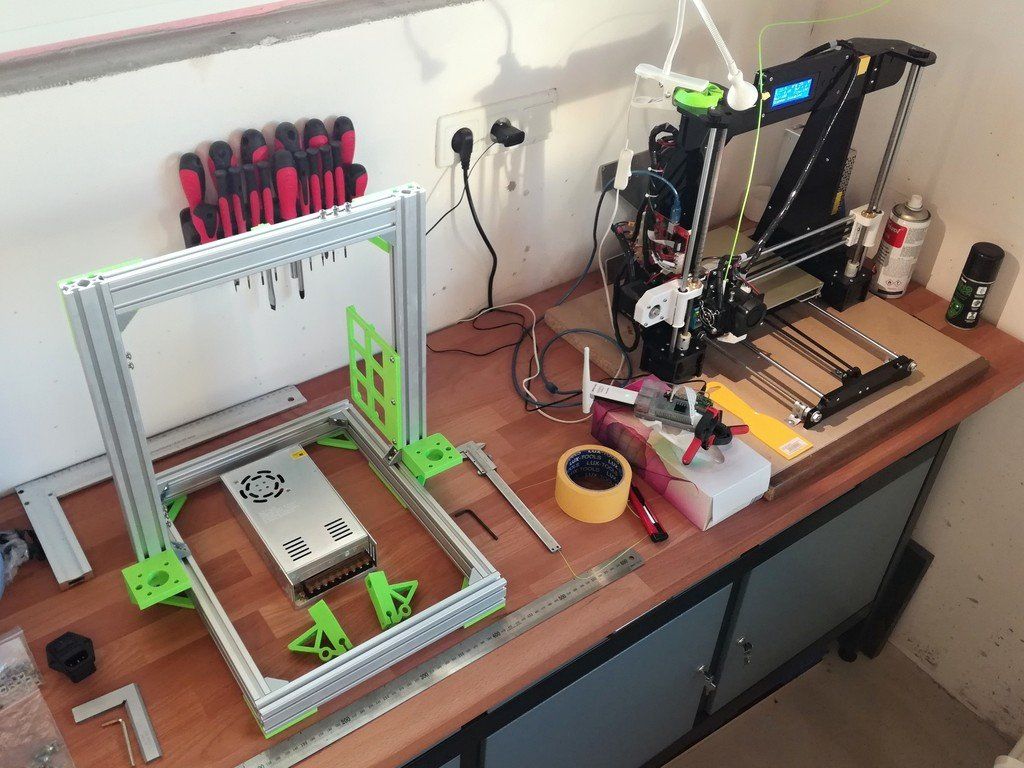

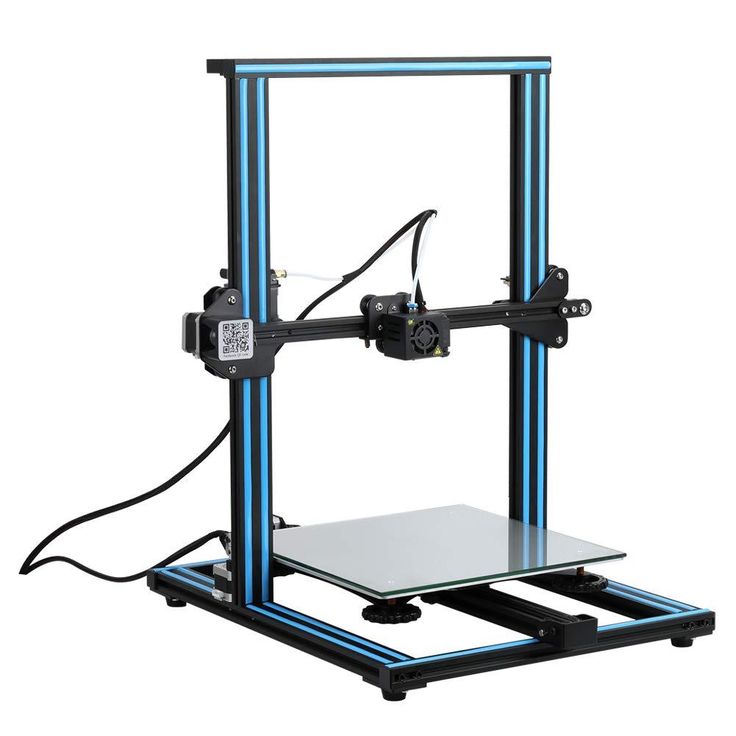

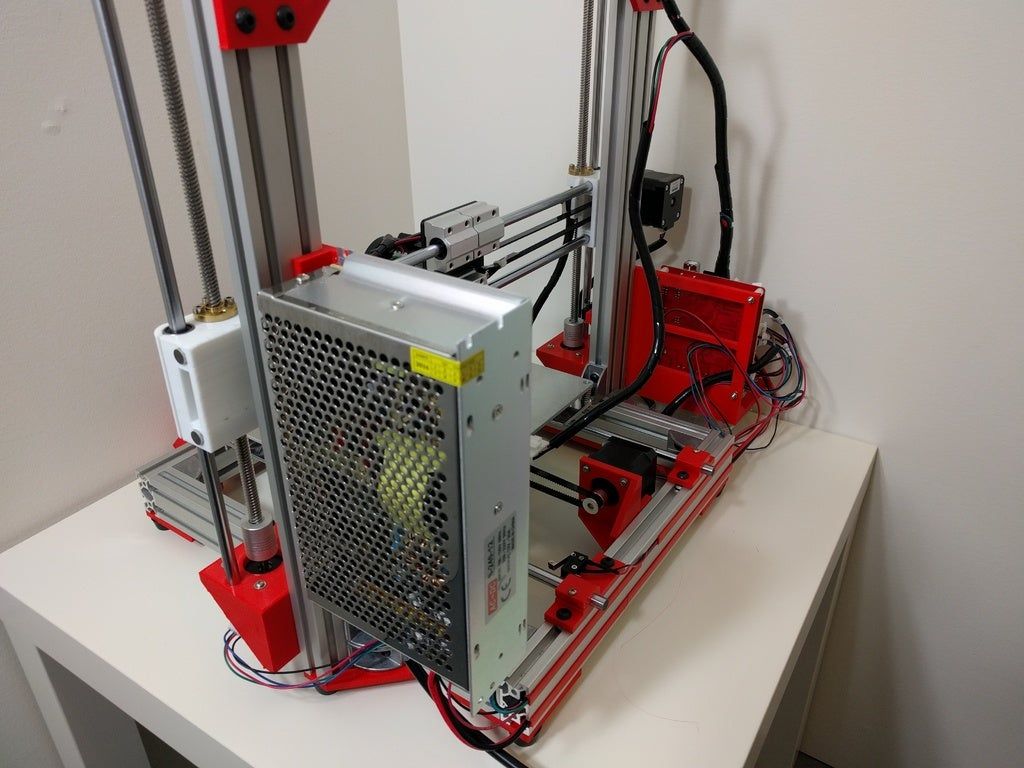

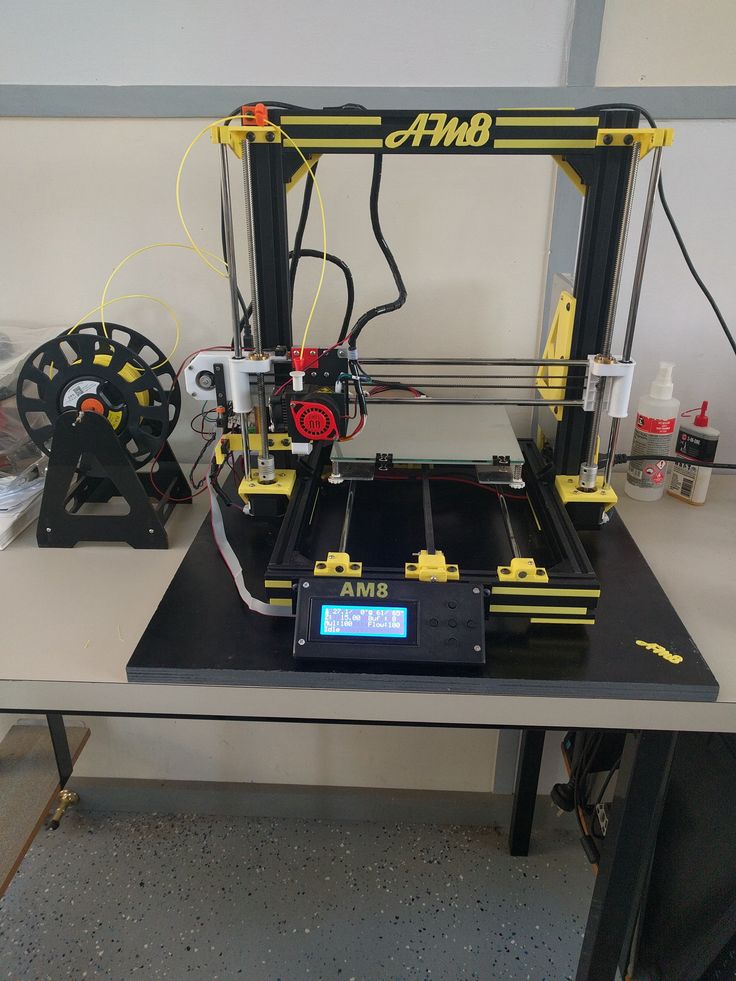

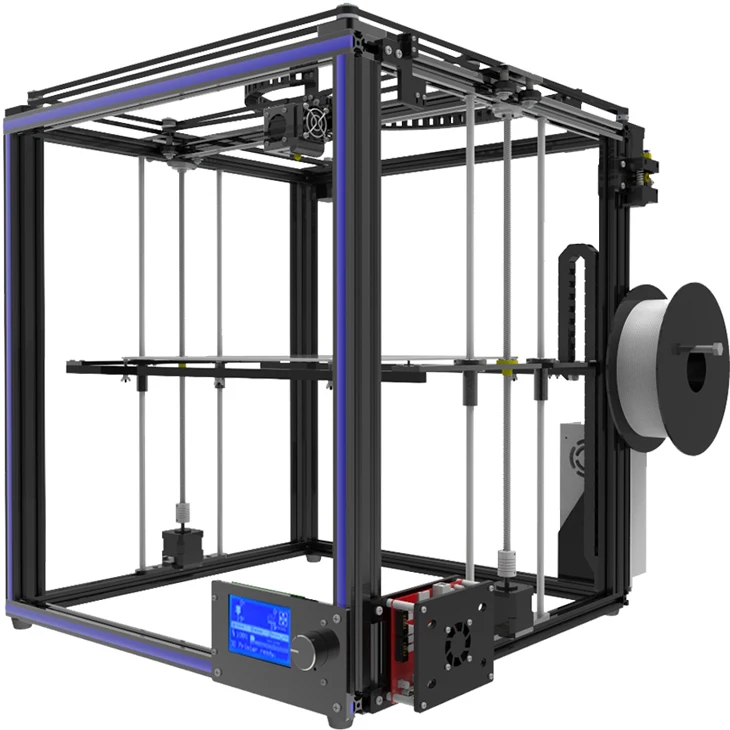

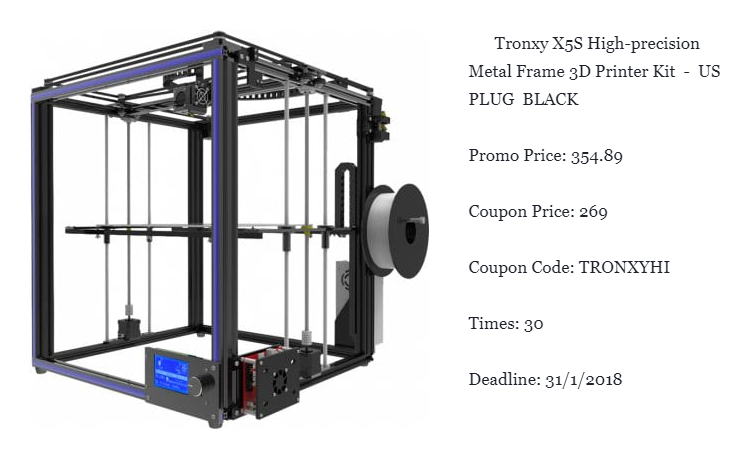

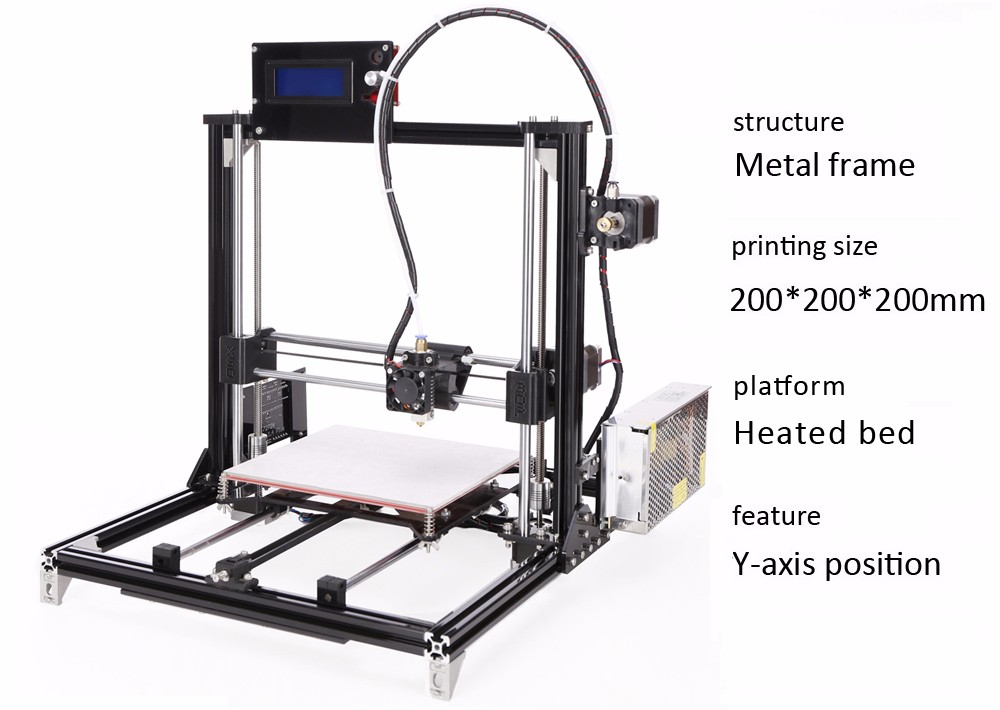

Metal frame 3d printer

3d Printer Enclosure Metal Frame

Etsy is no longer supporting older versions of your web browser in order to ensure that user data remains secure. Please update to the latest version.

Take full advantage of our site features by enabling JavaScript.

-

Loading

Click to zoom

658 sales |

5 out of 5 stars Price: €25. 30

Original Price: €28.42

(10% Off)

Loading

VAT Included

Listed on Dec 10, 2022

97 favorites

Report this item to Etsy

Choose a reason…There’s a problem with my orderIt uses my intellectual property without permissionI don’t think it meets Etsy’s policiesChoose a reason…

The first thing you should do is contact the seller directly.

If you’ve already done that, your item hasn’t arrived, or it’s not as described, you can report that to Etsy by opening a case.

Report a problem with an order

We take intellectual property concerns very seriously, but many of these problems can be resolved directly by the parties involved. We suggest contacting the seller directly to respectfully share your concerns.

If you’d like to file an allegation of infringement, you’ll need to follow the process described in our Copyright and Intellectual Property Policy.

Review how we define handmade, vintage and supplies

See a list of prohibited items and materials

Read our mature content policy

The item for sale is…not handmade

not vintage (20+ years)

not craft supplies

prohibited or that use prohibited materials

not properly labeled as mature content

Please choose a reason

Tell us more about how this item violates our policies.Tell us more about how this item violates our policies.

