Aurum 3d printing

Buy 3D printing filament by Australian manufacturer

Default sortingSort by popularitySort by latestSort by price: low to highSort by price: high to low- View:

- 12

- 24

- All

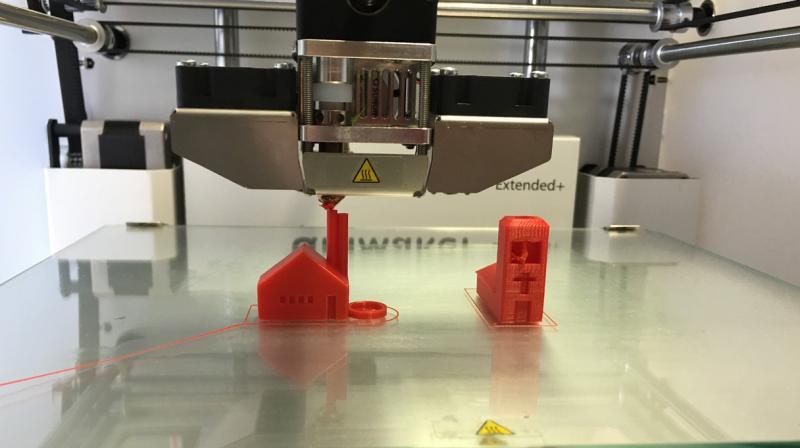

To start printing 3D objects, you need two things: a good 3D printer and suitable printing material. It may seem obvious, but many beginners stop researching after the purchase of a printer and print with the wrong filament, thus getting unsatisfactory results. To help you avoid this trap, we offer a guide on 3D printing filaments and their types.

First things first: what is a filament for 3D printer?

It is quite simple: filaments for 3D printing are plastics, or rather thermoplastics, pre-shaped into thin threads to be fed into a printer. ‘Thermoplastics’ mean that under heat impact, they don’t burn but melt and take a new shape. They retain this exact shape after cooling. This shape can be random, like warping of plastic bottles exposed to heat, or pre-defined, like it happens during 3D printing.

These plastic filaments are fed into the heating chamber of a printer, the hot paste is then pushed through the heated nozzle, and the nozzle moves all the time according to the pre-loaded 3D draft of an object. Layer by layer, a toy, a detail, or a prototype is created, and after cooling the object is ready for use.

Key features of filament to know before printing

Currently, on the market, there is a flood of plastics with difficult chemical names and mysterious abbreviations like PVA, ABS, PLA, HIPS, PETT, and whatnot. But actually, only three or four of them are in widespread use under different brand names.

These filaments have the essential package of features that make them fit for printing goals, and the rest is a matter of colors and particular object specifications. Filaments – after heating and cooling – are usually sturdy, solid, durable, and non-toxic. Filaments can differ in their capacity to withstand outdoor use since some are better fit for this purpose and do not crumble when long exposed to UV. Some filaments can be flexible, withstanding physical impact or twisting and not breaking into pieces.

Some filaments can be flexible, withstanding physical impact or twisting and not breaking into pieces.

Other than that, the properties of filaments are essentially the same.

Most popular types of filaments today

If you look for good multipurpose filaments in Australia, we have you covered. Three key filaments are freely available here, and you can pick the filament that matches your exact goals.

PETG filament in Australia is highly popular because it is food-grade plastic that has properties of glass (full transparency). It is durable, chemicals-resistant, but also more flexible than other filaments and so won’t break into pieces after impact. It does not shrink a lot during printing, thus, big flat parts can be printed with its help.

When to use it: to print medical parts, bottles, and containers, parts of electronics, transparent covers and guards, and heavy-duty displays for crowded areas.

ASA filament in Australia is another recommended type because it is really tough and resistant to long UV exposure during outdoor use (like anything supposed to be used in Australian heat). ASA can be exposed to chemicals without significant consequences, is water-resistant, and durable. It does require some precautions while printing, but it is fully compensated by the benefits of using this thermoplastic.

ASA can be exposed to chemicals without significant consequences, is water-resistant, and durable. It does require some precautions while printing, but it is fully compensated by the benefits of using this thermoplastic.

When to use: ASA is perfect for making parts that will go through the extensive tear and wear, like car parts, sports gear, gardening tools, outdoor equipment, etc.

