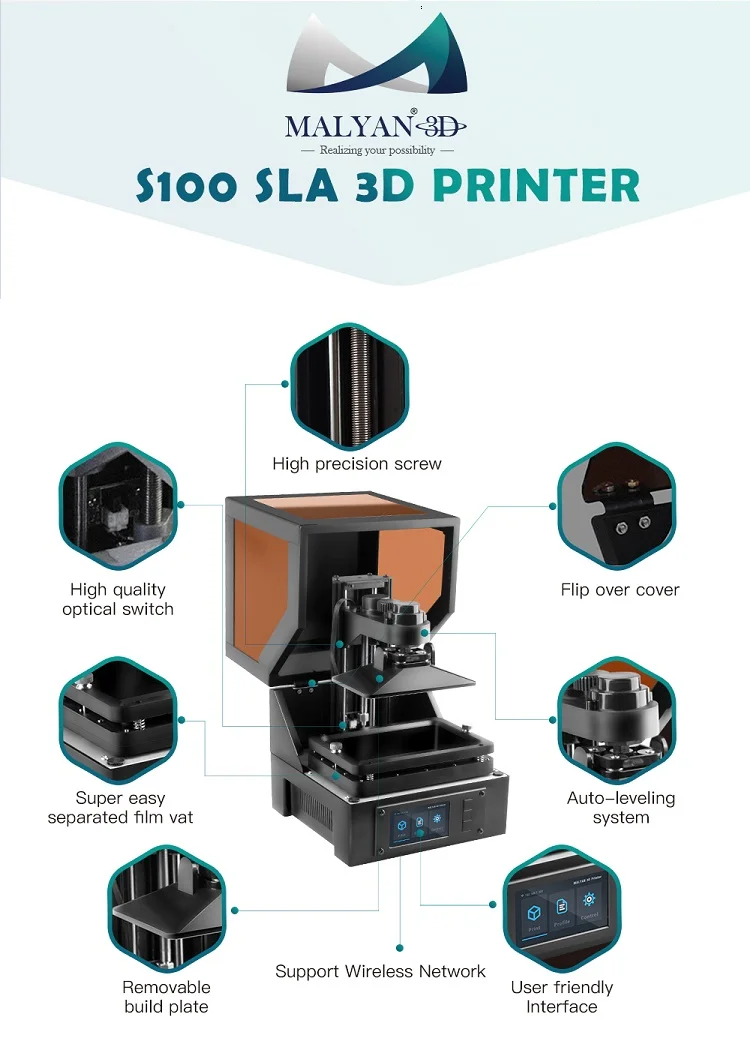

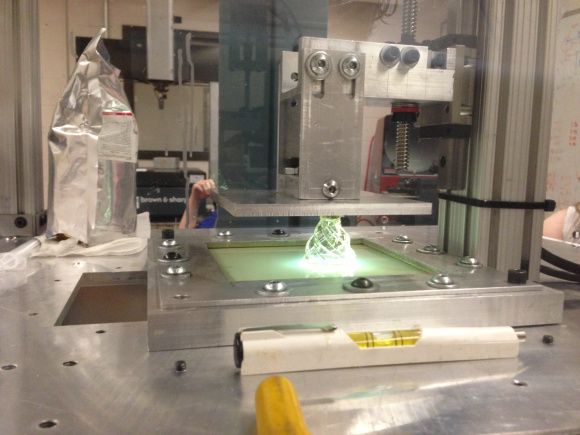

Laser resin 3d printer

Guide to Resin 3D Printers

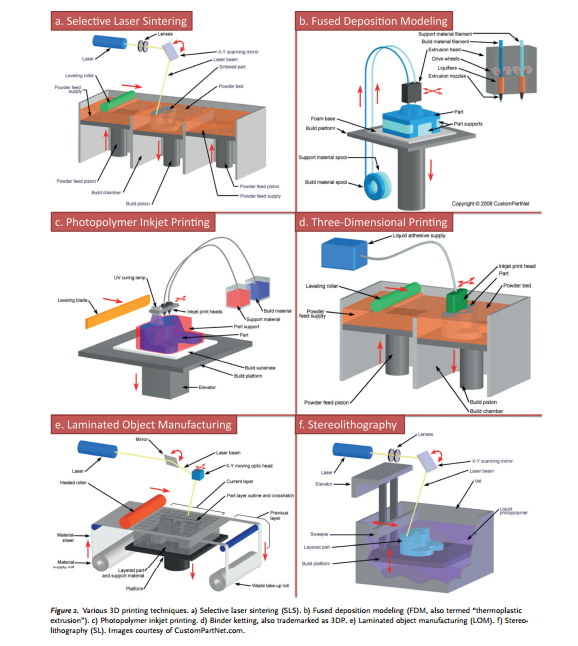

There are many 3D printing processes on the market. Getting familiar with the nuances of each helps to clarify what you can expect from final prints to ultimately decide which technology is suitable for your particular application.

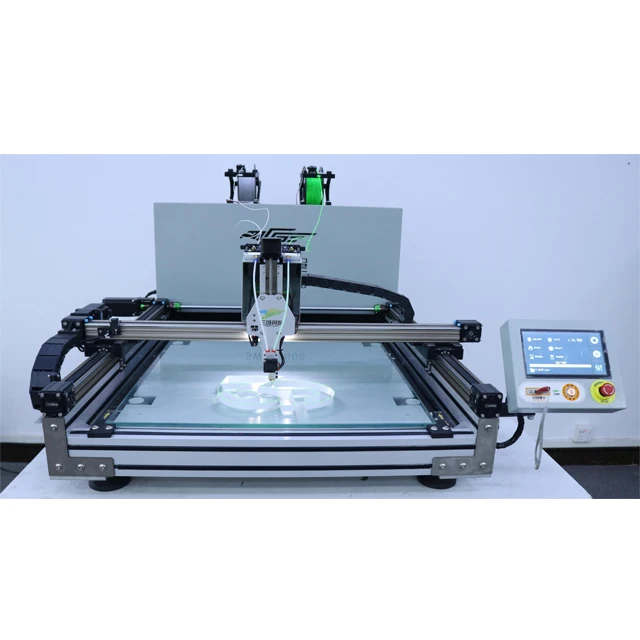

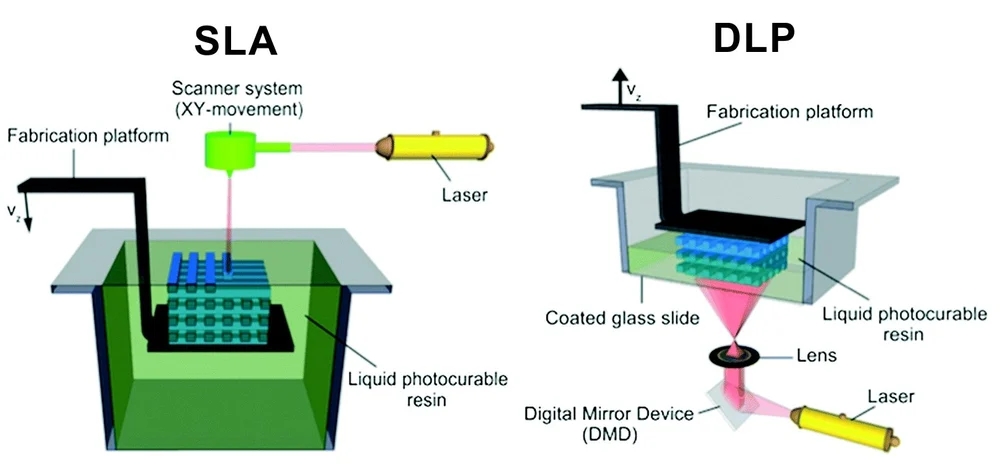

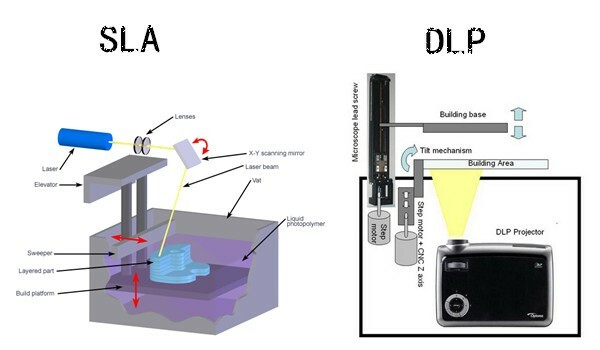

Stereolithography (SLA) and digital light processing (DLP) 3D printing are the two most common processes for resin 3D printing. Resin printers are popular for producing high-accuracy, isotropic, and watertight prototypes and parts in a range of advanced materials with fine features and smooth surface finish.

While these technologies were once complex and cost-prohibitive, today’s small-format desktop SLA and DLP resin 3D printers produce industrial-quality parts at an affordable price point and with unmatched versatility thanks to a wide range of materials.

Both processes work by selectively exposing liquid resin to a light source—SLA a laser, DLP a projector—to form very thin solid layers of plastic that stack up to create a solid object. While very similar in principle, the two technologies can produce significantly varying outputs.

In this in-depth guide, we walk through the details of the two resin 3D printing processes and explore how they compare in terms of resolution, accuracy, build volume, speed, workflow, and more.

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

Request a Free Sample Part

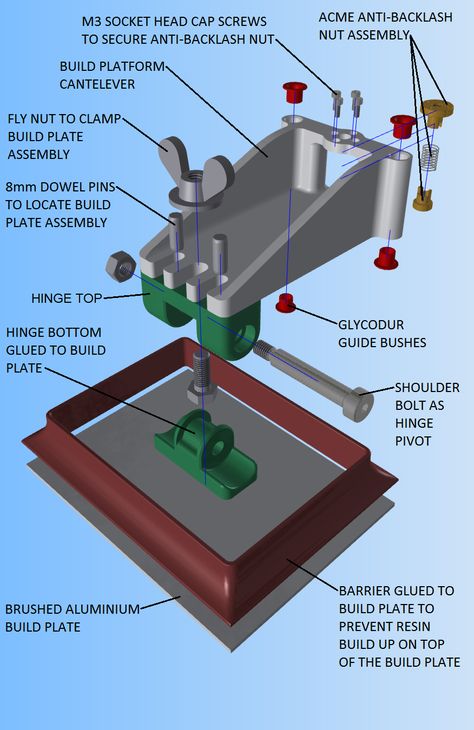

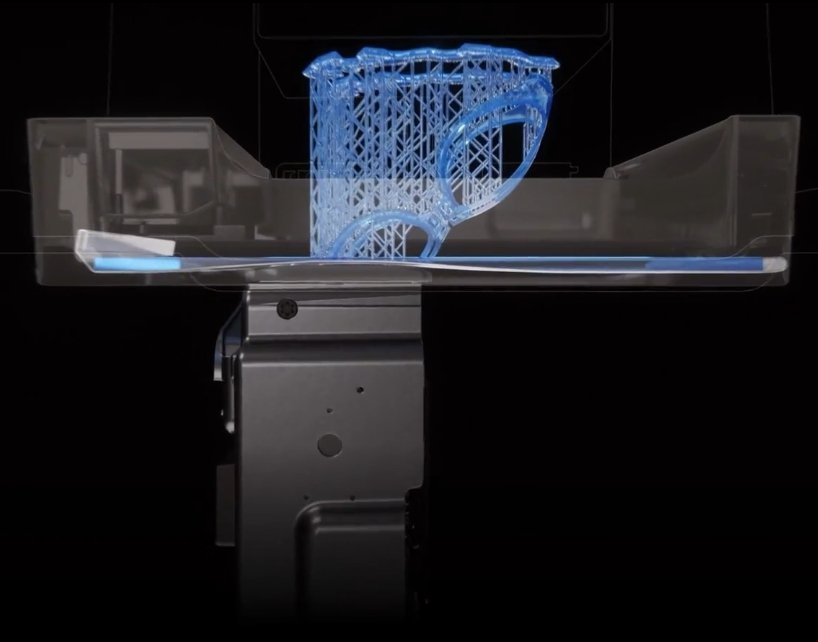

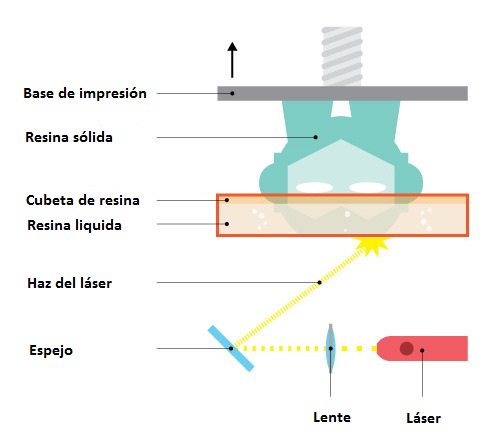

Desktop SLA 3D printers contain a resin tank with a transparent base and non-stick surface, which serves as a substrate for the liquid resin to cure against, allowing for the gentle detachment of newly-formed layers.

