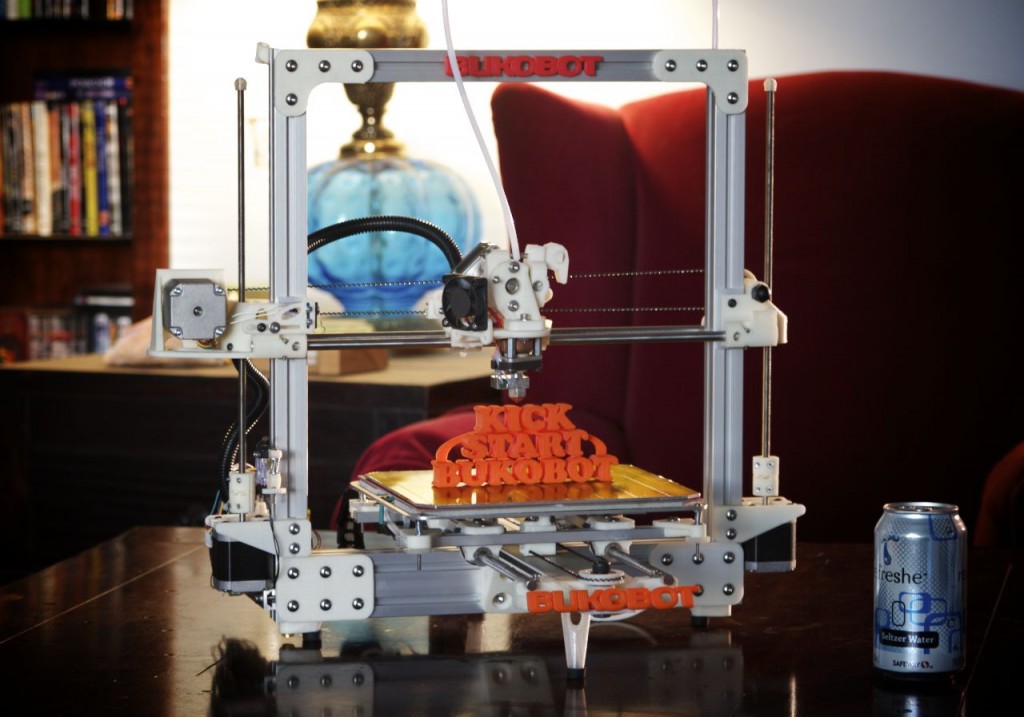

3D print store nyc

3D Printing | Large-Scale | The Factory NYC

3D-Printing

LARGE-SCALE 3D-PRINTING SERVICES

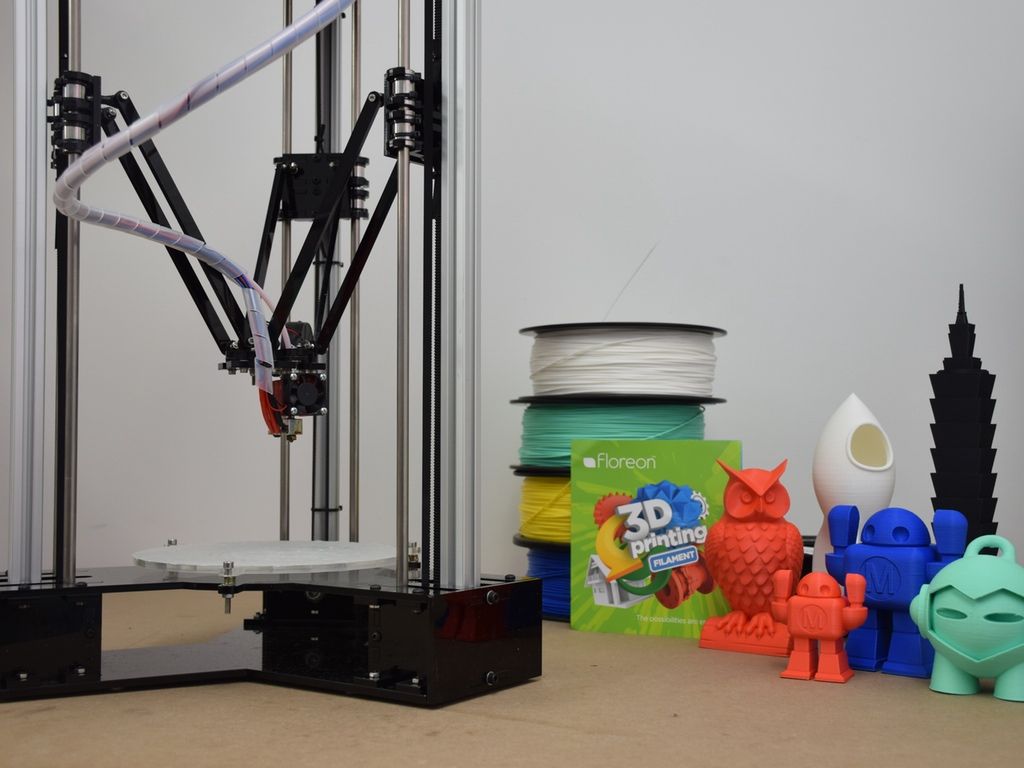

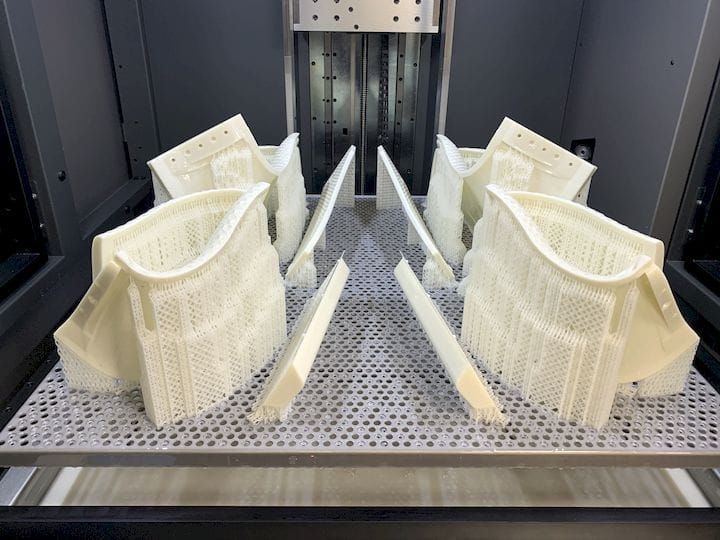

Massive 3D PrintsWe offer large-scale 3d printing for artists, engineers, and designers. Individual parts at 72" (177cm), and even larger with sectional fabrication. Start with a napkin sketch, a physical object to scan, or with fully engineered CAD files. Our design and production team at The Factory NYC will bring your project to life. Start your Project |

