3D printed cogs

3D Printed Gears: Guide & Best Free Downloads

3D printing your own working mechanisms is a big part of a lot of the more complex 3D printing projects you’ll come across. Naturally, many of these homemade mechanisms need 3D printed gears to work.

Whether it’s as cool fidget toys or part of a larger project, making reliable 3D printed gears is often the linchpin of a design.

Like different ways of tying knots have their own specific purpose, there are also a lot of different gear designs suited to what you’re building. 3D printing a simple cog-style gear will work for some mechanisms, while it won’t be viable for others.

Here we’re going to look at how to 3D print gears, what kinds you can print and why, and also some useful hints and tips to keep in mind when printing. By the time you’re done here, you’ll have all the know-how to print your own gears with confidence!

Common Uses for 3D Printed Gears

In this electrical age of ours, it can be hard to think about what gears are actually used for these days. Generally speaking, when we think of gears we often think of old factories, steampunk settings, and ancient Indiana Jones-style trap mechanisms.

But gears do still play an important part in a lot of machines and tools even now. Most mechanical locks still use gears and tumblers to work, as do analog watches, pulley mechanisms, and tools like woodworking and car repair equipment.

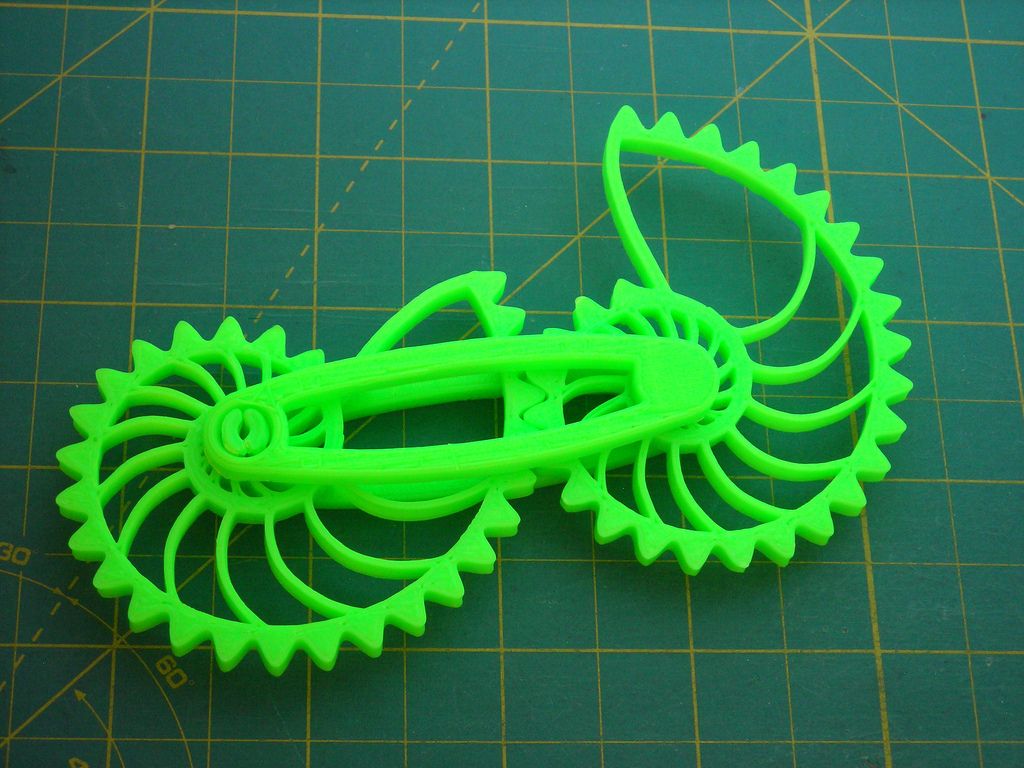

Even fun things like homemade fidget toys use 3D printed gears as a primary staple. The mechanical concepts of speed and torque are applied to gears to make toys like Beyblades too, which you can also 3D print.