The printing process starts as the build platform descends into a resin tank, leaving space equal to the layer height in between the build platform, or the last completed layer, and the bottom of the tank. A laser points at two mirror galvanometers, which direct the light to the correct coordinates on a series of mirrors, focusing the light upward through the bottom of the tank and curing a layer of resin.

The cured layer then gets separated from the bottom of the tank and the build platform moves up to let fresh resin flow beneath. The process repeats until the print is complete.

Low Force Stereolithography (LFS) technology, used by the Form 3+ and Form 3L, is the next phase in SLA 3D printing.

In LFS 3D printers, the optics are enclosed in a Light Processing Unit (LPU). Within the LPU, a galvanometer positions the high-density laser beam in the Y direction, passes it through a spatial filter, and directs it to a fold mirror and parabolic mirror to consistently deliver the beam perpendicular to the build plane and ensure accurate, repeatable prints.

As the LPU moves in the X direction, the printed part is gently peeled away from the flexible bottom of the tank, which drastically reduces the forces exerted on parts during the print process.

LFS 3D printing drastically reduces the forces exerted on parts during the print process, using a flexible tank and linear illumination to deliver incredible surface quality and print accuracy.

This advanced form of stereolithography delivers vastly improved surface quality and print accuracy. Lower print forces also allow for light-touch support structures that tear away with ease, and the process opens up a wide range of possibilities for future development of advanced, production-ready materials.

White Paper

Looking for a 3D printer to realize your 3D models in high resolution? Download our white paper to learn how SLA printing works and why it's the most popular 3D printing process for creating models with incredible details.

Download the White Paper

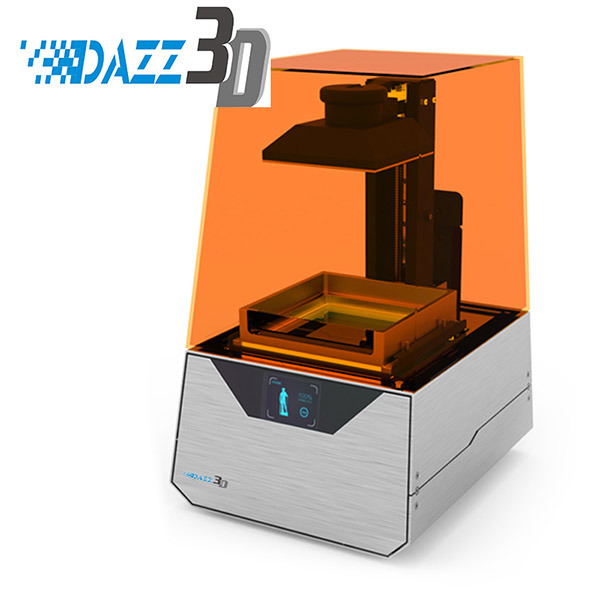

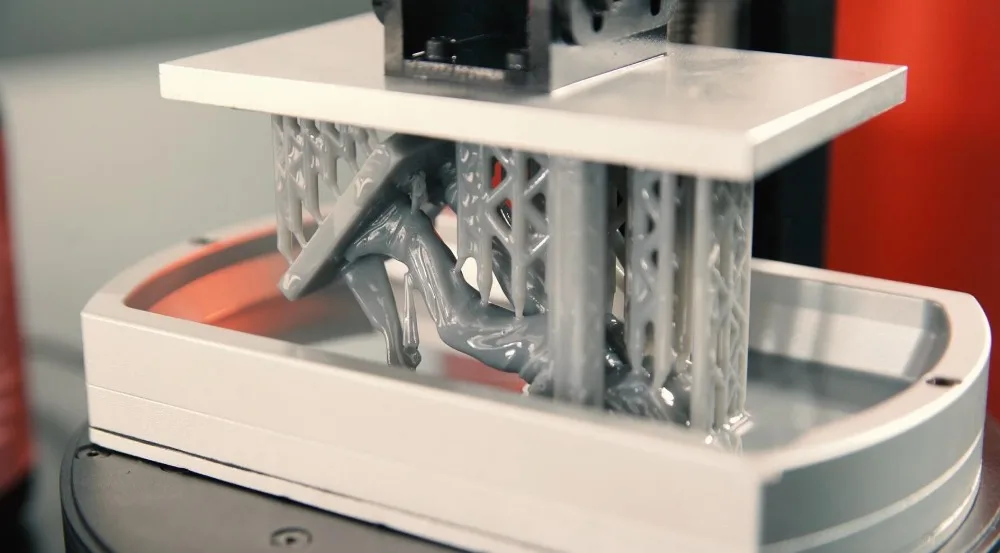

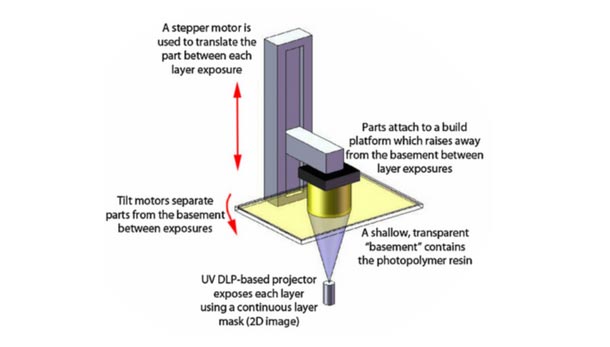

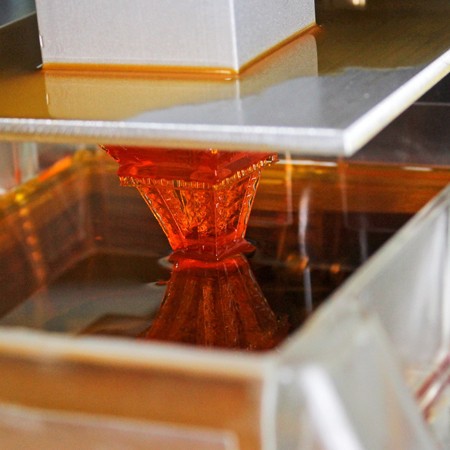

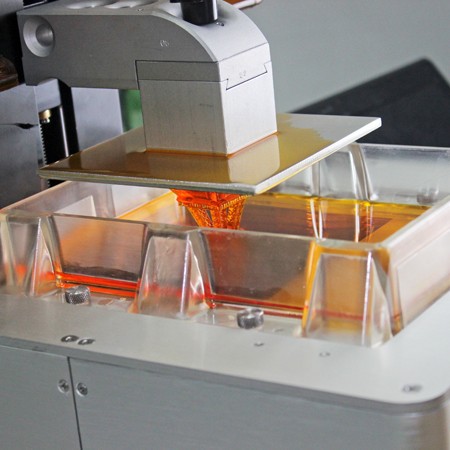

Just like their SLA counterparts, desktop DLP 3D printers are built around a resin tank with transparent bottom and a build platform that descends into a resin tank to create parts upside down, layer by layer.

The difference is the light source. DLP 3D printers use a digital projector screen to flash an image of a layer across the entire platform, curing all points simultaneously.

The light is reflected on a Digital Micromirror Device (DMD), a dynamic mask consisting of microscopic-size mirrors laid out in a matrix on a semiconductor chip. Rapidly toggling these tiny mirrors between lens(es) that direct the light towards the bottom of the tank or a heat sink defines the coordinates where the liquid resin cures within the given layer.

Because the projector is a digital screen, the image of each layer is composed of square pixels, resulting in a three-dimensional layer formed from small rectangular cubes called voxels.

Resolution shows up more often than any other value in 3D printer spec sheets, but it’s also a common ground for confusion. The basic units of the SLA and DLP processes are different shapes, making it difficult to compare the different machines by numerical specifications alone.

In 3D printing, there are three dimensions to consider: the two planar 2D dimensions (X and Y) and the third vertical Z dimension that makes 3D printing.

Z resolution is defined by the layer thicknesses a 3D printer can produce. Resin 3D printers like SLA and DLP offer some of the finest Z resolutions—thinnest layers—of all 3D printing processes and users can normally choose from a range of layer height options between 25-300 microns, allowing designers to strike a balance between detail and speed.

In DLP 3D printing, XY resolution is defined by the pixel size, the smallest feature the projector can reproduce within a single layer. This depends on the resolution of the projector, the most common being full HD (1080p), and its distance from the optical window. As a result, most desktop DLP 3D printers have a fixed XY resolution, generally between 35 to 100 microns.

For SLA 3D printers, XY resolution is a combination of the laser’s spot size and the increments by which the laser beam can be controlled. For example, the Form 3 LFS 3D printer features a laser with an 85 micron spot size, but because of the constant line scanning process, the laser can move in smaller increments and the printer can consistently deliver parts with 25 micron XY resolution.

However, resolution in itself is often just a vanity metric. It offers some indication, but it doesn’t necessarily correlate directly with accuracy, precision, and print quality.

Learn more about resolution in 3D printing in our in-depth guide.

Because 3D printing is an additive process, each layer introduces an opportunity for inaccuracy, and the process by which layers are formed affects the level of precision, defined as the repeatability of the accuracy of each layer. Accuracy and precision depend on many different factors: 3D printing process, materials, software settings, post-processing, and more.

In general, both SLA and DLP resin 3D printers are among the most accurate and precise 3D printing processes. Differences in accuracy and precision are often better explained by the differences between machines by various manufacturers than differences between the technologies themselves.

For example, entry-level SLA or DLP printers might use off-the-shelf projectors, lasers, or galvanometers, and their manufacturers will try to get the best performance possible out of these parts. Professional SLA and DLP 3D printers, like the Formlabs Form 3, feature a custom optical system adapted to the specifications required by professional customer applications.

Professional SLA and DLP 3D printers, like the Formlabs Form 3, feature a custom optical system adapted to the specifications required by professional customer applications.

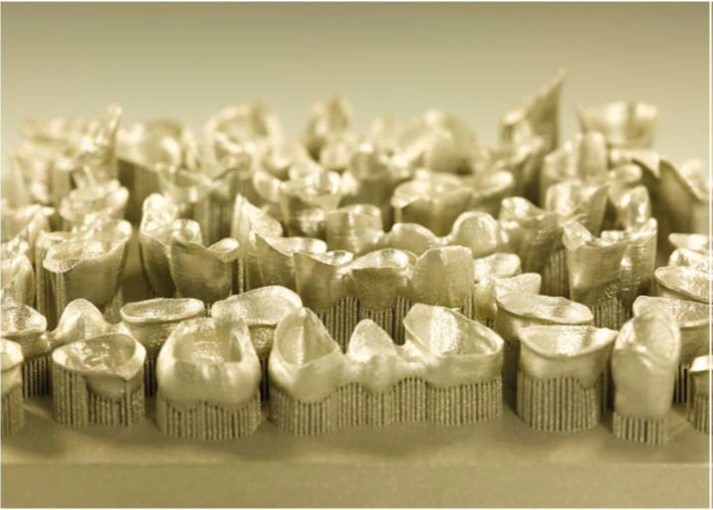

Accuracy and precision are crucial for parts like dental splints (left) and surgical guides (right).

Calibration is also crucial. With DLP projectors, manufacturers need to deal with the non-uniform light distribution on the build plane and optical distortion of the lenses—meaning that pixels in the middle are not the same size or shape as pixels on the edges. SLA 3D printers use the same light source for every part of the print, which means it’s uniform by definition, but they still require extensive calibration to account for distortions.

Even a 3D printer with the highest quality components and degree of calibration can produce widely varying results depending on the material. Different resins require optimized material settings to perform as intended, which might not be available for off-the-shelf materials or resins that are not thoroughly tested with a specific 3D printer model.

The takeaway? Accuracy and precision are almost impossible to understand from the technical specifications alone. Ultimately, the best way to evaluate a 3D printer is to inspect real parts or ask the manufacturer to create a test print of one of your own designs.

With DLP 3D printers, there’s a direct trade-off between resolution and build volume. The resolution depends on the projector, which defines the number of pixels/voxels available. If one moves the projector closer to the optical window, the pixels get smaller, which increases the resolution, but limits the available build area.

Some manufacturers stack multiple projectors next to each other or use a high-definition 4K projector to increase the build volume, but this leads to substantially higher costs that often price these machines out of the desktop market.

As a result, DLP 3D printers are generally optimized for specific use cases. Some have a smaller build volume and offer high resolution to produce small, detailed pieces like jewelry, while others can produce bigger parts but at a lower resolution.

The stereolithography process is inherently more scalable, since an SLA 3D printer’s build volume is completely independent of the resolution of the print. A single print can be any size and any resolution at any location within the build area. This makes it possible to 3D print large parts at high resolution or a large batch of detailed small parts to increase throughput with the same machine.

