Gsu 3d printer

EXLAB - Experience, Experiment, Explore

- IIT

-

Search:

- Georgia State

- Campus Directory

- Technology

Main navigation

-

Search:

- Technology

- Georgia State

- Campus Directory

The EXLAB offers the perfect place to soundboard ideas, create your own robot, 3D print custom jewelry and more.

- University Students, Faculty & Staff

- Public

University Students, Faculty & Staff

Tours for the University Community

The EXLAB is open to all Georgia State students, faculty and staff for walk-in tours. Stop by an EXLAB location and take a look at what Georgia State’s makerspace labs can help you create!

Public

Public Tours for Those Outside the University

Not a part of the Georgia State community, but still interested in exploring the EXLAB? The EXLAB hosts an open house the first Friday of every other month at our Atlanta location. These open house tours are free and open to the public!

REGISTER FOR A PUBLIC OPEN HOUSE TOUR

- iCollege Equipment Course

- Liability Waivers

iCollege Equipment Course

iCollege Equipment Course

This course will familiarize you with the equipment and safety procedures at the EXLAB and is required before you can use any equipment at our locations.

REQUEST THE ICOLLEGE EQUIPMENT COURSE

Liability Waivers

Liability Waivers

Georgia State students, faculty and staff should complete our online liability waiver before using equipment.

STUDENT, FACULTY, & STAFF LIABILITY WAIVER GUESTS & MINORS LIABILITY WAIVER

EXLAB Atlanta

Arts & Humanities, Room 200

404-413-4181

Fall Hours:

Mon-Thurs: 9 a.m. - 6 p.m.

Fri: 9 a.m. - 3 p.m.

EXLAB Dunwoody

Dunwoody Library, NLRC 2600

770-274-5008

Fall Hours:

Mon-Thurs: 10 a.m. - 6 p.m.

Fri: 9 a.m. - 5 p.m.

EXLAB @ CMII

CMII, Room 230

404-413-4181

Email [email protected] for a tour.

Fall Hours:

Mon & Wed: 10 a.m. - 5 p.m.

Fri: 10 a.m. - 5 p.m.

Connect

EXLAB Atlanta

Arts & Humanities, Room 200

404-413-4181

Summer hours:

Mon-Thurs: 9 a. m. - 6 p.m.

m. - 6 p.m.

Fri: 9 a.m. - 3 p.m.

EXLAB Dunwoody

Dunwoody Library, NLRC 2600

770-274-5008

Summer hours:

Mon-Thurs: 10 a.m. - 6 p.m.

Fri: 9 a.m. - 5 p.m.

EXLAB @ CMII

CMII, Room 230 (Limited access)

404-413-4181

Email [email protected] for a tour.

Summer hours:

Mon-Wed: 9 a.m. - 5 p.m.

Fri: 9 a.m. - 5 p.m.

Connect

- University Students, Faculty & Staff

- Public

University Students, Faculty & Staff

Tours for the University Community

The EXLAB is open to all Georgia State students, faculty and staff for walk-in tours. Stop by an EXLAB location and take a look at what Georgia State’s makerspace labs can help you create!

Public

Public Tours for Those Outside the University

Not a part of the Georgia State community, but still interested in exploring the EXLAB? The EXLAB hosts an open house the first Friday of every other month at our Atlanta location. These open house tours are free and open to the public!

These open house tours are free and open to the public!

REGISTER FOR A PUBLIC OPEN HOUSE TOUR

- iCollege Equipment Course

- Liability Waivers

iCollege Equipment Course

iCollege Equipment Course

This course will familiarize you with the equipment and safety procedures at the EXLAB and is required before you can use any equipment at our locations.

Liability Waivers

Liability Waivers

Georgia State students, faculty and staff should complete our online liability waiver before using equipment.

STUDENT, FACULTY, & STAFF LIABILITY WAIVER GUESTS & MINORS LIABILITY WAIVER

See Full Calendar

EXLAB SUGGESTION BOX

SUGGEST A WORKSHOP

BROWSE MAKER RESOURCES

3D Printing |

Since the EDGE magazine project is still in the planning stages, I thought I’d start out this semester by talking about an exhibition I saw recently that I highly recommend.

