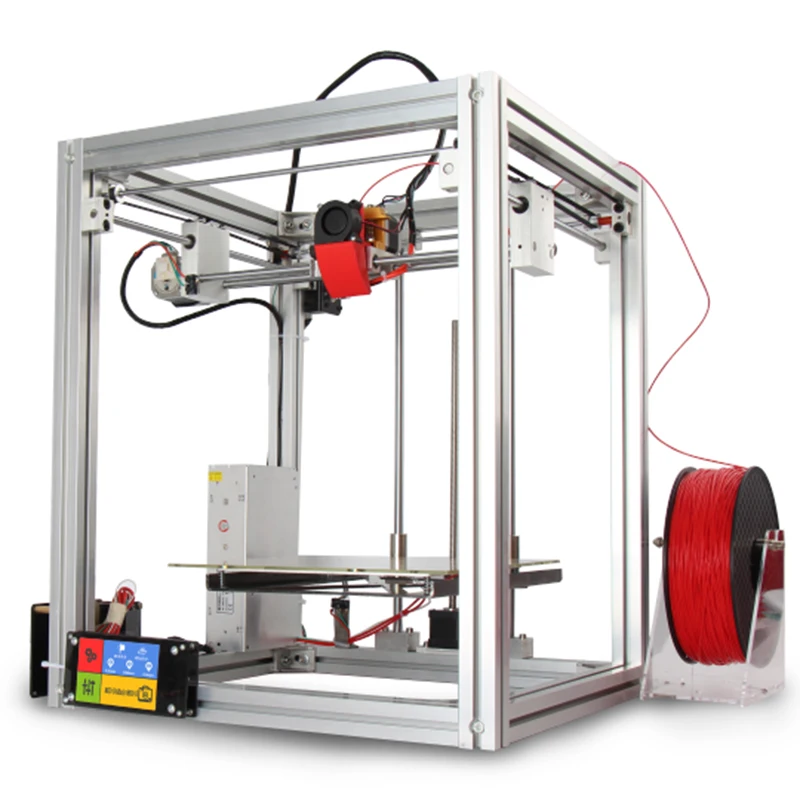

Big 3d printers

Large Volume 3D Printers | MatterHackers

Bring your most ambitious prints to life with these large-volume 3D Printers! From the enormously large Modix 3D Printers to flexible & industrial-grade 3D printers from brands such as Raise3D, MakerGear, or BCN3D; MatterHackers has the right large-volume 3D printer to fit your needs.

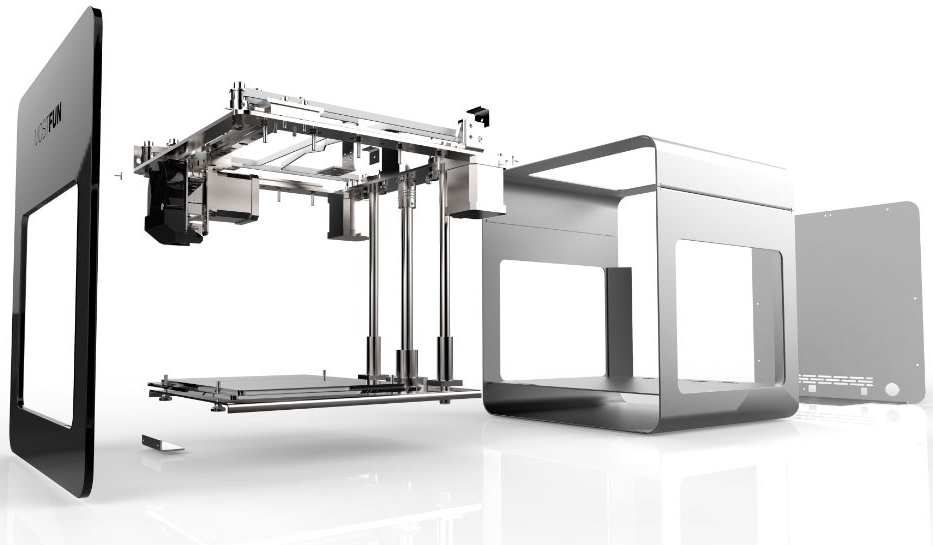

Available for purchase as kits or ready to ship fully assembled, these large-volume 3D Printers will enable you to print BIG and explore product development and prototyping without the need to invest in costly, full-scale additive manufacturing systems.

Guides & Articles

What is 3D Printing?

