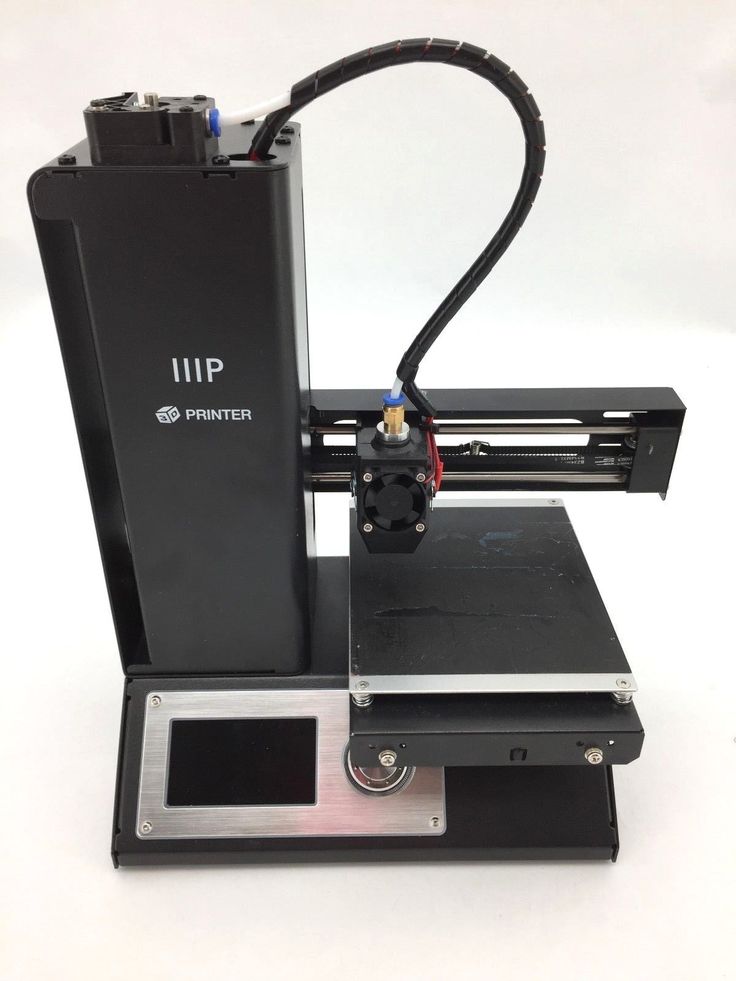

Monoprice maker v2 3d printer

Monoprice Maker Select V2 Review

The Maker Select V2 by Monoprice is a bare-bones, simple printer that did average to slightly above average across the board. It would be a good entry point for someone who doesn't want to shell out a bunch of cash and isn't afraid to tinker or troubleshoot a bit.

The Monoprice Maker Select V2 is an alright printer and a good value, making it something to consider for an introductory model.

Credit: Jenna Ammerman

Performance Comparison

To test these products, we conducted over 45 different tests and ranked their performance side-by-side. Our testing plan consisted of four weighted metrics — Print Quality, Ease of Use, Print Capabilities, and Support — with the following sections detailing how the Maker Select V2 stacked up against the rest of the printers in the test.

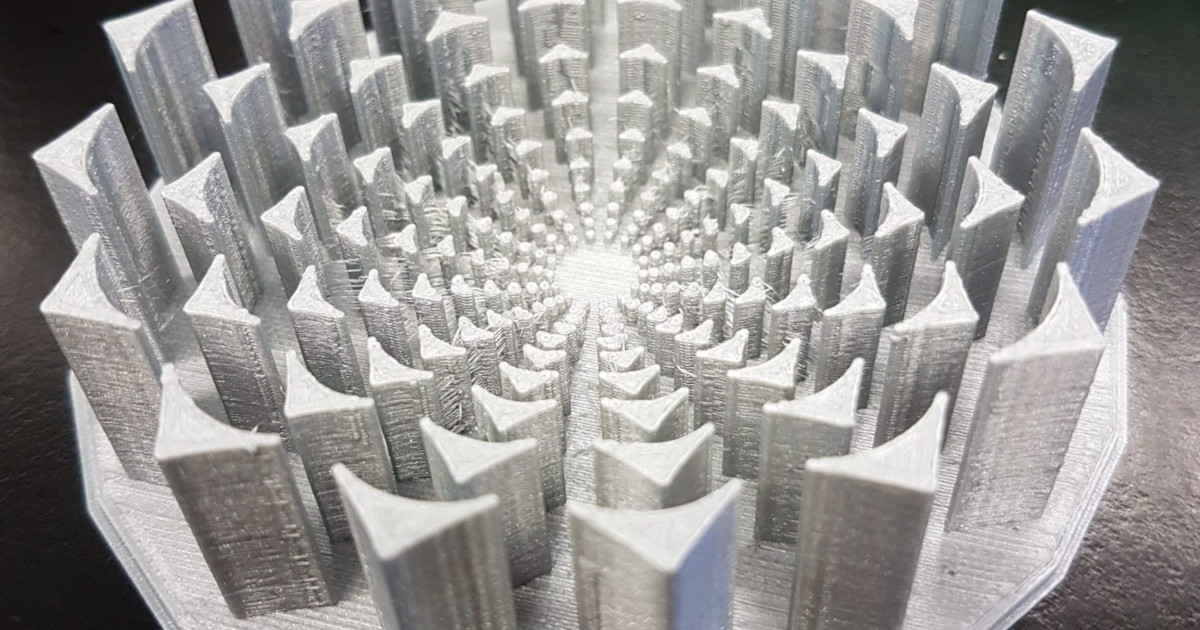

The collection of models printed by the Monoprice.

Credit: Jenna Ammerman

Print Quality

This metric accounted for the largest portion of the final score, accounting for 40% of the total. We printed a set of test models, in both ABS and PLA, and had a panel of novice and experienced 3D printer users rate the appearance of the sample prints. The panel did not know which printer had produced each set of prints, eliminating any bias or preconceived notions. The Maker Select V2 did an acceptable job, meriting a 5 out of 10.

The Maker Select did a subpar job at our first test print, the 3D Benchy tugboat, in both PLA and ABS. The ABS version had layers separating and a poor surface finish. The PLA version was superior to the ABS but still had some noticeable wobble in the Z-Axis and the layers were less smooth.

The tugboats made by this printer didn't impress us all that much.

Credit: Jenna Ammerman

This model also didn't excel at printing our bridging test or the Eiffel Tower. The Printer did about average in the PLA versions, with only some minimal sagging in the longest bridges and an alright Eiffel Tower. However, both ABS versions of this test print failed to complete.

The ABS versions of these complex prints were complete failures.

Credit: Jenna Ammerman

Moving on to our next three test prints, the Monoprice Maker Select didn't too much in boosting its score. While it did do quite well on our overhang test, both in PLA and ABS, printing up to the 70° mark, the underside wasn't quite as smooth as the Lulzbot or the QIDI. The articulated elephant turned out terrible in ABS, with a ton of layer separation. The PLA version was acceptable, with joints that moved alright but having a body that overall looked a little rough. The nickel test turned out to be slightly oversized, with the nickel falling through easily and the ABS version warped slightly, costing it a few points.

The ABS version of the elephant was splitting apart due to the layers warping and separating.

Credit: Jenna Ammerman

The next two prints — the platform jack and the hollow cube — were two of the more difficult prints in our test. Once again, the Maker Select didn't impress, doing a relatively subpar job. The PLA platform jack was acceptable — opening and closing, but having plenty of Z-Axis wobble and shoddy bridging. The ABS version failed to print entirely. The ABS hollow cube had some layer separation, while the PLA version also had plenty of Z-Axis wobble.

