Matter and form 3d scanner

Review: Matter and Form 3D Scanner from Jaycar (Updated with new info AND a new majorly DISCOUNTED price)

STOP PRESS: PS: As of tomorrow, the 27th December, you can buy the Matter and Form 3D scanner from Jaycar in Australia for AUD $999, a saving of AUD$500. BRILLIANT BARGAIN.Read the review below. And you can buy online at www.jaycar.com.au

There is a major addendum to this story below… and this IS important…

After waiting for months – 9 to be precise – I finally managed to get the part I needed to make my Skywatcher telescope operational again.

The telescope – a 650mm Newtonion reflector telescope – was a present from Jacqui to me when we first got back to Western Australia just over 4 years back, and later sadly, by accident it got knocked over and the focussing mechanism was damaged.

This was about 6 months into the COVID dramas last year, and the Australian distributors, TSA informed me that there would be a large delay on getting the spare part due to the Chinese factories simply not able to produce these sorts of goodies in a reasonable time frame.

Anyway, last week it turned up and I reassembled the whole thing, and it is working perfectly. Except for a small, but annoying irritation.

The lock on one of the tripod legs has gone AWOL and so moving the beast around is difficult with a single leg flaying around the place; the whole scope assembly with counterweights etc added is no lightweight either.

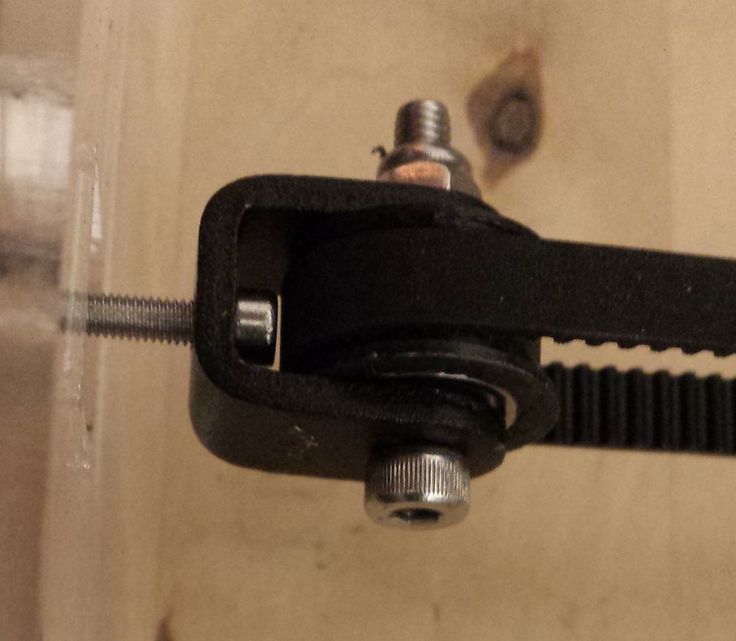

The locking mechanism is an 8mm fine threaded bolt with a plastic “key” head. The bolt part was a bit tricky to find as Mr Bunnings didn’t stock that type and I eventually ended up at a company called Konnect who had them off the shelf.

So all that remained was the plastic “key” part.

Which leads me nicely to the Matter and Form (MaF) 3D scanner, available from Jaycar stores (where else?)