In Designers, Makers, Users: 3D Printing the Future, The Museum of Design Atlanta is presenting an educational examination of the past, present, and future of 3D printing. The importance of 3D printing can’t be overstated, and the exhibition offers up a great overview of the technology and what it can do, but as a panel of informative text so eloquently states, “the dream of the Star Trek Replicator may not be immediately at hand.”

3d printed prosthetic arms.3D printing technology and definitions can get highly complex, but as a general primer for the uninitiated, 3D printing is a form of additive manufacturing that creates forms by stacking and binding layers of material from the ground up until the desired form is reached–as opposed to subtractive manufacturing like CNC routers or laser cutters, which removes raw material to create the intended form. In art terms, you could think of it like layering coils of wet clay to form a ceramic pot (additive), versus carving a marble block (subtractive).

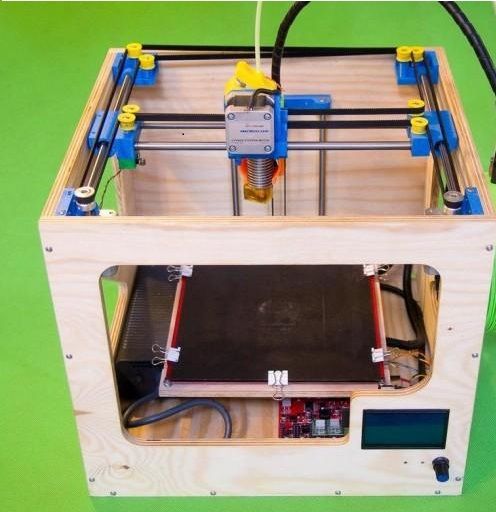

The most common form of 3D printing for the average consumer is called Fused Deposition Modeling (FDM) and is analogous to a computerized hot glue gun. This is the Makerbot you might have heard about, and most of the printers at GSU. A digital 3d model is sliced by software into lots of very small layers, which are then sent as instructions to the printer. Plastic filament in spools of (typically) plant-based PLA or petrol-based ABS (though many new materials are emerging, like brick, wood, metal and even pancake batter), is pushed through a heating element to its melting point, then extruded through a nozzle onto a build platform. The nozzle then moves up slightly, and repeats the process, continuing until the object is complete. A crucial requirement for 3D-printing material is that it cools quickly enough that by the time the nozzle is finished extruding its layer and moves up to the next, it can support the layers above.

Pancakebot extrudes batter onto a hotplate for custom pancakes.

MoDA has dedicated two rooms and a hallway to the exhibit, with gobs of informational text and video that showcase examples of 3D printing in several areas, including space exploration, medical, architecture, product design, and fashion. The only art-for-art’s-sake display I saw was a short stop-motion animated film by Gilles-Alexandre Deschaud called, Chase Me, where a monochrome ukulele-playing girl is chased by some malevolent blob of nastiness. Hijinks ensue. The film used what’s called replacement animation, where instead of animating a single articulated puppet bit by bit for each frame, character statues were printed whole for every single frame in whatever pose was needed and swapped out each time a new frame was shot, resulting in probably hundreds of individual character figures (the Jack Skellington character from A Nightmare Before Christmas used a combination of puppet and replacement: his body was articulated but 400 unique heads were created to swap in and out each frame to create his facial animation). Several were on display next to a monitor showing the video, including eight slightly-different versions of the girl lined up in a row. I assume from context that this was intended to show all the parts needed to execute an animated walk cycle, but a couple were out of order and listing dangerously close to falling over. This exemplifies a common occurrence throughout the exhibit, where the rough edges start showing through from wear and tear, tarnishing the polish of the initial presentation. I’m surprised everything’s held up as well as it has considering how many kids have gone through the place.

Several were on display next to a monitor showing the video, including eight slightly-different versions of the girl lined up in a row. I assume from context that this was intended to show all the parts needed to execute an animated walk cycle, but a couple were out of order and listing dangerously close to falling over. This exemplifies a common occurrence throughout the exhibit, where the rough edges start showing through from wear and tear, tarnishing the polish of the initial presentation. I’m surprised everything’s held up as well as it has considering how many kids have gone through the place.

