Materialise 3d printer

Online 3D Printing Service | i.materialise

Oops...Seems your browser is blocking cookies. Please adjust your settings to accept cookies.

i.materialise is your online 3D printing service. Upload your 3D model, choose from 100+ different finishes and materials, select the size of your print, receive a price quote instantly and let us take care of printing and shipping your products.

How to Get Started

How to Order a 3D Print

Upload your 3D file

Select material, color & finish

Get an instant price & order

Let us take care of production

Receive your products

Why Order 3D Models on i.

Get Instant Prices

Upload your 3D file and get an instant price, no login required »

Online Marketplace

Did you print a great product? Open a shop and start selling today! »

Materials

20 Different materials including plastics, resins and metals »

Rush 3D Printing Service

Printing Polyamide in less than 48 hours »

Educational Discount

10% discount for students and teachers »

Expertise

Over 25 years of Additive Manufacturing experience »

Upload and Order Your 3D Model

Get instant prices for your 3D design seconds after uploading. With no registration or login required, several user-friendly interfaces for uploading, and over 40 accepted 3D files formats, we’ve got you covered.

With no registration or login required, several user-friendly interfaces for uploading, and over 40 accepted 3D files formats, we’ve got you covered.

Single Upload

Upload and edit one 3D file at a time.

Upload and edit one 3D file at a time

Upload 3D File

Multiple Upload

If you would like to order multiple files, you can upload up to 20 files in one go.

If you would like to order multiple files, you can upload up to 20 files in one go.

Upload Multiple Files

Container Upload

Put multiple small parts in a grid container and print them all together.

Put multiple small parts in a grid container and print them all together.