Oversized 3D-printed headphones with built-in audio made for City Eventions |

Start thinking in 3DRapid large-scale 3D Printing opens up a world of possibilities.

|

The future of storytelling is sculptural(and it's here)

Click to set custom HTML |

Big Print EnergyThe Factory NYC is the only event fabricator in NYC with a large-format 3D-printer — and its up to a 100x times faster than typical 3D Printing; and there is no size limit. |

Requirements

| Adding sculpture to your next event is easy. You don't need 3D modelers on your team — we have you covered. The only requirement is bring your vision with a budget. We can accommodate your design concept for most situations:

Even if you just have a 2D logo or design on pen and paper. We can create a digital model from scratch, and/or use 3D models from open source libraries. There are many ways to get started. |

Huge 3D-Printing — Get Inspired and Imagine

Delivering amazing projects, daily. | Our team of installers works throughout the New York City greater area. Local, domestic, and international delivery available through air, land, and sea. |

Join our Email list:

Sign up, and we'll share the latest event fabrication technologies:

Best🥇 3d Printing Stores New York Near You☝

Sort by:

Relevance

Best 3d Printing Stores New York Near Me sorted by user rating

VALUATIONS:

1-2 = Improvable

3-4 = Pass

4-5 = Excellent

Add my business

5

66 reviews

Prices

Quality Product

Services

Customer Services

Product Variety

Address: 394 McGuinness Blvd, Brooklyn, NY 11222

Schedule: Opens at 10:00 AM

Telephone: (929) 213-9604

Guy: 3D printing service

Web page: http://prtwd. com/

com/

Review: "Lots of printer machine doing printing 3d objects"

Near PrintAWorld:

- a 12 meters away McGuinness Boulevard: The Creamery Studio

- a 21 meters away McGuinness Boulevard: The Greenpoint Gallery

- a 65 meters away demolition companies: Tri-State Dismantling Corporation

Are you the owner of the business? PROMOTE IT!

5

43 reviews

Prices

Quality Product

Services

Customer Services

Product Variety

Address: 132 32nd St Unit 411, Brooklyn, NY 11232

Schedule: Opens at 10:00 AM

Telephone: (718) 737-7061

Guy: Electronics store

Web page: http://www.imakr.com/us/

Near iMakr - 3D Printers, Scanners, Services:

- a 0 meters away sliding glass doors in: Glass Partition - Crystalia Glass LLC

- a 0 meters away community management specialists: FirstService Residential Brooklyn

- a 1 meters away renovators of commercial premises in: Star Renovations NY

Are you the owner of the business? PROMOTE IT!

4. 9

9

83 reviews

Prices

Quality Product

Services

Customer Services

Product Variety

Address: 325 Gold St, Brooklyn, NY 11201

Schedule: Opens at 10:00 AM

Telephone: (718) 355-0157

Guy: Manufacturer

Web page: https://makelab.com/

Review: "Best service for 3D printing in the city!"

Near Makelab | 3D Printing Services:

- a 1 meters away 3d printing shops in: Makelab

- a 2 meters away second hand motorcycle dealers: Team Obsolete Products Ltd

- a 27 meters away Mobil Gas Station in: Mobil

Are you the owner of the business? PROMOTE IT!

4.9

16 reviews

Prices

Quality Product

Services

Customer Services

Product Variety

Address: 147-30 Jamaica Ave, Queens, NY 11435

Schedule: Open until 12:00 AM

Telephone: (347) 491-8088

Guy: Print shop

Web page: https://www. nyc3dprints.com/

nyc3dprints.com/

Near NYC 3D Printing:

- a 4 meters away ophthalmological clinics in: New York Ophthalmology

- a 17 meters away clothing printing stores: Queens T-shirt Printing

Are you the owner of the business? PROMOTE IT!

5

32 reviews

Prices

Quality Product

Services

Customer Services

Product Variety

Address: 74-12 88th St, Glendale, NY 11385

Schedule: Opens at 10:00 AM

Telephone: (917) 558-2254

Guy: 3D printing service

Web page: http://www.prtwd.com/

Review: "Great customer service and high quality 3D prints"

Near PrintAWorld Factory:

- a 92 meters away tiling: Tiles Unlimited, Inc.

- a 140 meters away body painting: East Coast Auto Plaza - Body Shop

- a 203 meters away free veterinarian: ASPCA Spay/Neuter Clinic – For Rescue Professionals Only

Are you the owner of the business? PROMOTE IT!

5

31 reviews

Prices

Quality Product

Services

Customer Services

Product Variety

Address: 28 Orchard St, New York, NY 10002

Schedule: Opens at 12:00 AM

Telephone: (800) 239-8181

Guy: Manufacturer

Web page: http://makemode.co/

Review: "I was my first time in a 3D printing Studio and I really really like what I ..."

Near Make Mode:

- a 2 meters away 3d printing shops in: Voxel Magic

- a 10 meters away orchard stores: Mannahatta NYC

- a 15 meters away pizzas in: Scarr's Pizza

Are you the owner of the business? PROMOTE IT!

4. 2

2

42 reviews

Prices

Quality Product

Services

Customer Services

Product Variety

Address: 44 W 28th St, New York, NY 10001

Schedule: Opens at 9:00 AM

Guy: Digital printing service

Web page: http://www.shapeways.com/

Review: "Shapeways provides a great service for those who want to 3D print products."

Near Shapeways:

- a 2 meters away fashion jewelry stores: Lucky G & M Fashion Jewelry

- a 7 meters away structure companies in: J.T. Magen & Company

- a 13 meters away crossfit gyms: CrossFit NYC

Are you the owner of the business? PROMOTE IT!

