3D printing houston

3D Printing Service for Houston, Texas

CapabilitiesCustom Online 3D Printing ServiceTexasHouston

High Quality Houston, Texas 3D Printing | 60+ Materials Available

Endless Options

Choose from millions of possible combinations of materials, finishes, tolerances, markings, and certifications for your order.

Easy to Use

Get your parts delivered right to your door without the hassle of sourcing, project management, logistics, or shipping.

Guaranteed Quality

We back every part we ship with the Xometry Quality Guarantee. Our number one job at Xometry is making your custom parts to your specifications.

Your Houston, Texas 3D Printing Service: 3D Prototypes and Production Parts

A Global Leader in Industrial-Grade 3D Printing

Xometry is an industry-leading 3D printing service. Whether you need prototypes or production parts, we can make them for you in as fast as a day. We are your one-stop-shop for accurate, precise custom 3D printed parts at a low cost. Upload your 3D CAD file to get a quote and lead time within seconds. We use the latest additive manufacturing processes to build affordable functional prototypes & end-use parts in over 60 metals and plastics.

We offer eight high-quality 3D printing processes including selective laser sintering, fused deposition modeling, stereolithography, direct metal laser sintering, polyjet, Carbon DLS, binder jet metal, and HP Multi Jet Fusion. We use commercial and industrial-grade printers such as Stratasys Fortus 900mc and Fortus 450 FDM, EOS Polymer Laser Sintering (SLS) and DMLS, Concept Laser, SLM Solutions, 3D Systems, ExOne, and more.

Houston 3D Printing - Industries and Applications

3D printing, a form of additive manufacturing, is a tremendous manufacturing asset to businesses and organizations in Houston, Texas. If you're looking to better understand how 3D printing could add value to your project or industry, Xometry can assist you with your goals.

According to Thomasnet. com®'s 2022 sourcing data, the top six most popular manufacturing industries in Houston are Chemicals, Education, Transportation and Logistics, General Manufacturing, Metals, and Energy and Utilities. Here's how 3D printing can support local manufacturing in Houston in some of these popular sectors:

com®'s 2022 sourcing data, the top six most popular manufacturing industries in Houston are Chemicals, Education, Transportation and Logistics, General Manufacturing, Metals, and Energy and Utilities. Here's how 3D printing can support local manufacturing in Houston in some of these popular sectors:

- Chemicals: 3D printers can produce necessary complex multi-component chemical equipment within a laboratory, expediting chemical research and making it an invaluable resource for research and development in the chemical industry. Additive manufacturing also allows engineers to make custom sampling, holding, and compounding laboratory equipment and prototypes. Though only a fraction of the materials that are commonly used in conventional component manufacturing can be used for 3D printing, this avenue is being thoroughly explored.

- Education: 3D printing technologies play an increasingly important role in STEM education.

With greater access to CAD, 3D printers in education enable educators to teach students how to create tangible products and tools with a very low barrier to entry. Scientific concepts and deep theoretical constructs can be taught more efficiently with accurate physical 3D printed prototypes to hand. Integrated into classroom environments from elementary school to university, 3D printers are not only a useful hands-on learning tool for students but also a powerful research resource for teachers.

With greater access to CAD, 3D printers in education enable educators to teach students how to create tangible products and tools with a very low barrier to entry. Scientific concepts and deep theoretical constructs can be taught more efficiently with accurate physical 3D printed prototypes to hand. Integrated into classroom environments from elementary school to university, 3D printers are not only a useful hands-on learning tool for students but also a powerful research resource for teachers. - General manufacturing: Considered a necessary utility tool that the majority of manufacturing companies are employing, 3D printing is a low-cost and invaluable manufacturing solution used in many avenues, from parts of the production line and making jigs and fixtures to creating custom tooling for laser marking. It also allows for rapid prototyping to test design concepts ahead of production runs, thus reducing risk and eliminating costly design flaws. Top automotive companies are eager to leverage this technology, i.

e., BMW, which uses Xometry for custom assembly of purpose-designed soft-touch handheld jigs. One case study showed that these improved-quality, lighter-weight, 3D printed products not only reduce fatigue but they also reduce scrap rate, too. Additive manufacturing is also starting to become a substitute process for injection molding, particularly for low-volume projects that require complex tooling from plastic or metal. As 3D printing creates parts directly from the CAD model one layer at a time, it offers cost advantages by eliminating the upfront expenses of creating tooling or molds, such as with die casting, injection molding, or CNC machining.

e., BMW, which uses Xometry for custom assembly of purpose-designed soft-touch handheld jigs. One case study showed that these improved-quality, lighter-weight, 3D printed products not only reduce fatigue but they also reduce scrap rate, too. Additive manufacturing is also starting to become a substitute process for injection molding, particularly for low-volume projects that require complex tooling from plastic or metal. As 3D printing creates parts directly from the CAD model one layer at a time, it offers cost advantages by eliminating the upfront expenses of creating tooling or molds, such as with die casting, injection molding, or CNC machining. - Metals (raw, formed, fabricated): Though most commonly associated with plastic, 3D printing is seeing a rapid rise in the use of metal and the creation of tools to form metal in areas like sheet fabrication, rigid tooling, and even powder metallurgy. In metal injection molding and die casting processes, rigid tooling using extremely tough yet ductile maraging steel is being created with additive manufacturing without the need for a CNC machine.