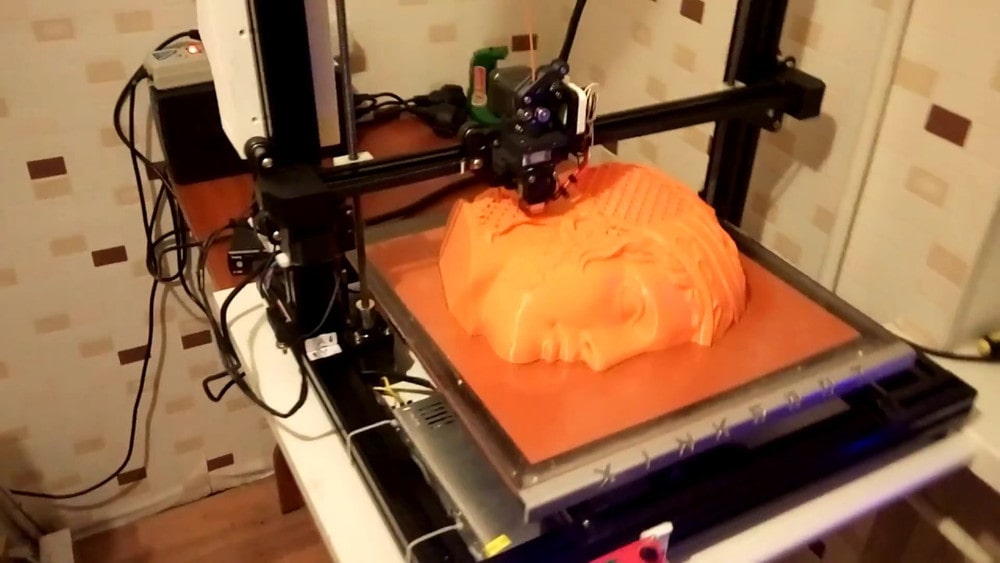

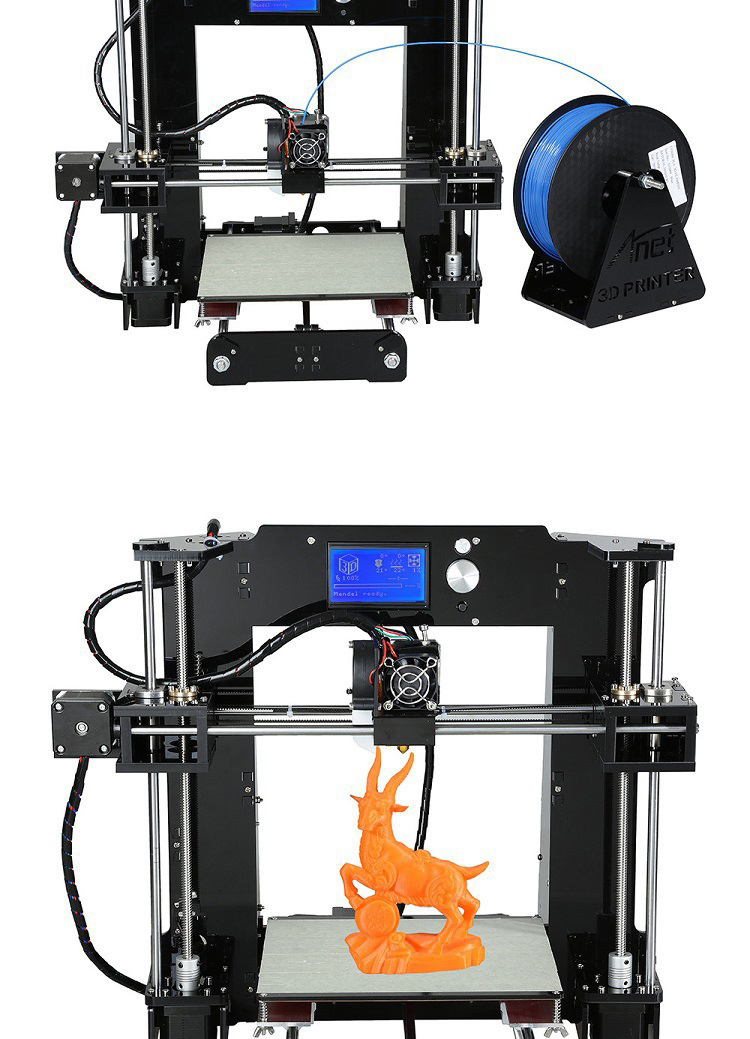

3D printing is a process where physical, three-dimensional objects, parts, or models are made layer-by-layer from Computer-Aided Design, or CAD, and digital files.

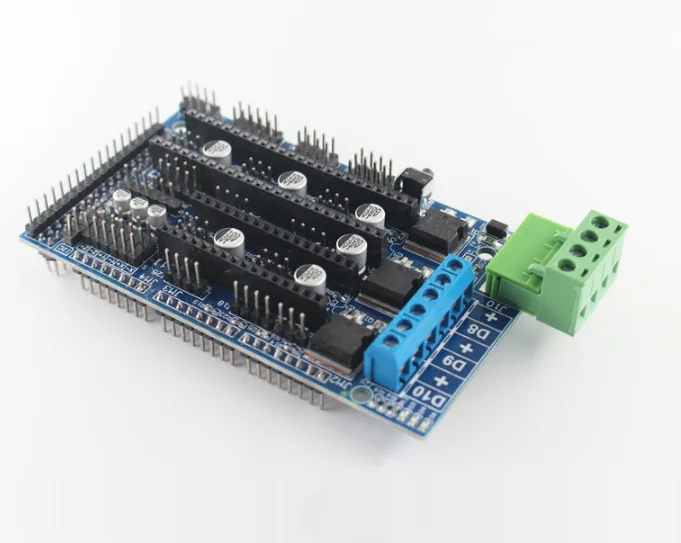

Anatomy of a 3D Printer

Get an understanding of how 3D printing works, from the inside and out. This guide will walk you through each of the critical components of a 3D Printer, answering the question: "How does a 3D printer work?"

The Top Ten Tips For Getting Started With 3D Printing

We were all noobs at one point! Here the ten best tips for getting started with 3D printing - whether it's your first time 3D printing or you need to brush up on the basics, this guide will help you out!

3D Printer Troubleshooting Guide

Use this guide to help you identify and solve the most common issues that may occur while 3D printing.