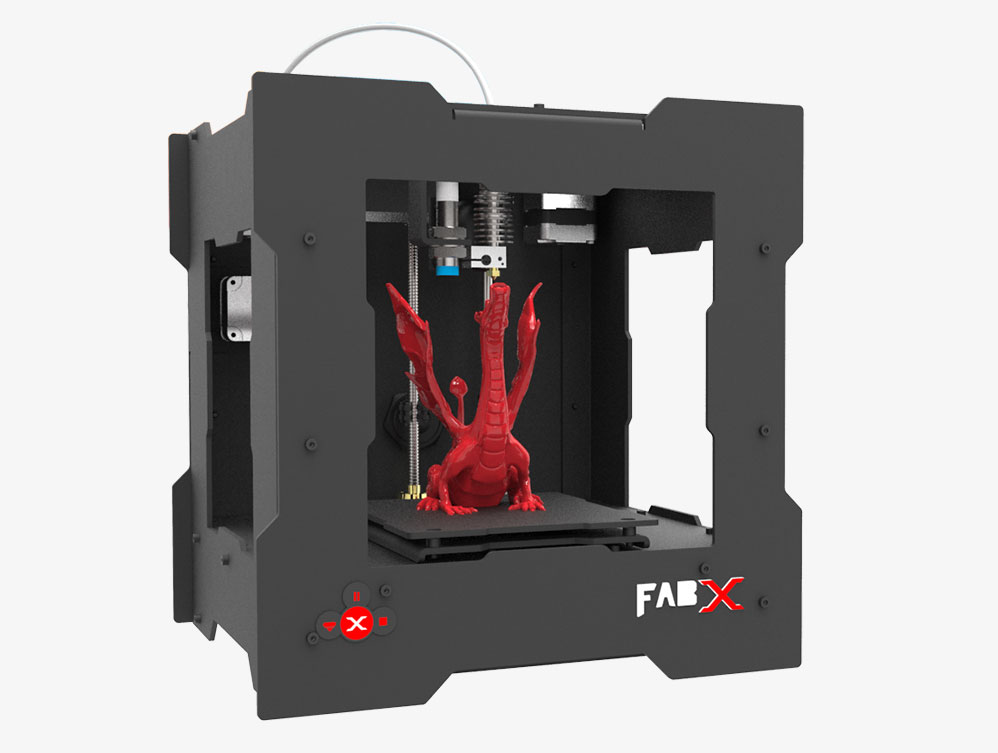

There are numerous examples of 3D-printed objects, from DIY prosthetics to a 3D-printed dress to giant (in 3D printing scale) architectural forms and even a desktop bio-printer. A borg of various brands and kinds of desktop 3D printers were whirring away throughout the exhibit. Some were printing parts for a 3D-printed puzzle-chair, others looked like parts for a prosthetic hand, and others I couldn’t discern at all because they were currently a mess of spaghetti-like strands. An on-site technician was vigorously running around trying to keep up with all the printer failures, and having built and used my own 3D printers, I didn’t envy him his task. This brings us back to our initial concern: though 3D printers are revolutionizing production, they’re not yet appliances. You don’t have to troubleshoot your toaster, or know how sugars caramelize with heat to create toast. You just put in your bread and out comes delicious and tasty toast. Not so with 3D printing.

An on-site technician was vigorously running around trying to keep up with all the printer failures, and having built and used my own 3D printers, I didn’t envy him his task. This brings us back to our initial concern: though 3D printers are revolutionizing production, they’re not yet appliances. You don’t have to troubleshoot your toaster, or know how sugars caramelize with heat to create toast. You just put in your bread and out comes delicious and tasty toast. Not so with 3D printing.