Even jewelers are digitally creating custom 3D printed prototypes using a master wax pattern. With the ability to create custom products that can be ordered to have the exact features and even bend desired, 3D printing is being used more and more in the metals industry.

Even jewelers are digitally creating custom 3D printed prototypes using a master wax pattern. With the ability to create custom products that can be ordered to have the exact features and even bend desired, 3D printing is being used more and more in the metals industry. - Energy and utilities: Thanks to its quick turnaround time compared to traditional tooling, 3D printing is also being explored for energy and utilities. Parts which are typically cast can be directly printed out of metal or a high-performance polymer substitute quickly and in fewer numbers. There are also many opportunities for large-format industrial printing in the fields of renewable energy and oil & gas. Bespoke, hard-to-transport parts such as metal tubular designs for drilling with internal features to cater to camera monitoring, circuit boards, and sensors can be 3D printed. In these industries, additive manufacturing is more than just engineering a machine component; with the ability to create state-of-the-art groundbreaking mechanisms with endless capabilities, 3D printing can significantly transform and modernize these sectors.

The additive manufacturing and material market is rampantly growing and is estimated to reach US$61.1 Billion by the year 2027. With the technology being so prolific, providing endless options, and the opportunity to greatly add to and advance your business, let Xometry cater to all your industrial-grade 3D printing needs.

Xometry's High Quality 3D Printing Services

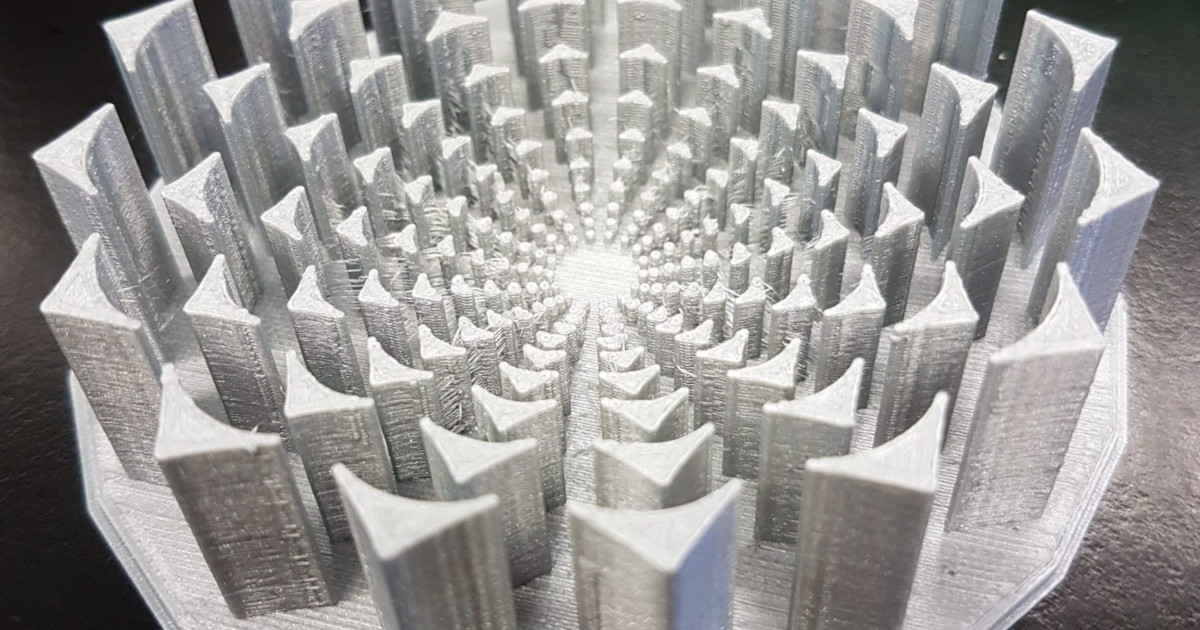

Selective Laser Sintering (SLS)

Selective Laser Sintering (SLS) is a powerful 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

An additive manufacturing layer technology, SLS involves the use of a high power laser (for example, a carbon dioxide laser) to fuse small particles of plastic powders into a mass that has a desired three-dimensional shape. The laser selectively fuses powdered material by scanning cross-sections generated from a 3-D digital description of the part (for example from a CAD file or scan data) on the surface of a powder bed. After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

After each cross-section is scanned, the powder bed is lowered by one layer thickness, a new layer of material is applied on top, and the process is repeated until the part is completed.