The other main barrier to increasing build volume in both SLA and DLP 3D printers is the peel force. When printing larger parts, the forces exerted on the parts increase exponentially as a cured layer separates from the tank.

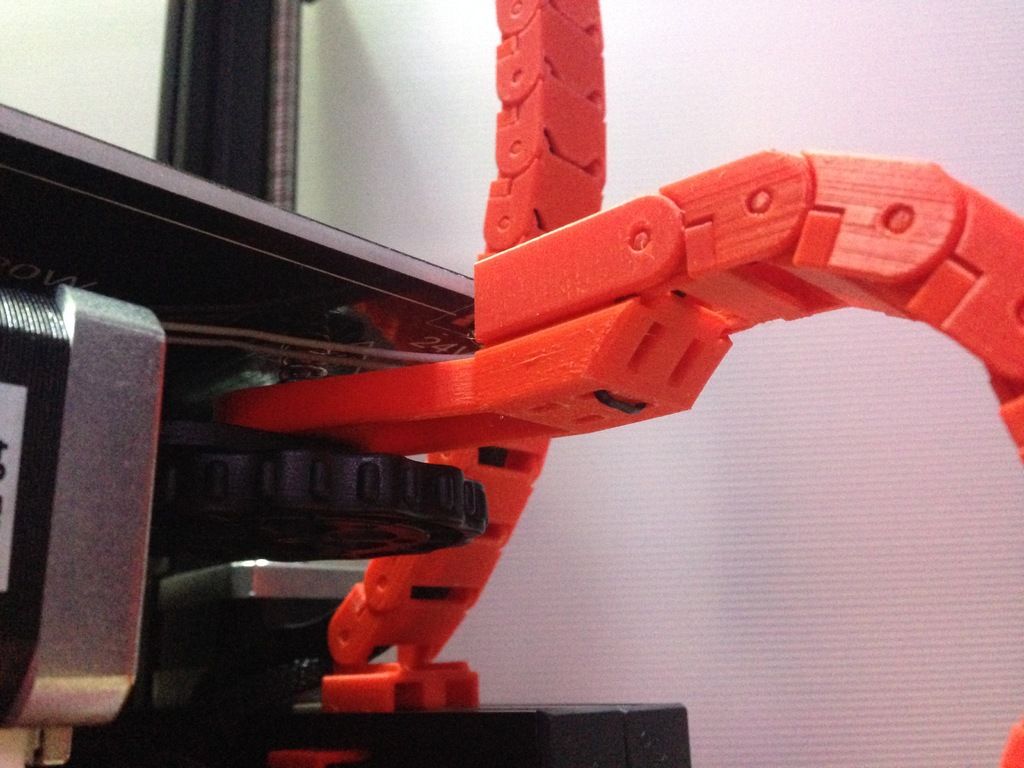

In LFS 3D printing, the flexible film at the base of the resin tank gently peels away as the build platform pulls the part up, significantly reducing the stress on the part. This unique feature has made it possible to substantially increase the build volume for the first accessible large format SLA 3D printer, the Form 3L.

The Form 3L is the first affordable large format SLA 3D printer with a build volume of 30 cm x 33. 5 cm x 20 cm.

5 cm x 20 cm.

Webinar

Want to learn more about the Form 3L and Form 3BL ecosystem, and the new large format post-processing machines?

In this demo, Kyle and Chris will expain how to navigate the Form 3L end-to-end workflow, including post-processing.

Watch Now

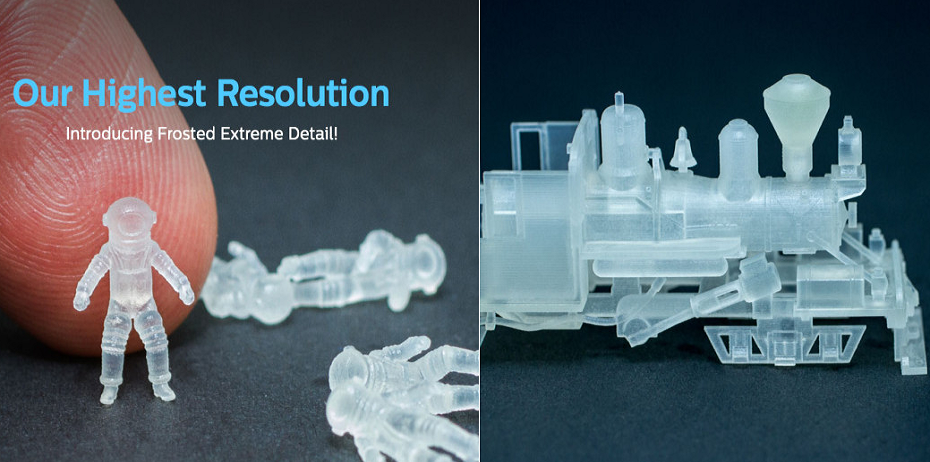

SLA and DLP resin 3D printers both known for creating parts with the smoothest surface finish of all 3D printing processes. When we describe the differences, in most cases these are only visible on tiny parts or highly detailed models.

Because objects are made of layers in 3D printing, 3D prints often have visible, horizontal layer lines. However, because DLP renders images using rectangular voxels, there is also an effect of vertical voxel lines.

DLP 3D printers render images using rectangular voxels, which causes an effect of vertical voxel lines. In this image, see the vertical voxel lines as they appear naturally on the left, and then outlined to more easily identify on the right.

Because the unit is rectangular, voxels also have an effect on curved edges. Think of building a round shape out of LEGO bricks—the edges will appear stepped on both the Z axis and the X-Y plane.

The rectangular shape of voxels makes curved edges appear stepped. Removing the appearance of voxel and layer lines requires post-processing, such as sanding.

In LFS 3D printing, layer lines are close to invisible. As a result, surface roughness is reduced, which ultimately leads to smooth surfaces, and for clear materials, more translucent parts.

When thinking about speed in 3D printing, it’s important to consider not just raw print speed, but also throughput.

Raw print speed for SLA and DLP resin 3D printers is comparable in general. As the projector exposes each entire layer all at once, print speed in DLP 3D printing is uniform and depends only on the height of the build, whereas, SLA 3D printers draw out each part with a laser. As a rule of thumb, this results in SLA 3D printers being comparable or faster when printing small or medium-size single parts, while DLP 3D printers are faster to print large, fully dense prints, or builds with multiple parts that fill up much of the platform.

But once again, it’s worth considering the trade-off between resolution and build volume for DLP printers. A small DLP 3D printer can print a small part or a (small) batch of smaller parts fast, at high resolution, but the build volume limits the part size and the throughput. A different machine with a larger build volume can print larger parts or a batch of smaller parts faster, but at a lower resolution than SLA.

SLA 3D printers can produce all of these options in one machine and offer the user the freedom to decide whether she wants to optimize for resolution, speed, or throughput.

SLA 3D printers offer a larger build volume, allowing users to batch parts and print overnight to increase throughput.

Speed can also depend on the material choice. Printing four times faster than Formlabs standard materials, Draft Resin fast-printing resin that is ideal for initial prototypes, rapid iterations, as well as dental and orthodontic models. From fast print initiation speeds to minimal support removal, wash, and cure times, Draft Resin has an optimized workflow to truly maximize efficiency.

100 microns | 200 microns |

|---|---|

100 microns | 200 microns |

|---|---|

100 microns | 200 microns |

|---|---|

Interactive

Try our interactive ROI tool to see how much time and cost you can save when 3D printing on Formlabs 3D printers.

Calculate Your Savings

Just like with accuracy and precision, the workflow and available materials differ more from machine to machine than technology to technology.

Most SLA and DLP 3D printers are “plug and play,” with easily swappable build platforms and resin tanks. Some more advanced models also come with a cartridge system to automatically refill the tank with liquid resin, which requires less attention and facilitates printing overnight.

Some printers come with proprietary software to prepare 3D models for printing, such as PreForm for Formlabs SLA 3D printers, while other manufacturers offer off-the-shelf solutions. Features differ by software tool, for example, PreForm offers one-click print setup, powerful manual controls to optimize support density and size, adaptive layer thickness, or functions to save material and time. Luckily, the software can be easy to download and test before purchasing a 3D printer.

Resin 3D printers offer a variety of materials for a wide range of applications.

One of the most significant benefits of resin 3D printing is the variety of materials that make it possible to create parts for diverse applications. Resins can feature a wide range of formulation configurations: materials can be soft or hard, heavily filled with secondary materials like glass and ceramic, or imbued with mechanical properties like high heat deflection temperature or impact resistance.

Resins can feature a wide range of formulation configurations: materials can be soft or hard, heavily filled with secondary materials like glass and ceramic, or imbued with mechanical properties like high heat deflection temperature or impact resistance.

However, the range of supported material options depend on the 3D printer model, so we recommend inquiring with the manufacturer before purchase.

Parts printed with both SLA and DLP technologies require post-processing after printing. First, the parts need to be washed in a solvent to remove excess resin. Some functional materials like engineering or biocompatible parts also require post-curing. For SLA 3D printers, Formlabs offers solutions to automate these steps, saving time and effort.

At last, 3D printed parts printed on supports require these structures to be removed, a manual process that is similar for both SLA and DLP 3D printers. LFS 3D printing simplifies this step by offering light-touch support structures that use very small touchpoints to enable easy removal with minimal support marks left behind.

Interactive

Need some help figuring out which 3D printing material you should choose? Our new interactive material wizard helps you make the right material decisions based on your application and the properties you care the most about from our growing library of resins.

Recommend Me a Material

After sorting out the differences in technology and outcomes, we hope it’s much easier to select a resin 3D printer that best matches your workflow and output needs.

To explore the next generation of SLA 3D printing, learn more about the Form 3 and Form 3L LFS 3D printers.

Curious to see the quality firsthand? Order a sample part shipped to your office.

Request a Free Sample Part

Best resin 3D printers in 2022

What is the best resin 3D printer on the market?

Resin 3D printers are able to offer a very high level of detail and smooth surfaces. They are most commonly seen in dental labs and clinics as well as in jewelry workshops but are also increasingly popular with hobbyists and makers.

They are most commonly seen in dental labs and clinics as well as in jewelry workshops but are also increasingly popular with hobbyists and makers.

The way a resin 3D printer works depends on its technology: laser SLA (stereolithography), DLP (Digital Light Processing), or LCD-based (using an LCD screen to mask projected light).

All resin 3D printers involve the same workflows, however, requiring several post-processing steps such as resin removal and post-curing.

In this guide, we take a look at some of the best resin 3D printers available in each category (SLA, DLP, and LCD) and provide you with key concepts linked to resin 3D printing.

The best resin 3D printers (SLA/DLP/LCD)

| Brand | Product | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|

| Prusa Research | Original Prusa SL1 | 120 × 68 × 150 mm4.72 × 2.68 × 5.91 in | Czech Republic | $ 1,6991 727 €1,507 £253,246 ¥ | Buy |

| Peopoly | Phenom | 276 × 155 × 400 mm10.87 × 6.1 × 15.75 in | China | $ 1,9991 899 €1,773 £297,963 ¥ | Contact |

| Formlabs | Form 3 | 146 × 145 × 185 mm5.75 × 5.71 × 7.28 in | United States | $ 3,4993 557 €3,104 £521,547 ¥ | Quote |

| UNIZ | SLASH 2 | 190 × 120 × 200 mm7.48 × 4.72 × 7.87 in | – | $ 3,5003 558 €3,105 £521,696 ¥ | Quote |