Once again, the Maker Select didn't impress, doing a relatively subpar job. The PLA platform jack was acceptable — opening and closing, but having plenty of Z-Axis wobble and shoddy bridging. The ABS version failed to print entirely. The ABS hollow cube had some layer separation, while the PLA version also had plenty of Z-Axis wobble.

The platform jack didn't look great but it did open and close.

Credit: Jenna Ammerman

The Monoprice did a mediocre job at our pair of low-poly figurines. One ABS version failed to print, while the successful prints had sloppy overhanging sections and some layer separation.

The overhangs on the low-poly figures could have been a little cleaner.

Credit: Jenna Ammerman

Continuing the trend, the Maker Select delivered a similar performance in our tall tower test and spiral vase but did surprise us slightly by its stellar performance in the support test — at least in PLA. Both ABS and PLA spiral vases had some thin spots and layer separation. The tall towers were both slightly subpar, with two sides exhibiting noticeable undulations. The PLA support test did score above average, with the sacrificial structure breaking away easily and leaving behind a clean surface. The ABS version failed to print.

The tall towers were both slightly subpar, with two sides exhibiting noticeable undulations. The PLA support test did score above average, with the sacrificial structure breaking away easily and leaving behind a clean surface. The ABS version failed to print.

You could clearly feel the waves in the towers as you moved up the vertical axis.

Credit: Jenna Ammerman

The Maker Select delivered a reasonable showing in the last two tests, a threaded jar and lid.

The threaded containers that printed were about average.

Credit: Jenna Ammerman

The PLA version of the jar had alright threads and was reasonably smooth, though the ABS version failed to print. The lids were pretty good, though not as high resolution as the FlashForge and the ABS version had a little warping.

The Monoprice required a little bit of assembly.

Credit: Jenna Ammerman

Ease of Use

The next metric in our review --Ease of Use — accounted for 30% of the total score. We compared the difficulty at initially setting up and unboxing the printer, changing filament, leveling the print bed, and connecting to the printer, as well as what sort of display the printer had. The Maker Select once again earned a 5 out of 10 for its overall average performance.

We compared the difficulty at initially setting up and unboxing the printer, changing filament, leveling the print bed, and connecting to the printer, as well as what sort of display the printer had. The Maker Select once again earned a 5 out of 10 for its overall average performance.

Unboxing the Maker Select V2.

Credit: Jenna Ammerman

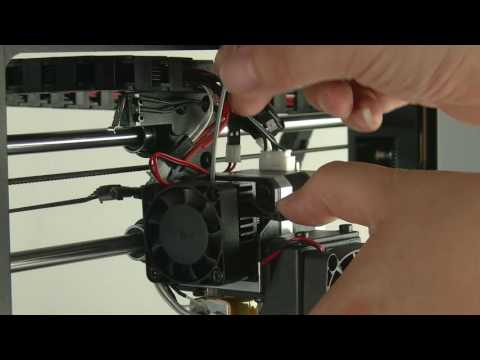

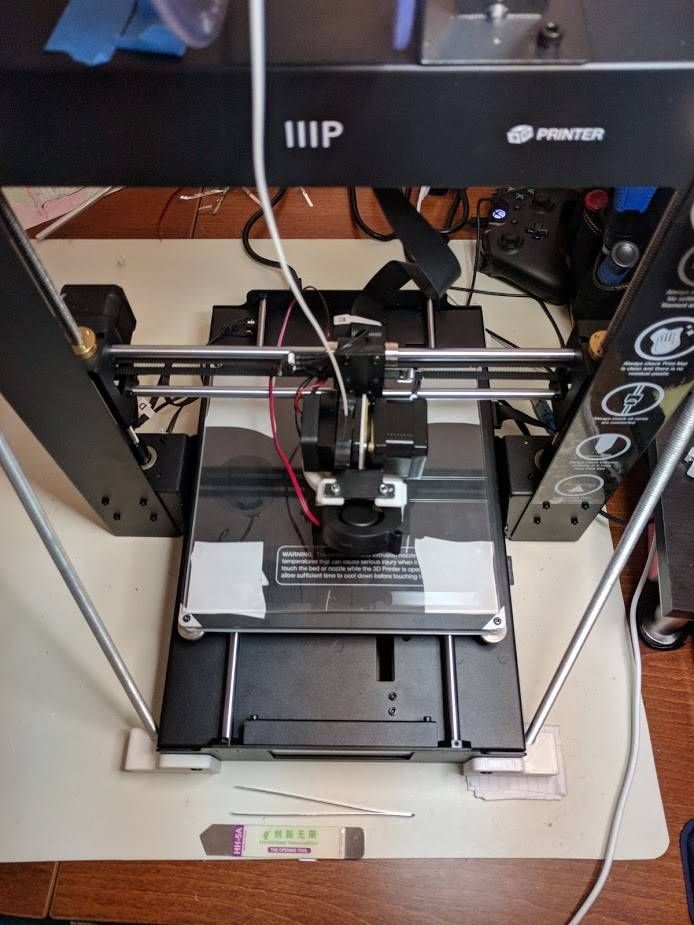

The initial setup was about average compared with other models. After unboxing, you only need to attach the base, connect the wires, and attach the spool holder. However, this was a little more difficult as the spool holder attached with fasteners, rather than snapping or sliding into place. We did find that the connector for the extruder cooling fan had worked loose in shipping, causing our first print to fail, but was easily remedied by re-attaching the connector.

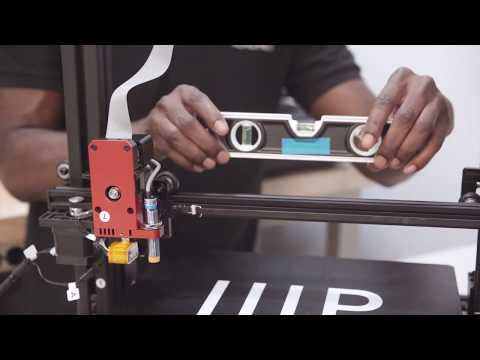

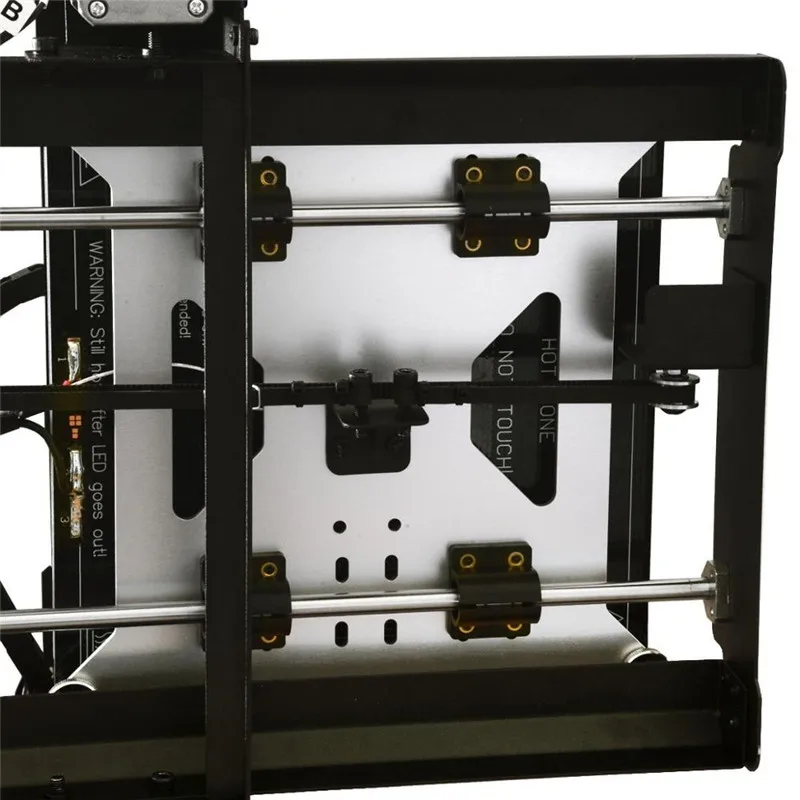

We found the manual leveling system to be a pain and this was one of our least favorite machines to level. We also found it easy to inadvertently hit the thumbscrews and change the bed level accidentally.