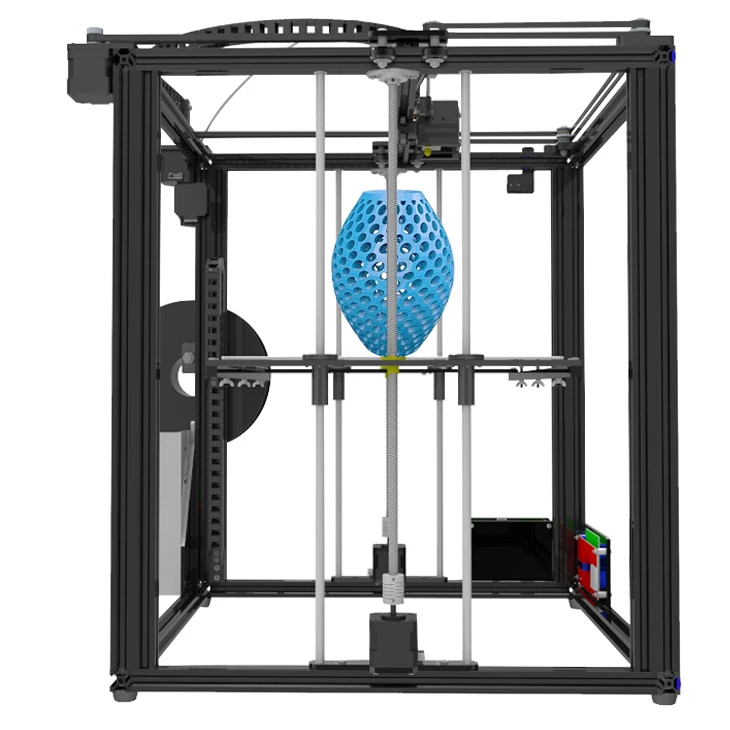

Qidi I-Mates, all metal frame 3d printer – QIDI TECHNOLOGY OFFICIAL STORE

Skip to product information1 / of 7

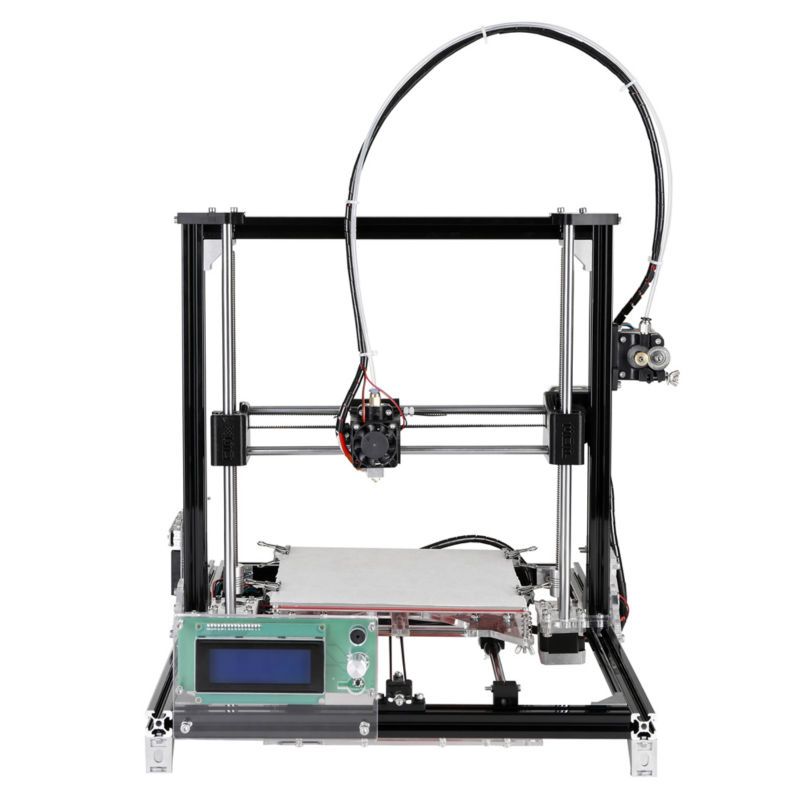

Qidi I-Mates, all metal frame 3d printer

- Regular price

- $369.

00

00 - Regular price

-

$419.00 - Sale price

- $369.00

Sale

Quantity

US EU countries UK Australia Brazil Japan OthersProduct Description

QIDI TECHNOLOGY

I-mates 3d printer

Technology: FDM

Support Material: PLA,ABS,TPU,PETG,etc

Extruder: 0. 4mm Extruder, 0.2mm Hot-End

4mm Extruder, 0.2mm Hot-End

Printing Size: 10.24''(L)x7.87''(W)x7.87''(H)

About QIDI TECHNOLOGY

QIDI Technology has been committed to the development of high-quality, high-performance 3d printers. As a consumer-level mid-to-high-end leader, we launch 3-4 types of new model 3d printers every year. The Qidi new i-series will be officially released in 2021, representing more advanced technology and pursuing the ultimate user experience!