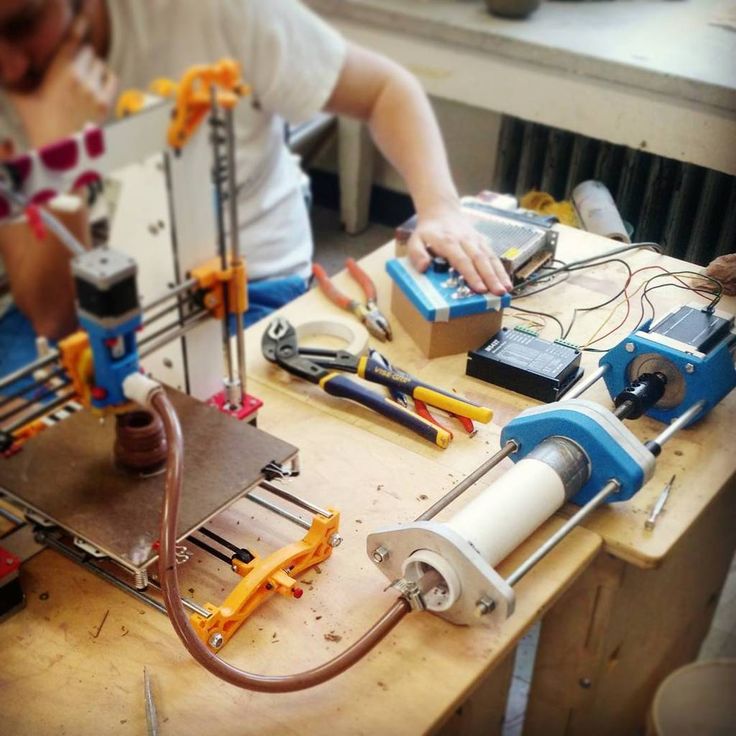

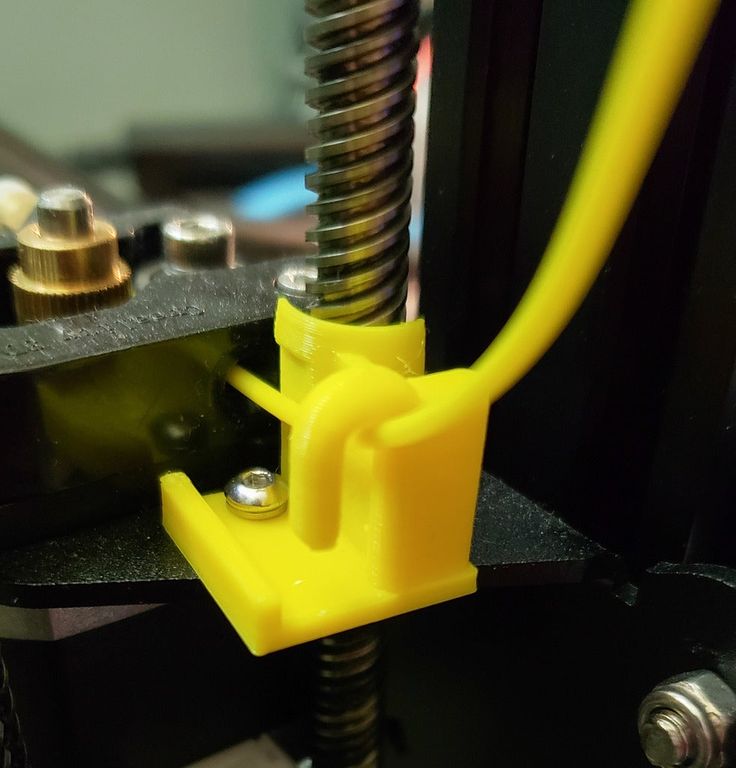

You can even use 3D printed gears to repair or enhance other machines like this geared extruder and this gluing gear print for general maintenance. Any of these designs are worth saving if you plan on working with mechanical prints for a while yet, but they also work well as one-off projects to further your 3D printing journey.

These kinds of gears are much cheaper than visiting repair stores or getting custom-made designs from professionals. As 3D prints vs. traditional metal gears, they won’t last as long, but they’re a good option if you’re on a budget or just prefer to fix or make things yourself.

As 3D prints vs. traditional metal gears, they won’t last as long, but they’re a good option if you’re on a budget or just prefer to fix or make things yourself.

3D Printing Gears: Ideal Filaments

Different 3D printing filaments are better suited to different projects. Gears are designed to be in near-constant motion, so the filament you use should be durable to ensure longevity and reliability.

