3D printers in arizona

3D Printing Service for Phoenix, Arizona

CapabilitiesCustom Online 3D Printing ServiceArizonaPhoenix

High Quality Phoenix, Arizona 3D Printing | 60+ Materials Available

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Quality Assurance

Our number one job at Xometry is making your custom parts to your specifications.

Your Phoenix, Arizona 3D Printing Service: 3D Prototypes and Production Parts

A Global Leader in Industrial-Grade 3D Printing

Xometry is an industry-leading 3D printing service. Whether you need prototypes or production parts, we can make them for you in as fast as a day. We are your one-stop-shop for accurate, precise custom 3D printed parts at a low cost. Upload your 3D CAD file to get a quote and lead time within seconds. We use the latest additive manufacturing processes to build affordable functional prototypes & end-use parts in over 60 metals and plastics.

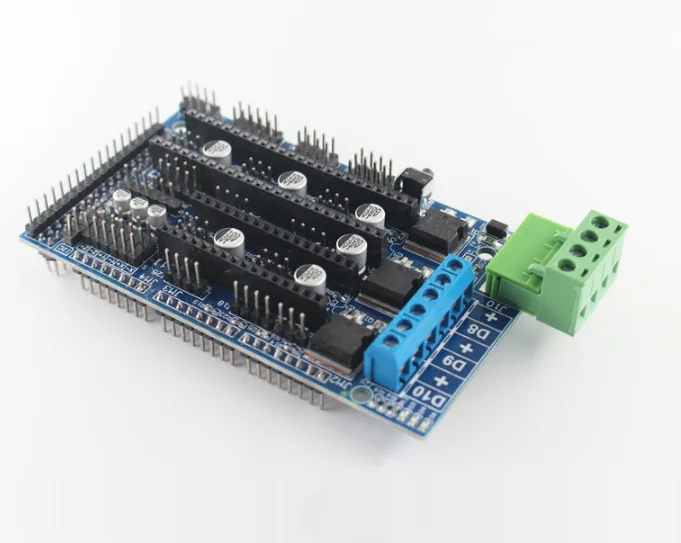

We offer eight high-quality 3D printing processes including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, polyjet, Carbon DLS, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more.

Xometry's High Quality 3D Printing Services

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a powerful 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

An additive manufacturing layer technology, SLS involves the use of a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic powders into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

Download the SLS Design Guide.

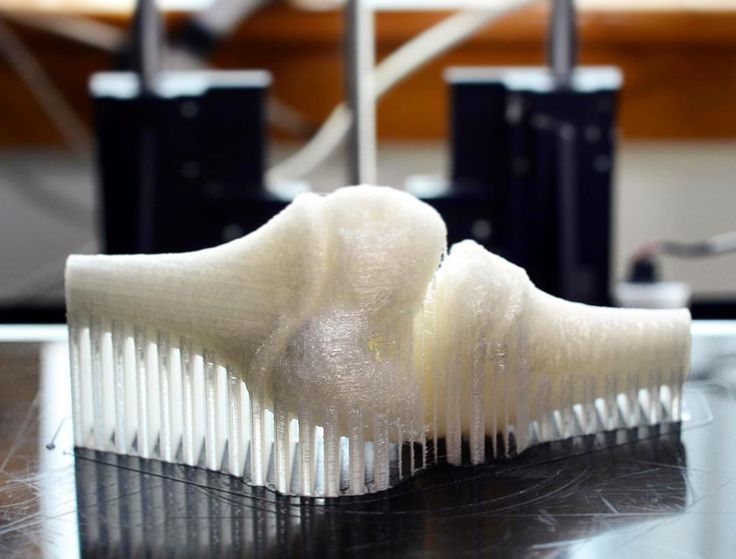

Stereolithography (SLA)

Stereolithography (SLA) is a robust 3D printing technology that produces extremely accurate and high-resolution parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

SLA is an additive manufacturing process that focuses an ultraviolet (UV) light on a vat of photopolymer resin. It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. SLA 3D printing is a highly-versatile platform for making custom parts in prototype and production settings; often acting as a stand-in for injection-molded plastic parts.