Learn more

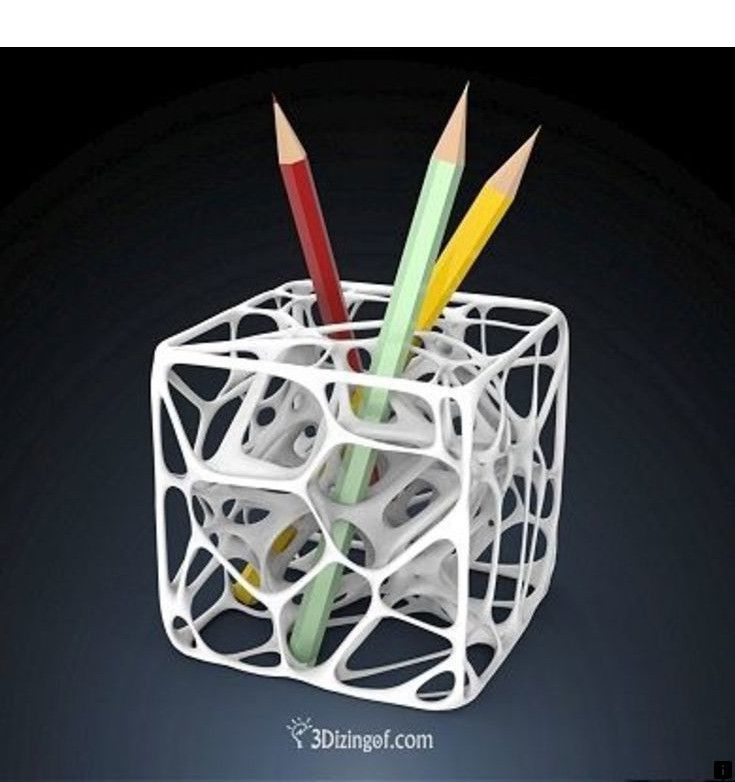

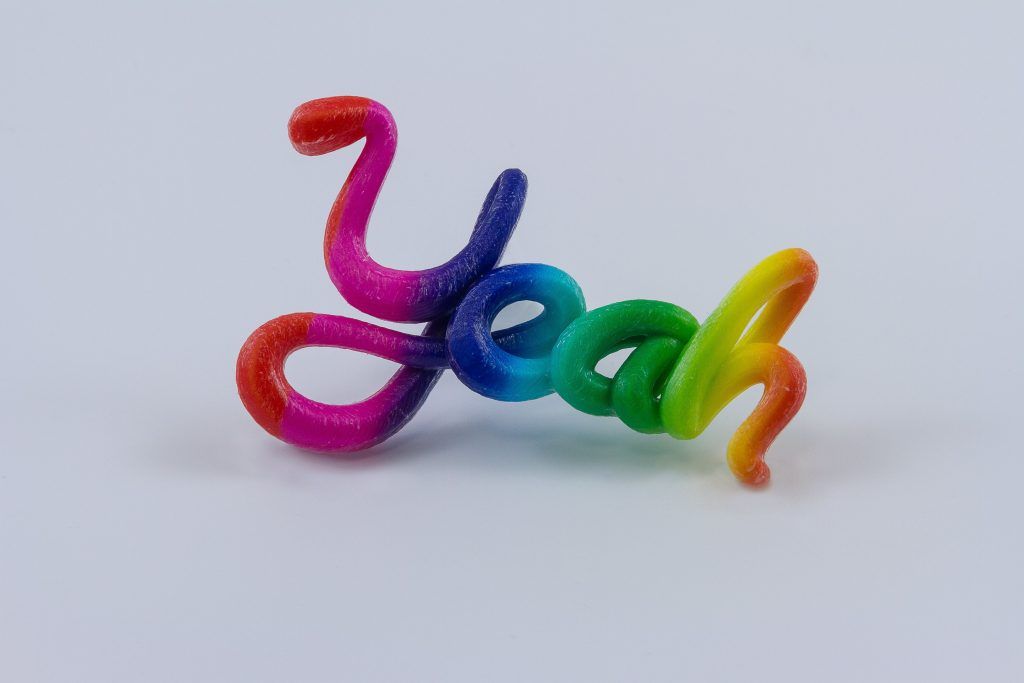

Choose from a wide range of 3D Printing Materials

From titanium to multicolor+, polyamide, 18K gold and more, i.materialise has what you’re looking for. With 20 different materials and over 100 possible color and finish combinations, we offer only the highest quality to turn your ideas into 3D printed reality.

Resins

Perfect for smooth surfaces, high-quality, detailed prints and a huge variety of finishing and post-processing possibilities.

Polyamide (SLS)

A strong, flexible nylon material that is available at a reasonable price and offers a wide variety of colors and finishes.

Multicolor+

Perfect for strong, full-color models that are equally as good as injection molded parts.

925 Sterling Silver

A precious metal with a very high electrical and thermal conductivity. The material is very malleable and shines brightly after polishing.

Titanium

Light, strong, corrosion-resistant metal for functional parts, spare parts and jewelry.

Brass

An incredibly versatile precious metal that is available in a wide variety of colors and plating.

Discover More

Trusted Partner Of

Materialise 3D Printing Software | GoEngineer

SEE CURRENT 3D PRINTING PROMOTIONS

800-688-3234

The Backbone of the 3D printing world

Materialise software tools work to manage additive manufacturing processes with efficiency and intelligence. With a range of products that span the 3D printing workflow, Materialise allows users to manufacture at the highest standards for demanding industries.

With a range of products that span the 3D printing workflow, Materialise allows users to manufacture at the highest standards for demanding industries.

Request More Information on Materialise Magics

30 Years of Additive manufacturing Experience

Headquartered in Belgium, Materialise brings together the largest group of software developers in the industry to focus on software solutions for 3D printing services.

Materialise

Magics

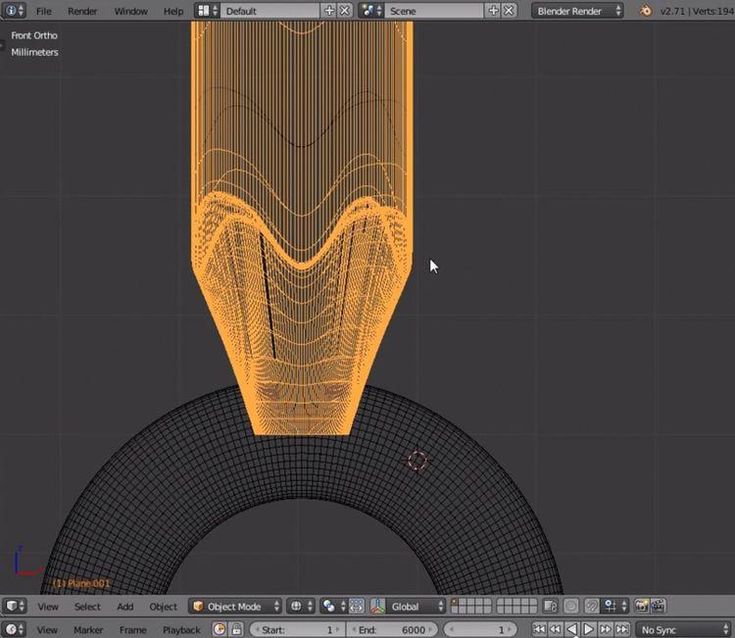

Prepare your part for 3D printing with the industry-leading data preparation and STL editor software. Convert files, correct errors, edit designs, and prepare your build platform.