If toasters were at the technological level of a typical consumer 3D printer, the toast-making process would be much different. First, you’d have to make your own bread. Sure, you could probably find someone who could make the bread for you but if you want true production freedom you need to invest in learning how to make bread in its various forms using specific bread-making tools and techniques–In 3D printing, you can download 3D files that someone else made, but if you want to make your own unique objects, you have to learn 3D CAD software. Next, you have to know how your particular toaster works, and coordinate your toasters heat, time, and spring tension to perfectly match your particular piece of bread’s chemistry. Get something wrong and you have to toss your ruined bread and start over–In 3D printing, each material melts at specific temperatures, and even the dyes used in plastic filament can cause the heat requirement to vary by degrees. Get the temperature wrong and your print is ruined. Then, once you’ve got your bread’s protein chemistry and your toaster’s electronic settings synced up, you’re ready to toast. Insert slice, push lever. But you can’t leave yet. Oh no. You have to sit there and watch the toaster start toasting for at least the first cycle, otherwise the bread could get jammed, or fall out of the toaster entirely, or decompose into its component parts–In 3D printing, the first layer is crucial, if it doesn’t go well, the rest of the print likely won’t either, and you’ll have to start over. Or, sometimes the print gets unstuck from the print bed, and you can’t just put it back on and continue where you left off, you have to start over and toss the ruined print.

Next, you have to know how your particular toaster works, and coordinate your toasters heat, time, and spring tension to perfectly match your particular piece of bread’s chemistry. Get something wrong and you have to toss your ruined bread and start over–In 3D printing, each material melts at specific temperatures, and even the dyes used in plastic filament can cause the heat requirement to vary by degrees. Get the temperature wrong and your print is ruined. Then, once you’ve got your bread’s protein chemistry and your toaster’s electronic settings synced up, you’re ready to toast. Insert slice, push lever. But you can’t leave yet. Oh no. You have to sit there and watch the toaster start toasting for at least the first cycle, otherwise the bread could get jammed, or fall out of the toaster entirely, or decompose into its component parts–In 3D printing, the first layer is crucial, if it doesn’t go well, the rest of the print likely won’t either, and you’ll have to start over. Or, sometimes the print gets unstuck from the print bed, and you can’t just put it back on and continue where you left off, you have to start over and toss the ruined print. Now that you’re sure your everything is running smoothly, you can let the toaster toast that yummy bread and go do something else. For 3-20 hours. Or more–it’s called rapid prototyping, but “rapid” is a very relative term. Oh, and at any point during the toasting process, your toaster might screw up your bread, and you have to toss it and start over, but not before troubleshooting and repairing your toaster yourself. Good luck on the forums.

Now that you’re sure your everything is running smoothly, you can let the toaster toast that yummy bread and go do something else. For 3-20 hours. Or more–it’s called rapid prototyping, but “rapid” is a very relative term. Oh, and at any point during the toasting process, your toaster might screw up your bread, and you have to toss it and start over, but not before troubleshooting and repairing your toaster yourself. Good luck on the forums.

Don’t let me nightmare toaster story deter you from the potential and wonderfulness that is 3D printing. Manufacturers are getting closer and closer to that appliance stage, so it won’t be long before we all have desktop 3D printers in our homes next to our toasters and inkjet printers. MoDA has presented an almost-comprehensive survey of 3D printing; I would have liked to have seen more examples of purely artistic uses of 3D printers, but regardless, Designers, Makers, Users: 3D Printing the Future is a must see for all ages and levels of technical savvy.

Written by Nathan Sharratt No comments Posted in 3D Printing

With the goal of bringing interdisciplinary, data-driven tools to artists, my first step is to learn the tech myself and to create proof-of-concept artworks as demonstration examples, and then lead workshops for interested artist students about how they can use these tools in their own artistic practice.

Project 1: Agisoft Photoscan

My first tech exploration is the process of 3D photometric scanning using Agisoft Photoscan, and then 3D print a sculpture based on manipulations of that scan. I thought this would be a good transition tech for artists since it is so visual and deals with real-world applications where big-data and similar tech seem abstract and untouchable (at first).

