Largest home 3d printer

The Best Large 3D Printers in December 2022 (Every Price)

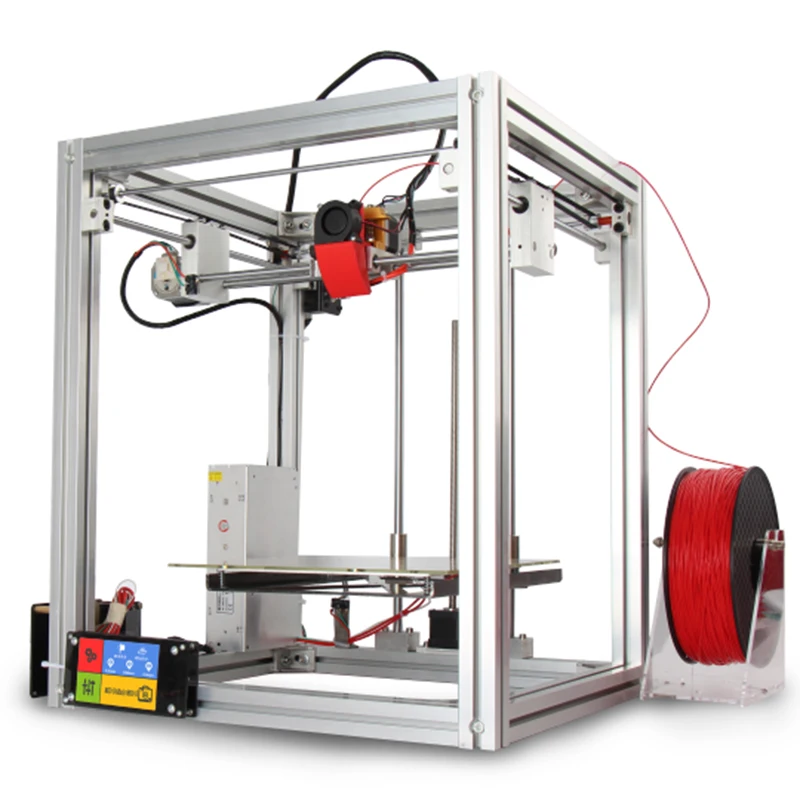

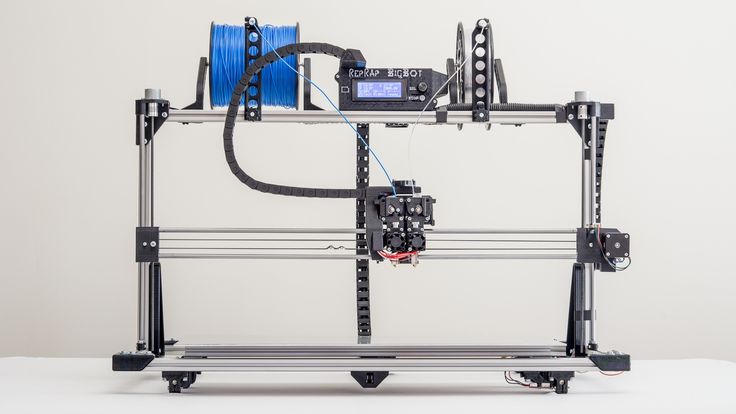

Some may be content printing within the confines of their small, desktop FDM 3D printer — but for big home projects, or large prototyping, size matters. For these bigger jobs, you’ll need a large 3D printer capable of printing the Goliath structures they need for their commercial business or hobbyist project.

So, whether you want to print large-scale figures, model cars or cosplay helmets as home projects, or large commercial prototypes, we’ve split this article into two sections covering both:

- The best under $1,000 (the largest 3D printers for home use)

- The best large-scale 3D printers for commercial use

Here are our top picks overall:

BUDGET PICK

Ender 5 Plus

Lowest cost reliable large 3D printer

Very versatile and upgradeable

Excellent 350x350x400mm build volume

Available at creality here Amazon here

MID-RANGE PICK

Anycubic Kobra Max

Even larger 450 x 400 x 400 mm print area

Upgraded accuracy and print speed

The largest 3D printer under $1000

Available At anycubic here Amazon here

PREMIUM PICK

Ultimaker S5

Fantastic 20-micron precision

Optional Pro Bundle adds on filament holder and air filter

Excellent for large part prototyping

Available at Dynamism here matterhackers here

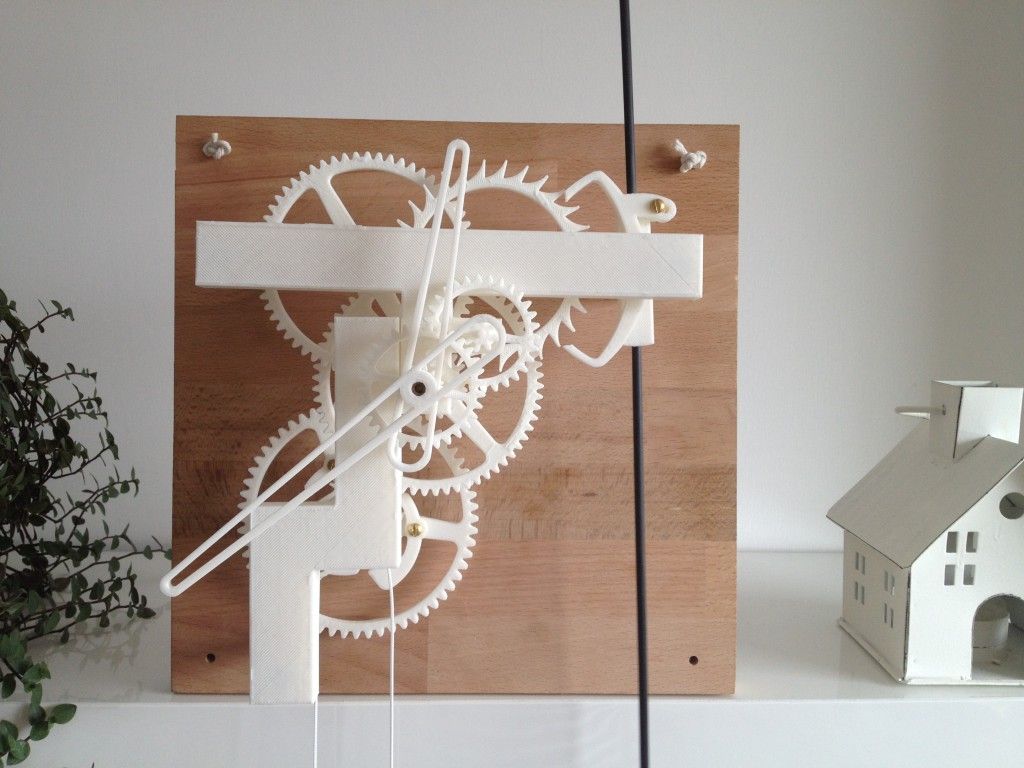

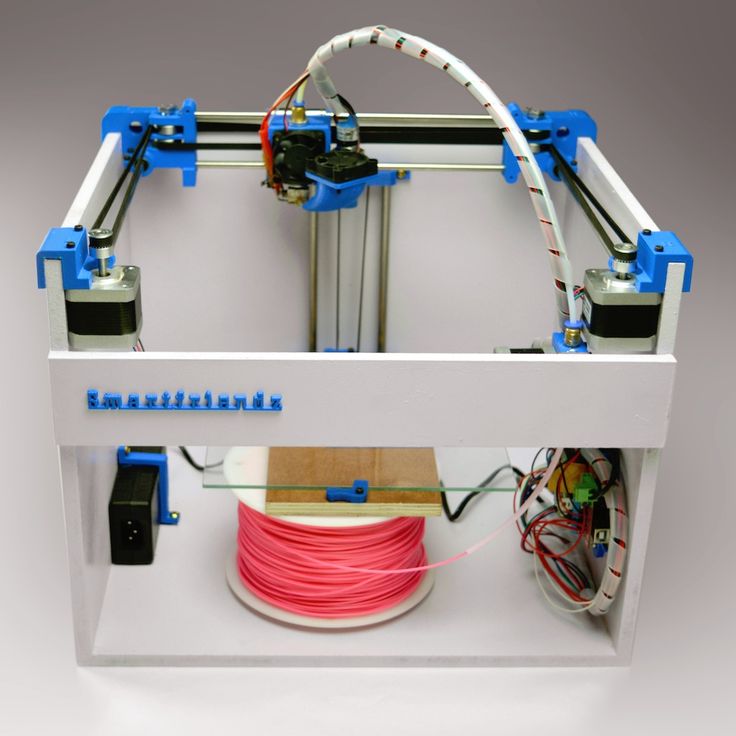

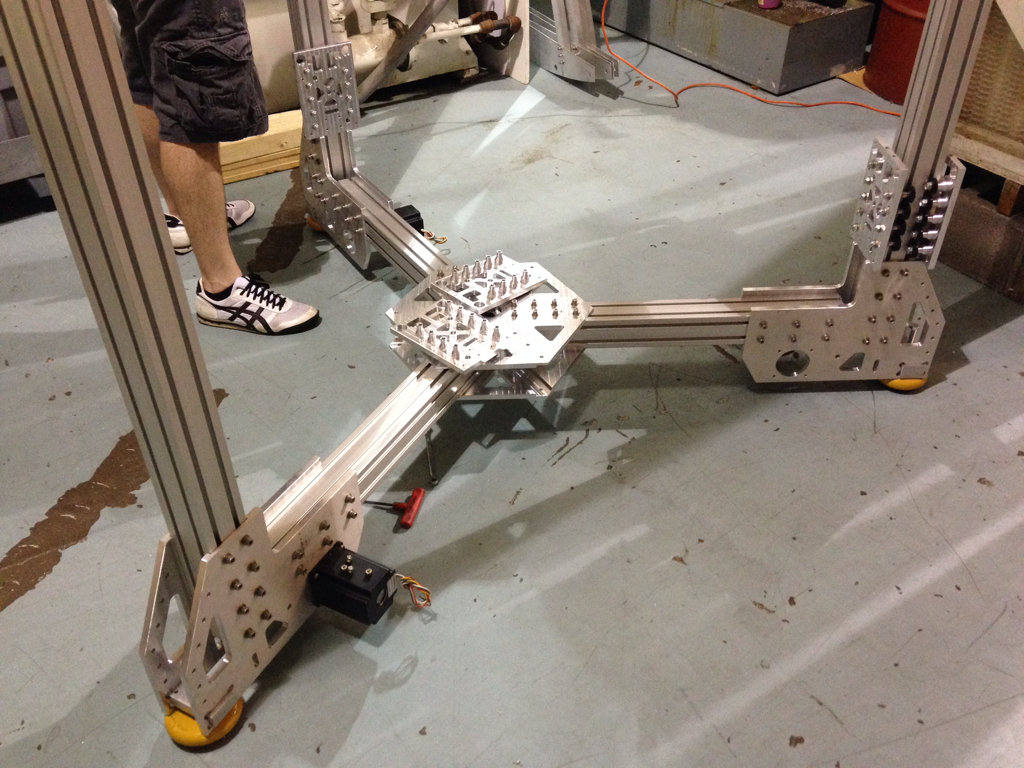

Some inspired makers have even built enormous 850mm tall printers at home as DIY projects.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

This article includes the best large bed 3D printers, as well as buying guide with what factors to consider when buying a larger printer, tips and tricks for printing based on the elements that change as you scale up print bed size, and some FAQs on large-scale printing.

| Brand and Name | Max Print Size (mm) | Price | Where To Buy for Best Price? | Alternative Purchase Option |

|---|---|---|---|---|

| FLSUN QQ-S PRO | 255 x 255 x 360 | $369 | Amazon here | |

| Qidi Tech X-Plus | 270 x 200 x 200 | $699 | Amazon here | |

| Tronxy X5SA PRO | 330 x 330 x 400 | $399 | Amazon here | |

| Creality CR-10 MAX | 450 x 450 x 470 | $1,099 | Amazon here | 3DJake UK & Europe |

| Peopoly Phenom | 276 x 155 x 400 | $1,999 | Matterhackers here | |

| Raise3D Pro2 / Pro2 Plus | 305 x 305 x 300 (605) | $3,999 / $5,999 | Pro2 on Amazon here | Dynamism Store here |

| BCN3D Sigma D25 | 420 x 300 x 200 | $3,995 | Dynamism Store here | Matterhackers here |

| Modix Big-60 V3 Kit | 600 x 600 x 660 | $4,700 | Matterhackers here | Dynamism Store here |

| Ultimaker S5 | 330 x 240 x 300 | $5,995 | Dynamism Store here | |

| BigRep Studio G2 | 1000 x 500 x 500 | Quote | BigRep |

Large 3D Printer Reviews: The Criteria

In assessing which of the following huge 3D printers deserved to be on our ranking, we used the following criteria:

- Size relative to price: a large print volume on a low-cost printer is relatively more impressive.