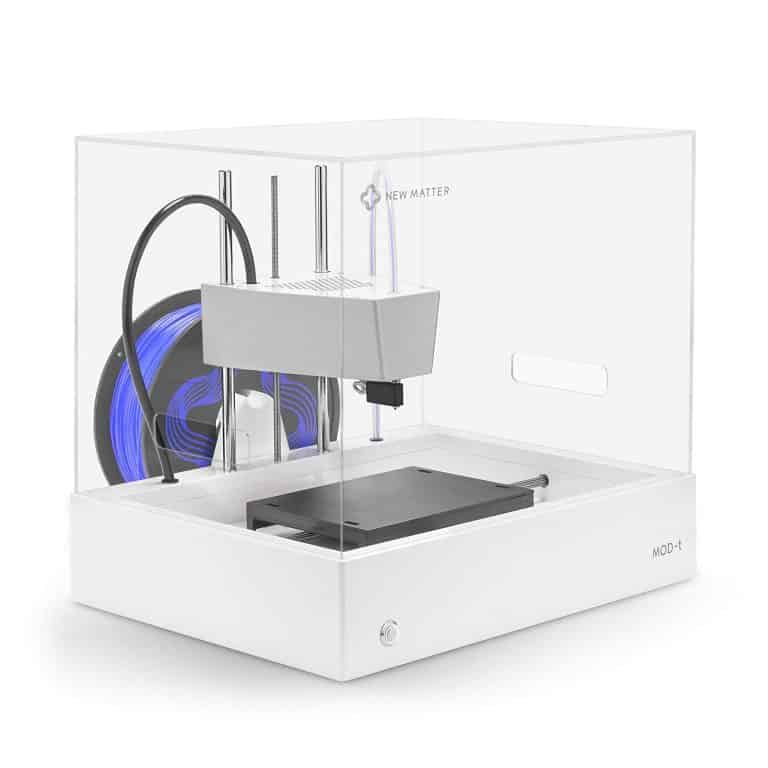

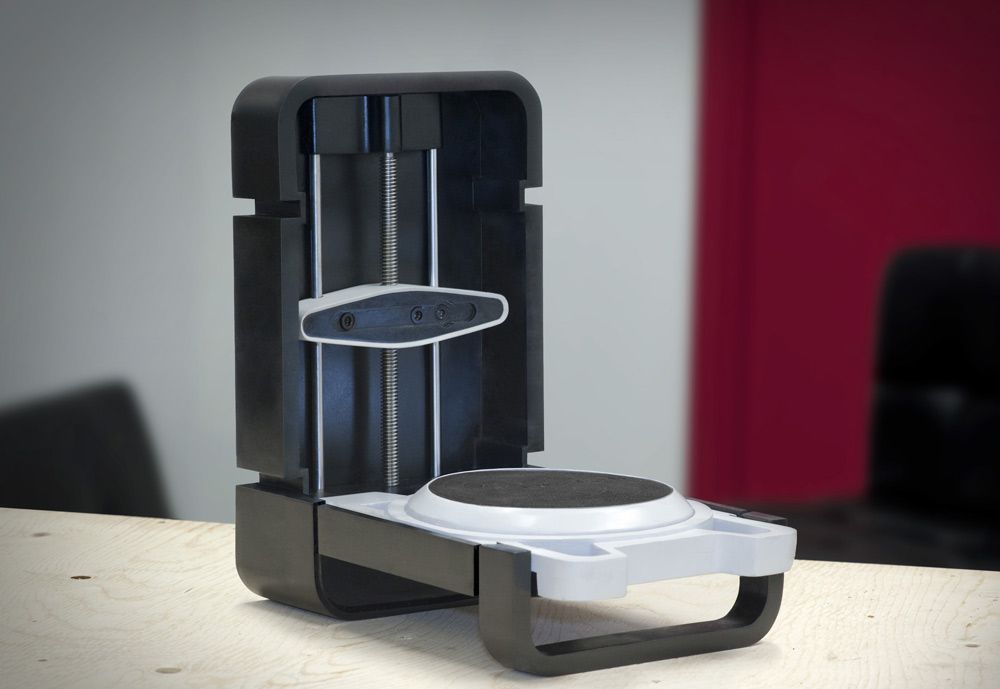

Priced at $1499, this unit contains a scanning head on a pair of threaded rods and a turntable. Allowing scans of up to 25cm height, a diameter of 18cm and a weight of 3Kg, it is ideal for smaller hobbyist tasks and for the home handyman.

And of course there are innumerable other uses that probably go into the realms of copyright breaking so I won’t go there …

The scanner is connected to the Mac / PC via a high speed 2.0 USB B cable as used by most printers. I substituted the original with one of my own as I found it was too short for practical purposes.