PLA filament in Australia is appreciated for ease of use and the endless range of colors and textures it comes in. Whatever visual effect you need to achieve, from realistic metal-looking to fairy-like glowing, PLA is your first stop. PLA can be mixed with metal powder or wood parts to be sturdier or can be enhanced to withstand higher temperatures. PLA lacks the durability of other filaments, but it wins in terms of looks.

When to use: when you need to print a prototype fast but accurately, or when you are making toys, models, or collectibles.

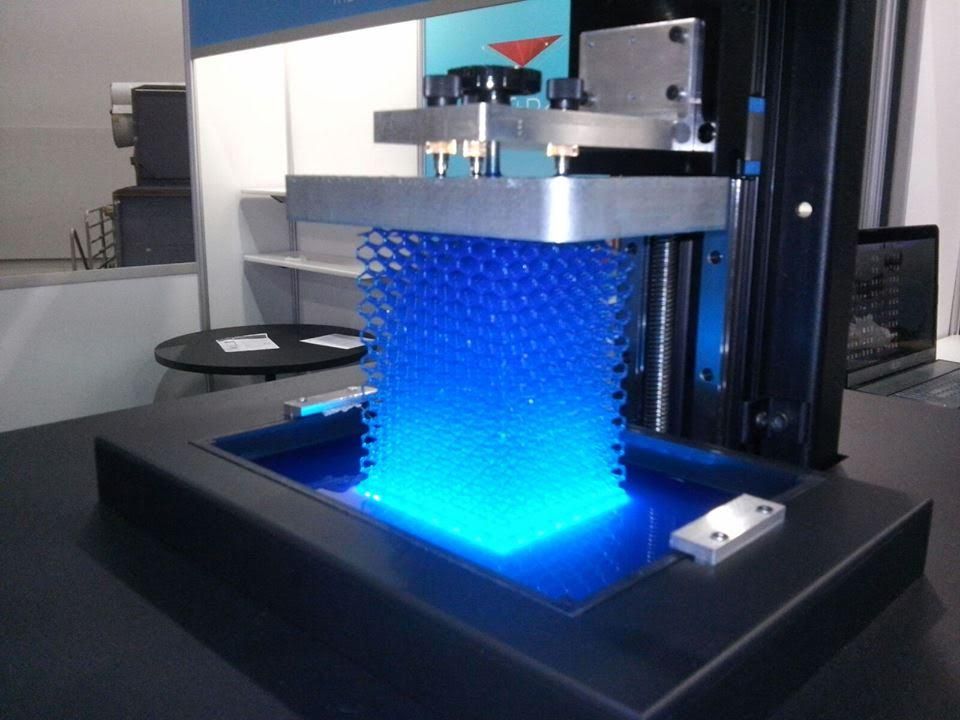

Resin for 3D printer in Australia belongs to a different category of materials, and the printing process is more complicated (and different from pushing the hot goop through the nozzle). Printers for resin are quite costly, like printing resin itself. You can start printing with filaments and see if you will need to transfer to printing with resins.

Printers for resin are quite costly, like printing resin itself. You can start printing with filaments and see if you will need to transfer to printing with resins.

Tips on how to choose filament for your project

As you see, there is no one-type-fits-all solution. Decide on the properties you need in a printed object and pick the filament with these very properties. Then buy filament in Australia from Aurarum, all locally manufactured with full guarantees of quality and true love for all things printing (and printed). In such a way, you can be sure that your projects will turn out as expected.

Buy 3D printers and Scanners in Australia

Default sortingSort by popularitySort by latestSort by price: low to highSort by price: high to low- View:

- 12

- 24

- All

Reprint Your World: Choosing a 3D Printer

In the not-so-distant past, the sole idea of printing and ore replicating real physical objects out of raw material seemed quite fantastic. Today, 3D printers are becoming common household appliances, standard equipment in factory shops, universities, engineering and prototyping companies, schools that have STEM projects, and medical laboratories alike.

Today, 3D printers are becoming common household appliances, standard equipment in factory shops, universities, engineering and prototyping companies, schools that have STEM projects, and medical laboratories alike.

But what 3D printer to buy for your specific business? To answer this question, you need to have an idea of the tasks you will be handling with the printer, take into account the necessary functions, size, and type of device. Let’s figure it out.

Why Buy a 3D Printer in the First Place

The main advantage of 3D printing technology is that it can be used to create a part or thing of any shape and configuration. And it's not just about plastic DIY crafts. Today, 3D printers in Australia and all over the world are widely used by architects and designers in the automotive, aviation, and aerospace industries.