Request More Information on Materialise Magics

Materialise

Build Processor

Get your 3D printer and software communicating seamlessly with a custom fit build processor for your additive manufacturing machines.

Request More Information on Materialise Build Processor

Materialise

3-Matic

Clean up rough data or convert your mesh back to CAD with 3-Matic, a premium and versatile tool to make design modifications at the mesh level.

Request More Information on Materialise 3-Matic

Materialise

e-Stage

Automate the creation of support generation to radically cut your design preparation time.

Request More Information on Materialise e-Stage

Materialise Magics

The Most Powerful 3D Printing Data Preparation Software

Materialise Magics makes prepping a 3D design file for printing easy, intelligent, and fast. Magics is a smart, versatile data preparation and STL editing software for 3D printing and additive manufacturing. The powerful industry-leading software walks the operator through every step of the 3D printing workflow.

The powerful industry-leading software walks the operator through every step of the 3D printing workflow.

Request More Information on Materialise Magics

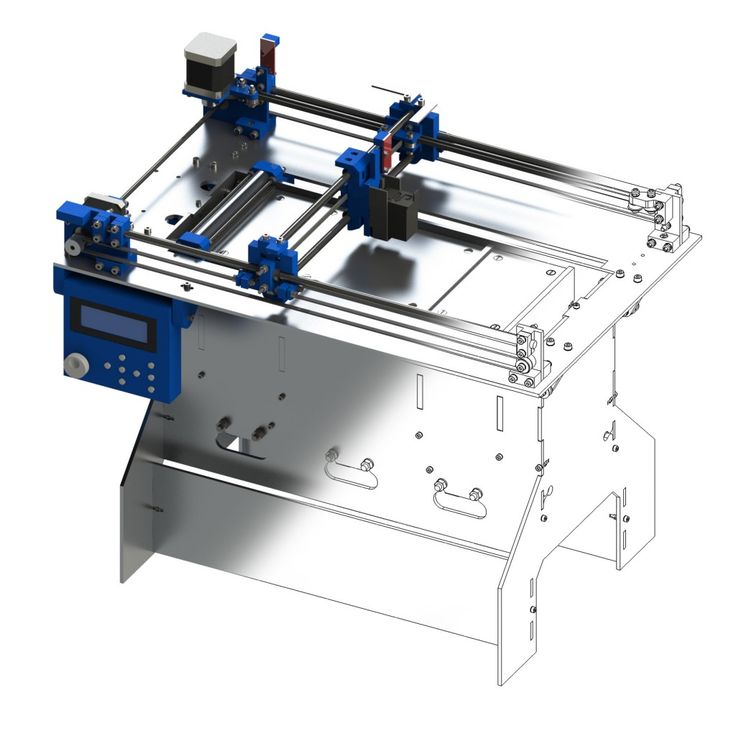

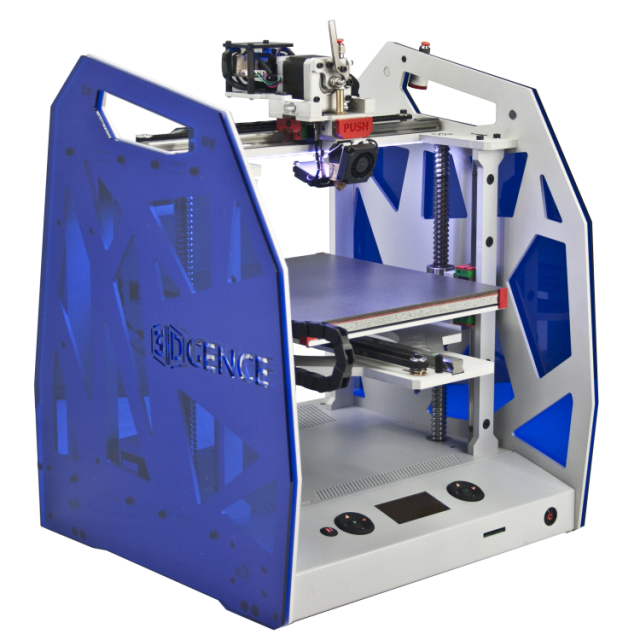

Materialise Build Processors

Tailor-Made Software For Over 130+ Additive Manufacturing Technologies

Each 3D printer has unique parameters and processes that need to be taken into account when designing and printing parts. With a Materialise Build Processor, you can ensure seamless communication between your additive software and hardware. With an intuitive interface operators can:

- Translate 3D data to machine-specific print instructions

- Leverage industry-standard software, tailored to each unique printer in your lab

- Process large, complex files

- Take advantage of advanced, multicore slicing algorithms

Request More Information on Materialise Build Processor

Materialise e-Stage

Generate Supports in Under 3 Minutes

Key features and benefits include:

- Reduce design time

- Eliminate print failures caused by human error

- Improve resin drainage

- Minimize support contact points

- Leverage the Gusset support type

- Run on over 40 machines, and 40+ material types

- Print complex parts fast

Request More Information on Materialise e-Stage

Materialise 3-Matic

Clean Up Rough Data in Hours – Not Days

3-Matic is a Windows-based program that allows you to execute design changes directly on STL mesh files. The functionality is easy to use for anyone familiar with Windows or CAD. 3-Matic offers a powerful workflow improvement for engineers struggling to efficiently implement topology optimization. A common struggle for topology optimization is that it takes a lot of time to convert the optimized files back to a computer-aided design (CAD) format, with 3-Matic this can be done in hours.