How To Calibrate Your 3D Printer's Extruder

This quick and informative guide will help you calibrate your extruder perfectly, resulting in accurate, quality prints.

3D Printing 101: How to Succeed with a Perfect First Layer for Every 3D Print

The first layer of your 3D print is the foundation of everything that comes after, which makes it such an important part of the 3D printing process.

How To Get The Best 3D Printed Parts By Understanding Extrusion Settings

Melting is a critical concept to 3D printing, and yet it hasn’t received a lot of in-depth attention. This article will teach you how to extrude your filament properly so it flows smoothly. Make filament jamming, delamination, and weak parts things of the past.

3D Printing Essentials: How to Succeed with Every Bed Surface Solution

Matching 3D printing filaments with the proper bed surface material is an important part of the 3D printing process. Read more to find out the best path to success.

Read more to find out the best path to success.

3D Printing Essentials: Filament Loading

Proper filament loading and unloading is a necessary part of 3D printing without trouble. Read on to learn the essential method you should be following.

3D Printing Essentials: Bed Leveling

For some, levelling a 3D printer's bed can be challenging, but it doesn't need to be. Read this essential guide to see what it takes to do it right.

Quick Tips: How To Get Started With Batch 3D Printing

Utilizing 3D printer time most efficiently is much easier once you start batch printing parts to maintain 3D printer uptime and minimize downtime.

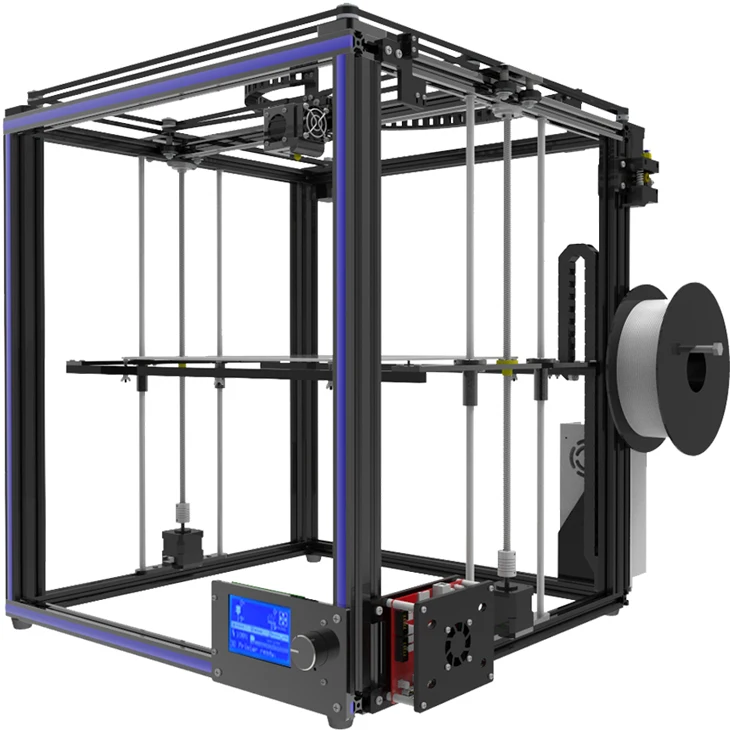

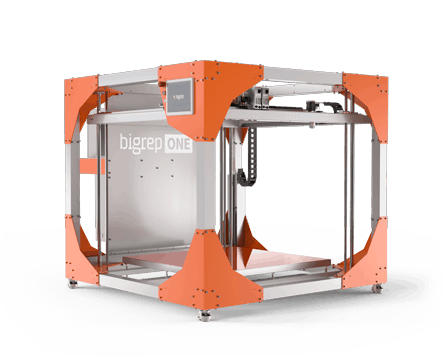

WHY SHOULD I SELECT A LARGE-VOLUME 3D PRINTER?The number of available large-volume 3D Printers is growing every day. Whether you are just getting started with 3D Printing, consider yourself an experienced hobbyist, or are a professional looking to take that next step into the world of large-scale production there is a large-volume 3D Printer to fit your needs.

Large-volume 3D Printers can range in price from as low as $500, such as the Creality Ender 5 Plus, while some can be as expensive as $15,000, such as the absolutely massive Modix Big-180X.

There are many other additional factors to consider when discussing the costs associated with large-volume 3D printers. It's important to thoroughly take into consideration things such as the type of 3D Printer Filament Or 3D Printer Resins you are planning to print with, the type of HotEnds and Nozzles required, as well as any other accessories such as Build Surfaces & Fume Extractors.

HOW LARGE CAN I PRINT?The Modix 3D Printer line easily takes the lead when it comes to print volume. Large, highly upgradable, and available exclusively as kits these printers are exceptional options for achieving ridiculously large prints.

- Modix BIG-40: 400mm x 400mm x 800mm, starting at $5,600

- Modix BIG-60 V3: 600mm x 600mm x 660mm, starting at $4,500

- Modix BIG-120X: 1200mm x 600mm x 640mm, starting at $7,550

- Modix BIG-120Z: 600mm x 600mm x 1200mm, starting at $7,450

- Modix BIG-180X: 1800mm x 600mm x 600mm, starting at $15,150

- Modix BIG-Meter: 1010mm x 1010mm x 1010mm, starting at $13,150

Raise3D E2 Industrial 3D Printer

- Home

- Store

- 3D Printers

- Raise3D 3D Printers

The Raise3D E2 3D printer is the result of Raise3D's many years of experience designing, building and supporting sturdy, feature-rich 3D printers like the N2 and Pro2.