It was about average to swap filaments and this printer used Cura as a slicer, which we found to be one of the better software programs.

Like many others, this model uses Cura as the recommended slicer.

Credit: Jenna Ammerman

This printer has an LCD display on it power supply box that shows current printing progress while it is operating.

The display is built into the power supply for this model.

Credit: Jenna Ammerman

This box also has a microSD card slot to allow for standalone printing and the USB connector for when the machine is tethered to a computer.

The Maker Select is a reasonably capable printer.

Credit: Jenna Ammerman

Print Capabilities

Boosting its overall score, the Monoprice Maker Select V2 performed above average in this metric, earning it a 6 out of 10. We compared the build volume and build plate, the filament capabilities, cooling setup, as well as the slicing software between models to determine scores.

The Monoprice uses Cura as a recommended slicer, with the option to upgrade to a more sophisticated program, such as Simplify3D.

This printer had a decently large build volume of 200 x 200 x 175mm, putting it in the middle of the pack. The print surface itself is slightly subpar, with a stick-on print bed attached to an aluminum plate. This print surface proved to be a little problematic, giving us a handful of bed adhesion issues.

We had multiple ABS prints detach from the print bed partway through, even when using adhesive and a raft to secure them.

Credit: Jenna Ammerman

The Maker Select is compatible with generic, 1.75mm filament. The extruder can hit a maximum temperature of 260°C. This wasn't exceptionally high but does allow this model to print ABS, PLA, PET, PVA, or HIPS — just none of the higher temperature filaments like Nylon. This model also has one layer cooling fan.

Support

Our fourth and final metric — Support — made up the residual 10% of the overall score. This was determined by the helpfulness of the customer support team and the ease at contacting them, as well as the quality of instructional videos on the manufacturer's site and the warranty included with the printer. The Monoprice Maker Select V2 did a good job, earning a 6 out of 10.

This was determined by the helpfulness of the customer support team and the ease at contacting them, as well as the quality of instructional videos on the manufacturer's site and the warranty included with the printer. The Monoprice Maker Select V2 did a good job, earning a 6 out of 10.

You can contact the support team via email, contact form, phone, or instant messenger. However, We didn't find the team to be that helpful, basically telling us that we needed to return the printer to fix what seemed to be a simple issue with print quality.

The printer does include a 1-year warranty — better than most. However, there wasn't a ton of helpful instructional videos on their website, losing it a few points.

Value

This printer is one of the most budget-friendly but it isn't necessarily a great value. Its low retail price is accompanied by an overall mediocre performance.

Conclusion

The Monoprice Maker Select V2 is a low-cost, budget-friendly model that had an impressively mediocre performance. This might be a good option for those diving into 3D printing and are unafraid of tinkering and troubleshooting, with a good probability of more difficult prints failing or requiring a few attempts to complete.

This might be a good option for those diving into 3D printing and are unafraid of tinkering and troubleshooting, with a good probability of more difficult prints failing or requiring a few attempts to complete.

Monoprice Maker Select V2 - 3D Printers - Talk Manufacturing

Athoss22

#1

I have had all the trouble in the world with my IIIP Maker Select V2 printer. The nozzle has recently been unable to get a first layer down 100%. I’ve tried resetting the bed thinking it may be the leveling, but that hasn’t been successful. While using the heated bed I usually always have a couple corners warped which completely ruins the layering farther up the print. I usually set up my prints with a bed temp of 210C-220C and an extruder temp of 65C-70C, so still not sure where to go with temps to fix the warping. Along with the first initial layers being a problem, it seems the nozzle catches small fibers of print that are part of the support inside the print. I bounce around with 30%-50% density And haven’t found the right spot. As far as adhesion I’ve tried attaching glass, gluesticks, painters tape, and hair spray (even combining some and still failed prints). Im just praying someone has some advice because in my attempt to talk to Monoprice they want me to send the while printer back and to get a replacement. Plz help.

Along with the first initial layers being a problem, it seems the nozzle catches small fibers of print that are part of the support inside the print. I bounce around with 30%-50% density And haven’t found the right spot. As far as adhesion I’ve tried attaching glass, gluesticks, painters tape, and hair spray (even combining some and still failed prints). Im just praying someone has some advice because in my attempt to talk to Monoprice they want me to send the while printer back and to get a replacement. Plz help.

1 Like

ChrisBuildsStuf

#2

Did you describe your temps correctly? Do you print with a raft or brim?

I have this printer and I usually run the bed temp at 60C and the extruder at 215C. If you have the bed too high the filament won’t cool fast enough and will warp. I only use PLA. I print with either .15 or .2 layer height and only 20-30% infill. Unless you need something really strong you likely don’t need 50%.

I only use PLA. I print with either .15 or .2 layer height and only 20-30% infill. Unless you need something really strong you likely don’t need 50%.

Also make sure the bed is high enough to make good contact with the extruded filament.

For adhesion I have had luck with the included build plate with the tape on, but sometimes I have used painters tape with a purple gluestick on top of that. The only downside is you have to reapply layers of tape because it tends to come off with the print.

You also may need to replace the nozzle and PTFE tube inside the extruder. Sounds a lot more complicated than it is. I can direct you to the replacement parts I used.

ASkillz

#3

I’m assuming you meant a bed temp of 65-70C & a extruder temp of 210-220C, not vice versa.

How long have you been printing with your existing nozzle, and what materials are you using?

There are only so many variables that can cause the problems you’re having, so we’ll figure it out!

Elliott8

#4

Personally, I would recommend using a raft. I use Cura for slicing and the automatically generated raft has completely removed warping. Furthermore, if you are using PLA, I would lower the extruder temp. I have had a lot of success with 195degrees C.

Athoss22

#5

Yes I meant to say my bed temp is around 65-70 and extruder 210-215. I have been using a brim for my prints that go 5 times around. I began using rafts and they always seemed to peel up. Next time I’ll have to try using less infill because on the print I just tested it was all sorts of messed up. I did my best to level out the bed and used a glue stick and hairspray.

I have been using a brim for my prints that go 5 times around. I began using rafts and they always seemed to peel up. Next time I’ll have to try using less infill because on the print I just tested it was all sorts of messed up. I did my best to level out the bed and used a glue stick and hairspray.

Spinrb8

#6

ChrisBuildsStuf

#7

You may want to try taking off the nozzle and the plastic tube and see if that is clogged. You’d have to heat it up to printing temps, cut the filament, and push down the lever and pull the filament out or extrude it through to clear it. Then just use pliers to hold the heating block and a socket wrench to loosen the nozzle. Usually 3/8 inch works. If you are still under warranty then may be best to just replace the printer. I only had to pay $50 shipping to send it back.

Then just use pliers to hold the heating block and a socket wrench to loosen the nozzle. Usually 3/8 inch works. If you are still under warranty then may be best to just replace the printer. I only had to pay $50 shipping to send it back.

Wacky

#8

Miss typed earlier.

Here’s a link to my own troubles with the Monoprice that might lead you to something useful.