- Quality of print: it’s irrelevant if you can print larger objects if they come out looking terrible. Only high-quality XXL 3D printers made the cut.

- Enclosed or open build chamber: a large print area is more impressive on an enclosed 3D printer.

- Reliability, versatility and ease of use: what materials does it support, how simple is the printer’s interface to navigate, and how prone is the printer to errors.

Best Large 3D Printer – 2022 Reviews

Ender 5 Plus – the best budget large 3D printer

- Price: Check latest price at Creality here / Amazon here

- Build Volume: 350 x 350 x 400 mm

- Minimum Layer Height: 100 Microns

- Max Nozzle Temperature: 260°C

- Filament Compatibility: PLA, ABS, TPU, PETG

Pros

Lowest cost reliable large 3D printer

Very versatile and upgradable

Excellent 350x350x400mm build volume

Cons

Open air printer requires an enclosure for ABS to prevent warping in a more stable printing environment

A perennial favorite among makers that balances great value and large print capacity, the Ender 5 Plus delivers on its large-format promise with a roomy 350 x 350 x 400 mm build volume.

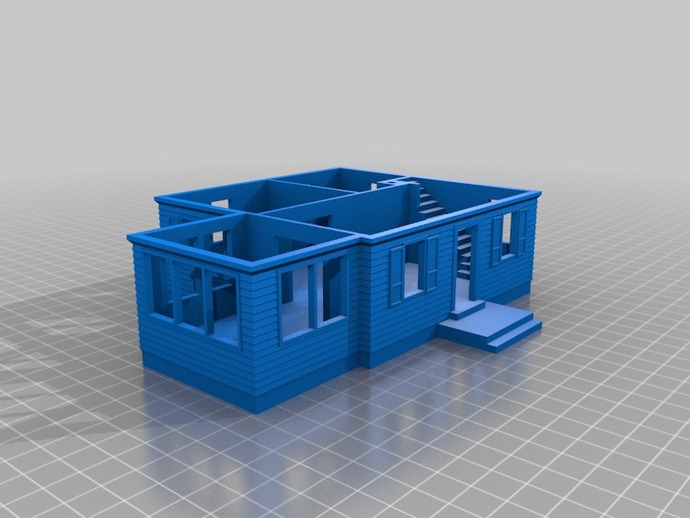

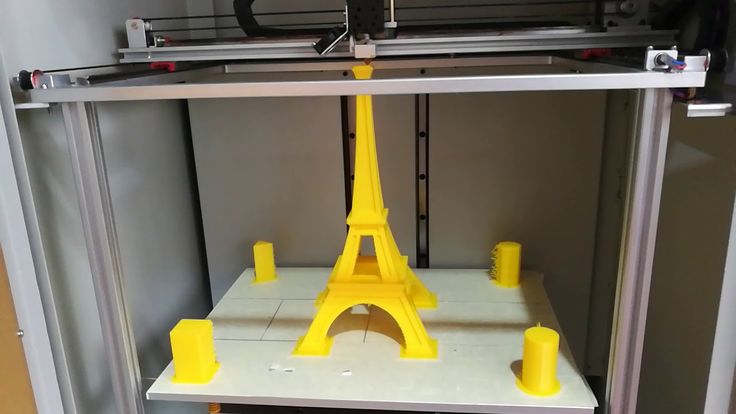

The capacity offered by the Ender 5 Plus opens the door to projects that simply aren’t on the cards with most standard-size printers: helmets, masks, cosplay props and accessories, tall vases, tabletop gaming terrain, and so on.

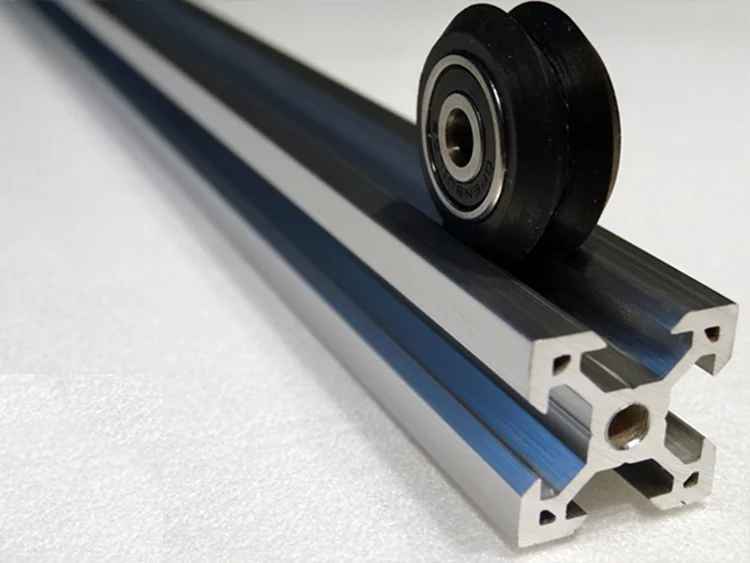

Size aside, the Ender 5 comes with other notable features. A pre-installed BLTouch automatic bed leveling probe makes easy work of calibrating the bed, while dual z-axis rods ensure smooth lead screw movement even when using the entire print bed for a huge print.

Speaking of axes, the Ender 5 uses a rather novel system whereby the Z-axis is responsible for lowering the bed. It’s bolstered by a beefy stepper motor that moves both belts on the Y-axis in unison for clean, precise movements that help reduce layer shifting.

Ender 5 Plus printing a mech. Source: TwitterExtras like print resume, a filament run-out sensor, and a removable tempered glass build platform, which delivers solid first-layer adhesion and ensures prints snap off cleanly with little effort, score points for ease of use.

If you’re partial to improving your printers through upgrades and modifications, the Ender 5 mimics its Ender 3 sibling with a wide array of upgrades available.

From 3D printed mods like cable strain relief brackets to extruder knobs all the way to purchased upgrades like an all-metal extruder, quiet mainboard, and why not a pivot to a direct drive system, there’s no shortage of ways to make the Ender 5 even better.

Anycubic Kobra Max – largest 3D printer under $1000

- Price: Check latest price at Anycubic here / Amazon here

- Build Volume: 450 x 400 x 400 mm

- Minimum Layer Height: 50 microns

- Max Nozzle Temperature: 260°C

- Filament Compatibility: PLA, ABS, PETG, TPU

Pros

Even larger 450x400x400mm area

Upgraded accuracy and print speed

Best large 3D printer under $1000

Cons

Open air printer requires an enclosure for ABS to prevent warping

The largest of Anycubic’s most recent batch of affordable large FDM printers, the Anycubic Kobra Max gives you a massive 450 x 400 x 400 mm – the largest build volume 3D printer under $600. That ultra-large build volume alone justifies a slot on our list, but there’s plenty more to like about the Kobra Max.

That ultra-large build volume alone justifies a slot on our list, but there’s plenty more to like about the Kobra Max.

Despite the large capacity, the Kobra Max is made stable by the dual z-axis threaded lead screws, each with a dedicated stepper motor and two support rods to reduce wobble and keep things running smoothly.

With a 50-micron minimum layer height, the Kobra Max delivers solid precision and can theoretically crank sprint speeds up to a dizzying 180 mm/s.

It also has a tempered carborundum glass print bed, coated with Anycubic’s proprietary Ultrabase microporous coating.Kobra Max printing models: a skeleton (Source: Reddit) and a 280% scale sluggo (Source: Reddit).

Elsewhere, Anycubic has bundled in its in-house-developed LeviQ fully automatic bed leveling. We tested it ourselves on the Kobra and continue to be impressed with the accuracy and hands-off, set-and-forget ease of use it delivers. Anycubic is on to something special here, and it’s a delight to see LeviQ ported over the larger Kobra Max.

Other notable features include filament runout detection, the same responsive 4.3″ touchscreen display found on the smaller Kobra, adjustable belt tensioners, an E3D Volcano-inspired hot end, and reasonably quiet operational noise levels at 58 dB.

Overall, it’s definitely the largest 3D printer for home use, and a reliable FDM pick.

Peopoly Phenom — Large Resin 3D printer

- Price: $1,999 — Available on Matterhackers here

- Maximum build volume: 276 x 155 x 400 mm

Pros

Largest set of resin 3D printers for the price

Super fast bulk printing due to resin printers curing entire layers at once

Cons

XY resolution falls slightly if you purchase a larger Phenom model

The Peopoly Phenom is the only resin 3D printer that features on our ranking. Resin printers are not known for having large print areas, making the Peopoly Phenom’s large size all the more impressive.

Peopoly first made a name for themselves following their successful Kickstarter campaign to bring the Peopoly Moai to market. Now they have the Phenom range, using MSLA technology (combining LCD screens with LED lights) to build parts.Phenom on a 49-hour print job (Source: Reddit) and a sample print (Source: Reddit).

Now they have the Phenom range, using MSLA technology (combining LCD screens with LED lights) to build parts.Phenom on a 49-hour print job (Source: Reddit) and a sample print (Source: Reddit).

The idea for an LCD 3D printer with a huge build area is a very good one. LCD 3D printing involves solidifying a whole layer of resin at once, unlike FDM where the 3D printer’s extruder needs to trace each layer. Combining this ability to print multiple objects simultaneously with a large format 3D printing area opens up possibilities for truly scalable 3D printing. It’s very exciting.

The printer itself is very impressive. 72-um accuracy is precise and will offer better surface finishes than almost all FDM 3D printers. Peopoly recommends you use their Deft resin, but this large 3D printer kit is compatible with those made by other manufacturers.

If you already own a smaller, low-cost resin printer like an Elegoo Mars or AnyCubic Photon, upgrading to the Phenom is easy as it also runs on the CHITUBOX.