With their help, medical prostheses, parts of human organs, and even parts of rocket engines for launch vehicles are reproduced.

Benefits of 3D printers:

- Rapid prototyping – the ability to design, manufacture and test a part in the shortest possible time.

- Flexibility – no extra tools, mold, die, or clamps are required to make a part. You can use multiple materials and mix colors, textures, and mechanical properties.

- Flexibility – since there are is no expensive tooling involved design changes can be done immediately if/when required

- Competitive edge ─ companies can release products faster. 3D printing allows you to physically demonstrate a new product and conduct cost-effective market testing without the risk of large investments.

- Material design and testing – often you can test the physical prototype and fix flaws by simply modifying the CAD file.

- Quality – 3D printing allows for step-by-step assembly of the product, which guarantees a sturdier, more reliable design.

- Smooth operation – every detail manufactured can be closely monitored so that errors can be detected in real time.

- Lower production risks – the technology allows prototypes to be tested before investing in a product.

- Accessibility – 3D printers are widely available in a wide price range, features, and sizes.

- Stability – with 3D printing, there is no need to operate energy-intensive factories, there is much less waste generated and the materials used are recyclable.

Which 3D Printer to Buy: Main Types of Manufacturing

Product development can be based on three major methods:

- Subtractive manufacturing – a process in which all excessive material is continuously removed from a solid block.

- Injection molding ─ production by injection of heated material into a mold.

- Additive manufacturing- the creation of 3D objects by adding material layer by layer.

The latter approach offers many outstanding benefits, which is why more and more companies in a wide variety of industries are using additive manufacturing.

