Deal extreme 3d printer

FDM 3D Printers on Sale Now

CHECK BACK OFTEN - NEW DEALS ADDED REGULARLY - Can't find the 3D printer deal you are looking for? That's okay. At MatterHackers, we offer the lowest prices guaranteed, so if you can't find the 3D printer you're looking for on the sale page, rest assured knowing that you're still getting the best deals possible.

Guides & Articles

How to Succeed with Quantum Dichromatic PLA Filament

Follow this guide for tips and tricks on how to get the best results when 3D printing with Quantum Dichromatic PLA filament.

How To Succeed with LayerLock SLA Build Surfaces

Successfully achieve strong bed adhesion for Laser, DLP, and SLA resin prints using LayerLock SLA Resin 3D Printing Build Surfaces.

How To Build A Successful Makerspace

Find out the necessary components to create an effective space for your maker community.

How to Succeed When 3D Printing with Polypropylene

Successfully produce 3D printed parts out of polypropylene filament with these tips on achieving stronger bed adhesion and minimizing shrinkage.

Tech Breakdown and How to Succeed: Ionic Hybrid Support Material

Supporting engineering-grade filament has been difficult without a support material dedicated to higher temperature 3D printing. Ionic aims to solve that.

How To Succeed with OBC 3D Printing Filament

From Dow Chemical, OBC combines flexible and rigid into one unique material with properties of both.

How To Succeed with LayerLock Garolite Build Surfaces

Successfully achieve strong bed adhesion for NylonX, NylonG, and standard filaments using LayerLock Garolite Build Surfaces.

How to Succeed with LayerLock Powder Coated PEI Build Plates

Powder coated PEI steel sheets are a great alternative build surface for strong bed adhesion. Here's how you can succeed using this durable build plate.

Here's how you can succeed using this durable build plate.

How To Succeed When 3D Printing With Nylon

Learn how to 3D print Nylon like a pro. Nylon is a stronger and more durable alternative to PLA or ABS and easy to 3D print with using these Tips and Tricks.

How To Succeed When 3D Printing With ASA Filament

Follow this step-by-step guide to learn how to print with ASA, the perfect material for any outdoor projects.

How to Succeed when 3D Printing with Polycarbonate Filament

Follow these helpful steps to start successfully printing with this extremely tough, professional grade material.

How to Succeed with NylonX

NylonX has quickly become one of our favorite filaments for strong, durable, and ready-to-use parts. Here's an in-depth look at Nylon X, and some printing tips to get the most out of this great new material.

Large Scale 3D Printers - Builder 3D Printers

Name

Company

Phone Number

Over 1 x 1 meter in build capacity with the Extreme 3000 PRO

With a build capacity of over 1 meter x 1 meter (XY axis), it is the perfect machine for creating large and full size parts, tools, jigs & fixtures in-house and on demand. Within days you can have a fully functional high quality prototype. Features such as automatic bed leveling, a battery pack and filament detection, make large scale 3D printing worry free. Manufactured to the highest standards.

Within days you can have a fully functional high quality prototype. Features such as automatic bed leveling, a battery pack and filament detection, make large scale 3D printing worry free. Manufactured to the highest standards.

Discover more

Your browser does not support the video tag.3D PRINT FULL SIZE PARTS - TOOLS - PROTOTYPES

IN-HOUSE PROTOTYPING

REDUCE PRODUCT DEVELOPMENT TIME BY WEEKS

Builder Extreme 3000 PRO

IN STOCK

The Extreme 3000 PRO is the perfect fit for industrial 3D printing applications. The extremely large build volume of 1100x1100x820 mm YXZ, allows you to 3D print large and complex shaped parts and prototypes on full scale. The frame has been designed in a way that you have easy access to the build plate from both sides by removing the side panels. 3 different nozzles diameters, 0. 4, 0.8 and 1.2 mm, are included to optimize print quality and time for your specific needs.

4, 0.8 and 1.2 mm, are included to optimize print quality and time for your specific needs.

Find out more

Builder Extreme 2000 PRO

IN STOCK

The Builder Extreme 2000 PRO is one of the tallest industrial 3D printers available today. With a print volume of 700 x 700 x 1700 mm (XYZ), it is the perfect 3D printer for extremely tall objects. Elements such as a 7-inch touch display, filament detection, UPS system that resumes operation after a power outage, door locking system and available extension for a BOFA air filter, make it a fully equipped large format 3D printer.

Find out more

Your browser does not support the video tag.Business Cases

Interested to see how other companies have integrated large industrial 3D printing into their product development process?