Download the SLS Design Guide.

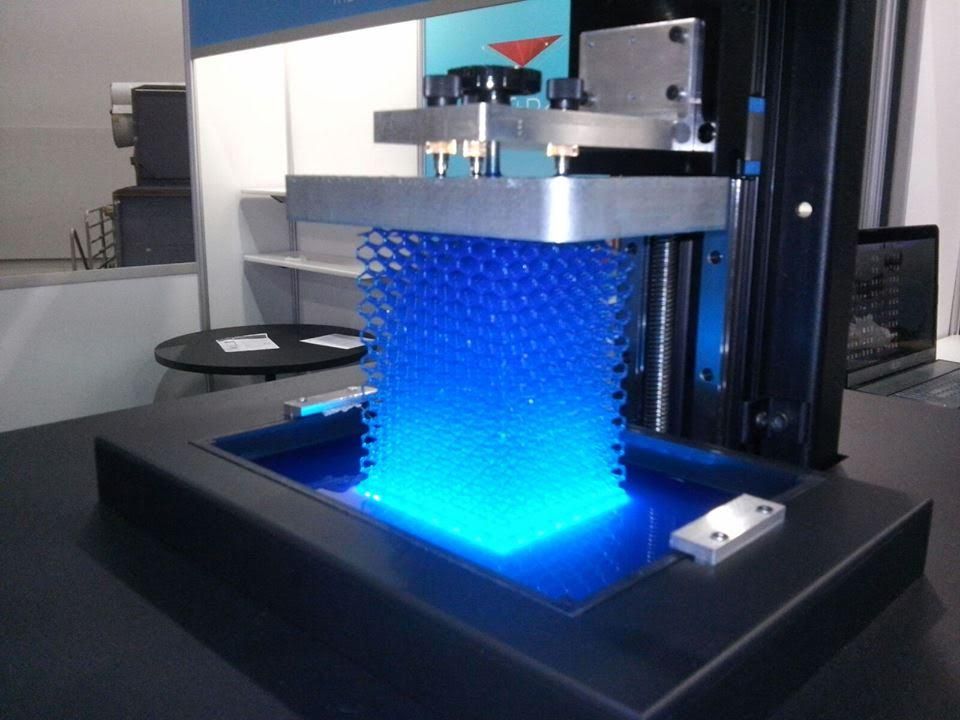

Stereolithography (SLA)

Stereolithography (SLA) is a robust 3D printing technology that produces extremely accurate and high-resolution parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping.

SLA is an additive manufacturing process that focuses an ultraviolet (UV) light on a vat of photopolymer resin. It offers higher resolution printing than many other 3D printing technologies, allowing customers to print parts with fine details and surface finishes. SLA 3D printing is a highly-versatile platform for making custom parts in prototype and production settings; often acting as a stand-in for injection-molded plastic parts.

Xometry offers both standard and high-resolution options for fine detail parts, and can also print larger sized parts and products, with some materials offering up to a 58" inch build area. In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

In addition, Xometry's manufacturing partner network allows us to offer a larger variety of materials than other 3D printing companies - we offer a wide range of both Accura and Somos brand materials.

Download the SLA Design Guide.