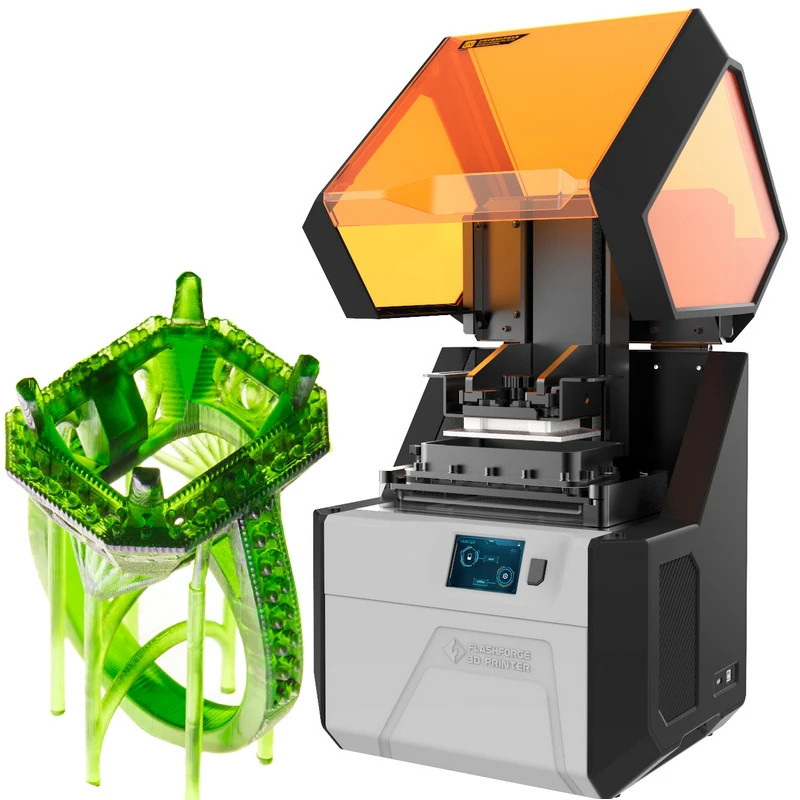

| FlashForge | Hunter DLP | 120 × 67 × 150 mm4.72 × 2.64 × 5.91 in | China | $ 3,9994 065 €3,547 £596,075 ¥ | Quote |

| DWS | XFAB | 180 × 180 × 180 mm7.09 × 7.09 × 7.09 in | – | $ 6,6006 000 €5,854 £983,770 ¥ | Quote |

| B9Creations | B9 Core 550 | 96 × 54 × 127 mm3. 78 × 2.13 × 5 in 78 × 2.13 × 5 in | – | $ 9,95510 119 €8,830 £1,483,852 ¥ | Quote |

| Asiga | MAX | 119 × 67 × 75 mm4.69 × 2.64 × 2.95 in | – | $ 10,99011 171 €9,749 £1,638,125 ¥ | Quote |

| ETEC | Envision One | 180 × 101 × 175 mm7.09 × 3.98 × 6.89 in | Germany | upon request | Quote |

Expand to see more specs

The products in the table are ranked by price (low to high).

| Brand | Product | Technology | Build size | Country | Price Approximate starting prices based on supplier-provided information and public data. Prices may vary by region, over time and do not include additional products or services (taxes, shipping, accessories, training, installation, …). | |

|---|---|---|---|---|---|---|

| Prusa Research | Original Prusa SL1 | LCD | 120 × 68 × 150 mm4.72 × 2.68 × 5.91 in | Czech Republic | $ 1,6991 727 €1,507 £253,246 ¥ | Buy on Prusa |

| Peopoly | Phenom | LCD | 276 × 155 × 400 mm10. 87 × 6.1 × 15.75 in 87 × 6.1 × 15.75 in | China | $ 1,9991 899 €1,773 £297,963 ¥ | Contact manufacturer |

| Formlabs | Form 3 | SLA | 146 × 145 × 185 mm5.75 × 5.71 × 7.28 in | United States | $ 3,4993 557 €3,104 £521,547 ¥ | Get a quote |

| UNIZ | SLASH 2 | LCD | 190 × 120 × 200 mm7.48 × 4.72 × 7.87 in | – | $ 3,5003 558 €3,105 £521,696 ¥ | Get a quote |

| FlashForge | Hunter DLP | DLP | 120 × 67 × 150 mm4.72 × 2.64 × 5.91 in | China | $ 3,9994 065 €3,547 £596,075 ¥ | Get a quote |

| DWS | XFAB | SLA | 180 × 180 × 180 mm7.09 × 7.09 × 7.09 in | – | $ 6,6006 000 €5,854 £983,770 ¥ | Get a quote |

| B9Creations | B9 Core 550 | DLP | 96 × 54 × 127 mm3.78 × 2.13 × 5 in | – | $ 9,95510 119 €8,830 £1,483,852 ¥ | Get a quote |

| Asiga | MAX | DLP | 119 × 67 × 75 mm4. 69 × 2.64 × 2.95 in 69 × 2.64 × 2.95 in | – | $ 10,99011 171 €9,749 £1,638,125 ¥ | Get a quote |

| ETEC | Envision One | CDLP | 180 × 101 × 175 mm7.09 × 3.98 × 6.89 in | Germany | upon request | Get a quote |

Overview of the best resin 3D printers (SLA/DLP/LCD)

This overview is divided into three sections according to the resin 3D printers’ technology (SLA, DLP, or LCD).

The best SLA 3D printers (laser stereolithography)

Formlabs has been one of the main players on the professional resin 3D printer market for years. The Form 3, evolution of the award-winning Form 1 and Form 2, is their latest model, along with the Form 3L (large volume). This professional liquid resin printer boasts an array of practical features that make it a great choice for many businesses.

In the past, users have praised Formlabs’ hardware quality and precision, while criticizing the company’s decision to limit compatible materials to expensive Formlabs proprietary resins only. Today, the Form 3 features an “Open mode” that allows the use of generic materials.

Today, the Form 3 features an “Open mode” that allows the use of generic materials.

Contact manufacturer Get a quote Add to comparison

The Phenom is an affordable and large-format LCD (MSLA) 3D printer that is suitable for hobbyists and professionals alike. An advantage of this resin 3D printer is large-format. The Peopoly Phenom 3D printer also exists in larger versions: Phenom L, Phenom Noir, Phenom XXL.

Contact manufacturer Get a quote Add to comparison

DWS Systems is specialized in manufacturing professional and industrial-grade resin 3D printers. The XFAB stereolithography 3D printer is their most affordable option, but is capable of delivering high-quality results. One of this SLA 3D printer’s most interesting characteristics is its cartridge resin system.

This makes material handling much easier and cleaner than with non-cartridge systems.

Contact manufacturer Get a quote Add to comparison

The best DLP 3D printers (Digital Light Processing)

This professional resin 3D printer boasts a number of user-friendly features including a touchscreen, automatic calibration, and Wi-Fi connectivity. FlashForge develops its own resins, but users may also use third-party materials.

FlashForge develops its own resins, but users may also use third-party materials.

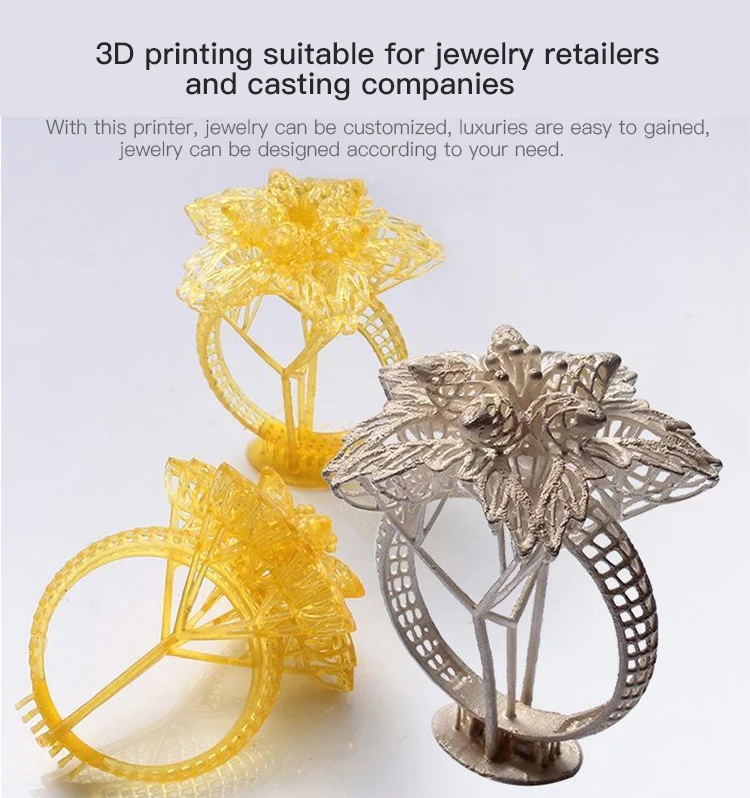

With its special jewelry support mode, the Hunter DLP mainly targets jewelers.

Contact manufacturer Get a quote Add to comparison

B9Creations’ Core series of 3D printers all provide fine levels of detail for professionals. According to the manufacturer, the B9 Core 550 resin 3D printer offers faster printing speeds (100+ mm/hour) than most DLP 3D printers in the same price range.

This digital light processing 3D printer is available with a smaller build volume (B9 Core 530).

Contact manufacturer Get a quote Add to comparison

The Envision One is a professional resin 3D printer produced by ETEC. ETEC, a German company known as EnvisionTEC before its acquisition by Desktop Metal in 2021, manufactures professional DLP 3D printers. The ETEC Envision One uses CDLP 3D printing technology. This 3D printer offers a build volume of 180 x 101 x 175 mm.

Contact manufacturer Get a quote Add to comparison

The Asiga MAX is equipped with a resin level sensor, automatic calibration function and touch screen. Asiga also provides free lifetime technical support.

Asiga also provides free lifetime technical support.

This 3D printer is particularly suitable for the medical and dental sectors, being compatible with silicone resins.

Contact manufacturer Get a quote Add to comparison

The best LCD 3D printers (liquid crystal display)

For many years, Prusa Research has been famous for manufacturing reliable 3D printers. The Original Prusa SL1 is Josef Prusa’s first resin 3D printer, but there is no doubt that it has been endowed with as much quality as the award-winning Prusa MK3 FDM 3D printers.

This LCD 3D printer– which is also available as a DIY kit– is packed with features such as a tilted print bed, auto calibration, vapor extraction, and more.

Buy on Prusa Get a quote Add to comparison

The SLASH 2 is a desktop resin 3D printer produced by UNIZ. UNIZ is a 3D printer manufacturer based in China. The UNIZ SLASH 2 uses resin 3D printing technology. This 3D printer offers a build volume of 190 x 120 x 200 mm.

Contact manufacturer Get a quote Add to comparison

Resin 3D printers under $1,000

As LCD screens are very affordable, they have been the key to bringing resin 3D printing to the masses. Indeed, more and more manufacturers are launching affordable desktop resin 3D printers with LCD 3D printing technology, and the price drop is radical.

These affordable resin 3D printers obviously can’t be expected to provide the same level of detail and accuracy as the professional 3D printers listed above. However, they are great as an introduction to resin 3D printing and they do produce good quality prints.

Read our full-length budget resin 3D printer article for a list of affordable machines (starting from $149).

Post-processing for resin 3D prints: necessary steps

Resin removal

Since the objects are printed within a tank of resin, resin drips off of the objects as they are lifted up and out of the tank. There’s always a layer of uncured resin left on the object, and it must be removed with IPA (isopropyl alcohol).

There’s always a layer of uncured resin left on the object, and it must be removed with IPA (isopropyl alcohol).

This can be done manually by dipping the part in an IPA bath and gently scrubbing the part with a soft brush, but it is quite time-consuming.

For users that produce resin parts on a regular basis, there are machines called resin washers, or resin cleaners. Ackuretta, for example, markets Cleani, a dual-tank resin cleaner that can wash both the parts and the printer’s platform (yes, that needs to be washed, too.).

Post-curing

When removing a resin 3D printed part from the build plate, it is still soft and slightly malleable. To reach its final physical state the part must go through a post-curing step. This means exposing the object to heat or light. Various SLA post-curing techniques exist:

UV curing chamber / UV cure box

Professional users will definitely want to use a dedicated UV curing chamber for their parts in order to get the most out of the material (strength, for example). Most resin 3D printer manufacturers have UV curing chambers available separately.

Most resin 3D printer manufacturers have UV curing chambers available separately.

UV nail lamp

For small parts, nail UV lamps can do the trick. There are dozens of nail UV lamps available for less than $50.

DIY UV curing chamber

Crafty people also have the possibility to make their own UV curing station!

How do resin 3D printers work and what are the differences between LCD, DLP, and SLA 3D printing?

SLA 3D printers, LCD 3D printers, and DLP 3D printers all use liquid resin as a 3D printing material. The resin, a photopolymer, becomes solid when cured (activated) by a specific light source.

That light source cures the liquid resin, which is stored in a tank or vat, to form the object layer after layer.

The resin solidification process (photopolymerization) is at the core of three main 3D printing technologies:

- Laser-based Stereolithography (SLA): a UV laser cures the resin in the tank to form the object point by point.

- Digital Light Processing (DLP): the resin is cured by a light projector one whole layer at a time. The light shines in a specific shape depending on the layer.

- Liquid Crystal Display (LCD) or Masked SLA (MSLA): An array of LED lights shine through an LCD screen. The LCD screen acts as a mask or stencil between the LED and the bottom of the resin tank, only letting light through in specific shapes.

All of these resin-based 3D printing technologies form part of the same family: stereolithography. That’s why some manufacturers include “SLA” in the name of their 3D printers, while they actually use DLP or LCD-based technology.

SLA, DLP, and LCD 3D printing technologies.Laser-based SLA 3D printing technology

An SLA 3D printer cures the liquid resin spot by spot with a laser, so it is potentially more precise than DLP 3D printing.

