Guardian 3d printing

When light meets liquid: the 3D printer replicating art | Science

It is no rival for the replicator that whips up meals on demand on the USS Enterprise, but it can transform gloop into useful objects and even works of art, such as miniature versions of Rodin’s Thinker.

The real-world version of the replicator, nicknamed after the handy 24th-century appliance, churns out detailed 3D shapes and components by beaming images of them on to a rotating container filled with a gooey liquid that reacts to light.

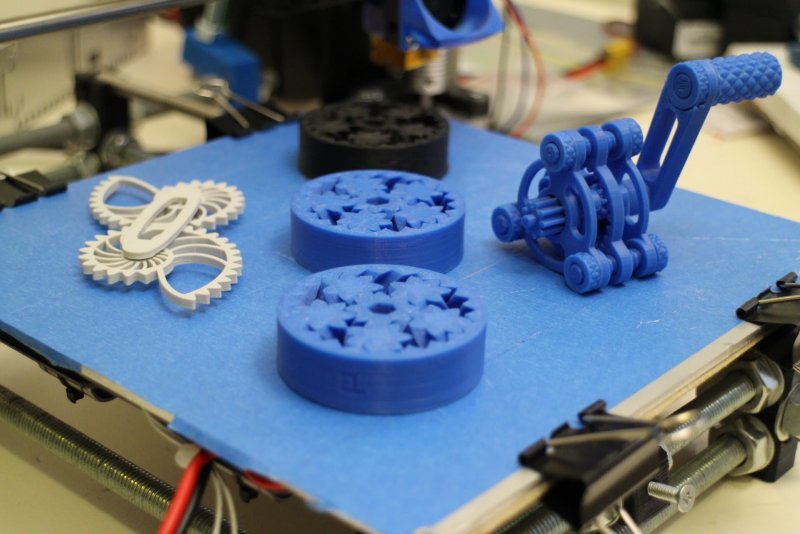

Researchers used the new 3D printing process to make model jaws, little planes and bridges, and more complex structures such as a ball inside a cage. In footage from the scientists’ lab, objects emerge from the light-sensitive fluid fully formed in under two minutes.

Christopher Spadaccini, at the US government’s Lawrence Livermore National Lab, said he was surprised at how well the first objects turned out. “We all knew right away we had something pretty exciting. ”

Traditional 3D printers build structures layer by layer, but this can leave tiny steps running up the sides of the printed objects. Another drawback is that certain shapes, such as arches, need supports to fill the gaps as the structure is built up. The new process, called computed axial lithography, produces objects with smooth surfaces and removes the need for supports.

replicator graphicTo print an object, the scientists start with a 3D representation either from a scan or a drawing on a computer. This is converted into a sequence of video images that show what the object looks like from different angles. A projector then beams the images one after another on to the rotating container filled with thick, light-sensitive polymer. The images change thousands of times during a single revolution.

“As the container rotates, the pattern that’s projected changes, so over time the amount of light that each point receives can be controlled,” said Hayden Taylor at the University of California, Berkeley. Spots that receive a lot of light solidify, while those that do not remain liquid.

Spots that receive a lot of light solidify, while those that do not remain liquid.

“The key thing is that the video being projected is perfectly synchronised with the rotation of the container,” said Indrasen Bhattacharya, also at Berkeley. “At every particular angle you choose a particular image to project.”

The replicator machine. Objects emerge fully formed in under two minutes. Photograph: Stephen McNallyIn the lab it took less than a minute for the printer to create a 2cm-high figure of Rodin’s sculpture The Thinker. The largest item they have made is about 10cm with features as small as 0.3mm. The gloop left over from each print run is drained off and reused, said Hossein Heidari, a co-author on the study published in Science.

The researchers are now exploring what products they can make and how big. Beyond scale models for designers, dental implants and medical prostheses are on the cards. But the process can also print on top of existing objects, so could add customised ergonomic handles to tools and sports equipment, and in the future, perhaps even print clear, soft hydrogels around tiny electronic circuits to make smart contact lenses.

Ian Campbell, who works on computer-aided product design in the Additive Manufacturing Research Group at Loughborough University, said the idea of “volumetric 3D printing” has been around for some time, but this was the first system he had seen that used multi-angle projections to make complex objects.

“The key advantages are reduced time and no supports being required. However, the second of these advantages depends on the high viscosity of the resin material used,” he said. If the light-sensitive liquid is not thick enough, parts of the object that solidify first might simply sink to the bottom of the container.