- Featuring an independent dual extrusion system

- A 7" touchscreen display

- RaiseCloud - a fully intuitive print management system

The Raise3D E2 is the perfect solution for modern manufacturing and prototyping.

Remove from wishlist Add to wishlist loading...

Available Add-ons (1)

Show More Addons

Product No. M-2RM-S6NN

| List Price: | $3,499.00 |

|---|---|

| Price: | $3,499.00 |

| Price: | $... |

| Order Now: | Ships in 1-3 business daysFree Shipping Truck Free U.S. Shipping - excludes Alaska and Hawaii |

This item cannot be shipped to a PO Box or APO/FPO/DPO address. This item takes longer to ship due to its size and/or weight.

Qty

Request Quote

Precise and Affordable 3D Printing with Raise3D's Industrial E2 3D Printer

Durable, fully-enclosed dual extrusion 3D printing is possible with the Raise3D E2 3D printer. This addition to the fleet of Raise3D's trusted 3D printer line features upgrades to make batch production 3D printing faster and easier. Printing multiple parts simultaneously makes the Raise3D E2 3D printer a manufacturing powerhouse, all at an affordable rate.

This addition to the fleet of Raise3D's trusted 3D printer line features upgrades to make batch production 3D printing faster and easier. Printing multiple parts simultaneously makes the Raise3D E2 3D printer a manufacturing powerhouse, all at an affordable rate.

The Raise3D E2 3D printer is an independent dual extrusion (IDEX) machine, so you can create complex, multi-color, and multi-material 3D prints. The Raise3D E2 3D printer is compatible with dissolvable support materials, which allows for more intricate 3D printing, like parts and components that have drastic overhangs and details.

IDEX is also perfect for small-batch printing, as each of the two extruders can be used to print the same part on opposite sides of the print bed. This duplication mode allows you to turn out twice as many parts in the same amount of time, bolstering your manufacturing workflow, and freeing you from much of the costly overhead of print startup and removal.

IDEX is an amazing innovation in 3D printing, but it's still only as good as its design, and the E2's dual extrusion 3D prints are excellent. In all of our tests, the Duplication Mode and multi-material prints came out beautifully, with no X shift or "leaning prints". Raise3D has paid perfect attention to the tiny details that build up to a powerful and easy 3D printing experience.

Clean, multi-material and multi-color prints are possible with the Raise3D E2 Industrial 3D printer.

Maintain Perfect Print Temperatures and Clean Workspaces with the E2's HEPA Filtered EnclosureWhen you need to print at the industrial level, tougher materials like ABS and PC require heat and consistency in their temperature-controlled environments, and the E2 provides that for you, right out of the box. With a strong safety latch and a huge viewing window, you can easily keep an eye on your quality 3D prints using professional materials. And with the dual filtration, using HEPA and activated carbon, the air that flows out of the E2 is as clean as a spring day, even as you print with polystyrene.

The Raise3D E2's fully enclosed, temperature-controlled build chamber allows for pristine 3D printed parts.

3D Printed End-Use Parts Produced Accurately and Efficiently

When timelines are important, it's essential that your 3D printer produces the parts you need - every time. The Raise3D E2 has been designed form the ground up to ensure just that. When calibrating the E2, the powerful quad-core A9 ARM chip uses advanced flatness detection to create a fine mesh model of its print surface, so even the subtlest variation in the surface is accounted for, and your 3D print's first layer is perfect.

During operation, if the printer encounters any power loss, it saves exactly where it was, so once you're back up and running, the print resumes as nothing happened. Lost prints can take weeks off your project timeline - the E2 from Raise3D adds an element of reliability that is unmatched.

Easy Batch Production with FlexPlate Print Removal

Once your prints are complete, simply remove the magnetic build plate and pop them off with a snap, thanks to the aluminum flexplate and BuildTak sheet that comes stock with every E2 3D printer. Your parts come away free, and the plate is ready to put back on the print bed, where the next print can immediately begin. Turn your workspace into a perfectly oiled production machine with the E2.

Your parts come away free, and the plate is ready to put back on the print bed, where the next print can immediately begin. Turn your workspace into a perfectly oiled production machine with the E2.

The Raise3D E2's flexible build plate makes it fast and easy to remove finished 3D printed parts.

Technical Specifications- Machine Dimensions: 23.9" x 23.5" x 18.3" (607mm x 596mm x 465mm)

- Build Area:

- Single Extrusion: 13" x 9.4" x 9.4" (330mm x 240mm x 240mm)

- Dual Extrusion: 11.6" x 9.4" x 9" (295mm x 240mm x 240mm)

- Extrusion Technology: IDEX

- Nozzle Diameter: 1.75mm x 0.40mm - 1.00mm

- Max Nozzle Temp: 300C

- Max Build Plate Temp: 110C

- Build Plate: Flexible Steel Plate w/ BuildTak

- Build Plate Leveling: Mesh-Leveling with Flatness Detection

- Enclosure Filtration: HEPA w/ Activated Charcoal

- Connectivity: Wi-Fi, LAN, USB, Live Camera

- Interface: 7" Touchscreen (Resolution of 1024 x 768)

- Slicing Software: ideaMaker

- Supported File Types: STL/OBJ/3MF

- Supported OS': Windows, MacOS, Linux

- Machine Code Type: GCODE

- Motion Controller: Atmel ARM Cortex-M4 120MHz FPU

- Logic Controller: NXP ARM Cortex-A9 Quad 1 GHz

- Power Input: 100 - 240 V AC, 50 / 60 Hz 230 V @ 2 A

- Power Output: 24 V DC, 350 W

- Noise: < 50 dB(A)

- Certifications: CB, CE, FCC, RoHS, RCM

The ARM Cortex-A9 Quad 1 GHz Controller is the brains behind this ingenious 3D printer.

