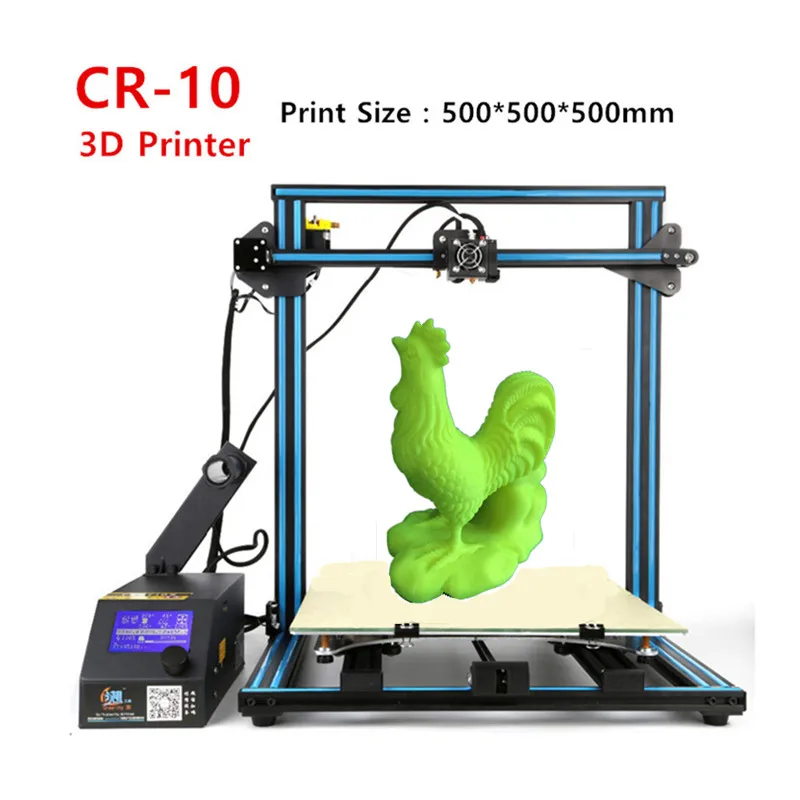

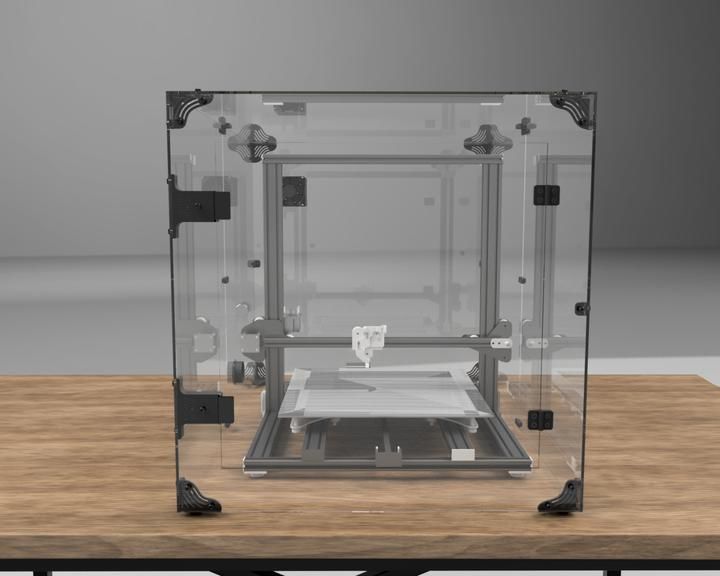

K10 3d printer

Kuongshun K10 Open Source Fast Assembly 3D Printer 220*220*260 High PFrinting Accur Manufacturers and Suppliers China - Pricelist