The functionality is easy to use for anyone familiar with Windows or CAD. 3-Matic offers a powerful workflow improvement for engineers struggling to efficiently implement topology optimization. A common struggle for topology optimization is that it takes a lot of time to convert the optimized files back to a computer-aided design (CAD) format, with 3-Matic this can be done in hours.

Request More Information on Materialise 3-Matic

3D Printing Services

AWARD WINNING TECHNICAL SUPPORT

GoEngineer’s extensive technical knowledge can assist with your additive manufacturing needs. Our Award winning team is ready to help. Reach out and see why GoEngineer is the #1 reseller of SOLIDWORKS and Stratasys systems in the world!

LEARN MORE

ADDITIVE MANUFACTURING TRAINING

Learn to utilize all features and tools of Stratasys commercial 3D printers with GoEngineer additive manufacturing on-boarding training. Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

Take advantage of our 3D printing team of experts to help launch all your 3D printing capabilities.

LEARN MORE

3D Print and Part Design

No matter your size, quantity or complexity of part(s) needed, GoEngineer can help you! Take advantage of our 3D Printing and Part Design Services to help your organization produce the best parts and prototypes available on the market.

LEARN MORE

Additional Resources

Take Advantage of GoEngineer’s Extensive Knowledge Base and Resources

Find a Solution

Our robust Knowledge Base contains over 12,000 resources to help answer your product design questions. From basic CAD questions to in-depth guides and tutorials, find your solution here.

Find a Solution

From basic CAD questions to in-depth guides and tutorials, find your solution here.

Find a Solution

PROFESSIONAL TRAINING

Improve your skills with professional training and certifications in SOLIDWORKS, CAM, 3D Printing, and 3D Scanning offered four ways: self-paced, online, on-site, or in-classroom. Certified Training Courses

BLOG

#1 Technical Resource Worldwide - Right at your fingertips. Search or browse through hundreds of SOLIDWORKS tips & tricks, additive manufacturing product developments, announcements, how-to guides, and tutorials. Blog

YouTube Channel

Our YouTube channel hosts hundreds of educational tutorials, product demonstrations, recorded webinars, and best practices for all of our products and services. GoEngineer's YouTube Channel

GoEngineer's YouTube Channel

ONLINE STORE

Order 3D printing materials and consumables, enroll in SOLIDWORKS training classes, and buy official GoEngineer gear directly from our online store. Online Store

FREE SOLIDWORKS Tools

Enjoy this collection of small ‘macros’ that were tailored to help our customers. These free SOLIDWORKS tools are for you to use, review, and modify. SOLIDWORKS Automation Tools

WEBINARS

Our engineering webinars are hosted by some of the top experts in the industry. They are always recorded, always free, and always offer a live Q&A.