Elite0077

#9

1. Don’t know the filment your using or if your using a off brands

2. Leveling I found is simple home your bed turn off power and use a sheet of paper on all 4 corners repeat if needed. Also make sure it the tip of nooze not some leftovers that are you rubbing agaisnt when senting.

Also make sure it the tip of nooze not some leftovers that are you rubbing agaisnt when senting.

3. Clean your Bed may help rough it up a bit. I know in my first print it scarred my center never had a problem there after.

4. If your that your pic your setting not right on your setup or something else going on.

5. 60c for bed for play is max I set it to. 190-210 for pla I found work on on my print here. May have to adjust for weather I know my prints suck in humid weather.

6. Nozzle head out can get filment on it can Drag your stuff around. Best and easiest way I found to clean it. Warm your extuder to 230c and plung half way in to pla. Let it cool and then twist or knock free lightly. I used some old print feet.

7. May be best to pull clean the inside noozle. warm it up and pull it out when it cools about 80-70c then pull. I had to do this with my glow 2-3 times get all out.

Overview of the budget 3D printer Monoprice Select Mini

3DPrintStory Reviews Overview of the budget 3D printer Monoprice Select Mini

Prices for desktop 3D printers continue to fall. There were times when a $600 3D printer was a delight and a desire to order it as soon as possible, but technology does not stand still, and developers and manufacturers are looking for new options to lower the price even lower. This review is dedicated to one of the budget 3D printers costing about $200 - Monoprice Select Mini. nine0005

There were times when a $600 3D printer was a delight and a desire to order it as soon as possible, but technology does not stand still, and developers and manufacturers are looking for new options to lower the price even lower. This review is dedicated to one of the budget 3D printers costing about $200 - Monoprice Select Mini. nine0005

It is worth noting that this inexpensive model breaks established traditions and did not start with Kickstarter, unlike others like M3D Micro, Tiko, OLO / ONO and Trinus, which attracted the attention of consumers and investors thanks to crowdfunding platforms (by the way, this is really an effective development strategy for small startups, but there is often a mismatch between expectations and the final product).

Monoprice is different. This is an American company that did not particularly bother with the development and production of its own 3D printer, but simply imported the Malyan M200 from China, hung its logo on it and put an attractive price of $199. What if you got a defective 3D printer? No problem, send it back and they will replace it for you.

What if you got a defective 3D printer? No problem, send it back and they will replace it for you.

A reasonable question arises: can such a cheap 3D printer compete with Ultimakers or Printrbots? And is it even worth comparing? We will try to answer these and other questions in the review below.

Features Monoprice Select Mini

- Available;

- Robust design;

- Easy to use;

- Predictable 3D printing at low speed; nine0018

- Works with any slicing software and standard 3D printing materials;

- Amenable to improvements and upgrades;

- I think we already mentioned the price?

Disadvantages Monoprice Select Mini

- Difficult to calibrate;

- Prints poorly at high speeds;

- Print table not protected;

- Faulty power supply;

- WiFi module not active;

- Unstable nozzle temperature;

- Strange quirks...

Short Verdict

The Monoprice Select Mini is a great 3D printer for the price. There is a heated table, easy to operate if you do not use high speeds, stable 3D printing quality.

There is a heated table, easy to operate if you do not use high speeds, stable 3D printing quality.

Naturally, there are disadvantages. During operation, the temperature of the nozzle may change, and at high speeds, 3D printing errors occur. The calibration process takes a lot of time and the first time you have to tinker. Well, the most interesting thing is that the power supply burned out after 12 hours. But the latter, incorrect, can be attributed to an accidental marriage. nine0005

Despite all the shortcomings, the Monoprice Select Mini is a wonderful little 3D printer with many great features. In general, it performs in accordance with the information in the technical specifications, and the quality of the 3D printing even exceeded our expectations.

If you are not afraid to take it apart / put it back together, then you can do a few upgrades. The first thing to do is to replace the hotend and update the firmware to activate the WiFi module ( be careful! These upgrades have not been tested as part of this review and may damage your 3D printer! ). You can install the glass on the print table. Even with these upgrades, the price will still remain acceptable.

You can install the glass on the print table. Even with these upgrades, the price will still remain acceptable.

Would you recommend the Monoprice Select Mini as your first 3D printer? Yes, definitely.

Specifications and features Monoprice Select Mini

Monoprice Select Mini workspace 120 x 120 x 120 mm. The maximum resolution of 3D printing is 100 microns. Heated table. The 3D printing speed is 55 mm/s. nine0005

You can upload your 3D model via micro SD card or USB. The manual states that compatible slicing programs are Cura, Repetier-Host, ReplicatorG, and Simplify3D. This means that the Monoprice Select Mini recognizes the standard G-code, and this 3D printer is not tied to any particular software. Cura was used during testing for this review.

Monoprice Select Mini doesn't limit your media usage. You can print with any standard 1.75 filament using PLA or ABS thermoplastics. In our case, PLA plastic from ColorFabb was used. nine0005

These two points - the freedom to choose software and filament - are very important in this price range, because manufacturers such as M3D Micro and XYZprinting, which are Monoprice's main competitors in this niche, tend to use proprietary software and their own materials for 3D printing .

Unpacking and installation of the Monoprice Select Mini

Installation of the Monoprice Select Mini is quite simple. You can start typing within 20 minutes.

Inside the box you will find a 3D printer, a power supply, an imbus wrench for calibrating the table, a plastic spatula to scrape off the rest of the material from the table after printing, a 256 MB micro SD card and a micro USB cable.

One piece of paper contains a basic instruction and a link to a website where you can download the full version.

You will also find a rectangular steel sheet, the purpose of which is not clear at first. It turns out that this is a coil holder that is attached to the side of the main unit. nine0005

It is important to note that the Monoprice Select Mini kit does not include media test samples. So stock up on filament with a diameter of 1.75 mm.

You can use the wheel to adjust. The menu is well structured and easy to understand. You can start the calibration process, preheat the extruder and feed the filament.

Calibration can be somewhat difficult. In theory, it should be carried out even before shipment, in production, and you should have a piece of paper between the nozzle and the printing table. If it doesn’t work, then hex keys will come in handy here. It will be necessary to try and tighten the screws at the corners of the table so that the sheet still passes. nine0005

At this stage, the first important shortcoming of this model becomes clear. The printing table is made of aluminum and does not have a special protective film or coating on it. So stock up on blue 3D printing tape or install glass right away. Otherwise, the table will wear out very quickly and you will have to change it.

Well, one more bug that got out in our particular case. The power supply burned out after 12 hours of use. Foaming it was not difficult, but it was very unpleasant. You can probably throw it off for marriage, but in any case, be prepared for a similar turn of events. nine0005

Design and build quality of the Monoprice Select Mini

Very pleased with the build quality of the Monoprice Select Mini. The construction is strong, reliable, with a steel sheet metal case that hides all the electronics. So don't worry about shipping damage.

The construction is strong, reliable, with a steel sheet metal case that hides all the electronics. So don't worry about shipping damage.

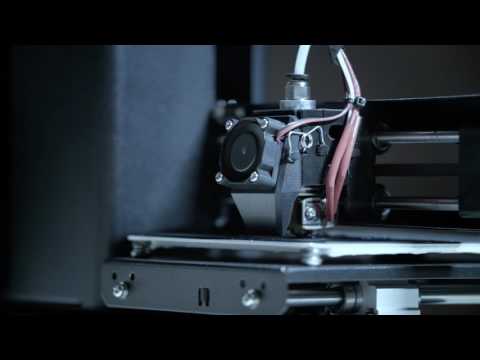

This 3D printer uses deposition modeling technology. The classical Cartesian coordinate system is used. The design is similar to Printrbot Simple. One cooler is used to cool the nozzle. It is likely that problems may arise during 3D printing with unusual materials. nine0005

The extruder has a diameter of 0.4 mm and can be heated up to 230°C. We have not been able to test how easy it is to change, but in the long run this is an important factor as the nozzle will still need to be changed over time.