The light-sensitive polymer used to create 3D objects. Photograph: Stephen McNallyThe main limitation of the process is that photoreactive polymers can be expensive and are not generally used to manufacture actual products. “Nevertheless, these materials have proved very effective for prototype production and this new system could also fit into this segment of the 3D-printing market,” he said.

“The system would need to be scaled up to be of commercial benefit to most companies but could be of immediate use to companies requiring small models, such as in the dental and jewellery industries,” Campbell added.

Scientists have a habit of making little replicas of Rodin’s Thinker to show off their latest breakthroughs. More than a decade ago Korean researchers went a step further than Willard Wigan’s tiny copy, which could sit on a pinhead, with a version no taller than half the width of a human hair. It is not clear how many people saw it.

3D Printing | Guardian Robot – Zelda BOTW

3D Printing

Save Subscribe

Please sign in to subscribe to this guide.

You will be redirected back to this guide once you sign in, and can then subscribe to this guide.

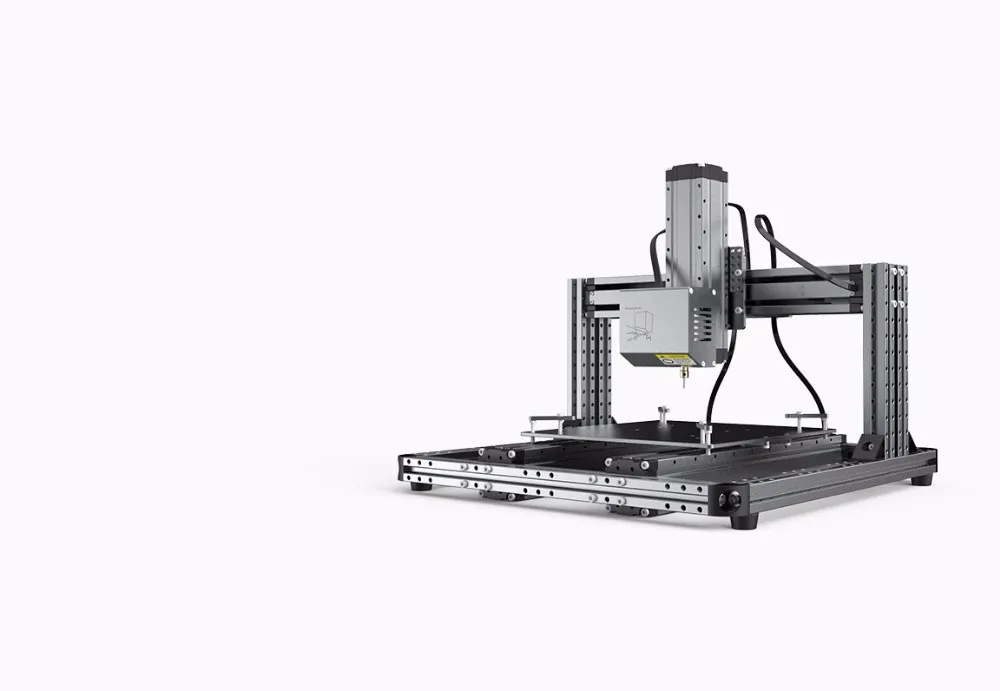

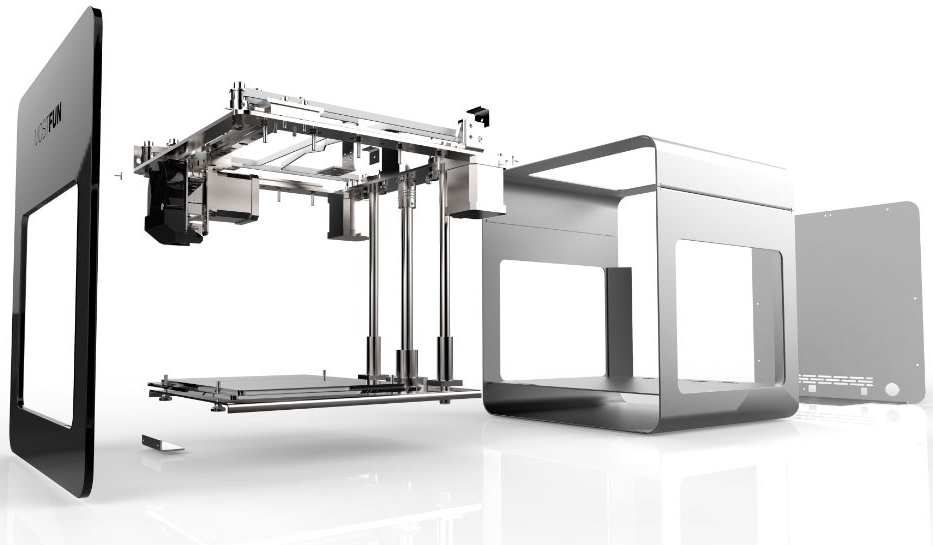

Dual Extrusion

The head and body are 3D printed with a dual extrusion setup. The swirling detail patterns are 3D printed in a translucent material to allow the glow of LEDs to shine through. The main body and head are 3D printed in a silver colored filament.

The main body and head are 3D printed in a silver colored filament.

We used an Ultimaker 3 and Sigma BCN3D 3D printers to produce the parts. They both achieve dual extrusion differently, but render similar results.

Other machines can be used, such as the flashforge creator pro, Prusa i3 MK2 with Multi Material upgrade kit or the Palette+ from Mosaic Manufacturing