WEBINARS

They are always recorded, always free, and always offer a live Q&A.

WEBINARS

3D Printing Services

Need to 3D print a part? Our Additive Manufacturing experts will 3D print your part and deliver it to you using the latest technology on one of our professional FDM, PolyJet, SL, or Metal 3D printers. 3D Printing ServicesMaterialization of any ideas with the help of a 3d printer

Miscellaneous

There is a popular 3d printer trend on reddit.

One of the most popular posts in the trend was written by two 3D designers Nimlot and Kaho.

They challenged the community by stating that they will make three ideas come true that will get more than

total votes.

The reddit community is very witty and the guys were offered to materialize things like:

- Sarah Palin being eaten by a polar bear

- The Death Star

- A horse the size of a duck riding a duck the size of a horse

- A crossbow that can be hidden in a sleeve watch and a suitcase in hand.

- Beyonce figurine

- Working mini catapult for the office

- Prosthetic arm and give it to the needy

- Antikythera mechanism

As a result of voting, the following ideas scored the most points:

Mini office catapult

Half brontosaurus, half ostrich, with a tie, looking at his watch and carrying a suitcase in his hand.

Beyonce's figurine from this photo

The guys have already modeled, printed and posted a mini catapult for sale.

Available for 26 tanks on shapeways In addition to the catapult, there are many more interesting figurines in Nimloth and Kaho's store:

For example Barack Obama with a machine gun riding a raptor

Or Kim Kardashian's ass with a horse's head.

It would be interesting to carry out similar things on 3d today.

Let's say if there is a brave enough 3d designer or a company that provides 3d modeling services.

As they say, we'll see.

And what would you suggest for materialization? What crazy idea?

Subscribe to the author

Subscribe

Don't want to

8

More interesting articles

ski

Loading

10/14/2022

972

5

Subscribe to the author

Subscribe

Don't want to

Video post about how taking the right idea and implementation, you can bring the whole concept to mind...

Read more

0

Follow author

Subscribe

Don't want

IMPRITA took part in the TECHNOFORUM 2022, which was held in Moscow, Expocentre, from 24. ..

..

Read more

arelav

Loading

03/17/2017

28488

86

Subscribe to the author

Subscribe

Don't want

Often when printing this or that complex model, for example, a case, or a mounting bracket, there is...

Read more

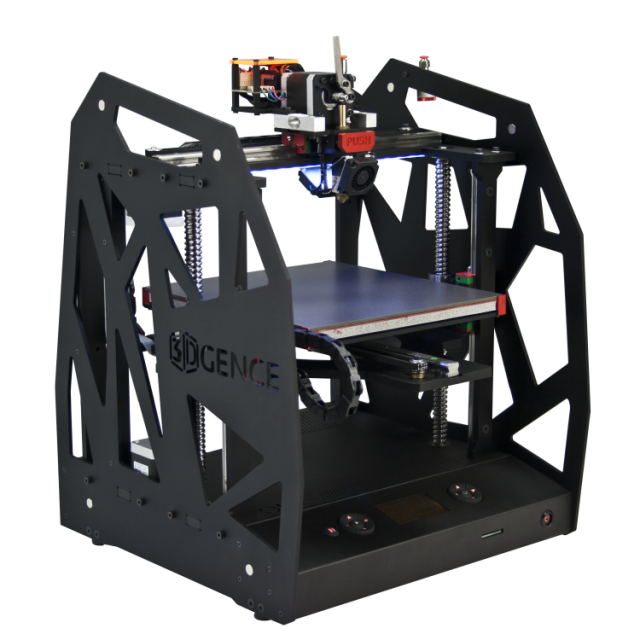

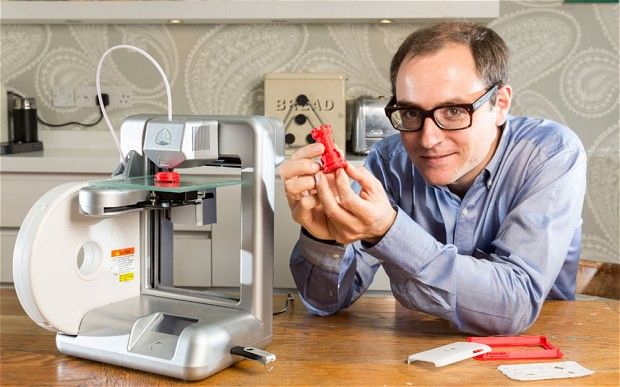

Printer for the materialization of ideas

Alexander Osinev

Printing deep and wide!

