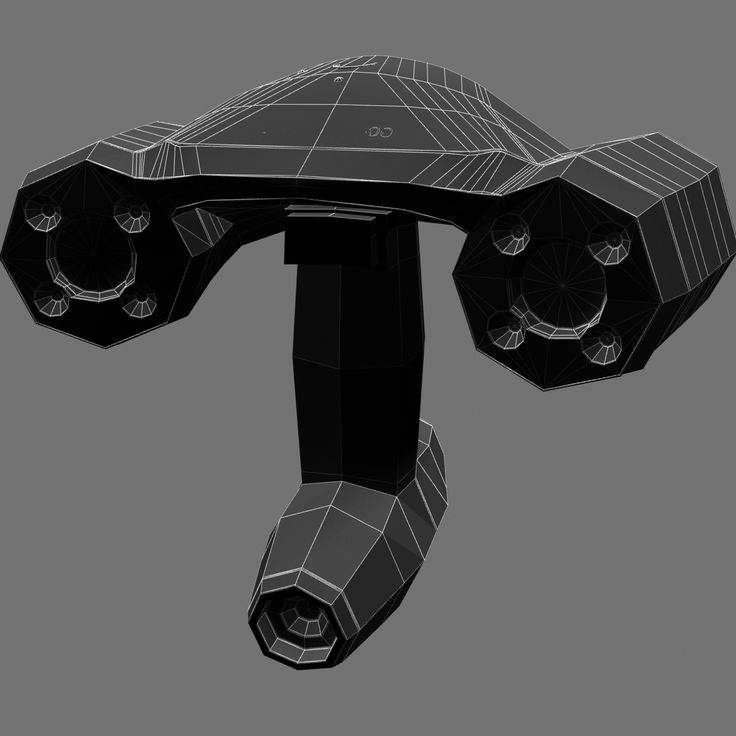

Leap 3d scanner

Could the leap motion scan 3d objects? - Pimax 8K Series - OpenMR

aesopfabled

#1

Looking to see if it would be useful for vr level design.

1 Like

kw23

#2

Technically, yes. It’s the same tech as the Kinect, which people hacked to make 3D scans. Though… you might be better off with a used Kinect and a turn table.

1 Like

aesopfabled

#3

What about scanning a room? I was guessing the leap motion 2. 0 was higher res than Kinect

1 Like

kw23

#4

You used to be able to use smart phone pictures to do this, but a lot of the tools don’t work anymore… might have to purchase photogrammetry tools.

1 Like

aesopfabled

#5

Photogrammetry is absurdly convoluted process. I haven’t seen any software that will just put it together and export in a useful format like fbx and fix meshes elsewhere.

1 Like

kw23

#6

Only other thing I’ve seen reviews on for room & scene scanning are portable lidar + EO cameras. I think they are $60k each, but the cost was high enough I mentally filed it under “not bloody worth pursuing.”

I think they are $60k each, but the cost was high enough I mentally filed it under “not bloody worth pursuing.”

1 Like

aesopfabled

#7

Photogrammetry would be great if someone made a software that wasn’t made for experts.

1 Like

kw23

#8

Are you familiar with any of those?

aesopfabled

#9

All the ones that don’t need external hardware, yea.