Parameters

| Machine Size | 582(L)*465(W)*435(H)mm |

|---|---|

| Print Size | 260*200*200mm |

| Print Accuracy | 0.05-0.2mm |

| Print Speed | 30-150mm/s |

| Extruder Quantity | Existing extruder + Additional hot-end |

| Extruder Temp | 250℃ |

| Nozzle Diameter | 0.4mm+0.2mm |

| Voltage | 110-220V |

| Power | 350W |

N. W. W. | 21.6KG |

| Support | Windows 64 bit/Mac |

| Connection Options | WIFI/USB Pen Drive |

| Support Material | PLA, ABS, TPU, PETG... |

| Compatible Software | QidiPrint/Cura/Simplify 3D |

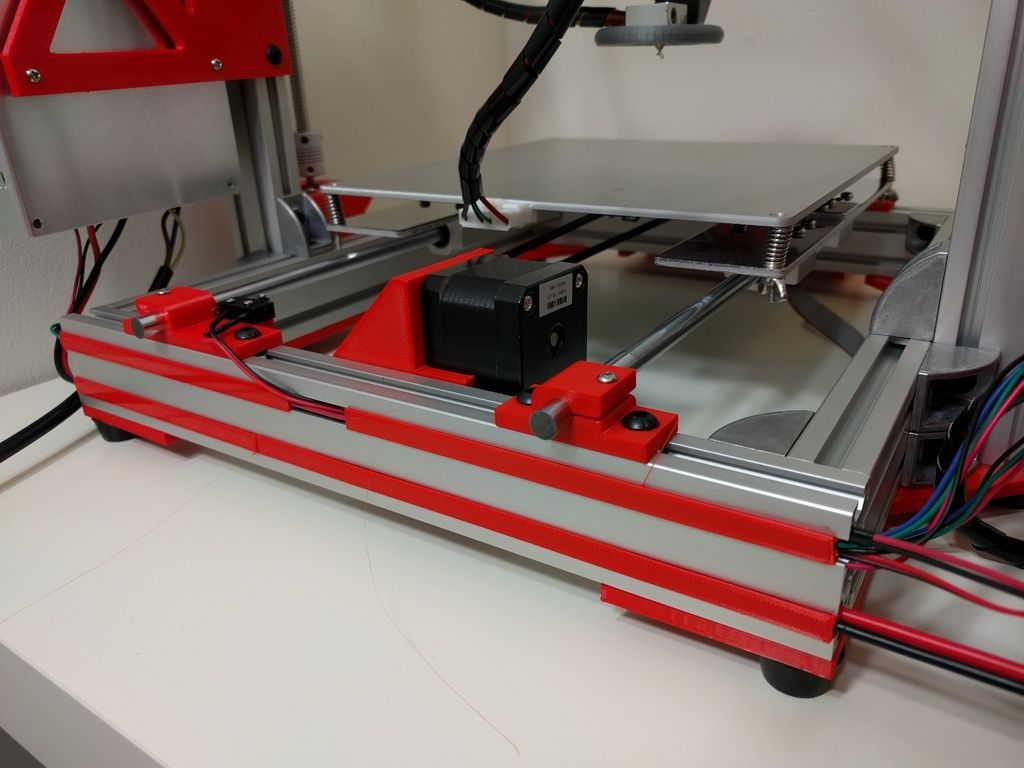

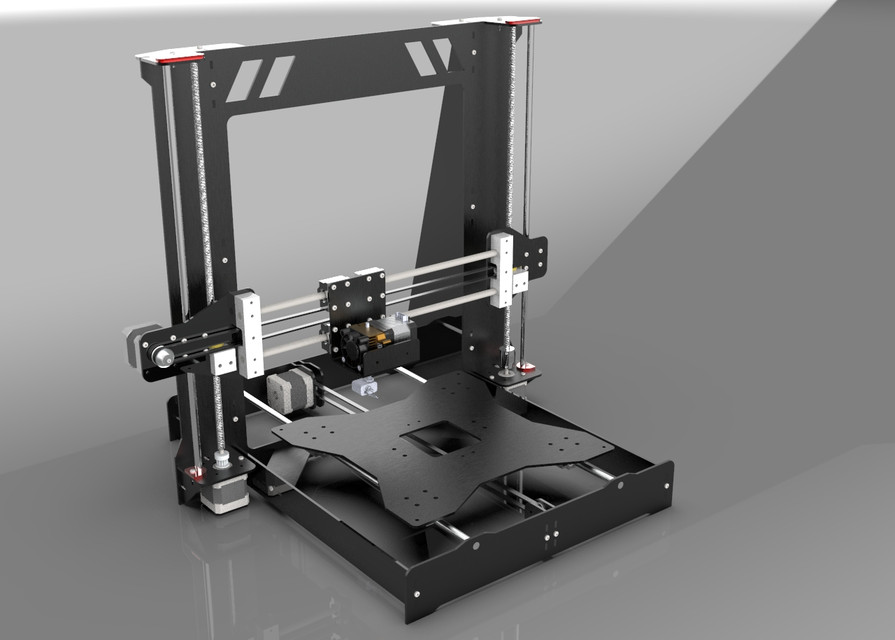

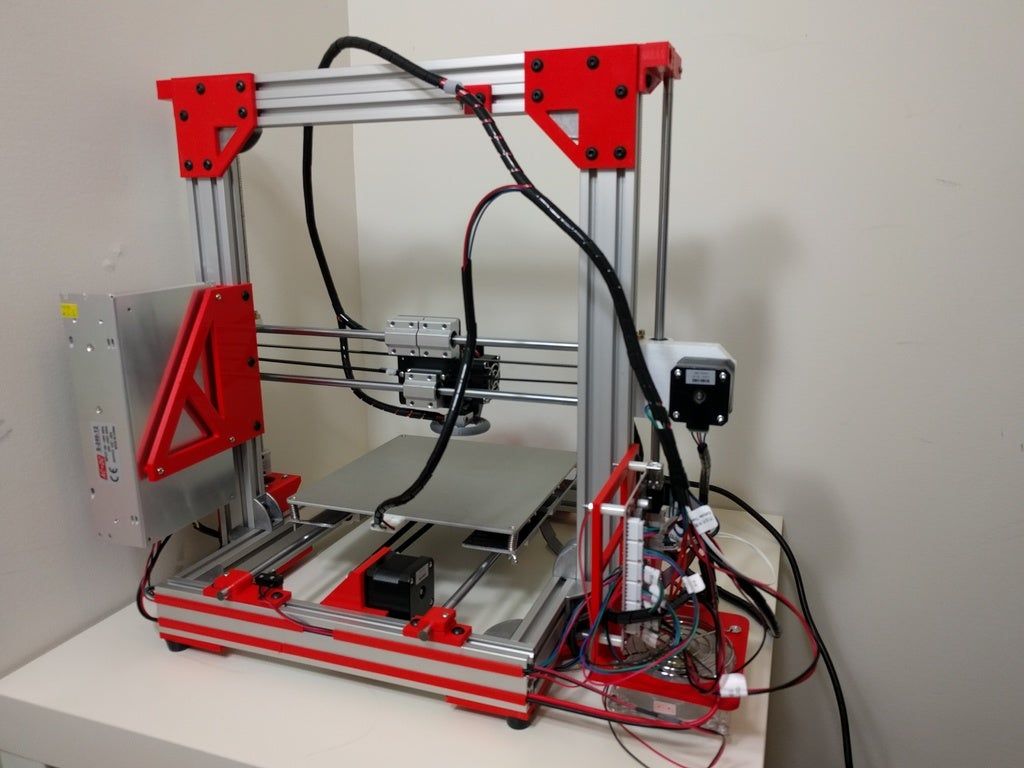

Overall Metal Frame

The overall metal frame and the printing platform weight reaches about 13.58 kg, which is different from the DIY assembly structure, i-mate X,Y axis keep running the print model horizontally. The z-axis structure gradually drops under the control of the program. Print with large-size model,it will be more accurate and not shaken.The platform is more stable.

