxel 3D has become a well-known organization that offers its customers not only 3D digitization, furniture design and production services, but also launched into the wide production of products created by 3D scanning, design and wood carving of furniture using a CNC machine.

One of the important activities is the combination of 3D scanning and CNC wood carving in the furniture industry. Having successfully completed a wide range of such CNC furniture production projects, Voxel 3D has become a well-known organization that offers its customers not only 3D digitization, furniture design and production services, but also launched into the wide production of products created by 3D scanning, design and wood carving of furniture using a CNC machine.

Mohamad Khalaj Amirhosseini, Founder and Owner of Voxel 3D, with a degree in mechanical engineering from university and experience in metrology and reverse engineering, realized early on the importance of a reliable, competitive and affordable 3D digitization product not only for his company , but also for its customers and project partners for resale. Since 2010, when the business relationship with SHINING 3D was established, Voxel 3D has been championing the versatility of EinScan 3D scanners among its customers and business partners, and is an expert regularly referred to in its region when it comes to products. SHINING 3D.

SHINING 3D.

“We chose SHINING 3D because of the excellent value for money for the manufacturing industry, as well as their excellent service and warranty. Their first-class support has helped us become a confident brand ambassador.”

Mohamad Khalaj Amirhosseini

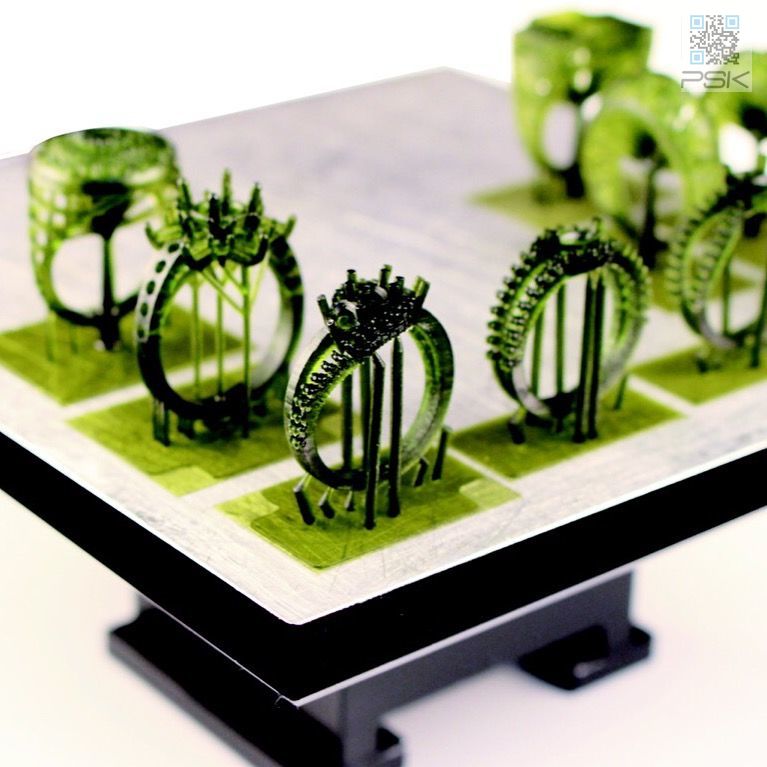

First, the parts to be digitized are cleaned, and if they have a shiny surface, they are prepared for scanning with developer powder. They are then scanned using the EinScan Pro 2X Plus multifunction handheld 3D scanner.

After the scanning process is completed, the mesh files are edited in Geomagic Studio. Holes are filled, surfaces are smoothed, edges are sharpened, and the object is scaled according to the requirements of the project. Finally, the project is saved as an STL file for CNC furniture production.

CNC furniture manufacturing

The resulting STL file is imported into the Autodesk powerMILL software and the CNC furniture is cut based on the G-code into which the STL file has been converted.

The price depends on the performance characteristics. There are cheaper models, and there are professional options. The second option is used in the industrial sector. Cheaper options are a solution for advertising and non-standard small tasks.

The price depends on the performance characteristics. There are cheaper models, and there are professional options. The second option is used in the industrial sector. Cheaper options are a solution for advertising and non-standard small tasks.