5

83 reviews

Prices

Quality Product

Services

Customer Services

Product Variety

Address: 327 Irving Ave Suite A - 1st Floor, Brooklyn, NY 11237

Schedule: Opens at 10:00 AM

Telephone: (347) 637-7599

Guy: Industrial design company

Web page: http://www. 3dbrooklyn.com/

3dbrooklyn.com/

Review: "I was recently looking for a company to design and print a 3D prototype."

Near 3D Brooklyn:

- a 4 meters away jewelry courses in: Bushwick Jewelry Casting

- a 43 meters away bookstore bars in: Mil Mundos Books and Cafe

- a 116 meters away Ecuadorian bars in: Esmeralda's

Are you the owner of the business? PROMOTE IT!

5

5 reviews

Prices

Quality Product

Services

Customer Services

Product Variety

Address: 261 W 35th St Ste 5066, New York, NY 10001

Schedule: Opens at 9:00 AM

Telephone: (917) 508-5303

Guy: 3D printing service

Web page: https://leosparq.com/locations/large-3d-printer-SLS-3d-printing-new-york/

Review: "This industrial 3D printer was a lifesaver for me, thank you guys. "

"

Near SPARQ Industrial SLS 3D Printers | 3D Printing Company - Rapid Prototyping:

- a 0 meters away airports near: Cape Air Manhattan Pickup (ZYP)

- a 1 meters away chinese clothing stores: Andaaz Fashion: Indian & Pakistani Wedding Dresses, Lehenga, Saree

- a 4 meters away computer companies: CompCiti Business Solutions, Inc.

Are you the owner of the business? PROMOTE IT!

4.6

22 reviews

Prices

Quality Product

Services

Customer Services

Product Variety

Address: 336 W 37th St, New York, NY 10018

Schedule: Opens at 8:00 AM

Telephone: (212) 490-3801

Guy: Commercial printer

Web page: http://www.abcimaging.com/

Review: "Fast, friendly and easy every time I've had any sized print needs"

Near ABC Imaging - New York:

- a 0 meters away veterinary pharmacies in: Mixlab

- a 0 meters away Family Offices in: Trusted Insight - the world’s biggest network of institutional investors.

- a 8 meters away retail corporate offices in: No Man Walks Alone

Are you the owner of the business? PROMOTE IT!

5

1 reviews

Prices

Quality Product

Services

Customer Services

Product Variety

Address: 160 Convent Ave, New York, NY 10031

Schedule: Opens at 9:00 AM

Telephone: (347) 730-9139

Guy: 3D printing service

Web page: https://3d-printing-service-at-ccny.business.site/

Near 3D CAD Modeling & Printing Service at CCNY:

- a 51 meters away vertical work courses in: The City College of New York

Are you the owner of the business? PROMOTE IT!

5

27 reviews

Prices

Quality Product

Services

Customer Services

Product Variety

Address: 576 5th Ave Ste 704, New York, NY 10036

Schedule: Opens at 9:00 AM

Telephone: (551) 277-0668

Guy: Manufacturer

Web page: http://tangiblecreative. com/

com/

Review: "While specializing in 3D printing, they have the knowledge and ..."

Near Tangible Creative:

- a 1 meters away acoustic insulation sites in: Quiet Zone Soundproofing NYC

- a 2 meters away second hand watches sale: Manhattan Buyers Inc. Rolex Buyer, Diamond Buyer, Gold Buyer, Sell Watch

- a 2 meters away stores to buy men's fluchos: Giorgio Armani Shoes Accessory

Are you the owner of the business? PROMOTE IT!

5

1 reviews

Prices

Quality Product

Services

Customer Services

Product Variety

Address: 98 S Franklin Ave, Valley Stream, NY 11580

Schedule: Open 24 hours

Telephone: (516) 366-0564

Guy: 3D printing service

Web page: http://3dprintnewyork. com/

com/

Near 3D Print New York:

- a 117 meters away linux specialists: BA Classes New York

- a 170 meters away awning companies: Globe Awning

- a 180 meters away electricity distributors in: Best Energy Power

Are you the owner of the business? PROMOTE IT!

5

56 reviews

Prices

Quality Product

Services

Customer Services

Product Variety

Address: 28 Orchard St Suite 4A, New York, NY 10002

Schedule: Opens at 9:00 AM

Telephone: (800) 239-8181

Guy: Graphic designer

Web page: http://voxel-magic.com/

Review: "Couldn’t have chosen a better 3D printing service!"

Near Voxel Magic:

- a 2 meters away 3d printing shops in: Make Mode

- a 10 meters away orchard stores: Mannahatta NYC

- a 14 meters away pizzas in: Scarr's Pizza

Are you the owner of the business? PROMOTE IT!

Prices

Quality Product

Services

Customer Services

Product Variety

Address: 28 Orchard St, New York, NY 10002

Schedule: Opens at 12:00 AM

Telephone: (800) 239-8181

Guy: Manufacturer

Web page: http://3dnyclab. com/

com/

Near 3D NYC Lab:

- a 3 meters away 3d printing shops in: Voxel Magic

- a 5 meters away 3d printing shops in: Make Mode

- a 9 meters away orchard stores: Mannahatta NYC

Are you the owner of the business? PROMOTE IT!

4

21 reviews

Prices

Quality Product

Services

Customer Services

Product Variety

Address: 75 Clinton St, Staten Island, NY 10304

Schedule: Opens at 10:00 AM

Telephone: (646) 598-7085

Guy: Manufacturer

Web page: http://assembyl.com/

Review: "Assembyl 3D is my "go-to" for all my 3D printed projects."

Near Assembyl 3D Printing:

- a 139 meters away second hand motorcycles: Gotham Motorcycles

- a 167 meters away motorcycle outlets: Bay Harbor Motors

Are you the owner of the business? PROMOTE IT!

5

3 reviews

Prices

Quality Product

Services

Customer Services

Product Variety

Address: 515 Madison Ave Suite 8089, New York, NY 10022

Schedule: Opens at 10:00 AM

Telephone: (347) 304-9119

Guy: Manufacturer

Web page: http://www. og3dprinting.com/

og3dprinting.com/

Review: "I've worked with a few 3D printing companies for some functional ..."