- Raise3D E2 3D Printer

- Spool Holders (x4)

- Power Supply

- Flash Drive

- Unboxing Instructions and Quick Start Guide

- Toolkit

- Allen Wrench Set

- Tweezers

- Scraper

- Feeler Gauge

- Pair of Gloves

- PLA Spool

- ABS Spool

- Spare Parts Kit

- Bowden Tubes

- Fuses

- PTC Fittings

- Plastic Clips

To learn about available discounts, training, and maintenance options, please use the form below and a MatterHackers Expert will contact you within one business day.

To get an instant quote, add everything you need to your cart, and click "Download as quote".

Product(s)

Email *

Full Name

Company/Organization

Questions

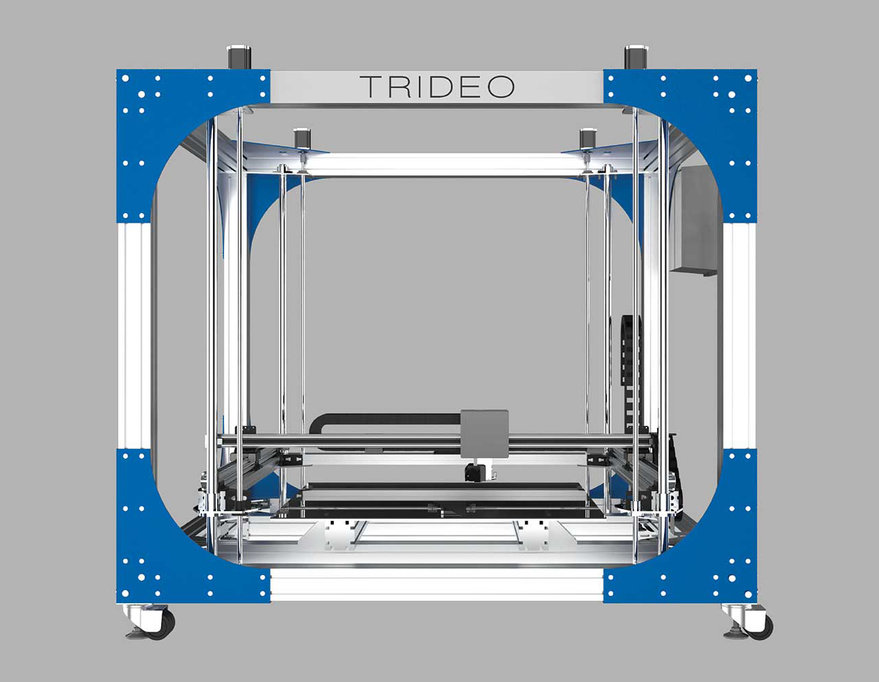

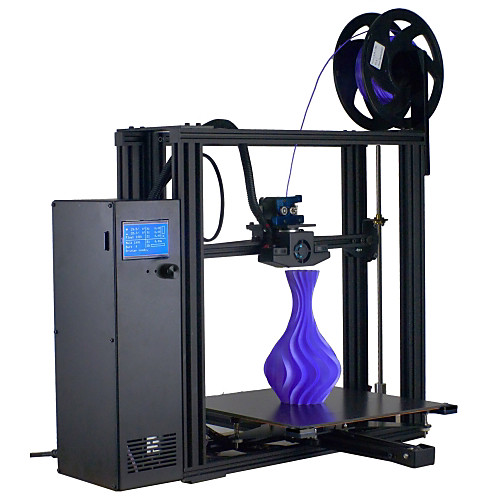

Large Modix 3D printers

Modix Large 3D Printer is the

your best next 3D printer!

- Two-headed IDEX printing-novelty

- premium components

- Superficent design

- Multiple additions

- High resolution

- Self service

- Easy to upgrade

- Within your budget

- Compact package

are supplied as sets for independent assembly: nine0011

Modix Large 3D Printer is your next best 3D printer!

- Premium Components

- Heavy Duty

- Multiple Options

- High Resolution

Supplied as DIY kits:

- Manage your configuration

- Self service

- Easy to upgrade

- Within your budget

- Compact package

New generation 4 November 22

Modix is proud to announce the release of its new unified 3D printing platform called Generation 4 with IDEX dual head technology. Modix continues its path to market leadership by integrating cutting edge technology while maintaining outstanding value for money. nine0026

Modix continues its path to market leadership by integrating cutting edge technology while maintaining outstanding value for money. nine0026

Generation 4 upgrades the Modix offering with new features such as printing models with internal geometry, faster print speeds, faster post-processing times and higher reliability.

Learn more about the fourth generation of Modix - click here.

IDEX allows you to print models with internal geometry, provides high quality surface finish while reducing post-processing time.

View details

The Griffin printhead delivers high print quality, impact resistance, easy replacement and higher print temperatures than ever before. nine0004 Learn more

A set of reliability sensors designed to save time on print jobs. It can detect filament runout, under extrusion and clogging.