Single Extrusion

If you don't have access to a 3D printer with a dual extrusion tool head but still want to make this project, you can print the "single extrusion" version of the models. You can 3D print the parts in a translucent filament and then paint the parts to achieve a similar effect.

CURA & Simplify 3D

We used CURA 2.6 to slice the parts for the Ultimaker 3. Simplify 3D was used for slicing for the Sigma BCN3D. Both use different slice settings and will have their own specific profiles.

Other machines will need to have their slice settings adjusted in order to produce the parts.

- Your browser does not support the video tag.

Post Processing

The parts can be sanded and painted for a more polished surface. I like how the surface looks a bit bumpy from the layers. In the video game, the guardian robots are ancient, so they look pretty rusty and weathered. If the parts are dual extruded, they may need some additional clean up. Some of the surfaces may have excess material. They can be clipped off using flush diagonal cutters.

Dry Fitting Head & Body Parts

It's a good idea to test the parts by fitting them together. The head attaches to the body and twisted to lock in place. You should be able to free rotate the head when it's attached to the body.

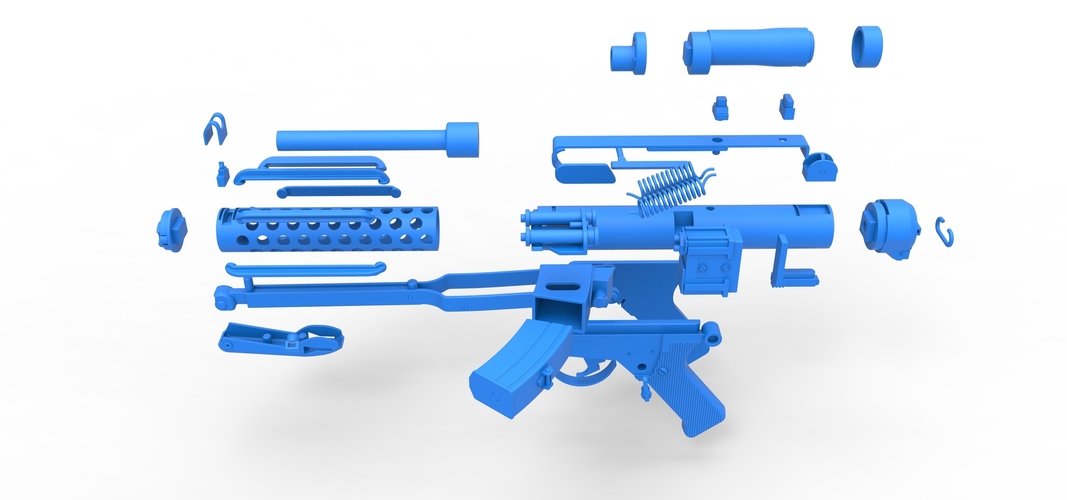

3D Models

The guardian robot was designed by Steve, you can find his work on thingiverse. Based on his original design, the Hackable version features parts for designed for electronics. Download the STLs using the links and 3D print them.

Download Guardian Robot STLs

Remixed Parts

I redesigned the bottom cover part to fit the micro servo, battery and slide switch. This can be downloaded from the remix section on the Thingiverse page or the link below.