What to pay attention to when choosing a 3D printer

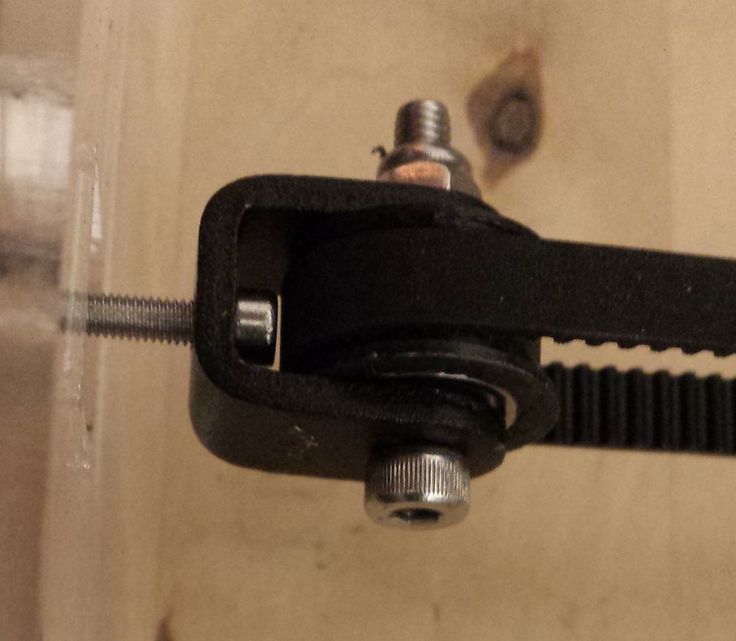

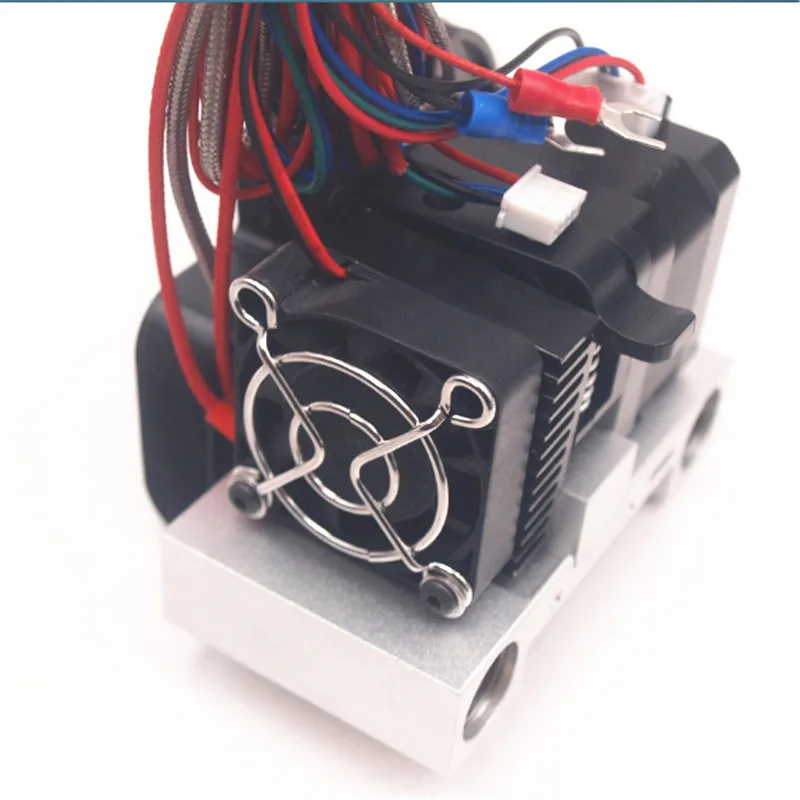

All types of 3D printing devices can be roughly divided into two major categories: FDM and SLA. The first assumes the layer-by-layer creation of an object from a plastic filament or pellets. The filament is melted and extruded through the nozzle and deposited on to the working platform where it cools and solidifies. The platform is lowered to a thickness of one layer most commonly 50-500 microns. The process is then repeated until the final 3D model is built. The FDM technology allows you to quickly print durable, three-dimensional objects of any shape in high detail.

The first assumes the layer-by-layer creation of an object from a plastic filament or pellets. The filament is melted and extruded through the nozzle and deposited on to the working platform where it cools and solidifies. The platform is lowered to a thickness of one layer most commonly 50-500 microns. The process is then repeated until the final 3D model is built. The FDM technology allows you to quickly print durable, three-dimensional objects of any shape in high detail.

SLA is the technology of sintering a photosensitive resin under the beams of a digital projector or a laser. When the resin hardens, the platform is lowered to form the next layer until the object is complete. Such printers are capable of very accurately reproducing objects of high complexity. The usual layer thickness is up to 200 microns.

Yet another approach is powder printing. A fine powder is applied to the surface and melted by a laser (a process called selective laser sintering SLS) or thinned with a solvent. The advantage of this method that it can be used with metals and glass. It is the most expensive 3D printing method.

The advantage of this method that it can be used with metals and glass. It is the most expensive 3D printing method.

When choosing an industrial 3D printer, look for the following features:

- Ability to print engineering materials. These are PEEK, ULTEM® (PEI), polycarbonate, or carbon fiber reinforced materials. In most cases, special conditions are required. For ULTEM/PEI, it is advisable to have a heated print chamber with a temperature of at least 70°C. Others require hardened drive gears, special work plates, or nozzles.

- A large, actively heated chamber with metal parts allows ABS to be printed at higher temperatures, increasing the sturdiness of products by 20-30%. The size of the build volume determines how large or how many parts can be printed at a time.

- Printing speed. High speed reduces print time and improves development/production speed.

- Dual extruder system. A dual extruder system allows printing support materials out of different plastic that can be water-soluble.

- Service time. Auro bed leveling function reduces setup and start-up times. Advanced systems have the ability to quickly change modules or nozzles.

- The total cost of ownership. A 3D printer should cut, not generate costs. You should check if the manufacturer permits the use of third-party materials in order not to lose your warranty. Some of the manufacturers have chipped filament and/or expensive replacement parts.

- Safety. The temperature inside the chamber can reach 100°C, and the nozzle melts the material at almost 500°C, it is recommended to have the doors with automatic lock.

The ideal solution is to use a 3D printer, software, and materials recommended by the same manufacturer.

Costs of 3d printers

The range of prices is pretty wide – from $100 to infinity. Thus, 3D printers may cost about the same as in the capital. But don’t forget to add the cost of consumables. Before you buy a device, it is important to decide on future tasks ─ you will be printing for fun or for more serious purposes. For instance, support for multicolor printing significantly increases the cost of a printer.

For instance, support for multicolor printing significantly increases the cost of a printer.

The Up and Tiertime models, some of the most popular in the educational environment, range from $1,100 to $6,500 in price. At the same time, the products comply with strict standards. For example, UP BOX+ 3D Printer has a HEPA filter, incandescent sensor, power stop function, automatic platform leveling and height detection, industrial design with internal steel chassis, and 100-micron print resolution!

Flashforge Adventurer 3 costs only $670. The device has a closed case, active fans, Wi-Fi functions, automatic filament feeding, support for SD cards, USB printing, and a color touch screen.