About the general in boxes and globes

How it works

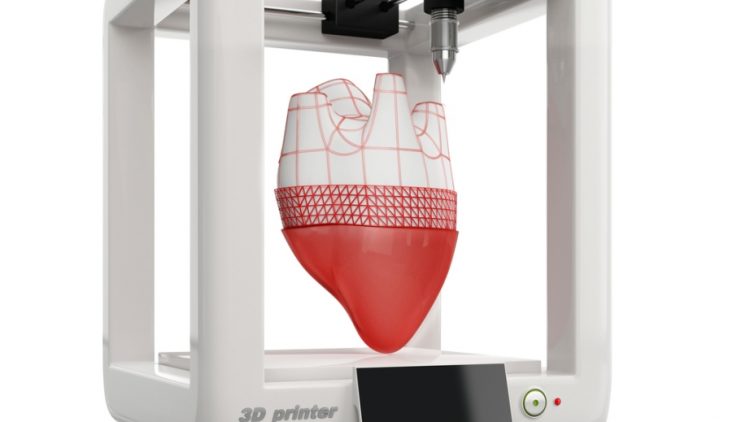

3D printer is a universal tool

Even for our parents, computer technology was inextricably linked with grinding numbers and solving mathematical problems formulated by specialists from various exact sciences. But obsession with mathematics is a thing of the past. The phrase "computer creativity" does not surprise anyone. If we talk about traditional creativity, it seems that writers were the first to move from typewriters to computer terminals, who appreciated the text editor as an alternative to marginal entries and manual reprinting of pages due to minor editing. Further more. The computer is now often almost the main tool for musicians, designers, architects and even filmmakers. It is especially important that the quality of films and books still depends not on the computer, but on the person. Computers, in fact, are still crunching numbers, saving us time (and most often money), leaving more opportunities for creativity itself.

If we talk about traditional creativity, it seems that writers were the first to move from typewriters to computer terminals, who appreciated the text editor as an alternative to marginal entries and manual reprinting of pages due to minor editing. Further more. The computer is now often almost the main tool for musicians, designers, architects and even filmmakers. It is especially important that the quality of films and books still depends not on the computer, but on the person. Computers, in fact, are still crunching numbers, saving us time (and most often money), leaving more opportunities for creativity itself.

Print deep and wide!

The development of computer peripherals - scanners, printers and other equipment - also did not stand still. New types of human activity, subdued by the general computer boom, often require special output and input devices. Computers have long been able to translate text, images and sounds into their native form and back, even the first developments in the field of analysis and reproduction of smells have appeared. In the 90s, a lot was done to make computer technology perceive and make digital models of real objects, which was solved by several 3D scanning technologies. Finally, the way back was paved: the computer was taught to create, on the basis of a digital three-dimensional model of an object, its completely material prototype. This was done thanks to 3D printing, which we will discuss in more detail in this article.

In the 90s, a lot was done to make computer technology perceive and make digital models of real objects, which was solved by several 3D scanning technologies. Finally, the way back was paved: the computer was taught to create, on the basis of a digital three-dimensional model of an object, its completely material prototype. This was done thanks to 3D printing, which we will discuss in more detail in this article.

3D printing is not so new as to claim any cutting-edge scientific developments: the roots of this technology go back to the early 90s. However, many of us may consider 3D printing a curiosity. 3D printers have not become widespread up to entry into every home, it is too early to even say that these devices are in every company where the creation of a three-dimensional prototype is one of the mandatory steps. You can print literally anything - from a one-to-one scale model of a bolt to a miniature copy of a satellite or a future stadium, but the development of technology has long been held back (and partly still held back) by important factors. A 3D printer is an expensive piece of equipment, and although prices have steadily declined over the years, not every organization can afford it. In addition, a fairly high qualification is required when creating a computer three-dimensional model, and in this sense it is gratifying that in recent years designing on paper with a pencil and a ruler has become an anachronism.