Near Obsessively Geek 3D:

- a 0 meters away cleaning offices in: Strictly the Best Cleaning Services

- a 0 meters away immigration lawyers: Sharon Khunkhun, Immigration Attorney

- a 0 meters away Executive offices in: Jay Suites Midtown East - Flexible Office Space NYC & Meeting Room Rentals

Are you the owner of the business? PROMOTE IT!

4.4

14 reviews

Prices

Quality Product

Services

Customer Services

Product Variety

Address: 575 8th Ave, New York, NY 10018

Schedule: Opens at 8:00 AM

Telephone: (212) 366-7250

Guy: Commercial printer

Web page: https://www. bluedge.com/

bluedge.com/

Review: "Last minute meetings, changes to projects, 3D prints: they have ..."

Near BluEdge:

- a 6 meters away souvenir stores: Nee York Gifts & Souvenirs

- a 6 meters away bakeries in: Angelina Bakery NYC

- a 10 meters away elderly care companies in: LeanOnWe Home Care

Are you the owner of the business? PROMOTE IT!

Prices

Quality Product

Services

Customer Services

Product Variety

Address: 4568 162nd St, Flushing, NY 11358

Telephone: (646) 346-0288

Guy: Digital printing service

Near FL-3Dprinting:

- a 54 meters away computer maintenance companies in: Flushing Computer Services

- a 91 meters away parks with ping pong table in: New York Table Tennis

- a 145 meters away truck repair shops: Frank's Tire Auto and Truck Repair

Are you the owner of the business? PROMOTE IT!

Prices

Quality Product

Services

Customer Services

Product Variety

Address: 68 Jay St Suite 201, Brooklyn, NY 11201

Schedule: Opens at 10:00 AM

Telephone: (347) 304-9119

Guy: Manufacturer

Web page: https://www. og3dprinting.com/

og3dprinting.com/

Near Obsessively Geek 3D:

- a 0 meters away couples photographer: Joshua Dwain Photography

- a 4 meters away express divorce: Premier Life Solutions (A Division of Premier Paralegal,LLC)

- a 14 meters away Web development specialists: Transfuture

Are you the owner of the business? PROMOTE IT!

3D-printed clothes: why haven't manufacturers made them mass-produced yet?

ThreeASFOUR showcased their 3D printed clothing collection for the first time at a fashion show at the Jewish Museum in New York. The dresses on the models were patterned and looked ephemeral, like the robes of robotic angels. One was woven from white, angular bubbles, which gave the impression that the girl had just taken a bubble bath.

But the girl who showed this dress to the world could not sit down, otherwise the dress would have broken. “The model wearing the dress was very unhappy,” said Bradley Rothenberg, a 3D architect who collaborates with threeASFOUR founders Gabi Asfor, Angela Donhauser and Adi Gil.

ThreeASFOUR dress at the fashion show at the Jewish Museum.

It happened in 2013, when threeASFOUR began to realize that in order to achieve the goal, they would have to take a step back. They did not even think that they would create such an impractical piece of clothing. On the contrary, they wanted to create an outfit worthy of a superhero. They dreamed that the fabric they printed would become invulnerable to bullets and fire, retain heat and protect the wearer from stress. They dreamed that people would start buying their clothes as soon as they hit stores.

But time has passed. With the Silicon Valley elite building personal bunkers, refugees pouring across the border into Canada, and Margaret Atwood back in vogue, threeASFOUR's vision is as close to reality as an apocalyptic dystopia. But if everyone has access to the stocks left on Doomsday, becoming a superhero is still unrealistic.

And the reason is quite simple. Thanks to thousands of years of experience, tailored clothes are more practical and comfortable than those printed by a 3D printer. But that doesn't seem to be stopping threeASFOUR and other designers.

But that doesn't seem to be stopping threeASFOUR and other designers.

“In the fashion world, you can control the patterns and structure of a dress to get the look you want,” Rothenberg says. “The problem is that right now it’s just a possibility. So I think Gaby Asfor is the most interesting person in the industry. We need people who will push the boundaries, striving to show the new.”

The vision of Gabi Asfor is evident in his work. He became interested in 3D printing in 2009 and has been experimenting with the internal structure of fabrics ever since.

Traditional fabric has two dimensions: the threads are arranged horizontally, vertically and diagonally in a certain way to create a weave. Asfor, who has a degree in mechanical engineering and architecture from the University of Maryland, worked with Donhauser and Gil to come up with a three-dimensional weave that was planned to be laser-cut. The desire to give fabric a third dimension led them to 3D printing.

“The most innovative recent invention in the industry is the four-way stretch fabric,” says Asfor. “But ordinary fabric can only stretch in the X and Y planes. 3D printing will allow the material to stretch in the Z plane as well.” He believes that such a fabric will be better breathable, less restrict movement, and will not have folds.

ThreeASFOUR was interested in 3D printing, which led them to collaborate with Materialise, a 3D printed model company, and Rothenberg, who came up with 3D printed wings for the 2013 Victoria's Secret fashion show.

“When we first started, Gabi kept asking, “Can you print fabric? What material will be needed for this?” Rotenberg says. It turned out that this would not be easy.

Pangolin dress from the Biomimicry collection. Source: Backchannel

The main problem is that the materials used for 3D printing are stiffer than regular fabric. ThreeASFOUR experimented with the structures of various materials, trying to add elasticity to them, but any printed model came out very fragile.

But new materials have arrived, and ThreeASFOUR has teamed up with Stratasys and Travis Fitch to design dresses like Pangolin for their new fall 2016 collection, which they call Biomimicry. It took 500 hours to print (not including assembly) Pangolin! The dress, named after a scaly mammal, was reminiscent of dark armor (Björk appeared in it during a tour in Australia last year). To create the "scales", the designers used an algorithm that simulates cell division, thus obtaining an intertwining pattern.

On the ground floor of the ThreeASFOUR studio, there are employees who work with the most ordinary sewing machines. The dress itself is located on the next floor. Up close, the Pangolin bib, detached from the other parts of the dress, is somewhat reminiscent of a bicycle tire that has been cut to look like fish scales (it even wiggles like a fish tail). Such a deflection was not possible a few years earlier.