Take a look at the different business cases. 54% of our European customers invested in a second, third or fourth Builder Extreme within 6 months after their initial purchase.

54% of our European customers invested in a second, third or fourth Builder Extreme within 6 months after their initial purchase.

From extremely large prototypes to customized mannequins, marketing displays and dinosaurs, industrial 3D printing is great asset for all industries.

View business cases

Builder Extreme 1500 PRO

IN STOCK

The Builder Extreme 1500 PRO is one of the longest industrial 3D printers available on the market. With its unusual large X axis size, it fits perfectly into the smallest office corners. The print volume is 1100 x 500 x 820 mm (XYZ), and the machine is comes with features such as a 7-inch touch display, filament detection system and the UPS system that resumes the print job after a power cut. This combination makes it a fully equipped large format 3D printer.

Find out more

Builder Extreme 1000 PRO

IN STOCK

The Builder Extreme 1000 PRO is one of the biggest industrial 3D printers available on the market. With a print volume of 700 x 700 x 820 mm (XYZ), it is the perfect printer for large prototypes, molds, tooling or even functional parts. Features such as a 7-inch touch display, filament detection and a UPS system that resumes printing after a power cut, make large scale 3D printing uncomplicated.

With a print volume of 700 x 700 x 820 mm (XYZ), it is the perfect printer for large prototypes, molds, tooling or even functional parts. Features such as a 7-inch touch display, filament detection and a UPS system that resumes printing after a power cut, make large scale 3D printing uncomplicated.

Find out more

The Builder Extreme is preferred by industrial leaders

“We needed to print larger prototypes in 1 piece and without worrying about failed prints – the Builder 1500 ticked all the boxes”.- Eventuri

This website uses cookies to improve your experience. We'll assume you're ok with this, but you can opt-out if you wish.Accept Read More

PrintBox3d. 3d printer in Russian / Sudo Null IT News

What I want to share with habrachitateley.

It's not a gadget, it's a workhorse that will last for years.

Unlike consumers of "home" models, our customer is a professional or an amateur, but with high demands on print quality, ready to deal with software and for whom accuracy and performance are more important than convenience and design.nine0011

Tokens:

– 2 motors per Z axis

— Meteorite resistant frame

- Own stepper motor controllers based on developments for industrial CNC

— Many spare partsCaution! Lots of aluminum!

When designing the printer, we took into account the design of a good machineGeneral view

( pictured is the very first prototype printer )

93/H

LAYER THICKNESS 50 µm, WALL THICKNESS 190 µm

OPERATING SYSTEMS WINDOWS XP, WINDOWS 7, MAC OSX, WINDOWS 8, VISTA, LINUX

WEIGHT (WITHOUT PACKAGING) 10.5 KG

DIMENSIONS (WITHOUT PACKAGING) 320 x 360 x 390 mmSoft

The printer runs on open source software (Cura, Slic3R and Repetier-Host).

For the convenience of users, the printer developers have translated the Cura program into Russian. (for which respect to them)Frame

“A good printer, in our understanding, starts with a frame”

Printer accuracy (print head positioning) starts from the frame.The reliability of the design allows it to withstand even "extreme transportation" (Russian Post).

(In terms of prevalence in the earth's crust , aluminum occupies the 1st among metals and 3rd place among the elements, second only to oxygen and silicon. The mass concentration of aluminum in the earth's crust, according to various researchers, is estimated from 7.45 to 8.14% ). nine0006

(In the body of an adult there is up to 140 mg of aluminum. The daily requirement of an adult for aluminum is estimated at 2.45 mg.).

(The oldest product containing 85% aluminum dates back to the 3rd century AD)

"Our difference from the world leaders is that we put a powerful frame as the basis" .

(Aluminum compounds are found not only on Earth, but also on the Moon and Mars. Aluminum is found even in apples - up to 150 mg / kg.)

8mm pure aluminium.

(The first product made of aluminum was a rattle made for the French emperor Napoleon III in the 50s of the 19th century).

