3D printing technology evolution

The Evolution of 3D Printing: Past, Present and Future

0Shares

The Past

When we talk about the history of something, it makes sense to start at the beginning. For 3D Printing, that beginning was way back in the late 1980’s or, as I like to call it, ‘Pre-Me’. Charles Hull invented the SLA Printer around 1987. Back then it would cost you somewhere in the vicinity of $300k to purchase one.

How does that translate to 2016? Well, accounting for total inflation of 116%, that $300k printer would cost nearly $650k today. So it wasn’t really an inexpensive hobby that people were investing in.

Up until 5 years ago, the average cost of a 3D printer was floating around the $50k mark. But, due to consumerism and an increase in demand and, subsequently, production, you can now purchase a respectable 3D printer for the substantially lower cost of $1800. If that’s still too expensive for your pockets there is even a $49 3D printer available for pre-order on Kickstarter.

So, whichever way you look at it, you’ve got at least 2 options, which is probably more than what you were expecting.

Of course, this decline in the cost of 3D printing is not too surprising as the demand for the ability to print your own plastic cups and what-have-you has increased.

However, for printing enthusiasts, businesses and schools around the world, this is great news. I mean, over half of the primary and secondary schools in the UK today have access to 3D printers.

Of course, now that I’ve said today, I guess we’ve left the past behind and should move on.

The Present

The world is changing. Yes, we know it, we’ve read it before. So I won’t bore you with another piece on consumerism and inherent societal impatience. Instead, let’s jump straight to the point. That point is convenience; people want what they want and they want it yesterday.

Heck, I’ve even heard someone complain that his 2 minute noodles were taking too long to cook. Granted, that ‘someone’ was me, but whatever, case in point… I wasn’t asking you anyway!

Granted, that ‘someone’ was me, but whatever, case in point… I wasn’t asking you anyway!

Just like every other industry under the sun, the 3D printing industry is affected by the trend of more, faster and for less. It’s the modern matter of cost versus convenience. Paying someone to do something that we could do on our own is almost the trademark of this generation. If there’s a way to pay a little bit of money to get something done a lot faster, most people will go for it. Paying to save time on necessities so we can waste it on social media and Pokemon is the latest trend and it just won’t die.

Of course, this trend only works until a point. If 3D printers still cost 300k dollars, you can bet people wouldn’t be nearly as eager to throw their hard-earned money at the power to produce their beer pong cups.

In this modern age of 3D printing, we are constantly seeing new feats accomplished with this technology. Whole industries are reexamining the manner in which they operate. And it’s all thanks to this technology that is so readily at their fingertips.

And it’s all thanks to this technology that is so readily at their fingertips.

There is an ever-growing list of astounding things being accomplished with 3D printing that we could talk about. But, we’re just going to look at one.

Back in 2004 and 2005, Chinese company WinSun developed a 3D printing spray nozzle and automatic material feeding system. Three years later, in 2008, they printed an actual wall for a building.

Now, before you start hurling insults and saying “Jesse! That’s 8+ years ago. Do you even understand what the present is?” read on.

Late last year WinSun printed (yes, that’s right, printed) a five-storey residential apartment building. But they didn’t stop there. To top off this feat, they also built a 3D printed 1,100 square metre villa that came complete with internal and external decorations.

Now, that’s just one example of the things being achieved with 3D printing TODAY. As this impressive technology continues to develop we can ask: “What will the future bring?”

The Future

Predictions are a tricky thing. For instance, take the second Back to the Future film. It’s 2016 and I’m not wearing self-lacing Nike shoes and I don’t own a hover-board (a real one! Not those two-wheeled gadgets that call themselves hover-boards). This is the inherent risk in prophecy; unless you are God, you can’t guarantee the things you predict will happen as you predicted.

For instance, take the second Back to the Future film. It’s 2016 and I’m not wearing self-lacing Nike shoes and I don’t own a hover-board (a real one! Not those two-wheeled gadgets that call themselves hover-boards). This is the inherent risk in prophecy; unless you are God, you can’t guarantee the things you predict will happen as you predicted.

With that in mind, let’s make a one or two “educated guesses.”

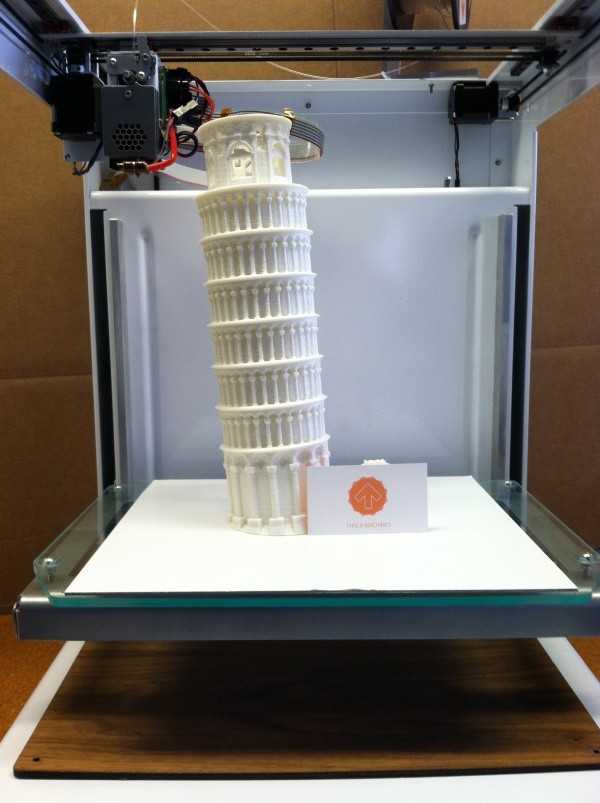

I’m going to start by talking about the accomplishment of MIT’s Computer Science and Artificial Intelligence Laboratory (CSAIL) earlier this year. They developed a 3D printing technique that allows for the simultaneous printing of both solid and liquid materials.

Using this technology, they were able to print a fully-functional robot in a single print run. Well, an almost fully-functional robot. But wait; there’s more.