Monoprice Select Mini Print Quality

Pre-loaded models will already be on the micro SD card. They are supposed to be optimized for 3D printing on the Monoprice Select Mini. So before uploading our own models, we printed test ones. nine0005

The cat was printed first. The resolution was 200 microns. Everything went well until the last layers. The upper part of the paw and ears could not be printed even once. There were 3 attempts in total.

The upper part of the paw and ears could not be printed even once. There were 3 attempts in total.

G-code analysis in Simlify3D showed that the table accelerated up to 55 mm/s during the printing of the last layers. That is why the error was repeated. Quite a strange decision of the company - to provide a test model, which a priori will be printed with errors...

The second model that we printed is a test elephant. The resolution was also 200 microns and 10% infill. There were no problems! The result is excellent and you can see it in the photo below. nine0005

Next we moved on to our own models. We used Cura for slicing. This article reveals the excellent Cura settings for 3D printing on the Monoprice Select Mini and we used them.

We printed a classic 3DBenchy and Graphica model: a MEGA Ghost with 200 micron resolution and 10% infill, a V29 whistle with 200 micron resolution and 100% infill, and another 3DBenchy model with 100 micron resolution and 10% infill. nine0005

nine0005

The simple 200 micron models worked well. There are no special problems with small protrusions and holes, although there are sagging. The layers are laid evenly along the X and Y axes.

The V29 whistle sounds as loud as intended, which means the partitions were printed correctly. The Graphica Mega Ghost with its long tongue also printed correctly. The hinge glided smoothly. The

3DBenchy at 100 microns worked well too. When you look at the photo, don't forget that this is a $19 3D printer.9.

We have noticed that most errors in 3D printing occur when the spool of filament clings or there is not enough adhesive coating on the printing table. This cannot be attributed to the shortcomings of the Monoprice Select Mini itself, since this is a global problem for all FFF printers.

During operation, the print table may block access to the control wheel. This point is implemented in the design is not very ergonomic.

Another disadvantage is that the nozzle temperature has an error in the region of 5°C. For example, when the 3D printing temperature is set to 215°C, it jumps between 213°C and 217°C on the control panel. nine0005

For example, when the 3D printing temperature is set to 215°C, it jumps between 213°C and 217°C on the control panel. nine0005

This does not particularly affect printing with PLA plastics, but may have a negative effect during 3D printing with materials that are more sensitive to temperature changes.

Finally, we printed a Low Poly Moai bust. We scaled the model by 50% and printed with 100 micron settings and 30% infill. It turned out well on the whole, the only small marriage is the influx of material on the chin. By the way, we observed the same effect when printing 3DBenchy with resolution settings of 100 microns. nine0005

Life hacks and upgrades Monoprice Select Mini

A few words about upgrading the Monoprice Select Mini 3D printer. There are no official upgrades! But here are a few options that you can try to implement on your own.

In our opinion, it is necessary to deal with the temperature of the extruder, make it more stable. For example, you can implement a PID temperature controller.

You can activate the WiFi connection by downloading the original Malyan M200 firmware. nine0059 But be careful! This option has not been tested and there is a possibility that you may damage your 3D printer!

Monoprice Select Mini Summary

After testing the Monoprice Select Mini, this is one of the best 3D printers you can buy for $200.

But it's important to realize that the print quality can't be compared to the Original Prusa i3 MK2 or LulzBot Mini. Not to mention the more expensive models.

If you're looking for a small business 3D printer or just high-quality 3D without bugs, then the Monoprice Select Mini is not for you. In addition to the print quality, you will obviously not be satisfied with periodic bugs and a small workspace. nine0005

But if you are just starting to explore the world of 3D printing, then this is a great choice and a good alternative to the Chinese Anet A8 3D printer.

The Monoprice Select Mini has some drawbacks, but it's still a great option for learning and just having fun. It's easy to use and print quality rivals more expensive models.

It's easy to use and print quality rivals more expensive models.

Top 20 Inexpensive 3D Printers ($199 to $1000)

3DPrintStory Reviews Top 20 Inexpensive 3D Printers ($199 to $1000)

Just 10 years ago, a 3D printer cost over $100,000. Today, you can easily find a cheap 3D printer for under $200. It's amazing.

Naturally, the lower the price, the more restrictions. Some of the printers on our list will not have a heated bed and the workspace will be small. Naturally, the quality of most of the models presented below cannot compete with more expensive counterparts. nine0005

But with a little patience and diligence, it is quite possible to achieve high-quality 3D printing on a printer that costs half the price of a flagship smartphone. And it's really cool!

And it's really cool!

Important note : All 3D printers in this top are supplied assembled by the manufacturer. If you have free time and want to spend less money, you can buy DIY kits and assemble the 3D printer yourself according to the instructions.

List of the best cheap 3D printers in the $200 to $1000 price range

05 PLA, ABS, exotic

If you want to buy them, even if you live in large cities such as Kyiv, Moscow, St.

Petersburg, Minsk, it may turn out that these models will not be in the online stores of your city, or they may be with a decent mark-up relative to the cost that indicated in the article. nine0005

Since most of them are European / American, it is possible that they will not be in stores at all.

Therefore, before making a choice, I recommend looking directly at eBay, Amazon, Aliexpress, etc. - many sellers on these planforms deliver to the CIS countries within 1-4 weeks on average.

It is especially worth monitoring these platforms during the discount period - Black Friday or Chinese New Year (Aliexpress or Gearbest) - prices on such days can be 2 or more times lower than usual and it is worth waiting for a few weeks. nine0005

Monoprice MP Select Mini ($199)

Probably the best 3D printer on our list. Why? Because the Monoprice MP Select Mini is an impressive development with a thoughtful, compact design at a very low price. This model has a quick-change steel material feed wheel, a cooler for cooling the nozzle, a color LCD screen, a heated table, plus the ability to transfer models for 3D printing via microSD or USB.

The heated bed and the wide temperature range of the extruder are especially pleasing, because for such a small price you get the opportunity to print in different materials: from ABS B to PLA or exotic materials like conductive PLA plastic, wood, metal-based composites and PVA. nine0005

For those who are worried about the lack of a guarantee - for such a price it is possible without it. This model is upgradeable. For example, you can install a new nozzle, change the table and add WiFi connectivity.

Small working space - 120 x 120 x 120 mm. Over time, this will definitely not be enough for you.

Specifications of cheap 3D printer Monoprice MP Select Mini

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic; nine0018

- Working space: 120 x 120 x 120 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- 3D printing speed: 55 mm/s;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.

75 mm;

75 mm; - 3D printer control panel: yes;

- Connection: SD card, USB.

Back to 3D printer list

M3D Micro Retail ($249)

M3D Micro 3D printer hit the market thanks to Kickstarter. This model was presented with an incredible price of $349.

The working space of the M3D Micro is 109 x 113 x 166 mm. There are several body color options. The company has implemented "Micro Motion Technology" - a set of innovative solutions - thanks to which you get excellent quality 3D printing at a small price.

Today, this inexpensive 3D printer already costs even less than the price announced on Kickstarter. You can buy it for $249with a 12 month warranty. By the way, it is already possible to pre-order the next "pro" version.

