Impact of 3d printing on supply chain

Five Ways 3D Printing Will Impact The Global Supply Chain

In January 2019, 3D printer company BigRep unveiled the first 3D printed motorbike."

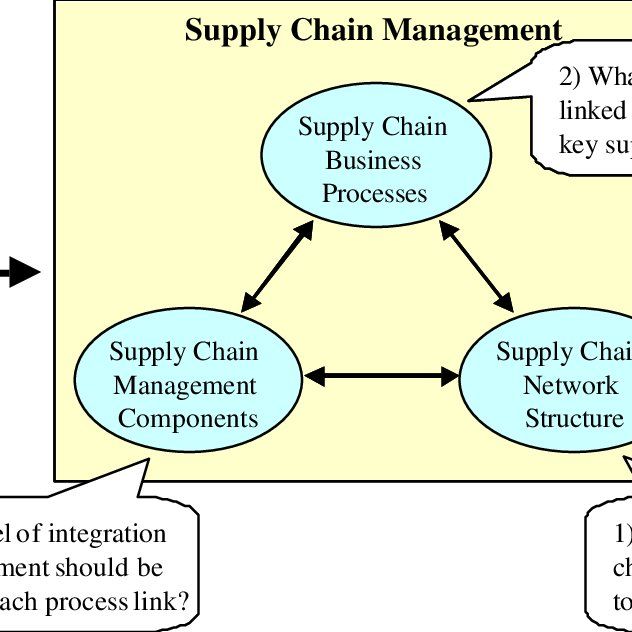

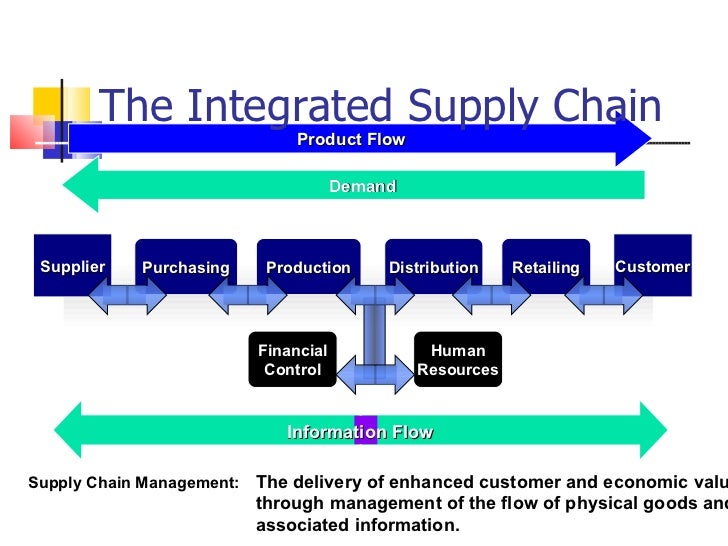

3D printing, or additive manufacturing (AM), is a disruptive innovation which will have a far-reaching impact on global supply chains and operations. Far from being the technology of the future, it is the technology of the here and now. According to the Global Supply Chain Institute white paper, New Supply Chain Technology Best Practices¹, "some supply chain professionals predict 3D printing will eventually rival the impact of Henry Ford's assembly line." This technology has the power to help companies significantly reduce costs, overcome geopolitical risks / tariffs, improve customer service, reduce their carbon footprint and drive innovation for competitive advantage. Whether you believe the technology will revolutionize the production and supply chain process or merely enhance it, you cannot afford to ignore it.

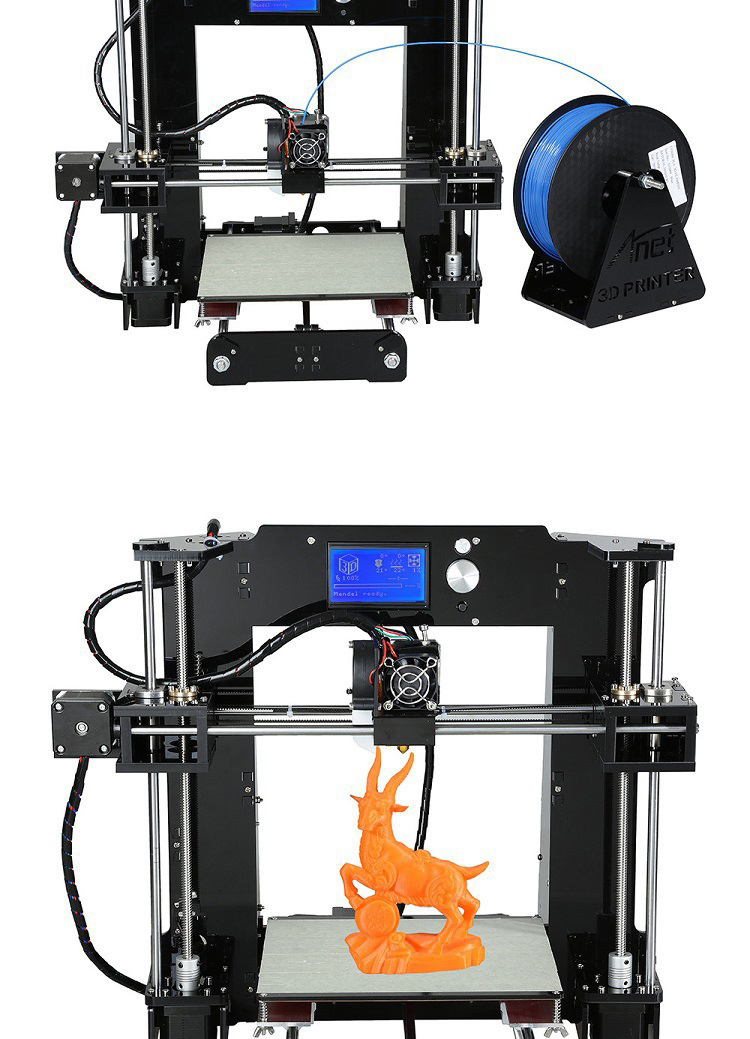

Also known as additive manufacturing, 3D printing is a process which uses a three-dimensional digital model to create a physical object by adding many thin layers of material in succession, subsequently lowering cost by cutting out waste. This is radically different from current, subtractive production methods where up to 90% of the original block of material can be wasted. Although we tend to think of it as a new technology, the first 3D printer was introduced nearly 30 years ago. So far, issues such as durability, speed and protection of intellectual property rights have prevented 3D printing from entering mainstream manufacturing. However, the industry is making rapid advancements and it's only a matter of time before we see it significantly impacting global supply chains.