My first artwork will conceptually explore how 3D printing and scanning fit into the art/craft dialectic and how gender roles are defined. Traditionally, “craft” has been assigned primarily to the female gender, especially decorative and soft-material crafts like embroidering or floral arranging. Men have engendered hard craft, using materials like wood and metal that have practical uses. With the advent of at-home production using complex and technical 3D printers, men have traditionally dominated the genre for whatever reason. Now, in a role reversal, 3D printers on the consumer level are overwhelmingly known to create either parts for building and engineering, or decorative trinkets and gadgets.

Traditionally, “craft” has been assigned primarily to the female gender, especially decorative and soft-material crafts like embroidering or floral arranging. Men have engendered hard craft, using materials like wood and metal that have practical uses. With the advent of at-home production using complex and technical 3D printers, men have traditionally dominated the genre for whatever reason. Now, in a role reversal, 3D printers on the consumer level are overwhelmingly known to create either parts for building and engineering, or decorative trinkets and gadgets.

Using a craftbook from the 1970s written specifically for “housewives with leisure time,” I’ll recreate one of the projects using new technology. Specifically, I’ll 3D scan a foam egg carton, then in the computer attempt to use the virtual modeling tools as if they were real-world tools to follow the steps in the book to create a decorative peacock. The result will be 3D printed and highlight the mutations that occur from multiple role transpositions and translations.

Future posts will outline the process.

Written by Nathan Sharratt No comments Posted in 3D Printing, Art Tagged with 3d printing, Art, kitschThat the debate over the art/kitsch divide has been theorized since at leat the 1930s shows that the supposed divide is arbitrary and the argument then breaks down into relativism. Like industrial culture production, the argument itself is of itself. To exist, it must already belong to the existing argument, otherwise it has no historical reference and the argument collapses. Unlike craft, kitsch cannot be defined by the intent of its creator. It is an outward-inward categorization that ignores embedded meaning planted by the creator. It is instead demarcated by an outside observer, who judges it to have no “pure” cultural value. Whether this is due to funcionality, quantity, or aesthetics, the judge claims it lacking in qualities needed to elevate it into true art. In modern times, the art/not art battle rages on through technology-based art.

In modern times, the art/not art battle rages on through technology-based art.

The industrialization of culture, specifically post-war culture, wherein normative benchmarks measure the acceptable deviation range allow for new correlaries through technology. What once was mass-produced physically on assembly lines is now (theoretically) endlessly able to reproduce itself through digital copies. This includes pixel-based images as well as digital-physical production methods, such as 3D printing. In the mid-20th century, artists avoided the production of kitsch, but since artists like Jeff Koons and Damien Hirst began to break the normative benchmark by intentionally producing “non art,” the range of acceptable mutation has grown almost to the point of meaninglessness.

3D-printed art relies almost entirely on the intent of the creator to define it as pure art and not kitsch. Most 3D-printed objects could be defined as kitsch in that they are representations of mass culture intended to be easily digestible and not require difficult thought to comprehend: to which thousands or perhaps millions of almost-identical 3D-printed Yoda busts can attribute. When peasants are able to download a digital model of artwork and reproduce it at home to near-exact tolerances, the distance between art and kitsch begins to narrow. That gap again narrows when considered against the previous need to be educated to understand or have access to pure art: 3D printing requres a degree of education and technical know-how previously thought unavailable to or lacking in presence among the kitsch-consuming peasants (as Clement Greenberg calls the public-at-large). Now, peasants can produce their own (low) culture.

When peasants are able to download a digital model of artwork and reproduce it at home to near-exact tolerances, the distance between art and kitsch begins to narrow. That gap again narrows when considered against the previous need to be educated to understand or have access to pure art: 3D printing requres a degree of education and technical know-how previously thought unavailable to or lacking in presence among the kitsch-consuming peasants (as Clement Greenberg calls the public-at-large). Now, peasants can produce their own (low) culture.

3d printing now encompasses many of the struggles that existed with another formerly-new culture system: photography. Where is the value in a photograph if it can just be reprinted? The same argument applies to 3d printing. Through the years artist photographers have (mostly) sidestepped this issue through ideological cosensus and the forced scarcity of producing a limited number of physical prints. The art world considers a photograph art through comparison to various normative benchmarks, such as technical skill and content. However, the desire to succinctly categorize photography as art or not again breaks down to relativism when considered alongside non-art photographs that meet the same criteria. 3D-printed objects face similar challenges that artists are still trying to solve.