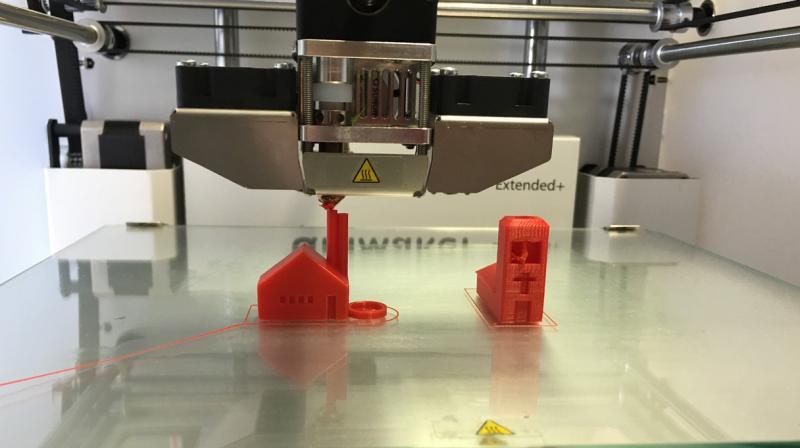

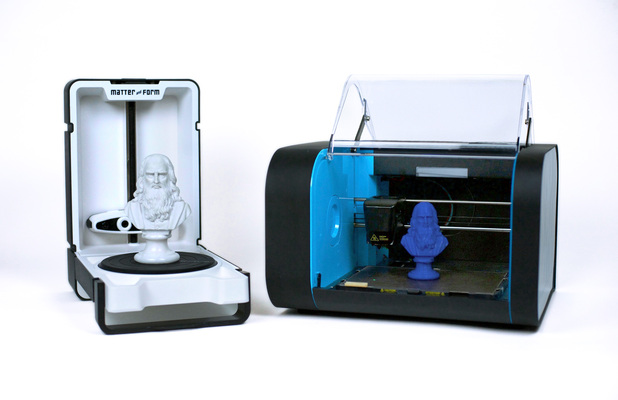

To create a scan, the Matter and Form scanner has its own software package called MF Studio. Available for both Mac and PC, this software lets you perform multiple scans of an object placed on the turntable to create a composite model that can be exported as an STL file for 3D printing or as other file types such as OBJ for further manipulation in a package like Blender or in my case, Cinema 4D.

The stated accuracy by the way is said to be +/- 0.1mm which is pretty impressive.

The key to a successful scan as I found, is lighting.

Let me explain.

When setting up the scanner, you need to go through a calibration process using a supplied calibration card placed vertically on the turntanble. This takes about 10 minutes and may, as it did in my case, fail in the first few attempts for some reason.

This takes about 10 minutes and may, as it did in my case, fail in the first few attempts for some reason.

When actually setting up for each scan, you need to “fine tune” the laser reader for this specific scan so that you end up with a solid vertical green bar showing on the subject. This is done by setting the aperture of the scanner correctly with a slider, along with the right amount of ambient light and it coming from the right direction.

It takes a bit of trial and error as a scan is not a rapid process and it may take a few goes to get it right. I suspect practice makes perfect in this case.

Thankfully, a Quick Scan option lets you run a sort of trial to see how accurate it is going to be.

A second slider lets you further fine tune if texture and colour matching is required, but I found I will rarely use that option. You can also set the minimum mand maximum heights of the scan head for each scan as well as the amount of 360° rotation used.

When all is correct, clicking the scan button starts the process. As the scan proceeds, you can rotate the image in real time to get an idea of how it is all coming together.

As the scan proceeds, you can rotate the image in real time to get an idea of how it is all coming together.

As I said, this is not a quick thing, and my initial scan of the key head for the tripod lock took nearly ¾ of an hour. A subsequent further two scans were needed to “fill in the holes” so to speak”.

Addendum: Matter and Form has pointed out to me I used the “version 1” system to perform this scan. By switching to Quickscan, which I wrongly assumed to be a sort of preview system, a different laser and part of the software is used and what took 45 minutes was down to mere minutes.

(The object here is a “Sonic Screwdriver” from “Dr Who ” and was my first attempt – a tad ambitious perhaps.)

Once a set of scans is completed, you then merge them to make the completed object. There are cleaning tools to remove any stray points the scanner may have picked up in the process as well as cropping tools.

The scan creates the 3D model using what MaF call the “Point Cloud” and is essentially a representation of the model using pixels as against vectors as used in 3D software.

You can view the completed object as a Point Cloud or as a Mesh with texture.

The scanned image can then be exported as a Point Cloud file in PKY or XYZ formats or as a Mesh using STL, OBJ, DAE, PLY or gITF2.