Xometry offers both standard and high-resolution options for fine detail parts, and can also print larger sized parts and products, with some materials offering up to a 58" inch build area. In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

Download the SLA Design Guide.

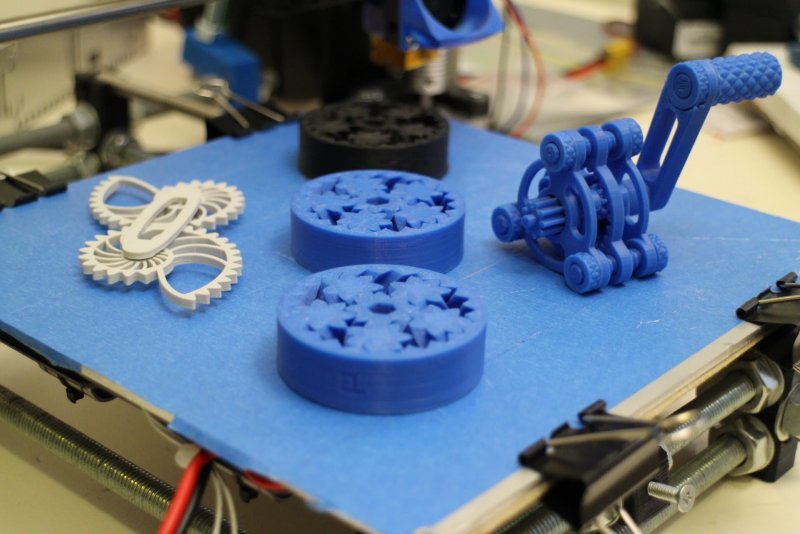

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a 3D printing technology widely known for its speed, accuracy, and competitive cost. A machine precisely extrudes melted plastic filament to create a part. Parts are very rigid, especially compared to Selective Laser Sintering (SLS), which makes them a great fit for projects with a rigidity requirement. Xometry's FDM solution offers large build volumes up to 24″ x 36″ x 36″, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem.

Download the FDM Design Guide.

HP Multi Jet Fusion (HP MJF)

HP Multi Jet Fusion is a new 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping. Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other powder bed fusion technologies.

Download the HP Multi Jet Fusion Design Guide.

PolyJet 3D (PJ3D)

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a process that is somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports a wide variety of build materials including rigid and rubber-like plastics. Xometry's PolyJet solution has a maximum build envelope of 19. 3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

Download the PolyJet 3D Design Guide.

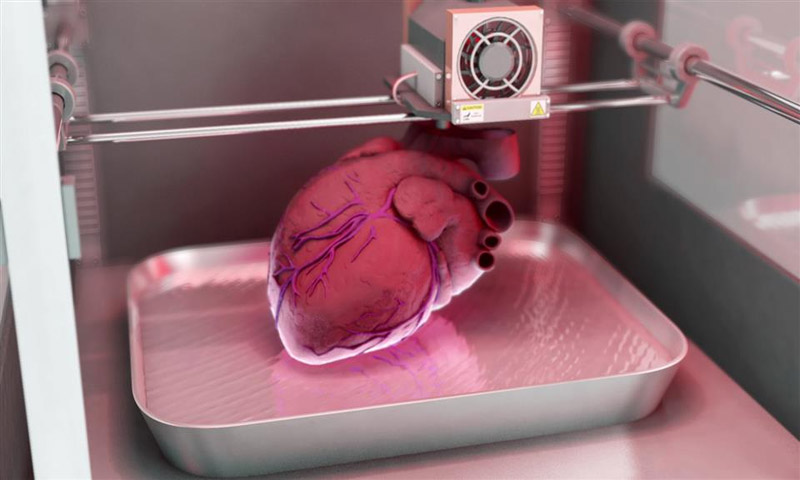

Direct Metal Laser Sintering (DMLS)