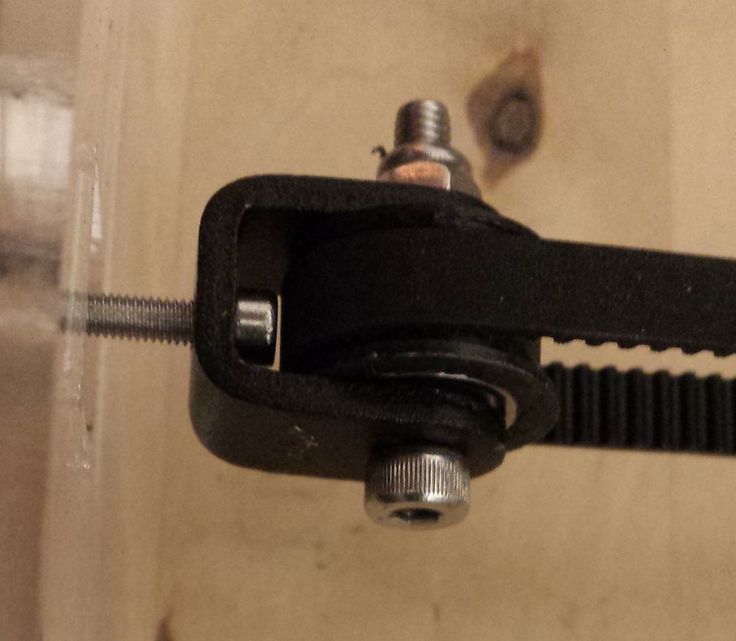

Guides

What provides the position / movement of the printhead / platform (guides) are of 3 types - screw, cylinder or rail.

Screw guides are slow and are mainly used for positioning on the Z axis.

The main load for high-speed and accurate movement falls either on the cylinders or on the rails. nine0005 The developers of PrintBox3d opted for rails, because “Cylinders have only 2 support points and there have been cases when the cylinders bend, while the rails have support points every 2 cm and the rails have a longer life span than the cylinder.”

The resource of the rail is higher than that of the cylinders.

Support points every 2 cm.

Platform

Aluminum is stronger than plastic, glass, textolite. Yes, and it has better thermal conductivity properties. nine0006

Aluminum platform with flexible heater at the bottom. The size of the heater is smaller than the size of the platform - 15x15 cm.

But, due to the good thermal conductivity of aluminum, the heating of the platform is uniform.Horizon adjustment (platform calibration) is done manually with screws, done 1 time in production (mounting rigidity and design features allow you to make adjustments once and for a long time.)

Electronics

There is an arduino as a control board - but for each motor - its own stepper motor controller (this allows you to better dampen inertia, work at higher powers.)0005

for each motor - its own controller (total 4 controllers, remember that we have 2 motors for the Z axis.)

Fuse. Saves. (These are Russian sockets)

Controllers - own design and own production.

Comparison red - Russian controller, blue - Chinese controller.

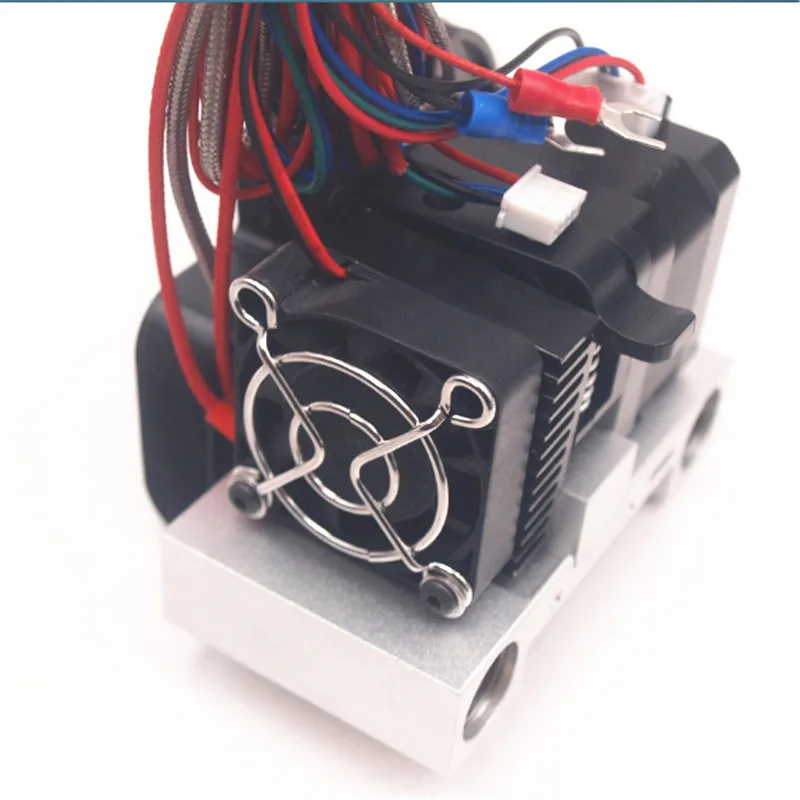

There are also spares.Extruder

Large = powerful motor on the extruder. (The rigidity of the frame and proprietary drivers allow precise control of a heavy workpiece at high speeds with sudden changes in direction.