Read more: the best large build volume resin 3D printers

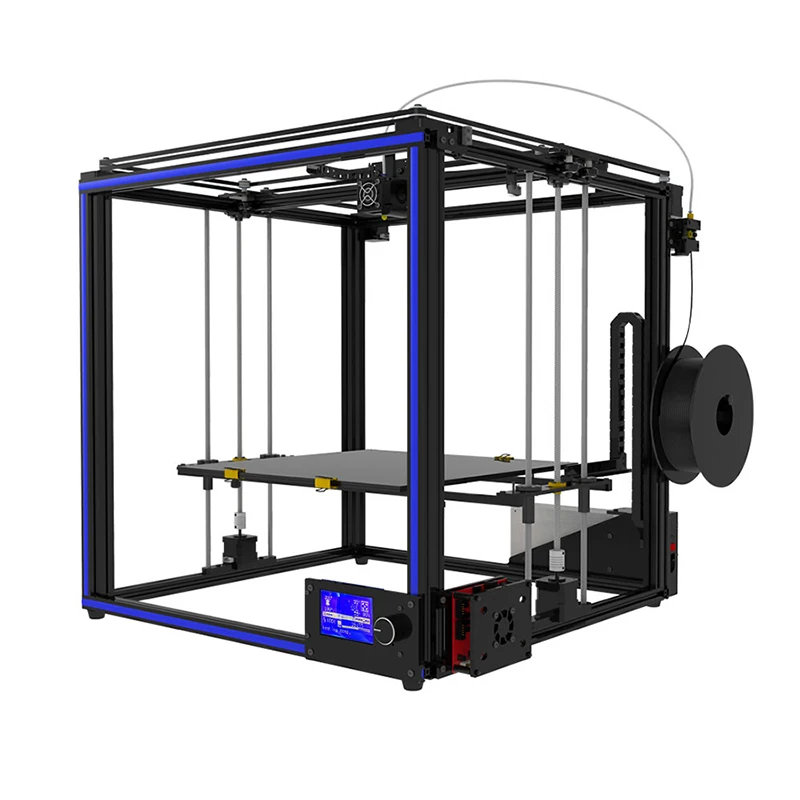

Modix Big-60 V3 Kit — huge 3D printer for heavy-duty use

- Price: $4,700 — Available at Matterhackers here / Available at Dynamism here

- Build volume: 600 x 600 x 660 mm

Pros

Excellent for large part prototyping

Premium parts – E3D hot ends and Duet3D controllers

Cons

Kit so needs to be assembled — rather than being plug’n’play

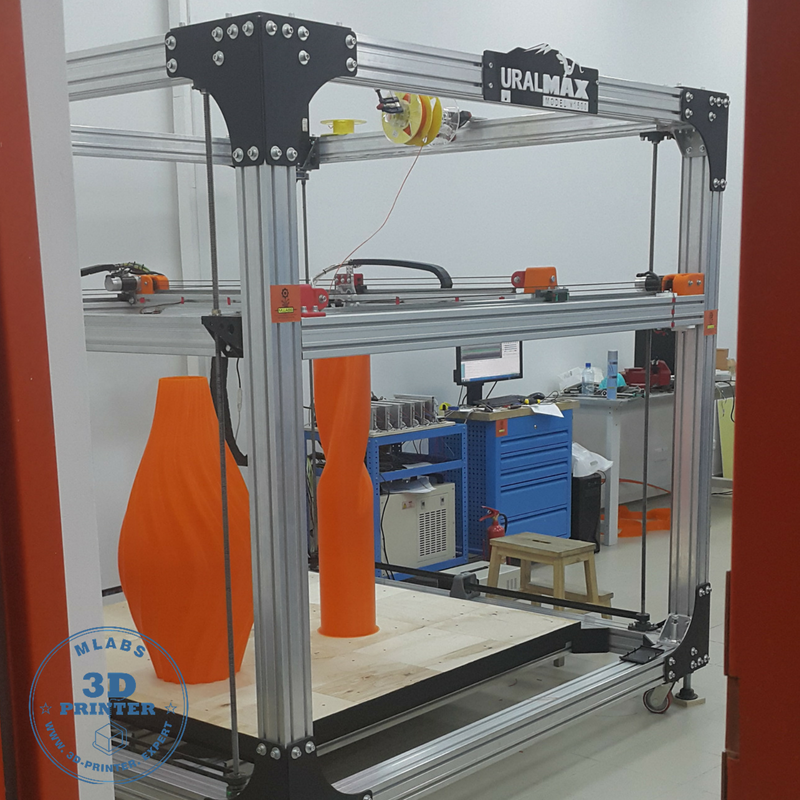

The Big-60 makes the previously mentioned printers look tiny, with its enormous 600 x 600 x 660 mm build volume able to print even the largest prototypes and parts in one large part.

This is a huge advantage as you can print these large models without having to assemble them together – so surface finish isn’t affected by post-processing.

It’s a large 3D printer kit, but experienced operators or 3D printing makers will have no trouble assembling the Model Big-60 V3, especially as it comes with such detailed instructions that take you through every step of the assembly process. Big-60 V3 printing a model. Source: Modix3D

Big-60 V3 printing a model. Source: Modix3D

The Big-60 V3 kit features premium parts all around, for example, a high-quality E3D hot end, and Duet3D controllers as standard. Despite being designed for industrial, heavy-duty use, the Big-60 is designed also to be modular enough that you can easily install any upgrades tailored to your 3D printing needs.

These could be custom, third-party upgrades, or any one of a number of available upgrades you can buy with the printer, such as the enclosure kit, a super high-temperature nozzle for industrial material printing like PEEK or ULTEM, or a secondary print head.

Overall, it’s a large area 3D printer but at a much lower medium-range price, and it’s certainly a large 3D printer for big 3D printer projects.

Modix Big 40 – Best 400mm 3D Printer

- Price: $5,250 — Available at Matterhackers here / Dynamism here

- Build Volume: 400 x 400 x 800 mm

- Minimum Layer Height: 40 microns

- Max Nozzle Temperature: 340°C

- Filament Compatibility: PLA, ABS, Carbon Fiber, Wood, Copper, Brass, Magnetic, PHA, PVA, HIPS, Nylon, TPE, TPU, PETG

Pros

Ideal for tall part production with 800mm z-axis height

Seamless workshop/small business workflow: 7” ergonomic touchscreen, accessible WiFi, 100-point auto-levelling system for fast calibration

Cons

Kit so needs to be assembled — rather than being plug’n’play

While the Modix Big 60 V3 pitches towards a large uniform build volume on all axes, the Modix Big 40 is all about giving makers and businesses extra height to produce tall parts and models.

To achieve this, it offers a 400 x 400 x 800 mm build volume. Even a 3D printer with 400 x 400 x 400 mm is considered large, but the Modix Big 40 doubles that again with higher z-axis.

The advantage is clear, with the Modix 40, you can print large pieces, such as leg prosthetics and towering prototypes, in a single print, removing the need to print in parts and assemble them post-print.

Turning to the Modix Big 60’s other specifications, it ships with Wi-Fi connectivity, 100-point mesh automatic bed leveling, a premium powder-coated laser cut chassis, and a 7′ inch touch screen.Printing with PVA. Source: Modix3D

Elsewhere it has a precise 40-micron minimum layer height, milled cast aluminum print bed, PEI print surface, and a proprietary Griffin print head consisting of a custom-made Bondtech extruder and an in-house developed hot end reaching up to 340°C with a heated bed to handle carbon fiber and other tough filaments.

Much like the Big 60 V3, the Modix Big 40 is all about options and additional upgrades, available when you order the printer. This suits small businesses with different needs and requirements, with upgrades including:

This suits small businesses with different needs and requirements, with upgrades including:

- An enclosure

- Second print head

- High-temperature nozzles

- An E3D Aero or E3D Volcano hot end

- Magnetic beds, casters, air filters, and more

Raise3D Pro2 & Pro2 Plus — Large Build Area 3D Printer for Small Businesses

- Pro2 Price: Check price on Amazon here / Dynamism Store here

- Pro2 Plus Price: Check price on Amazon here / Dynamism Store here

- Maximum build volume: 305 x 305 x 300 / 605 mm (300 mm for Pro2, 605 mm for Pro2 Plus)

Pros

Choice of standard or extra-large Pro2 Plus version

Excellent built-in analytics for in-depth real-time print analytics

Ideal prototyping 3D printer for industry

Cons

Newer versions are now available (but are more expensive)

Raise3D printers feature in our best 3D printer ranking as well as our best dual extruder 3D printer ranking — and for good reason.

It’s ideal for multi-material printing (for example, ABS with dissolvable HIPS supports) as well as standard large format printing — and we recommend it for any small business looking to print large prints and prototypes in-house.

Raise3D are a highly reputed 3D printing company whose printers are used by 3D printing services and small businesses as these large 3D printers can create big parts on demand. Expanded to a 605mm max part height, you should have no problems printing large structures with the Pro2 Plus.A Pro2 printing in vase mode (Source: Youtube) and a Pro2 Plus getting tuned up (Source: Reddit)

For a closed build chamber (with better temperature control), even the Pro2’s build volume is huge. But the Pro2 Plus expands it further, doubling the maximum height you can print up to a whopping 605 mm.

Not only is this colossal 3D printer large, but both the Pro2 and Pro2 have strong reputations for being reliable workhorses. And even if you do have a problem, Raise3D has a California-based support team to help solve your problems.

Raise3D cleverly appeals to the customer segments in between consumers and professional printers, offering industrial-grade quality on their large-format 3D printers but at lower than industrial prices. The 7-inch touchscreen and features offered make it feel like a factory-grade machine, when in fact even the Pro2 Plus costs the same as the Ultimaker S5.

BCN3D Sigma D25 — Large Workhorse 3D Printer

- Price: $3,995 — Available on Dynamism Store here / Available on Matterhackers here

- Build volume: 420 x 300 x 200 mm

Pros

IDEX dual extruder for multi-material, multi-color, or duplicate print options

Very reliable and well-known workhorse

Cons

Not as large as some other options on this list

Another very effective fused deposition modeling printer, Spanish industrial 3D printer manufacturer BCN3D have outdone themselves with their latest iteration of the Sigma range, the Sigma D25.

Featuring a dual extruder and immense print volume at 420 x 300 x 200 mm, the Sigma D25 still stands out for reasons other than just being a 3D printer with a large print bed. It’s extraordinarily versatile, happily printing with 3D printer filaments ranging from ABS and PLA to HIPS, ASA, and more.

However, this is no standard dual extruder — instead, BCN3D’s IDEX (independent dual extruder) system allows each of the extruders to move independently, vastly speeding up part production for similar parts, as well as allowing for multi-material printing and soluble filament printing, such as PVA.

Newly set up Sigma D25. Credit: Al DeanPerhaps most impressively, the Sigma’s duplication and mirror modes capitalize on its dual extruder to enhance the scalability of part production. Duplication mode prints identical models simultaneously, while mirror mode prints mirror designs to speed up part production.

The D25 has also been upgraded with a stainless steel frame to anchor down the X and Y axes and improve print quality and features E3D hotends and Bondtech extruders for extremely reliable and high-quality printing. It’s a large enclosed 3D printer- ideal for printing ABS and other high-temp filaments with a stable thermal environment.

It’s a large enclosed 3D printer- ideal for printing ABS and other high-temp filaments with a stable thermal environment.

The 5-inch touchscreen makes the Sigma D25 a very simple-to-use large-format 3D printer, with fantastic 50-micron minimum layer heights and very precise XY and Z resolutions for intricate part printing.

- For more information on resolutions, we have a guide to resolutions in 3D printing.

Moreover, Sigma D25 is a BCN3D printer that now has WiFi printing capabilities as well as USB and SD card printing, and even updates itself automatically with the latest firmware for the latest developments.

Ultimaker S5 — Extremely precise large format 3D printer

- Price: $5,995 — Available on Dynamism Store here / Available on Matterhackers here

- Maximum build volume: 330 x 240 x 300 mm

Pros

The gold standard in high-quality desktop FDM 3D printing

Excellent, best-in-class precision and accuracy

Fits well into an existing workflow: Ultimaker offer software products for industrial needs and 3D printer factories

Cons

Not as large as some cheaper alternatives

The follow-up to the acclaimed Ultimaker 3, the Ultimaker S5 is the Dutch company’s launch into a higher price range, more industrial printer.

A large build volume 3D printer, the S5 is geared towards a more professional and industrial clientele, expanding the build volume and focusing on the scalability of rapid prototyping.