Five ways 3D printing will have a massive impact on the supply chain and drive competitive advantageMajor chemical companies are already working directly with 3D printer manufacturers to invent new resins, polymers and powdered metals to take manufacturing into a new era."

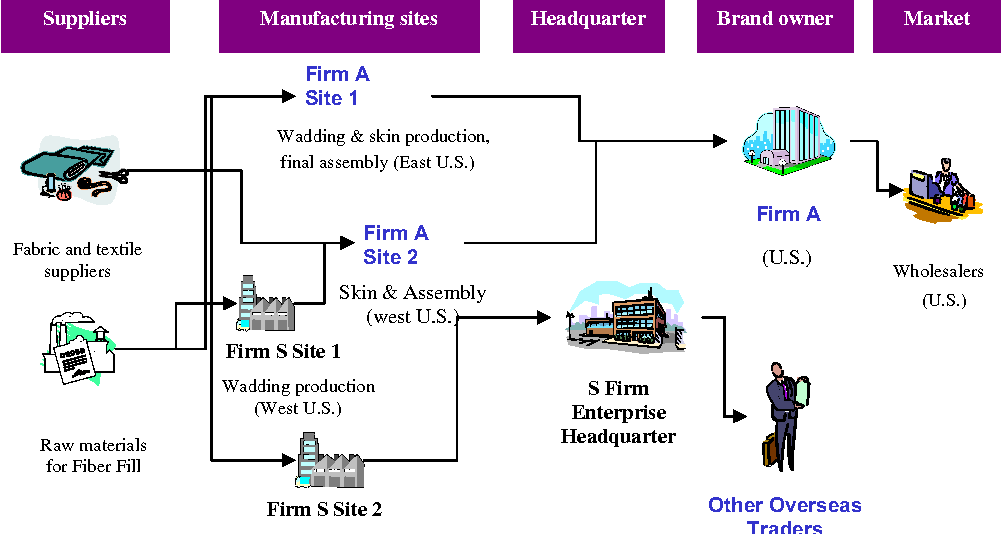

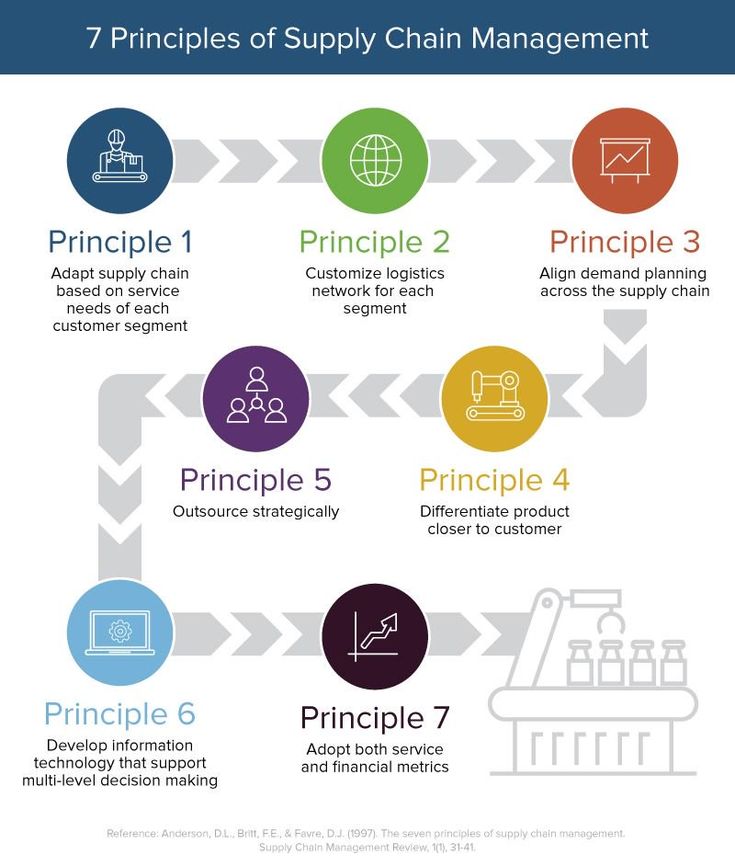

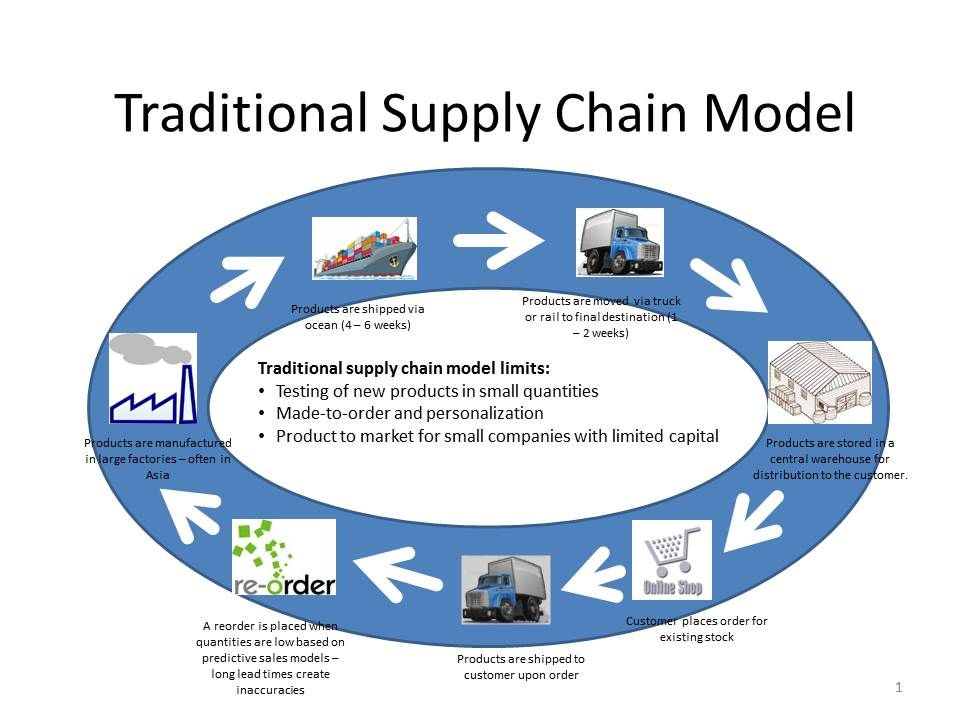

1. Decentralize production -- The 'portable' nature of the technology will enable businesses to take production to local markets or customers faster. As a result, we will see a shift away from mass production in low-cost countries in favor of more local assembly hubs. Companies will have the capability to produce components closer to home rather than rely on imports. This is especially important during times of geopolitical tension, for example during a trade war, when the cost of purchasing components globally can increase rapidly.