This can be downloaded from the remix section on the Thingiverse page or the link below.

Download Remix Bottom Part

Software LED Eye

This guide was first published on Jul 18, 2017. It was last updated on Jul 18, 2017.

This page (3D Printing) was last updated on Jul 18, 2017.

Text editor powered by tinymce.

Gryphon guardian OBJ file・3D printed model for download・Cults

FISHERMAN

0,50 €

HALLOWEEN cat

0,50 €

DRAGON 2D

0,50 €

cat and moon and star

0.50 €

balloon MERRY CHRISTMAS

0.50 €

totem HALLOWEEN

0,50 €

DRAGON

0,50 €

fishing

0. 50 €

50 €

Best Files for 3D Printers in the Art Category

Shigaraki Tomura Ruka

4,50 €

nine0003 NFL DENVER BRONCOS5.87 €

Izuku Midoriya (Deku)

0.62 €

Low Poly Optimus Prime

2.76 €

Bat bust

2.74 €

Inspector Gadget and Brain (easy printing without support)

2 €

nine0003 DOG WITH SUGAR SKULL5.82 €

Animal Crossing - DAL Sign!

€1.15

Art category bestsellers

Crystal Dragon Articulating Animal Flexi Wiggle Pet Printing In Place Fantasy

3. 68 €

68 €

Cute kitten with flexi print

2.71 €

CUTE CROCODILE WITH FLEXIBLE PRINT IN PLACE

2.71 €

Pink Dragon, Valentine's Day, Articulating Animal Flexi Wiggle, Print on the Spot, Fantasy

3.73€

Wyvern Wyvern Baby Dragon, cute articulating Easy to print on the spot

3,22 €

nine0003 Item 7€ -80% 1.40 €

Archaeopteryx nibbler

3 €

Flexi-print Imperial Dragon

3.63 €

Leopard gecko articulated toy, imprinted body, snap head, cute flexi

€3. 20

20

GHOST ZU - GHOST WITH FEET

2,70 €

Cute T-Rex dinosaur with flexi print

2.71 €

POKEMON - VALENTINE 3 KANTO STARTERS (EASY PRINT WITHOUT SUPPORT)

4,99 €

Angel Experiment 624 (Light printing without support)

1.50 €

Annoying gift box

2.76 €

Cute skeleton with flexi print

2.71 €

Baby Crystalwing, Cinderwing3D, articulating Flexi Wiggle Pet, print on site, fantasy

3.68 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so it is very easy to support us in maintaining activities and creating future developments. Here are 4 solutions available to everyone:

Here are 4 solutions available to everyone:

-

ADVERTISING: Disable the AdBlock banner blocker and click on our banner ads.

-

affiliation: Shop online by following our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE YOUR FRIENDS: * Invite your friends, discover the platform and the great 3D files shared by the community!

Guardian Stabilization Expander for OSD PRO

JavaScript seems to be disabled in your browser. nine0147

You must have JavaScript enabled in your browser to utilize the functionality of this website.

Proceed to Checkout

Total price

$0.00

Basket 0

Want free shipping? click here Learn more!

{{/findAutocomplete}}

SKU: {{sku}} {{#isFreeshippingEnabled}} Free shipping on eligible orders {{/isFreeshippingEnabled}}

{{#isDiscountFlag1Enabled}} nine0006

{{/isDiscountFlag1Enabled}} {{#isDiscountFlag2Enabled}}

{{/isDiscountFlag2Enabled}} {{#isDiscountFlag3Enabled}}

{{/isDiscountFlag3Enabled}} {{#isDiscountFlag4Enabled}}

{{/isDiscountFlag4Enabled}} {{#isDiscountFlag5Enabled}}

{{/isDiscountFlag5Enabled}} {{#isDiscountFlag6Enabled}} nine0006

{{/isDiscountFlag6Enabled}} {{#isDiscountFlag7Enabled}}

{{/isDiscountFlag7Enabled}} {{#isDiscountFlag8Enabled}}

{{/isDiscountFlag8Enabled}} {{#isDiscountFlag9Enabled}}

{{/isDiscountFlag9Enabled}} {{#list_image_url}}{{/list_image_url}} {{^list_image_url}}{{/list_image_url}} nineisProhibited}} More {{/isProhibited}} {{/is_combo_product}} {{#isProhibited}}

We are sorry, this product is not available in your country

{{/isProhibited}}

{{#hbk_price.