Aurarum Sirius large-scale 3D printer costs $19.5 thousand. At this price, the device features automatic bed leveling, Meanwell universal power supply, and a Bondtech extruder with a door. Duet3d Wifi controller with 5 '' touch screen can be conveniently controlled from a mobile phone.

Aurarum's customized 3D printers cater to any need. The cost of products depends on the size. These are the cheapest 3D printers in Melbourne as the manufacturer is based in Knoxfield, VIC.

The cost of products depends on the size. These are the cheapest 3D printers in Melbourne as the manufacturer is based in Knoxfield, VIC.

Where to Buy 3D Printer Equipment?

A local Australian manufacturer will provide better support, software updates, and warranty service.

Before you buy – pro tips:

- Order a sample of the product created with the desired model;

- Learn how fast it was created and how much the whole production cost;

- Clarify the total ownership costs, support and maintenance conditions, warranty specifics, etc.

The printer is often supplied with consumables out-of-the-box. The software is usually bundled or available for free download.

3D printers are still just entering the homes, but at Aurarum, we are confident that they will soon be in every home and in every production. Contact us and start using the technologies of the future today!

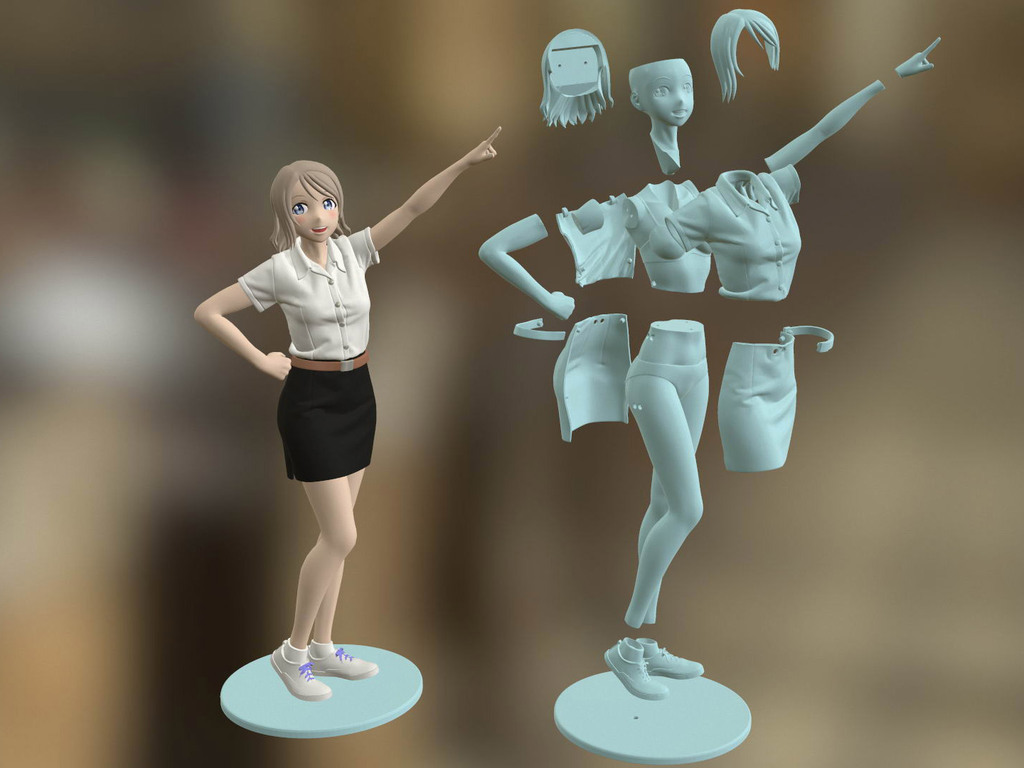

Cindy Aurum 3D File・3D Printer Design Download・Cults

Themis - Goddess of justice

3,50 €

Cute unicorn

1,50 €

sports girl

2,50 €

bathtub plant pot

0,80 €

nine0003 Vietnam Buffalo0,50 €

Ballet

2,50 €

Little angel

6. 80 €

80 €

male statue

0,50 €

Best Files for 3D Printers in the Art Category

Bust of Queen Elizabeth *Commercial license*

2.65 €

Pinocchio version by Guillermo del Toro

2.87 €

Sandman Helmet ARTICULATED Dream Helmet Dream Helmet

4,80 €

Cube minus Cubes

Free

Star Wars Cute Y-wing Chibi SD

1.25 €

nine0003 Eagle mobile suspensionFree

Star Wars Force Be With You Silhouette

Free

Mars Attacks

70 €

Art category bestsellers

Cute frog with flexi print

1. 84 €

84 €

2,78 €

Stitch Love (easy printing without support)