They accomplished this, not with some uber-expensive, state-of-the-art printer but, with a modified, off-the-shelf printer. So, with the right know-how, you could do this at home. Though chances are you’ll mess it up. No offence, but there’s a reason you don’t work at CSAIL…

Though chances are you’ll mess it up. No offence, but there’s a reason you don’t work at CSAIL…

Once it’s printed, the robot still needs to have a battery added on before it can operate. So yes, it isn’t complete in a single step. But so what? That’s still a two-stage process to a dynamic robot!

By now you’re probably wondering how this relates to the future of 3D printing.

Well, unfortunately, you probably won’t be printing out robotic butlers or maids anytime soon, so don’t throw away your dishwasher just yet. Plus, divorces are expensive, so…

What is more likely (than your own servant-bots, I can’t speak for the state of your marriage), is that we’ll see local print centres popping up as places where those of us without 3D printers can take our USB sticks and blueprints to print off whatever it is that strikes our fancy. And as the industry continues to grow, the complexity of what we’ll be able to print will undoubtedly grow.

But that’s just for you and me. For the larger-scale manufacturer, don’t start selling your factories or firing your assembly-line workers just yet. It isn’t likely that 3D printing will ever be more cost-effective than injection molding to, say, make 100,000 smartphone cases. But, 3D printing will likely affect the ease of getting new and innovative products to market quicker and for less money. As an example, you could test the fit of a smartphone case before sending it off to manufacturing, to make sure it’s exact.

For the larger-scale manufacturer, don’t start selling your factories or firing your assembly-line workers just yet. It isn’t likely that 3D printing will ever be more cost-effective than injection molding to, say, make 100,000 smartphone cases. But, 3D printing will likely affect the ease of getting new and innovative products to market quicker and for less money. As an example, you could test the fit of a smartphone case before sending it off to manufacturing, to make sure it’s exact.

As for me? I’m going to stick with LEGO for the time being.

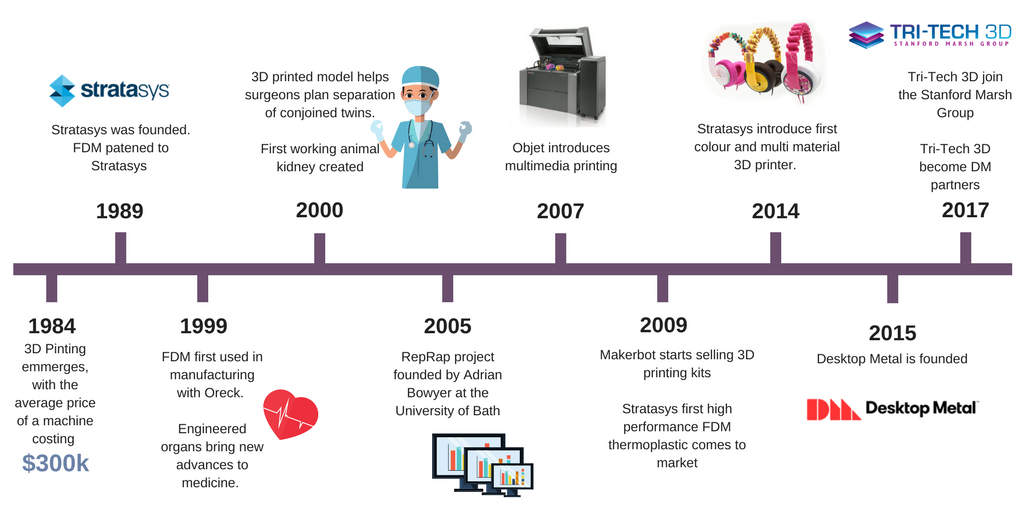

Finally, if you’d like a nice, easy-to-read summary of all this, here is a handy little infographic:

Tags history of 3d printing infographic Report Reports

Alicia Miller

Alicia Miller is a culture writer from New York dedicated to all things creative. Her studies in media have immersed her in the digital world, although she prefers to spends her free time reading classic literature.

Evolution of 3D Printing, How 3D Printing Will Change Manufacturing

3D printing has been around for nearly 40 years, but its only in the more recent history of the evolution of 3D printing that we’ve really seen 3D printing changing manufacturing in major ways. Starting around 2005, as 3D printing equipment lowered enough in cost to become a viable method of production for applications such as prototyping, design testing and short runs, the industry has seen major advances in the ways that this technology can be applied.

Starting around 2005, as 3D printing equipment lowered enough in cost to become a viable method of production for applications such as prototyping, design testing and short runs, the industry has seen major advances in the ways that this technology can be applied.

Along with this expansion of 3D printing applications came a major shift in interest and adoption of the technology. 3D printing even enjoyed a short time in the late 2000s as a “buzzword,” leading industry experts and observers to wonder, “Will 3D printers replace manufacturing?

How Is 3D Printing Changing the Manufacturing Industry?

The answer to the question of replacing manufacturing is, in most cases, “no” — at least in the foreseeable future. But if we look instead at how 3D printing will change manufacturing, that process is well underway. Once 3D printing reached the tipping point of accessibility in the mid-2000s, it led to changes occurring in several important areas of manufacturing. These include:

- Prototyping: 3D printing changed the speed, materials and functionality with which prototypes could be efficiently produced, leading to faster overall production, fewer prototyping iterations and lower overall costs.

With 3D printing, one-off prototypes can be produced in a matter of hours, with total turnaround times as short as a day.