I found the scanner to be quite easy to setup and use, but the downside is you will need some practice to get the best from it. My advice is to get a nice simple object and simply have a play on a rainy afternoon (or in Western Australia at the moment where it is 40 degrees C +, a nice airconditioned room).

In the box MaF supply a “plastic toy” for this very purpose, in my case a little yellow rubber duck. This is also used in the very good tutorial shown below. The website at https://matterandform.net/ too has a lot of information and tips to get you up and running.

Play around with different lighting and apertures and make a note of each setting for each scan, and this way you’ll get an idea for future more complex scans.

This is not a dissimilar method to the tutorial I wrote a few years back on understanding depth of field coincidentally.

So how did my key lock go? In truth, as I needed it pretty quickly in order to try and get some shots of the “Christmas Comet”, I used Cinema4D to make a quick and dirty one, but I aim to master this scanner for some ideas I have in other areas.

So yes, it is on my shopping list for Christmas… If you want to buy one, then you can order online at https://www.jaycar.com.au/desktop-3d-scanner-v2-with-quickscan-software/p/TL4420 or any Jaycar store should have one in stock.

PS: As of tomorrow, the 27th December, you can buy the Matter and Form 3D scanner from Jaycar in Australia for AUD $999, a saving of AUD$500. BRILLIANT BARGAIN.

Like this:

Like Loading. ..

..

Matter and Form 3D Scanner

Notes from the Workshop:

The Matter and Form team will soon be releasing their new products known as Cashew and Bevel. Cashew is an online platform for users to upload their 3D files and have the option of sharing or selling via storefront to other members in the community. Bevel is the first smartphone attachment capable of capturing physical objects in full 3D, otherwise known by the team as “Genuine 3D Photography”. Using an eye safe laser, users can pan around an object, take pictures of each angle, and quickly combine and convert the images into a 3D printable file.

Emphasizing compact design with affordability, the Matter and Form tabletop 3D scanner is ready to use out of the box; boasting high resolution scans in under 5 minutes. Objects can be processed in full color thanks to a built-in, commercial grade, HD camera capable of capturing up to 2,000 points per second via 360° turntable. The Matter and Form 3D scanner provides rapid processing of objects as point clouds are instantly generated in real-time. With a 0.08 cubic meter scan volume, Matter and Form has created a robust unit that yields a small desktop footprint; easily transportable thanks to an integrated carry case built directly into the unit. This scanner is designed for streamlined workflow, worry-free setting adjustments, and easy creation of watertight meshes for 3D printing.

With a 0.08 cubic meter scan volume, Matter and Form has created a robust unit that yields a small desktop footprint; easily transportable thanks to an integrated carry case built directly into the unit. This scanner is designed for streamlined workflow, worry-free setting adjustments, and easy creation of watertight meshes for 3D printing.

At under 3.77 lbs (1.71 kg), the Matter and Form scanner is both lightweight and easy to handle for storage or deployment on any workspace. The unit’s case is integrated directly with the scanner’s camera and turntable, easily folding together. Tethered to a PC via USB, Matter and Form features a simple one-time setup process to get started. The moving CMOS HD camera, combined with dual lasers to scan rotating objects, creates a dependable combination of performance for home or office needs. Capable of handling objects up to nearly 10” in height, this 3D scanner packs ample punch despite its discreet size.

The Matter and Form 3D scanner’s adjustable color output allows users to generate high resolution surface details for smooth or rugged objects. The 7.0” (18 cm) diameter turntable steadily rotates and as the sensor utilizes a full 360° field of view. While compact in size, the scanner’s turntable motor will still accommodate objects up to 6.6 lbs (3.0 kg) and capture details as small as 0.43 mm. It’s fully assembled and ready to go, giving users the ability to create digital 3D representations at the click of a button.

The 7.0” (18 cm) diameter turntable steadily rotates and as the sensor utilizes a full 360° field of view. While compact in size, the scanner’s turntable motor will still accommodate objects up to 6.6 lbs (3.0 kg) and capture details as small as 0.43 mm. It’s fully assembled and ready to go, giving users the ability to create digital 3D representations at the click of a button.

Each unit is bundled with Matter and Form’s OEM scan software that’s compatible with Windows or OSX. Developed with custom meshing algorithms to optimize performance, users can create watertight meshes instantly that are converted to STL and ready for 3D printing. At under $600.00, the unit is an easy choice for those who understand the balance between cost and resolution in a small package. Matter and Form makes high quality scanning easy, fast, and accurate for a variety of applications.