S5 and some test prints. Source: TwitterThough more expensive than its predecessor, clocking in at just under $6K, Ultimaker are not struggling for clients. The printer is said to be used by Volkswagen, showing just how highly rated Ultimaker’s printers are. It’s the best 300mm 3D printer around – though you may require larger build volumes than 330 x 240 x 300 mm offers.

While not enormous, the sheer precision, quality and reliability still earn it a place as one of the best large 3D printer ranges for professional prints. Its broad material compatibility is a plus (Ultimaker sell their own brand of high-temperature materials) for printing large objects in PP, CPE, Nylon, PC, and more.

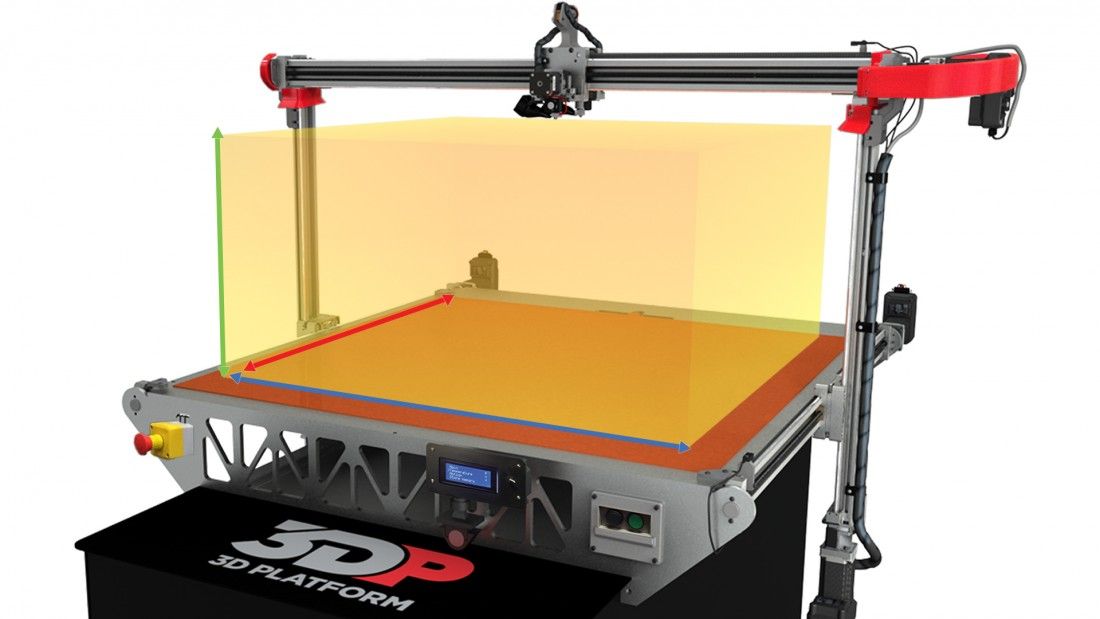

BigRep Studio G2 — Gigantic 3D Printer!

- Price: requires a quote

- Build volume: 1000 x 500 x 500 mm

This behemoth is a huge 3D printer, one of the many immense beasts that German manufacturer BigRep sells to their industrial clientele. It’s quite possibly the largest FDM printer you’ll come across.

It’s quite possibly the largest FDM printer you’ll come across.

Used for prototyping and in the medical, automotive, and aerospace sectors, the BigRep Studio weighs in at over a quarter of a ton owing to its massive build volume.Studio G2 and some test prints: Source: Reddit

BigRep sells a number of custom materials for use in their large 3D printers, including commonly used printer filaments like PLA and PETG, as well as more niche materials such as flexible filaments, HT, and HS. The advanced air filtration system, completely enclosed build area, and tool steel nozzle makes it perfect for 3D printing carbon fiber filaments, ASA, and Polyamides like Nylon.

The Studio G2 works seamlessly with BigRep’s Blade 3D printer software, prints up to 100mm/s, and can print with up to 0.1mm minimum layer heights.

Get a quote*

*One of our trusted partners will be in touch following a quote request.

Concept Laser X Line 2000R — Largest 3D printer in the world

- Price: request a quote

- Build volume: 800 x 400 x 500 mm

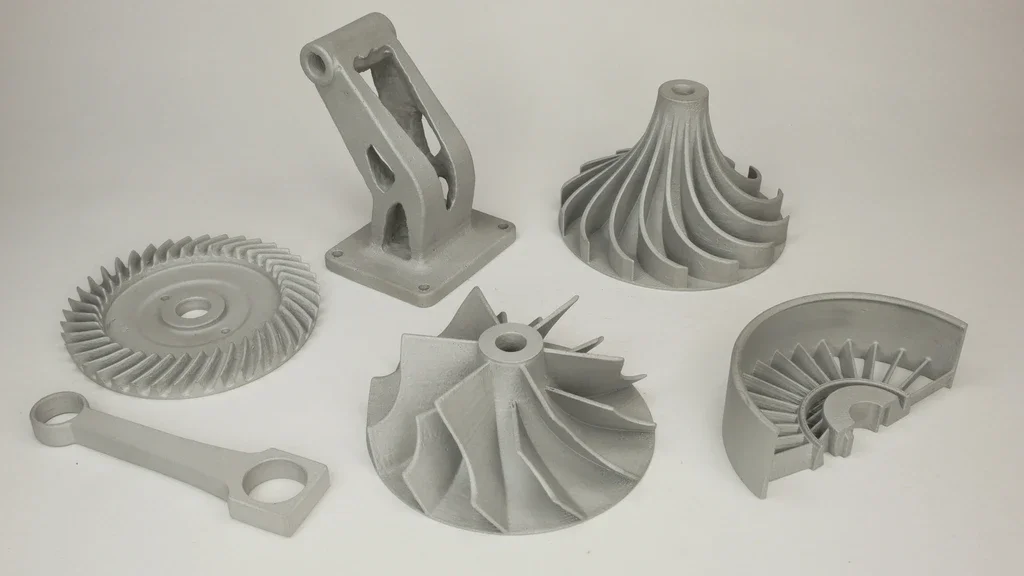

One of the world’s largest 3D printers and also one of the world’s most expensive, the Concept Laser X Line 2000R uses Direct Metal Laser Sintering to print strong and accurate metal parts, and costs millions. However, this machine is such an engineering feat that we felt compelled to include it, with large print volumes exponentially harder to achieve with metal 3D printing technologies.

However, this machine is such an engineering feat that we felt compelled to include it, with large print volumes exponentially harder to achieve with metal 3D printing technologies.

Undoubtedly a leader in its sector — and you can also check out our metal 3D printer ranking — the ability to create metal parts up to 800 x 400 x 500 mm in size is an invaluable asset. If you’re not a billion-dollar company then you’re unlikely to buy one, but this machine is a lock-in for our large 3D printer list, able to print metal structures at sizes never achieved prior.

Get a quote*

*One of our trusted partners will be in touch following a quote request.

Tips for Large-Format 3D Printing

Keep time in mind

It’s important to remember how long it takes to print these enormous parts. In rapid prototyping, it’s common to leave your printer running overnight and come back to it the next day, but if you’re printing a 50 x 50 cm prototype with a 0.4mm nozzle and small-ish layer heights, it could take several days to print.

A natural solution is to replace the standard 0.4mm nozzle that comes on most large-scale 3D printers with a larger (0.8-1.2mm) nozzle. Then, if printing larger layer heights (200 – 400 microns) you massively increase print speed.

However, this opens another can of worms. Less powerful hotends can struggle to melt such a large amount of filament quick enough to extrude in time, so you may want to upgrade your hotend to print without issue. We have a guide to some great hotends here.

Is it worth buying a large 3D printer, or using a 3D printing service instead?

This is another question you should ask yourself. If you’re only planning on printing a few prototypes for the year, you might find it advantageous to instead outsource your printing needs to an external service.

It’ll be more expensive than if you were to just pay for the materials to print yourself, but if you don’t have much use for the large-scale 3D printer, it’ll sit there collecting dust in your workshop for the rest of the year.

This is a simple value judgment — do you think you’ll use it enough?

The answer could even be to keep/buy a standard smaller 3D printer, use that for day-to-day prototyping, and if you have an enormous printer project, outsource those. We have a ranking of some of the best 3D printing services.

1 big 3D printer, or multiple smaller printers for many small parts

A common line of thought is that buying one large 3D printer gives you the capacity to print many smaller parts simultaneously.

This is true, but not necessarily efficient. Yes, you can print 10-20 small pieces at the same time on a large 3D printer, but it’ll take 20 times as long as you could have printed these parts on 20 desktop 3D printers. So, if you’re planning on printing many small parts, consider instead going with a 3D printer farm.

That said, the best 3D printer for large objects is certainly one with a big print volume – it’s a hassle gluing multiple parts together, and affects the final part’s strength.

Large 3D Printer Applications

- Large, single-part prototypes — for parts where surface finish is important, and where assembling multiple parts post-print would make this difficult. Also when time is not an issue it’s less hassle to just print one large part over time.

- TV and movie props, and cosplays — Redditors have shown extensions they’ve made to their enormous 3D printers to print large cosplay parts, and the TV & film industry have begun using 3D printing for props and other appliances for sets.

- Furniture — increasingly, large volume 3D printers are being used in similar ways to 4×8 CNC routers to create furniture like chairs, stools, and tables. We cover a variety of ways to do this in our feature story on 3D printed furniture.

Large 3D Printer FAQs

What’s the Biggest 3D Printer You Can Buy?

The largest 3D printer you can currently buy is the Massivit 10000. It offers a massive 1420 x 1110 x 1500 mm build volume and is roughly the size of a small room.

What 3D Printer Has the Biggest Bed Size?

The Massivit 10000 has a 1420 x 1110 x 1500 mm build volume, followed closely by the Industry Magnum, which has a 1500 x 1200 x 1200 mm build volume. Other notable mentions include the CreatBot F1000 with a 1000 x 1000 x 1000 mm build volume, and the BigRep Pro, which has a 1000 x 1000 x 1000 build volume.

How Much Does a Huge 3D Printer Cost?

A consumer-grade 3D printer with an ultra large-format build volume can cost as low as $600, such as the Anycubic Kobra Max and Ender 5 Plus. For an industrial-grade printer, prices sort well into the thousands of dollars, with some, such as the Industry Magnum, costing well above $100,000.

What Is the Biggest 3D Printer Out There and What Does It Print?

The biggest 3D printer out there is the Massivit 10000. It can print custom molds, tools, mandrels, jigs, fixtures, and plugs for the marine, rail, automotive, construction, sporting, and aerospace industries.

If you enjoyed this ranking, you may also be interested in:

- Our ranking of the best small 3D printers

- The best dual extruder 3D printers

- The best 3D pens

- How much does a 3D printer cost to buy and maintain?

- The best commercial 3D printers

- The best 3D printers for small businesses

- Best 3D printers for $5000

- 500x500x500mm 3D printers

- Nylon 3D printer buyer’s guide

Shop the Best Large Format 3D Printers in 2022 (Including Best Large 500mm 3D Printer)

Welcome to the Thomas guide to the best large format 3D printer 2022. Thomas has been connecting North American industrial buyers and suppliers for more than 120 years. When you purchase products through our independent recommendations, we may earn an affiliate commission.

Thomas has been connecting North American industrial buyers and suppliers for more than 120 years. When you purchase products through our independent recommendations, we may earn an affiliate commission.

Printing larger items with most at-home or small-scale 3D printers is possible but consists of separately printing different parts of the project and then connecting them all together afterward to make the much larger finished product. In this way, many 3D printing enthusiasts, such as cosplayers, for instance, are able to get past the 3D printing size limitations and use their machines for much larger products than the print bed will allow.