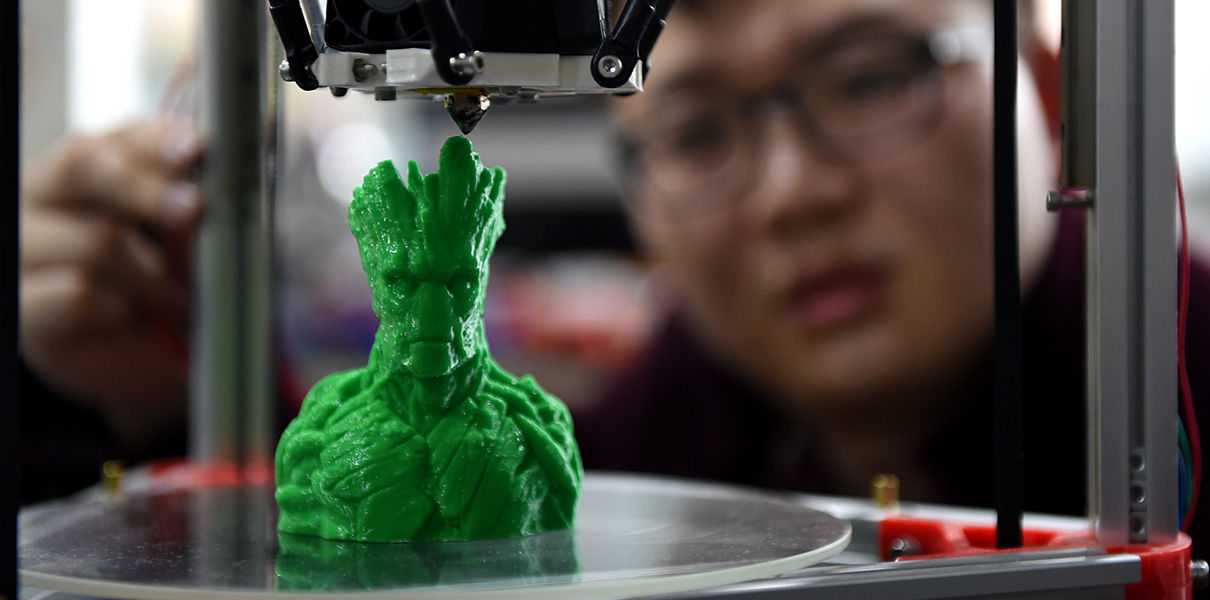

With 3D printing, one-off prototypes can be produced in a matter of hours, with total turnaround times as short as a day. - Design and testing: When asking, “How has 3D printing changed over the years?” … desktop 3D printers are one of the most important advances. With the advent of desktop 3D printing equipment, every shop and even every designer can have a 3D printer right on their desk. This means designs can quickly be replicated in three-dimensional space, without the need to order a prototype from a vendor. 3D printing technology has even advanced to the point where desktop machines can create useful working prototypes, testing functionality as well as design.

- Short run manufacturing: 3D printing for production is often considered as the payoff of one of the earliest promises of the technology. While we mentioned earlier that 3D printing is unlikely to fully replace traditional manufacturing anytime soon, this is one area where 3D printing can, in fact, be used in place of more traditional methods.

Advances in the types of materials available, and the material properties that can be replicated in 3D printing materials, mean that workable, sellable parts can be made through the process.

Advances in the types of materials available, and the material properties that can be replicated in 3D printing materials, mean that workable, sellable parts can be made through the process.

Advantages of 3D Printing

From the outset, 3D printing has always offered the promise of advantages over traditional manufacturing in certain scenarios. Throughout the evolution of 3D printing, as the technology has been developed, those advantages — and more — have become reality. Let’s take a look at some of them now:

- Better quality prototypes, faster and at lower costs: Before 3D printing, sacrifices typically had to be made in the production of viable prototypes, whether in materials, fidelity to the design, or the speed and cost of prototype creation. Production quality prototypes were available, but costs would typically become prohibitive given the practicalities of one-off production on high-volume machinery. 3D printing, and the pace of advances in materials and equipment speed, means that high-quality prototypes can be created at a fraction of the cost and time involved in other processes.

- Ability to iterate and adjust design: The ability to get high-quality prototypes quickly and at low cost means designers and engineers are able to iterate more efficiently, ultimately resulting in a better product created in less time. When time or cost limits the number of prototypes that can realistically be involved in a development process, engineers must, at a certain point, move forward with an imperfect design. With 3D printing, that end point is much further off on the horizon.

- Faster overall production speeds: The time that 3D printing can save in the design and prototyping processes means overall time-to-market is reduced. This equates to bottom line benefits for you as well as your customers.

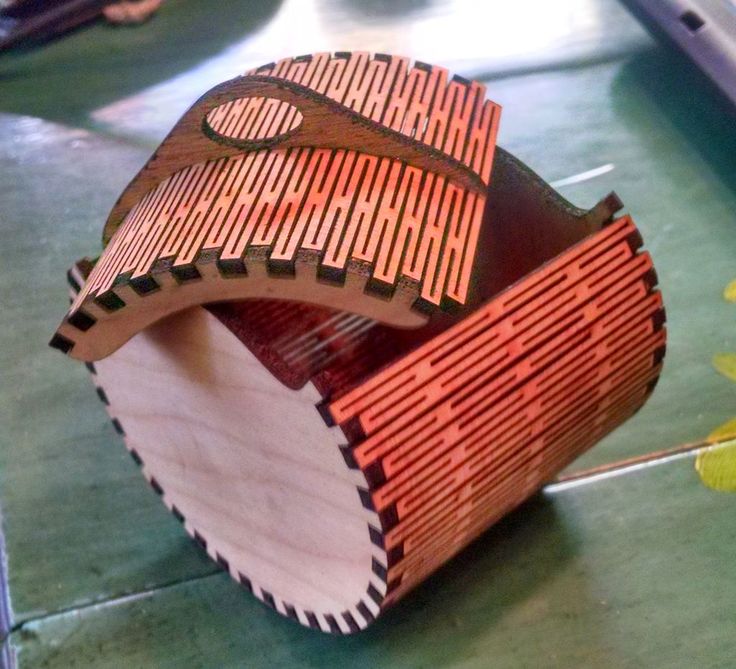

- More design flexibility: In scenarios where 3D printing will be used for short-run production, the possibilities of product design are greatly expanded. Whereas traditional manufacturing methods have limitations in the geometries, thicknesses, and other physical aspects that can be designed and created, thanks to the realities of each respective process the additive 3D printing process offers far fewer restrictions.

This allows entrepreneurs and innovators to create products that would have been difficult, or even impossible, to produce via traditional methods.

This allows entrepreneurs and innovators to create products that would have been difficult, or even impossible, to produce via traditional methods. - Reduced waste: As an additive manufacturing process, 3D printing uses only the material required to create a part (with the exception of supports that may be removed for certain types of designs). This is in contrast to other processes, where material is removed from the raw base in order to produce the final shape. With these processes, this material must be disposed of, not to mention paid for initially, resulting in higher costs and facility waste.