However, the desire to succinctly categorize photography as art or not again breaks down to relativism when considered alongside non-art photographs that meet the same criteria. 3D-printed objects face similar challenges that artists are still trying to solve.

Due to its newness, artists are applying various techniques to force value onto their culture objects. Some follow suit with photographers and promise to make only a limited number of duplicates, or even unique objects. Others are considering the by-hand post-processing of 3d-printed objects to transform a replicable object into a unique one. Others still are using 3d-printed objects in mixed-media works as a single element among others. In this sense, the 3d-printed object piggybacks onto previously-accepted benchmarks for acceptable pure art.

So is 3d-printed culture art or kitsch? The answer denies binary simplification, and in my opinion relies on multiple factors much like other pure artforms that have low-art counterparts. However the prevailing benchmark seems to be consensus. Like the famous judicial argument defining pornography, “I know it when I see it.”

However the prevailing benchmark seems to be consensus. Like the famous judicial argument defining pornography, “I know it when I see it.”

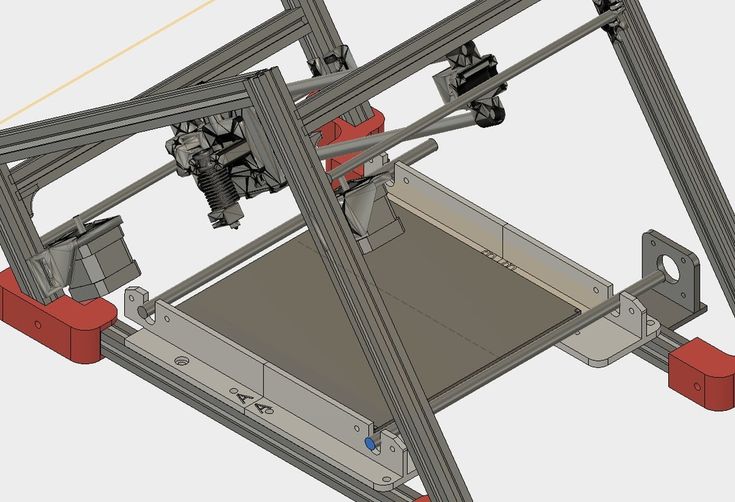

A collaboration between Hasso Plattner Institute and Cornell University has produced a new step in the 3D-printing workflow. Typically, 3D models go directly from virtual space to physical space in high resolution. This takes quite a long time and requires greater expense in plastic filament, especially if the object will be refined and reprinted multiple times.

With this new workflow, multiple lo-res wireframe prints can give the designer a fast and cheap method of envisioning the object in actual space. No details on when or if the software will be available for download, but I’d love to get a copy and see what it can do.

No details on when or if the software will be available for download, but I’d love to get a copy and see what it can do.

Read more here.

Written by Nathan Sharratt No comments Posted in 3D Printing Tea, Earl Gray, HotStar Trek made us think that the advent and widespread consumer adoption of 3D printers would soon have us calling out, “Tea, Earl Gray, hot” and like magic the item appears. Unfortunately, the current state of the technology is far from magic. They’re clunky, complicated to operate, difficult to calibrate, and are constantly requiring fixing or tweaking to keep them running smoothly. Occasionally, things go well, and while many manufacturers are coming closer to the holy-grail of the 3D-printer-as-appliance, more often as not you’ll end up fiddling with something on the machine when things start to go bad. You’re also limited by two other factors: material and accuracy.

You’re also limited by two other factors: material and accuracy.

While industrial machines are close to being able to print fantastic things like human organs, consumer printers are usually relegated to plastic: either ABS (think LEGO bricks) or PLA. PLA is becoming the dominant material for consumer machines because it doesn’t require a heated build platform to prevent warping (ABS suffers from temperature differentials while cooling, causing lower layers to shrink more quickly while upper layers are still warm, curling edges). It’s also biodegradable and made from plants, so it’s more eco-friendly.