Asphor hands me a piece of another dress, a Harmonograph modeled after a sound wave. It was made from a rubber mesh that can expand and contract like a pillow-top mattress. The bottom of the dress shrinks when a person sits down and returns to shape when they stand up.

It was made from a rubber mesh that can expand and contract like a pillow-top mattress. The bottom of the dress shrinks when a person sits down and returns to shape when they stand up.

Harmonograph dress by ThreeASFOUR. Source: Instagram

With this flexibility, 3D wearers can now sit comfortably, although comfort is far from ideal. “Matter resembles artificial skin. It is not very pleasant to the touch and, in addition, sticks to the skin, ”says Rotenberg.

The idea of making printed clothes gained popularity at the beginning of the 21st century, but developed rather slowly.

Few people know this better than Aaron Rowley, founder of Electroloom, a 3D printed clothing startup. At first, many well-known brands were interested in his work, but gradually, one by one, they left. “There was an idea that people could print tools at home,” says Rowley, referring to the days when there was a lot of hype around 3D printing. It was believed that clothes could also be printed, since wardrobe items are used every day and need to be updated regularly.

But progress has not gone far. “The process of creating fabric is fundamentally different [from 3D printing],” says Rowley.

“Textiles are an advanced technology,” says Scott Hudson, a researcher at Carnegie Mellon University who has worked with Disney on soft print materials. Calling the textile industry a technology, he was not exaggerating: some experts believe that the loom is an early version of the computer. In the middle of the 18th century, Joseph Marie Jacquard figured out how to save a fabric pattern on a punched card, which made it possible to set the machine to work and automate the process.

3D printing technology is not that polished yet. “You have to find a compromise between stiffness and strength,” says Hudson. 3D printers create an object by layering, and this process is very different from how fibers are turned into fabric.

Rowley took fabric raw materials and created blends that resemble existing fabrics. However, the 3D printer has created something that looks like a "chaotic web". It took a long time before they got a soft, stretchy, foldable and lightweight material that at first glance resembled fabric. But even the final version was not suitable: the material was torn as soon as it was pulled harder.

It took a long time before they got a soft, stretchy, foldable and lightweight material that at first glance resembled fabric. But even the final version was not suitable: the material was torn as soon as it was pulled harder.

“Fibers that are physically connected, as in the case of 3D printing, remain stationary, while woven fibers move smoothly relative to each other,” Rowley explained. Electroloom shut down last October.

Until the material issue is resolved, the printed garment will look more like a work of art than a piece of clothing. A year ago, threeASFOUR dresses were featured at the Met Gala-sponsored Costume Institute show. The Manus x Machina show in 2016 also emphasized the role of technology in the fashion world: stars and celebrities dressed in silver at the show, and Zayn Malik appeared in a suit with robot arms.

Oscillation Dress by ThreeASFOUR. Source: Instagram

This year, threeASFOUR has introduced another novelty: a white and blue lattice dress, pictured above, it hugs a mannequin in their studio. The dress consists of 30 pieces, which are first printed and then carefully assembled.

The dress consists of 30 pieces, which are first printed and then carefully assembled.

“We are looking for new technologies,” says Asfor. “I believe that in the near future we will have a unique opportunity to move in this direction.”

At the same time, the quality of other garments (such as jewelry or sportswear) printed on a 3D printer is much higher. Nike and Adidas use 3D printing to create shoe padding and soles, which are usually made from foam. NASA is developing a project similar to Pangolin - a printed "chain mail" designed to protect astronauts from the impacts in space.

Read also: Adidas launches mass 3D printing of sneakers

Maybe not only astronauts. Although T-shirts and pants are still made in the traditional way, protective armor will soon be printed. It will come in handy in case there is a revolution, aliens attack or you need to flee abroad.

Source.

Related materials:

“Print me food!” – what printing technologies of the 21st century are capable of

Smart home in Russian: how 3D printing helped create a cool gadget

A service for creating models for 3D printing inside virtual reality is launched

Ford is testing 3D printing of car parts

Where to go to learn and work with 3D printing?

Overview of leading companies in the provision of 3D printing services / Sudo Null IT News0001

I got the impression that in Russia there is a stereotype that there are only two ways to make money with 3d printers:

1) Become a dealer of an international company / set up the production of your own 3d printers

2) buy several 3d printers and take orders from architects/doctors/military

This post will focus on the fact that there are many more opportunities, the "entry price" to this market for an individual designer person is lower than it seems, and the future, which is distributed/distributed unevenly and not entirely in Russia, is already here.

Under the cut you will find a brief overview of the three giants of the European and American 3d printing industry, which do not specialize in the production of their own 3d printers, but develop communities, create a "marketplace", act as platforms for startups, designers, etc. After the review of the "big three" follows a review of the most interesting projects created around these giants.

Some projects are commented by Konstantin Ivanov (consst), who attended the European (3DPrintShow) and American (Inside 3D Printing) conferences.

Three giants in 3D printing marketplaces from USA and Europe

www.shapeways.com

en.wikipedia.org/wiki/Shapeways

The company, organized in 2007 in the Netherlands (originates from the Philips business incubator), but is headquartered in New York. The company employs 90 people. At the moment, it has attracted about $40 million in investments. It has two full-fledged productions in the Netherlands and in New York. The number of ordered products has exceeded one million.

The number of ordered products has exceeded one million.

Konstantin: “World and US market leader, Shapeways. Successfully located its head office in Queens, NY, becoming a Mecca among the creative people. For a pretty decent history of its existence, Shapeways has gathered a huge community of designers, at the end of 2013 - 300,000 people. Of course, the number of active and prolific designers is much smaller, but the total number and products on the marketplace cannot fail to impress.With each of the active designers, Shapeways community managers (they are usually called community managers, which is rather rare in Russia so far) work a lot, communicate, and help resolve any issues: high-quality photography of products, placement on the marketplace, correction of 3d models. In general, the community is the heart of Shapeways.

The huge knowledge base they have collected on the forum and in the Tutorials sections on the site allows you to find the answer to almost any question that arises when working with 3d models for printing.