A 3D printer is an expensive piece of equipment, and although prices have steadily declined over the years, not every organization can afford it. In addition, a fairly high qualification is required when creating a computer three-dimensional model, and in this sense it is gratifying that in recent years designing on paper with a pencil and a ruler has become an anachronism.

General information in boxes and globes

There is a company in Noginsk near Moscow that has been mainly engaged in the production of packaging with full-color printing for many years. Here, quite a long time ago, they appreciated the convenience of working with computer three-dimensional models when creating a construct and design, and therefore they also mastered the corresponding software products. “When, over time, we learned how to operate with computer images well,” says Alexander Dobrolyubov, head of the Public Market company, “the idea arose to show customers not yet existing boxes in three-dimensional form. We found and mastered complex software products like Autodesk Maya, and then realized that you can not limit yourself to packaging alone.”

We found and mastered complex software products like Autodesk Maya, and then realized that you can not limit yourself to packaging alone.”

The company began to look for the right technology and discovered 3D printing. In 2007, a ZPrinter 510 3D machine was purchased. “Through trial and error,” says Alexander Dobrolyubov, “we came to the conclusion that some products at the prototyping stage can be done quickly and well by 3D printing. We began to take orders for the creation of prototypes of all kinds of products from outside. In order to be less dependent on external orders for 3D printing, the Public Market made sure that the company also had its own project for a 3D printer. This project was the creation of a large relief globe. By itself, the globe may not be 100% used for its intended purpose, but as an original piece of furniture it will decorate the office of any leader and will be a great gift. The choice was based not so much on opportunistic considerations as on the personal sympathies of employees for such a project. Nevertheless, the project needed to be brought to the stage where a globe of one size or another could be placed on the floor or on a table, and not stop only at the contemplation of the model on the computer screen. And the ZPrinter 510 helped with that.

Nevertheless, the project needed to be brought to the stage where a globe of one size or another could be placed on the floor or on a table, and not stop only at the contemplation of the model on the computer screen. And the ZPrinter 510 helped with that.

How it works

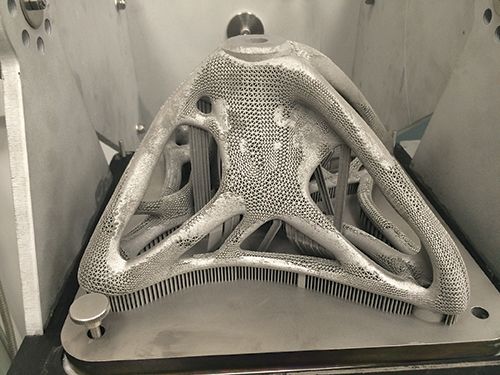

The technology used by Z Corporation printers (namely, this company produces devices under the ZPrinter brand) basically involves layer-by-layer growth of a model from plaster powder in a special chamber. In various models of Z-printers, the build chambers have different volumes, which determine the maximum size of the object being grown.

The model to be printed must be as realistic as possible, without infinitely thin walls and open surfaces. If it’s quite simple, it should fully correspond to the future subject, and not be its simplified likeness. For example, it is not enough if the computer models of the fragments of the globe are only some parts of the surface of the sphere. These fragments must have a certain thickness, calculated on the basis of the expected loads on the final product. The printer software is able to point out a number of errors in the simulation, but the operator, based on his own experience, must also see the weaknesses himself.

These fragments must have a certain thickness, calculated on the basis of the expected loads on the final product. The printer software is able to point out a number of errors in the simulation, but the operator, based on his own experience, must also see the weaknesses himself.

If everything is in order with the computer model, the printer driver programmatically breaks it into layers of 0.1 mm, which are then applied one after another. In the course of printing, the gypsum particles are held together with a special binder, and the surface of the future model is simultaneously painted in accordance with the developed design.

Printing is from top to bottom, while the movable bottom of the chamber drops slightly after applying the next layer. The chamber is gradually filled with gypsum over the entire area to the current level of the height of the model, but the binder unites only those particles that should become part of the final prototype. It turns out that at every moment the model being built is surrounded on all sides by powder - it performs the function of supporting the model and its individual parts. This is necessary because the printer allows you to print objects with fairly small details, and before special processing after printing, gypsum remains a very fragile material that breaks even with a slight impact. An additional plus of this approach is that Z Corporation printers allow you to grow several models at once, which can be located throughout the volume of the chamber. So, for example, it happens when growing fragments for three-dimensional globes in the Public Market.