The nature of 3D printing means you’ll never really have anything as strong and tough as something factory-made and metal, but that doesn’t mean there aren’t a few things to keep in mind to ensure you get the best results.

Naturally, you’ll want to use the strongest filament available to you to 3D print your gears.

These include filaments like:

- Nylon

- Polycarbonate

- PETG

But, if none of those are available you can actually 3D print gears using PLA if that’s all you have available.

PLA may not be the first choice when it comes to strength, but with careful measurements and post-processing, you’d be surprised at how well it holds up over time.

If you’ve got the means, though, then I recommend using PLA+ if you can. PLA+ is an enhanced version of PLA in terms of durability and longevity. While more expensive, and a little trickier to find, PLA+ has been proven to make surprisingly reliable 3D printed gear mechanisms before.

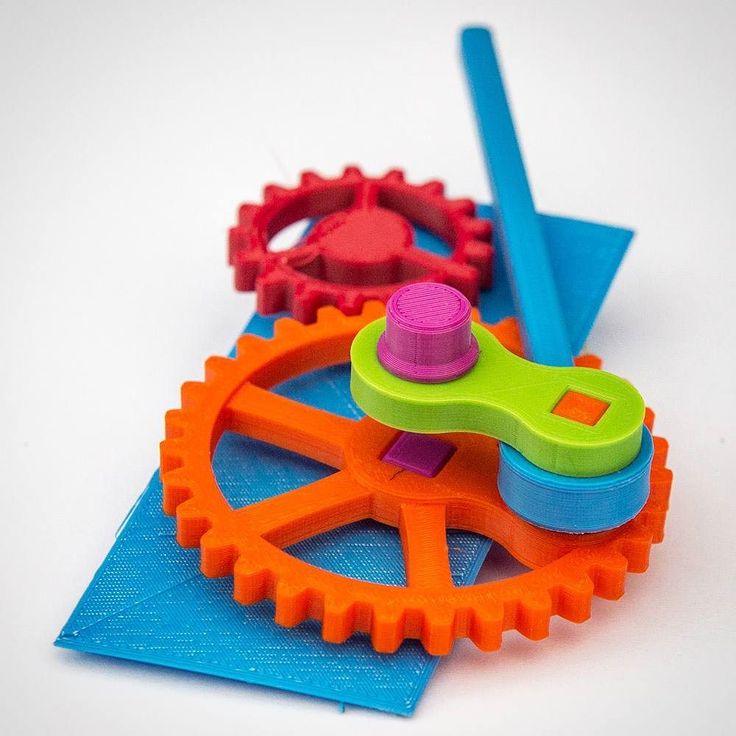

Cool 3D Printed Gears

Now that you know what to do, it’s time to get printing gears! While you’ve probably got some ideas in your head already, there are still plenty of cool 3D printed gear designs and projects out there to sink your teeth into.

Here we’re going to look at a few of the best 3D printing projects that use gears practically in their designs.

Spider-Man Web Shooter

Maybe not the first thing that came to mind when thinking about 3D printed gears, but definitely the first one I wanted to talk about.

This working Spider-Man web shooter uses small 3D printed gears originally designed for watch repair to shoot webs just like everyone’s favorite web-head!

Walking Cat

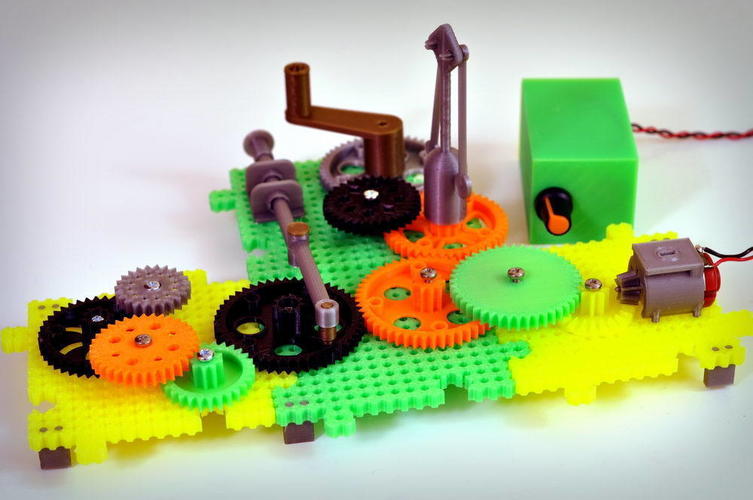

Gears are an important part of many moving mechanisms, and this walking cat makes for a great project both in general and also for testing out your skills with 3D printing gears.