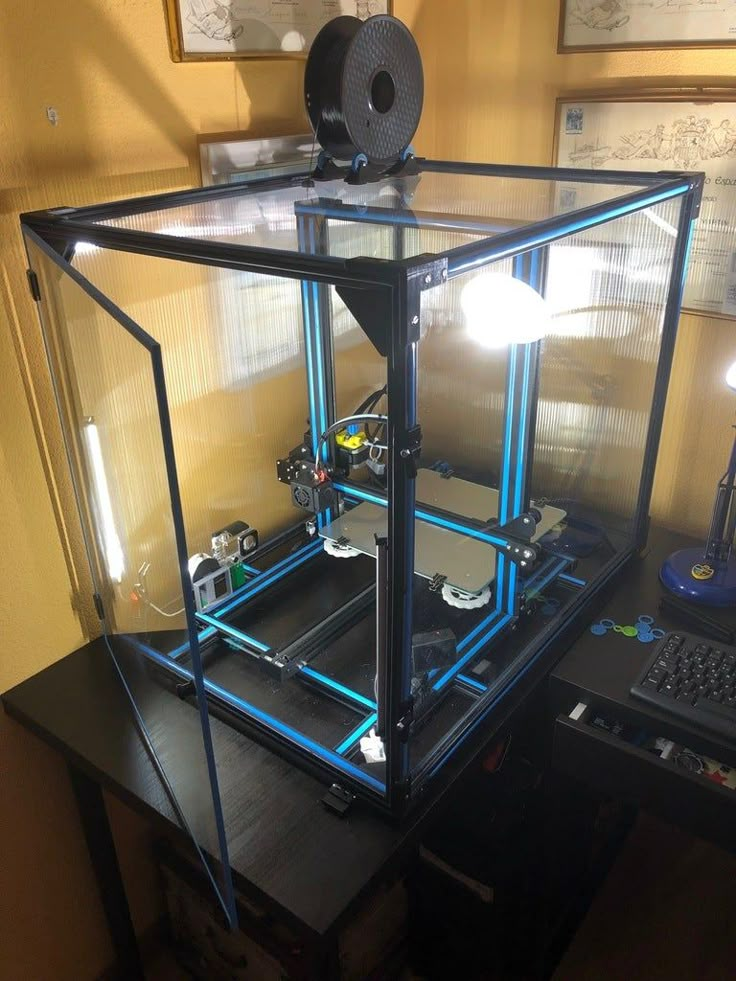

Kuongshun K10 3D printer, using open source 2560 control board, is reliable, cost-effective and easy-to-assemble. Running stably, it aims to provide users with quality printout and satisfactory printing experience.

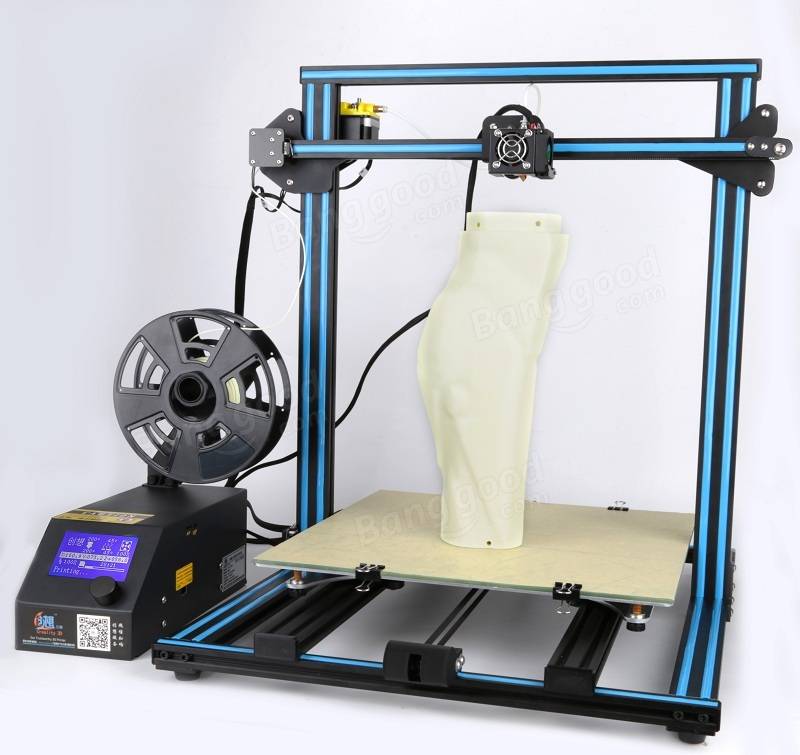

Its classic blue and black color combo imparts a touch of solemnity and simplicity, which also embodies our commitment to quality products. The modularized design provides you with an easier assembly experience.

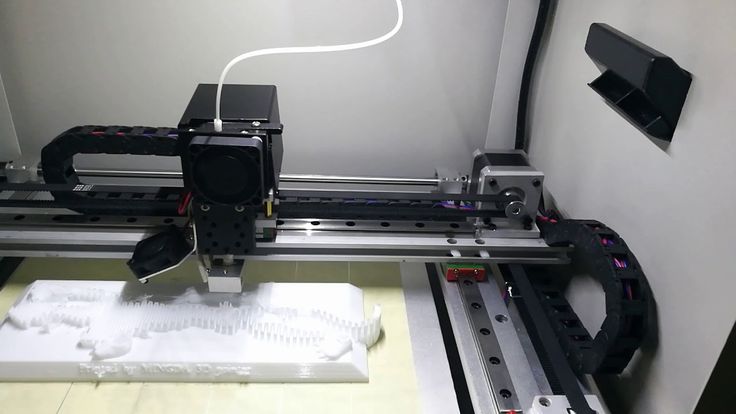

Keeping Prusa I3 3D printers’ gantry structure and with its build volume as 220*220*260mm³, K10 makes the best of the building platform and gives you a full view of the printing details. Its well-designed extruder greatly reduces the risk of clogging or leaking. The Bowden design of the extruder makes the printing head move lightly and stably, greatly enhancing the printing efficiency. The V-shaped wheels and rails on each axis, made from wear-resistant aluminum profile, could, in a large measure, reduce the printing noise and offer you a quiet 3D printing environment.

Main Features:

1. Its classic blue and black color combo imparts a touch of solemnity and simplicity.

2. With its build volune as 220*220*260mm³, K10 makes the best of the building platform and gives you a full view of the printing details.

3. Featuring printing accuracy of 0.1 mm, K10 delivers exquisite prints with delicate texture, sleek contour and stable structure.

4. The V-shaped wheels and rails on each axis, made from wear-resistant aluminum profile, could, in a large measure, reduce the printing noise.

5. K10 comes with OPEN SOURCE 2560 control board, providing limitless space for you to modify the firmware and tinker with your printer.

Printing parameters

Printing technology: FDM

Build volume: 220*220*260 mm³

Printing accuracy: 0.1mm

Positioning precision: X/Y:0.011mm. Z: 0.0025mm

Printing speed: 180 mm/s (max)

Filament diameter: 1.75mm

Nozzle diameter: 0.4mm

Filament: ABS / PLA /flexible PLA/wood-polymer/PVA/HIPS/PETG, etc.