With Matter and Form scan software, you can also combine two different scans of the same object. This ensures that any missing features from the first scan attempt can be filled in with features captured at a different angle during the second scan attempt. In future updates, new tools will be developed that allow misaligned combined scans to be merged together permanently.

In future updates, new tools will be developed that allow misaligned combined scans to be merged together permanently.

With over 10,000 units sold worldwide, the team at Matter and Form combines design and programming with value. Since 2014, Matter and Form has made it their goal to provide high-resolution 3D scanners to those who could not afford professional grade units at premium prices. Backed by an extensive reseller program and key distribution partners across the globe, Matter and Form has established itself as a formidable player for affordable 3D scanning.

how to assemble a 3D scanner from scrap materials and digitize reality — T&P

The first 3D printers that cost less than a gaming computer have become a mandatory attribute of almost any hackspace or fablab (laboratory of technical creativity and electronic art). Now 3D scanners have joined them. MIPT student and employee of the Polytechnic Museum Daniil Velovaty himself assembled a three-dimensional scanner from a laser, a webcam, and scrap materials.

As part of the special project Phystech. Reader" he told T&P about the future of reality scanning. nine0003

As part of the special project Phystech. Reader" he told T&P about the future of reality scanning. nine0003

Daniil Velovaty

It was easy to get used to 3D printers: I drew the desired detail or figure on the computer, loaded it into the printer, and a few hours later I took its embodiment in plastic. Yes, what about plastic, they are already printing in metal, and even in organic matter: they recently printed a living liver. No wonder you want to go further. The next step is scanning. Oddly enough, but before the advent of 3D printers, there was no great need to transfer a real object to the digital world: the creators of games and films simply hired artists who drew whatever was needed. The need for scanners arose only when it was important to convey the relief and shape of an object with very high accuracy. At the same time, neither the duration of the scan nor the cost were often completely unimportant. This is how the first representatives of 3D scanners appeared: lidars. nine0007

nine0007

Lidar (from English Light Detection and Ranging) is an expensive but very accurate device. It allows you to build 3D models of objects with an accuracy of millimeters, the size of which can be compared with the size of a building. From the decoding of the abbreviation LIDAR, it follows that it is any rangefinder that measures distance using light. An incredible number of devices fall under this description. But most often, devices like this are called lidars:

A special system of mirrors is placed inside the device. A phase laser rangefinder is installed here, which measures the distance using a laser, and two mirrors serve to deflect the laser beam in two planes. Thus, the ray runs through a certain sector of space and builds its 3D model. As you might guess, the speed of such a scanner depends on the speed of the rangefinder and the speed of rotation of the mirrors. And since all this is quite complex equipment that requires fine tuning, it costs quite a lot of money. It is much more profitable to order a scan than to buy the machine itself. Moreover, you still need to figure out how to use it. nine0007

It is much more profitable to order a scan than to buy the machine itself. Moreover, you still need to figure out how to use it. nine0007

As industrial devices were, to put it mildly, beyond the reach of the average consumer, and the need to scan reality grew, cheap desktop and handheld 3D scanners appeared. The former, as a rule, have a turntable on which the object under study is placed. A few minutes after the start of the scan, we will get the finished model. Of course, the scan quality and the size of the scanned area are incomparable with lidars, but they cost several orders of magnitude cheaper. It is to this class of devices that the scanner we developed belongs. The main problem with these scanners is that the object to be scanned must fit on a turntable, which greatly limits the scope. Another significant disadvantage of these scanners is the incompleteness of scanning and blind spots. If, for example, you try to scan a vase, the scanner will only see its outer part, and not the cavity inside. nine0007