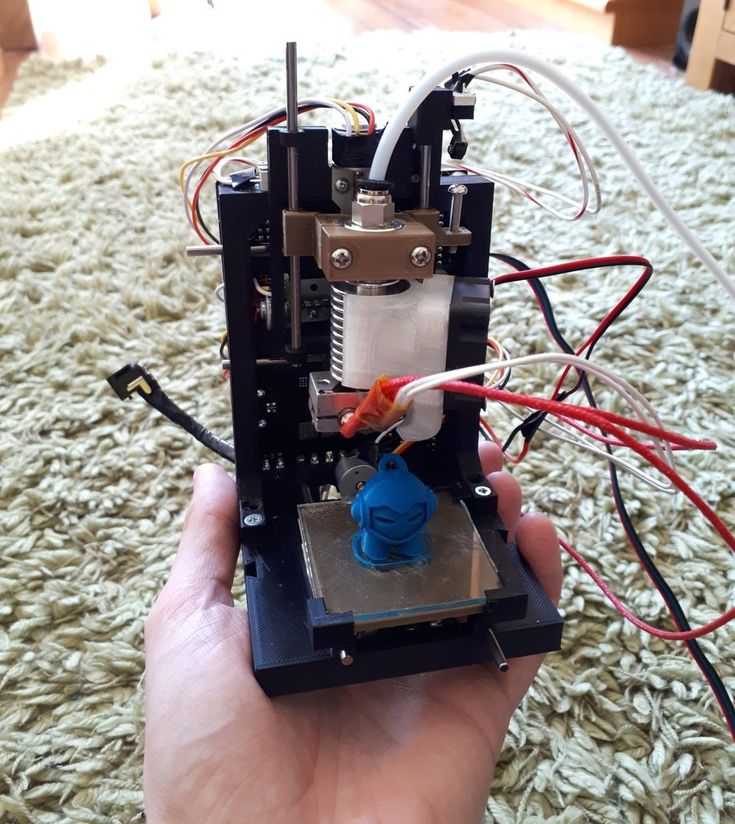

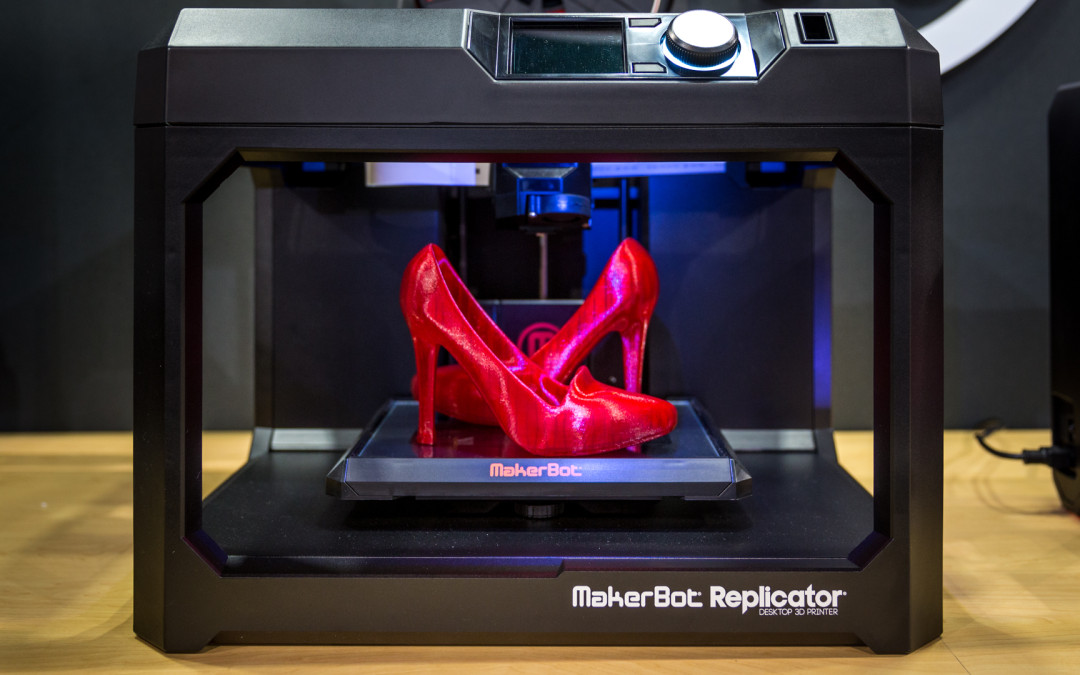

Fused Deposition Modeling (FDM)

Fused Deposition Modeling (FDM) is a 3D printing technology widely known for its speed, accuracy, and competitive cost. A machine precisely extrudes melted plastic filament to create a part. Parts are very rigid, especially compared to Selective Laser Sintering (SLS), which makes them a great fit for projects with a rigidity requirement. Xometry's FDM solution offers large build volumes up to 24″ x 36″ x 36″, a variety of colors, and a diverse selection of production-grade thermoplastics — from ABS to Polycarbonate to Ultem.

Download the FDM Design Guide.

HP Multi Jet Fusion (HP MJF)

HP Multi Jet Fusion is a new 3D printing technology that produces highly accurate and durable parts that are capable of being used directly in end-use, low-volume production, or for rapid prototyping. Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other powder bed fusion technologies.

Since the process uses well-established 2D printing ink-jetting, it has remarkably fast layer times compared to other powder bed fusion technologies.

Download the HP Multi Jet Fusion Design Guide.