As a result, we will see a shift away from mass production in low-cost countries in favor of more local assembly hubs. Companies will have the capability to produce components closer to home rather than rely on imports. This is especially important during times of geopolitical tension, for example during a trade war, when the cost of purchasing components globally can increase rapidly.

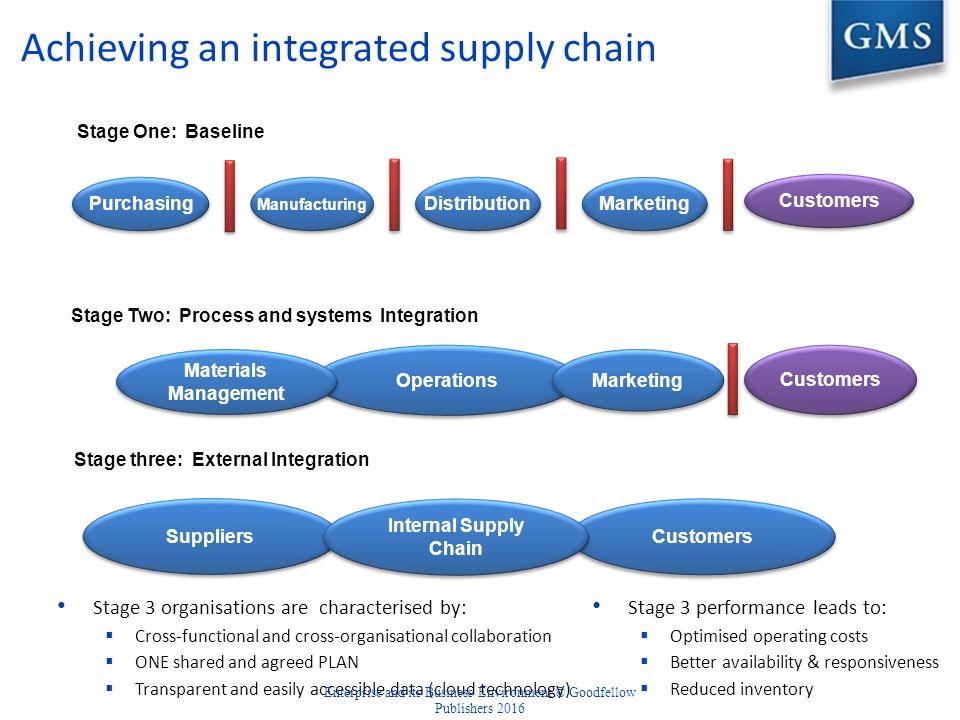

2. Drive product customization -- As a tool-less process, 3D printing technology gives manufacturers unprecedented freedom to tailor offerings to clients' specific requirements and enhance the customer experience. This will result in more agile supply chains which can rapidly adapt to changes in the market. Eventually, we could see design, production and distribution merge into one supply chain function with greater client involvement in the entire design and production process.

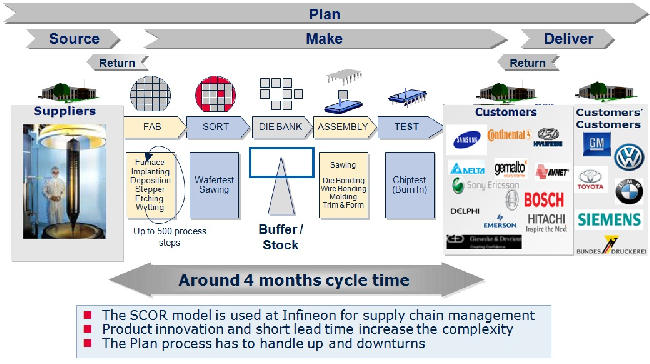

3. Reduce complexity and improve time-to-market -- 3D printing technology consolidates the number of components and processes required for manufacturing. This will have a significant impact on global supply chains, decreasing complexities, saving on production costs, enhancing lead times and improving time-to-market.

This will have a significant impact on global supply chains, decreasing complexities, saving on production costs, enhancing lead times and improving time-to-market.

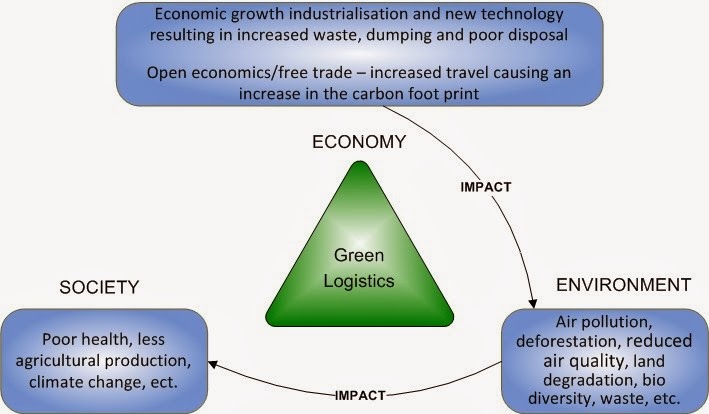

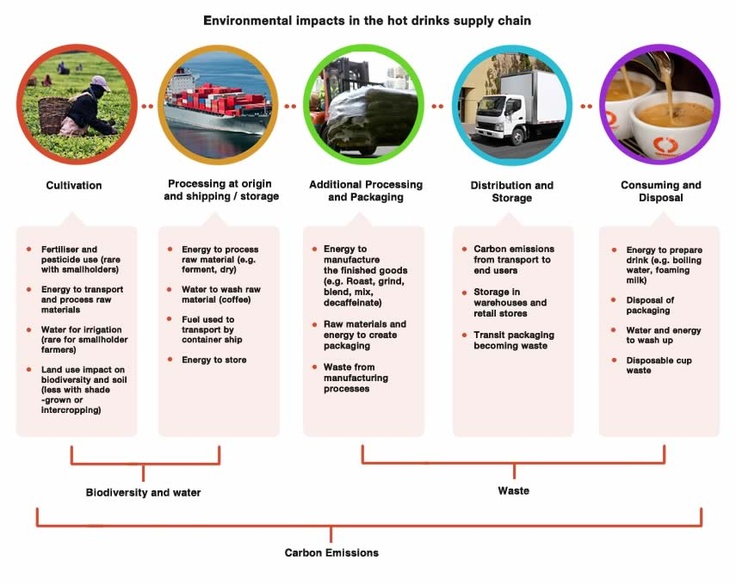

4. Improve resource efficiency -- 3D printing is a 'greener,' more energy-efficient and cost-efficient production method. It creates almost zero waste, lowers the risk of overproduction and excess inventory and reduces the carbon footprint. It takes 'Just-in-Time' manufacturing to a new level.