As well as being a fun toy and a great way to get used to the more complex designs 3D printing is capable of, the walking cat also uses plenty of different gears at different sizes and angles.

This makes it both a great project to sink your teeth into, as well as an excellent learning resource to see how different gears interact with each other in one mechanism.

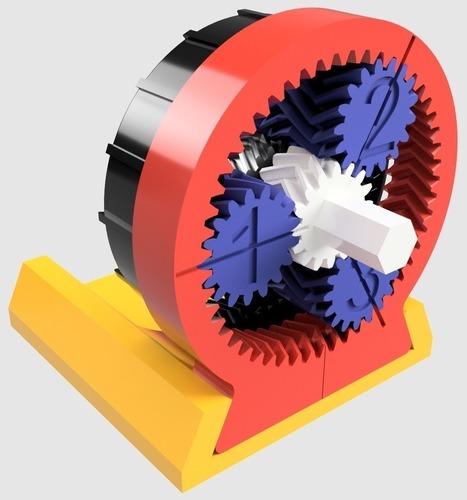

Planetary Gearbox

Another great learning resource, as well as a fun print, is this planetary gearbox. It works like a numbered padlock, but with the inner workings visible to you.

This not only looks cool, but also makes for a good introduction to the basics of gear functionality as well as a learning tool for children or beginners in mechanical engineering.

Lotus Automata

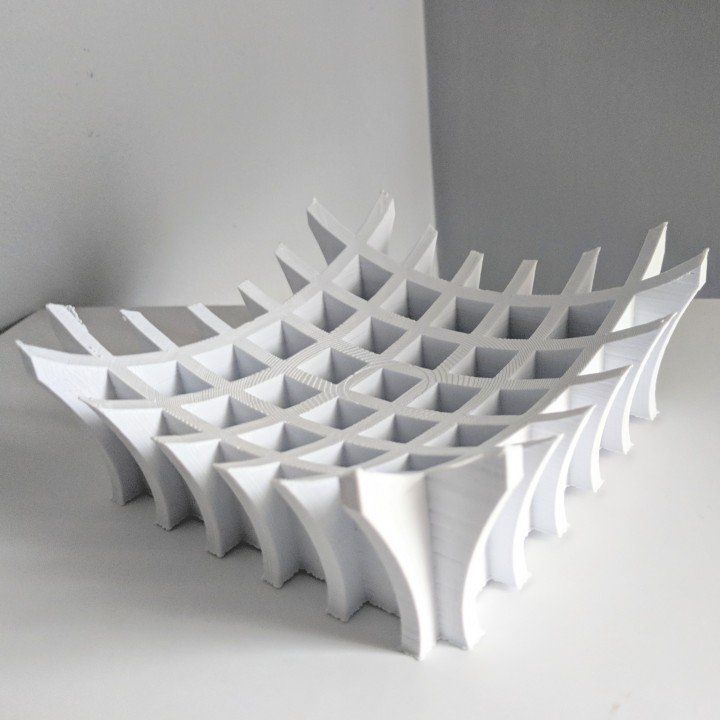

One of the coolest (and prettiest) 3D printed gear mechanisms I’ve come across is the lotus automata, a hand-cranked display piece that opens up like a real lotus flower.

While you’ll need plenty of different prints with different colors, the outcome is a great centerpiece that works well with different kinds of gears to make a fun and beautiful print that’s well worth the time and effort.

Types of Gears

There are a lot of kinds of gears, each with their own ideal purposes. Knowing which one is best for you is important for making sure your mechanism works at peak performance.

While it’s unlikely you’ll be 3D printing generators or high-end water pumps, we’re going to briefly go over what kinds of gears best fit which uses so you’ll have a better idea going forward.