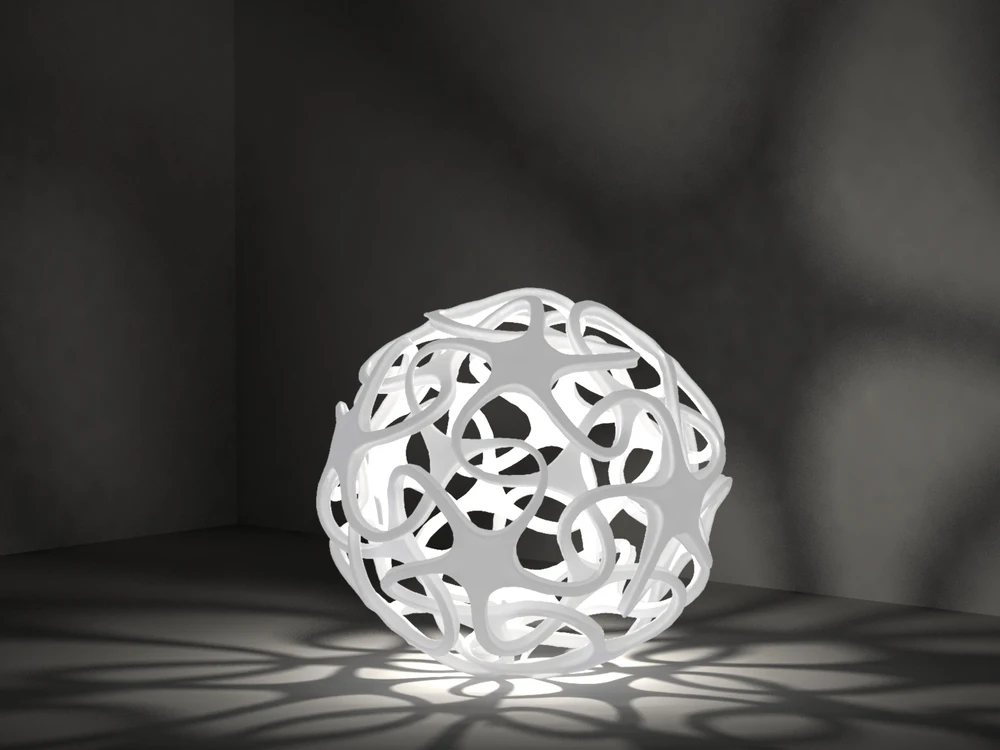

PolyJet 3D (PJ3D)

PolyJet 3D is a 3D printing technology known for its customizable material properties and excellent surface finish. It works by jetting UV curable resin onto a build tray in a process that is somewhat similar to inkjet printing. PolyJet 3D printing offers one of the most advanced industrial 3D printing solutions available, producing parts with incredible precision and speed. It also supports a wide variety of build materials including rigid and rubber-like plastics. Xometry's PolyJet solution has a maximum build envelope of 19.3 × 15.4 × 7.9 in. (490 × 390 × 200 mm) in a variety of colors and materials.

Download the PolyJet 3D Design Guide.

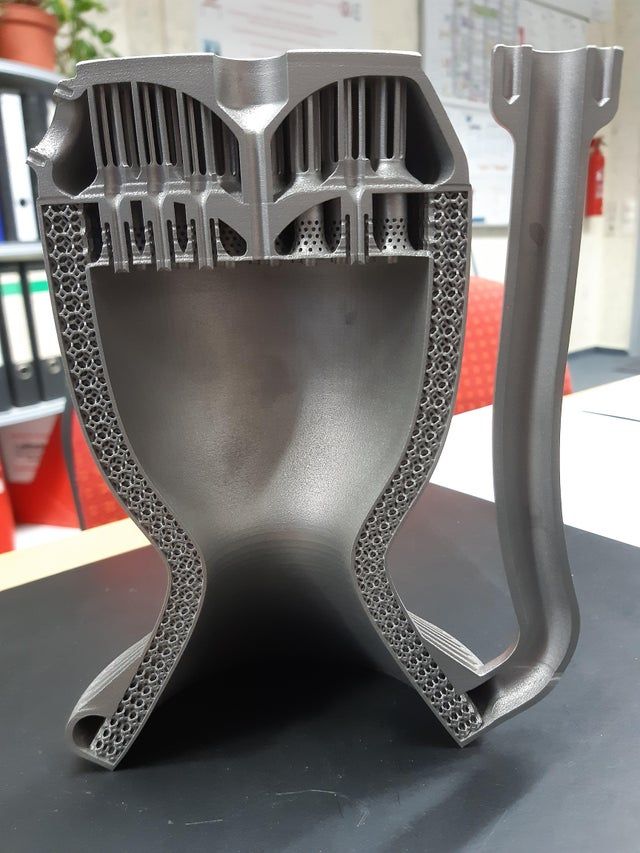

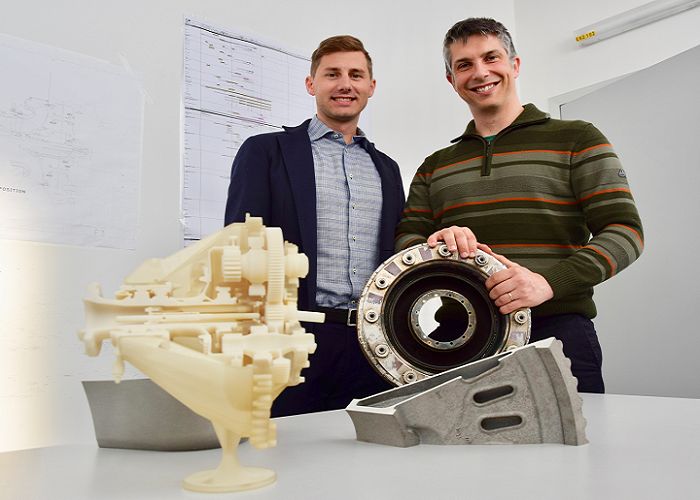

Direct Metal Laser Sintering (DMLS)