Temp:

Max temp for hotbed: 100℃

Max temp for extruder: 250℃

Software resources:

Control software: Repetier-Host, Simplify 3D, Cura, Slic3r, etc.

File format: .STL, G.code

Electrical:

Power supply: Input: 115V/230V

Output: DC 24V, 360W

Connectivity: SD card (support stand-alone printing)

Display screen: LCD 2004

Mechanical:

Frame: Aluminum profile

XY Rods: Wear-resistant aluminum profile

Z axis: Lead screw

Stepper Motors: 1.8°step angle with 1/16 micro-stepping

Physical Dimensions & Weight

Machine Dimension: 478 x 413 x 485mm³

Shipping box Dimension: 500 x 470 x288 mm³

Machine Net weight: 7.6kg

Machine Gross weight: 9.6 kg

Hot Tags: kuongshun k10 open source fast assembly 3d printer 220*220*260 high pfrinting accur suppliers China, manufacturers, low price, buy discount, pricelist, price, made in China

K10 3d Printer With 2004lcd Mage 2560 Suppliers, all Quality K10 3d Printer With 2004lcd Mage 2560 Suppliers on Alibaba.

com

comSuppliers › Computer Hardware & Software › Printers › 3 Supplier(s)

Favorites Compare

Country/Region:

China

Main Products:

Starter Kit,Remote Control Car Kit,3D Printer,PCBA

Total Revenue:

US$5 Million - US$10 Million

Top 3 Markets:

South Asia 25. 0% , North America 15.0% , Oceania 15.0%

0% , North America 15.0% , Oceania 15.0%

87.2% Response Rate

Contact Supplier

Favorites Compare

Country/Region:

China

Main Products:

Industrial Robot,Intelligent Robotic Arm,3D Printer,Screw Machine,Automatic Soldering Machine

Total Revenue:

Below US$1 Million

Top 3 Markets:

Domestic Market 45. 0% , North America 30.0% , Southeast Asia 10.0%

0% , North America 30.0% , Southeast Asia 10.0%

93.9% Response Rate

Contact Supplier

Favorites Compare

Country/Region:

China

Main Products:

power bank,LED LCD screen,outdoor,Oil painting,Promotion packing

Total Revenue:

US$10 Million - US$50 Million

Top 3 Markets:

Eastern Europe 25% , North America 25% , South America 15%

0. 0% Response Rate

0% Response Rate

Contact Supplier

2004lcd mage k10 3d printer ( View all 3 Supplier(s) )

Favorites Compare

Country/Region:

China

Main Products:

Industrial Robot,Intelligent Robotic Arm,3D Printer,Screw Machine,Automatic Soldering Machine

Total Revenue:

Below US$1 Million

Top 3 Markets:

Domestic Market 45.0% , North America 30. 0% , Southeast Asia 10.0%

0% , Southeast Asia 10.0%

93.9% Response Rate

Contact Supplier

Favorites Compare

Country/Region:

China

Main Products:

power bank,LED LCD screen,outdoor,Oil painting,Promotion packing

Total Revenue:

US$10 Million - US$50 Million

Top 3 Markets:

Eastern Europe 25% , North America 25% , South America 15%

0. 0% Response Rate

0% Response Rate

Contact Supplier

Favorites Compare

Country/Region:

China

Main Products:

Starter Kit,Remote Control Car Kit,3D Printer,PCBA

Total Revenue:

US$5 Million - US$10 Million

Top 3 Markets:

South Asia 25.0% , North America 15.0% , Oceania 15. 0%

0%

87.2% Response Rate

Contact Supplier

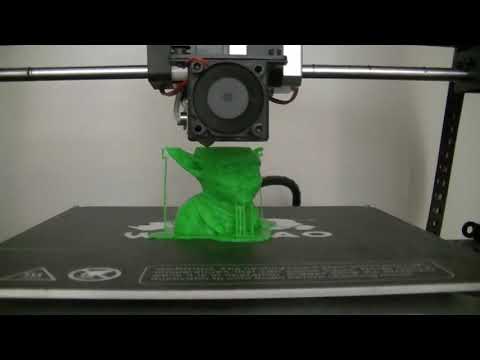

As a beginner I bought a 3D printer. Choosing, setting up, problems and solving practical problems / Sudo Null IT News

A few months ago, I was thinking about purchasing such a device because I wanted to print a broken part of my robot vacuum cleaner. About a month ago I bought a device I liked on eBay. That's what was important to me when choosing a 3D printer. nine0005

Which printer was needed?

Considering that I knew almost nothing about 3D printers (except for a few articles read here, on Habré), the important points were:

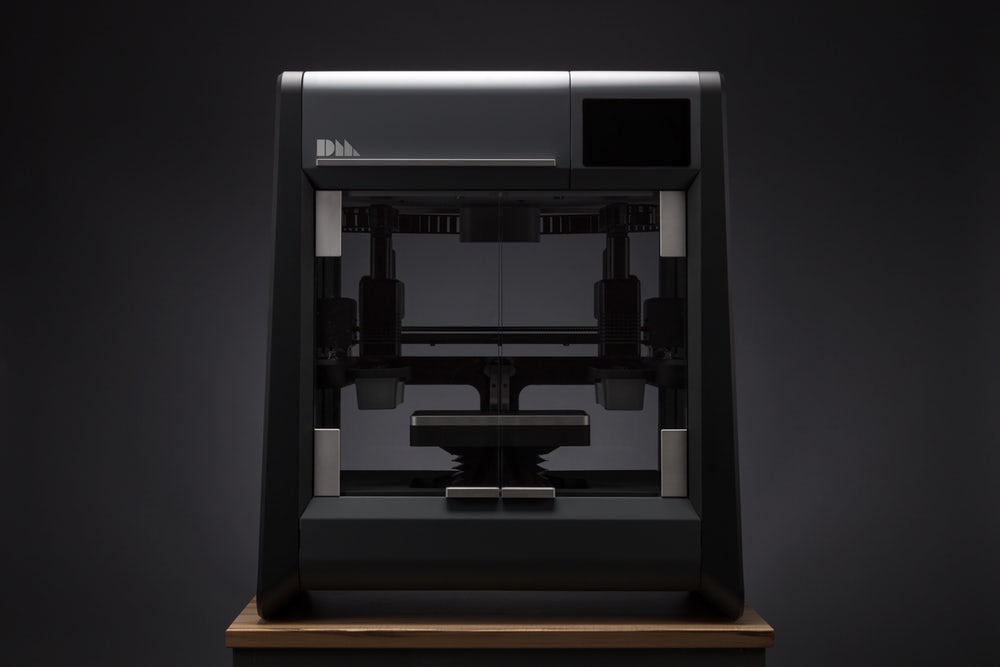

- Printer performance out of the box. I have seen several articles describing how long it takes to set up a "simple Chinese printer". It needs to be assembled from a large number of parts, and it is not a fact that there will not be defective ones among them.

Once assembled, you can mess around with the device for a couple of days, and then it turns out that for some reason it does not work. In short, I needed a printer that didn't need to be assembled and that could work right out of the box. nine0014

Once assembled, you can mess around with the device for a couple of days, and then it turns out that for some reason it does not work. In short, I needed a printer that didn't need to be assembled and that could work right out of the box. nine0014 - It shouldn't be too expensive. Seriously, I'm new, I was not sure that after a couple of days I would not abandon the device. And a printer for 500-600 euros would be too expensive a toy. So I was willing to spend a couple of hundred, no more.

- It must not be too large. Before buying, I allocated a little space for installing the printer, somewhere around 50 * 50 cm. Therefore, the printer had to stand on the allocated area without any problems.

- It shouldn't be too difficult to maintain. This point is closely related to the first. I didn’t want to spend a lot of time on operation and maintenance work - there is sorely not enough time, so constantly eliminating emerging glitches is not an option. nine0014

- I wanted to get a printer with WiFi, it was not critical, but important.

What did I end up buying?