Contrary to DLP 3D printing, the build volume is completely independent of the resolution of the 3D print. A 3D print with a laser stereolithography 3D printer can be of any size and resolution.

A 3D print with a laser stereolithography 3D printer can be of any size and resolution.

DLP 3D printing technology (digital light processing)

DLP 3D printers use a light projector. The layer’s shape is defined by reflecting or deflecting light with mirrors. With DLP, the 3D printer is able to cure a whole layer of resin at once. Therefore, a DLP 3D printer can potentially 3D print faster than an SLA 3D printer, as an entire layer is exposed all at once instead of one spot at a time with a laser.

However, a DLP 3D printer’s resolution depends on its projector and how many pixels/voxels are available (a full HD projector usually offers 1080p). A 3D printer with a large build volume has a fixed number of pixels, making it impossible to 3D print small details when building at full scale.

The projector used by the DLP 3D printer is less expensive and easier to change than the laser used by SLA 3D printers.

LCD-based resin 3D printing technology

Most LCD resin 3D printers use an LCD screen as a photomask– like a stencil– above another light source (LED, UV…). This is where LCD resin 3D printing is different than DLP 3D printing, which makes use of mirrors or other complex systems to direct the light into a certain shape. The technology is also called Masked Stereolithography (MSLA).

This is where LCD resin 3D printing is different than DLP 3D printing, which makes use of mirrors or other complex systems to direct the light into a certain shape. The technology is also called Masked Stereolithography (MSLA).

Since LCD screens are inexpensive, this technology has made resin 3D printing much more affordable than before and there are now dozens of low-cost, budget resin 3D printers available for a couple of hundred dollars.

In some cases, the light emitted by an LCD screen is used to directly cure the daylight-sensitive resin.

What is best between LCD, DLP, and SLA 3D printers?

The answer depends on the user’s needs in precision, speed, and budget. We can highlight that:

- Laser SLA 3D printers are best for 3D printing highly detailed and intricate 3D prints, big or small.

- LCD and DLP 3D printers are best for 3D printing batches of small parts, or quickly 3D printing large parts without too many details.

- LCD-based 3D printers are generally much more affordable than SLA and DLP 3D printers.

Main resin 3D printing applications

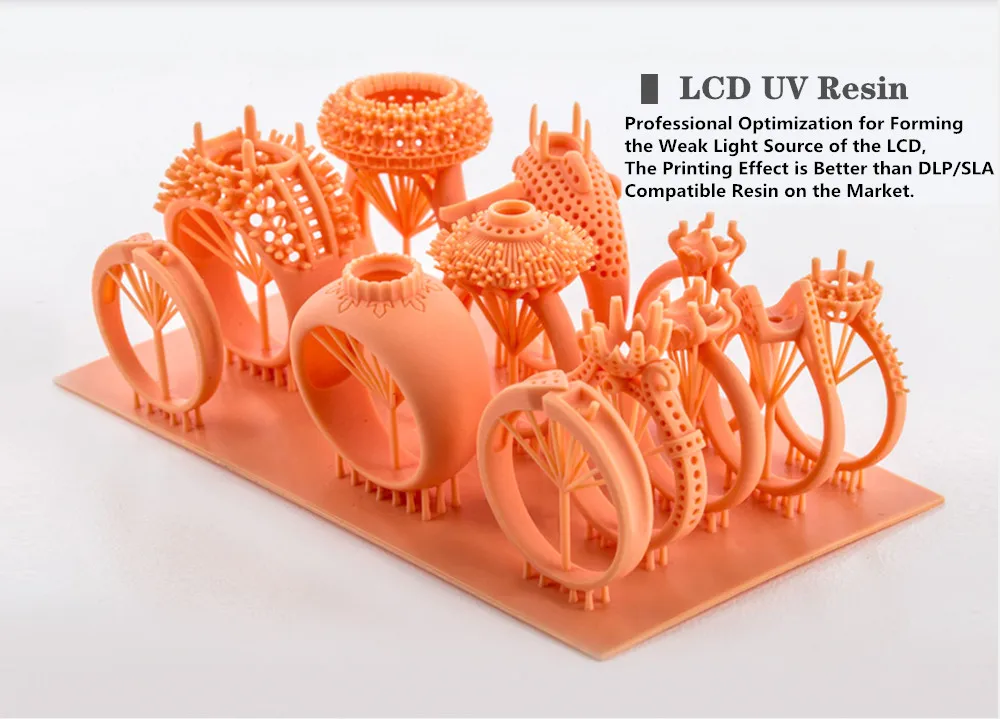

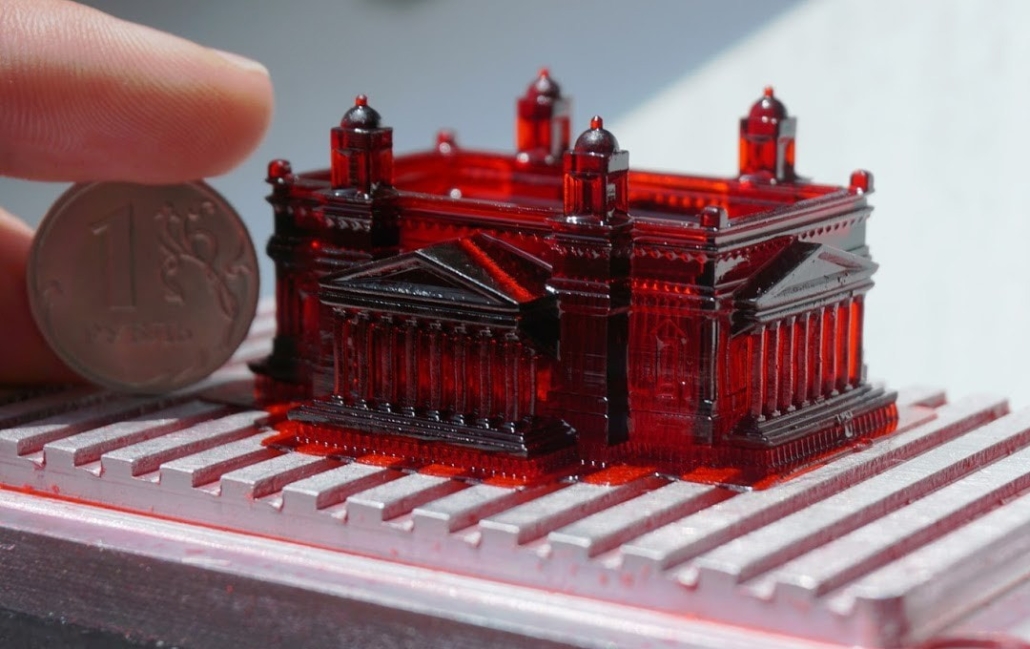

Samples by La Bête à Pois, SprintRay, and Photocentric (top to bottom). Source: AniwaaResin 3D printers mostly target professional users. Indeed, they are suited for specific applications requiring high levels of detail and top-quality finishes. These applications include:

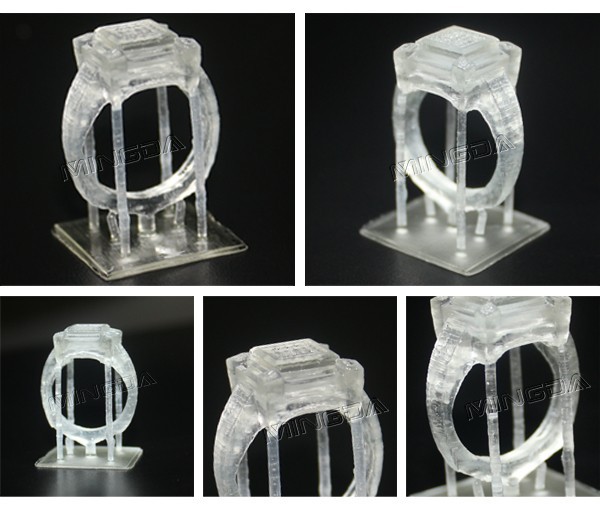

Resin 3D printers for jewelry

Jewelers use high-precision 3D printers to create molds with the lost wax technique and create incredible jewels.

SLA, DLP, and LCD 3D printers in dentistry

Dentists and dental labs are starting to use resin 3D printing to build dental crowns, mouth guards, surgical guides, and much more.

Resin 3D printing in medical and healthcare fields

SLA and DLP 3D printing can be used to create medical appliances such as hearing aids.

Hobbies: resin 3D printer for miniatures

Some tinkerers, DIYers, and cosplayers love 3D printing miniatures and figurines.

Key benefits and limitations of resin 3D printing

Benefits of LCD, DLP, and SLA 3D printing technologies

These are some of the advantages of 3D printing with resin:

- Ability to build small and very detailed parts or objects with fine, complex geometries

- Diversity of 3D printable resin materials (ceramic, metal, biocompatible, flexible, rigid, etc.)

- Smooth finish of the parts produced (no easily visible layers like with FFF 3D printers)

Limits of resin 3D printing

As with any technology, resin 3D printing has its limits:

- Post-processing is mandatory (removing delicate support structures, post-curing, resin removal, etc.) and requires a UV curing chamber for good results

- Requires time-consuming cleaning time (for the vat and for the 3D printed part)

- Very smelly and toxic fumes

- Safety precautions required when handling the material

Resin 3D printer price

Laser SLA resin 3D printer price

SLA 3D printer prices depend on many factors. The price for a basic SLA 3D printer kit like the Peopoly Moai usually starts at about $1,200. Industrial resin 3D printers, on the other hand, can reach several hundred thousand dollars.

The price for a basic SLA 3D printer kit like the Peopoly Moai usually starts at about $1,200. Industrial resin 3D printers, on the other hand, can reach several hundred thousand dollars.

DLP resin 3D printer price

The price of a DLP 3D printer generally starts around $2,000 or $3,000. DLP 3D printers with higher precision and more features cost around $10K to $20K. More expensive digital light processing 3D printers also exist.

LCD resin 3D printer price

LCD-based resin 3D printers are the most affordable resin 3D printer type. There are many LCD resin 3D printers available for under $1,000, and even under $300. Higher-quality LCD 3D printers may cost a few thousand dollars.

UV curing chamber price

Most resin 3D printer brands sell UV curing chambers separately, with prices starting around $300 to $500.

FAQ

What does SLA stand for in 3D printing?

In 3D printing, SLA stands for stereolithography.

What does DLP stand for in 3D printing?

In 3D printing, DLP stands for Digital Light Processing.

What does LCD stand for in 3D printing?

LCD stands for Liquid Crystal Display, which is a type of screen used in electronic devices (smartphone, TV, etc.). A growing number of resin 3D printers use an LCD screen’s light to cure light-sensitive resin and form objects in 3D.

What is SLA resin made of?

SLA resin is a photopolymer material, which is mainly composed of monomers, oligomers, and photoinitiators. Depending on the “recipe”, the stereolithography resin can be plastic, ceramic, or even metal-based.

How much does a resin 3D printer cost?

A resin 3D printer can cost anywhere from $500 to over $250,000. However, there are many resin 3D printers available for under $10,000.

What is a resin 3D printer?

A resin 3D printer (stereolithography) is a machine that solidifies liquid resin layer by layer to form an object in 3D.

Where are resin 3D printers for sale?

There are resin 3D printers for sale on major e-commerce sites like Amazon, AliExpress, GearBest, and Banggood. Online retailers specialized in 3D printing also exist, such as MatterHackers.

Photopolymer 3D printer

3D printers can be sorted not only by the printing technologies used, but also by the consumables used. In this section, we will look at devices that use photopolymer resins to build models.