nine0007

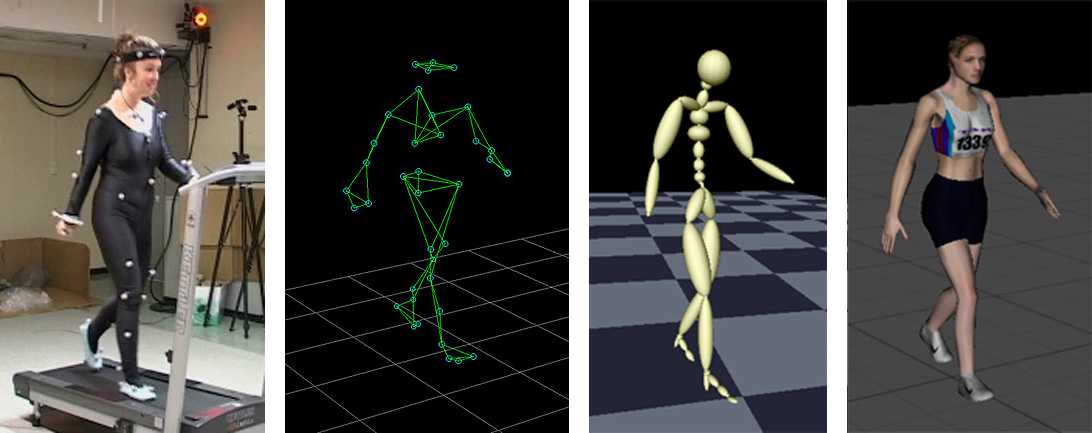

The second type of scanners are handheld 3D scanners. They need to be moved around the object by hand, but they build a model with the help of cameras. The operation algorithm of such scanners is much more complicated, they are more expensive, and the quality of the result is worse, but they allow you to scan large objects and spend less time on it. They look something like this:

One of the main advantages of such a scanner is that it is not limited by the scanning area. We can scan, for example, a person's face without having to place their head on a turntable. With a certain diligence, even an entire room can be scanned, if only the positioning accuracy allows it. To improve accuracy, you can stick special marks that the scanner finds and uses as reference points. Actually, in the photo above, this is what was done. This approach limits the scanning area, but, unfortunately, here either the sheep are safe or the wolves are full. nine0007

In our lab, we decided to create a cheap 3D scanner with an accuracy comparable to that of 3D printing. This was our first serious project, so we made mistakes, misunderstood a lot, and learned even more along the way. We first built a simple laser rangefinder using a laser pointer and a webcam. To understand how a 2D camera can measure distance, you have to use your imagination. Imagine a thread stretched in the air, along which a spider is crawling. If we stand close to the rope, we see how the spider is crawling straight towards us (not a very pleasant sight). And if now we shine a lamp on this whole structure from the side, we will see a shadow on the floor. Since the light comes from the side, the projection of the spider will move along the projection of the thread. By measuring the distance from the beginning of the thread's shadow to the spider's shadow, we can calculate how far the spider has crawled by multiplying by some factor, because we are creating a contraction mapping. nine0007

This was our first serious project, so we made mistakes, misunderstood a lot, and learned even more along the way. We first built a simple laser rangefinder using a laser pointer and a webcam. To understand how a 2D camera can measure distance, you have to use your imagination. Imagine a thread stretched in the air, along which a spider is crawling. If we stand close to the rope, we see how the spider is crawling straight towards us (not a very pleasant sight). And if now we shine a lamp on this whole structure from the side, we will see a shadow on the floor. Since the light comes from the side, the projection of the spider will move along the projection of the thread. By measuring the distance from the beginning of the thread's shadow to the spider's shadow, we can calculate how far the spider has crawled by multiplying by some factor, because we are creating a contraction mapping. nine0007

Our scanner works in much the same way. Only instead of a thread - a laser beam, and instead of a screen with a shadow - a camera. Just as a spider moves along a thread, a spot moves along the laser beam, which occurs when this beam encounters an obstacle. Having found the position of the spot in the photograph, we can determine the distance to the object on which this spot is located. In words, it is difficult. It looks simpler in the picture:

Just as a spider moves along a thread, a spot moves along the laser beam, which occurs when this beam encounters an obstacle. Having found the position of the spot in the photograph, we can determine the distance to the object on which this spot is located. In words, it is difficult. It looks simpler in the picture:

The farther the wall, the closer to the dotted line will be the pfc point on the camera matrix

But such a rangefinder measures the distance to a single point, and this takes a very long time. Therefore, we put a lens on the laser, which turns the laser spot into a laser line. Now we measure the distance to hundreds of points at once (after all, a line can be represented as a set of points), it remains to build a system that allows this line to go through the entire object, and for this we need a turntable on which the object is placed.