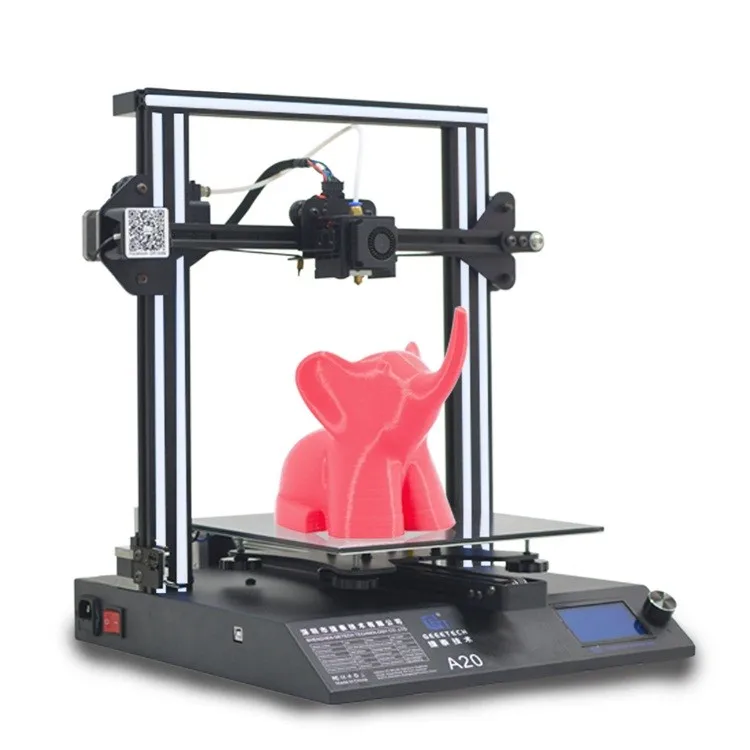

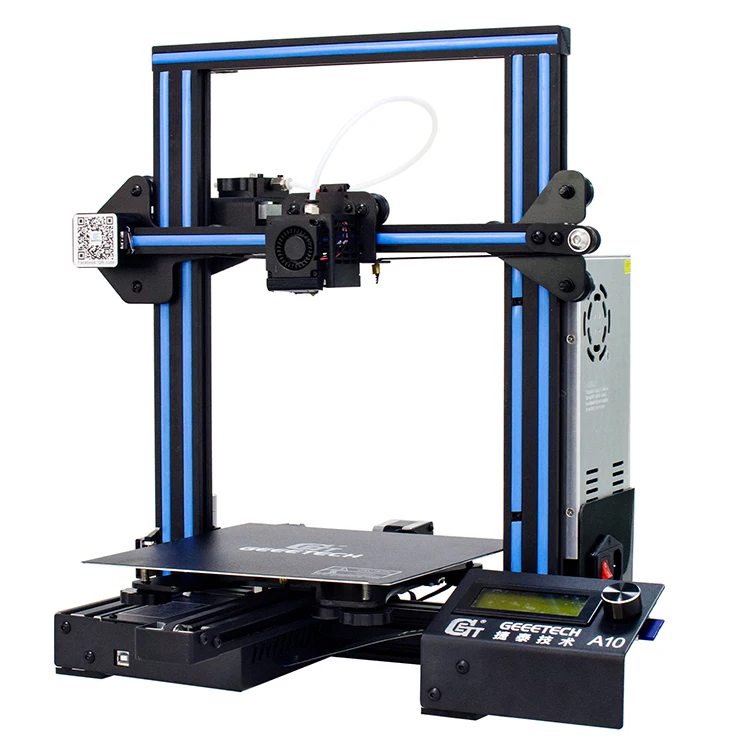

Model Geeetech E180. It was shown by Google after the query “3D printer for beginners”. There were other models in the search results, but this one was liked by the design and the presence of WiFi.

The developers of this printer raised money for it with the help of Kickstarter and a couple of years ago it appeared on the free market. Its price is from 200 to 350 euros, depending on the company that sells it and the store. nine0003

Bought on eBay, starting price was 200 euros, but the seller agreed to drop 50 euros, so the total price is 150.

Printer specifications:

- Print technology: FDM

- Working space dimensions: 130 x 130 x 130 mm

- Printing accuracy: 0.05 mm

- Positioning accuracy: X / Y 0.11 mm, Z 0.0025 mm

- Print speed: 80-110 mm/s

- Thread diameter: 1.75 mm

- Nozzle diameter: 0.4 mm

- Supported material: PLA declared by the manufacturer, but can work with other materials

- Operating system: Windows

- Management software: EasyPrint 3D

- File format: .

STL, G-code

STL, G-code - Maximum extruder temperature: 230 °C

- Power supply: DC 12V 6A

- Connectivity: WiFi, USB, TF card (offline printing support)

- Display: 3.2" full color touchscreen

- Chassis: metal plate + injection molding (portable console 3D printer)

- Work table: aluminum alloy plate

- XYZ Rods: wear resistant, stainless steel screw and lead (Z axis)

- Stepper motors: 1.8 degree stepped angle with 1/16 micro stepping

Unpacking and setup

Before setting up, I looked at several reviews and tests of the printer. If not for them, I would not have done it myself, the explanation in the instructions is slurred. The setup is simple, but not for a beginner. nine0003

The printer "wound up" as soon as I connected it to power and a laptop. I calibrated the position of the table - it turned out to be simple - inserted a microSD card into the slot, found the contents through the menu on the printer screen, inserted the fiber into the channel and started printing. The printer made a noise and started printing. Or rather, I thought that he started typing, in fact it was not so.

The printer made a noise and started printing. Or rather, I thought that he started typing, in fact it was not so.

Problems

The printhead moved, the temperature reached 205 degrees Celsius, but there was almost no plastic - in the first few seconds, a few plastic “hairs” came out and that was it. The printer continued to work, but the plastic was not squeezed out of the head. nine0003

I wasted several Saturday hours trying to figure out why. I tried to look for an explanation on the net, but solutions to similar problems did not suit me.

The joy of buying disappeared in the first couple of hours of fuss. I wanted a printer that “just works”, but it didn’t work out. As a result, I realized that the fiber was not being fed - the feed mechanism hidden under the plastic cover simply did not work. It did not work because the constituent elements did not rotate. There was no movement at all.

I have decided that the printer has a defective electric motor that is responsible for feeding, and I cannot repair it. The next step is to click the Return to Seller button on eBay. After clicking the button and describing the problem, I decided to pack the printer for shipping. Before sealing it in a foam box, just in case, I decided to carefully examine those “insides” that are visible through the holes in the case. nine0003

The next step is to click the Return to Seller button on eBay. After clicking the button and describing the problem, I decided to pack the printer for shipping. Before sealing it in a foam box, just in case, I decided to carefully examine those “insides” that are visible through the holes in the case. nine0003

And the reason was immediately found - the assembler at the factory simply forgot to connect the power supply to the engine. Seriously, the cable just dangled inside the case. I connected it to the right connector with tweezers without disassembling the printer. Then I turned on the device again and this time everything was fine, the plastic feed worked as it should.

Then a few more minor problems arose:

- Misaligned table. This caused the table to skew and the print head was pressed against the surface in one place. As a result, the plastic could not be squeezed out of the head, which led to solid print defects; nine0014

- Unable to directly print models downloaded from the Internet.

Being a beginner, I thought that everything works like with a regular printer - I downloaded a document, sent it to print. It turns out that slicing is also needed. I will not repeat what it is and why it needs to be perfectly described in this article on Habré;

Being a beginner, I thought that everything works like with a regular printer - I downloaded a document, sent it to print. It turns out that slicing is also needed. I will not repeat what it is and why it needs to be perfectly described in this article on Habré; - Slicers are not compatible with the printer model. The slicer needs to set the printer desktop size. Some slicers for some reason did not want to work with the dimensions of my printer (13*13*13 cm). Some even crashed (including the printer's native application), some did not "understand" the dimensions. As a result, I settled on ideaMaker; nine0014

- No WiFi. As it turned out, there are two varieties of E180 - one with an integrated WiFi module, the second - without a module, you need to buy it in addition. At the seller, the inscription "need a separate module" was applied to one of the photos of the printer, small and in French (everything else was in English). Not a scam, but close to it.