5. Rationalize inventory and logistics -- As 'on demand' production becomes the norm, the need to transport physical goods across countries and continents will reduce. Combined with the lower number of SKUs required for production, this will have a major impact on warehousing and logistics and will have the potential to overcome tariffs.

To bring these points to life, GE has built a prototype 3D printed aircraft engine, the GE9X,² that is lighter, faster and more fuel-efficient than any of its predecessors. The firm says 3D printing enabled it to reduce 855 separate parts to just twelve.

The firm says 3D printing enabled it to reduce 855 separate parts to just twelve.

Tomorrow's technology, todayAirbus is already talking about constructing entire airplanes with large scale 3D printers."

While 3D printing technology may sound like science fiction, it is actually science fact and it's making its presence felt right now. Here are a few more real-world applications already a reality or just around the corner:

Aerospace -- It may surprise you to learn some non-critical 3D printed parts are already in use on aircraft. GE already have more than 300 3D printers and GE Aviation wants to produce 100,000 additive parts by 2020. The US Air Force has installed seventeen 3D printed parts on the C5 Super Galaxy, which could save tens of thousands of dollars. Other high-profile users of the technology include Airbus / EADS, Rolls-Royce and BAE Systems. Airbus is already talking about constructing entire airplanes with large scale 3D printers.

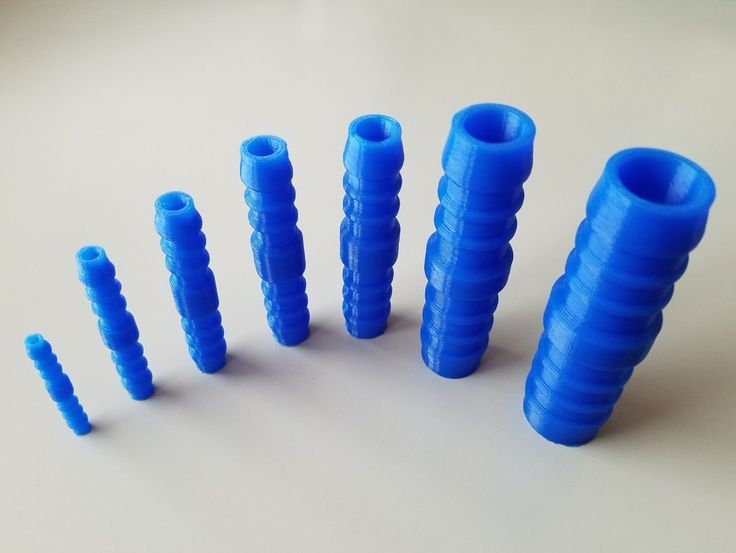

Medical -- The technology is already being applied to manufacture stock items, such as hip and knee implants, and bespoke patient-specific products, such as hearing aids, orthotic insoles for shoes, personalized prosthetics. Success stories include Open Bionics, a UK-based producer of 3D prosthetic arms which, in February 2019, secured a £4.6M investment to take its business to the international market.

Automotive -- Many automotive companies are already making use of 3D printing to help with prototyping. Ford has been using 3D printing technology since the 1980s. According to Ford's website, traditional methods would take four months and $500,000, but with 3D printing, the same process takes four days and $3,000. Future possibilities are almost limitless. In January 2019, 3D printer company BigRep unveiled the first 3D printed motorbike.³ The bike, which is not available on the market, took three days to print and cost just £2000.

Construction -- Although the technology is still in its infancy, significant advances have been made with the use of 3D printers in the construction industry as construction giants begin to see the potential of the technology. 3D concrete printing is developing rapidly, and the market is expected to reach $56.4M by 2021. More and more companies are starting up in the sector to create new, innovative projects. For example, Russian 3D printing manufacturer, Apis Cor printed an entire house in just 24 hours.4

3D concrete printing is developing rapidly, and the market is expected to reach $56.4M by 2021. More and more companies are starting up in the sector to create new, innovative projects. For example, Russian 3D printing manufacturer, Apis Cor printed an entire house in just 24 hours.4

Chemicals -- There is an incredible opportunity for the chemical industry to innovate and drive new revenue streams using 3D printing technology. The industry could find itself at the heart of the manufacturing process as it works closely with 3D printer manufacturers to develop new materials specifically designed for additive manufacturing. Major chemical companies are already working directly with 3D printer manufacturers to invent new resins, polymers and powdered metals to take manufacturing into a new era. Chemical giant BASF is one of the companies leading the way with a dedicated 3D printing division and partnerships with a string of hardware OEMs, software vendors, and materials specialists.

Food -- We could be seeing 3D printed food in restaurants or in our kitchen in the near future. Initiatives that mix 3D technologies and food are more and more numerous; this new manufacturing method would make it possible to create and mass produce food with more complex and original shapes and innovative recipes. It would also offer personalized meals to better adapt to the diversity of diets. Hershey's has already entered into partnership with 3D Systems to make a 3D printer for chocolate and other edible products though there is no word when the chocolate-making machine may be available.

Oil and Gas -- Although adoption of additive manufacturing technology in the oil & gas industry is behind other industries, the technology has enormous potential in this industry. For example, 3D printing could allow organizations to access a bank of digital designs for on-site printing in the field. This will have a major impact on the speed and efficiency of equipment repairs and maintenance, reducing the necessity to either maintain physical inventories of spare parts on site or wait for them to be manufactured and transported to a facility.

Shape the future of your supply chain and operationsThanks to 3D printing, it is now possible to build a home in 24 hours."

Additive manufacturing represents a major opportunity for companies to re-engineer their buy-make-move-fulfill supply chain for competitive advantage. With the market size predicted to reach $11,223.6Bn in 2019 and $41,587.1Bn by 20275, it's an opportunity executives can't afford to overlook. Yet, according to the Global Supply Chain Institute, only 16% of firms have a documented multiyear supply chain and operations strategy.

What next?The global 3D-printing market is predicted to reach $11,223.6Bn in 2019 and $41,587.1Bn by 2027"

The additive manufacturing revolution is coming, and it could impact your supply chain sooner than you think. The smart move is to start preparing now by answering the following questions:

- What areas in my supply chain and operations are potentially impacted by 3D printing?

- How do I protect my business and take advantage of the opportunities that will come my way?

- What needs to change across my buy-make-move-fulfill supply chain to help stay ahead of the game?

- What's the business case and what should my supply chain and operations transformation journey look like?