- Mobility: 3D printers offer vastly improved portability over traditional manufacturing methods (which often can’t be accomplished outside of a traditional facility). 3D printers can be brought on boats, into remote environments, even into space — offering fast production of needed parts when they may not have otherwise been available.

The Future of 3D Manufacturing

The above benefits have major implications for where 3D printing can take us in the future.

The mobility aspect means replacement parts can now be created on extended missions (such as military missions or space exploration), instead of needing to be supplied in advance. This has a huge impact on the potential duration of these types of projects.

In addition, the speed, low cost and versatility of 3D printing drive access and innovation, meaning more creators are able to make their visions a reality, at lower costs.

Finally, the reduced waste created by 3D printing means a more environmentally friendly process overall, which over the long run can make a big difference in sustainability.

With all of these benefits and advantages in mind, we may one day not be asking “How has 3D printing changed manufacturing?” but rather “How has 3D printing changed the world?”

History of 3D printing

In this section, we wanted to trace the history of 3D printing from its inception to the present day, as well as give a forecast regarding the future development of technology.

The first 3d printer was invented by the American Charles Hull, he worked on the technology of stereolithography (SLA), a patent for the technology was issued in 1986. The printer was a fairly large industrial installation. The installation "grew" a three-dimensional model by applying a photopolymerizable material to a moving platform. The basis was a digital model pre-modeled on a computer (3D model). This 3d printer created three-dimensional objects, rising by 0.1-0.2 mm - the height of the layer. Despite the fact that the first device had many disadvantages, the technology has received its application. Charles Hull is also the co-founder of 3dsystems, one of the world's leading manufacturers of industrial 3D printers.

Charles Hull was not the only one to experiment with 3D printing technology, as in 1986 Carl Deckard invented Selective Laser Sintering (SLS). You can learn more about the method in another article, briefly: a laser beam sinters a powder (plastic, metal, etc. ), while the mass of the powder is heated in the working chamber to a temperature close to the melting point. The basis is also a digital model pre-modeled on a computer (3D model). After the laser passes through the horizontal layer, the chamber is lowered to the layer height (usually 0.1-0.2 mm), the powder mass is leveled with a special device and a new layer is applied.

), while the mass of the powder is heated in the working chamber to a temperature close to the melting point. The basis is also a digital model pre-modeled on a computer (3D model). After the laser passes through the horizontal layer, the chamber is lowered to the layer height (usually 0.1-0.2 mm), the powder mass is leveled with a special device and a new layer is applied.

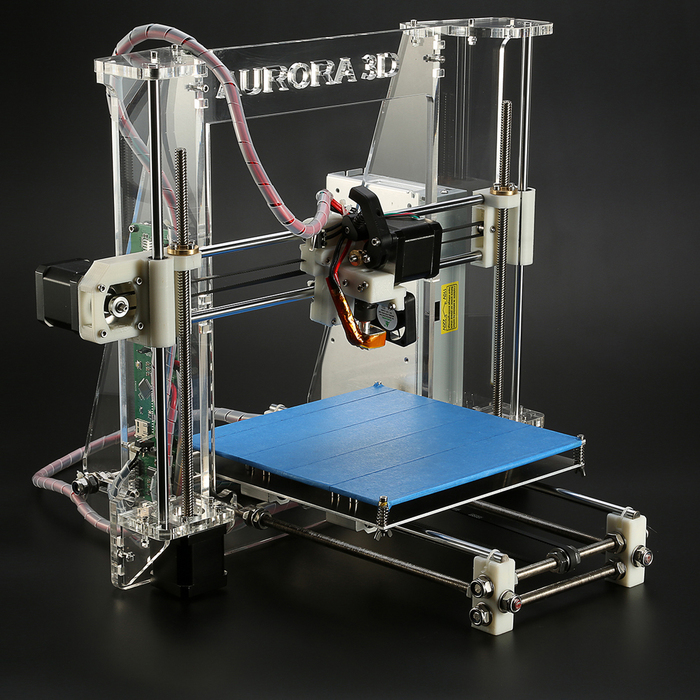

However, the most famous and widespread 3D printing method today is layer-by-layer direction (FDM). The idea of technology belongs to Scott Crump (Scott Crump), the patent dates back to 1988. You can learn more about the method in another article, in short: material (usually plastic) is fed from the heated nozzle of the print head using a stepper motor, the print head moves on linear guides along 1 or two axes, and the platform moves along 1 or 2 axes . The basis of the movement is also a 3D model. The molten plastic is laid on the platform along the established contour, after which the head or platform is moved and a new layer is applied on top of the old one. Scott Crump is one of the founders of Stratasys, which is also one of the leaders in the production of industrial 3D printers.

Scott Crump is one of the founders of Stratasys, which is also one of the leaders in the production of industrial 3D printers.

All the devices described above belonged to the class of industrial devices and were quite expensive, so one of the first 3d Dimension printers from Stratasys in 1991 cost from 50 to 220 thousand US dollars (depending on the model and configuration). Printers based on the technologies described above cost even more and until very recently, only a narrow circle of interested specialists knew about these devices.