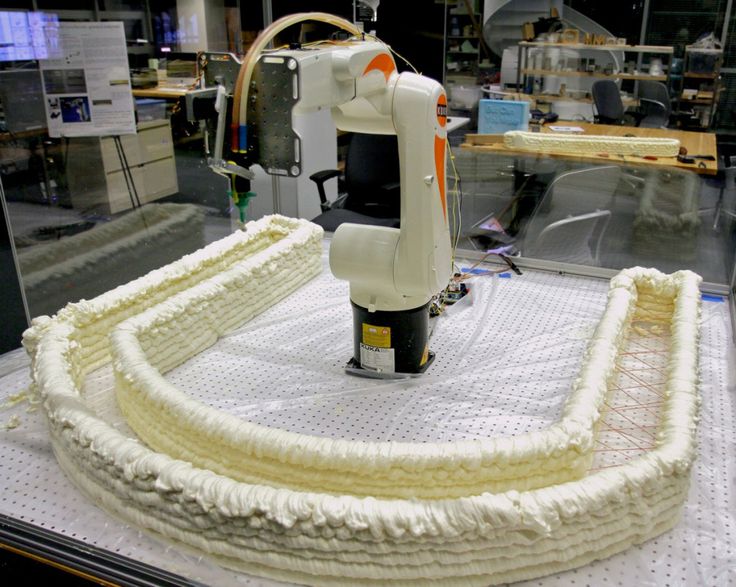

A large-format 3D printer in actionImage credit: Shutterstock/asharkyu

However, purchasing a large-format 3D printer can provide an increase in opportunities for creativity and a decrease in the amount of "putting together" necessary for those larger projects.

Large-Format 3D Printer—Buying Guide

With the average printing bed size of a 3D printer intended for general use being around 150–300mm, if you wanted to scale up the size of your 3D creations, a printer of 350mm–500mm would be ideal, and luckily, there are a few worthy large-scale models available on the market for you to choose from.

Benefits of a Large 3D Printer

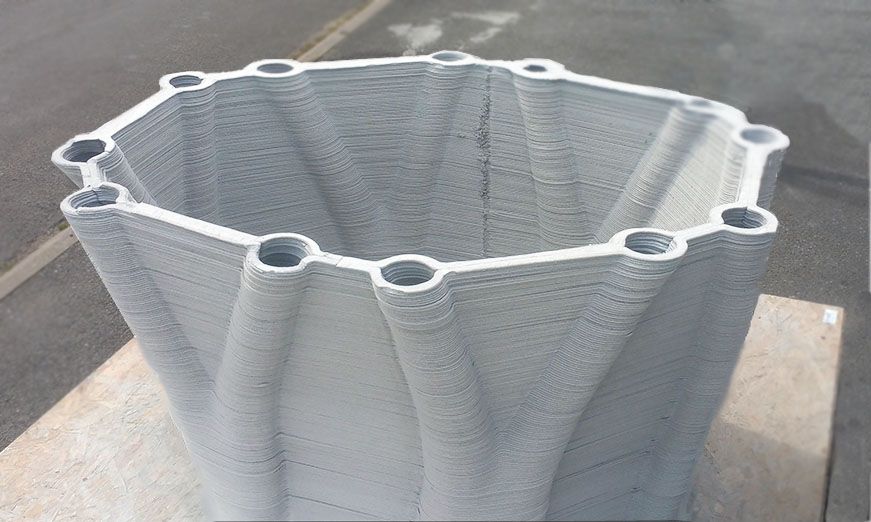

Development in 3D printing technology means that we've recently been presented with 3D printed houses, cars, bikes, camper vans, life-size statues, and even sofas and other pieces of furniture.

Obviously, the "large format" we're referring to in this article is less about making grand-scale structures, and more about moving on from miniatures, ornaments, and other small objects or parts that an ordinary, non-industrial-sized 3D printer can produce.

Since you'll have a little more print bed area to play with, with a large-format 3D printer you can create detailed products that don't require a magnifying glass to really appreciate and also larger parts that would otherwise need to be printed in separate sections.

Thomas’ Top Picks for the Best Large Format 3D Printer 2022

If you're ready to step up your 3D printing game, and have a blast doing it, here are some of the best large format 3D printers currently available to buy now.

Scroll down to see more on our top picks for the best large format 3D printer, according to many happy buyers.

*Prices listed in this article were as shown in US$ on Amazon.com (USA) and other online retailers as of February 2022

1. Best Large 500mm 3D Printer—Crealty Large 3D Printer 500x500x500mm

As one of the 3D printers with the largest printing beds currently available, the Creality CR-10 S5 3D printer has 500x500x500mm of printing space meaning you can really let your imagination run wild.

Installation is super quick and easy as the machine comes in three pre-assembled parts with clearly labeled wires and instructions. Other features include a resume-printing function in the event of loss of power, and you also get a one-year warranty from the manufacturer.

One buyer who gave this machine five stars helpfully mentioned that you need to have plenty of room to accommodate this huge printer, writing, "The main thing to consider is its sheer size. It requires over a yard, possibly a full meter of depth to move the build plate."

BUY NOW: US$719, Creality 3D2. Best Large 400mm 3D Printer—ANYCUBIC 3D Printer 400x400x450mm

A large-format 3D printer from a trusted brand, the ANYCUBIC Chiron is for anyone who doesn't mind spending some extra time and effort on leveling the bed or working out the settings.

Users have reported this as being rather tricky, but the trade-off is a great 400mm 3D printer with impressive capabilities, plus, a superb customer service department that helped with any and all issues pertaining to the printer, from setup to product completion. One fan wrote, "It took me a long time to dial in my settings and get high-quality prints but I was able to get the printer working and printing decent quality the same day I put it together."

One fan wrote, "It took me a long time to dial in my settings and get high-quality prints but I was able to get the printer working and printing decent quality the same day I put it together."

Another happy user who has "completed more than 4,000 hours of printing" and "used many hundreds of rolls of filament," described, "The results I am getting are amazing even with some prints taking over 300 hours to complete. In fact, I have just started a seven-part 700-hour print which is going very well."

BUY NOW: US$623.75, Amazon3. Best Large 3D Printer Under $1000—Creality Ender 5 Plus 3D Printer 350x350x400mm

With pretty much the same capabilities as its equally highly-rated sister model, the Creality Ender 5 Pro, including an automatic bed leveling sensor, bed stabilizer, color touch screen, and easy assembly, the Ender 5 Plus has one major difference; its huge size which accommodates its large build plate.

This sturdy thing works straight out of the box, and in addition to great customer support, there is also a massive Creality community to quickly get any answers and assistance you may require.

"I have printed several large helmets with great results," one happy purchaser wrote, and another added, "I love having the bigger print bed for very big projects. There is some fine-tuning you will have to do but after that, you are ready to rock and roll."

BUY NOW: US$599 (Was US$649), Amazon4. Best Industrial Large 3D Printer—Snapmaker 3-in-1 3D Printer 320x350x330mm

For advanced hobbyists or pros who want to up their 3D printing game, the Snapmaker 2.0 will make a proud addition to your workspace and open up a world of 3D opportunity and creativity. In addition to its large printing capacity, it is fast, powerful, and also allows you to do much more than 3D printing, like engraving, cutting, and CNC carving.

At this price, it's a unit for those who are pretty serious about 3D printing, but for small businesses that rely on the craft, it will end up paying for itself in no time. One reviewer who bought this to enhance their graphic design business, wrote, "It's been a valuable asset so far. We are making our own business cards on metal which is super unique and our customers love the added services we can now offer."

Another happy buyer who raved about its versatility and build quality, added, "I have been making non-stop with this machine... [It] allows for the imagination to go absolutely wild with ideas!"

BUY NOW: US$1,799, Amazon5. Best Large 3D Printer under $500—SUNLU S8 3D Printer 310x310x400mm Upgraded

Another good printer with a large print bed, and a tiny price to boot, the upgraded SUNLO S8 only weighs around 26 pounds so is not as much of a task to move as some of the other large 3D printers.

At under US$300, you get many features like high stability, accurate printing, filament runout detection, a Z-axis dual linear rail, and simple assembly. There's also a resume printing function for power failures.

"This printer provides great value for the cost," one buyer explained. "Not only is the print size large enough to do just about anything you can think of, but at 310x310x400 it is the largest in its price class." Another happy customer wrote, "Awesome printer for the price. Can't beat it. It's open-source so it's super easy to add upgrades if you want. Huge build size."

BUY NOW: US$279.99, Amazon6. Best Cheap Large 3D Printer—LONGER LK1 3D Printer 300x300x400mm

With an even smaller price tag, the Longer LK1 3D printer is another option for those wanting to dabble in 3D printing but unsure whether to fork out the big bucks just yet.

It provides plenty of features to learn the art, and the customer service is helpful with any questions you may have. The leveling is not the best, but it is easy to assemble and users have been satisfied with the print quality.

The leveling is not the best, but it is easy to assemble and users have been satisfied with the print quality.

"This is an awesome entry-level printer," one satisfied shopper explained. "I was pleasantly surprised, how easy it was to set up... If you're looking for bang for your buck and [to] familiarize yourself with 3D printing, then don't go wasting money on expensive printers; this one works great."

BUY NOW: US$270.39, WalmartThe Best Large Format 3D Printer—Summary

With one of the largest printing beds currently available for a non-industrial 3D printer, the Creality CR-10 S5 3D printer (US$719, Creality 3D) provides an impressive 500x500x500mm of printing space. The Anycubic Chiron (US$623.75, Amazon) is another large-format printer with impressive capabilities and has a superb customer service department too.

We hope our review of the best large format 3D printer has been helpful. For more 3D printers and other 3D printing suppliers, including 3D printer filaments suppliers, additive manufacturing suppliers, 3D photographic printing services, and 3D sand printing additive manufacturing, consult our additional guides, or visit the Thomas Supplier Discovery Platform.

- The Best 3D Printers under $300

- The Best 3D Printers under $200

- The Best 3D Printer Under $1000

- The Best 3D Printer Under $500

- Top 3D Printing Services Companies in the USA

- Origins of 3D Printing and Additive Manufacturing

- Overview of 3D Printing Technologies

- Top 3D Printing Manufacturers and Suppliers (Publicly Traded and Privately-Owned)

- Top Suppliers of Additive Manufacturing Consulting Services

Other Best Product Articles

- The Best Cordless Impact Wrenches

- The Best Portable Generators

- The Best Portable Band Saws

- The Best Electric Space Heaters

- The Best Mini Milling Machine

- The Best Attic Ladders

- The Best Air Purifiers for Smoke

- The Best Circuit Breaker Locator

- The Best Engine Hoists and Accessories

- The Best Drywall Lifts

- The Best Whole-House Generators

- The Best Home Automation Systems

- The Best Quietest Portable Generators

- The Best Uninterruptible Power Supply Systems

- The Best Commercial Patio Heaters

- The Best Electric Bikes

- The Best Electric Pressure Washers

- The Best Keyless Door Locks

- The Best Electric Lawnmowers

- The Best Electric Hand Warmers

More from Custom Manufacturing & Fabricating

top 10 rating according to KP

A 3D printer opens up incredible opportunities for a person. The first prototype of such a device was born back in 1984. The idea of the invention belongs to the American Charles Hull, he received a patent for it only two years after development. The printer was a rather massive industrial installation and, despite many inaccuracies and shortcomings in operation, the technology was used.

The first prototype of such a device was born back in 1984. The idea of the invention belongs to the American Charles Hull, he received a patent for it only two years after development. The printer was a rather massive industrial installation and, despite many inaccuracies and shortcomings in operation, the technology was used.