The module decided not to buy more, it is not really needed;

The module decided not to buy more, it is not really needed; - Long printing time. I thought it would take several tens of minutes to print. I was not ready for the fact that large models can be printed for 6-8 hours. This is my own fault - I did not carefully look at the reviews. nine0014

Practical use

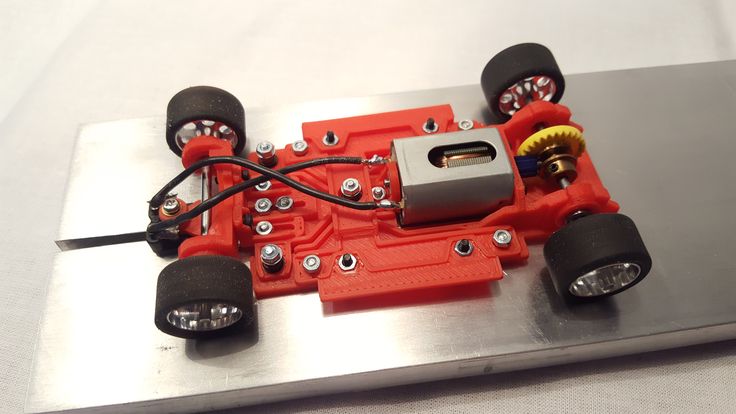

I didn’t buy a printer for a game, I wanted to get a device that would allow me to create things I need in everyday life, and not run to the store. Before buying, I outlined what I wanted to create:

The lever for separating the water tank in the iRobot Scooba robot vacuum cleaner, the repair review of which I published on Habré. His native pen broke, he did not want to spend money on buying a new one (they are relatively rare, since Scooba is no longer produced and expensive). nine0003

Finally found a suitable model on Thingiverse and printed it. To my surprise, everything fell into place the first time, the pen still works quite normally (it's been about a month since this part was printed).

Chinese electron microscope stand. I needed it for soldering small parts. I do not want to buy a professional microscope for 400 euros, since I myself do not do repairs very often. A Chinese microscope connected to a laptop is quite an option. But his native tripod is just terrible. Therefore, I wanted to make a new, normal one with my own hands. nine0003

Soldering iron stand. I just need a comfortable stand that won't let the soldering iron fall off, like from a Chinese stand that I once bought.

Paste tube squeezer. Yes, the thing is not the most necessary, but practical.

iPhone stand. Convenient, there is a hole for the cable, sound amplification.

Toys for children. Why buy another small doll or dollhouse piece when some things can just be printed out? nine0003

Stylus for Nintendo DS Lite. I had a game console bought at a flea market for a long time. The stylus was lost and I (and my daughter) played using the PDA stylus. Recently I found a stylus model for the console, printed it out - it turned out perfectly. It fits into the connector like a factory one.

Recently I found a stylus model for the console, printed it out - it turned out perfectly. It fits into the connector like a factory one.

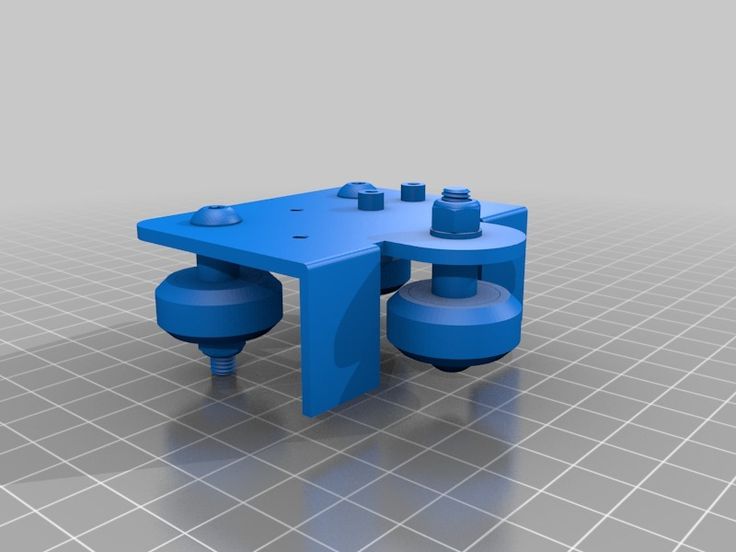

Extractor for printed parts stuck to the table. Nearly all parts stick to the printer's desktop backing. You can’t do without a special device - an ordinary knife will scratch and cut a special sticker. I found a model that is compatible with the blades of a standard utility knife - works great. nine0003

The printer lived up to my expectations. It was possible to print almost everything that is indicated above. All these things fulfill their purpose, and most importantly, I am not afraid that any of them may fail. You can always print a new one.

There are a lot of ready-made models on the net. If you need some detail or thing, in 90% of cases you can find everything you need.