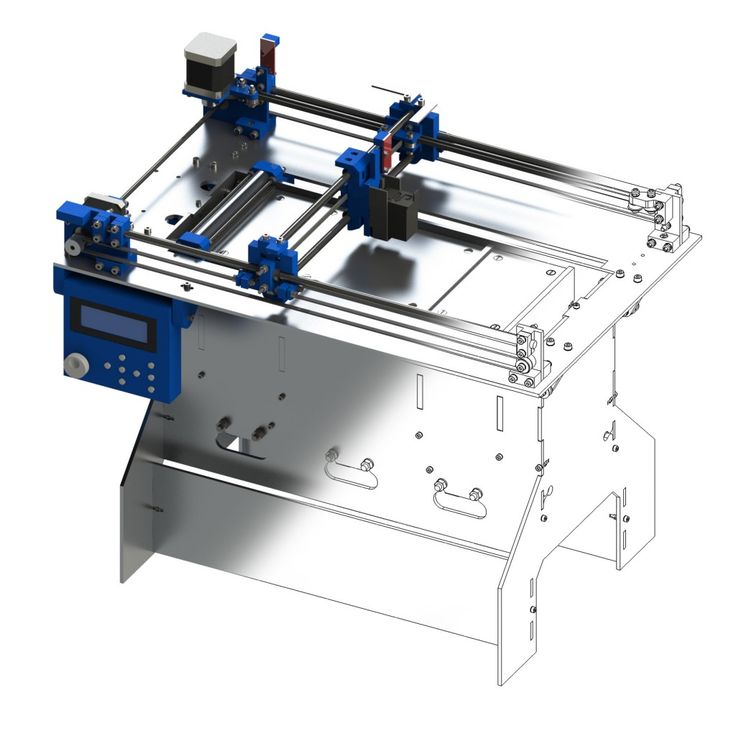

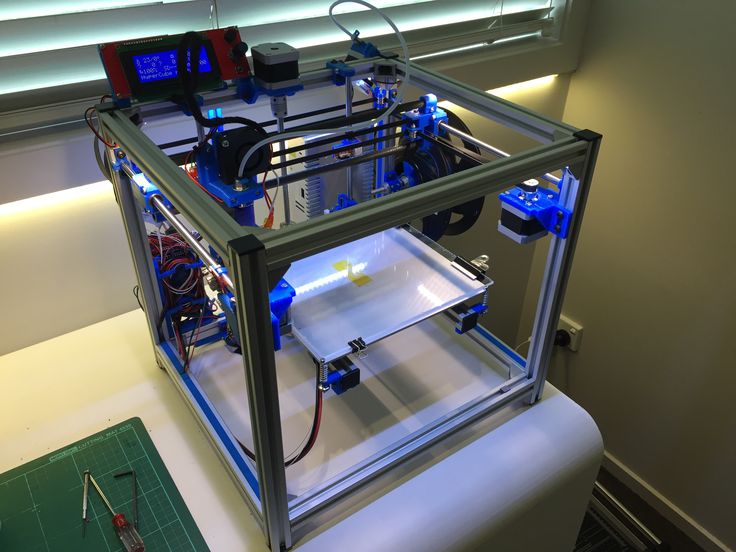

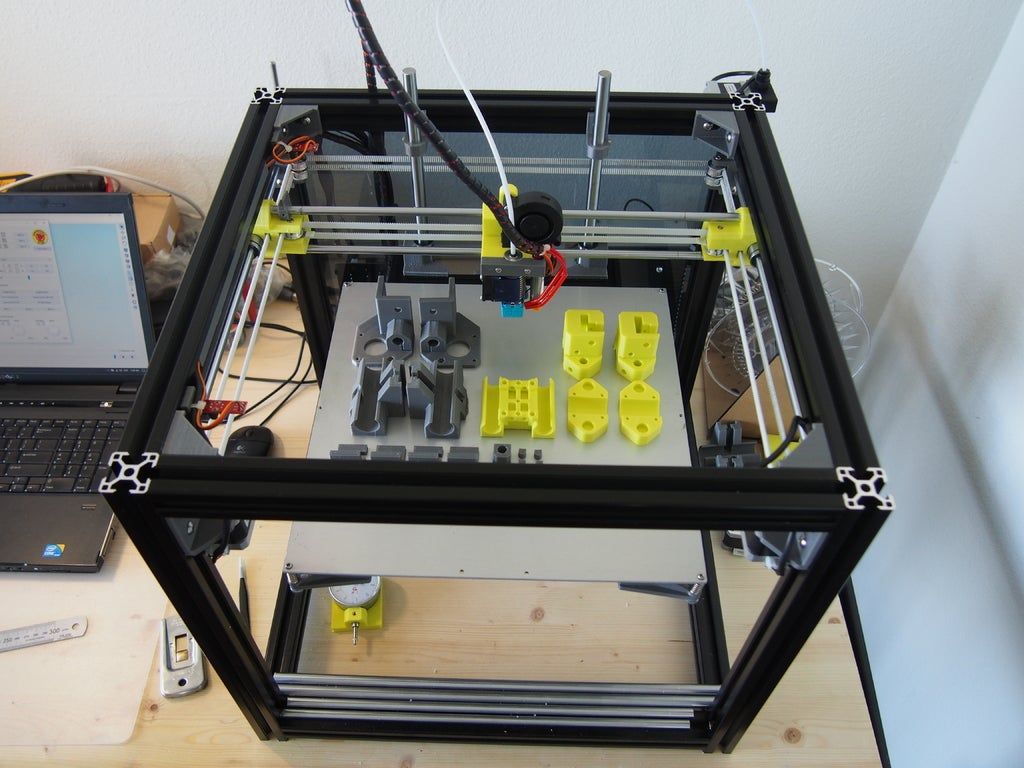

Everything began to change since 2006, when the RepRap project (from the English Replicating Rapid Prototyper - a self-replicating mechanism for rapid prototyping) was founded, with the goal of creating a self-copying device, which was a 3D printer working on technology FDM (layer by layer deposition). Only, unlike expensive industrial devices, it looked like a clumsy invention made from improvised means. Metal shafts serve as a frame, they also serve as guides for the print head. driven by simple stepper motors. The software is open source. Almost all connecting parts are printed from plastic on the 3D printer itself. This idea originated among English scientists and aimed at spreading available additive technologies so that users can download 3D models on the Internet and create the necessary products, thus minimizing the production chain.

driven by simple stepper motors. The software is open source. Almost all connecting parts are printed from plastic on the 3D printer itself. This idea originated among English scientists and aimed at spreading available additive technologies so that users can download 3D models on the Internet and create the necessary products, thus minimizing the production chain.

Leaving aside the ideological component, the community (which exists and develops to this day) managed to create a 3d printer accessible to the "ordinary person". So a set of unprinted parts can cost around a couple of hundred US dollars and a finished device from $500. And even though these devices looked unsightly and were significantly inferior in quality to their industrial counterparts, all this was an incredible impetus for the development of 3D printing technology.