)

Powerful motor allows sticky plastic to be forced through a narrow nozzle at high speeds and with high quality/accuracy

Original design - air passes inside the radiator (round holes in the center).

Working prototype (left) and final industrial version of the radiator (right).

One of the first versions of the radiator and heater - passed numerous tests.

Seen a lot…

Extruder with cap removed. nine0006Gears are made of high quality European PTFE.

It glides pretty well, doesn't wash very well, and holds high temperatures.

Non-scratch (crimp) plastic feed format, which allows printing with very thin nozzles at high speed

The plastic is clamped and pulled through the hole between the gears.

In conventional printers, the plastic is pushed by the teeth and because of this it is scratched and deformed, which introduces a distortion in the speed / accuracy of printing, but here the plastic is not pushed by the teeth, but is crimped from all sides.As a result - the absence of "artifacts" and "gaps". nine0006

Lots of little things

Because production is located in Russia, then there are a lot of spare parts on this side of the border. (Has anyone tried to get a replacement extruder/parts for the Replicator or Solidoodle from USA/Germany/Dutch/China?)

Are they buzzing?

The largest number of fans.

cable channel for fixing the wires going to the extruder.

Own production of gears for the extruder.Extreme angles

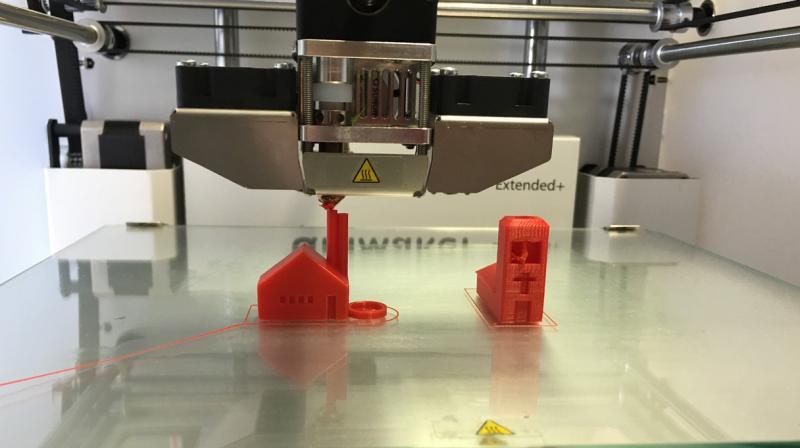

One of the distinguishing features is printing at an extreme angle without supports.

This figure is printed without supports - the chin and the back of the head are printed almost overhead.

If a “foreign” 3D printer breaks down (although 3D printers break down very rarely), then it will have to be sent for warranty repairs to Germany / USA, and then wait for it back.Read about the speed of delivery from abroad here. nine0005 For a Russian printer, this period is reduced (not six months, but weeks).

cable channel for fixing the wires going to the extruder.

All printers are tested before being sent to the client - they print out several details. Pictured

detail for checking the evenness of the table and the accuracy of stacking layers.We look at the 3D printer as a working toolPrinting example

P.S. Great video from TED, motivating to create instead of consume. nine0005 I also want to express my gratitude to the creators of 3D printers for their contribution to the cause of the “creators” and for the opportunity to “spy” on this process a little.