Footnotes

¹ New Supply Chain Technology Best Practices, Global Supply Chain Institute, available to download at, https://haslam. utk.edu/gsci/publications

utk.edu/gsci/publications

² 3D Printing Media Network, GE Prepares 777X for take off with 3D printed turbine blades

³BBC News, Nera, the 3D printed electric Motorbike

43D Natives, Thanks to 3D printing, you can now build a home in just 24 hours

5 2019 Additive Manufacturing Market Outlook and Summary of Opportunities, SmartTech Analysis

Further reading

50 cool things to 3D print in February 2019, All3DP

The free beginner's guide, 3DPI

About Us

Maine Pointe is a global supply chain and operations consulting firm trusted by many chief executives and private equity firms to drive compelling economic returns for their companies. We achieve this by delivering accelerated, sustainable improvements in EBITDA, cash and growth across their procurement, logistics and operations. Our hands-on implementation experts work with executives and their teams to rapidly break through functional silos and transform the buy-make-move-fulfill supply chain to deliver the greatest value to customers and investors at the lowest cost to business. We call this Total Value Optimization (TVO)™.

We call this Total Value Optimization (TVO)™.

Maine Pointe's engagements are results-driven and deliver between 4:1-8:1 ROI. We are so confident in our work and our processes that we provide a unique 100% guarantee of engagement fees based on annualized savings. www.mainepointe.com

Talk to a Maine Pointe Specialist

Using 3D Printing to Solve Supply Chain Challenges: 5 Examples

Learn Blog

“

We provide the physical article in near real-time to a variety of places. It’s the closest thing to teleportation I think you can get.”

– Jeremy Haight, Principal Engineer for Additive Manufacturing & Advanced Concepts at Vestas

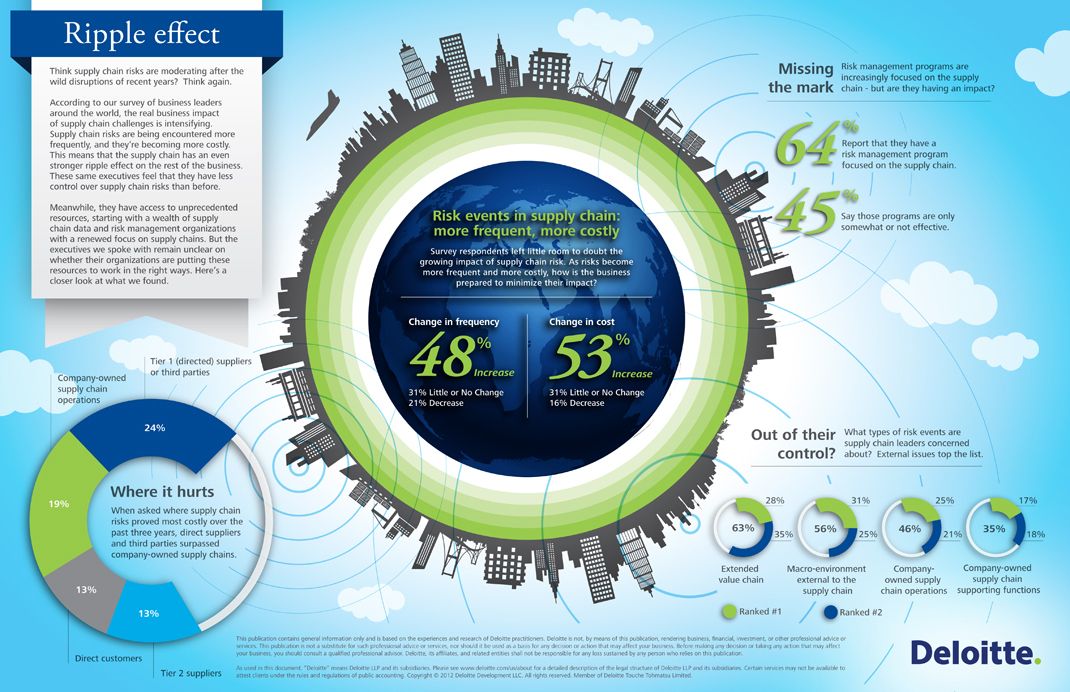

Pull up any major news outlet and you’ll surely see it: supply chain disruptions are still ongoing on a global scale. For manufacturers all over the world, supply chain issues present a major threat to productivity and their ability to meet critical business deadlines.

These ever-persistent supply chain issues continue to antagonize businesses of all types and sizes, manifesting as anything from a tequila drought at your local bar to medical supply shortages, to companies like Apple leaking billions at the hands of chip shortages. The expert prognosis is that external supply chain issues are likely here to stick around for the foreseeable future.

However, by bringing in a fast and reliable professional 3D printing platform, manufacturing businesses can bypass many of these risks — while also making their supply chains tighter and more efficient than before, with full control.

So, how specifically are companies using 3D printing to solve supply chain issues, while reinventing their supply chains to be more efficient and less disruptable than ever? Read this article to learn how, with 5 real-life examples — organizations from the U.S. Army to manufacturers of aircraft parts and wind turbines.

Why Additive, Why Now?

Learn how the expanded range of capabilities seen in today's 3D printers are allowing companies to change their supply chain game for new applications.

How does 3D printing build resilient supply chains?

Supply chain issues for manufacturers

For manufacturers, supply chain issues can create a number of major problems. Suboptimal supply chain logistics can create lead times that hinder growth and compromise the ability for businesses to meet critical deadlines. If a critical part needs to be replaced in the factory, manufacturing operations can easily stall for however long it takes for the part to be built, shipped, transported, and received — oftentimes, this is in the range of months.

If a critical part needs to be replaced in the factory, manufacturing operations can easily stall for however long it takes for the part to be built, shipped, transported, and received — oftentimes, this is in the range of months.

For organizations who rely on third party external suppliers to manufacture supply chain-critical parts, there is substantial time and effort between when a company first identifies a need, and when the final part arrives. Engineers must spend time drafting drawings, submitting purchase orders, and managing the bidding process with multiple vendors. Even once the third party finishes fabricating the parts, they then must be shipped out to the specific sites where they are needed.

Serious delays can arise from a hiccup in any point in this process — such as shipping or handling complications, or an upstream supplier experiencing a material shortage. If the received parts contain defects or other quality issues, this long, arduous cycle must be repeated, which can lead to extended downtime or other serious business consequences.