Learn more

Full set of automatic calibration tools including: bed tilt calibration, bed leveling, gantry leveling and z-offset calibration.

Learn more

Don't limit future ideas, get a bigger printer today! nine0026

For more information about our large 3D printer technology, please CLICK HERE

IDEX

Double independent extruders

touch screen

7-inch touch screen and web interface for remote monitoring

Duet Controller

Improved Electronics with a control web 9000 9000 9000 9000 your health with a set of charcoal and HEPA filters. nine0004 (Optional)

Shielded wires

IGUS signal cables for greater reliability.

Magnetic bed

Easily remove printed objects when finished.

(Optional).

Fault Detector

Detect hardware failures and prevent failures.

High Quality

One of the most significant benefits of Modix large-scale 3D printers are carefully selected premium components, each of which contributes to high quality printing. These components include: Bondtech Extruder (Sweden Made), E3D Nozzles (UK Made), DUET3D Controller (UK Made), Trinamic Motor Drivers (German Made), IGUS Shielded Signal and Power Wires (German Made), Alcoa Cast Aluminum Plate Mic-6 (made in USA), Meanwell power supply (made in Taiwan) and more. Nearly every component in our large format 3D printers contributes to print quality and reliability, which is why we choose the highest component standards, even for the smallest parts, such as aircraft grade power adapters, durable castors, fiberglass reinforced belts, etc.

Nearly every component in our large format 3D printers contributes to print quality and reliability, which is why we choose the highest component standards, even for the smallest parts, such as aircraft grade power adapters, durable castors, fiberglass reinforced belts, etc.

Heavy Duty

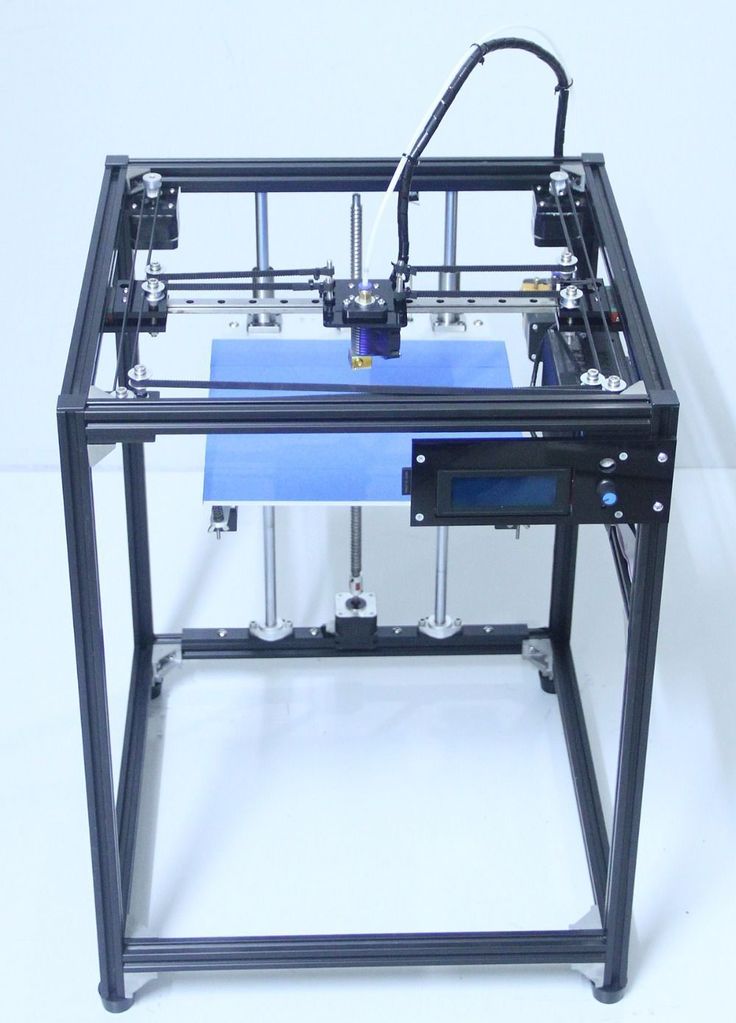

A key design factor in our large scale printers is the heavy duty design. Because our large format 3D printers are supplied as DIY kits, we place great emphasis on ensuring that the end user achieves the highest levels of accuracy and consistent calibration. This includes a very detailed online build guide with 3D models that can be rotated and scaled, several detailed video tutorials for each step, and more. In addition, we provide our clients with calibration methods and tools that help make this process as successful and as smooth as possible. nine0026