MR-Alex

#10

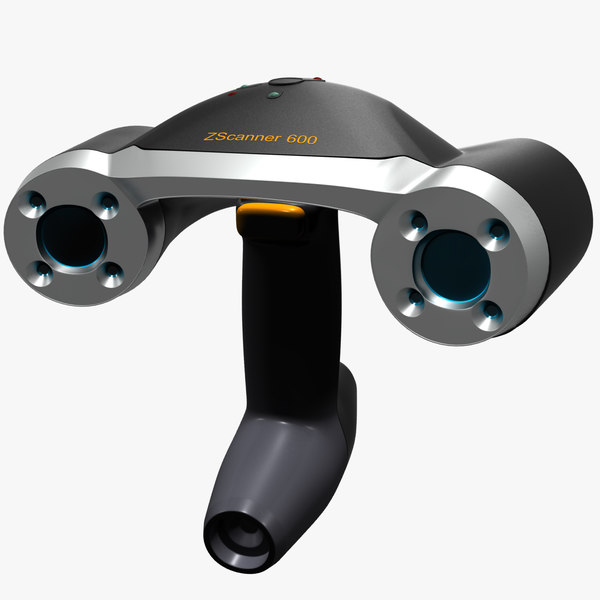

Sorry but Kinect used a different technologies. Kinect 360 used structured infrared laser light for depth and Kinect V2 used time of flight infrared lasers for depth calculation. Leap motion uses 2 infrared cameras for depth calculation. So its more similar to ZED and ZED mini which use also dual cameras. In theory you should be able to scan objects with Leap Motion using the raw image feed and tracking data of the headset. However you likely won’t get a scan with good resolution and the textures would be off, since you have only black and white images to work with.

2 Likes

Heliosurge

#11

Not sure but kinect xb360 can but xb1 reported a lot nicer. (Volumetric scanning) @lukeb posted xb1 kinnect long ago.

(Volumetric scanning) @lukeb posted xb1 kinnect long ago.

Heliosurge

#12

Not sure of leap res. 360 kinect is 720 & xb1 is 1080.

TruePoint Helps Pro Sports Leap Off the Screen

TruePoint 3D Laser Scanning Helps Mixed Reality Masters, The Famous Group, Make Magic For Sports Fans

There’s no denying that The Famous Group knows how to make an entrance. If you visit the Culver City, California company’s website, you’re greeted by either a sleek, powerful panther leaping at you from atop the Bank of America Stadium in Charlotte, North Carolina or a giant, menacing raven swooping down across M&T Stadium’s field in Baltimore, Maryland.

None of those mind-boggling, real-time fan experiences could have occurred without our 3D laser scans, point clouds and modeling.

TruePoint is excited to continue our long-standing relationship with The Famous Group because it demonstrates the flexibility and unexpected applications of our services. Like most of The Famous Group's staff, TruePoint is full of sports fans, so we’re thrilled to watch our work come to life in the games we love to watch.

“Most of the work we do is completed and then we move on to the next project,” says Jason Schaff, Senior Vice President of Customer Service & Marketing. “These types of projects are more rewarding because you can see the results of your efforts implemented in such a fun way.”

Our History in Mixed & Augmented Reality For Professional Sports Venues

Explosive augmented and mixed reality (AR & MR) fan experiences have been the calling card of The Famous Group for 20 years. That’s why TruePoint leapt at the chance to be a part of their groundbreaking projects, including the iconic return of “the big game” to Los Angeles with Super Bowl LVI.![]() To read more about how we helped put everything from a virtual Halle Berry to the Lombardi Trophy and the L.A. Memorial Coliseum at the 50-yard line at SoFi Stadium, click here.

To read more about how we helped put everything from a virtual Halle Berry to the Lombardi Trophy and the L.A. Memorial Coliseum at the 50-yard line at SoFi Stadium, click here.

TruePoint helps make MR moments reality for NFL fans with our state-of-the-art 3D laser scanning services. Since 2019, we’ve scanned football stadiums, basketball courts, baseball parks, golf courses and ice rinks for the NFL, NHL, MLB, NBA and the PGA to create the 3D point clouds that are the framework underpinning MR and AR experiences.

When COVID-19 kept fans away for their personal safety, we were tasked with mapping 15 NFL stadiums to help create a virtual fan experience. You can read more about our virtual fan project for Silver Spoon Animation, here.

In the case of the now-famous Carolina Panther video, we spent 1.5 days onsite, scanning Bank of America Stadium with a Leica P40 Scan Station to provide a hyper-accurate backdrop for their mascot.

We also scanned and modeled the statue of the fierce cat that guards the stadium gates so The Famous Group could bring Todd Andrew’s “Gentle Giant” sculpture to life to prowl, growl and celebrate with fans – both on television through the NFL broadcast and on the stadium’s own Jumbotron.

And the Baltimore Raven presented its own particular challenges because it needed to be able to perch on the goal posts and be highly visible in the night sky.

"The beauty of mixed reality is the ability of computer-generated objects to interact with the physical environment, this sells the realism," The Famous Group’s Greg Harvey said of the project.