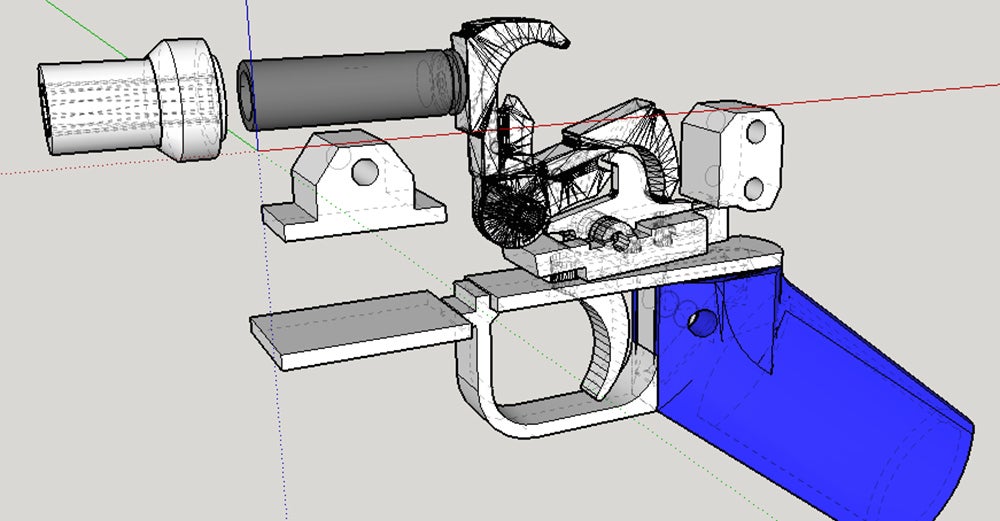

Newly Developed Extruder

Besides the 0.4mm extruder, the Qidi i mates 3d printer adopts one set of 0.2mm extruder which makes the printing details better.

Constant Temperature Cycle

The front door, top cover makes Qidi i mates 3d printer in a closed environment, has the function of constant temperature cycle.

Pull Rod Filament Spool Holder

Qidi Tech's exclusive design of the pull rod filament spool holder can make the filament feeding and printing more smoothly, and it is also more convenient to watch the filament usage.

Magnetic Printing Platform

Magnetic printing platform is equipped with 9 pieces of special high temperature magnets and a special metal panel. After printing, you can easily move the platform panel and take off the model by bending the panel. This innovation is well welcomed by amazon users.

Latest Generation Slicing Software

Qidi Tech latest generation slicing software version 6.2.2: Redesigned UI interface of Qidi Print software is more convenient to operate. It has been changed the software's slicing algorithm and improves the print quality by 30 percent and speed by 20 percent. The Qidi Print software compatible with all types of Qidi Tech 3d printers, life-time free, an alternative to paid software.

| i-mates | i-fast | |

|---|---|---|

| Technology | Fused Deposition Modeling | Fused Deposition Modeling |

| Build Volume | 10.24''x7.87''x7.87''(260x200x200mm) | 14.17‘’x9.84‘’x12.60''(360×250×320mm) |

| Filament Types | PLA,ABS,TPU,PETG,etc | PLA,ABS,TPU,PETG,Nylon,PC,Carbon fiber,PVA,etc |

| Platform Support | Single Z axis | Double Z axis |

| Extruder Configuration | 1 set of 0.4mm extruder, 1 set of 0.2mm hot-end | Dual extruder &High Temperature Extruder |

| Printing Plate | heated, removable plate | heated, removable plate |

| Support | 1-Year with Infinite Customer Support | 2-Year with Infinite Customer Support |

| Printing Extruder | Single Extruder | Dual Extruder |

| Filament runout sensor | √ | |

| Camera | √ |

Construction 3D printing is waiting for a breakthrough The first construction projects using this technology appeared only in 2014.

We are talking, first of all, about the so-called small architectural forms (benches, flower beds, fences). They never even dreamed about building houses. But already in 2015, the Russian startup Apis Cor made a splash - it printed a whole house in the Moscow region. Since then, news about new 3D printed houses has periodically appeared. However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed. nine0003

We are talking, first of all, about the so-called small architectural forms (benches, flower beds, fences). They never even dreamed about building houses. But already in 2015, the Russian startup Apis Cor made a splash - it printed a whole house in the Moscow region. Since then, news about new 3D printed houses has periodically appeared. However, despite the fact that the technology proved to be very promising in terms of the speed of construction of housing and the reduction in the cost of construction, no mass implementation followed. nine0003 Construction is the world's number one market. And, if many technological innovations are being introduced in the field of high-rise construction, then little has changed in the field of low-rise construction over the past decades. The last 30 years have seen the availability of the Internet, mobile phones, mobile internet, robotics taken to a new level, etc., but when you get to a house construction site, you are unlikely to find many technological innovations. Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more. nine0003

Automation is practically non-existent, and manual labor prevails. 2020 was a test of strength for the whole world, and also led to the highest level of inflation, which, first of all, hit the construction market, there was a dramatic change in prices for metals, cement, wood and much more. nine0003

This Internet meme shows what happened to the cost of building materials in just a year. And the process is still going on. At the same time, there is a serious rise in the cost of labor, and there is an acute shortage of it. All this leads to a sharp rise in the cost of building houses. No matter how strange it may sound, statistics show that the growth of automation does not occur when everything is fine, but precisely in crisis situations, during increased competition, reduced demand and the need to urgently look for new technologies to increase production efficiency. So it happened this time, and after some stagnation, construction 3D printing received a new impetus for development. nine0003

nine0003

Preparing to write an article, I turned to the founder of Arkon - Boris Kozlov y. Arkon was established in 2020 and is engaged in the production of construction 3D printers, both a workshop type for creating prefabs (prefabricated houses) and a portal one capable of printing a two-story house. I asked Boris the key, in my opinion, question:

- Construction 3D printing appeared in 2014, but no mass introduction of this technology followed in 7-8 years. Why do you think this happened, and why is there a surge of new projects right now? nine0010

- It seems to me that the reason is the snowball effect. The technology had to mature, grow from a hypothesis to a pilot implementation, and finally to commercialization and scaling (what is happening now). In addition, it should be borne in mind that construction is one of the most conservative industries, where, unlike even aviation and the automotive industry, there is still an extremely low introduction of digital solutions and automation in the field of the production process itself - the construction itself.

The issue of regulation and certification also plays an important role - this process is long and creates an additional lag. nine0021

In 2014-2016 the first samples of building 3D printers and prototypes of printed buildings appeared. The concepts of various form factors of construction 3D printers and types of printing materials were tested.

In 2017-2018 in the world, the first notable investments were made in a number of construction 3D printing start-ups. Further, by 2020, these investments "rolled" in the form of reaching a certain level of technology maturity - the first commercial products (3D printers and houses) appeared. nine0021

Finally, in 2020-2022 it became clear that the hypotheses of the effectiveness of construction 3D printing were justified (cheaper, faster, more environmentally friendly), and large investments began in the industry. A striking example is the investment of GE (the French division of General Electric) in the Danish COBOD or the achievement of a capitalization of $ 2 billion by the American company ICON.