This is necessary because the printer allows you to print objects with fairly small details, and before special processing after printing, gypsum remains a very fragile material that breaks even with a slight impact. An additional plus of this approach is that Z Corporation printers allow you to grow several models at once, which can be located throughout the volume of the chamber. So, for example, it happens when growing fragments for three-dimensional globes in the Public Market.

After printing is completed, the grown models are dried. Then the chamber is freed from excess powder, which will be reused. Almost finished and still very fragile models are carefully moved into a special blowing chamber, where powder residues are removed from them and treated with an impregnating composition that makes the model durable. Which one depends on the specified strength criteria. Finally, in order for the model to dry after impregnation and be ready for use, you need to wait a few more minutes. Depending on the model, ZCorp printers allow you to perform certain auxiliary actions automatically.

Depending on the model, ZCorp printers allow you to perform certain auxiliary actions automatically.

3D printer - universal tool

The above technology, of course, limits the designer's imagination to some rules, but for the most part they are tied to the elementary laws of physics. Otherwise, you can print the most complex models, which makes the scope of the printer very wide. According to Alexander Dobrolyubov, the possibilities of 3D printing technology awaken creativity, which he sees in the example of Public Market employees. “Our ZPrinter 510 is especially interesting and often indispensable for creating prototypes of products that have a great artistic component. These are shoes, architectural objects, and clothes,” says Alexander. “Healthcare institutions are asking us questions about preparing ideal training models.” In this regard, he spoke about a recent call from doctors who needed help preparing for a complex operation - a full-size model of a human head that accurately takes into account the internal structure of a particular patient and was created on the basis of tomography results. “And I don’t know how it would be possible to solve such a problem without a 3D printer,” Alexander concludes.

“And I don’t know how it would be possible to solve such a problem without a 3D printer,” Alexander concludes.

At the same time, it must be admitted that 3D printing is still expensive due to the low prevalence of the technology and the lack of awareness among end users. The price of components, consumables and, as a result, the cost of printing is very high. Buying a printer for occasional use may not justify itself. Alexander has no doubt that without his own project, his company would certainly not have profited from the printer. “It so happened,” he explains, “that the embossed globe is a unique product, and we can really make money on it. The uniqueness of the project is that we can make the globe the way the customer wants to see it: we vary the sizes, textures, colors. In addition to being unique, it is also convenient for both us and our clients.” Public Market has already produced a considerable number of various products, including globes, and on the day when Alexander answered questions for this article, another globe was in the works, the diameter of which, at the request of the customer, will be 1 m 20 cm.

The secret of Public Market's success is that they have not forgotten the main thing here: a printer, even if it performs three-dimensional printing, is just a tool. To make money with such a device, you need ideas and the ability to bring them to mind. “The production of globes is not only printing,” says the head of the Public Market. - Print - twenty percent of the whole case. Bringing the product to such a form that it can be used for a long time is not easy. Fragments must match in color and size, and meet strict strength criteria. To solve some problems, it was necessary to develop their own techniques. But it is the 3D printer that suits us more than any other technology.”

Our interlocutor admits that the ZPrinter 510 is not only expensive, but also difficult to use. At the same time, he is convinced that any thinking person understands that complex, unique equipment requires additional efforts from the user, including intellectual ones. “Developers from Z Corporation do not stand still, they offer new options for both software and equipment,” notes Alexander. “I think that with proper service support, reasonable prices for spare parts and consumables, 3D printing technology will definitely have a worthy future.”

“I think that with proper service support, reasonable prices for spare parts and consumables, 3D printing technology will definitely have a worthy future.”

Public Market decided not to reduce its own three-dimensional projects to globes alone. The site www.mentalauto.ru has recently started working, where users are invited to implement their tuning ideas based on computer 3D prototypes of popular car models by editing some elements of the car design directly on the site. After installing a small free 3D player, you can operate a full-fledged 3D model, use your own graphics and save the results of your work. Thus, a car enthusiast can not only enjoy a virtual three-dimensional model of his tuned iron horse, but also, using 3D printing, reproduce each tuning element to adjust and refine the three-dimensional model. After all, it is better to first experiment on plaster, and only then embody ideas in metal and plastic. Perhaps this is one of those steps towards the consumer 3D printing, which in the future will make the technology available to everyone.