- 1 Consumables

- 2 Laser stereolithography (SLA)

- 3 Projector stereolithography (DLP)

- 4 Multi-jet (MJM and PolyJet)

- 5 3D pens

- 6 Additional illumination

Consumables

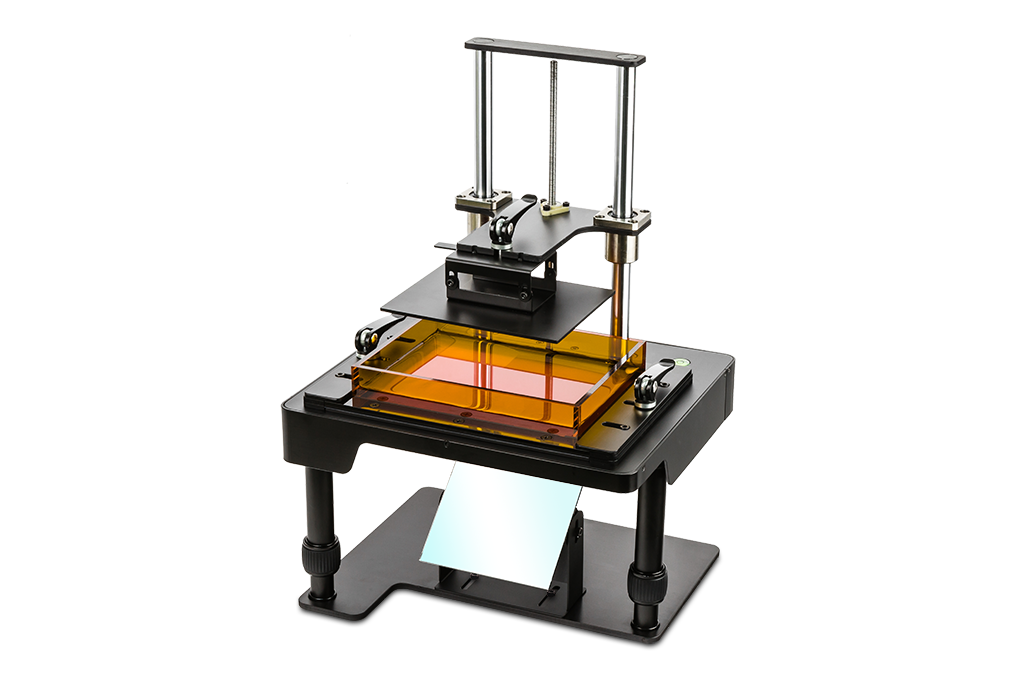

Photopolymer resins are liquid polymers that harden when exposed to light. As a rule, such materials are sensitive to the ultraviolet range, which determines the design of photopolymer printers. One of the common design elements is a transparent colored cap or housing made of a material that filters ultraviolet radiation. This is done both to protect the user's eyes and to protect the supplies inside the printer from exposure to sunlight and background lighting.

As a rule, such materials are sensitive to the ultraviolet range, which determines the design of photopolymer printers. One of the common design elements is a transparent colored cap or housing made of a material that filters ultraviolet radiation. This is done both to protect the user's eyes and to protect the supplies inside the printer from exposure to sunlight and background lighting.

Photopolymer resin loaded into Form 1 3D printer

The physical properties of resins after polymerization vary widely. Both rigid and flexible options are available, transparent and matte. A wide selection of colors is also available. Resin consistency and exposure times also vary, so a range of compatible media should be considered when choosing a printer.

The last aspect to consider when choosing a material is its toxicity. There are both quite toxic options and biologically safe ones.

The cost of consumables can be considered the Achilles' heel of photopolymer printing. The plants themselves are already reaching quite acceptable price levels, but it is still quite difficult to find inexpensive photopolymer resins. It is hoped that the proliferation of inexpensive photopolymer printers will lead to an increase in the production of consumables and lower prices.

The plants themselves are already reaching quite acceptable price levels, but it is still quite difficult to find inexpensive photopolymer resins. It is hoped that the proliferation of inexpensive photopolymer printers will lead to an increase in the production of consumables and lower prices.

Laser Stereolithography (SLA)

SLA Model

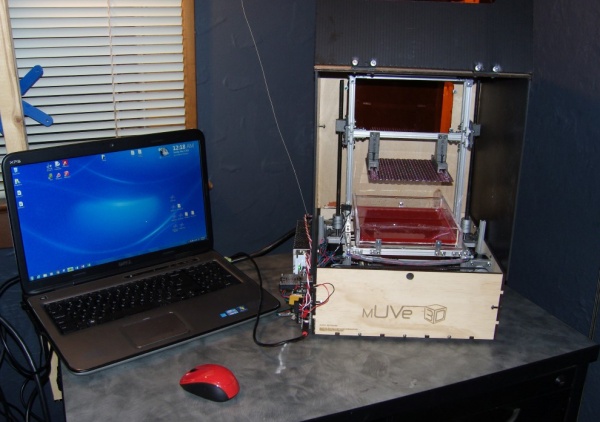

The firstborn of photopolymer printing and modern 3D printing in general. The technology was developed in 1984 by Charles Hall, who later founded 3D Systems.

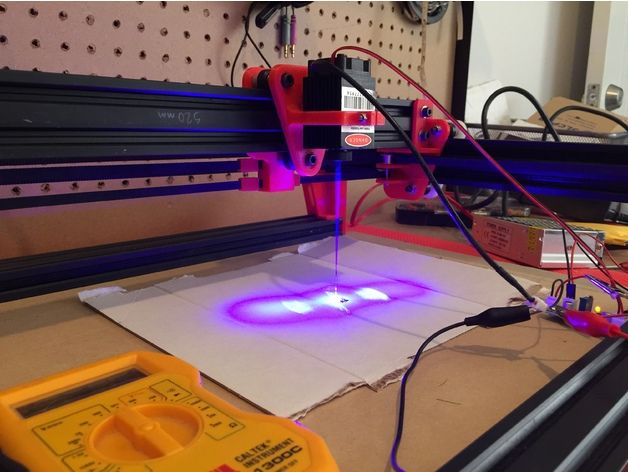

SLA printers use laser emitters to cure the photopolymer supply.

A typical SLA printer consists of a consumable tray sitting under a build platform driven vertically by a raise/lower mechanism.

Alternatively, the cuvette itself can be driven - what matters is the relative movement of the platform and the container. Above the cuvette is a laser emitter and a mirror system for deflecting the laser beam.

During the printing process, the platform is immersed in the consumable for the thickness of one layer of the digital model.

Since photopolymer resins can be quite thick, a leveling mechanism is often used to speed up the process.

SLA printer operation scheme

After leveling, the process of illumination of the material begins. Illumination is produced by laser irradiation. Most photopolymer resins are designed to cure (polymerize) when exposed to ultraviolet light, which determines the choice of laser frequency. The movement of the beam along the X and Y axes is determined by the operation of the deflecting mirrors.

After the drawing of the layer is completed, the platform is immersed in the material for the thickness of one more layer, and the process is repeated with the drawing of the next layer of the digital model.

Model building animation

SLA printing takes quite a long time, and printers using this method tend to have relatively small build areas.

This is mainly due to the high cost of laser emitters: printing large objects with a single laser will take too much time, and installing additional emitters and mirrors will complicate the design, increase the dimensions of the installation and raise the price to an unacceptable level for most users.

Despite the success of this technology, projected stereolithography is considered to be a more promising, although very similar method.

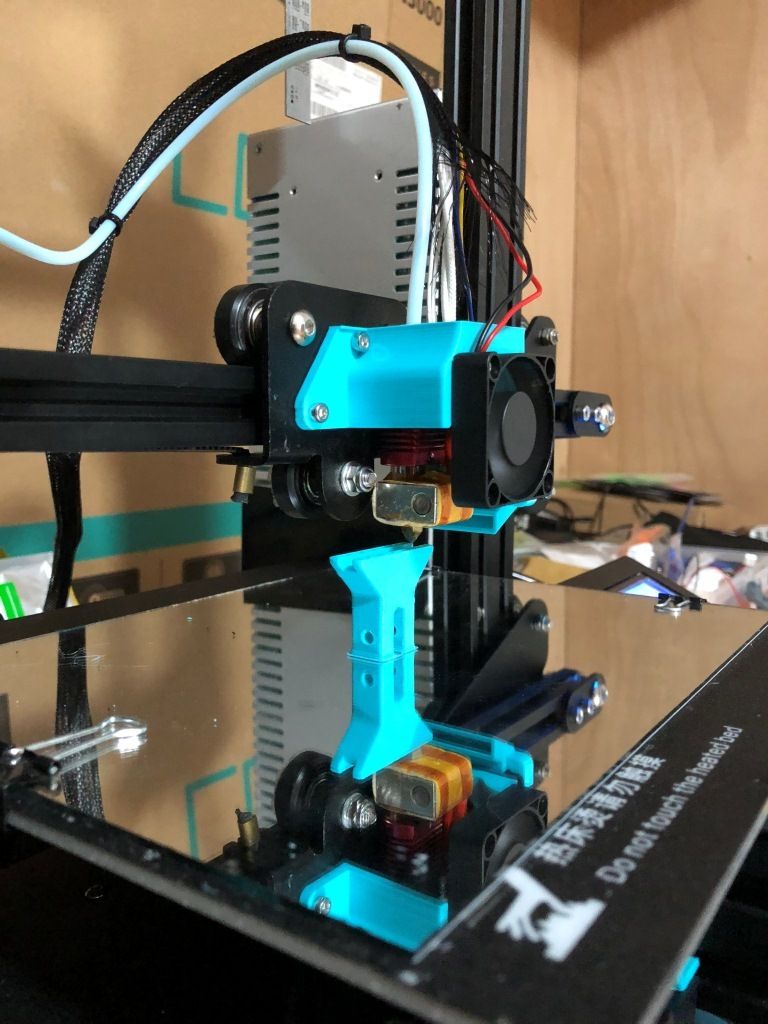

Projector Stereolithography (DLP)

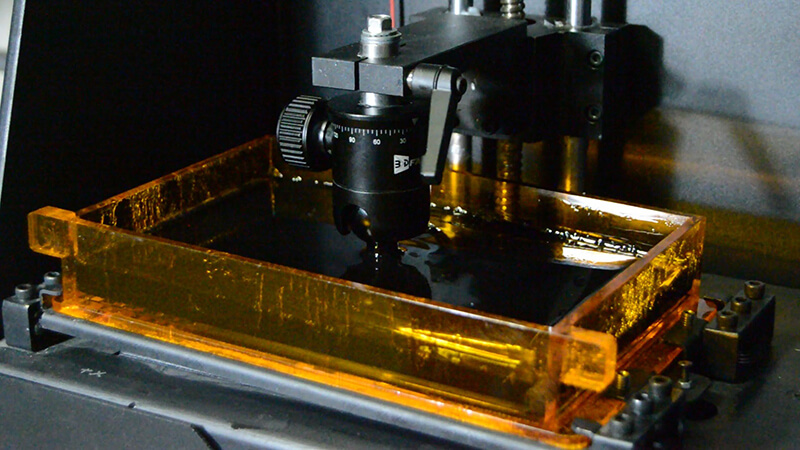

Formlabs Form 1 Desktop DLP Printer

A close relative of laser stereolithography, this method uses digital LED projectors instead of laser machines with mirror deflection systems. The method became popular due to the development of technology for the production of low-cost high-resolution digital projectors by Texas Instruments.

Layers are illuminated using a digital projector that highlights patterns of the entire layer, which distinguishes this method from SLA, where the "picture" emerges progressively using an ultraviolet laser.

A similar approach has previously been used on SGC-type plants, but this technology used physical photomasks, making the process costly, time consuming, slow and noisy.

At the moment, the FTI technology continues to exist - the development of SGC, almost indistinguishable from DLP printing, since it also uses digital LED projectors.

DLP printer design

Simultaneous illumination of an entire layer using projectors can significantly speed up the printing process even compared to SLA printers that have a high scanning speed (ie beam movement).

In addition, these printers are less sensitive to rough physical impact due to the absence of delicate mirror systems.

The absence of mechanical mirror systems improves accuracy. Finally, the cost of projectors sets them apart from laser systems.

Projection size can be quite significant, reaching the average of popular FDM printers.

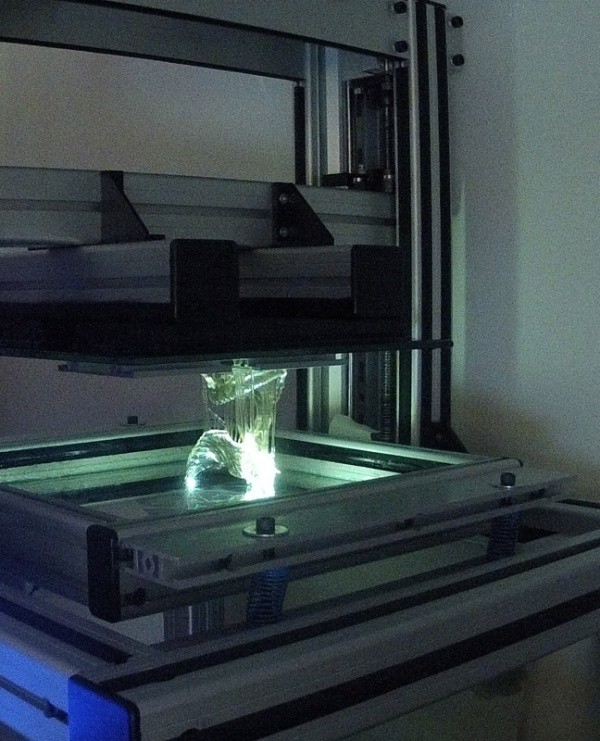

An interesting feature of DLP printers is the ability to "reverse" or "reverse" printing.

In this case, the projector is installed under a transparent (material choice for transparency in relation to ultraviolet light) cuvette, and the platform does not sink into the material, but gradually rises, pulling out the layers of exposed polymer.

This approach eliminates the alignment mechanism and achieves even higher Z resolution than SLA printers.