Hal co-founded 3dsystems, a leader in industrial 3D printers. However, this material is not dedicated to these large machines. 3D printing is becoming more and more part of everyday life. Thus, the technology is used to create unique toys, various models, figurines, packaging, clothes, shoes and jewelry. For these purposes, it is not at all necessary to purchase a large-sized printer. You can get by with a small device. It has a compact size, and its technology is completely identical to the industrial one. Heated plastic is fed through the nozzle (spout) of the device, which is laid out on the surface in accordance with the drawing specified in the program. And if earlier such a device was a luxury that only a few can afford, today a 3D printer is available to everyone. nine0003

And if earlier such a device was a luxury that only a few can afford, today a 3D printer is available to everyone. nine0003

Top 10 rating according to KP

1. Creality3D Ender 3

Creality3D Ender 3. Photo: market-yandex.ruOur rating opens with a model from the world's largest manufacturer of 3D printers. The Ender 3 features an elegant and thoughtful design, excellent print quality and a wide build area. Manufacturers have provided a good arrangement of wires that do not get confused during operation. The small control unit of the device is located to the right of the work surface. The gadget prints perfectly with various types of plastic. In particular, we are talking about varieties of ABS, PLA, TPU and PETG. The scope of this printer is quite wide. It can be used to produce minifigures, do artistic modeling, and make small prototypes of parts and functional elements. nine0003

Main characteristics

| Print technology | fdm/fff/pjp |

| Field | PLA, Wood |

| Workspace width | 220 mm |

| Workspace height | 250 mm |

| The depth of the workspace | 220 mm |

| Features | Heated table, displays, active cooling, nozzle change, USB, Micro SD |

| Press speed | 180 mm/sec | Number of extruders | 1 |

Pros and cons

Possibility of using various types of plastic, high quality of parts, reliable design

A small display that displays only basic information

2.

FlashForge Adventurer 3 FlashForge Adventurer 3. Photo: market-yandex.ru

FlashForge Adventurer 3 FlashForge Adventurer 3. Photo: market-yandex.ru The model from the Chinese developer FlashForge took the second position in our rating. The device is equipped with a Wi-Fi receiver, a removable heated pad for printing. In addition, manufacturers have provided a built-in webcam, a closed case and a color touch-screen display. The latter, although it does not support the Russian language, is intuitively understandable. The ergonomics of the device is provided by the filament sensor: if the printer runs out of plastic, it automatically goes into standby mode and does not idle. nine0017 Features

Pros and cons

Webcam and Wi-Fi receiver allows you to monitor the work, unusual design, simplicity from anywhere in the world in the setup, the presence of a filament sensor

Despite the rather wide functionality, this model is hardly suitable for an experienced printer or a small production due to the small area of the working space, high price

3.

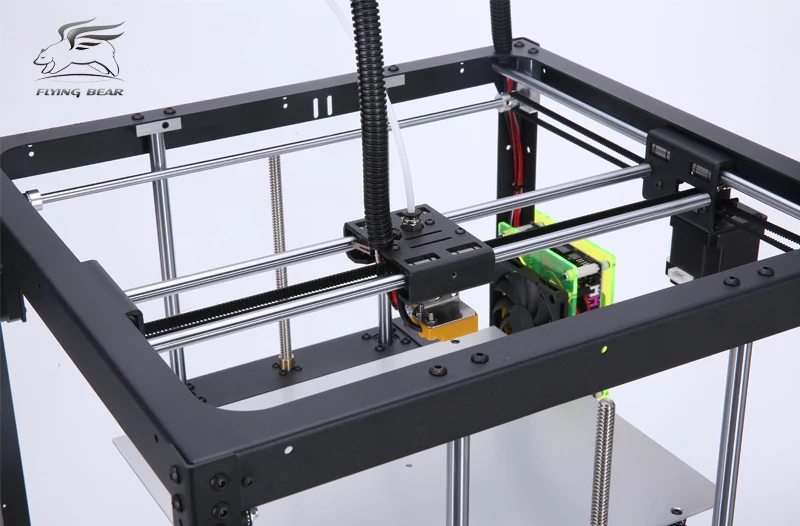

FlyingBear Ghost 5 FlyingBear Ghost 5. Photo: market-yandex.ru from FlyingBear is ideal for semi-professional use. Uniform supply of filament (plastic) provides good opportunities for creating three-dimensional figures with a fairly high resolution. High productivity is achieved thanks to the transparent Dual Drive extruder with BMG double drive. The gadget has a body closed on three sides. Its walls are made of heat-resistant non-toxic ABS plastic. This protection prevents the accumulation of dust on the working parts of the device, which greatly facilitates the maintenance of the printer. The device is controlled using a 3.5-inch color TFT display. nine0003

FlyingBear Ghost 5 FlyingBear Ghost 5. Photo: market-yandex.ru from FlyingBear is ideal for semi-professional use. Uniform supply of filament (plastic) provides good opportunities for creating three-dimensional figures with a fairly high resolution. High productivity is achieved thanks to the transparent Dual Drive extruder with BMG double drive. The gadget has a body closed on three sides. Its walls are made of heat-resistant non-toxic ABS plastic. This protection prevents the accumulation of dust on the working parts of the device, which greatly facilitates the maintenance of the printer. The device is controlled using a 3.5-inch color TFT display. nine0003 Main characteristics

| Print technology | fdm/fff/pjp | |||

| Field | for house/diy, initial level | |||

| Open Camera | Open Camera | Open Cam | ABS, PLA, Wood, HIPS | |

| Workspace width | 255 mm | |||

| Workspace height | 210 mm | |||

| Working space | 210 mm | |||

| Features | Heated table, display, active cooling, nozzle adjustment, temperature control | |||

| Connection | Wi-Fi, SD | , SD , SD 9001|||

| Print speed (extruder speed) | 150mm/s | |||

| Number of extruders | 1 | |||

| Printing accuracy | X, Y 0. 01 mm 01 mm | |||

| Positioning accuracy | Z 0.002 mm |

Pros and cons

Short power cord, inaccuracies in the Russian-language menu, weak airflow system.

4. Anet N4

Anet N4. Photo: market-yandex.ruThe budget model from the Chinese manufacturer Anet N4 is equipped with all the necessary functions for a small domestic production. The base of the device is made of cast aluminum alloy. The weight of the gadget does not exceed 9kg. A transparent tinted hood protects the work surface from external sources of ultraviolet radiation. It can be removed to remove the finished product and clean the printer. Also, manufacturers have provided a removable resin bath and a working platform, which greatly facilitates the use of the device.

Key Features

| Print Technology | LCD | |

| Application | Home/DIY Professional | 30 mm/h |

Pros and cons

Ability to use photopolymer resins from any manufacturer, high polymer curing speed

Small work surface, slightly inferior to competitors in some parameters

Photon Scu0bic0 Anycu0bic08 5. S. Photo: market-yandex.ru

S. Photo: market-yandex.ru In the middle of our rating is the Anycubic Photon S model. It is equipped with an advanced optical system and a large working camera. The device has a matrix light source that provides a uniform luminous flux over the entire plane of the desktop. This allows a very high curing speed of the layers to be achieved. In addition, the printer has an original function that allows you to simultaneously print eight identical models. According to the developers, the target audience for this device are orthodontists and jewelers. Most parts of the device are made of plastic. This factor significantly reduces the weight of the device and makes it convenient to transport. nine0018

Plus and minuses

High printing quality

Small worktop

6. ELEGOO Mars Pro

ELEGOO Mars Pro. Photo: market-yandex.ru

Photo: market-yandex.ru This model is significantly different from its predecessor Elegoo Mars. Thanks to the advanced Z-axis mechanics and directional UV light from the diode array, it is suitable not only for hobbies, but also for fields of activity such as dentistry and jewelry. In addition, the developers moved the USB connector to the front of the device. Now there is no need to constantly rotate the gadget in the process. The weight of the device is only 7.5 kg, which makes it very convenient for transportation. A translucent plastic cover will reliably protect against extraneous radiation and will allow you to monitor the production process. nine0003

The main characteristics

| Print technology | LCD |

| Scope | for home/diy, for medicine |

| Print speed: (layer build-up) | 22. 5 mm/h 5 mm/h |

| Print precision | X, Y 0.047 mm |

| Positioning accuracy | Z 0.125 mm |

| The wavelength of light source | 405 Nm |

PLASS AND MINCOUS COUREDENDENT, LIGHT price, good UF-Room Light 9,0008 7. Two Trees Bluer

Two Trees Bluer. Photo: market-yandex.ru This is one of the most popular home models of 3D printers. It is ideal for getting acquainted with technology, various experiments, training and prototyping. Distinctive features of Two Trees Bluer are: "quiet" drivers, which are the engine of the device, a heated table, two-way airflow and a thread break sensor. The mechanics of the printer is quite simple, and at the same time very effective. The open type case will be very convenient when cleaning the work surface. The firmware of the device provides the functions of auto-calibration and automatic resumption of printing in case the power was accidentally turned off. nine0018

nine0018

Pros and cons

Low price, easy and convenient to use

Lack of protection for the work surface, poor quality of spare parts

8. Wanhao Duplicator i3 Mini

Duplicator Mini i3. Photo: market-yandex.ruMiniature 3D printer does not look like other devices. However, this feature does not affect its technical characteristics. The plastic spool is located on the right side of the bracket. Wanhao branded coating is pasted over the table. There is no platform heating, so it is recommended to use PLA plastic for printing. The manufacturer clearly states in the manual that the printer is designed to work only with PLA material and nothing else. The body of the gadget is made of sheet steel. The memory card slot and all printer control elements - a monochrome liquid crystal display, a universal knob-button and a Reset micro-button - are placed on the front panel of the printer. nine0003

The main characteristics

| Print technology | FDM/FFF/PJP | ||||||||||||||||||

| Field | Educational, for House/DIY, for medicine | ||||||||||||||||||

| Openly Camera | Open | PLA | |||||||||||||||||

| Working space width | 120 mm | ||||||||||||||||||

| Working space height | 100 mm | ||||||||||||||||||

| The depth of the workspace | 135 mm | ||||||||||||||||||

| Features | displays, active cooling, speed control, temperature control | ||||||||||||||||||

| USB, SD card | ) | 70 mm/s | |||||||||||||||||

| Number of extruders | 1 | ||||||||||||||||||

| Printing accuracy | X, Y 0. 012 mm 012 mm |

| Print technology | FDM/FFF/PJP |

| Scope | Educational, for house/DIY, Industrial, Professional Material |

| ABS, Flex, Nylon, PLA, PETG, SBS, CopperFILL, DuraForm TPU | |

| Working width | 220 mm |

| The height of the workspace | 250 mm |

| Dent of the workspace | 220 mm |

| Features | Heated table, Active streaming, Control adjustment, Tempension |

| USB, micro-SD | |

| Print speed (extruder speed) | 150 mm/s, |

| Number of extruders | 1 |

Pros and cons

Spacious work surface, robust housing

Little functionality for a rather high price, lack of work surface protection, few functions on the control screen.

10. Tianfour Sparkmaker

Tianfour Sparkmaker. Photo: market-yandex.ruThis model is ideal for beginners, as it does not require additional settings at all before starting work. Externally, the printer has the shape of a cylinder with a height of 27.5 cm and a diameter of 17 cm. The realistic contours and smooth curves of the figures are ensured by LCD technology. The printer works with any photopolymer resins for 3D printing with a flash length of 405nm. nine0003

How to choose a 3D printer

Choosing a 3D printer is not such a difficult task as it might seem at first glance. Despite the relentless interest in 3D printing and the incredible number of devices on the market, the basic requirements for models remain unchanged. Komsomolskaya Pravda turned to Svyatoslav Vulf, a blogger and host of a YouTube channel about modern technologies and experiments, for help in this matter. He regularly monitors new products on the 3D technology market and tests them at home. nine0003

nine0003

Product size

Initially, you should decide what size of products you expect to receive in the end. The required area of the working surface depends on this. Note that the price of the device also depends on the size of the latter. For work at home, there will be enough indicators: 200 × 250 × 200 (WxHxD).