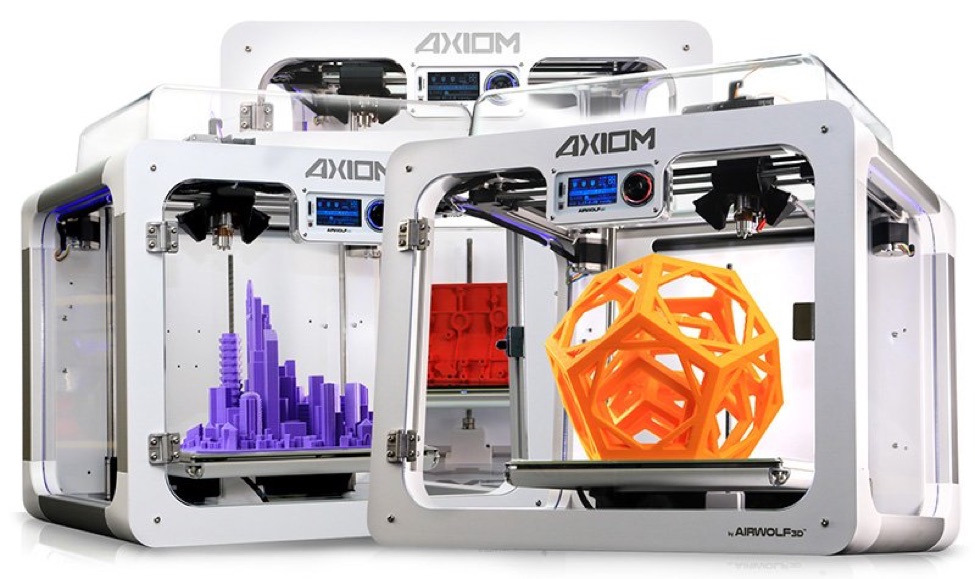

As the RepRap project developed, 3D printers began to appear, taking as a basis the base laid down by the movement in technical and, sometimes, ideological terms (for example, commitment to the concept of open source - OpenSource). The companies that made printers tried to make them better both in terms of performance, design and user experience. The first RepRap printers cannot be called a commercial product, since it is not so easy to manage (and even more so to assemble) and it is not always possible to achieve stable work results. Nevertheless, companies tried to close the more than significant gap in quality, leaving a significant gap in cost whenever possible.

The companies that made printers tried to make them better both in terms of performance, design and user experience. The first RepRap printers cannot be called a commercial product, since it is not so easy to manage (and even more so to assemble) and it is not always possible to achieve stable work results. Nevertheless, companies tried to close the more than significant gap in quality, leaving a significant gap in cost whenever possible.

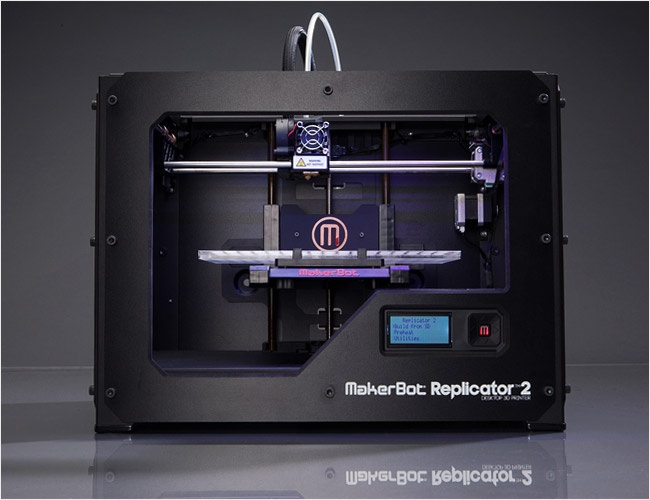

First of all, it is worth mentioning the MakerBot company, which started as a startup, took RepRap ideas as a basis and gradually turned them into a product of a new quality.

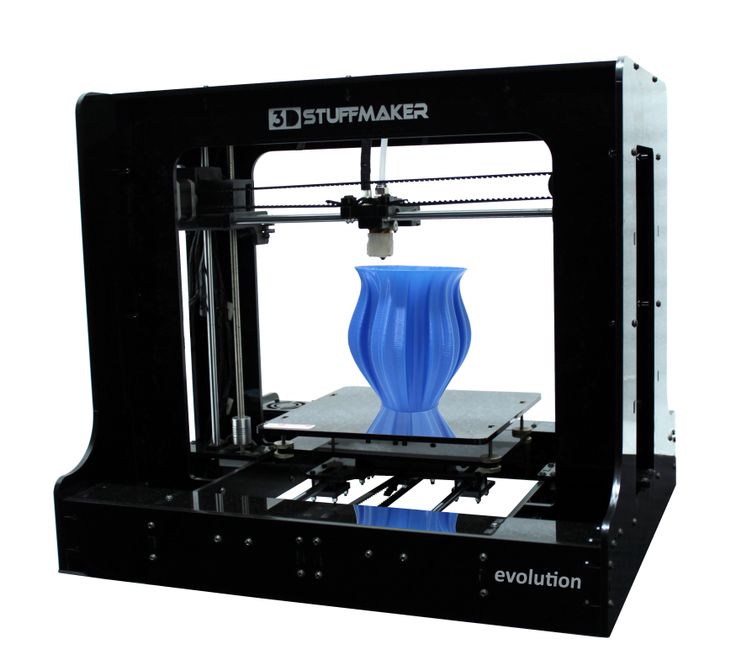

Their flagship product (and in our opinion the best to this day) remains the MakerBot Replicator 2 3D printer. The model was released in 2012 and later discontinued, but remains one of the most popular 3D printer models to this day " personal" segment (according to 3dhubs). The word "personal" is in brackets because this printer, which cost $2,200 at the time of release, was (and is) primarily used for business purposes, but falls into the personal segment due to its cost. This model differs from its progenitors (RepRap), being, in fact, a finished commercial product. Manufacturers abandoned the concept of OpenSource, closing all sources and software codes.

This model differs from its progenitors (RepRap), being, in fact, a finished commercial product. Manufacturers abandoned the concept of OpenSource, closing all sources and software codes.