Storehouse of knowledge.

Some of the people from Shapeways (former community managers, production managers) are already creating their own separate businesses in the field of 3d printing. Shapeways encourages and develops an entrepreneurial culture.

However, competitors really, really dislike Shapeways for dumping the market. Indeed, their prices for 3d printing from many different materials are almost always lower than competitors from Europe. They can afford it, with so many investments involved)

Shapeways have created and are developing an excellent powerful API for developers of various online 3d model customizers, which can also be made through them. As a result, in addition to the marketplace, they work as a production and API, which is very convenient.

They have completely stopped delivering to Russia since last year, citing problems at customs. By the way, I must say that the experience of ordering 3D printing from them in NY is also not ideal: they missed the delivery time for samples, I had to write to support, but the issue was quickly resolved.

”

A few videos and articles in English for a deeper understanding

Video about the company. Keanu Reeves is there too.

Number of unique items produced from 2008 to 2013

Founder Peter Weijmarshausen

Forbes article (10/10/2011)

Wired article by Bruce Sterling (10/3/2011)

BusinessInsider article (12/19/2012)

Petermarijhausen speech TechCrunch

Another performance by Peter Weijmarshausen

www.sculpteo.com

en.wikipedia.org/wiki/Sculpteo

French startup launched in 2009. Has attracted several million investments, has a small fleet of its equipment

Strengths: a very interesting online service, with the ability to not only analyze your model, but also prepare it online for printing. There is a mobile application 3DPcase

Konstantin: “French guys who started after Shapeways was on the market.Small team, own small production (industrial 3d printers) in Paris.

Like many other players in the market, part of their production capacity is outsourced. This is quite logical, since to control a huge production, including from metals, ceramics, etc. - Pretty messy story.

Quite often you can meet them at exhibitions. The last time, while talking with them at 3DPrintShow in London and Inside3DPrinting in New York, the guys shared their opinion on the pace of market development in Europe and the USA and a little more about competition in Europe, where Shapeways is also actively going.

The main focus of Sculpteo's development is applications, their own online software for calculating, correcting and even preparing 3d models for printing. This is very impressive, none of the competitors do this. For comparison, Shapeways uses only half of its software, the second part is Netfabb's software.

Sculpteo is great for those who are already quite proficient with 3d models and use 3d printing for prototyping.

The team is also developing its API. Delivery to Russia, according to the director of the company Clement, they do, but in fact this is not possible.”

Once they kept their blog on Habré, with some quite useful articles, for example, the translation of the article about the “Industrial Revolution” 1, 2, 3, 4, 5.

Konstantin: has an office both in Belgium and, for example, in Ukraine. The main activity is prototyping of industrial, engineering, medical, aviation, etc. products.However, the company also has its own consumer direction, which was named i.Materialise. The marketplace and community are also being developed. If you look closely, they very much follow the example of their American colleagues, up to copying interface elements, which is quite logical - the usability in Shapeways is really very good.

Recently launched the so-called Boutiques, separate shops for selected designers. Continue their movement to the consumer segment.

A number of important advantages: its large production with the most experienced staff and a large number of different technologies, printers and post-processing. Completely own software that works well with models (but no better than Sculpteo does). And, of course, the API, which they are actively developing and connecting more and more partners to it.

I also offer a white label option for companies that don't want their customers to know exactly where their products are made.”

A little video about projects Materialise

Video with TED (in English)

How the largest stereolithographic machine

Print clothing

4 How to earn on 3D-printing no 3D.Aggregators:

3DHubs.com - allow owners to register their 3d printer in the database. Thus, it becomes possible for any person to find either the nearest 3d printer, or exactly the printer that is needed (all over the world).

Plus, they can collect useful statistics and publish monthly trend reports. They take a commission of 15-20%

Konstantin: “I was introduced to the founders of a fairly recent startup 3dhubs by one of the investors from a London fund, who also invested in the company. Brian and Bram came up with and are making a great international story that actually makes life easier for those who need to print something “close to home”.The service works all over the world and even a little in Russia. The guys are attentive to the customer service inside, help each client if one of the hub owners has problems with printing. Very comfortably.

Coming to each new city or exhibition, they do the so-called unlock of the city and open new hubs with printers there. This was also the case at the exhibition in London last year.”

makeXYZ.com

Texas Entrepreneurs Project. Allows you to search for 3d printers and 3d designers.Received investment from Intel.

Standing on the shoulders of giants

www.sols.co

Allows you to create personalized insoles.

Konstantin: “A great example of how, growing inside a small start-up company, Sols founder Kegan Schouwenburg caught the entrepreneurial spirit and started her own project to produce custom orthopedic insoles made using 3d printing!Kegan was one of the people who did the entire Shapeways production from scratch, which is a really big job.

Her company has now raised about $8 million in funding from the same investors who invested in Shapeways and is actively building its business. At the same time, he uses polyamide (nylon) for the manufacture of the base for the insoles and makes all samples using Shapeways. Proper collaboration and collaboration.”

mixeelabs.com

An online application that allows you to create figurines ($25), molecules, key chains for dogs, cufflinks and wallets for cards.

Konstantin: “Second success story in the 3d printing business, also from a former Shapeways employee. Nancy Yi Liang is the founder of product customizer Mixeelabs, who makes money from his brainchild and lives in New York.At our last meeting with her, she told how well things are going with the sale of her products from the site (80% of sales), a little worse from the Shapeaways marketplace (20% of sales), but at the same time, the very first viral effect gave her the same Sad Keanu, which she invented and distributed perfectly everywhere.

Her project is a great example of how, having come up with an interesting and rather viral thing, you can earn money on it in the long run.”

joshharker.com

Joshua Harker — Artist, sculptor, musician, digital adventurer, imagination architect, troublemaker

Konstantin: later he went into business, opened his own company, developed his own unique and recognizable style (which was later copied by many others) and showed how to effectively apply new design approaches to 3d printing.