Specifications of cheap 3D printer M3D Micro Retail

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 116 x 109 x 113 mm;

- Minimum layer height: 50 microns;

- Maximum layer height: 350 microns;

- Number of extruders: 1;

- XY accuracy: 15 microns; nine0018

- Open source: no;

- 3D printing speed: 55 mm/s;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: no;

- Connection: USB.

Back to the list of 3D printers

XYZprinting da Vinci Mini ($289)

The Da Vinci Mini is a successful attempt at making a 3D printer user-friendly. This model has only one button and 5 multi-colored indicators that reflect the current status of 3D printing. In addition, this affordable 3D printer is WiFi capable so you can control it over a network in your home, office or lab. nine0005

Unfortunately, you can only use the manufacturer's own 3D materials. On average, they cost 20% more than usual. However, the company also argues that the materials used (PLA) will be 100% non-toxic.

Specifications of cheap 3D printer XYZprinting da Vinci Mini

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 150 x 150 mm;

- Minimum layer height: 100 microns; nine0018

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: no;

- Heated table: no;

- Nozzle diameter: 1.

75 mm;

75 mm; - 3D printer control panel: yes;

- Connection: USB, WiFi.

Back to 3D printer list

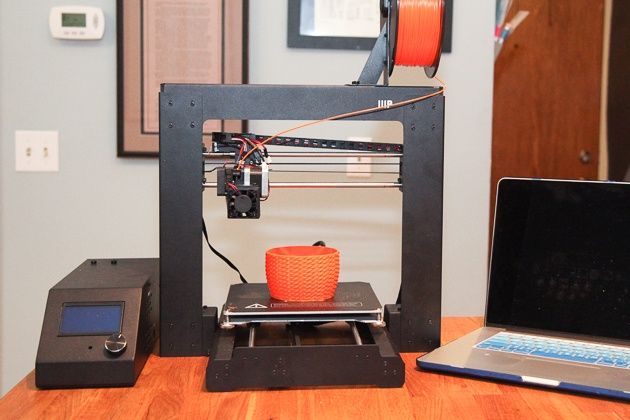

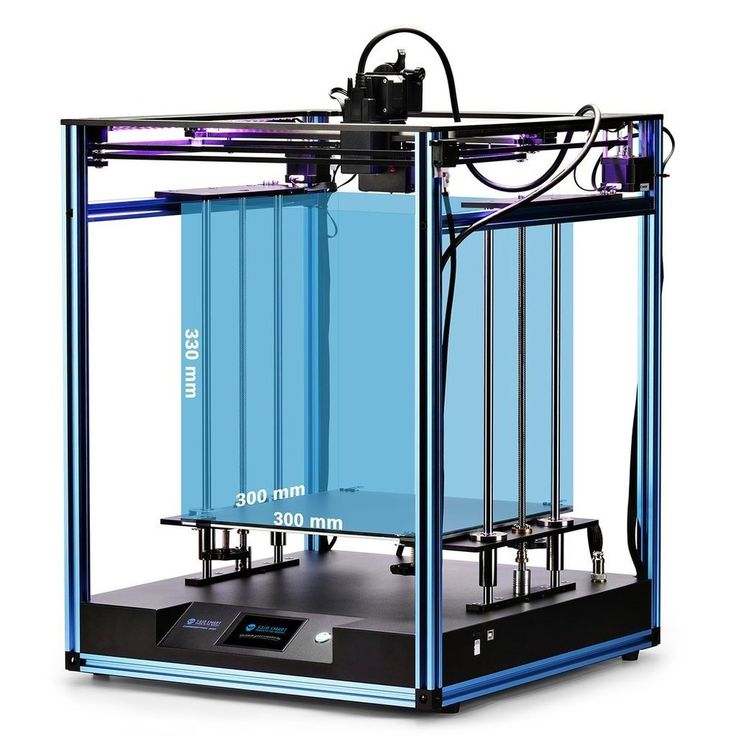

Monoprice Maker Select V2($299)

The next cheap 3D printer with a good reputation is the Monoprice Maker Select V2. nine0005

This model is an analogue of the Wanhao Duplicator i3, which, in turn, borrowed the design from the Prusa i3. But this does not affect the quality, as the Monoprice Maker Select V2 is easy to use and gives excellent 3D printing results.

Monoprice Maker Select V2 design feature is that the power supply and control panel are placed outside the 3D printer. The working space of this model is 200 x 200 x 180 mm. And this is really a good indicator for the money. nine0005

Specifications of cheap 3D printer Monoprice Maker Select V2

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 200 x 200 x 180 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: software;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.

75 mm; nine0018

75 mm; nine0018 - 3D printer control panel: yes;

- Connection: USB, SD card.

Back to the list of 3D printers

New Matter MOD-t ($299)

New Matter is a young startup that offers a 3D printer MOD-t - An interesting design with a minimalistic design. This cheap 3D printer is WiFi enabled so you can manage print settings and print from your computer, tablet or smartphone. The working space is 150 x 150 x 125 mm. Thanks to the case, the noise during its operation is reduced. But the most interesting and attractive thing about MOD-t is the price. Only $299. In general, this is an interesting, high-quality model.

Specifications of cheap 3D printer New Matter MOD-t

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 100 x 125 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.

75 mm; nine0018

75 mm; nine0018 - Control panel on 3D printer: no;

- Connection: USB, WiFi.

Back to the list of 3D printers

Printrbot Play ($399)

The Printbot Play is a very popular budget 3D printer that is often used in education. This inexpensive, reliable model, which is almost entirely made of metal.

The working space is 100 x 100 x 130 mm. Printbot Play has an extruder manufactured by the company itself - Alu Extruder v2. The body is made of powder coated steel and aluminium. SD slot provided. nine0005

You can upgrade the basic design of the Printrbot Play with a heated stand or increase the Y-axis stroke.

Wanhao Duplicator i3 Plus ($459)

The Wanhao Duplicator i3 Plus is an upgraded version of the popular Wanhao Duplicator i3 (which in turn is based on the Prusa i3).

The main features of this cheap 3D printer are a large working space of 200 x 200 x 180 mm, a steel frame, electronics integrated into the design itself (previously it was taken out separately), a slot for a full-size SD card and a touchscreen display for control. nine0005

Wanhao Duplicator i3 Plus Cheap 3D Printer Specifications

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 200 x 200 x 180 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: design and software;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.75 mm; nine0018

- 3D printer control panel: yes;

- Connection: USB, SD card.

Back to the list of 3D printers

Flashforge Finder ($499)

FlashForge Finder is one of the newest 3D printers on our list. This affordable 3D printer offers an average working space of 140 x 140 x 140mm.

This Finder features a transparent sidewall design so you can view the 3D printing process from any angle. A color display is installed, it is possible to transfer data via WiFi network. The printer comes with some supplies and a USB flash drive, so you can start 3D printing almost immediately. nine0005

Specifications of cheap 3D printer FlashForge Finder

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 140 x 140 x 140 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- XY accuracy: 11 microns;

- Open Source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.

75 mm; nine0018

75 mm; nine0018 - 3D printer control panel: yes;

- Connection: USB, WiFi.

Back to 3D printer list

XYZprinting da Vinci Jr. 1.0 Pro ($499)

What's so special about the da Vinci Jr. 1.0 pro? This is a new model from XYZPrinting, which includes many advanced features, such as support for printing materials from other manufacturers and increased speed of 3D printing.

Also features an auto-calibration mechanism, a closed chamber with a unique cooling system, and a 0.3mm nozzle option for high-quality printing of fine model details. All in all, this is a great 3D printer with a lot of useful features and at a low price. nine0005

Specifications for cheap 3D printer da Vinci Jr. 1.0 Pro

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 150 x 150 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.

75 mm;

75 mm; - 3D printer control panel: yes; nine0018

- Connection: USB, SD card.