Technology

Today, there are several technologies for printing on a 3D printer. They differ significantly from each other. Let's consider some of them. nine0003

SLA-technology — works on the basis of a liquid photopolymer, which under the influence of laser light changes its physical properties and hardens. It allows you to create figurines with the highest precision of microforms.

DLP technology is an alternative SLA method. However, instead of laser systems, LED projectors are used here, which significantly reduce the cost of 3D printers. When using this technology, the future prototype is formed layer by layer. nine0003

nine0003

The FDM method is ideal when prototypes are required that will be actively used and not just sitting on a shelf. Here, high-strength industrial plastics will be used for production. Please note that there are other technologies, but they are very similar to the above.

Material

Before buying a printer, you should also pay attention to what materials it works with, as they have significant differences from each other. For example, ABS can take many different polymeric forms. This is a very durable plastic. It is easily sanded and processed. PLA plastic is considered more environmentally friendly. It is made from agricultural products - corn, potatoes, beets and others. In its original form, it is transparent and can be colored. PLA is just as strong but tougher than ABS. The ductility and heat resistance of SBS make it the material of choice in engineering and mechanical applications. nine0003

Noise level and drivers

An important factor when choosing a 3D printer are drivers - device engines (not to be confused with software). They affect the overall noise level of the device. For example, if you buy a printer with cheap A4988, then even neighbors will hear its work. In this case, you should pay a little more and purchase a gadget with more expensive drivers.

They affect the overall noise level of the device. For example, if you buy a printer with cheap A4988, then even neighbors will hear its work. In this case, you should pay a little more and purchase a gadget with more expensive drivers.

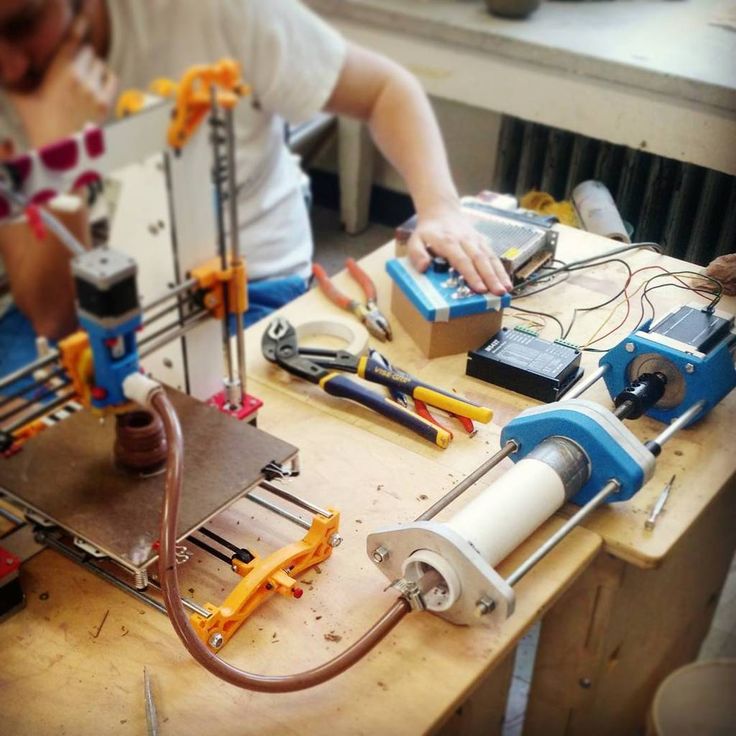

Self-assembly

Some manufacturers prepare the model completely before sale. The buyer can only get the printer out of the box and connect the power. However, there are some models that require self-assembly. Be sure to consider this factor before purchasing. If you are purchasing such a device for the first time, then it will not be easy for you to assemble it. nine0003

technologies, equipment, materials and new opportunities

There is no hotter trend in 3D printing today than metal. We will talk about metal printing at home, how it is done on an industrial scale, about technologies, applications, printers, processes, prices and materials. Over the past few years, 3D metal printing has been actively gaining popularity. And this is quite natural: each material offers a unique combination of practical and aesthetic qualities, can be suitable for a wide range of products, prototypes, miniatures, decorations, functional details and even kitchen utensils. The reason metal 3D printing has become so popular is because the printed objects can be mass-produced. nine0003

The reason metal 3D printing has become so popular is because the printed objects can be mass-produced. nine0003

In fact, some of the printed parts are just as good (if not better) than those made by traditional methods. In traditional production, working with plastic and metal can be quite wasteful - there is a lot of waste, a lot of excess material is used. When an aircraft manufacturer makes metal parts, up to 90% of the material is simply cut off. 3D printed metal parts require less energy and waste is reduced to a minimum. It is also important that the final 3D printed product is up to 60% lighter than a traditional part. Billions of dollars could be saved in the aviation industry alone—mainly through weight savings and fuel savings. So, what do we need to know about metal 3D printing? nine0003

3D metal printing at home

If you want to make objects at home that will look like metal, your best bet is to look at metalized PLA filaments (Photo: colorFabb)

Where to start if you want to print metal objects at home? Given the extreme heat required for true metal 3D printing, a conventional FDM 3D printer will not be able to do this. nine0003

nine0003

It is unlikely that in this decade it will be possible to print with liquid metal at home. Until 2020, you probably will not have a printer specialized for this purpose at home. But in a few years, as nanotechnology advances, we may see significant developments in new applications. This can be 3D printed with conductive silver, which will emit in much the same way as it does in 2D home printers. It will even be possible to mix different materials like plastic and metal in one object. nine0003

Materials for Metal 3D Printing at Home

Even though you can't print actual metal objects at home, you can turn to plastic filament that has metal powders added to it. Bestfilament, ColorFabb, ProtoPasta and TreeD Filaments offer interesting metal-PLA composite filaments. These filaments, containing a significant percentage of metal powders, remain pliable enough to be printed at low temperatures (200 to 300 Celsius) on virtually any 3D printer. At the same time, they contain enough metal to make the final object look, feel, and even weigh like metal. Iron-based filaments even rust under certain conditions. nine0003

Iron-based filaments even rust under certain conditions. nine0003

But you can go further. Typically, up to 50 percent metal powder is added to 3D printing filament. Dutch company Formfutura says they have achieved 85 percent metal powder with 15 percent PLA. These filaments are called MetalFil Ancient Bronze and Metalfil Classic Copper. They can be printed even at "moderate" temperatures from 190 to 200 degrees Celsius.

Metal 3D Printing Filament Spools, in this case by SteelFill and CopperFill colorFabb (Steel and Bronze), Ancient Bronze by Formfutura

Here are the key points about metal printing at home

- Gets a unique metal surface and look

- Ideal for jewelry, figurines, housewares, replicas

- Durability

- Objects are not flexible (structural dependent)

- Objects do not dissolve

- Not considered food safe

- Typical print temperature: 195 - 220°C nine0855 Extremely low shrinkage on cooling

- Table heating not required

- Printing complexity is high, requires fine tuning of nozzle temperature, feed rate, post-processing

Preparing Your Home Printer for Metal 3D Printing

Since getting metal 3D prints is more difficult than usual, you may need to upgrade your 3D printer nozzle, especially if you are an entry-level printer. The metal filament wears it out quickly. There are hard-wearing hot-ends (like the E3D V6) that are themselves made of metal. They can withstand high temperatures and fit most printers. Be prepared for the fact that the nozzles will have to be changed frequently, because the metal filament is very abrasive. nine0003

The metal filament wears it out quickly. There are hard-wearing hot-ends (like the E3D V6) that are themselves made of metal. They can withstand high temperatures and fit most printers. Be prepared for the fact that the nozzles will have to be changed frequently, because the metal filament is very abrasive. nine0003

You will also need to take care of the final finishing of the surface (cleaning, grinding, oiling, waxing or priming) so that the printed metal object shines as it should.

How much is metal filament for 3D printing?

And what about metal filament for 3D printing? - you ask. Here are some examples:

- A 500-gram BFSteel and BFBronse coil from Bestfilament costs 1600–1800 ₽

- ColorFabb's 750 gram Bronzefill spool is $56.36

- ColorFabb's 750 gram Copperfill spool is $56.36

- Protopasta's Polishable Stainless Steel PLA Composite is $56 for 56 grams

- Protopasta's Rustable Magnetic Iron PLA Composite is $34.

99 for 500 grams

99 for 500 grams

Industrial Metal 3D Printing

But what if you want better results or even full metal 3D printing? Should a real "metal" 3D printer be purchased for business needs? We wouldn't recommend it - unless you're going to be doing it every day. A professional metal 3D printer is expensive: EOS or Stratasys devices will cost you 100-500 thousand dollars. In addition, the costs will be even greater, since you will have to hire an operator, a worker to maintain the machine, as well as to finalize the printouts (polishing, for example). Just a note: In 2016, an affordable metal 3D printer didn't exist. nine0003

Reducing Metal 3D Printing Costs

If you are not going to open a metal 3D printing business, but still need a professionally 3D printed metal part, it is better to contact the appropriate company that provides such services. 3D printing services like Shapeways, Sculpteo and iMaterialise offer direct metal printing. They currently work with the following metal materials in 3D printing:

- aluminum

- steel

- brass

- copper

- bronze

- sterling silver

- gold

- platinum

- titanium

If you are a jeweler, you can also order wax models for casting in precious metals. If we talk about wax models, then in most cases it is they (with subsequent melting) that are used when printing with metals (including gold and silver). Not all orders are carried out directly by these firms. They usually turn to other metal 3D printing companies to complete the order. However, the number of such services around the world is growing rapidly. In addition, metal 3D printing techniques are becoming more and more common in companies that offer such services. nine0003

If we talk about wax models, then in most cases it is they (with subsequent melting) that are used when printing with metals (including gold and silver). Not all orders are carried out directly by these firms. They usually turn to other metal 3D printing companies to complete the order. However, the number of such services around the world is growing rapidly. In addition, metal 3D printing techniques are becoming more and more common in companies that offer such services. nine0003

The reason big companies love 3D printing so much is that it can be used to build fully automated lines that produce "topologically optimized" parts. This means that it is possible to fine-tune the raw materials and make the components thicker only if they must withstand heavy loads. In general, the mass of parts is significantly reduced, while their structural integrity is preserved. And this is not the only advantage of this technology. In some cases, the product turns out to be significantly cheaper and affordable for almost everyone. nine0003

nine0003

Please note that metal 3D printing requires special CAD programs for modeling. It is worth paying attention to the recommendations of Shapeways - 3D printing metal guidelines. To delve further into the topic, check out Statasys’ information on related 3D printers and the nuances of metal 3D printing.

Here are some examples of the Benchy test model price for metal 3D printing:

- Metal plastic: $22.44 (former alumide, PLA with aluminum)

- Stainless steel: $83.75 (plated, polished)

- Bronze: $299.91 (solid, polished)

- Silver: $713.47 (solid, mirror polished)

- Gold: $87.75 (gold plated, polished)

- Gold: $12,540 (solid, 18K gold)

- Platinum: $27,314 (solid, polished)

As you might expect, solid metal 3D printing prices are quite high.