Spur Gears

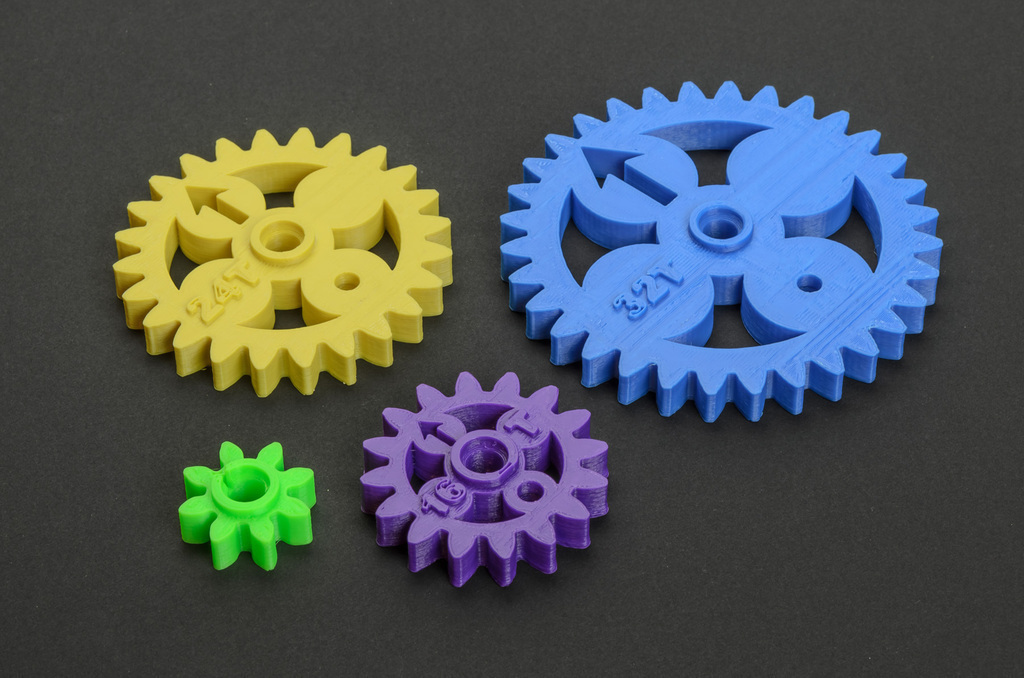

Spur gears are what most of us picture when we think of gears, and are the most common type of gear to 3D print.

Spur gears are simple toothed cogs that move with each other for mechanisms like pulleys and clocks, and are very useful in a variety of sizes to keep machines ticking along nicely.

Helical Gears

Helical gears are best described as curved spur gears. They are capable of withstanding more torque than their simple counterparts, and are commonly used for more load-bearing machines like generators and high-strength pumps.

Worm Gears

Worm gears employ a changing parallel design. Unlike standard gears, they can be manipulated to lock in place. This comes in handy for self-locking mechanisms like doors and hard packaging.

Unlike standard gears, they can be manipulated to lock in place. This comes in handy for self-locking mechanisms like doors and hard packaging.

Worm gears effectively work against each other, and require a lot more care and maintenance as this causes a lot more wear over time.

Bevel Gears

Bevel gears are cone-shaped gears that work perpendicular to each other. The curved teeth and size difference between two touching gears mean they can handle a lot more speed than most other gear types with ease.

Bevel gears come in a lot of different types on their own, which we’re not going to go over here. The most common uses for these are in fast-moving machines and tools like vehicles and power drills.

While bevel gears can be 3D printed for fun and practical uses, their most common uses aren’t ideal for 3D printing as the heat generated by the speed is too much for most filaments to handle.