Back to 3D printer list

XYZprinting da Vinci Jr. Mix 2.0 ($599)

XYZprinting provides a wide range of low cost 3D printers. And paying attention to each model is quite difficult, although many of them are very interesting.

XYZprinting da Vinci Jr. Mix 2.0 stands out because it can print with two different materials and mix them to create multi-colored models. This dual-color 3D printing technology is rare in this price range ($500 to $1,000), so if you're interested in experimenting with multicolor printing, XYZprinting da Vinci Jr. Mix 2.0 is a great choice. nine0005

However, there is a drawback. This 3D printer is not compatible with materials from other manufacturers, so you will have to buy special materials from XYZprinting (as we mentioned above, they cost 20% more, but are not toxic).

Specifications of cheap 3D printer XYZprinting da Vinci Jr.

Mix 2.0

Mix 2.0 - Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 150 x 150 mm;

- Minimum layer height: 200 microns; nine0018

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: no;

- Heated table: no;

- Nozzle diameter: 1.75 mm;

- 3D printer control panel: yes;

- Connection: USB, SD card, WiFi.

Printrbot Simple ($599)

Printrbot Simple is the flagship of the Printbot empire. This model has a great open design with a solid aluminum frame and a working space of 150 x 150 x 150mm. This inexpensive 3D printer comes fully assembled at a very good price. As you need and want to experiment, you can add a heated table and expand the workspace in the horizontal plane. nine0005

Specifications of cheap 3D printer Printrbot Simple

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 150 x 150 x 150 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- 3D printing speed: 80 mm/s;

- Open Source: design and software;

- Compatible with materials from other manufacturers: yes;

- Heated table: optional; nine0018

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: no;

- Connection: USB.

Back to the list of 3D printers

UP mini 2 ($599)

The UP mini 2 is a low cost 3D printer that packs in impressive design and functionality. For starters, it has a touch screen panel and the ability to connect via WiFi.

But the most interesting is further. Implemented power failure protection system. 3D printing will continue after the emergency stop. Built-in HEPA air filtration system. Automatic detection of the height of the extruder nozzle. A separate, closed container for the material, thanks to which it does not deteriorate under the influence of moisture from the environment. nine0005

Great 3D printer for a small price. The only thing that upsets me a little is the small working space - 120 x 120 x 120 mm.

Specifications of cheap 3D printer UP mini 2

- Printer type: FDM;

- 3D printing materials: PLA, ABS;

- Working space: 120 x 120 x 120 mm;

- Minimum layer height: 150 microns;

- Maximum layer height: 350 microns;

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.

75 mm;

75 mm; - 3D printer control panel: yes;

- Connection: USB, WiFi.

Back to 3D Printer List

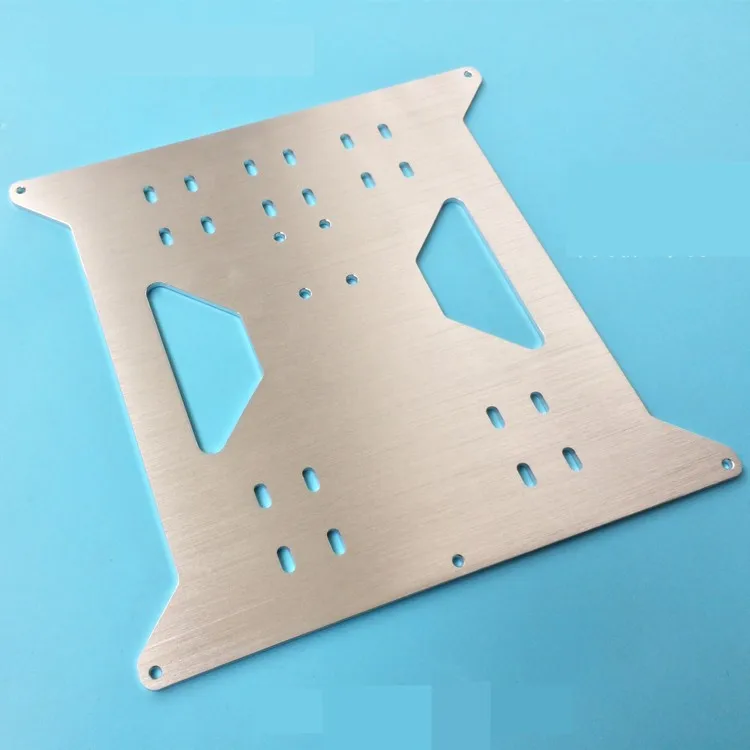

Monoprice Maker Select Ultimate ($699)

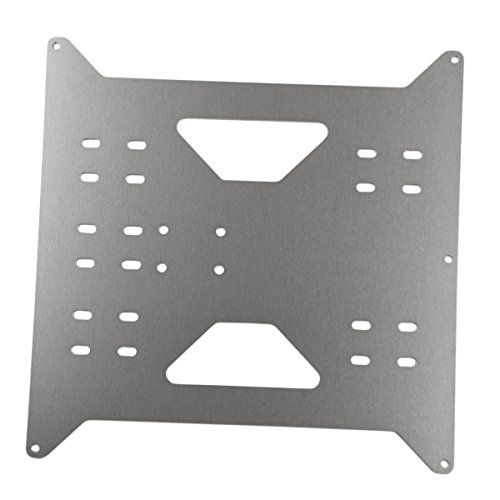

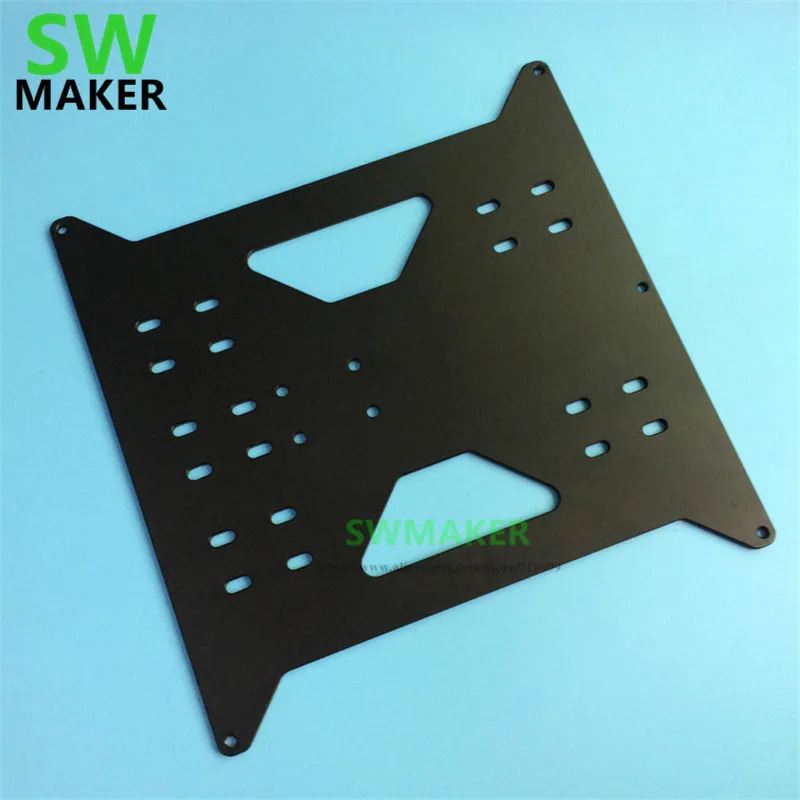

The Monoprice Maker Select Ultimate is an extraordinary beast that combines elements from two leaders in the world of 3D printing, Zortax and Ultimaker. The Monoprice Maker has an aluminum perforated printing table, which was offered in the Zortax M200 (thanks to this table, the grip of the base of the model with the table is much better), and the software part is almost identical to Ultimaker 2 (very user-friendly interface and functionality). nine0005

This model uses a "Bowden extruder", i.e. the feed units and nozzle are separated, unlike the direct feed. This improves reliability and reduces the likelihood of 3D printing errors (although, most likely, it was necessary to sacrifice printing speed, as the weight of the printing unit increases). Given the cost, this is a good model, the analogues of which are much more expensive.