In 2022-2023 over 1,000 buildings will be printed worldwide already, scaling from single buildings/pilot projects to entire villages and major infrastructure/reinforced concrete implementations. In addition, in a number of countries, by now, a regulatory framework has been created or is being actively created for the introduction of additive technologies in the construction industry. nine0021

Thus, I believe that the specified time period is a fairly natural cycle of technology development, which is likely to experience exponential growth in the next decade.

According to ResearchAndMarket report, the global construction 3D printing market is valued at USD 354.3 million in 2022 and is projected to reach USD 11068.1 million by 2027, growing by 99.04%.

Various market processes affect the prices and behavior of participants in the global 3D construction printing market. They create price signals that are the result of changes in the demand and supply curves for a product or service. They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals. nine0003

They can be associated with both macroeconomic and microeconomic factors. Even human emotions can also drive decisions, influence the market, and create price signals. nine0003

Now let's take a quick look at what the construction 3D printer is. Without delving too deeply into the technology, we can say that construction 3D printers are very similar to classic FDM/FFF printers that print with plastic, but instead of plastic, the material here is a cement mixture, which is fed directly into the nozzle and forms an object by layer-by-layer overlay. Printers are also portal, on the basis of a flying boom, with a robotic arm.

Pictured left is a construction printer based on a boom. The figure on the right is a gantry construction 3D printer

In the figure above, a construction 3D printer in the form of a robot arm installed on a mobile platform.

Everything changed completely when, in the summer of 2021, the American company ICON, which was trying to introduce 3D printing into the construction of various auxiliary facilities, signed a contract with one of the largest American developers, Lennar, to build a village of 100 houses in Texas and immediately became a unicorn , having received 200 million dollars of investments from several investment funds. nine0003 Pictured is a 3D printed house in Austin, Texas. A 3D printed house in Austin, Texas.

nine0003 Pictured is a 3D printed house in Austin, Texas. A 3D printed house in Austin, Texas.

At the same time, the Danish company COBOD, created by the world's largest construction formwork company PERRI, began selling its gantry 3D construction printers and participating in construction projects around the world. In the photo below, a modern two-story house built in Germany and a school building in Malawi, built in record time with a minimal budget.

Few things unite developed, developing and poor countries, everywhere their problems and tasks, but Affordable housing shortage is a global agenda . If in poor countries there is an acute problem with the increase in the number of homeless people due to a lack of housing, as such, then in developing countries it is necessary to dramatically accelerate the number of new housing being built to meet the needs of a growing population. In developed countries, the problem is primarily in the cost of housing, which has risen in price to such an extent that it has become practically inaccessible to young people. And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse. nine0003

And with the simultaneous increase in life expectancy in these countries, this problem is only getting worse. nine0003

At the same time, the trend towards "green agenda " is developing, reducing CO2 emissions, building with more environmentally friendly materials, etc. But, unfortunately, so far the construction industry is the absolute leader in CO2 emissions, as well as in the amount of garbage that each construction site leaves behind. This is not to say that construction 3D printing solves all these problems, but at least it is moving in the right direction. Let's look at this with a few illustrative examples. nine0003 3D printed walls.

Today, when we talk about 3D printing houses, we are talking about printing walls. Everything else (foundation, windows, doors, ceilings and roof) is done in the traditional way. 3D printed walls are built as fixed formwork, which significantly saves the amount of cement used , and this, in turn, reduces the cost of construction and reduces the environmental impact of cement production. In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly. nine0003

In addition, with this method of construction, no additional waste is produced, the strength of the structure does not suffer. It can be reinforced, as shown in the photo on the left, and engineering communications can be immediately laid, as shown in the photo on the right, which also affects the final speed of the construction of the object. At the same time, the total weight of the structure is reduced, the remaining cavities can be filled with lightweight foam concrete, insulation, straw or any other available material. Such a lightweight design can use a lighter foundation. The construction method itself is more economical in terms of material, and therefore environmentally friendly. nine0003

Eco-concrete with the addition of polymers is being actively developed, the production of which reduces CO2 emissions from 30% to 100%. The Apis Cor company mentioned at the beginning of the article, which built a house in the suburbs in 2015, is now based in hot Florida, plans to start using this material in its projects.

Another startup from Russia, Mighty Buildings, headquartered in California, initially relied on a polymer with the addition of mineral chips. And while the company doesn't build entire homes, it only makes wall panels, it has won numerous design awards, as well as a $400 million valuation in several investment rounds. nine0003

As a result, with a rough calculation, we can say that the total savings on the construction of walls can reach 30%, and the total cost of the house can be reduced by 10%. This is true for houses designed for conventional construction. And if you initially design with 3D printing, you can improve this ratio by optimizing the laying of communications, the ability to immediately print interior walls, bookmark niches for bathrooms, fireplaces, built-in wardrobes and kitchens, as was done in the house built by COBOD in Germany. nine0003

"There are spots on the sun." Despite all the advantages of construction 3D printing, has several significant disadvantages of . The main one is layering, which cannot be avoided at the current level of technology development.

The main one is layering, which cannot be avoided at the current level of technology development.

The photo above shows the layering of the 3D printed walls.

This task can be worked in several directions:

-

Ribbed walls can be plastered, painted and played with as a design element. That's how ICON does it in the US, for example their latest project House Zero is done that way and has won a number of design awards. nine0003

-

Use special "shutters" on the print head that allow smooth layers, as COBOD and other manufacturers do. The photo below shows that this does not ensure the complete absence of layering.

-

Fully sand the surface to get the usual smooth wall for plastering, painting, wallpapering or other finishing. It is possible, but it will require huge labor costs, which can reduce the overall efficiency of using 3D printing.

nine0003

nine0003

Pictured above is a 3D printed wall sanded smooth.