3D printers work through a process called fused-deposit modeling (FDM). Plastic filament is heated and then extruded through a nozzle in little spaghetti-like threads, building up forms layer by layer. The smaller the distance between layers, the smoother the surface appears.

Example of layer heightsAccuracy isn’t much of an issue for the typical hobbyist, it doesn’t really matter if you’re only downloading open-source models from the internet and printing iPhone cases and Yoda heads. It begins to matter, however when you consider the educational uses of 3D printers.

It begins to matter, however when you consider the educational uses of 3D printers.

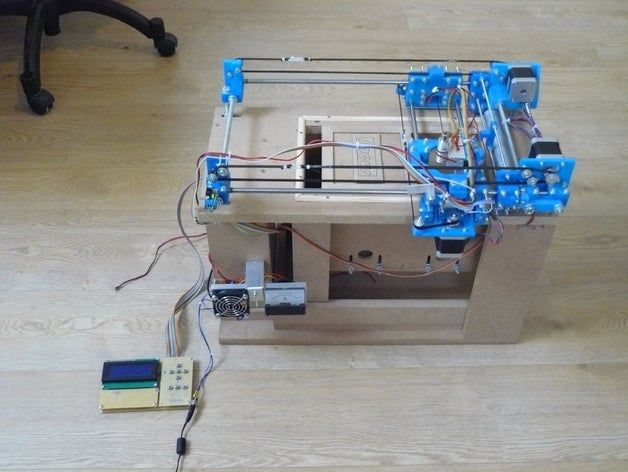

More and more institutions are 3D scanning their artifacts and making the models available for download. Consider the Taung Child Skull. The ability to examine this artifact in all likelihood would be out of reach for the average student. However, if your school has a 3D printer, you could download the model and print it for yourself, making the unreachable tangible. The accuracy of your print, however, is limited to the accuracy and resolution of your printer. Below, you can see the result of my attempt to print the skull on a 3D printer I built from a kit. Even without looking too closely, the coarse lines are highly visible.

During my Student Innovation Fellowship, one of my long-term goals is to explore and understand the limitations and capabilities of consumer 3D printers. Through understanding, 3D printers no longer seem like magic, and instead become useful learning tools.

Any sufficiently advanced technology is indistinguishable from magic.

– Arthur C. Clarke

Written by Nathan Sharratt No comments Posted in 3D Printing Tagged with 3d printing No comments Posted in

"Rostec has launched a 3D printer to create large aircraft engine parts" in the Modernization blog

© rostec.ru

The Center for Additive Technologies of Rostec State Corporation put into operation the largest automated laser machine with the largest construction area in the Russian Federation. The new equipment will make it possible to “grow” large-sized parts of the promising VK-1600V engine for the Ka-62 helicopter using the additive method.

Domestic materials will be used to create engine components, and the characteristics of the new 3D printer will allow creating overall designs of any complexity.

“Stator parts for the promising VK-1600V engine will be printed at the facility. This unit is being created for the promising multi-purpose Ka-62 helicopter. In total, it is planned to produce more than 10% of the parts for this machine on 3D installations. The use of additive technologies will reduce the production time for individual components from 6 months to 3 weeks,” said Oleg Yevtushenko, Executive Director of Rostec.

This unit is being created for the promising multi-purpose Ka-62 helicopter. In total, it is planned to produce more than 10% of the parts for this machine on 3D installations. The use of additive technologies will reduce the production time for individual components from 6 months to 3 weeks,” said Oleg Yevtushenko, Executive Director of Rostec.

In addition to a shorter production time, AM parts are lighter without sacrificing performance. This will increase the payload and improve other characteristics of the helicopter.

Center for Additive Technologies JSC is the leading and largest Russian enterprise specializing in additive manufacturing and the only one in Russia with a full cycle production. JSC "CAT" was created on the basis of the holding corporations of the aviation complex of the State Corporation "Rostec" in 2018 as a single integrator in the field of additive technologies. The shareholders of the organization are UEC JSC, Technodinamika JSC, KRET JSC and Russian Helicopters JSC. The company has the largest industrial equipment park in Russia (3D printers, measuring machines, machining and laboratory equipment) for additive manufacturing and a professional team of technical specialists with rich experience in the field of additive technologies. The company's strategy provides for the provision of the entire cycle of services - from reengineering of structures to full-cycle serial production.