I could not resist and decided that the worse we are, we will make one for ourselves. Here is the result:

www.minetoys.com

For all Minecraft fans. Prints your character from the game.

www.twikit.com

The service allows you to customize gifts and jewelry made of plastic and metal.

n-e-r-v-o-u-s.com

Konstantin: “Nervous are practically gods in 3d printable design, they come up with new shapes and structures and constantly impress.

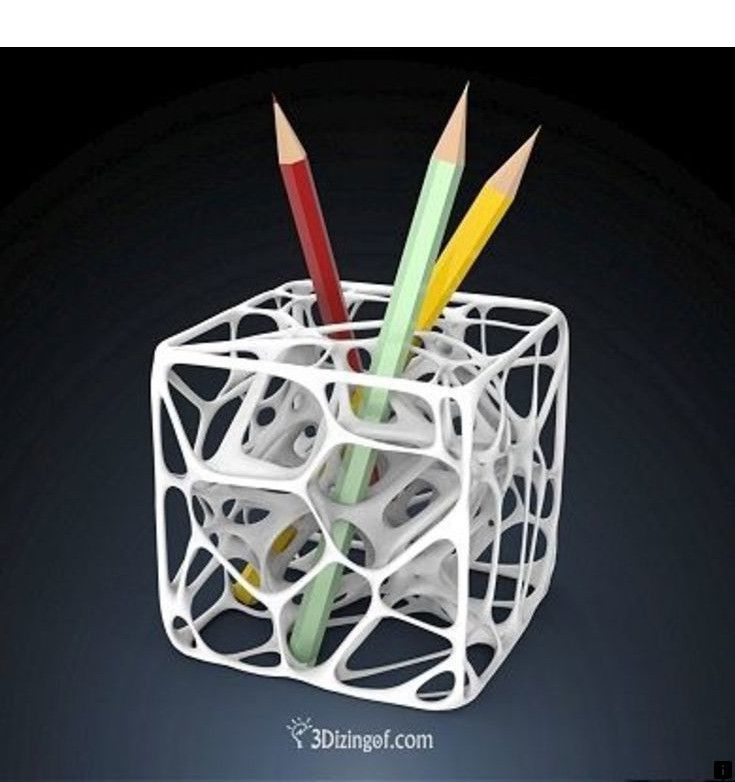

In addition to the beautiful futuristic design, they came up with an incredible online thing that creates amazing kinetic structures right in the browser, right in front of you. All this is flexible and allows you to actually make wearable objects made using 3D printing.Photos of works from Nervous System

Octopussy which I printed a year ago (report on Habré)

Blokify.

com

A mobile application that makes it very easy to create a 3d model and send it to print. Convenient for working with children.

Video and a couple of photos

draw

materialize

WhiteClouds.com

»Submit your ideas (even on a napkin). We will bring them to life."

The company does not require its customers to be able to handle a computer: you can send a simple sketch made by hand, and the company's specialists will turn it into a digital three-dimensional model, print it on a 3D printer and send the finished product to the customer. Once, they even sent a cardboard model to the company, asking them to print a copy on a 3d printer, and the order was completed.

Portfolio under the spoiler

A little zombie:

Russian projects

5222 The following picture speaks eloquently about the state of affairs in Russia:

3D Printing Map of the Worlda parable on the topic

One company once sent a shoe salesman to an African city.

Shortly after arriving in Africa, he wrote to the office:

“You can take me back. Here everyone walks barefoot.

They returned him to his homeland.Then they sent another shoe seller.

Almost immediately upon arrival, he sends an urgent telegram to the office:

“Send all the shoes you have. Here everyone walks barefoot!zdravprint.ru

A service for the creation of individual fixators, which are printed on a 3D printer and are designed to replace plaster at certain stages of recovery.

Konstantin: “My good friend Fedor Aptekarev at the last Yandex Startup Camp launched a project to create plaster using 3d printing. With such a cast, the fracture can be endured a little easier.”What awaits us in the future

Me : Konstantin, while collecting materials for this post, I came across some skeptical statements by very respected people (for example, the director of Epson) about the future of 3d printing, but you, in turn, You have been actively developing this industry in Russia for a year already, holding training seminars, developing a community, holding competitions for designers, planning to launch an API for your project, what is the basis for your confidence that this is worth doing?

Konstantin: Glad you asked.Let's clarify what exactly the head of Epson said. Something like this: “There is no big future for plastic 3D printing at home. We will only make commercial 3D printers.” He talks about building an industrial design printer. Epson itself is going to develop industrial printers. And I completely agree with them.

In my opinion, industrial 3d printing technologies, which we also use, can really bring 3d printing to a new consumer level. Here you need to immediately make a reservation that the head of Epson is talking about home printing, but he only means FDM technology (plastic filament melting), as the most popular home 3d printing technology. At the same time, do not forget that after the end of the patent for SLA technology (stereolithography), for example, a completely “home” Formlabs 1 printer appeared, which gives a very acceptable quality. Yes, of course, it can not be compared with the industrial one.

I'm talking about the fact that rather than home 3d printing, there is no future, but FDM technology.

She will live herself. It is suitable for too narrow an application and the quality is very, very low.

I am sure that what we are doing now will create (and is already creating it abroad) a new market and new opportunities for consumers and designers, will speed up the solution of many problems and, of course, will become more accessible. Confidence is fully confirmed by the facts, the results of communication with colleagues from abroad and in Russia, and, of course, by the numbers, which are constantly growing.

Me: Konstantin, having talked to the CEO of the world's leading companies and "having been a little bit in the future", what will the world expect in the coming years?

Konstantin: In the very near future, I can say with full confidence, the following awaits us:

- the widespread integration of the "print on a 3d printer" button into all conceivable and unthinkable applications, programs, games, and so on. We will print both in 3d printing services and for enthusiasts on home 3d printers- the end of patents for the main industrial 3d printing technologies (SLA (already), SLS, 3DP, DMLS) will lead to a more serious development of smaller and less expensive printers, respectively, the growth of both industrial technologies and quality will also skyrocket

- Google , actively introducing 3D scanners into their phones, will also contribute to the growth of the market, since many people will have the most important thing for the market - a model for printing.