In parallel with the release of equipment, the company actively developed the Thingiverse resource, which contains many models for 3d printing, available for download for free. During the development of the first printer and beyond, the community has helped the company a lot, testing the product and offering various upgrades. After the release of the Replicator 2 (and the closure of development), the situation has changed. You can learn more about the history of MakerBot and other companies and people associated with 3d printing by watching the film Print the legend.

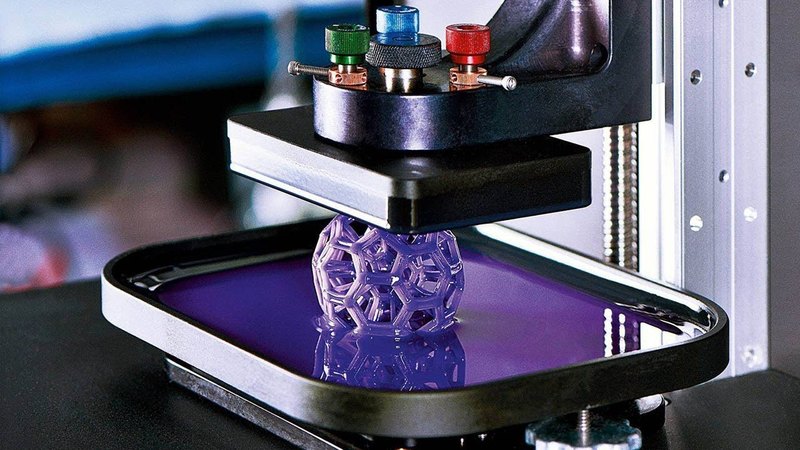

This film also highlights the history of Formlabs, one of the first companies to launch an affordable 3D printer based on SLA (Strereolithography) technology. The company raised funds for the first FORM 1 model through crowdfunding, encountered production difficulties, but eventually released an affordable and productive 3D printer, closing the quality gap described above.

And although the 3D printers described above were far from perfect, they laid the foundation for the development of affordable 3D printing technology, which continues to this day. At the moment, the quality of FDM and SLA printers is increasing, but there is no significant price reduction, rather, on the contrary, it is growing slightly. Along with FDM and SLA, many companies are developing in the field of powder sintering (SLS), as well as metal printing. Despite the fact that such printers cannot be called affordable, their price is much lower in comparison with analogues from the professional segment. It is also worth noting the development of the line of materials, in addition to the standard ABS and PLA plastics, today many different materials are used, including nylon, carbon fiber and other durable and refractory materials.

Personal 3d printers of today are very close to professional devices, the development of which also does not stop. In addition to the "founders" of the technology (Stratasys, 3dsystems), many small companies specializing in industrial 3D printing technologies (metal in particular) have emerged. 3D printing is also attracting the attention of large corporations, which, with varying degrees of success, are striving to take their place in a growing market. Here it is worth highlighting HP, which recently released the HP Jet Fusion 3D 4200 model, which has gained popularity among 3d printing professionals (as of 2018, it is at the top of the ranking of professional 3D printers in the quarterly reports of the 3dhubs portal).

3D printing is also attracting the attention of large corporations, which, with varying degrees of success, are striving to take their place in a growing market. Here it is worth highlighting HP, which recently released the HP Jet Fusion 3D 4200 model, which has gained popularity among 3d printing professionals (as of 2018, it is at the top of the ranking of professional 3D printers in the quarterly reports of the 3dhubs portal).

However, 3D printing technologies are developing not only in breadth, but also in depth. One of the main disadvantages of 3D printing, compared to other production methods, is the low speed of creating models. A significant advance in terms of accelerating 3D printing was the invention of CLIP technology by CARBON, printers operating on this technology can produce models 100 times faster than classic SLA technology.

There is also a constant expansion of the range, properties and quality of materials and post-processing of products. All this accelerates the transition to the use of 3d printers in production, and not just as prototyping devices. Today, many large and not only companies and organizations are closely using a 3D printer in their production chain: from consumer goods manufacturers NIKE and PUMA to BOEING and SPACE X (the latter prints engine parts for its rockets that could not be made in any other way) .

All this accelerates the transition to the use of 3d printers in production, and not just as prototyping devices. Today, many large and not only companies and organizations are closely using a 3D printer in their production chain: from consumer goods manufacturers NIKE and PUMA to BOEING and SPACE X (the latter prints engine parts for its rockets that could not be made in any other way) .

In addition to the "classic" scope of 3D printing, today more and more often you can see news about how a house or some organ (or rather, a small part of it) was printed on a 3D printer from bio-material. And this is true, several companies around the world are testing or already partially using 3D printing in the construction of buildings and structures. This mainly concerns the contour pouring of walls (similar to the FDM method) with a special composite concrete mixture. And in Amsterdam there is a 3D printed bridge project and this list will only expand over time, since the use of 3D printing in construction can significantly reduce costs and increase the speed of work at certain stages.

With regards to medicine, here 3D printing also finds application, but at the moment it is not printing organs, but rather the use of technology in prosthetics (of various kinds) and bone replacement. Also, 3D printing technology is widely used in dentistry (SLA technology). Regarding the printing of organs, this is still far in the future, at the moment bio-3D printers are experimental facilities in the early stages, the success of which is limited to printing a few limited-viable cells.

Looking to the future, it is safe to say that 3D printing technology will expand both in breadth and depth, improving technology, speeding up processes, improving quality and improving material properties. 3D printers will increasingly replace old methods in production chains of various scales, and world production, due to this, will move towards the “on demand” scheme of work, increasing the degree of product customization. Perhaps someday, 3D printers will be widely used at the household level for the production of necessary things (the dream and goal of the RepRap movement), but this requires not only the development of technology, but also a paradigm shift in social thinking, as well as the development of a powerful design ecosystem ( 3d modeling) products (which is often forgotten).

3d printing of houses (and other structures) will no doubt also develop, reducing costs and production time, which, together with the development of new approaches in architecture and urban planning (such as modular construction and the prefabricated method), will give a tangible impetus to development the industry as a whole.

Biological 3D printers will be an important tool in scientific research. However, before they appear in hospitals and clinics, where they will print new organs, it is still very, very far away (in fact, this is science fiction).