In addition, the size of models in height is not limited by the depth of the cuvette, which favorably affects the dimensions of the printer and the possibility of increasing the build area.

Multi-jet printing (MJM and PolyJet)

3D Systems ProJet 3500HDMax MJM printer

MJM and PolyJet technologies are practically indistinguishable from each other. The name difference comes from the respective patents: Multi Jet Modeling is owned by 3D Systems, while PolyJet is owned by rival Stratasys.

The very principle of multi-jet polymer printing was developed by the Israeli company Objet, which eventually became a division of Stratasys.

Multi-jet printing technology combines features of 3D inkjet printing (3DP) and projection stereolithography (DLP).

How the MJM PolyJet printer works

Models are built by spraying photopolymer using linear arrays consisting of multiple nozzles.

The applied layer is immediately exposed to ultraviolet lamps - as a rule, two processes occur simultaneously.

By the time the array reaches the end of the build chamber, the previously deposited material is hard enough to print a new layer.

Composite models created on the ProJet 3500 DP dental printer

This approach allows to achieve very high printing speed, but is characterized by high design complexity, which negatively affects the cost of such installations and limits their distribution to professional use.

One of the advantages of MJM and PolyJet technologies is the ability to create composite structures from photopolymer resins with different physical characteristics.

It is therefore possible to create models with easily removable supports, use multiple colors and use flexible and rigid materials in parallel within the same model.

3D Pens

CreoPop 3D Pen

Recently, there has been a craze for hand-held printing devices called 3D pens. At the moment, there are three main options for such devices: drip-jet pens (DOD), called BioPen and used in the development of new methods for treating damaged tissues, FDM 3D pens, which are manual extruders (essentially similar to the usual hot glue guns, but using thermoplastics) and developments in 3D-drawing with photopolymer resins.

CreoPop 3D pen was the first "handheld resin printer". The design of this device is quite simple, because the most complex function, positioning, is performed by the user himself. The pen only extrudes resin through the tip surrounded by LED emitters.

CreoPop 3D pen in action

This way the resin hardens immediately after application, allowing you to literally draw on air.

The advantage of such handles over FDM-analogues is the low operating temperature - there are no heating elements in the device. As a result, with such pens you can even draw on the skin.

In addition, a wide range of photopolymer resins with different physical properties can be used with such devices, which greatly expands the range of possible applications. At a minimum, this is a relatively inexpensive, but entertaining toy.

The only drawback is the relatively high cost of consumables, but such devices are unlikely to require large volumes of photopolymer resin when used in everyday life.

Additional Lighting

Final Lighting of Resin Models in a Homemade Camera

Full curing of models can take quite a long time, so models during SLA and DLP printing are only partially polymerized, sufficient to maintain the physical shape of the part.

After production, the models are usually placed in chambers equipped with ultraviolet lamps until fully cured. Of course, if possible, you can simply lay out the models in the sun - the effect will be the same.

Of course, if possible, you can simply lay out the models in the sun - the effect will be the same.

Just keep in mind that ordinary glass practically does not transmit ultraviolet light, so exposure to sunlight must be direct.

If desired, a UV-transparent quartz glass container can be used.

Go to the main page of the Encyclopedia of 3D Printing

Selective Laser Sintering (SLS) 3D Printing Guide

Selective Laser Sintering (SLS) 3D printing is a technology trusted by engineers and manufacturers across industries to create durable and functional models.

In this detailed guide, we'll explain selective laser sintering technology, the different systems and materials on the market, the workflow and different applications of SLS printers, and when to choose 3D printing with this technology over others. additive and traditional manufacturing methods.

White paper

Looking for a 3D printer to create durable, functional models? Download our white paper to learn how selective laser sintering (SLS) technology works and why it is popular in 3D printing for functional prototypes and end-use products.

Download white paper

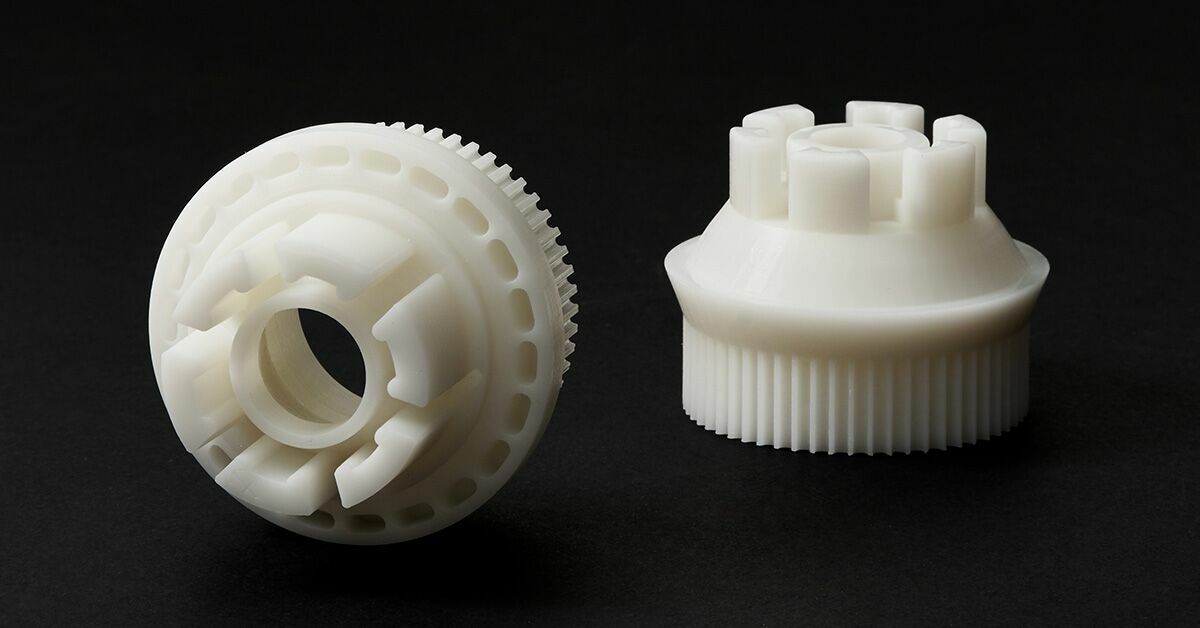

Selective laser sintering (SLS) is an additive manufacturing technology that uses a powerful laser to sinter fine polymer powder particles into a solid structure based on a 3D model.

SLS 3D printing has been popular with engineers and manufacturers for decades. With its low model cost, high productivity, and common materials, this technology is well suited for a wide range of applications, from rapid prototyping to low-volume production, limited trial runs, or custom-made products.

Recent advances in technology, materials and software have opened up the possibility of SLS printing to a wider range of companies. Previously, such tools were used only in a few high-tech industries.

Introducing the Fuse 1 high performance SLS 3D printer, finally available.

Webinar

Watch our product demo to learn about Fuse 1 and SLS 3D printing from Formlabs.

Watch webinar

Schematic representation of the selective laser sintering process. The SLS method uses a powerful laser to sinter small particles of polymer powder into a solid structure based on a 3D model.

-

Seal: A thin layer of powder is applied to the top of the platform inside the working chamber. The printer preheats the powder to just below the melting point of the feedstock. This allows the laser to more easily raise the temperature of certain areas of the powder bed and monitor the solidification of the model. The laser scans the cross section of the 3D model, heating the powder to the material's melting temperature or just below. Particles are mechanically joined together to form a single solid object. The unsprayed powder supports the model during printing and eliminates the need for special support structures. The platform is then lowered into the working chamber one layer, typically 50-200 µm thick, and the process is repeated for each layer until the models are complete.

-

Cooling down: after printing and before post-processing, the build chamber should cool down a little in the printer body, and then outside the body, to ensure optimal mechanical properties of the models and avoid their deformation.

-

Post-processing: finished models must be removed from the working chamber, separated from each other and cleaned of excess powder. The powder can be recycled and printed models can be blasted or tumbled.

To learn more about the workflow, see the SLS 3D Printing Workflow section below.

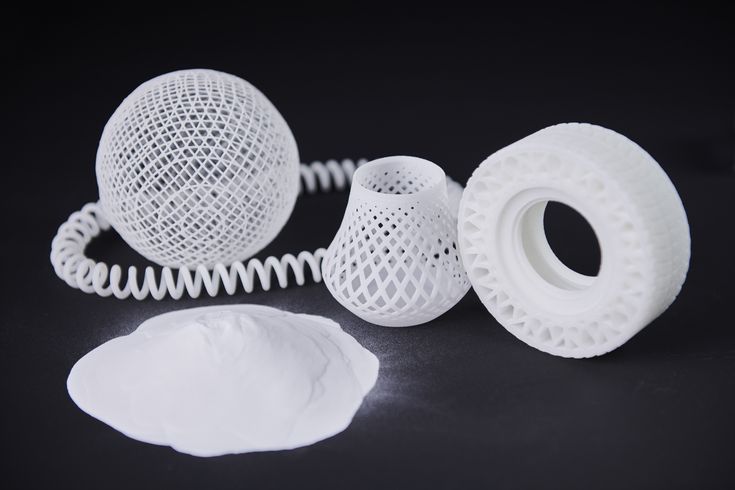

Models created using SLS technology have a slightly grainy surface, but the layer lines are almost invisible. To achieve a smooth surface, SLS models are recommended to be blasted or tumbled. This sample was printed on a Fuse 1 industrial 3D printer with SLS technology for workshops from Formlabs.

The green powder supports the model during printing and eliminates the need for special support structures. This makes SLS ideal for complex geometries, including internal features, undercuts, thin walls, and negative draft features.

This makes SLS ideal for complex geometries, including internal features, undercuts, thin walls, and negative draft features.

Models created using SLS 3D printing have excellent mechanical properties: their strength is comparable to that of injection molded models.

Compare Selective Laser Sintering (SLS) 3D printing with other common plastic modeling technologies: Fused Deposition Modeling (FDM) and Stereolithography (SLA).

Selective Laser Sintering (SLS) is one of the first additive manufacturing technologies developed in the mid-1980s by Dr. Carl Deckard and Dr. Joe Beeman at the University of Texas at Austin. Since then, the method has been adapted to work with a variety of materials, including plastics, metals, glass, ceramics, and various powdered composite materials. Today, all of these technologies are classified as wafer synthesis, additive manufacturing processes that selectively sinter regions of a powder layer under the influence of thermal energy.

The two most common substrate synthesis systems currently available are a plastic based method commonly referred to as Selective Laser Sintering (SLS) and a metal based method known as Direct Metal Laser Sintering (DMLS) or Selective Laser Melting (SLM). ). Until recently, both systems were very expensive and complex, which limited their use to the production of small batches of expensive models or custom-made products, such as aerospace components or medical devices.

Innovation in this area will make plastic-based SLS as affordable as other 3D printing technologies such as stereolithography (SLA) and Fused Deposition Modeling (FDM) and widely available in affordable, compact systems.

All selective laser sintering 3D printers use the process described in the previous section. Basically, such printers differ in the type of laser, the volume of printing and the complexity of the system. Different solutions are used for temperature control, powder dosing and layering in different devices.

Selective laser sintering technology requires high precision and strict control during the printing process. The temperature of the powder and (incomplete) models must be controlled within 2°C during the three stages of production: preheating, sintering and storage before extraction, in order to minimize warping, stress and thermal deformation.

For decades, selective laser sintering has been one of the most popular professional 3D printing technologies, but due to its complexity, strict requirements and high price, only service bureaus and large enterprises could use it.

Conventional industrial SLS 3D printing systems have one or more powerful lasers. An inert atmosphere (nitrogen or other gases) is needed to prevent the powder from oxidizing and breaking down during the printing process, which requires specialized air handling equipment.

These installations also require special heating, ventilation and air conditioning (HVAC) systems and industrial power supplies. In addition, even the smallest industrial installations occupy an area of at least 10 square meters. m.

In addition, even the smallest industrial installations occupy an area of at least 10 square meters. m.

Due to the high initial cost of approximately $100,000 (and much more for complete solutions), traditional industrial systems with SLS technology were out of reach for many enterprises.

As with other 3D printing technologies such as Fused Deposition Modeling (FDM) and Stereolithography (SLA), more affordable, compact systems with SLS technology have recently begun to appear on the market. However, these solutions had significant drawbacks. These include low quality models and complex manual workflows due to a lack of post-processing solutions. This severely limited their use in industrial production.

The Formlabs Fuse 1 printer is in a new category with these deficiencies fixed . It is the first industrial SLS 3D printer for the workshop, delivering high quality, compact size, streamlined workflow, and cost far less than traditional industrial systems of the same type.

The Fuse 1 printer does not require any special infrastructure and will easily fit into your workplace.