Troublesome little things

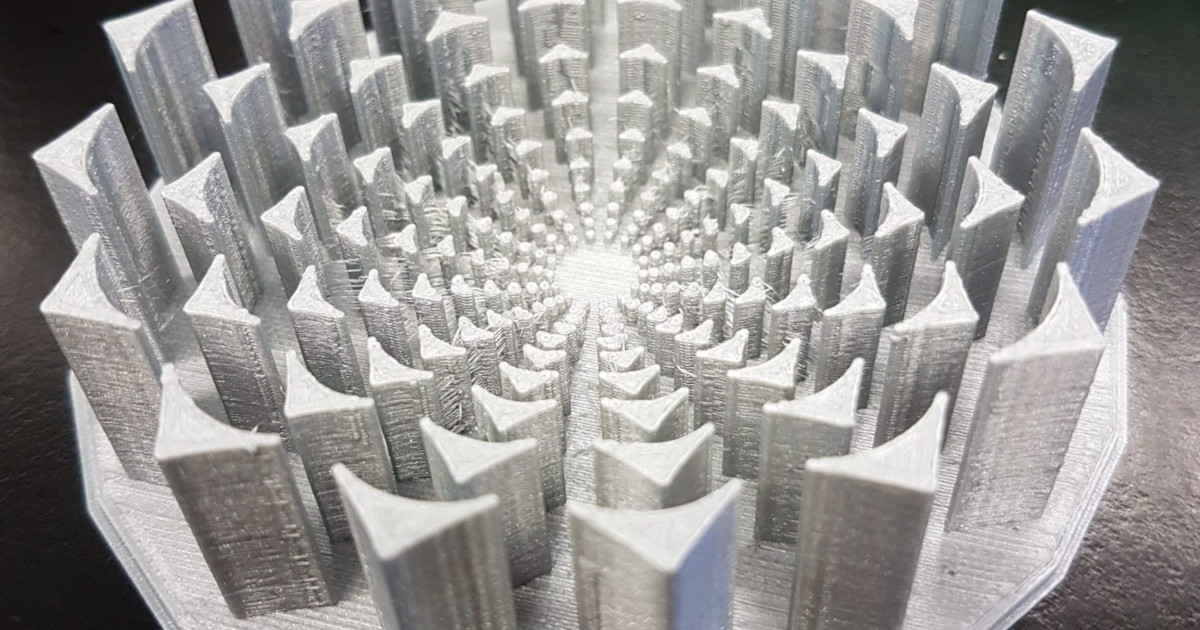

Printed parts are far from perfect. In some cases, deformation of some elements occurs and it is necessary to “finish” manually, using a knife and, in fact, a file. It doesn't happen that often, but I wish the printed part didn't need to be reworked (yes, I know you can get it by buying a professional 3D printer). nine0003

It doesn't happen that often, but I wish the printed part didn't need to be reworked (yes, I know you can get it by buying a professional 3D printer). nine0003

Sometimes details are printed, but for some reason the real and declared size do not match. So, I tried several times to print different dispensers for AA and AAA batteries, but for some reason the ready-made dispensers did not fit. The diameter of the holes into which the batteries are inserted was always somewhat smaller than the diameter of the batteries themselves. I still do not understand whether the problem is on my part, or the model is problematic. As a solution, you can simply increase the scale of the part in the slicer, by 10 percent. But it’s a pity for the spent plastic - after all, you can find out whether a quality part will turn out or not only after a solid part of it is ready. nine0003

It takes a long time to print a part. Some printouts take hours to complete, so making a simple car phone stand can take half a day.

In order to develop something of your own, you need knowledge of CAD , at least at an elementary level. Otherwise, you will have to look for ready-made objects on sites that host models created by someone. In the end, I never found a battery cover for one of the remotes. I am not able to develop it myself - there is almost no time to master CAD. nine0003

My printer desktop is small . Not all objects that I would like to print can be implemented. In particular, I wanted to get a different microscope stand model. But it did not work out, because it is larger than the printer table. The same problem with the handle of a robot vacuum cleaner (not the one in the photo, another one).

Fin

Am I satisfied, as a beginner, with the printer? Yes very. It met my expectations almost completely. True, it must be borne in mind that I got the printer relatively inexpensively. If I had bought it for, say, 300-400 euros, I would have been less satisfied with the purchase. The main thing is that with the help of a 3D printer you can solve practical problems, this is far from just a toy. The opinion about the “toy” had to be heard from many. nine0003

The main thing is that with the help of a 3D printer you can solve practical problems, this is far from just a toy. The opinion about the “toy” had to be heard from many. nine0003

Well, now the question is - what useful for everyday life or work do you print on your printers?

Casting varnishes for 3D printing

Good day to you earthlings.

Many of you have encountered the problem of poor adhesion of the 3D printer bed when printing with ABS plastic (and not only). Someone used already proven methods read on the Internet, someone tried and tried to find their own methods to keep the plastic on the table.

I went both ways) But about the second way in the end. nine0003

(who doesn't like water, turn down, turn down)

- The first way - hairspray

At the factory where I work, they bought us two 3D printers - Picaso 3D and Prism mini. Both of them came with varnish, and it so happened that for these two printers we began to use varnish for adhesion. And soon, as it usually happens, the varnish ended unexpectedly. And a reasonable question arose - 'aaaaa!!! what to do, how to live next?!', go to the store of course) for candidates for the role of a suitable varnish for printing on a 3D printer. nine0003

And soon, as it usually happens, the varnish ended unexpectedly. And a reasonable question arose - 'aaaaa!!! what to do, how to live next?!', go to the store of course) for candidates for the role of a suitable varnish for printing on a 3D printer. nine0003

Candidates passed the primary selection according to strict criteria, namely the obligatory presence of the inscription 'peace' on the fence 'strong fixation', 'very strong fixation', 'super strong fixation', 'extreme fixation', 'extra fixation', 'super mega duper fixation', 'ultra 3000 fixation with customer turbocharging' and numbers '5', '6', '10' and '2851' on the bottle.

Yee... welcome! 10 winners who passed the primary selection:

In order from left to right:

- Taft three weather invisible hold (super strong hold, number 5)

- hairspray great price 365 days all year round (super strong hold) (hairspray called hairspray - HTA?!)