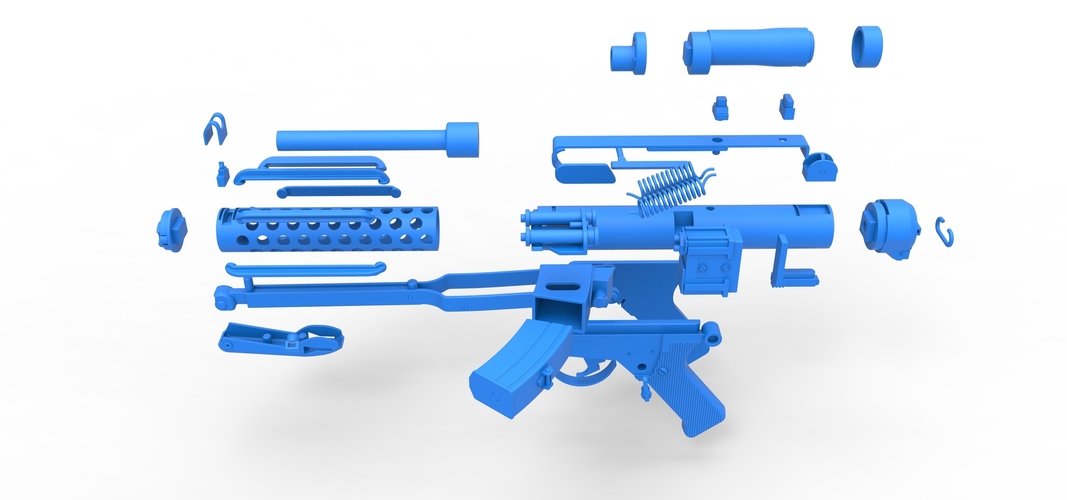

Direct Metal Laser Sintering (DMLS) is an 3D metal printing technology that builds prototype and production metal parts from a CAD file using a laser to selectively fuse a fine metal powder in either stainless steel or aluminum materials. A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

Our DMLS metal 3D printing service typically offers build volumes up to 250 x 250 x 325 mm, but we may be able to accommodate larger part volumes upon request in the quote. (See our Manufacturing Standards for more details) A good first step is to find out the cost of the parts you need using DMLS and compare them to other 3D printing processes and CNC machining.

Download the DMLS Design Guide.

Carbon DLS™

Carbon DLS™ uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce products with end-use durability, resolution and surface finish. This 3D printing technology is called Digital Light Synthesis™, or DLS for short. Another legacy term for the process is Continuous Liquid Interface Production (CLIP). Along with Carbon’s custom liquid resins, DLS unlocks new business opportunities and product designs previously impossible, including mass customization and on-demand inventory of end-use products.

Carbon bridges, and sometimes substitutes, for processes like Urethane Casting and Injection Molding service production, because the materials are urethane-based or epoxy-based, giving excellent mechanical properties. There are even elastomer and silicone resins that outperform most additive manufactured rubber-like materials.

The typical build area is 7.4” x 4.6” x 12.8”. Parts with dimensions exceeding 4” x 4” x 6” will require manual review.

Download the Carbon DLS Design Guide.

Metal Binder Jetting

With binder jetting, an inkjet print head quickly deposits a bonding agent onto a thin layer of powdered particles -- either metal, sand, ceramics or composites. This process is repeated, layer-by-layer, using a map from a digital design file, until the object is complete. Binder jetting is offered through our Digital RFQ Marketplace through Xometry's partnership with ExOne.

Download the Binder Jetting Design Guide.