Direct Metal Laser Sintering (DMLS) is an 3D metal printing technology that builds prototype and production metal parts from a CAD file using a laser to selectively fuse a fine metal powder in either stainless steel or aluminum materials. A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

A DMLS machine is capable of producing highly complex features and all-in-one assemblies using metal materials that would be difficult to achieve with subtractive manufacturing techniques.

Our DMLS metal 3D printing service typically offers build volumes up to 250 x 250 x 325 mm, but we may be able to accommodate larger part volumes upon request in the quote. (See our Manufacturing Standards for more details) A good first step is to find out the cost of the parts you need using DMLS and compare them to other 3D printing processes and CNC machining.

Download the DMLS Design Guide.

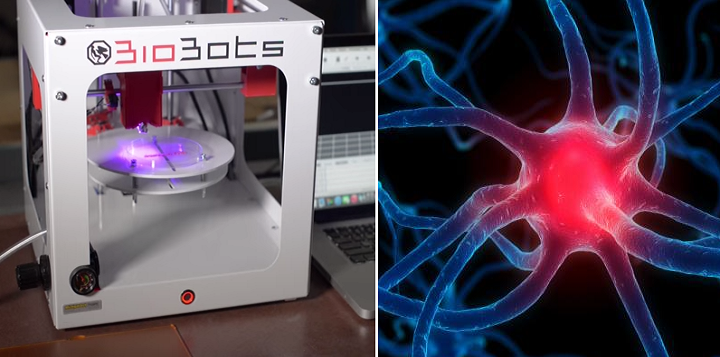

Carbon DLS™

Carbon DLS™ uses digital light projection, oxygen-permeable optics, and programmable liquid resins to produce products with end-use durability, resolution and surface finish. This 3D printing technology is called Digital Light Synthesis™, or DLS for short. Another legacy term for the process is Continuous Liquid Interface Production (CLIP). Along with Carbon’s custom liquid resins, DLS unlocks new business opportunities and product designs previously impossible, including mass customization and on-demand inventory of end-use products.

Carbon bridges, and sometimes substitutes, for processes like Urethane Casting and Injection Molding service production, because the materials are urethane-based or epoxy-based, giving excellent mechanical properties. There are even elastomer and silicone resins that outperform most additive manufactured rubber-like materials.

The typical build area is 7.4” x 4.6” x 12.8”. Parts with dimensions exceeding 4” x 4” x 6” will require manual review.

Download the Carbon DLS Design Guide.

Metal Binder Jetting

With binder jetting, an inkjet print head quickly deposits a bonding agent onto a thin layer of powdered particles -- either metal, sand, ceramics or composites. This process is repeated, layer-by-layer, using a map from a digital design file, until the object is complete. Binder jetting is offered through our Digital RFQ Marketplace through Xometry's partnership with ExOne.

Download the Binder Jetting Design Guide.

Ready to start making custom 3D printed parts?

First-ever multi-level 3D printed home is being built in Houston

Features

Zachery Lashway, Reporter/Anchor

Published:

Updated:

Tags: 3D, Houston, Spring Branch, 3D Printing, Hannah, 3D Construction

Sign up for our Newsletters

10 minutes ago

Robert Fratta case update: Supreme Court denies to grant stay of execution

24 minutes ago

Free health screenings, affordable immunizations available in Houston for Walmart Wellness Day

1 hour ago

Chick-fil-A to open drive-thru, carry-out-only restaurant in southwest Houston

1 hour ago

Lotus Seafood honors local police officers with discount for National Law Enforcement Appreciation Day

Celebrate your ancestry in the new year and take 29% off this complete DNA kit

Features

Zachery Lashway, Reporter/Anchor

Tags: 3D, Houston, Spring Branch, 3D Printing, Hannah, 3D Construction

The first-ever multi-story 3D printed home is being built in Houston.HOUSTON – The first-ever multi-story 3D printed home is being built in Houston.

The project in progress in Houston’s Spring Branch neighborhood focuses on how to integrate 3D printing more efficiently, with the rest of conventional building trends.