Metal 3D printing. Applications

GE LEAP aircraft engine parts 3D printed at Avio Aero (Photo: GE)

There are several industries already using 3D printers to make everyday objects - you may not even know that these objects are printed. nine0003

- The most common case is surgical and dental implants, which in this design are now considered the best option for patients. Reason: they can be tailored to individual needs.

- Another industry is jewelry. Here, most manufacturers have abandoned resin 3D printing and wax casting, switching directly to metal 3D printing.

- In addition, the aerospace industry is becoming more and more dependent on 3D printed metal objects. The Italian company Ge-AvioAero was the first to do all-metal 3D printing. It manufactures components for LEAP aircraft engines. nine0856

- Another industry targeting metal 3D printing is the automotive industry. BMW, Audi, FCA are seriously considering this technology, not only for prototyping (3D printing has been used for this for quite some time), but also for making real parts.

Before metal 3D printing really takes off, however, there are some hurdles to overcome. And first of all, this is a high price, which cannot be made lower than during molding. Another problem is the low production speed. nine0003

3D metal printing.

Technologies

Most metal 3D printing processes start with an “atomized” powder

You can talk a lot about “metal” 3D printers, but their main problems remain the same as any other 3D – printers: software and hardware limitations, material optimization and multimateriality. We won't talk too much about the software, we'll just say that most of the major specialized software companies, such as Autodesk, SolidWorks and solidThinking, try to emphasize as much as possible the fact that as a result of the 3D metal printing process, you can get any shape you want. nine0003

In general, printed metal parts can be as strong as parts made by traditional processes. Parts made using DMLS technology have mechanical properties equivalent to casting. In addition, the porosity of objects made on a good "metal" 3D printer can reach 99.5%. In fact, manufacturer Stratasys claims that 3D printed metal parts perform above industry standards when tested for density. nine0003

Parts made using DMLS technology have mechanical properties equivalent to casting. In addition, the porosity of objects made on a good "metal" 3D printer can reach 99.5%. In fact, manufacturer Stratasys claims that 3D printed metal parts perform above industry standards when tested for density. nine0003

3D printed metal can have different resolutions. At the highest resolution, layer thickness is 0.0008 - 0.0012" and X/Y resolution is 0.012 - 0.016". The minimum hole diameter is 0.035 - 0.045″. Let's, however, consider what metal 3D printing technologies are.

Metal 3D Printing Process #1:

Powder Bed Fusion

The metal 3D printing process that most relevant large companies use today is called Powder Bed Fusion. This name indicates that some source of energy (a laser or other energy beam) melts an "atomized" powder (i.e., a metal powder that is carefully ground into spherical particles), resulting in layers of a printed object. nine0003

nine0003

There are eight major manufacturers of metal 3D printers in the world that already use this technology; while we are talking here, there are more and more such companies. Most of them are in Germany. Their technologies are called SLM (Selective Laser Melting - selective laser fusion) or DMLS (Direct Metal Laser Sintering - direct metal laser sintering).

Metal 3D printing process #2:

Binder Jetting

With ExOne 3DP technology, metal objects are printed by binding the powder before it is fired in a forge (photo: ExOne)

Another professional approach that also uses a powder base is called Binder Jetting. In this case, the layers are formed by gluing metal particles together and then sintering (or fusing) them in a high-temperature furnace, just like it is done with ceramics.

Another option, which is also similar to working with ceramics, is mixing metal powder into metal paste. A pneumatically extruded 3D printer (similar to a syringe bioprinter or an inexpensive food printer) forms 3D objects. When the required shape is reached, the object is sent to the furnace, i.e. in the mountains This approach is used in the Mini Metal Maker, apparently the only inexpensive "metal" 3D printer.

A pneumatically extruded 3D printer (similar to a syringe bioprinter or an inexpensive food printer) forms 3D objects. When the required shape is reached, the object is sent to the furnace, i.e. in the mountains This approach is used in the Mini Metal Maker, apparently the only inexpensive "metal" 3D printer.

Metal 3D printing process #3:

Metal Deposition

It may seem that the only 3D printing process that is left out of working with metals is layer-by-layer deposition. This is not entirely true. Of course, on some desktop device, simply fusing metal threads onto the base will not work. However, very large steel companies can do it. And they do. There are two options for working with "metal surfacing".

One is called DED (Directed Energy Deposition) or Laser Cladding. Here, a laser beam is used to melt the metal powder, which is slowly released and solidifies as a layer, and the powder is fed using a robotic arm. nine0003

nine0003

Usually the whole process takes place in a closed chamber, but in the MX3D project, conventional 3D printing techniques were used to build a full-sized bridge. Another option for metal fusion is called EBAM (Electron Beam Additive Manufacturing - additive electron beam technology), which is essentially soldering, in which a very powerful electron beam is used to melt 3 mm titanium wire, and the molten metal forms very large finished structures. As for this technology, its details are known so far only to the military. nine0003

Metal 3D printing. Metals

3D Printing Metal #1: Titanium

Pure titanium (Ti64 or TiAl4V) is one of the most commonly used metals for 3D printing and is definitely one of the most versatile, strong and lightweight. Titanium is used both in the melting process in a preformed layer and in the process of spraying a binder and is used mainly in the medical industry (for the manufacture of personal prostheses), as well as in the aerospace industry, automotive and machine tools (for the manufacture of parts and prototypes). But there is one problem. Titanium is very reactive and explodes easily in powder form. Therefore, it is necessary that titanium 3D printing takes place in a vacuum or in an argon environment. nine0003

But there is one problem. Titanium is very reactive and explodes easily in powder form. Therefore, it is necessary that titanium 3D printing takes place in a vacuum or in an argon environment. nine0003

3D Printing Metal #2: Stainless Steel

Stainless steel is one of the cheapest 3D printing metals. At the same time, it is very durable and can be used in a wide range of manufacturing and even artistic and design applications. The type of steel alloy used also contains cobalt and nickel, is very difficult to break, and has a very high elasticity. Stainless steel is used almost exclusively in industry.

3D Printing Metal #3: Inconel

Inconel is a superalloy manufactured by Special Metals Corporation, its registered trademark. The alloy consists mainly of nickel and chromium and is very heat resistant. Therefore, it is used in the oil, chemical and aerospace (for black boxes) industries.

3D Printing Metal #4: Aluminum

Due to its lightness and versatility, aluminum is very popular in 3D printing. Aluminum alloys are commonly used. nine0003

Aluminum alloys are commonly used. nine0003

3D Printing Metal #5: Cobalt-Chromium

This alloy has a very high specific strength (i.e. strength divided by density, which generally indicates the force required per unit area to break). It is most commonly used in the manufacture of turbines, dental and orthopedic implants, where 3D printing has become the dominant technology.

Metal for 3D printing №5. Copper and Bronze

With few exceptions, copper and bronze are used in wax melting processes, rarely in layer melting. The fact is that these metals are not very suitable for industry, they are more often used in the manufacture of works of art and crafts. ColorFabb offers both metals as the basis for a special metal filament. nine0003

Metal for 3D printing №6. Iron

Iron, incl. magnetic, also mainly used as an additive to PLA-based filaments, which are produced, for example, by ProtoPasta and TreeD.

Metal for 3D printing №7.

Gold, silver, and other precious metals

Gold, silver, and other precious metals

Most preformed-layer companies can 3D print precious metals such as gold, silver, and platinum. Here, along with the preservation of the aesthetic properties of materials, it is important to achieve optimization of work with expensive starting powder. Precious metal 3D printing is required for jewelry, medical applications and electronics. nine0003

Metal 3D printing. Printers

Do not even hesitate - the purchase of a metal 3D printer will not pass without a trace on your budget. It will cost at least 100-250 thousand dollars. Here is a list of a variety of "metal" printers, some of which can be found in firms providing 3D printing services.

Metal 3D Printer #1:

Sciaky EBAM 300 Metal Filament Printing

If you need to print really large metal structures, Sciaky's EBAM technology is your best bet. By order, the device can be built in almost any size. This technique is used mainly in the aerospace industry and the military. The largest of Sciaky's serial printers is the EBAM 300. It prints objects in a volume of 5791 × 1219 × 1219 mm.

This technique is used mainly in the aerospace industry and the military. The largest of Sciaky's serial printers is the EBAM 300. It prints objects in a volume of 5791 × 1219 × 1219 mm.

The company claims the EBAM 300 is also one of the fastest industrial 3D printers on the market. A three-meter-sized titanium part for an aircraft is printed on it in 48 hours, while the material consumption is about 7 kg per hour. In general, forged parts that usually take 6-12 months to complete can be made in 2 days with this 3D printer. nine0003

Sciaky's unique technology uses a high energy electron beam that melts a 3mm titanium rod at a typical melting rate of 3 to 9 kg per hour.

Metal 3D Printer #2:

Fabrisonic UAM - Ultrasonic 3D Printing

Another way to print large metal parts is UAM (Ultrasound Additive Manufacturing Technology) from Fabrisonic. The devices of this company are three-axis CNC cutters, to which welding heads are added for the additivity of the process. The metal layers are first cut and then ultrasonically welded. The largest Fabrisonic 7200 printer operates in a volume of 2 x 2 x 1.5 m.

The metal layers are first cut and then ultrasonically welded. The largest Fabrisonic 7200 printer operates in a volume of 2 x 2 x 1.5 m.

#3 Metal 3D Printer:

Concept Laser XLine 1000 Metal Powder 3D Printing

modeling - 630 × 400 × 500 mm, and itself the size of a house.

Its German company, one of the main suppliers of 3D printers for aerospace giants like Airbus, recently introduced a new device, the Xline 2000.

This equipment uses two lasers and the working volume is 800 × 400 × 500 mm. Uses LaserCUSING laser technology (a variant of selective laser fusion) from Concept Laser, which allows you to print alloys of steel, aluminum, nickel, titanium, precious metals and even some pure substances (titanium and stainless steel).

Metal 3D printing. Services

There are more than 100 companies worldwide offering metal 3D printing services. We list the most popular services for consumer needs. nine0003

nine0003

#1 Metal 3D Printing Service: Shapeways

The world's most popular 3D printing service, Shapeways offers two types of services. As a consumer, you can choose from a wide range of professionally designed objects, customize them, and then have them printed to your specifications. Like other 3D printing services, Shapeways offers a platform for designers to sell and print their work. Shapeways is also a good place for rapid prototyping: customers benefit from industrial-grade printers (EOS, 3D Systems) and personal technical support. nine0003

3D printing metals: aluminium, brass, bronze, gold, platinum, precious metal plating, silver, steel. There are also wax molds for jewelry purposes.

Metal 3D Printing Service #2: Sculpteo

Like Shapeways and i.materialise, Sculpteo is an online 3D printing service that allows anyone to upload 3D models and send them for fabrication in a wide range of materials. Like its competitors, Sculpteo provides a platform for hobbyists and professionals to showcase and sell their designs. The stable of Sculpteo printers includes highly professional machines from 3D Systems, EOS, Stratasys and ZCorp. Extensive technical documentation will help identify design flaws and select the right material for the project. nine0003

The stable of Sculpteo printers includes highly professional machines from 3D Systems, EOS, Stratasys and ZCorp. Extensive technical documentation will help identify design flaws and select the right material for the project. nine0003

3D printing metals: alumide (plastic with aluminum particles), brass, silver.

Metal 3D Printing Service #3: iMaterialise

Materialise is a company that works with industrial clients to prototype 3D printed products. For casual users and designers, Materialize offers an online 3D printing service called i.materialise. As with Shapeways, this service allows anyone to upload their 3D designs and print them out. Once an object has been uploaded and successfully printed, a designer can list it for sale either in the gallery of the i.materalise online store or by embedding some code into their site. nine0003

3D printing metals: alumide (plastic with aluminum powder), brass, bronze, copper, gold, silver, steel, titanium.