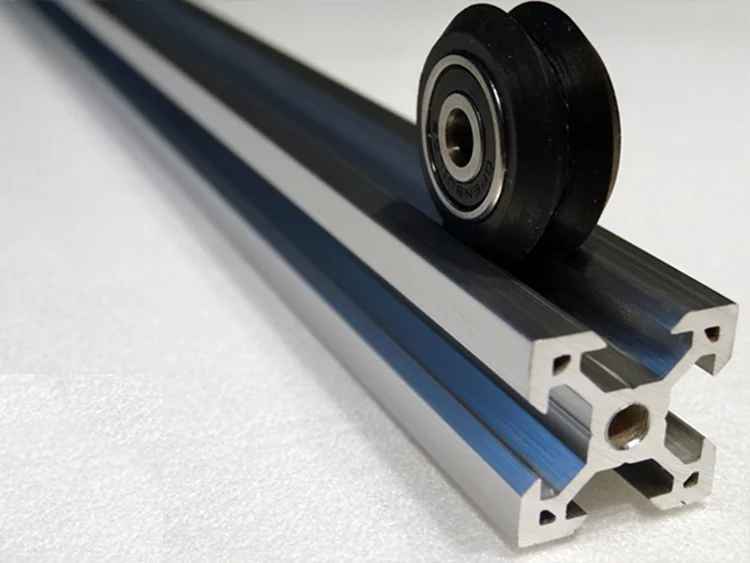

Rack and Pinion Gears

Rack and pinion gears involve one gear moving with a straight, toothed line. Designed to move back and forth seamlessly, they work best as guides for steering mechanisms on tools and vehicles as well as weighing scales and seesaws, which need to move in two directions with ease.

Designed to move back and forth seamlessly, they work best as guides for steering mechanisms on tools and vehicles as well as weighing scales and seesaws, which need to move in two directions with ease.

How to 3D Print Gears: Helpful Tips

As you’ve probably already guessed, 3D printing gears requires more preparation and precision than the average print. To make sure you get working gears, you’re going to need to think and plan ahead, especially if you’re printing your gears from scratch.

Here are some helpful steps and tips to make sure you get reliable results.

Plan Before You Print

Careful planning is an important step in any 3D print, but it’s even more important when you’re printing working mechanisms with moving parts.

While a millimeter or two in any given direction won’t make much of a difference in most 3D printing projects like statuettes and ornaments, with gears it can mean the difference between a functioning mechanism and a weird paperweight.

Always double-check your measurements before you get printing. You can do this with particular precision if you have particularly good STL editing software that can test your mechanisms before they’ve even been printed.

Test and Prototype

There’s nothing worse than having a great design only to find out all too late that it doesn’t quite work. The waste of both materials and time is always frustrating, which is why testing and prototyping is a great way to avoid this annoyance.

Scaling your design down before printing is one way of prototyping. The print will use less material overall and take less time to print. What you’ll have will be a miniature version of your gears so you can see for yourself if they fit well together and work as they should.

Just be sure to scale the model down exactly without tweaking anything else, otherwise you’ll get inaccurate measurements that will ultimately be useless as prototypes.

It’s not just the gears you’ll want to test, though, so be sure to also scale down the shaft on which the hears will be turning. The distance between the gears is just as important as the teeth fitting together, so be sure to test every inch of your mechanisms before beginning what will hopefully be the final print.

The distance between the gears is just as important as the teeth fitting together, so be sure to test every inch of your mechanisms before beginning what will hopefully be the final print.

Make Notes and Save the Files

Once you’ve got a working file, be sure to save it as is so you can return to it at any time. This will help for not only duplicate prints, but also later repairs and sharing with your friends.

As mentioned above, 3D printed gears won’t last as long as traditional metal ones, regardless of what filament you use. So keeping the file safe and easy to find will be handy when you need to replace worn parts.

FAQs

Are 3D printed gears any good?

Generally speaking, 3D printed gears won’t be as durable as store-bought metal gears. This isn’t to say they’re not good, however, and with enough careful planning, 3D printed gears will be perfectly workable.

Is PLA strong enough for gears?

Despite being one of the weaker filaments, PLA can be used to make 3D printed gears. While other filaments like nylon and PETG are preferable, PLA will still do the job. If you must use PLA, we recommend looking into PLA+ for any 3D printed gears and moving parts.

While other filaments like nylon and PETG are preferable, PLA will still do the job. If you must use PLA, we recommend looking into PLA+ for any 3D printed gears and moving parts.

How do you 3D print gears?

3D printing gears is as simple as any other project, the main thing to keep in mind is the precision of both the gear teeth and the shaft. With enough planning and prototyping, you can make working gears with just about any FDM filament.

How do you attach 3D printed gears to a shaft?

If you’re working with a pre-existing design, your gears and shaft should already fit together easily. However, if you’re designing your gears from scratch, you’ll need to make sure the shaft and the gear opening match in size.

Gears can be attached to shafts using screws or adhesives. For 3D printed gears, adhesives work better as they will be easier to remove for future repairs.