Leslie Lok is co-founder of HANNAH and assistant professor at Cornel University Department of Architecture. She said, “There’s an incredible housing demand and given the context of Houston as well, the weather, prone to intense weather, hurricanes and so on.”

“This home is essentially a bunker; it has traditional steel reinforced columns throughout the entire building,” explained Samuel Hager, head of US engineering with Peri 3D Construction.

According to Lok, 3D printing has multiple advantages.

“It depends on the type you want to build. If you want very straightforward structures, 3D printing can fulfill and eliminate the number of labor and time involved. For us, the design of this project, and the construction of this project is not about one single-family home, but rather how can we develop a system that we can print larger scalable multifamily housing in the country.”

This home will be 4,000 square feet with mass customization and design solutions that integrate conventional construction methods. HANNAH is collaborating with Peri 3D Construction to make this house into a home.

“Here we are really focusing on designs and showcasing the technology and all the interesting things you can get away with like overhangs, unique designs, corners, integrated furniture and bookshelves and benches you will see today. So, this house is not focused on affordability, per say. We are trying to learn a lot, and leap bound forward off this project. So, a lot of the elements you see in this project can be easily rolled into a multi-family construction.,” explained Hager. “The main point of this project is to learn as much as possible and really push the limits of what the printer and technology can get away with.”

So, a lot of the elements you see in this project can be easily rolled into a multi-family construction.,” explained Hager. “The main point of this project is to learn as much as possible and really push the limits of what the printer and technology can get away with.”

KPRC 2 News crew got a birds-eye view of the progress from scaffolding.

The insulation inside the walls of the home consists of 10,000 recycled plastic bottles.

Chief Strategy Officer of Huntsman Building Solutions Douglas Brady said the insulation is extremely energy efficient.

“Using this particular insulation package, you’re going to save on energy up to 50%.”

Printing is expected to be complete on this home by the end of the year.

While this first-ever multi-level 3D printed home does not focus on affordability, it does detail solutions to key building techniques and paints a clear picture of where the industry is headed.

HANNAH, PERI 3D Construction, and CIVE, in collaboration with building industry partners, are printing a two-story single-family home.

Copyright 2022 by KPRC Click2Houston - All rights reserved.

About the Author:

Zachery Lashway

Best Houston・Cults

3D Printer ModelsHOUSTON STARS

2.46 €

Houston Astros logo

1.89 €

Keychain UH Cougar - University of Houston

0.94 €

Keychain UH - University of Houston

0.94 €

nine0002 Downtown Houston skylineFree

Houston Rockets Keychain NBA

1.07 €

Bust of Mariah Carey for 3D printing

25.62 €

Decorative frame "Whitney Houston"

2,50 €

Texans cup lid

0. 71 €

71 €

Free

3D Houston | Digital Files | 3D STL File | Houston 3D Map | 3D City Art | 3D Printed Landmark | Model of Houston Skyline | 3D Art

15 €

MSR Houston

Free

Houston Astros keychain

0,97 €

nine0002 BOOST YAO MING4.75 €

USB and Pencil Holder U of H

Free

USB and Pencil Holder - Houston Astros (Multicolor)

Free

USB and Pencil Holder - University of Houston Downtown UHD

Free

USB and Pencil Holder - Houston Astros

Free

Sam Houston State University Logo/Tag

1. 19 €

19 €

DJ Screw Chain

Free

Madonna bust 3D printing ready stl obj formats

23 €

Payday 2 Houston Mask

Free

nine0002 Houston Texans keychainFree

Astros Keychain

0.62 €

Stevie Wonder bust 3D printing ready stl obj formats

30 €

James Harden 3D printing ready stl obj

30 €

James Harden bust ready for full color 3D printing

34 €

James Harden bust 3D printing ready stl obj

30 €

Houston Texans - Logo

Free

Ultimaker 3.

Breaking the pink glasses. Houston We're in trouble!

Breaking the pink glasses. Houston We're in trouble! So hello everyone ;) !

I immediately warn that I do not have a CIE printer, and all of the following - observations !

Therefore, who needs photos, evidence, more clearly and so on, you can not read, but who is interested in the process of observation and conclusions - Welcome :{}.

A long time ago

The fairy tale began a long time ago, and it started with the release of a new generation of Ultimaker with two nozzles, he received the number ' 3 '. And at this time, strangely enough for our country, ALL stores rushed to ** rake local printers and praise foreign pride. No one saw it in the eyes, they got into a marketing hook. A beautiful video (very), licked pictures (in general, like everyone else), the process of dissolving supports and all that. Grand

drill model in 2 colors, everything is chic.

And of course.... seasoned printers know until the client feels it - everything is crap, but there is nothing for stores to do, they believed in the bright future of this printer and began to pour money into promotion in advance.... In the photos, the developers are SMILING , then there is GLORY, money, a golden future!