The second problem is the required temperature. Ideally, printing should take place at temperatures between +5C° and +30C°. Humidity is also important. Using additives, you can push these boundaries, but not indefinitely. At strong sub-zero temperatures, printing will be possible in the field only if the construction site is covered with a dome and the required temperature is reached inside with the help of heat guns. In conditions of intense heat, it is preferable to print at night. Another solution could be to print the wall panels in the shop and assemble them on site. Of course, each of these decisions will have a negative impact on the economic efficiency of the project. nine0003

Building 3D printing can be useful not only for the construction of houses . With its help, you can solve many other problems, and there its disadvantages will not matter. For example, the American concern GE uses COBOD printers to build towers for wind turbines in the shop. Ribbed surface and temperature restrictions in this case do not play any role. Construction takes place in the shop, after which the object is transported to the installation site.

Ribbed surface and temperature restrictions in this case do not play any role. Construction takes place in the shop, after which the object is transported to the installation site.

Alexander Kornveits

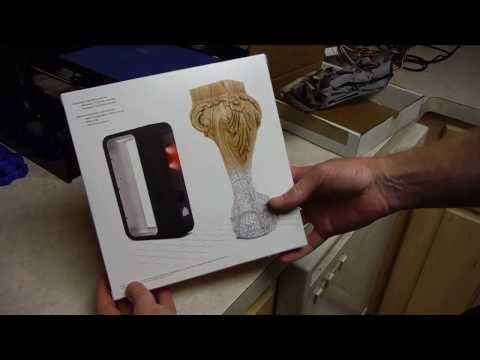

Expert in the field of additive technologies and 3D printing, head of the Tsvetnoy Mir company equipment to manufacture dental implants.

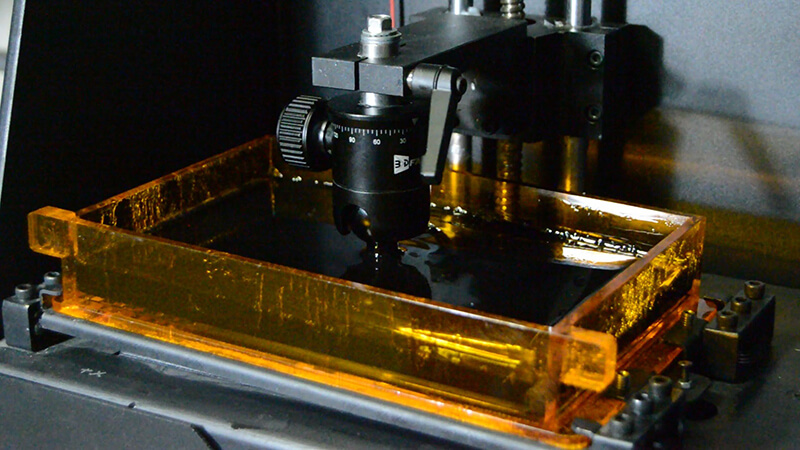

In Tver, Family Stomatology was the first company in the region to start using a unique 3D-printer for metal 3DLAM Mini. And if until recently in our region the basis for dentures was made only by casting or simply ordered in the capital's workshops, now the latest technologies have reached the Upper Volga region. This is a high-precision technology that allows you to create products of a completely new quality. nine0003

3DLAM Mini is Russian-made equipment, most of the components for which are made in our country. We can say import substitution in action.

At the moment, using a 3D printer, a metal frame of a cobal-chromium prosthesis is printed, on which a ceramic mass is then applied. In addition, they began to produce individual implants from titanium. But this topic is still under development.

It should be noted that the lasers themselves, that is, the radiation sources, are produced in Russia. According to this indicator, we can say that our country is a leader. nine0003

nine0003

– 3D printed prosthetics have significantly reduced the cost of the product and its price for patients. Thanks to this, more citizens could afford to improve their health. And dare to smile! - explains the deputy director of the network of clinics "Family Dentistry" Andrey Panteleev.

The 3DLAM Mini is a machine with many uses. It is used for the manufacture of various metal products, including jet engine parts in the military-industrial sector. With it, you can easily create something that is either impossible or very expensive to do in the traditional way. The main thing is that the machine is suitable for the manufacture of individual products. nine0003

– Every crown is different. We are always remodeling it. The use of such equipment allows you to create high quality products, on the one hand. On the other hand, make a reasonable cost price. For example, with standard casting, the accuracy is 100-120 microns, and with a 3D printer, the accuracy is up to 15 microns,” says dental technician Pavel Smirnov.

The traditional method of making prostheses is more energy intensive and time consuming than using a 3D printer. nine0003

How does one work with such technology? First, a plaster model of the jaw is taken, scanned on special equipment and digitized. 3D-image can be edited taking into account the individual characteristics of the customer. After that, another digital model is prepared, which can be read directly by a 3D printer.

Printing on the unique 3DLAM Mini technique is a separate process that, one might say, delights and fascinates. First enter the print settings. Then fine metal powder is poured onto the area where the laser will shine. The dental technician then turns on the argon gas, which fills the chamber. Processing of particles of raw materials with a laser takes place in a special gaseous medium. nine0003

After that, for how many hours, layer by layer, with the help of a laser, the product is burned out of the metal powder. It will be tailored to the needs of the patient. In this case, the process can be stopped and then started from the same place.

It will be tailored to the needs of the patient. In this case, the process can be stopped and then started from the same place.

The resulting metal cap is lined with ceramics and placed in an oven where everything is baked at a temperature reaching 900 degrees. Master ceramist works with a brush. He stressed that for the time being, no machine can replace a person in this matter. nine0003

- Despite the fact that there is a color palette for dentures, these are still average options. We strive to ensure that each person picks up his shade of enamel. It must be understood that the color of the teeth is influenced by different factors. And we take into account their influence, - says dental technician Mikhail Maslov.

As Andrei Panteleev, Deputy Director of the Family Dentistry clinic network, notes: “Teeth are health!”. If a person takes care of his teeth, he can meet any difficulty with a smile, and overcome it by clenching his teeth.