3D Printed Gears | igus®

- Home

- Custom Parts Services

- 3D printed gear

Upload CAD data and order

Create CAD file of your gears

Use the gear service life calculator

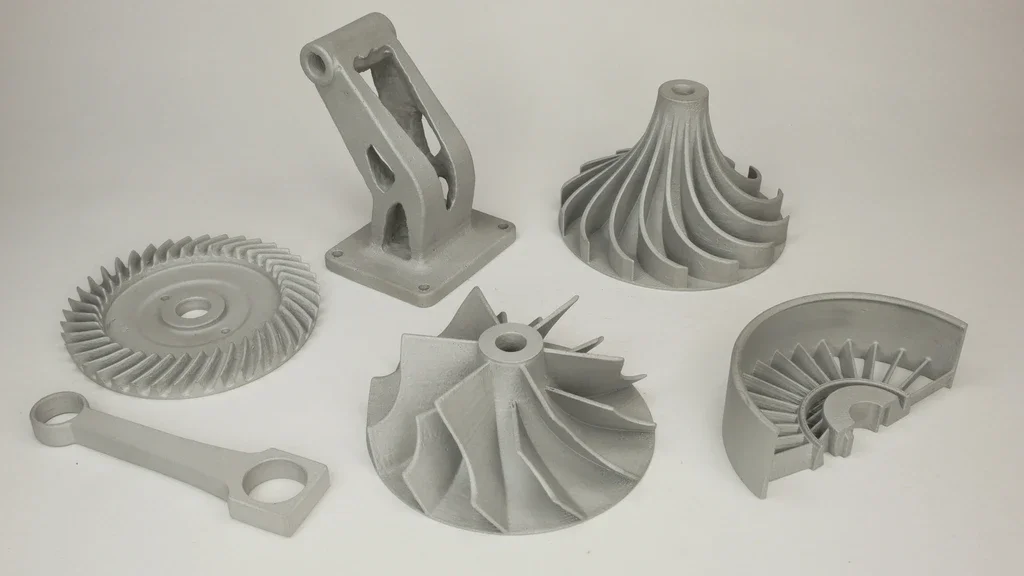

Additive manufacturing for low-wear gears, spur gears, bevel gears, sprockets and worm wheels

Our 3D-printed gears are made of low-friction, maintenance-free, self-lubricating plastic printing materials that have been engineered to last up to 50 times longer than standard 3D-printing materials inside moving applications. We extensively test our iglide® polymers inside our 41,000ft.2test laboratory to ensure every 3D-printed part offers exceptional wear resistance comparable to injection-molded components. All gear types can be customized to meet your requirements, including weight, tooth shape, and transmission ratio, and can be printed with a wall thickness of 0.5mm or more.

We extensively test our iglide® polymers inside our 41,000ft.2test laboratory to ensure every 3D-printed part offers exceptional wear resistance comparable to injection-molded components. All gear types can be customized to meet your requirements, including weight, tooth shape, and transmission ratio, and can be printed with a wall thickness of 0.5mm or more.

Benefits:

- Gears, spur gears, bevel gears, worm wheels, sprockets and more made of durable iglide® materials

- Shipped in 24 -72 hours

- Individual gears - no minimum order quantity

- Long service life thanks to optimized tooth shape in our gear configurator

- Low-wear and friction-optimized iglide® materials to choose from

- Service life and specifications comparable to iglide® injection-molded parts

Gears made of wear-resistant polymers

POM vs. iglide® I6: downtime at POM, iglide® I6 hardly any abrasive wear

Test parameters:

- Torque: 4.

9Nm

9Nm - Speed: 12 [rpm]

- Counter partner: hard anodized aluminum

- Duration: 2 months

1. POM: 321,000 cycles: High wear

2. POM: 621,000 cycles: downtime

3. iglide® I6: 1 million cycles: low wear

Test result: We tested a variety of 3D-printed and mechanically manufactured polymers in the worm gear test. No other polymer reached as long of a service life as our wear-resistant iglide® I6 material (in SLS 3D printing). Worm gears made of iglide® I6 are also used inside our robolink® robotic arm modular system.

Calculate service life of your gear

Our service life calculator allows you to optimize the size, number of teeth or teeth module of your gear to improve its durability.

Use the gear service life calculator

3D printing service

Use our online gear shop to print gears, spur gears, bevel gears, sprockets and worm gears made of our low-friction, self-lubricating, maintenance-free iglide® polymers. iglide® lasts 50 times longer inside moving applications than standard 3D-printing materials.

iglide® lasts 50 times longer inside moving applications than standard 3D-printing materials.