"To achieve this, parts of the stadium were captured with a laser scanning technique. We scanned where the goal post was, where the field was, the vertical boards and brought that into a computer. When the bird is actually on the uprights, its claws wrap around the cross bar and its wings appear behind the uprights."

To learn more about how we employ state-of-the-art Leica and RTC360 3D laser scanners, click here.

Super Bowl LVI

Super Bowl LVI kicked off with every one of L.A.’s SoFi Stadium’s expanded 100,240 seats filled to watch the game, the amazing hip-hop halftime show headlined by Snoop Dogg, Eminem, and Dr. Dre, and something the live audience did not see coming: a total immersion, mixed reality fan experience featuring everything from Halle Barry to a perfectly rendered L.A. Memorial Coliseum, to virtual drones delivering the Vince Lombardi Trophy to centerfield.

Dre, and something the live audience did not see coming: a total immersion, mixed reality fan experience featuring everything from Halle Barry to a perfectly rendered L.A. Memorial Coliseum, to virtual drones delivering the Vince Lombardi Trophy to centerfield.

After two years of pandemic lockdown measures that resulted in a mere 25,000 fans in attendance for Super Bowl LV, it was important to L.A. County and the NFL that they pull out all the stops in Super Bowl LVI: both for the 100,000 fans in the stands and the more than 208 million people watching at home.

And they knew exactly who to call to blow the doors off the crown jewel of L.A.’s pro sports venues, SoFi Stadium: mixed reality masters, The Famous Group, and TruePoint 3D Laser Scanning, among others, to create an out-of-this world fan experience.

“Our team are all sports fans at heart,” The Famous Group’s Executive Producer, Andrew Isaacson told sportsvideo.org, “and we’ve been blown away and humbled by the impact and reach these projects have. These productions that combine live performance with real-time effects are not easy to pull off, but we’re proud to be the at the forefront of brining cutting-edge technology to the sports industry to enhance the fan experience and create more immersive events.”

These productions that combine live performance with real-time effects are not easy to pull off, but we’re proud to be the at the forefront of brining cutting-edge technology to the sports industry to enhance the fan experience and create more immersive events.”

And when The Famous Group came calling again for their 17th year of providing outstanding effects for the Super Bowl, we were up for our biggest MR challenge yet: to scan and digitally map all of SoFi Stadium and render hyper-accurate point clouds and 3D models so that the VR artists and filmmakers could create virtual elements like a realistic 3D model of the Los Angeles Memorial Coliseum, and digital drones that matched the real drones that would deliver the Lombardi Trophy to the winners at the end of the game.

“We wanted the creative to lean into SoFi as a canvas and focus on the incredible,” The Famous Group’s CCO, Lauren Fisher, told sportsvideo.org.

One of The Famous Group’s biggest challenges was creating the cyclorama curtain depicting the L. A. Memorial Coliseum “hanging” in SoFi’s field and opening to reveal the virtual Coliseum and jumbotrons within. Every virtual piece had to look seamless for both the audience at home and the fans who were viewing the show in the stadium on the state-of-the-art Infinity Screen at SoFi.

A. Memorial Coliseum “hanging” in SoFi’s field and opening to reveal the virtual Coliseum and jumbotrons within. Every virtual piece had to look seamless for both the audience at home and the fans who were viewing the show in the stadium on the state-of-the-art Infinity Screen at SoFi.

That’s where we come in. Because just like in Charlotte and Baltimore, before any of The Famous Group’s Hollywood movie magic can happen, they need to be able to re-create the backdrop – the entire stadium itself – as the canvas for their virtual elements. That canvas has to be exact so that when the panther, the raven, or the entire L.A. Memorial Coliseum is placed on it, it looks like it’s really happening in the stadium. That means the 3D perspective, movement and measurements have to be precise. Otherwise, the illusion is ruined.

To give you some idea of the scale of the SoFi project, their Infinity Screen alone weighs well over two tons and is 70,000 square feet of area. We had to scan every millimeter of the stadium, encompassing…

- 298 acres

- 3.