Tools for supply chain risk management

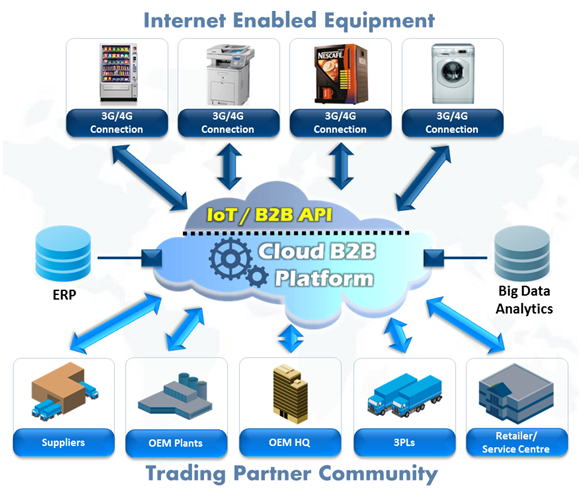

3D printing platforms can allow manufacturers to circumvent these hurdles and uncertainties. With a cloud-enabled distributed manufacturing model, the right parts can be quickly printed at the precise locations where they are needed, when they are needed. Individual printers can be placed across different geographic locations. Due to 3D printing software, parts stored in a cloud-based digital inventory can then be sent to be printed at any 3D printer within the network.

With just a CAD file, manufacturers can go from art to part entirely in-house — eliminating dependence on third parties and the associated risks, such as shipping issues, logistical complications, and issues with upstream suppliers that cause rippling effects.

By effectively bypassing certain steps of traditional supply chain logistics — such as the common need to receive shipments to obtain parts — 3D printing trims off the associated risk for supply chain disruptions. For parts that must be machined, using an AM system for rapid prototyping will help engineers ensure that when the machined part is finally received months later, it will work as expected.

For parts that must be machined, using an AM system for rapid prototyping will help engineers ensure that when the machined part is finally received months later, it will work as expected.

Combating supply chain disruptions with disruptive technologies

As additive manufacturing continues to move forward and expand in capabilities, 3D printing is able to solve an increasing number of major supply chain issues.

Worried about the aluminum shortage jacking up the prices? No problem — today’s professional 3D printers can make composites stronger than aluminum, in anywhere from just hours to days. Due to distributed manufacturing powered by cloud-based manufacturing networks and 3D printer connectivity to Industry 4.0 technologies, print jobs can be initiated by an operator from halfway across the globe and have it appear at the exact point of need.

The strength and material properties of today’s continuous fiber-reinforced (CFR) composite parts make it a faster, cheaper, and easier replacement for almost any part — even parts that must meet the demanding needs of the most specialized applications. These high-performance composites can replace many parts that were previously made from machined metals.

For parts that must be made from metal, metal fused filament fabrication (FFF) technology makes metal 3D printing more accessible, safer, and more simple for everyday use compared to other metal 3D printers — which are more expensive, have handling difficulties and safety risks associated with use of loose powder, and require highly trained operators.

1.) Vestas

Vestas, based in Denmark, is a global wind energy leader that designs, manufactures, installs, and services wind turbines across the globe. With wind turbines located in 86 countries, Vestas is the world’s largest on and offshore manufacturer of both wind turbines and wind turbine blades. Vestas operates out of over 15 manufacturing plants worldwide.

In Corporate Knights’ Global 100 ranking of the 100 most sustainable corporations, Vestas was ranked first. The company is using additive manufacturing for sustainability in its goal of net-zero decarbonization by the year 2030, and plans to produce zero-waste wind turbines by 2040.

Supply Chain Challenge:

For Vestas, many critical tools and parts are needed at each manufacturing facility and installation site. Tools like inspection gauges are needed to ensure precision and accuracy in the manufacturing and installation processes. Vestas has no room for error during manufacturing and installation: wind turbines are expensive machines, and downtime can be costly.

Vestas historically has outsourced the manufacturing of many parts to multiple third party vendors around the world. Detailed manufacturing instructions would be provided for each part, such as the inspection gauges and top center (TC) marking tools. The finished parts would then be sent to Vestas’s manufacturing facilities and installation sites.

However, outsourcing manufacturing of critical parts created a few problems that ultimately led to delays in final product delivery and installation:

- Many of the final inspection gauges supplied by third party manufacturers were not 100% up to spec and did not pass final inspection.

- Manufacturing was time expensive and costly for the parts that did make it through the specialized inspection process. Lead times would average about 5 weeks for some parts, and a minimum of 12 weeks for others.

Supply Chain Solution:

Due to the strength and material properties of Markforged’s continuous fiber-reinforced (CFR) composite parts made with Onyx, many parts that were previously machined could be 3D printed on-site on a Markforged industrial 3D printer (X7) instead of using third party manufacturers.

Vestas turned to the cloud-based Digital Forge to solve these supply chain problems with additive manufacturing, and launched its direct digital manufacturing (DDM) program in 2021. With a network of 3D printers at Vestas’s many different sites, connected by Markforged Eiger™ 3D printer software, employees at any Vestas location — with little to no expertise in additive manufacturing — can easily access a cloud-based digital inventory of 2000+ Vestas parts.

Thanks to this digital repository, Vestas employees can print up-to-spec parts on a moment's notice, anywhere in the world, without the need for specialists. Printed using exact digital specifications with the accuracy of the Digital Forge, Vestas does not have to worry about parts failing compliance tests. Vestas can verify the accuracy of their tools during the fabrication process using Markforged Blacksmith™ software for in-process inspection, analysis, and reporting.

Manufactured lead times are dramatically reduced, from 5-12 weeks to just 1-2 days. Costs for each part were dramatically reduced, and ongoing shipping and freight costs were eliminated.

Costs for each part were dramatically reduced, and ongoing shipping and freight costs were eliminated.

2.) U.S. Army

The U.S. Army’s Fort Irwin National Training Center is a major training base for the U.S. Army. Located in San Bernardino, CA, the NTC provides realistic joint and combined arms training to develop the U.S. Army’s soldiers and leaders for the battlefield. They train soldiers for upcoming deployments, wherever that may be in the world.

Supply Chain Challenge:

The Fort Irwin National Training Center requires many specialized resources, such as military-grade vehicles and equipment, to provide realistic battlefield training. The equipment receives a tremendous amount of wear and tear due to repeated use, as the NTC is constantly training new sets of soldiers for deployments.

If any part broke during training, it historically meant that soldiers would simply have fewer resources to use at the training center. Due to the Fort Irwin National Training Center being based in a remote location, replacement parts would carry lead times of up to 3 months.

Due to the Fort Irwin National Training Center being based in a remote location, replacement parts would carry lead times of up to 3 months.

A single part breaking could have severe ramifications on the quality of training for a squadron — even just a single component could render a piece of equipment or vehicle completely unusable.