1,50 €

Adorable articulated axolotl, imprinted body, snap head, cute flexi

3,28 €

Astronaut on flexi printer

2,78 €

nine0003 Cute sloth with flexi print2,78 €

Flexi-print Imperial Dragon

3.72 €

Kangaroo and Joey on flexi printer

2.78 €

Cute little fox with flexi print

2,36 €

Cute skeleton with flexi print

2.78 €

Archaeopteryx nibbler

3 €

Flexi PRINT-IN-PLACE Hand

1,84 €

CHRISTMAS TREE WITH LEGS

2. 83 €

83 €

GHOST ZU - GHOST WITH FEET

2.66 €

☃️ Monster Snowman - XMAS TREE ORNAMENT☃️

2.50 €

Leopard gecko ball joint toy, imprinted body, snap head, cute flex

3,28 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people , so support us in maintaining activities and making future designs of is very easy. Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

Open Technologies

Cronus 3D is the latest in 3D scanning. You will receive an accurate model of the scanned object, regardless of its volume. All necessary settings can be made at the stage of system acquisition. This scanner is an excellent tool that will cope with the work of any complexity. nine0006 The

Cronus 3D is a major step towards fast color scanning, which is easy to do thanks to the user-friendly interface of the control software.

All necessary technical parameters are set immediately before using the device. The image obtained after scanning has a maximum resolution and accuracy of ± 20 ÷ 40 µm

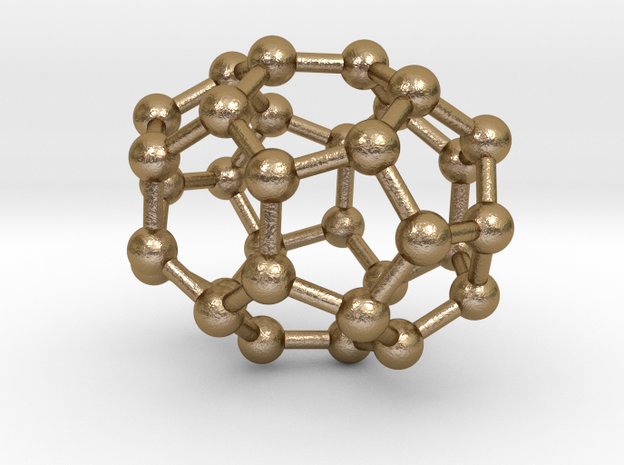

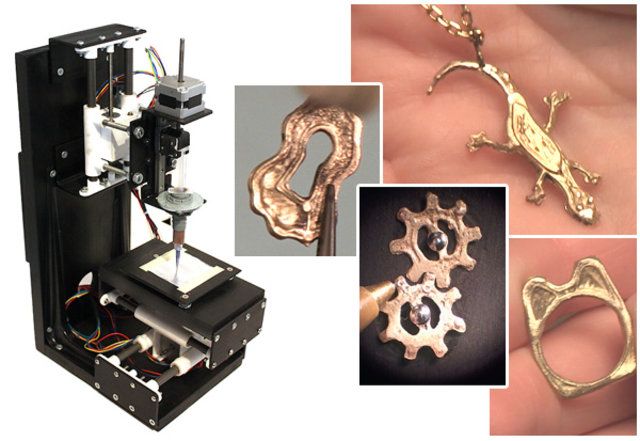

Small parts scanning made possible with desktop 3D scanning system Aurum3D ! You will be able to quickly obtain images of objects with complex shapes thanks to the automatic rotation mechanism.

Aurum3D is perfect for high-quality digitization of jewelry, small mechanical parts, coinage and a wide range of other areas.

3D system Stone 400 is designed to work with marble objects. High fidelity reproduction of sculptures, bas-reliefs and statues with the ability to edit the resulting image and scale while maintaining small details. nine0006

Stone 400 will help you maintain style and finish when restoring or reproducing volumetric elements. The resulting 3D model can be edited, adjusted in size for subsequent milling.

|

| Cronus 3D | Aurum 3D | Stone 400 | nine0234

| Light source | LED | LED | LED |

| Camera resolution | 1. |