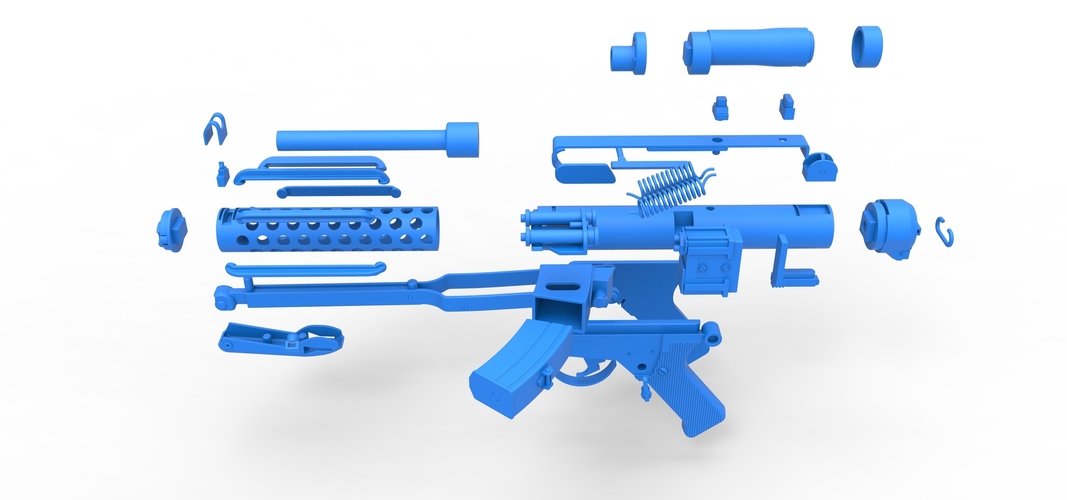

IDEX Dual Extrusion

IDEX's dual print head technology allows internal geometry to be printed using a dissolvable support filament. Once completed, you can dissolve the support material and enjoy high-quality results without the tedious manual removal of the support. With tear-off support, you can quickly remove the support immediately after printing is complete. In addition, you can enjoy the smooth surface of the bottom surfaces. With a secondary support thread, you can maintain zero distance between dense support layers and the model itself, so the surface will be much smoother than when printing support from the same material. nine0026

Once completed, you can dissolve the support material and enjoy high-quality results without the tedious manual removal of the support. With tear-off support, you can quickly remove the support immediately after printing is complete. In addition, you can enjoy the smooth surface of the bottom surfaces. With a secondary support thread, you can maintain zero distance between dense support layers and the model itself, so the surface will be much smoother than when printing support from the same material. nine0026

Customizable Platform

Modularity is our flagship concept. In fact, the Modix brand is called "modular technology". At Modix, we're constantly making new optional add-ons available to easily add to your printer, including air filters, multiple printhead configurations, and more. There are several additional setup guides on our customer's online services portal.

Wide Choice

Our Griffin printhead offers a wide range of nozzle and heater block configurations. Modix offers three heat block sizes: the default high performance Griffin hot end, the short E3D-V6 hot end for detailed fine prints, and the E3D Super Volcano for rough and fast 3D projects. Each of the thermoblocks has several options for nozzles, some of them are offered as part of our set. Other materials can be purchased directly from the E3D online store, such as high-quality hardened steel nozzles that can print with abrasive filaments (such as filament containing carbon fiber). nine0026

Modix offers three heat block sizes: the default high performance Griffin hot end, the short E3D-V6 hot end for detailed fine prints, and the E3D Super Volcano for rough and fast 3D projects. Each of the thermoblocks has several options for nozzles, some of them are offered as part of our set. Other materials can be purchased directly from the E3D online store, such as high-quality hardened steel nozzles that can print with abrasive filaments (such as filament containing carbon fiber). nine0026

Open Architecture

Our clients are not locked out! Modix believes in freedom of choice, especially for passionate innovators. Users can select filament from any source and use a variety of modeling and slicing software solutions to suit their needs. We recommend the Simplify3D slicing software, but recognize that users may have other software preferences such as Cura and Slic3r. They also work great and are compatible with our larger 3D printers. Our customers are provided with print profiles for each of these slicing software packages. nine0026

nine0026

Self Assembly

Self assembly is the preferred method of purchasing a 3D printer for many professionals for several reasons. Practical approach - you build your own machine to better understand the motion system, print head and calibration. You will gain invaluable insight into how to maintain your printer and how to upgrade it in the future. Just like your PC's operating system, Modix large format 3D printers are specifically designed to be customized and adapted to your specific needs. nine0026

Future Ready

We are constantly developing and innovating, so when you buy a Modix 3D printer, you are actually investing in a platform that can be upgraded from time to time. Owners of earlier versions are now offered the benefits of our latest version (Generation 4.0). This alone improves the long-term sustainable use of the printer and increases your return on investment.

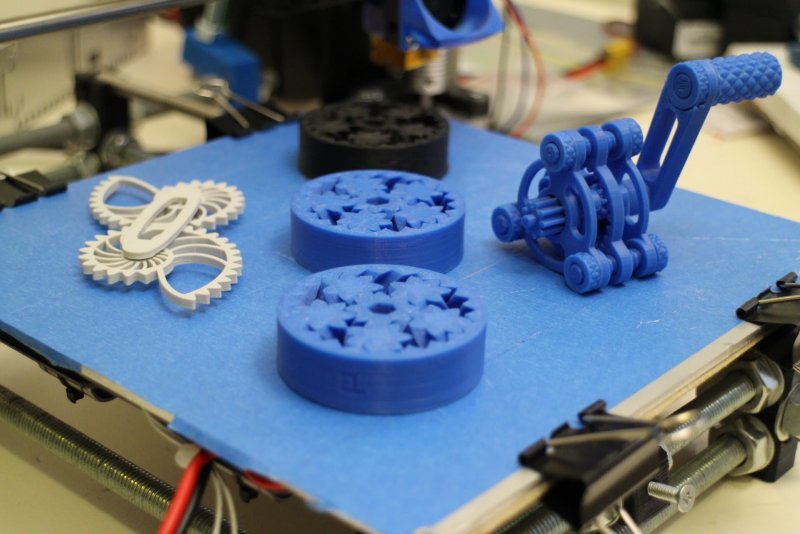

Large Benefits of 3D Printer

Experienced 3D printer users who already own one or more small desktop 3D printers and are now looking to expand their printing capabilities should consider the following unique advantages of large format 3D printers:

1. Printing large, one-piece 3D models makes them stronger.

Printing large, one-piece 3D models makes them stronger.