1 million square feet

1 million square feet - 100,240 seats

- 260 luxury suites

- 100,000 tons of installed steel and cable

- 23 elevators, 40 escalators, and 2,638 doors…

- Not to mention, the field itself

To complete the job, we employed our RTC360 laser scanner, and finished the scans in just two days. We then delivered an intensity map point cloud and a 3D Revit model to The Famous Group so they could work their magic. You can read the case study for Super Bowl LVI, here.

“We brought the Coliseum into SoFi, bridging the past with present with a special nod to history,” The Famous Group’s Fisher said. “Tim Tubito and his team at the NFL were amazing creative partners in developing these ideas; it was a true collaborative effort.”

And we received this fantastic feedback for our part in the Super Bowl LVI collaboration from The Famous Group:

“Thank you to the TruePoint team for all the help on this one. It was super-important for everything to line up as accurately as possible on this huge stage, and your team was excellent again! We really enjoy working with you all and look forward to the next opportunity that come our way. ”

”

We at TruePoint are honored and excited to continue to collaborate with The Famous Group to continue to wow fans and audiences all over the world. We’ve now scanned so many fantastic sports venues, that Lidar News featured us in “12 Days of Laser Scanning From 2021,” and we can’t wait to continue.

If you’d like more information about our 3D laser scanning, mapping, and modeling services, for entertainment or for your next construction project, click here to learn more.

The first step into the world of CAD/CAM is choosing a dental 3D scanner! - Dental articles

The first step into the world of CAD/CAM is choosing a dental 3D scanner!

It's happening faster than anyone expected!

Dental laboratories and clinics in Ukraine are actively transferring their work to the world of 3D technologies. Over the past 2 years, Ukraine has seen a very fast jump in the introduction of CAD / CAM technologies in the dental industry. Leading dentistry of the country, as well as dental laboratories, have been equipped with all kinds of milling cutters and 3D scanners in order to bring the quality of work to a higher level and make their work faster and more predictable.

Leading dentistry of the country, as well as dental laboratories, have been equipped with all kinds of milling cutters and 3D scanners in order to bring the quality of work to a higher level and make their work faster and more predictable.

Each new owner of 3D technology had to work hard to collect the necessary information about the varieties of this equipment, and the functions that they can perform. The fact is that in Ukraine there is still not much information about this, and there are not many specialists who could give an extensive comparison.

Therefore, we decided to share our knowledge and help our colleagues a little by giving basic information on choosing a 3D scanner. After all, it is the 3D scanner that will first appear in the laboratory, almost every dental technician, in the coming years!

The first step into the world of CAD CAM technologies is choosing a 3D scanner!

When choosing a CAD CAM system, a number of questions arise, one of the main ones is the choice of a scanner. After all, this is the first step! If you have a small amount of work, then it will be enough for you to purchase only a scanner and a CAD program for modeling (this is part of a complete system). On the one hand, it does not require large investments of money, and does not require a lot of additional knowledge to get the finished product. In this case, you scan and model your work yourself, and you send the finished stl file to any milling center convenient for you so that what you modeled is milled there. True, you need to take into account that in order for you to be completely independent in choosing a milling center, you must have both a scanner and a program that will produce an stl file “open”!

After all, this is the first step! If you have a small amount of work, then it will be enough for you to purchase only a scanner and a CAD program for modeling (this is part of a complete system). On the one hand, it does not require large investments of money, and does not require a lot of additional knowledge to get the finished product. In this case, you scan and model your work yourself, and you send the finished stl file to any milling center convenient for you so that what you modeled is milled there. True, you need to take into account that in order for you to be completely independent in choosing a milling center, you must have both a scanner and a program that will produce an stl file “open”!

Having your own scanner with the program, you will have several main advantages:

Thanks to the CAD program, you can model the work yourself, put your vision into the modeling, and get what you want.

Save time by at least 50%! Milling the work sent to the milling center in the finished stl file is usually made 50% faster than working on the model. You also save shipping time by sending the file via email in a matter of seconds.

You also save shipping time by sending the file via email in a matter of seconds.

If you have a scanner with a CAD program, you immediately begin to “beat off” money for it, thanks to the fact that you save. After all, milling from stl files is usually 30-40% cheaper than milling from a model.