The Fuse 1 uses a single laser and has a smaller working chamber that requires less heat. The powder is exposed to elevated temperatures for a shorter period of time, so there is no need for inert gases and specialized ventilation equipment. Thanks to its lower power consumption, it can run on a standard AC power supply without requiring special infrastructure.

The Fuse 1 features patent pending Surface Armor technology. This creates a semi-baked shell that heats evenly around the models as they are printed. This results in excellent surface quality, stable mechanical properties, high reliability and a high material renewal rate.

In addition, to provide a compact, self-sustaining ecosystem and complete powder handling capability, Fuse 1 is complemented by the Fuse Sift Station, a separate stand-alone device for model retrieval, recovery, storage and powder mixing.

Overall, the Fuse 1 industrial 3D printer with SLS for workshops has slightly less print volume than traditional entry-level SLS systems, but is smaller, easier to work with and less expensive.

| Fuse 1 Industrial SLS Workshop Printer | Traditional Industrial SLS 3D Printers | from 18,500 US dollars | 100 000 - 500,000 US dollars and more than | |||

|---|---|---|---|---|---|---|

| Press volume | to 165 x 165 x 300 mm | to 550 x 550 x 750 mm | 90EAL BenefitsAvailability High quality models High performance Simplified workflow Compact dimensions Low maintenance | High print volume High quality models High performance Many material options | ||

| Disadvantages | Less print volume Limited material options | Expensive equipment Big sizes Infrastructure Requirements Large amount of maintenance Special Operator Required |

The most common selective laser sintering (SLS) material is nylon. It is a high performance engineering thermoplastic for both functional prototyping and end-use fabrication. Nylon is ideal for the production of complex knots and strong models with high environmental resistance.

It is a high performance engineering thermoplastic for both functional prototyping and end-use fabrication. Nylon is ideal for the production of complex knots and strong models with high environmental resistance.

3D printed SLS nylon for strength, rigidity and durability. The final models are impact-resistant and highly wear-resistant. Nylon is resistant to UV, light, heat, moisture, solvents, temperature and water. Nylon models printed on a 3D printer are also biocompatible and do not cause allergic reactions. This means that they can be worn and used safely in many situations.

Nylon is ideal for a range of functional applications, from consumer product design to healthcare applications.

Nylon is a synthetic thermoplastic polymer from the polyamide family. It is available in several versions, each designed to print different products. Nylon 12 Powder has a wide range of applications and is a general purpose, general purpose SLS 3D printing powder. Nylon 12 GF Powder is a composite material with a high fiber content, increased stiffness and heat resistance for difficult industrial conditions. Nylon 11 Powder helps fill a gap in prototyping and end-use applications where increased ductility, impact resistance and the ability to withstand wear without brittle fracture are required.

Nylon 11 Powder helps fill a gap in prototyping and end-use applications where increased ductility, impact resistance and the ability to withstand wear without brittle fracture are required.

- Impact proof prototypes, fixtures and fittings

- Thin-walled pipes and bodies

- Rivets, fasteners and latches

- Orthopedic products and prostheses*

- High Performance Prototyping

- Small batch production

- One-piece clamping and holding fixtures and tooling

- Conventional SLS models

- Heavy-duty clamping and fastening fixtures and spare parts

- Continuous models

- Threads and sockets

- High temperature models

* Material properties may vary depending on model design and manufacturing method. It is the manufacturer's responsibility to confirm the suitability of printed models for their intended use.

| 40% | ||||||

| extension when rupture, Z (%) | 6% | 3% | ACCOUSSIBLE | |||

|---|---|---|---|---|---|---|

| DISCOUNTION ON THE CURSED | 3 J/M | JO/MJ/M | J/M | J/M | 3 | 71 J/m |

Bending temperature under load at 1. 8 MPa (°C) 8 MPa (°C) | 87 °C | 113 °C | 46 °C | 170°C | 171°C | 182 °C |

Nylon 12 Powder and Nylon 11 Powder are one-component powders, but some SLS 3D printers can also use two-component powders, such as coated powders or powder blends.

Nylon 12 GF Powder is a composite material with a high fiber content, while other nylon composites with aluminide, carbon or glass are designed to increase the strength, stiffness or flexibility of models. In such two-component powders, only the component with the lower glass transition point is sintered, which binds both components.

SLS 3D printing accelerates innovation and helps businesses in a wide range of industries such as engineering, manufacturing and healthcare.

Manage the entire product development process, from iteration of first concept design to production of ready-to-use products:

- Rapid Prototyping

- Product mockups for user feedback

- Functional Prototyping

- Functional testing of products under severe conditions (e.

g. piping, brackets)

g. piping, brackets)

Manage your supply chain and respond quickly to changing needs:

- End-Use Manufacturing

- Small batch production

- Mass production of new customized consumer products

- Spare parts manufacturing, supply chain sustainability

- Durable, durable clamping and fastening devices (such as clamps and clamps) and accessories

- Custom manufacture of automotive, motorcycle and marine equipment parts, and restock military items on demand

Self-manufacturing of ready-to-use medical devices, taking into account the individual characteristics of patients:

- Prototyping of medical devices

- Prostheses and orthotics (e.g. prosthetic limbs and orthoses)

- Surgical models and instruments

- End-Use Products (Nylon 12 is biocompatible and can be sterilized*)

* Material properties may vary depending on model design and production method. It is the manufacturer's responsibility to confirm the suitability of printed models for their intended use.

It is the manufacturer's responsibility to confirm the suitability of printed models for their intended use.

Use any CAD software or 3D scan data to design the model and export it to a 3D printable format (STL or OBJ) file. All printers with SLS technology use software that allows you to adjust settings, position models, estimate print times, and layer your digital model. Once set up, the model preparation software sends commands to the printer via a wireless or cable connection.

The Fuse 1 uses PreForm print preparation software (free download). It allows you to easily duplicate and place multiple models on a 3D grid to maximize your print volume. PreForm automatically suggests the optimal orientation and position of models with the ability to make manual changes.

The workflow for preparing the printer varies from system to system. Most traditional SLS systems require extensive training, tools, and physical actions to prepare and maintain them.

Fuse 1 redefines the SLS workflow, making it simple and efficient, as well as providing trouble-free printing and complete powder handling thanks to modular components.

The Fuse 1 can be easily loaded with powder using a special cartridge.

The Fuse 1 uses a detachable build chamber so you can start a new print while the previous build chamber is still cooling.

Once all pre-checks have been completed, the machine is ready to print. Depending on the size and complexity of the 3D models, as well as their density, printing using SLS technology can take from several hours to several days.

When printing is completed, the build chamber in the housing should cool down a bit before proceeding with the next steps. To start the next print, you can remove the build chamber and insert a new one. Before post-processing, the working chamber must cool down to ensure optimal mechanical properties of the models and avoid their deformation. This can take up to half of the total print time.

Fuse 1 is equipped with a touch screen that allows you to see in real time how each new layer is formed during the printing process. This camera image can also be transferred to a computer using PreForm to monitor the print without leaving the workplace.

Compared to other 3D printing processes, post-processing of SLS-printed models requires minimal time and effort. With no supporting structures, it is easy to scale and provides consistent results across batches of models.

After printing is completed, remove the finished models from the build chamber, separate them and clean them of excess powder. As a rule, this is done manually at the cleaning station using compressed air or a jet apparatus.

The excess powder left after the creation of the model is filtered to remove large particles from it. After that, it can be recycled. Under the influence of high temperature, the properties of green powder deteriorate slightly, so for subsequent printing it must be mixed with new material. Due to the possibility of reusing materials, SLS technology produces a minimum amount of waste.

SLS technology typically uses separate devices for powder recovery, storage and mixing. The Fuse 1 workflow uses a single Fuse Sift to retrieve patterns and greens, store, dispense, and mix material streams.

Fuse Sift completes the Fuse 1 SLS printing workflow. This system is used for safe and efficient model retrieval and powder recycling.

Fuse Sift automatically doses and mixes used and new powder, reducing waste and controlling powder delivery.

After the powder has been sifted, the 3D models printed using selective laser sintering technology are ready for use. However, there are a few more post-processing steps you can perform on these models.

By default, the surface of 3D models created using SLS technology remains grainy. To achieve a smooth surface, Formlabs recommends blasting or tumbling models made using this method. Models can be spray painted, lacquered, electroplated or otherwise to achieve the desired color, surface quality and properties such as water resistance (special coating) and electrical conductivity (electrolytic coating). Models created with SLS Formlabs are dark in color and therefore not well suited for staining.

Immersion printed SLS model from Partial Hand Solutions.

SLS models can be electroplated for a metal-like surface.

Selective laser sintering is preferred by engineers and manufacturers for its wide design options, high productivity, low model cost and proven end use materials.

Most additive manufacturing processes, such as stereolithography (SLA) and Fused Deposition Modeling (FDM), require specialized support structures to fabricate overhang structures.

Support structures are not needed for selective laser sintering, as unsintered powder surrounds the model during printing. SLS printing makes it easy to create overhangs, intricate geometries, interconnecting parts, internal channels and other intricate details.

Intricately patterned arm splint for weight reduction.

Engineers typically design models in terms of the capabilities of the final manufacturing process, also known as design-to-technology (DFM). When additive manufacturing is only used for prototyping, it comes down to creating models and designs that can be replicated in the manufacturing process using traditional tools.

Selective laser sintering is emerging as a viable rapid manufacturing method and its application area continues to expand, so it can open up new possibilities in design and construction. 3D printers with SLS technology can create complex geometries that are impossible or incredibly expensive to manufacture using traditional processes. SLS technology also allows design professionals to combine complex assemblies into a single model that would normally require multiple models to be created. This helps avoid the problem of loose connections and saves assembly time.

Selective laser sintering can unleash the potential of generative design, as it allows the creation of lightweight models that use complex lattice structures that cannot be fabricated with traditional methods.

Selective laser sintering is the fastest additive manufacturing technology for producing functional, durable prototypes and end-use products. Lasers used for powder sintering have much faster scanning speeds and are more accurate than the layering methods used in other processes such as Industrial Fused Deposition Modeling (FDM).

To maximize the available print volume in each printer, multiple models can be placed side by side. Operators can use the software to optimize print volume and maximize productivity by leaving only minimal clearance between models.

SLS technology allows operators to fill the build chamber with as many models as possible, as it allows them to be printed without supporting structures, saving time in post-processing.

SLS 3D printing requires the right materials for functionality and versatility. Nylon and its composites are proven, high quality thermoplastic materials. Laser-sintered nylon models have close to 100% density and mechanical properties that are comparable to products made using traditional manufacturing methods such as injection molding.

Screwdriver printed in Nylon 12 Powder. After a simple post-processing, nylon models have a smooth, professional quality surface.

SLS Printable Nylon is an excellent replacement for conventional injection molded plastics. The latches and other mechanical connections produced from it are superior to products created using any other additive manufacturing technology. It is ideal for making functional plastic parts that will work and not break down over time like products created through other additive manufacturing methods.

The latches and other mechanical connections produced from it are superior to products created using any other additive manufacturing technology. It is ideal for making functional plastic parts that will work and not break down over time like products created through other additive manufacturing methods.

When calculating the cost of one model, it is usually necessary to take into account the cost of ownership of equipment, material costs and labor costs:

-

Equipment cost of ownership: The more models a printer can produce over its lifetime, the lower the cost per model. Therefore, higher performance results in a lower cost of ownership per model. With high laser scanning speeds, the ability to produce multiple models at once to maximize the working volume, and a simple post-processing process, SLS 3D printing guarantees the highest productivity of any additive manufacturing method.

-

Material: Most 3D printing technologies use proprietary materials, while nylon is a common thermoplastic that is produced in large quantities for industrial applications.

This makes it one of the most inexpensive raw materials for additive manufacturing. SLS 3D printing requires no support structures and allows you to print with recycled powder with minimal waste.

This makes it one of the most inexpensive raw materials for additive manufacturing. SLS 3D printing requires no support structures and allows you to print with recycled powder with minimal waste. -

Labor: Labor is a disadvantage of many 3D printing solutions. Work processes in most technologies are quite laborious and difficult to automate, which can significantly affect the cost of one model. Easy post-processing with SLS printing reduces manual labor and allows for easy scalability.

A 3D printer with SLS technology is a significant investment initially, but this investment often pays off even faster than buying smaller devices. SLS for workshop technology significantly reduces initial acquisition costs and also reduces model costs in most applications.

If 3D printing is rarely used in your business, it is recommended to use the services of third-party service bureaus. But in this case, the cash costs will be higher and you will have to wait longer for the order to be completed. One of the main advantages of 3D printing is its speed compared to traditional production methods. But this advantage loses its value when it takes up to several weeks for a third-party company to deliver a model.

One of the main advantages of 3D printing is its speed compared to traditional production methods. But this advantage loses its value when it takes up to several weeks for a third-party company to deliver a model.

REEKON Tools