(Photo taken from a post from the forum)

Then the FormNEXT exhibition went on, where people saw the print quality in reality, and put 4 instead of 5+, the stores quieted down, again the advertising of all the market favorites went on a par with the ultimaker (in general, America was not discovered) . nine0005

Now it means that Brave Seryoga is connected! Yes, he is the best! And storms social networks! What's new? How does it work? Is there anything interesting?

EU, but like any new product, there are a lot of interesting things in this printer, people didn't hammer boards with nails, but used high-tech 'things' that are pleasing to the eye, but!!!! After the sale, there were practically no reviews from customers. I guess everyone was busy 'stroking' their new boyfriend and looking to befriend him. nine0005

I guess everyone was busy 'stroking' their new boyfriend and looking to befriend him. nine0005

I've been actively following the posts on Instagram with the hashtag #ultimaker3 #u3 every evening for half a month. A very meager start, there are practically no posts. There are more and more posts from the company itself, everything is beautiful, excellent, and people are silent. Then I got tired of looking into an empty box, I started rummaging through YouTube, there were SOOOOO many reviews. And all as one tell new features and practically do not print on it. Prosto Obzor - new 'welcome' subscribers. I was annoyed by this and continued to surf the Internet again in search of articles, all in vain ... everything is lapped up from a couple of sites and declined from the beginning of the Internet to the end, again everything is on the level, but there is no new information ....

Desperate, I gave up on this idea and, no, no, I looked at insta in search of posts. Finally, the first attempts went, the printing of the drill went on its own, all and sundry launched this model and were proud. And so, little by little, seals with supports popped up, and then it became more and more interesting [IMG], the hand of the 'masters' was visible. People picked up a usable 3D printer and, without defeating it, they began to print complex things - it turned out to be 3 + -4. But this is not enough! More information is needed to get an impression of this equipment. nine0005

And so, little by little, seals with supports popped up, and then it became more and more interesting [IMG], the hand of the 'masters' was visible. People picked up a usable 3D printer and, without defeating it, they began to print complex things - it turned out to be 3 + -4. But this is not enough! More information is needed to get an impression of this equipment. nine0005

And now it's August 2017. a significant number of posts have accumulated with the work of Ultimaker 3. The works are diverse, like all printers. Someone saddled a horse, someone was running nearby ... in general .... I say right away, I sympathize with ALL the creators of printers - YOU have golden heads, you create the future and wish you success, but let's remove the veil of secrets, throw out rose-colored glasses and humbly understand how marketing affects our minds. Beautiful wrapper hides the same problems as all modern '9 printers0123 snot, blockages, stuck, boils, breakages, sprains and more '.

Photos to the studio

A man calls for a guarantee. Apparently there is no way to restore the head.

Apparently there is no way to restore the head.

The same problem, but in a more beautiful version for another person.

The style of an unknown artist, with all the 'obvious' attempts to stay in the saddle.... smeared so smeared.

Someone thinks it's beautiful. Art 2017

The beauty of the 'lost tower'. I wonder what's on the other side)))

PVA welding.

Minus one more turret. as if he is making a masterpiece out of garbage) And with some kind of interesting collapse with supports.

It's interesting how it draws snot.

Frog, our beloved. Not everyone succeeds.

Part of the model remained in support. And so it will do :)

Not for everyone . . after washing it is a masterpiece.

. after washing it is a masterpiece.

Ripples after washing off supports. Straps or joint problem with supports.

an incorrectly made file for two-color printing, or simply cannot sometimes. nine0005

Table sizing problem or uneven extrusion ..or Xs

Africa, it's time for you to rest. Disrespect for the lower shores.

A ...this is the pride of one of the makers, which demonstrates the joint of the lower part of the model, clearly visible on the right arm (relative to the picture) and left leg.

Stripes, ripples on the teeth.

Small two-color also happens with glitches.

Uneven extrusion when creating supports in 1 nozzle... I don't know, maybe it's on purpose. nine0005

Either a defective printer printed, or material from experimental ones, or the printer together with the BIL printer during the entire printing period :) sometimes they print on it.

Something went wrong, but the result will be 'NORM'

And this lady is doing cosplay. A very nice account, makes ammo for suits on his friend, of course there is a primer on some, and prints without supports, but the quality of Ultimeyker shows with a bang. nine0005

Also a wonderful model of demonstrations of the possibility, however, due to the initially uneven surface of the model, nothing is clear, but it looks GORGEOUS.

BUT then we run into the Clawed Claw in the supports and look at the photo... it’s exactly there, it means that the model has already been shamanized, and it means that they did LIKE EVERYONE 8)

The video with the side mirror from the car looks very impressive.

In general, they ended with beauty, but the beginning was not ice.

What is this post for? nine0133I'm a fan of our manufacturer, and it's not a secret for anyone.

Learn more