The company has the largest industrial equipment park in Russia (3D printers, measuring machines, machining and laboratory equipment) for additive manufacturing and a professional team of technical specialists with rich experience in the field of additive technologies. The company's strategy provides for the provision of the entire cycle of services - from reengineering of structures to full-cycle serial production.

Rostec State Corporation is one of the largest industrial companies in Russia. It unites more than 800 scientific and industrial organizations in 60 regions of the country. The key areas of activity are aircraft manufacturing, radio electronics, medical technologies, innovative materials, etc. The corporation's portfolio includes such well-known brands as AVTOVAZ, KAMAZ, UAC, Russian Helicopters, UEC, Uralvagonzavod, Shvabe, Kalashnikov Concern, and others. Rostec actively participates in the implementation of all 12 national projects. The company is a key provider of Smart City technologies, is engaged in the digitalization of public administration, industry, social industries, is developing plans for the development of 5G wireless technologies, the industrial Internet of things, big data and blockchain systems. Rostec is a partner of the world's leading manufacturers such as Boeing, Airbus, Daimler, Pirelli, Renault, etc. The corporation's products are supplied to more than 100 countries around the world. Almost a third of the company's revenue comes from the export of high-tech products.

Rostec is a partner of the world's leading manufacturers such as Boeing, Airbus, Daimler, Pirelli, Renault, etc. The corporation's products are supplied to more than 100 countries around the world. Almost a third of the company's revenue comes from the export of high-tech products.

Source: https://rostec.ru/media/pressreleas...astit-detali-dlya-dvigatelya-ka-62/

Deputy head of the Main Investigative Committee of the ICR Nikandrov charged 07/27/2016

| In the country and the world 18:22 27.07.2016 Denis Nikandrov, a high-ranking official of the Investigative Committee, who was arrested in a high-profile case of a bribe, was charged today. It is reported by TASS with reference to its own source. Read us on: Denis Nikandrov, a high-ranking official of the Investigative Committee, who was arrested in a high-profile case of a bribe, was charged today. The deputy head of the capital's head office of the Investigative Committee is charged with "taking a bribe on an especially large scale." According to the case file, Nikandrov and his accomplices received about a million dollars for the reclassification of the charge to a softer and subsequent release of crime boss Andrei Kochuykov, nicknamed Italian. He was suspected of taking part in a shootout in which two people died and eight were injured. FSB officers followed Denis Nikandrov for several months. He participated in the investigation of a number of high-profile major cases, now all these materials are being rechecked by . Together with him, two more employees of the Investigative Committee were arrested - the head of the department's own security department and his deputy. All three will be held in a pre-trial detention center until September 15.

Expert opinion and analytics | Picture of the day 11:19 In the country and the world Popova assured that in the Russian Federation there are no more contagious variants of COVID-19, as in the West 09:23 In the country and the world The number of victims of the gas explosion in Nizhnevartovsk rose to nine 07:33 In the country and the world Bastrykin stated the need for the right for the UK to immediately seize property before trial 06:18 Sport The Telegraph: Russian tennis players may be allowed to compete in Wimbledon in 2023 05:01 Army The danger of unstable weather: how the crews of Su-25 attack aircraft work in the NVO zone Popular Cosmic carnival: simultaneous opposition of Mars and its occultation by the full moon was shown on video Putin called the appearance of new territories in the Russian Federation a significant result "In the Shadow of the Volcano": Honored Pilot of the Russian Federation spoke about the most dangerous flight in his life The author of "Gangster Petersburg" called "Crosses" the ruined castle of Lucifer The expert explained how the conspirators from Germany and Russian gas are connected "The most combative minister": footage of the meeting between Shoigu and Lukashenka in Minsk |

Read more

read below the next news

/news/next/?referer=/news/201607271822-e0xq.

It is reported by TASS with reference to its own source.

It is reported by TASS with reference to its own source.