A Brief History of 3D Printing / Sudo Null IT News

3D printing was born 40 years ago and opened up amazing possibilities for creating various models in prototyping, dentistry, small-scale production, customized products, miniatures, sculptures, mock-ups and much more.

Who invented the 3D printer? What was the first 3D printing technology? And what was the first thing they printed on a 3D printer? Let's open the veil of secrecy over a huge number of interesting facts and stories about the emergence of technology. 9. , which layer-by-layer formed a rigid object from a photopolymer resin with the help of UV illumination.

9. , which layer-by-layer formed a rigid object from a photopolymer resin with the help of UV illumination.

In fact, he described a modern photopolymer printer, but failed to provide the necessary data for patent registration within a year, as required by patent law, and abandoned the idea. However, in many sources it is he who is called the inventor of 3D printing technology.

In 1983, three engineers - Alain Le Meho, Olivier de Witt and Jean-Claude André from the French National Center for Scientific Research, in an attempt to create what they called a "fractal object", came up with the idea of using a laser and a monomer, which, under the influence of a laser, turned into a polymer. They applied for a patent 3 weeks before the American Chuck Hal. The first object created on the apparatus was a spiral staircase. Engineers called the technology stereolithography, and the patent was approved only in 1986 year. Thanks to them, the most famous file format for 3D printing is called STL (from the English stereolithography). Unfortunately, the institute did not see any prospects in the invention and its commercialization, and the patent was not used to create the final product.

Unfortunately, the institute did not see any prospects in the invention and its commercialization, and the patent was not used to create the final product.

Laser Stereolithography At the same time, Chuck Hull was working for a company that made countertop and furniture coatings using UV lamps. The production of small plastic parts for prototyping new product designs took up to two months. Chuck came up with the idea to speed up this process by combining UV technology and layering thin plastic. The company gave him a small laboratory for experiments, where he worked in the evenings and weekends. As a material, Chuck used acrylic-based photopolymers that harden under the influence of ultraviolet radiation. One night, after months of experimentation, he was finally able to print a sample and was so elated by luck that he walked home. Chuck showed his invention to his wife. It was an eyewash cup, more like a communion cup, according to the wife. It is considered officially the first 3D printed model in the world and is still kept by the Hull family, and after their death will be transferred to the Smithsonian Research Institute in Washington.

It is considered officially the first 3D printed model in the world and is still kept by the Hull family, and after their death will be transferred to the Smithsonian Research Institute in Washington.

Chuck Hull filed a patent on August 8, 1984 and was approved on March 11, 1986. The invention was called "Apparatus for creating three-dimensional objects using stereolithography." Chuck founded his own company - 3D Systems, and in 1988 launched the first commercial 3D printer - the SL1 model.

Carl Deckard and Joe Beeman (right), inventors of SLS 3D printing (1987) Another new 3D printing method appeared around the same time as SLA printing. This is selective laser sintering SLS , which uses a laser to turn loose powder (instead of resin) into a solid material. Carl Deckard , a young undergraduate student at the University of Texas at Austin, and his teacher Prof. Dr. Joe Beeman were involved in the development. And the idea belonged to Karl. In 1987, they co-founded Desk Top Manufacturing (DTM) Corp. However, it will take at least another 20 years for SLS 3D printing to become commercially available to the consumer. In 2001, the company was bought out by Chaka Hull, 3D Systems.

And the idea belonged to Karl. In 1987, they co-founded Desk Top Manufacturing (DTM) Corp. However, it will take at least another 20 years for SLS 3D printing to become commercially available to the consumer. In 2001, the company was bought out by Chaka Hull, 3D Systems.

Surprisingly simpler and cheaper 3D printing is FDM (Fused Deposition Modeling) was created after SLA and SLS, in 1988. Its author was aeronautical engineer Scott Crump . Crump was looking for an easy way to make a toy frog for his daughter and used a hot glue gun to melt the plastic and pour it into layers. Thus, the idea of FDM 3D printing was born, a technology for layer-by-layer deposition of a plastic thread. Crump patented a new idea and co-founded Stratasys with his wife Lisa Crump at 1989 year. In 1992, they launched their first production product, the Stratasys 3D Modeler, on the market.

Milestone 2: 3D printing becomes available

The first machines built by 3D Systems and Stratasys were bulky and expensive. The cost of one was hundreds of thousands of dollars, and only the largest companies in the automotive and aerospace industries could use them. Printers had a lot of limitations and could not be widely used. The development of technology has been very slow. 20 years later, in 2005, the RepRap (Replicating Rapid Prototyper) project appeared - a self-replicating mechanism for rapid prototyping.

The cost of one was hundreds of thousands of dollars, and only the largest companies in the automotive and aerospace industries could use them. Printers had a lot of limitations and could not be widely used. The development of technology has been very slow. 20 years later, in 2005, the RepRap (Replicating Rapid Prototyper) project appeared - a self-replicating mechanism for rapid prototyping.

It was inspired by Dr. Adrian Bauer from the University of Bath in the UK. The goal of the project was to "self-copy", replicate the components of the 3D printers themselves. In the photo, all the plastic parts of the "child" are printed on the "parent". But in fact, a group of enthusiasts led by Adrian were finally able to create the budget 3D printer for home or office use .

The idea was quickly taken up by three New York technologists and started a desktop FDM printer company, MakerBot. This was the second turning point in the modern history of 3D printing.

Other technologies were being developed in parallel. One of them is bioprinting. Thomas Boland of Clemson University has patented the use of inkjet printing to 3D print living cells, making it possible to print human organs in the future. Dozens of companies around the world conduct research in this area.

Another important use of the new technology was the creation of prostheses, first conventional, and then bionic. In 2008, the first printed prosthesis was successfully transplanted into a patient and allowed him to return to a normal lifestyle.

Another milestone has been the emergence of open source print files on the Internet. Websites www.thingiverse.com, www.myminifactory.com and many others contain both free and paid files for 3D printing. Users share models online and print them themselves.

Stage 3: 3D printing today

In recent years, 3D printing has become available to the mass consumer: the price of printers has dropped significantly, and their use has become more convenient.