In the future, you will be able to purchase a router from any manufacturer, and connect everything you already have into a single working system. This is a great advantage of open systems!

What should I pay attention to when buying a scanner and modeling software?

Let's start with what has already been mentioned, with a simple one: open system or closed?

Closed systems are becoming rarer these days. In a closed CAD system, the modeling program produces a file either encoded for a specific milling center or for a specific milling system (CAM). That is, you will not be able to decide for yourself where you will be milled - everything has already been decided for you.

Owners of an open system, get their modeled work in the form of a free stl file, compatible with all open routers, and have the full right to choose: where to mill, from what materials and at what price!

There is also an intermediate option, an open system, but requiring a monthly or annual subscription fee for program updates. If you do not pay the required amount at the end of the year, then at 00.01 the scanner will turn into a useless breadbasket. J

Which scanning principle should I choose?

There are three basic principles of scanning:

Tactile, using a touch stylus that slides over the scanned surface. This method is the most accurate, but also the longest. In practice, not many people use it.

Laser, scanned with a laser beam. Scanning accuracy 20-15 microns.

Optical, scanning with structured light. Scanning accuracy 5-15 microns. Optical ones come in white light and blue light. The light-emitting diode (LED) projector is used as a source. Blue light allows you to read more information.

Blue light allows you to read more information.

Hybrid type - optical + tactile. In this case, 2 scanners are used simultaneously, debugged together into a single working system, and providing maximum accuracy and good scanning speed.

The most popular today are laser and optical scanners. Scanning speed, on modern laser and optical scanners, does not differ significantly. And often, optical scanners are faster than laser ones. For example, when scanning individual columns, the optical scanner can scan up to 8 columns at the same time, the laser one will scan each separately.

Which simulation program should I choose?

3shape DentalDesigner and Exocad are currently the main competitors in modeling software.

More and more users are turning to Exocad. This program is sold both in its original form and modified for such systems as Zirconzahn, Amman Girrbach and others.

We will talk about the features of the programs in detail in a special topic in the next issue.

What's included with the scanner?

The scanner is not only a scanning box, accessories play an important role, without the help of which, it is almost impossible to perform some high-quality work. There are all kinds of fasteners. Pay attention to their presence when buying a scanner, as individually they cost a lot of money. Among them:

fixture for scanning multiple columns at the same time

model fixture for working with implants

fixture for articulated model

fixture for scanning impression tray

fixture for scanning wax modeling

and others.

We have listed the main differences between scanners and hope that this information will be useful to you when choosing a scanner. We wish you to make the right choice that will meet your needs!

Sincerely, Fedor Moiseev

Head of the Stakhanovets CAD/CAM technology center, Kyiv

#Zubotekhnika #Orthopedics #Release

Interdent Lab

6368 • 05/20/2014

+ Add article

NaviStom

Anesthesia

Dental Design

Magazine

Dentistry

Interesting on the net

Crime

Marketing Management

Equipment

Orthodontics

Orthopedics

Periodontology Hygiene

release

Dental unit

Therapy Endodontics

Surgery Implantology

Aesthetic dentistry

["13508","13375","13368","13359","13349","13351","13325","13300","13249","13210","13065","12992 ","12909","12890","12822","12809","12664","12796","12734","12754","12784","12782","12779","12757", "12745","12742","12741","12713","12668","12616","12610","12608","12599","12590","12582","12581","12546","12539","12532","12499","12487","12439","12426","12447","12349" ,"12331","12315","12314","12302","12266","12249","12246","12239","12227","12218","12204","12202"," 12198","12184","12180","12154","12153","12119","12070","12058","12031","12023","12015","12010","12000" ,"11999","11959","11956","11953","11952","11951","11932","11923","11920","11917","11913","11902"," 11897","11893","11890","11885","11877","11874","11867","11865","11857","11856","11853","11837","11833" ,"11830","11823","11811","13524","13523","13521","13520","13522","13519","13518","13517","13516"]

The art of making ideas come true: what you need to know about modern 3D printers

A sharp leap in the development of 3D printing has made the technology accessible to everyone. The market provides a huge range of solutions of different cost, capabilities and specifics. That is why many people still have uncertainty based on ignorance of the basic nuances. Together with the guys from the 3dVision online store, we will tell you everything you need to know about modern 3D printers.0005