Locations near Phoenix, Arizona

Glendale

ArizonaTempe

ArizonaScottsdale

ArizonaMesa

ArizonaChandler

ArizonaGilbert

ArizonaTucson

ArizonaHenderson

NevadaLas Vegas

NevadaChula Vista

CaliforniaMoreno Valley

CaliforniaSan Bernardino

CaliforniaRiverside

CaliforniaFontana

CaliforniaOntario

CaliforniaAlbuquerque

New MexicoIrvine

CaliforniaSanta Ana

CaliforniaAnaheim

CaliforniaHuntington Beach

California

Ready to start making custom 3D printed parts?

3D printing | University of Arizona Libraries

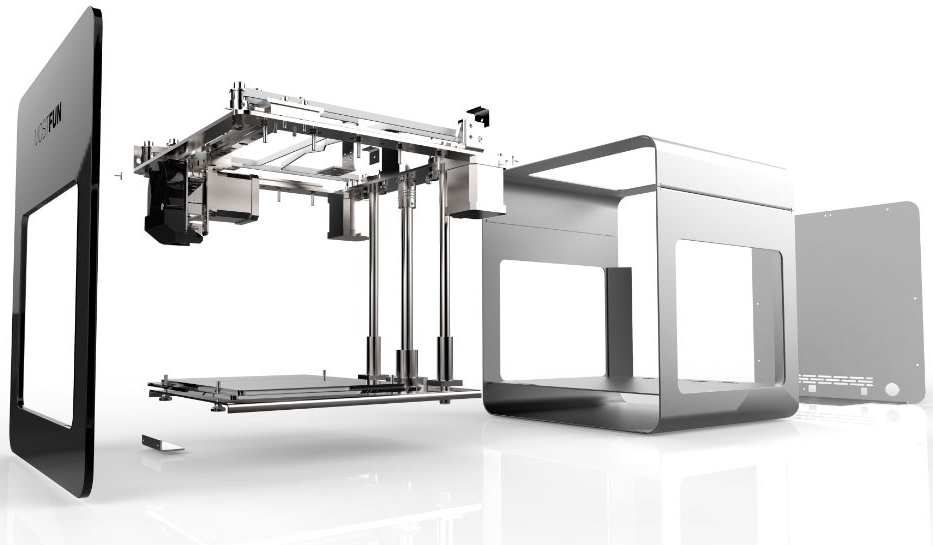

What equipment and materials do you use?We have a variety of 3D Printers across our libraries.

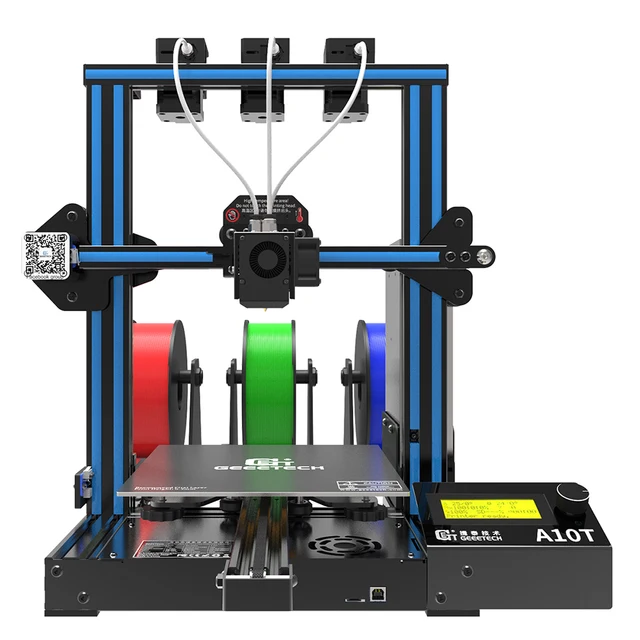

Ultimaker

The Ultimaker 3 and Ultimaker S5 are innovative dual extrusion machines with large build areas (UM3: 200 x 200 x 195 mm & S5: 310 x 220 x 295 mm) that print high resolution, production quality parts. Filaments available for these printers include: ABS, PLA, TPU (Flexy) and PolyCarbonate. Water soluble supports are available upon request.