Supply Chain Solution:

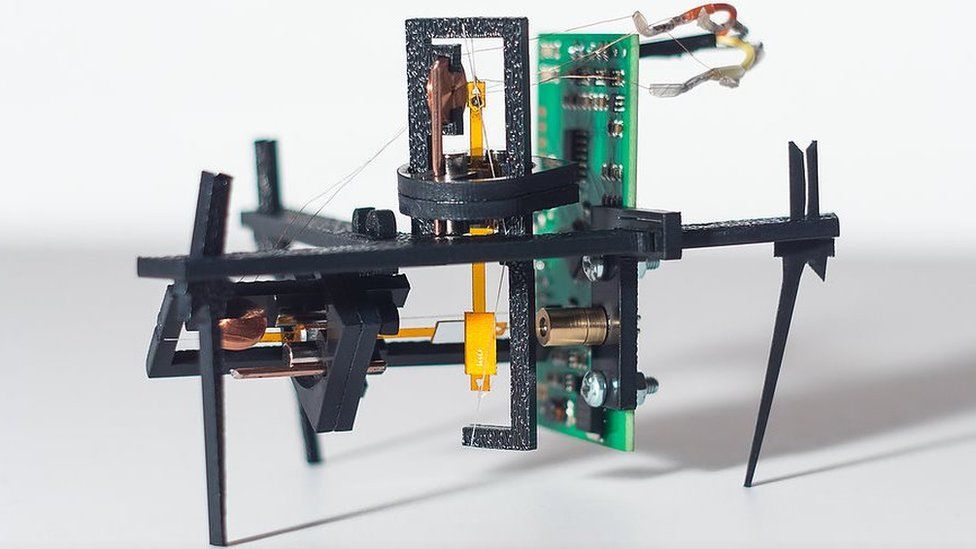

With metal 3D printing (Metal X system), a Markforged X3, and a desktop 3D printer (Mark Two), bringing additive manufacturing on-site to Fort Irwin through the Digital Forge has helped the Army NTC create readiness factors and maintain availability of equipment and vehicles to be used in training.

The U.S. Army’s Markforged composite printers have been used to print personal protective equipment (PPE), military vehicle parts (window wiper brackets, hatch plugs, and more), an assortment of tools, and other low-volume production parts.

One specific application has saved the U.S. Army $244,000 alone — hatch plugs that sit on top of vehicles, used in low-light scenarios to help the driver see at night. The hatch plug is a critical low-volume replacement part for a specific component that is not in production and no longer available anymore. Without in-house additive manufacturing, each hatch plug would cost roughly $10,000 to reproduce, and carry a 3-month lead time. On the Digital Forge, hatch plugs could be printed in Onyx for $230, or with 17-4PH Stainless Steel for $800.

The hatch plug is a critical low-volume replacement part for a specific component that is not in production and no longer available anymore. Without in-house additive manufacturing, each hatch plug would cost roughly $10,000 to reproduce, and carry a 3-month lead time. On the Digital Forge, hatch plugs could be printed in Onyx for $230, or with 17-4PH Stainless Steel for $800.

3.) Automation Alley (Project DIAMOnD)

Automation Alley is a non-profit Industry 4.0 knowledge center based in Troy, Michigan. Their mission is to embrace the Fourth Industrial Revolution: helping local small to mid-sized manufacturers in Michigan scale up their Industry 4.0 activity to innovate, increase resiliency, and improve agility.

Final tourniquet using a 3D-printed Onyx clip. (source: https://3dprintingforukraine.com/) Tourniquet components, featuring 3D printed Onyx clip on top. (source: https://whatt.io/alphaone/ukr/04:c7:4d:8a:83:72:80)

(source: https://whatt.io/alphaone/ukr/04:c7:4d:8a:83:72:80) Supply Chain Challenge:

For a large portion of the ongoing global pandemic, efforts to mitigate COVID-19 have been hindered by critical gaps in the supply chain for personal protective equipment (PPE). With supply chain delays and shortages still ongoing in 2022, medical equipment has been nearly impossible to manufacture swiftly in response to any time-sensitive need.

Furthermore, in response to an acute need, timely production of medical equipment would not be possible through traditional manufacturing processes, which require tooling to be made before production of the final parts can even be initiated. Processes like injection molding would add weeks before the earliest steps of production could be started.

Supply Chain Solution:

Automation Alley, using grant funding from the CARES ACT in 2020 from Michigan’s Oakland and Macomb counties, was able to start the world’s largest distributed manufacturing network, which is known as Project DIAMOnD (Distributed, Independent, Agile Manufacturing on Demand).

The purpose of Project DIAMOnD is to improve local manufacturers’ agility and resiliency by helping them scale up their Industry 4.0 activity, while also creating a large-scale emergency response network for printing physical objects on demand. Supplying small to mid-sized manufacturers across Michigan with Markforged 3D printers, the manufacturers in exchange will print critical medical equipment (such as PPE for frontline healthcare workers) when called upon to do so.

In April of 2022, the emergency response network of over 300 Markforged printers was activated for the first time. The Project DIAMOnD network was used to mass produce tourniquet clips out of Onyx, which were then shipped overseas to aid Ukrainians in need of medical assistance.

Coordinating mass print jobs between over 300 3D printers sounds like a complicated and daunting task. However, 3D printing software using the Eiger Fleet API made it simple.

Eiger provides a digital repository for part files, and Automation Alley was able to instantaneously distribute the tourniquet clip design throughout the entire network, adding it to each printer’s queue with just the click of a button.

4.) Cabin Management Solutions

Cabin Management Solutions (CMS), based in Conroe, Texas, is an aerospace company that designs and installs cabin control and entertainment systems for luxury private and business jets. CMS works with aircraft maintenance, repair, and overhaul (MRO) companies and private owners to deliver these bespoke aircraft interior solutions.

Supply chain challenge:

CMS was founded to provide a cost-effective, quick-turn alternative to the long lead times and high costs associated with cabin management maintenance, upgrades, and replacements within aircraft. However, many aspects of their business are quite time consuming, which can potentially stretch project timelines and extend customer lead times.

- Each custom one-off job is generally time consuming: parts must often be designed, manufactured, and fit into pre-existing aircraft layouts.

With it being not uncommon for customer requests to change in the middle of production for these parts, CMS must still maintain the agility to make modifications on the fly — customers’ projects must be finished in a timely fashion to uphold their value proposition of fast lead times.

With it being not uncommon for customer requests to change in the middle of production for these parts, CMS must still maintain the agility to make modifications on the fly — customers’ projects must be finished in a timely fashion to uphold their value proposition of fast lead times. - With many of CMS’s repair and update jobs being on luxury jets, these projects often require specific parts and components that have been discontinued from production.

- For each part and material CMS uses in its projects, it must be thoroughly tested and traceable to quality for approval from the Federal Aviation Administration (FAA).

Supply chain solution:

Bringing in a Markforged X7 industrial 3D printer to produce the needed parts and components in-house, Cabin Management Solutions can now take on more jobs and increase the speed of completion for each individual project.