2. Printing models as one part also saves post-processing time. There is no need to fit smaller pieces together or try to hide a seam.

3. Another unique advantage of the large printbeds is the fact that you can print multiple small items in one batch. Batch production can be set up to complete one object before starting another ("sequential printing") for greater reliability. nine0026

Premium Support since 2015

Modix prides itself on its prompt and professional support!

We believe that any product is only as good as its service, and since the beginning in 2015 we have worked hard to maintain this concept. If received, help requests are cleared daily. If necessary, videoconferencing sessions are scheduled to better understand the ground situation. This saves time both in understanding the problem and in quickly finding a solution. nine0026

Reviews

Mr. Brian Grimm

Engineering Garage USA

BIG-60 B3

Mr. James Lowick

James Lowick

Australia

BIG-60 B3

MR. Jeff Raymond

Real Martian USA

BIG-120V3

Frank 3D Print

Lab USA

BIG-60 V3 (Open Mode)

Use Cases

Canon Restoration 1.6 meters

Made in Ireland

Made in Germany

Motorcycle engine cover

Made in Czech Republic

Bronze cast

Made in Turkey

Goodyear Farm Tire

Made in USA

Cutter cover

Made in Israel

PCB maker

Made in France

Prosthesis cover for high legs

Made in Portugal

Trusted By

Aerospace

Automotive

Protection

Production

Production

Educational

Get an overview of our new product:

The product overview includes a detailed technical review, updated specifications, and answers to frequently asked questions, including how to print at high temperature, software comparability, and more. nine0026

nine0026

Top 10 biggest 3D printers in the world

Share on Facebook Share on Twitter Share on Vkontakte

Have you ever wondered how big 3D printers can be? If this has happened to you, then it's time to satisfy your curiosity, we will tell you about 10 largest 3D printers in the world. The selection criterion was the size of the object that can be created in the camera (or workspace) 3D printer .

At the end of the article you will find a slider with examples of the work of 3D printers included in this top ten.

So, let's start with the smallest large printer in our top ten.

10. Norsk Titanium

This 3D printer was created by the American company "Fabrisonic" . The technology by which it works is direct metal deposition. The size of 3D printed parts is 120 x 120 x 180 cm. Although the maximum length of the product can be up to 215 cm according to the company. nine0026

nine0026

9. ExOne Exerial

This is Dual Chamber 3D Printer, each chamber measures 220 x 120 x 70 cm, can use metal, ceramic and sand as material, the latter is used to create sand cores and molds .

8. Voxeljet VX4000

The chamber measures 4 x 2 x 1 m and is by far the largest industrial machine, mainly used for making sand molds. nine0026

7. D-shape

The work surface of this 3D printer is a 6 x 6 meter aluminum frame. To create three-dimensional objects, a special sand material is applied layer by layer, the layers are fixed with a special binder.

The printer was patented in 2006 by Enrico Dini, founder of the British company "Monolite UK Ltd" . The first model of the printer used epoxy resin as a binder, but Dini later switched to using a magnesium-containing substance. After making this change, he again patented 3D printer in 2008. In the future, Dini wants to use the 3D printer to create full scale buildings.

6. Sciaky EBAM 300

The working chamber size of this 3D printer is 7.620 x 2.743 x 3.353 m. The electron beam melts the metal, which is fed in the form of a wire, and a three-dimensional object is created layer by layer according to the CAD model. Sciaky EBAM 300 works with metals such as titanium, titanium alloys, inconel 718 and 625, tantalum, niobium, stainless steel, aluminum alloy 2319 and 4043, steel 4340, zircalla and others.

5. KamerMaker

This printer was one of the very first large scale 3D printers, it uses fusing technology. With his help, the first 3D printed house was built on one of the canals of Amsterdam. The sizes of printed objects reach dimensions of 2 x 2 x 3.5 m, bioplastics and bioplastics are used as materials. This is an open public project that anyone can join. nine0026

4. WASP GigaDelta

This 3D printer can grow objects up to 8-10 meters high. The creator of this machine, Massimo Moretti, dreamed of building houses using clay as a material and with minimal energy consumption. Now the company is developing a printer with a special extruder. After the work is completed, it will be possible to create objects up to 12 meters high.

The creator of this machine, Massimo Moretti, dreamed of building houses using clay as a material and with minimal energy consumption. Now the company is developing a printer with a special extruder. After the work is completed, it will be possible to create objects up to 12 meters high.

3. Cincinnati Incorporated's BAAMCI

Working space is 25 cubic meters. nine0004 This huge thermoplastic machine was created to print the "Strati" car for "Local Motors" , which was shown at an international technology event in Chicago in 2014. Now the creators of BAAM are working on the next, even larger version of the machine, its name will be "Bertha" .

2. BetAbram P1

Working space 288 cubic meters.

Slovenian company BetAbram manufactures (on request) 3D printers in three sizes for house printing. The largest of them has a span of 9 x 16 m (the average is 12 x 6 m, and the smallest is 4 x 3 m).