Specifications of cheap 3D printer UP mini 2

- Printer type: FDM; nine0018

- 3D printing materials: PLA, ABS, exotic;

- Working space: 200 x 200 x 175 mm;

- Minimum layer height: 20 microns;

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.75 mm;

- 3D printer control panel: yes;

- Connection: USB, SD card.

Back to the list of 3D printers

Robo C2 ($799)

The Robo C2 is a small 3D printer with tons of connectivity options. Using a specialized application, you can monitor the status of 3D printing from your smartphone or tablet. It can be connected to a Chromebook. Thanks to the built-in slicing program, you do not need to install additional printing software.

Probably the most impressive is the integration with Amazon Alexa. Users can stop, cancel and check the status of 3D printing in real time using voice commands. nine0005

nine0005

What does this inexpensive 3D printer offer? Working space 127 x 127 x 150 mm. The 3D printing speed is 300 mm/s and the resolution is 20 microns. There is a built-in 3.5'' color touch screen, a system for monitoring the amount of remaining material for printing, automatic calibration and a removable self-aligning print platform. The only drawback is that the table is not heated, so you have to use PLA plastic.

Specifications of cheap 3D printer Robo C2

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 127 x 127 x 150 mm;

- Minimum layer height: 20 microns;

- Number of extruders: 1;

- Open Source: software;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.75 mm;

- 3D printer control panel: yes;

- Connection: USB, WiFi.

Back to the list of 3D printers

Wanhao Duplicator 4S ($829)

The Duplicator 4S has 2 extruders. It's essentially a copy of the MakerBot Replicator. Behind the steel body is the MK10 material feed mechanism, which is currently the easiest to use and most sought after in the market for 3D printer components.

It's essentially a copy of the MakerBot Replicator. Behind the steel body is the MK10 material feed mechanism, which is currently the easiest to use and most sought after in the market for 3D printer components.

One of the features of this model is a high-precision material feed wheel, which ensures the same filament feed speed. The Duplicator 4S is equipped with a 0.4mm precision nozzle. nine0005

Specifications of cheap 3D printer Duplicator 4S

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 225 x 145 x 150 mm;

- Minimum layer height: 100 microns;

- Maximum layer height: 500 microns;

- Number of extruders: 2;

- XY accuracy: 11 microns;

- 3D printing speed: 40 mm/s;

- Open Source: software;

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 0.4 mm;

- 3D printer control panel: yes;

- Connection: USB, SD card.

Polar 3D Printer This causes the table to rotate and the print head to move up, down, right, and left. nine0005

Polar 3D Printer This causes the table to rotate and the print head to move up, down, right, and left. nine0005 Thanks to the polar coordinate system, this 3D printer is powered by two stepper motors, so it consumes less power. In addition, it turned out to realize a larger size of the working area: 203 (table diameter) x 152 (Z coordinate) mm.

Nominal price $899, but there are special discounts for educational institutions. The discounted price is only $599.

Specifications of cheap 3D printer Polar 3D

- Printer type: FDM;

- Materials for 3D printing: PLA;

- Working space: 203 (table diameter) x 152 (Z-coordinate) mm;

- Minimum layer height: 50 microns;

- Maximum layer height: 400 microns;

- Number of extruders: 1;

- 3D printing speed: 40 mm/s;

- Open Source: no;

- Compatible with materials from other manufacturers: yes;

- Heated table: no;

- Nozzle diameter: 1.

75 mm;

75 mm; - Control panel on 3D printer: no; nine0018

- Connection: USB, WiFi, SD card.

Back to 3D printer list

FlashForge Creator Pro ($899)

You've probably heard of this 3D printer. FlashForge Creator Pro is very similar to Makerbot Replicator 2X. This inexpensive 3D printer has 2 extruders, it has a steel closed body.

Other features include a table sizing system, and a guide screw that makes the guide system more stable and durable. The design is nothing special, but this model has earned positive reviews from the 3D community due to its reliability, versatility and ease of use. nine0005

Specifications of cheap 3D printer FlashForge Creator Pro

- Printer type: FDM;

- 3D printing materials: ABS, PLA, exotic;

- Working space: 225 x 145 x 150 mm;

- Minimum layer height: 100 microns;

- Maximum layer height: 500 microns;

- Number of extruders: 2;

- XY accuracy: 11 microns;

- 3D printing speed: 40-100 mm/s;

- Open Source: design and software; nine0018

- Compatible with materials from other manufacturers: yes;

- Heated table: yes;

- Nozzle diameter: 1.

75 mm;

75 mm; - 3D printer control panel: yes;

- Connection: USB, SD card.

Back to 3D Printer List

Dremel Idea Builder ($899)

The Idea Builder is plug and play. This 3D printer is designed by Dremel. It has a color touch screen display. Sufficiently large working space - 230 x 150 x 140 mm. Unfortunately, the table is not heated. On the other hand, since only PLA plastics can be used, this model is great for classrooms and teaching labs. nine0005

Specifications of cheap 3D printer Dremel Idea Builder

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 230 x 150 x 140 mm;

- Minimum layer height: 100 microns;

- Number of extruders: 1;

- Open Source: no;

- Compatible with materials from other manufacturers: no;

- Heated table: no;

- Nozzle diameter: 1.75 mm;

- 3D printer control panel: yes; nine0018

- Connection: USB, SD card.

Back to 3D printer list

Printrbot Simple Pro ($999)

Printrbot Simple Pro is a major upgrade of the original Simple. Same open design, no body. Like its predecessor, the Printrbot Simple Pro is compact and portable. All-metal construction for excellent vibration damping and shock resistance.

The main difference is the built-in color touch screen, the ability to connect via WiFi and free cloud service (optional), which greatly improves the 3D printing process. Simple Pro has a 32-bit processor, which ensures smooth and fast movements. And at the same time, this model is included in our top 20 cheap 3D printers, since its cost is $999.

Specifications of cheap 3D printer Printrbot Simple Pro

- Printer type: FDM;

- 3D printing materials: PLA;

- Working space: 200 x 150 x 200 mm;

- Minimum layer height: 50 microns;

- Number of extruders: 1;

- Open Source: design and software;

- Compatible with materials from other manufacturers: yes;

- Heated table: optional;

- Nozzle diameter: 1.

75 mm; nine0018

75 mm; nine0018 - 3D printer control panel: yes;

- Connection: USB, WiFi.

Back to 3D printer list

Prusa i3 Mk2 ($999)

This is one of the best 3D printers you can buy in this price range. All nodes are open-source licensed and part of the Rep-Rap project, so there are many copies around ... but all replicas are worse than the original.

The Prusa i3 Mk2 is equipped with a heated table that has technology to compensate for temperature differences in the center and corners. There is an automatic calibration system. And of course, amazing documentation. This is an extremely versatile 3D printer that you will 100% appreciate when you start printing with unusual materials such as PLA, PET, HIPS, Flex PP or Ninjaflex, etc. nine0005

The Prusa i3 Mk2 is a 3D printer that is constantly being developed and supported by the manufacturer. Its developer Josef Prusa regularly adds new features, software and design improvements (for example, the ability to color 3D print).

Learn more