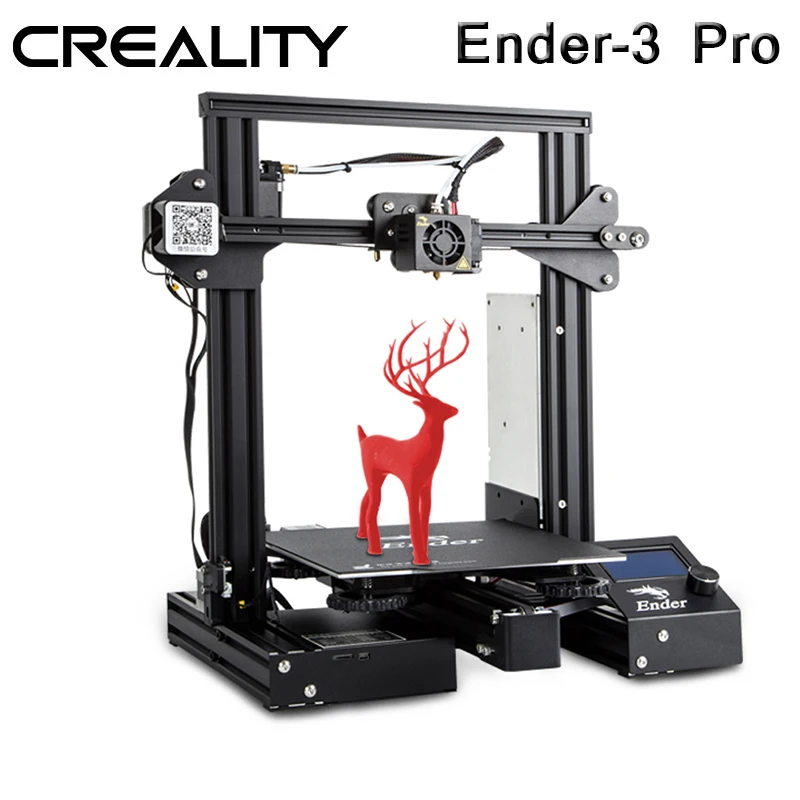

FDM 3D printer Picaso 3D Designer

Picaso 3D Designer printer based on FDM technology (Fused Deposition Modeling - layer-by-layer deposition modeling), otherwise called FFF (Fused Filament Fabrication), is produced by the Scientific and Production Enterprise Intelligent Information Systems ("NPP IIS"), which has been developing 3D printers for the mass consumer since 2011.

FDM is an additive manufacturing technology: the creation of three-dimensional objects is carried out by applying successive layers of material (in this case, ABS or PLA thermoplastic) that follow the contours of a digital model. Layers are formed by extrusion (extrusion) of molten thermoplastic through a nozzle located in the print head of the printer together with a heating element and a mechanism that feeds the plastic thread - an extruder. Plastic hardens immediately after extrusion. nine0006

Features:

- Print technology: FDM

- Print area (LxWxH): 200x200x210mm

- Print material: ABS and PLA plastic

- Layer thickness: 50 to 250 microns

- Closed chamber

- Heated platform

- Ability to work offline from an external drive

- File format: stl

ABS plastic

ABS plastic (acrylonitrile butadiene styrene, ABS) is an impact resistant thermoplastic that is widely used in both industrial and additive manufacturing.

The production of one kilogram of ABS requires the equivalent of approximately 2 kg of oil in the form of materials and energy. nine0006

Specification ABS

Glass transition temperature

approx. 105°C

Flexural strength

41 MPa

Tensile strength

22 MPa

Tensile modulus

1627 MPa

Elongation

6%

Shrinkage on cooling

up to 0.8%

Material density

approx. 1.05 g/cm³

Actual plastic parameters may vary from manufacturer to manufacturer.

Advantages of ABS plastic:

- moisture resistance

- acid resistance

- oil resistance

- relatively high heat resistance

- increased impact resistance

- high elasticity

- high durability (no direct sunlight)

- easily machinable

- dissolves well in acetone, which allows post-processing of products with acetone vapor, as well as printing large models in parts, followed by gluing

Disadvantages of ABS:

- relatively low resistance to direct sunlight

- When ABS plastic is heated, toxic acrylonitrile fumes are released, so products made from such plastic are not suitable for food use (storage of hot food and drinks)

- reacts with ethanol to release styrene, so products made from this plastic are not suitable for storing any type of alcohol

- high tendency to shrink (loss of volume and deformation of geometric dimensions during cooling)

PLA plastic

PLA plastic (polylactide, PLA) - is a biodegradable, biocompatible, thermoplastic aliphatic polyester, the structural unit of which is lactic acid.

Made from corn or sugar cane. nine0006

PLA specification:

Melting point

173-178°C

Softening point

50°C

Hardness (Rockwell)

R70-R90

Elongation at break

3.8%

Flexural strength

55.3 MPa

Tensile strength

57.8 MPa

Tensile modulus

3.3 GPa

Flexural modulus

2.3 GPa

Glass transition temperature

60-65°C

Density

1.23-1.25 g/cm³

Manufacturing shrinkage

nine0245no

Moisture absorption

0.

5-50%

Advantages of PLA plastic:

- non-toxic due to its natural origin

- no shrinkage of patterns during printing

- is ideal for moving parts and mechanical models

- excellent glide details

- the possibility of obtaining more detailed models than from ABS plastic

Disadvantages of PLA plastic:

- high gyroscopicity

- Machining brittleness

- fragility (products last from several months to several years)

Printed examples:

Subsonic nozzle for experimental stand. PLA plastic. nine0245 Model of a turbine. ABS plastic. Printable architectural kit. PLA plastic. Rotary to linear drive model. ABS plastic. Gearbox model 1:27 with herringbone gears.

Learn more