The scanner itself is assembled from plywood pieces that have been laser cut. To rotate the table, a stepper motor is used, which is controlled by a board developed by us. It also controls the brightness of the laser and backlight. nine0007

It also controls the brightness of the laser and backlight. nine0007

The image from the camera is processed on a computer; a Java program was written for this. After scanning is completed, the program generates a so-called point cloud, which, using another program, are combined into a full-fledged model. This model can already be printed on a 3D printer, that is, a copy of a real object can be obtained.

Don't miss the next lecture:

Theory and practice

Tags

#3D printers

#MIPT

#Technologies

-

9 357

Select 3D scanner: Types, advantages, Tasks solved

3D-scanners

Fundamentals 3D

reverse engineering

9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 9000 Best by Topic

Automation of Quality Control

Author: Semen Popadyuk

Author: Semyon Popadyuk

Benefits of 3D Scanners | What tasks does 3D scanning solve | Criteria for choosing a 3D scanner | Professional 3D scanning for fast and efficient production solutions nine0007

Modern 3D scanners have a wide range of features and a variety of functionality. They are used everywhere - in manufacturing, construction, education, the entertainment industry and are used even in everyday life. In order to choose the scanner that suits your needs, there are a number of aspects to consider, which we will discuss in this article.

They are used everywhere - in manufacturing, construction, education, the entertainment industry and are used even in everyday life. In order to choose the scanner that suits your needs, there are a number of aspects to consider, which we will discuss in this article.

Order a free test 3D scan using equipment from the world's leading manufacturers:

Leave a request

Benefits of 3D scanners

What is a 3D scanner? This is a device designed to quickly analyze a physical object and create its accurate 3D computer model. The principle of its operation is based on calculating the distance to the object using two cameras. In addition to the cameras, a backlight is used - LED or laser.

3D scanners are classified both according to their form of execution (stationary and portable) and according to the areas of use, mainly divided into professional and household. nine0007

Watch the video review series of the ZG AtlaScan handheld 3D laser scanner

3D scanners make it possible to significantly reduce the time and costs at the development stage, improve the quality of products and, ultimately, speed up the release of the product to the market. They can be used at any stage of product lifecycle management and will help to optimize the production process of enterprises in various industries, including: nine0007

- automotive,

- mechanical engineering,

- aerospace industry,

- oil and gas industry,

- shipbuilding,

- construction and architecture,

- arts and culture,

- medicine,

- jewelry,

- science and education.

3D scanning devices remove many of the limitations of traditional measuring equipment. Such tools familiar to the metrologist as templates, micrometers, calipers are inexpensive, but they are characterized by subjective readings and are not suitable for complex measurements. Coordinate measuring machines are more accurate than 3D scanners, but they are more expensive, larger, and require specialized operator training. nine0007

Such tools familiar to the metrologist as templates, micrometers, calipers are inexpensive, but they are characterized by subjective readings and are not suitable for complex measurements. Coordinate measuring machines are more accurate than 3D scanners, but they are more expensive, larger, and require specialized operator training. nine0007

Optical inspection systems, which include 3D scanners, are the best solution in terms of price and quality, as they provide:

- measurement speed,

- high precision digitization of objects of complex geometry,

- can work autonomously,

- are easy to operate.

Thanks to a 3D scanner, the work of a designer, technologist, and constructor is greatly facilitated: the performance of time-consuming complex measurements and the creation of a design from scratch are a thing of the past. nine0007

nine0007

What tasks does 3D scanning solve?

- Quality control: the ability to check any geometric parameters, including input and output control, metrological control of parts and production equipment.

- Reverse engineering of products for prompt receipt of project documentation and product upgrades.

- Design and simulation for the purpose of prototyping and evaluation of the appearance of products, modernization of production facilities and equipment. nine0054

- Digital archiving of any required assortment (eg discontinued parts). Models stored in digital libraries are available remotely from anywhere in the world.