The market provides a huge range of solutions of different cost, capabilities and specifics. That is why many people still have uncertainty based on ignorance of the basic nuances. Together with the guys from the 3dVision online store, we will tell you everything you need to know about modern 3D printers.0005

1. Different areas need their own 3D printers

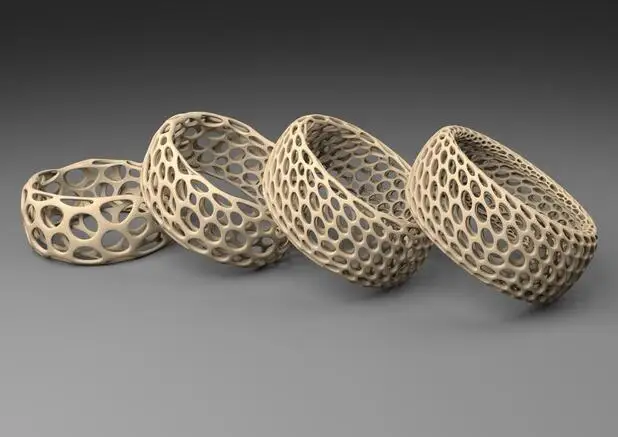

Now the technology has developed so much that individual modifications of 3D printers are used in completely different industries. There are already medical bioprinters that can print organs from stem cells, jewelry that create detailed molds for casting, or industrial ones that can print durable parts and components of various designs. The latter, for example, is used by the Swedish car manufacturer Koenigsegg to create One:1 model turbochargers.

Fashion, functional testing, prosthetics and even construction are also actively developing. The specific use and main tasks of the product require different printing methods and types of materials.

2. Variety of materials

The more technology develops, the more new materials appear: wood simulants, metal and sandstone simulants, and even melted chocolate. If we consider the most popular and common for home printing, then we can distinguish three types of thermoplastic:

ABS. Differs in a good ratio of hardness in a frozen state and plasticity in a heated state. It lends itself well to grinding, cutting and painting, which, coupled with impact-resistant properties, allows you to print parts from it, for example, for car bodies.

PLA . Made primarily from corn. It decomposes and contains no toxins, making it environmentally friendly. It surpasses ABS in hardness, but is more susceptible to sunlight: already at 50 degrees PLA becomes soft.

SBS. Products made from it are more flexible than ABS, so this material is well suited for engineering and mechanical work. It is more transparent (93% light transmission), so you can make lamps, dishes, vases and so on from it.

View material catalog

3. Can be used in conjunction with 3D scanners

3D printing is impossible without pre-prepared models. They can be created manually in special applications, but if you need to recreate an existing item, it is better to use a 3D scanner. With it, you will digitize the desired part from all sides in a 1: 1 size and you can print it almost immediately.

By adjusting the scale, you can adapt the resulting model to different tasks, for example, to create reduced or enlarged copies of mechanisms, accessories, and so on. You can even scan your face and print a 3D mask or bust. The application potential is only limited by your imagination.

View 3D Scanners

4. Modern 3D printers are incredibly accurate

3D printing technology has now crossed the line of creating rough and uncouth models. Accuracy and error are now measured in microns, which allows you to print even small, but very detailed jewelry blanks, complex geometric shapes and detailed models.

This takes the use of 3D printing to a new level. For example, Amos Dudley was able to straighten his teeth using only a 3D scanner and a 3D printer. He made a cast of his jaw and made 12 eilaners made of non-toxic plastic with varying degrees of pressure on problem areas. The amount of expenses was only 60 dollars instead of 2,000-4,000 if he went to the dentist.

5. Speed up the production process and reduce waste

For small-scale production, 3D printing significantly speeds up the manufacturing process, reduces costs and makes the whole process more environmentally friendly. For example, in jewelry, you just need to design a model in the application, and then you can print dozens of casting molds at once, instead of fiddling with molding wax by hand.

If we consider the production of collectible figurines, then you do not need to create factory mechanisms from scratch, sharpened for each individual model. Any workpiece can be printed on an existing printer, which saves a lot of time and money.