- Learn more about Ultimaker filament options.

Prusa

The Original Prusa i3 MK3S+ is the latest iteration of Prusa Research’s original fused deposition modeling (FDM) machine. The MK3S+ has a build volume of 250 x 210 x 210 mm build volume and is known for its excellent and reliable prints. Filaments available for these printers include: PLA and PETG.

Learn more about Prusa filament options.

Phrozen

The Mega 8K LCD resin printer allows high resolution & fine detail of SLA but with an increased build plate size, 325 x 175 x 375mm. This machine excels at art and display models, with a single color selection and no engineering resins. This machine is the best choice for objects that need to look excellent with minimal mechanical stress.

This machine is the best choice for objects that need to look excellent with minimal mechanical stress.

Learn more about Phrozen Mega 8k resin

Who can use this service?

The service is open to all, but the priority is for UA students, faculty, and staff. Members of the community may submit requests to the Main Library, but the requests may be backlogged during peak use during the semester.

What does it cost?

| Material Type | Cost |

| PLA & PETG & ABS | $0.10/per gram |

| Specialty Filament (TPU) | $0.15/per gram + $1 set up fee |

| Resin | $.10/gram + $1 set up fee |

Set Up Fees

A $1.00 set up fee will be applied to any job printed with specialty filament or resin or that requires special handling.

For those objects printed with regular filament, a $1.00 set up fee may be added to your price quote. This determination is based on: the object's complexity, its build process, and the amount of staff attention needed to complete the job.

Please also note that a set up fee will apply to each file that must be created in order to print your objects. If your request contains multiple objects, we will combine as many objects onto the same build plate while still maintaining print integrity.

Payment

For students faculty, and staff, we add the charges to your library account, for members of the community, we’ll send a generic login you can use to pay.

What is the turnaround time?

Printing times vary based on size, complexity, and any backlog. If requested, we will contact you within two business days with an approximate turnaround time. To best accommodate large orders, please contact us 4-6 weeks prior to your "need by" date at [email protected]. For instructors, please contact us at the beginning of the semester so we can coordinate the best time for

your class to submit their projects.

Where can I get help?

You can prepare your own 3D file for printing and learn how to use the slicing software by visiting CATalyst Studios, located on the 2nd floor of the Main Library. A staff member can help you prepare your model for printing and set up the print job. If you are interested in becoming certified to use 3D printers in CATalyst Studios, please sign up for a 3D printing user certification workshop.

Please note, CATalyst Studios can only accommodate smaller 3D print jobs during their open hours. If you need to print larger items or require special materials, submit a 3D Printing request to our production service and we will take care of your 3D print for a fee.

Visit our 3D modeling resources page for modeling software, design libraries, and tutorials. Consultants from the Office of Student Computing Resources are available in the OSCR Zone to answer software questions.

Contact us

For any questions or concerns please email us at:

3D@lib. arizona.edu

arizona.edu

The 3D printing service is not available by phone.

3D printers for furniture printing. Large build chamber.

We are all used to factory furniture. However, designer furniture is valuable. 3D furniture printers make it possible to turn very original objects into reality: chairs, tables, lamps, vases, etc.

3D printers use different materials to print furniture. Most often it is high-strength plastic, although a printer has been created in America that prints wooden furniture. To do this, small chips and sawdust are taken, pressed and mixed with a polymer material. Thus, additive technologies make it possible to manufacture furniture from different materials. It remains only in a special program to develop the design of future furniture. nine0003

Almost every layman mistakenly believes that 3D printing is one of the benefits that the volatile 21st century has brought to our lives. However, this is a big misconception. A patent for this invention was registered in the mid-80s of the last century.