3D scanner selection criteria

The main criterion is scanning accuracy . High-precision devices (10-30 microns) will help to get a phenomenal result: they are able to transfer the most complex surface geometry into 3D with minimal errors. Such 3D scanners are used in reverse engineering, quality control, medicine, and are used to digitize molds, device parts, etc. 3D scanners with an accuracy of 30–100 engineering. nine0007

3D scanners with an accuracy of 30–100 engineering. nine0007

ZG AtlaScan is the world's first 3D scanner with hole capture

When choosing a 3D scanner, you should also take into account resolution (detail) , i.e. the degree of discreteness that is available when digitizing an object. The highest level of detail allows you to display the smallest elements in the 3D model.

Р the size of the scanned objects and, accordingly, the mobility of the 3D scanner directly depend on the type of device that you select. When digitizing parts and objects of small and medium parameters, hand-held scanners are usually used. Stationary scanners are suitable for capturing complex small and medium-sized products with small details. Scanning of large objects (buildings, structures, communications) is performed using ground-based laser devices (range finders).

When studying the functionality of 3D scanners, pay attention to such points as the conditions of use, scanning speed, the surface of the scanned object, and color. nine0007

nine0007

Please note that the next step after scanning is to obtain and further work with the CAD model, and for this you will need specialized software.

Processing 3D Scan Data for Reverse Engineering in Geomagic Design X Software

Professional 3D scanning for fast and efficient production solutions

iQB offers cutting-edge solutions that successfully operate in leading enterprises around the world: nine0007

- Portable devices for metrological 3D measurements from ZG Technology (China). The line includes a wide range of instruments, from an affordable handheld 3D scanner to a powerful optical tracking measurement system, as well as photogrammetry and portable CMM. ZG's unique strengths include the world's first handheld MarvelScan solution with three cameras for markless laser scanning and tracker, and proprietary instant hole capture technology. ZG Technology 3D scanners provide measurement speed up to 1 million 350 thousand points per second and accuracy up to 0.

01 mm. nine0054

01 mm. nine0054 - Stationary Russian-made RangeVision PRO 3D optical scanner is an industrial solution for metrology, available to companies of any level. The device is designed to digitize objects from 1 mm to 5 m and offers the highest level of accuracy (up to 0.018 mm) and 3D resolution (up to 0.04 mm). This is the first domestic 3D scanner approved by the Federal Agency for Technical Regulation and Metrology as a type of measuring instrument.

- Creaform handheld 3D scanners for digitizing products ranging in size from a few centimeters to 6 meters. The Go!SCAN series devices (including the latest Go!SCAN SPARK) are based on structured illumination technology; HandySCAN 3D and MetraSCAN 3D are laser devices that are certified industrial grade metrology tools. The new generation MetraSCAN BLACK|Elite model is the fastest handheld 3D laser scanner on the market (1.

8 million measurements per second). The volumetric accuracy that Creaform technology can provide is up to 80 microns per 16 cc. m.

8 million measurements per second). The volumetric accuracy that Creaform technology can provide is up to 80 microns per 16 cc. m. - Creaform also produces 3D scanners and software under the peel 3d brand, combining affordability, ease of use and high quality. The line is designed to solve the problems of reverse engineering and digitalization of objects in such areas as art, preservation of cultural values, consumer goods, science and education, human body scanning. Peel 3d devices are capable of measuring objects from 0.3 to 3 m with an accuracy of 0.1 mm.

RangeVision PRO Fixed Scanner Creates Yamaha R3 Sport Fairings with Improved Aerodynamics, High Strength and Lighter Weight nine0007

- Solutionix fixed optical 3D scanners for small objects (10-500 mm) with many small parts. Allow to receive an error less than 8 microns.

- FARO Focus 3D geodetic laser scanners perform fast and accurate scanning of large objects, complex structures, premises and landscapes. They operate in the range from 0.6 to 350 m, they are distinguished by increased accuracy, ease of operation and the ability to operate in the most difficult environmental conditions.

nine0054

nine0054 - EPiC budget 3D terrestrial laser scanners are based on the principles of simplicity, convenience and affordability. Their main advantages are super light weight, high shooting speed (from 30 to 90 seconds), 360-degree panoramic camera and the ability to control from a mobile device.

Many of the above scanners are included in the register of measuring instruments of the Russian Federation and have the appropriate certificates.

nine0004 A variety of 3D scanning devices on the market will allow you to choose exactly the model that is needed for solving specific problems. The price range is also wide: from simple devices costing up to $500 to high-precision professional 3D scanners costing tens and even hundreds of thousands of dollars.