- Syoss many beeches ceramide complex (maximum strong fixation, number 5)

- Pure Line (herbal medicine seems to be written, it’s hard to see on the photo, it’s not the essence, it still didn’t pass)) Nettle extra fixation (very strong fixation, number 5)

- Taft three weather Volume millions of CALogen molecules (mega hold, number 5)

- Taft three weather Power with caffeine firming formula (mega fix, number 5)

- Professional perfection in the form of Scosmetic (mega strong hold, number 5)

- Beauty Professional Effect memory (extra strong hold number 5)

- Beauty Professional Ultra Power (extreme hold number 6)

- Jet Personal Styling (extra strong hold number 5)

I can't imagine what is written on these bottles is the name of the varnish, the manufacturer, or just the text 'ala I'm the coolest of all'. I just rewrote what I considered a distinctive feature, so that it could not be confused with the rest of the variety of similar products.

I just rewrote what I considered a distinctive feature, so that it could not be confused with the rest of the variety of similar products.

I won't pull the rubber, let's move on to the main thing:

- Final selection

'Stick' tests were carried out on an open printer (Prism mini), freshly printed REC ABS plastic. It's not advertising, it's just plastic. nine0003

Table temperature 100 parrots, extruder temperature 245 degrees, print speed 40 mms. We print Facebook 'thumbs up' or down, whoever shows himself. The varnish was applied in one thin layer on a hot table. After each candidate, the glass table was removed, washed with running water, wiped dry, and, before the test of the next subject, warmed up in its native place for 2-3 minutes.

Let's go!

1 - Taft three weather invisible hold (super strong hold, number 5)

We spray, the smell is quite pleasant, but perhaps only

Failed at the very beginning. Farewell, Mr. Taft, we are not on our way.

Farewell, Mr. Taft, we are not on our way.

Our next one is

2 - Hairspray great price 365 days all year round (super strong hold)

Next

3 - Syoss many beeches ceramide complex (maximum strong hold, number 5)

Pshhhhhhh towards the table.. the smell is below average in my opinion.

Yes, I forgot to film him posing in front of a prism, who doesn't happen to. And yes, to celebrate, I forgot to take a picture of what was printed on it. You'll have to take my word for it. Syoss gets a 'thumbs up' achievement!) The first candidate to make it to the finals!

After finishing printing, tore off part with little effort.

Next in line

4 - Pure line extra fixation nettle (very strong fixation, number 5)

The smell is average, not irritating at all.

and as I said earlier, it did not pass the test, it does not hold at all.

Let's move on

5 - Taft three weather Volume millions of CALogen molecules (mega fixation, number 5)

We apply, the smell is average.

I tried to keep something somehow, I gave him a chance again and again, but alas, this candidate is also leaving us.

Next

6 - Taft Three Bears Power Caffeine Firming Formula (Mega Fix Number 5)

The smell is average, or I've already inhaled these smells and can't distinguish them at all.

Not his path, it doesn't work for him, apparently it was created for hair.

Next! do not hesitate to pass

7 - Professional perfection in the form of Scosmetic (mega-strong fixation, number 5)

The smell is like a smell.

Generally not surprised, does not hold at all.

This is mine

8 - Charm Professional Memory effect (super strong hold, number 5)

Smells like hairspray.. probably.

Worried and screwed up the test.

Who's next? oh yes

9 - Charm Professional Ultra Power (extreme fixation, number 6)

It should smell somehow.

And he did the job! After printing, the part came off quite easily, I would give it a 4 out of 5. Requires additional tests.

Last

10 - Jet Personal Styling (extra strong hold, numeral 5)

The room smells. It's not me. These are varnishes varnishes..

And he copes with our task perfectly! After the end of printing and the cooling of the table, the part did not come off by itself, I had to tear it off with a little effort.

Group photo with earned achievements

and photos of the winners separately

Phew.. have passed fierce tests and now you can breathe deeply, preferably going out into the street.. otherwise your head already hurts.

3 candidates out of 10, excellent result in my opinion)

Further dry calculations according to the results of

Laki suitable for printing

SYOSS Many Ceramide Complex beams (the most strong fixation, number 5)

Jet Personal Styling (Extreme fixation, number 5)

9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009 9009Charm Professional Ultra Power (extreme fixation, number 6)

(you need to make sure it is suitable until you get your hands on it) from Kazakhstan, who needs to transfer to rubles, dollars, euros, bitcoins)

Oh yes, I almost forgot

- The second way - Glue Master klein

Discovered by me in the course of experiments with different substances (not narcotic!) method of printing ABS plastic. This glue is Master klein, I took it as glue for fillets in construction,

This glue is Master klein, I took it as glue for fillets in construction,

(photo honestly stolen from the expanses of tyrnet)

is diluted with medical alcohol (alcohol-soluble glue, 90% alcohol) about 1 to 10 (1 part glue and 10 alcohol , you can experiment). Next, we apply the composition on a cold table. It is problematic to apply on a hot one due to the fact that the alcohol evaporates quickly and it becomes problematic to evenly distribute the liquid over the table. This is the first drawback, the second drawback is a thin film that will definitely remain on the bottom surface of the part. Not to say that this is a problem, but if there are a lot of holes on the bottom of the printed part, then peeling off the film from each hole becomes a little tedious. nine0003

But there are also advantages - almost complete absence of smell, it does not smell strongly of alcohol, and maybe it will be more familiar to someone)) Another plus is good adhesion, tearing off a part from a hot table is simply not realistic.