The 3D prototyping technology was copyrighted by Charles Hull. It was he who founded the company 3D Systems, which still holds a leading position in the production and sale of equipment for 3D printing. Their printers, such as the Cube Pro Trio or CubeX Duo, create great products that are accurate and durable. nine0003

With the light hand of this man, 3D printing later began to spread and many other companies appeared that produce equipment aimed at creating a variety of objects. Some 3D printers may well settle down even at home. For example, there is a 3D Quality company based in Russia. In its assortment there are many names like Prism Mini V2, Prism Uni or Prism Pro, among which everyone can find the right one for him.

In recent years, more and more designers are taking on the creation of furniture on 3D devices. It has a number of undeniable advantages:

- It is possible to create a unique design. You can even arrange everything in such a way that not a single item produced will be similar to the previous one.

- The designer's fantasy is not constrained by any conventions, such as the complexity of manufacturing. Any figment of the imagination can be brought to life.

- Anything can be printed, from lamp shades to tables and chairs. nine0020

For all its advancement, furniture made using 3D printing is still available only to a few. And the point here is not at all the prevalence of such printers, but the cost. The furniture is really exclusive. The concern of many specialists in this field at the moment is to find ways to reduce the cost of production.

However, for those who have a printer on hand, I can give you a piece of advice: you can't furnish your apartment just yet, but a doll house for children can acquire a unique style and sparkle with a unique design. You can call it layouts. Science does not stand still, and soon you will be sitting on chairs printed by 3D printers. nine0003

Already, many online stores offer designer furniture printed on a 3D printer. Would you like to prove yourself as a furniture and interior designer? You only need to buy 3D printers for printing furniture and everything will become real. And you can easily do this in our 3DMall online store.

Would you like to prove yourself as a furniture and interior designer? You only need to buy 3D printers for printing furniture and everything will become real. And you can easily do this in our 3DMall online store.

3D Printer in Arizona City - johnmani John

Email yourself a 10% off coupon

Send

Coupon sent! Check your email

Proceed to checkout: € nine0003

Add more 3D models

Upload 3D model

get an instant quote

or

Find 3D Models

files accepted: stl, obj, zip, step, stp, iges, igs, 3ds, wrl

files accepted: stl, obj, zip, step, stp, iges, igs, 3ds, wrl €

discount applied: was €

+ Upload more 3D models

Proceed to checkout: €

For instance, while the paybacks are numerous, some don't want to part with lots of money and time. The good news is that many professionals are available to assist in the writing process. Besides, anyone can get to this pointy situation.

The good news is that many professionals are available to assist in the writing process. Besides, anyone can get to this pointy situation.

The trick to ensuring that you get the best during your academic journey is to ensure that you settle for a legit company. This translates to getting a reliable establishment to write as per your instructions and quality. You must confirm that the service has seasoned writers to avoid any disappointments. nine0003

You can only get a trustworthy writing company if it provides excellent samples. Example examples to prove the worth of a company. You should see how the articles are written, the structure follows the right format, and formatting are consistent. If other aspects are not consistent, a new company has to be formed.

When seeking for a paper online, advanced tools like Grammarly are also essential. This helps to prevent plagiarism, which is a serious academic offense. Using online grammar checkers to proofread your work ensures that you the final document is 100% unique. nine0003

nine0003

What to Expect When you Purchase a Paper Online

A dependable writing service will have a clear understanding of the expectations of the client. The expected standards and quality will vary based on the type of assignment and topic. Therefore, the first step is to find out what the service offers.

Apart from checking whether the company has a support team, another crucial thing is to look at the reviews. What previous customers have to say about the service is also an important factor to consider. nine0003

Good reviews always tell you the kind of service to anticipate. Satisfied clients will leave a positive review. Originality is one of the top considerations, and the last thing you need is to make a bad choice.

Reliable customer support is another crucial element to consider. The support team works to empower the writer to tackle different subjects and deliver quality pieces. The customer care unit will ensure you get prompt answers whenever you have a problem.