Learn more

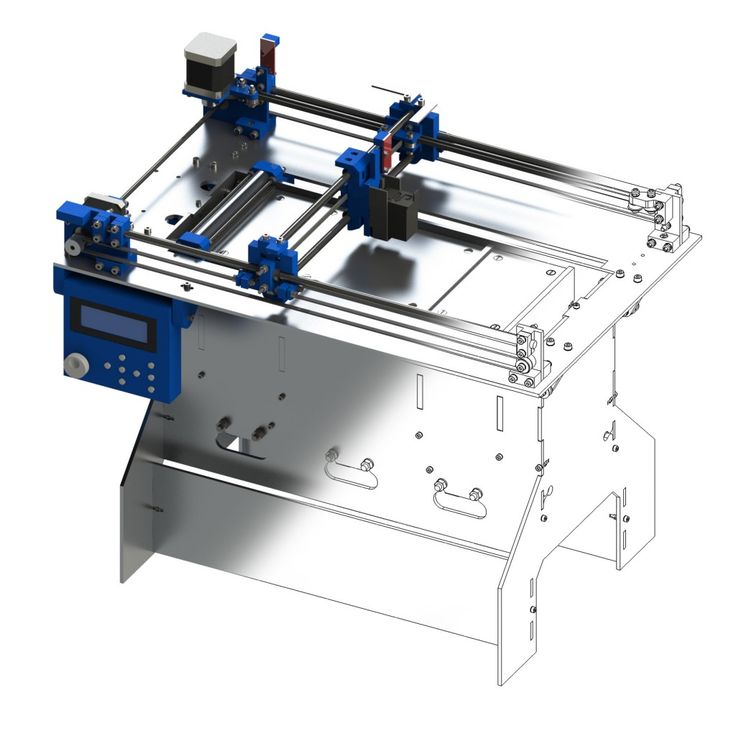

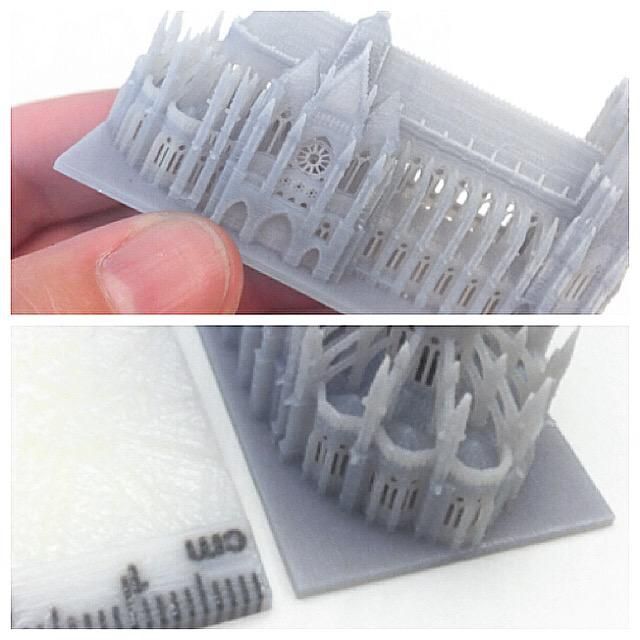

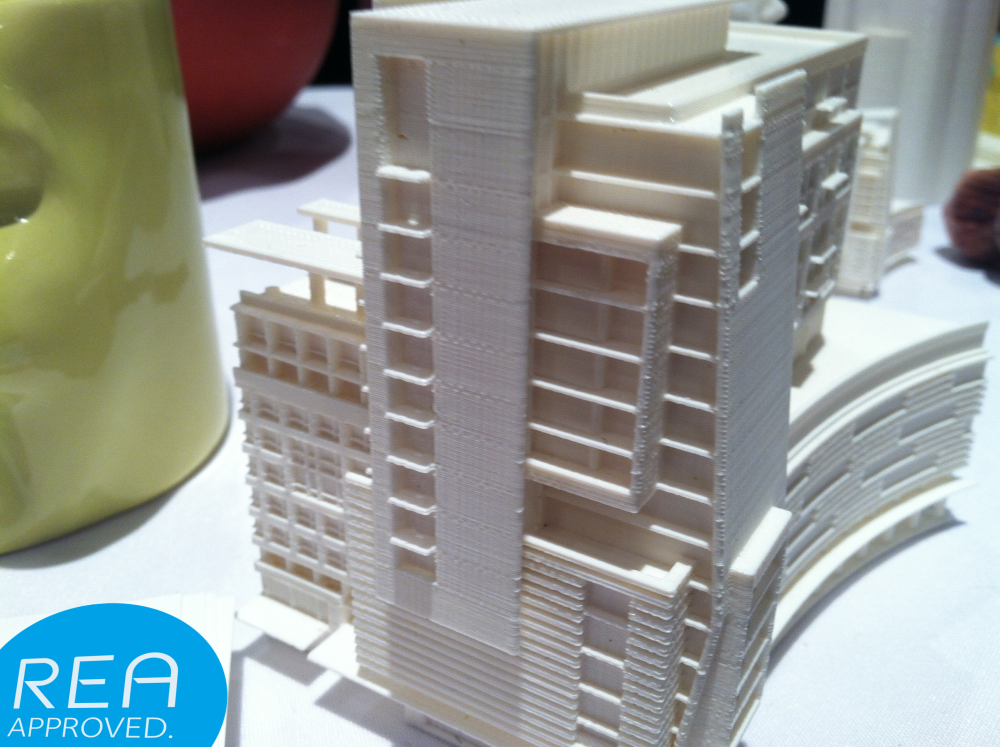

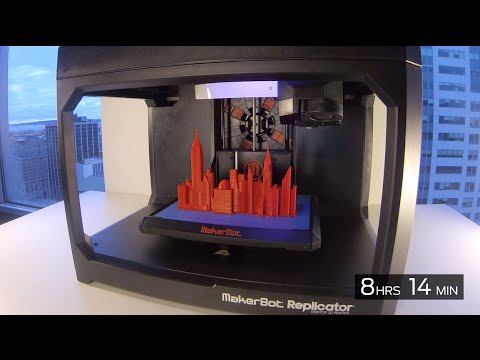

We can print and assemble hundreds of parts to build forms at colossal scales.

We can print and assemble hundreds of parts to build forms at colossal scales.