Visit our 3D printing lab

We continuously test the tribological properties of our iglide® materials inside our 41,000-square-foot test lab.

Filament and laser-sintering powder made of iglide® polymers

- Up to 50 times more abrasion resistant than standard material

- Wear-resistant components for prototypes and small batches

- Simple processing

- Ideal for tribological applications

- Self-lubricating and dirt resistant

Learn about our 3D printing materials

Discuss your project with a 3D Printing expert

Whether you're interested in turnkey, fully assembled solutions or looking to build your own customizable project, learn more about how igus® can assist you with a solution based on your specific application and requirements. Contact us via the form below or call us at (800) 521-2747 to discuss your project today!

Contact an Expert

Free STL file M4 screws 3D printed flat bottom・Design for download and 3D printing・Cults

Curse D20

Free

Baby Yoda remix in the form of a keychain or earring.

Credit for jamesjenuwine

Credit for jamesjenuwine Free

Single ring LOTR

Free

nine0003 Keyboard key with skullFree

1/4 20 Camera screw

Free

Yoda Mini Keychain Remixed by itech4dP

Free

Key ring with logo and weed symbol

Free

Rock concert stage

Free

The best files for 3D printers in the Tools category

Optapi, hive optimization accessory

2.49 €

Automatic irrigation

0,50 €

RADIAL TRAY FOR SMD ELECTRONIC COMPONENTS

1 €

UFS-061B Improved Spin Drill

Free

WALLET

0,50 €

Stringing Test

Free

Bumper for Arduino Uno Clone

Free

9g servomotor prosthesis

Free

Bestsellers in the Tools category nine0037

Bambu AMS Stand for placement raised 2nd block behind

1. 13 €

13 €

Armadillo - flexible wire conduit

1.67 €

SUPERBOX

1,50 €

Quick print stackable parts containers / storage boxes

2.86 €

nine0003 telephone ring holder0.90 €

PET-Machine, make your own plastic bottle filament at home!

15 €

Ender 3 S1 Air duct for stock fan

€1.20 -10% 1.08 €

2.50 €

Fire hydrant container

1.88 €

Shrek Pooping Toothpaste Topper

2. 82 €

82 €

Phone holder

2.44 €

PRECISION CALIPER 3D PRINT DIY

3.11 €

Bit holder Spartan 4 mm Hex

1,80 €

Ender 3 Briss fang Gen2, red lizard, spider, nf crazy, dragonfly, etc.

1.72 €

209 Flash Bang / Ukrainian Hot Potato

0,94 €

ENDER 3 S1/PRO SPRITE, HOTEND 4020 OR 5015 FAN PROBE NO Y OFFSET

€2.28 -twenty% 1.82 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so support us in maintaining activities and creating future developments is very simple. Here are 4 solutions available to everyone:

Here are 4 solutions available to everyone:

-

AD: Disable your AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community! nine0006

3D printed propellers and other ship parts are being tested in Arkhangelsk

News

abroad, said the governor of the Arkhangelsk region Alexander Tsybulsky.

“This work makes it possible to produce parts on 3D printers, including those that were not available due to Western sanctions. This is direct import substitution. Parts such as turbine blades for power plants on ships have already been manufactured, installed and are in operation. Prototypes of ship propellers are now being tested. This is a new generation in the production of components, any part of even the most complex shape can be ergonomic, lightweight and can be produced and assembled directly on the ship,” Alexander Tsybulsky said at the Arctic Ports forum taking place these days. nine0006

This is a new generation in the production of components, any part of even the most complex shape can be ergonomic, lightweight and can be produced and assembled directly on the ship,” Alexander Tsybulsky said at the Arctic Ports forum taking place these days. nine0006

According to the official, research is being conducted by employees of the Zvyozdochka ship repair center, the St. Petersburg State Marine Technical University (SPbGMTU), the Kurchatov Institute and the Lomonosov Northern (Arctic) Federal University (NAFU).

Gleb Turichin (left) with a propeller printed on an additive machine using direct laser growth technology

DED Star SPbGMTU ILiST Arctic ports

Follow author

Follow

Don't want

2

Article comments

More interesting articles

17

Subscribe to the author

Subscribe

Don't want

At the end of November, the Almaz-Almaz concern announced the launch of serial production of Dobryn quadrocopters.