Printing in Onyx FR reinforced with carbon fiber on the X7, end-use parts can be produced quickly. Even for CMS’s visible applications where aesthetics are at the forefront of importance, parts printed from the X7 do not require additional post-processing.

Even for CMS’s visible applications where aesthetics are at the forefront of importance, parts printed from the X7 do not require additional post-processing.

“

Other printers don’t generate as high quality a finish, leading to additional post-processing that the CMS team is able to avoid when using the X7.”

– Jeff Pike, VP of Engineering, Cabin Management Solutions.

Furthermore, Onyx FR is a certified UL 94 V-0 rated flame retardant material. Parts printed in Onyx FR are high-strength, low-weight, and bring the necessary flame-retardance to quickly achieve FAA compliance in every application.

In one particular project, CMS printed over 100 different parts on their X7 for a jet. The parts included adjustable touch screen brackets, light switch panels, USB-C and drop-in USB-A chargers, a cabin climate controller, latches, release buttons, and more.

The parts included adjustable touch screen brackets, light switch panels, USB-C and drop-in USB-A chargers, a cabin climate controller, latches, release buttons, and more.

5.) Nieka Systems

Nieka Systems is a Canadian manufacturer of borate fusion sample prep equipment for customers in the mining and cement production industries. Using Nieka’s machines, ore and cement samples can be fused into glass discs in preparation for precise compositional analysis, and to assist with quality control.

Nieka’s machines work by mixing and dissolving material samples in molten borate flux in a platinum crucible at temperatures exceeding 1000 degrees Celsius. These platinum crucibles are suspended over gas burners or electric heating elements by thin metal clips which connect the crucible to the machine. When the sample is fully dissolved in the flux, the machine upends the crucibles and pours the molten contents into a platinum mold to cool. Later the room-temperature prepared samples can be removed and analyzed via X-ray in a separate machine.

Later the room-temperature prepared samples can be removed and analyzed via X-ray in a separate machine.

Supply chain challenge:

Initially, Nieka outsourced manufacturing of Inconel-based crucible clips to a third-party service bureau to 3D print. However, lead times were slow, highly variable, and difficult to forecast.

Nieka was a growing business: its products were available to customers in over 20 countries around the world. But due to the slow lead times and uncertainties associated with using the service bureaus, Nieka faced growing uncertainties about their ability to keep up with global demand for their products.

Supply chain solution:

Bringing additive manufacturing in-house with the Metal X system, Nieka has been able to manufacture its Inconel crucible clips in drastically reduced lead times that are consistent and predictable.

From start to finish, each batch of Inconel crucible clips can be made, and put to use, in just four days. Compared to the third party manufacturer’s average lead time of over four weeks per batch, this is an 86% reduction in lead times.

Producing each batch of the crucible clips is also ten times cheaper than the price of outsourcing their production to the third party manufacturer. Louis Croisetiere Ph.D, Founder of Nieka Systems, estimates that Nieka saves an average of $108,000 CAD per year from this application alone.

Learn more about 3D printing and supply chains

Why Additive, Why Now?

Learn how the expanded range of capabilities seen in today's 3D printers are allowing companies to change their supply chain game for new applications.

All of the blogs and the information contained within those blogs are copyright by Markforged, Inc. and may not be copied, modified, or adopted in any way without our written permission. Our blogs may contain our service marks or trademarks, as well as of those our affiliates. Your use of our blogs does not constitute any right or license for you to use our service marks or trademarks without our prior permission. Markforged Information provided in our blogs should not be considered professional advice. We are under no obligation to update or revise blogs based on new information, subsequent events, or otherwise.

and may not be copied, modified, or adopted in any way without our written permission. Our blogs may contain our service marks or trademarks, as well as of those our affiliates. Your use of our blogs does not constitute any right or license for you to use our service marks or trademarks without our prior permission. Markforged Information provided in our blogs should not be considered professional advice. We are under no obligation to update or revise blogs based on new information, subsequent events, or otherwise.

Never miss an article

Subscribe to get new Markforged content in your inbox

Subscribe

The impact of 3D printing on supply chains

Many industries today rely heavily on manufacturing and supply from China and Southeast Asia, especially in sectors such as manufacturing and logistics. During the global pandemic, disrupted supply chains have affected companies in many industries. More than 94% of FORTUNE 1000 companies said the crisis had severely affected their supply chains. Thus, the pandemic has highlighted the limitations of traditional methods, in particular their lack of flexibility.

Thus, the pandemic has highlighted the limitations of traditional methods, in particular their lack of flexibility.

Can 3D printing add flexibility to existing supply chains?

In the first few months of the pandemic, 3D printing became an important sector. This has been particularly noticeable in the medical sector, where it has been used to produce emergency equipment for medical personnel and patients worldwide. In a matter of days, 3D printers have managed to create critical devices for the healthcare sector, from masks to ventilator kits, to save lives.

In the medical sector, 3D printing has been used to urgently produce face shields to protect healthcare workers.

At the same time, manufacturers from all industries also suffered from the limitations of existing supply chains. Particularly due to the lack of local production and long lead times.

So, could 3D printing be part of the solution?

One of the main advantages of additive manufacturing is its portability. This allows businesses to bring products to local markets faster. Instead of giving preference to mass production in other countries, manufacturers could give preference to developing it locally. Other benefits include greater product customization, less complexity, and faster time to market. For example, imagine a supply chain where the customer will be more involved in the design and production processes (because the price per unit of the part does not change). In fact, every detail can be personalized for the client at no additional cost.

This allows businesses to bring products to local markets faster. Instead of giving preference to mass production in other countries, manufacturers could give preference to developing it locally. Other benefits include greater product customization, less complexity, and faster time to market. For example, imagine a supply chain where the customer will be more involved in the design and production processes (because the price per unit of the part does not change). In fact, every detail can be personalized for the client at no additional cost.

In addition, additive manufacturing is a much faster way. By combining the components and processes required for manufacturing, complexity, manufacturing costs can be reduced and therefore lead times and time to market can be reduced. While traditional parts need to be prefabricated to exist, 3D printed parts only need a digital file. What's more, shifting to on-demand production could become the norm. This will mean that the need to transport physical goods across countries and continents will decrease, which will have a major impact on warehousing and logistics.

Manufacturers can increase local production through AM CNC, will always be more competitive. Thus, additive manufacturing has the ability to optimize existing supply chains and close some of the gaps that exist today, but not replace traditional methods.

How are manufacturers embracing 3D printing?

Many companies have not yet integrated 3D printers into their supply chains. For a long time, barriers to market entry have been a lack of know-how and initial investment in equipment. This partly explains why 3D printing service providers have grown in volume in recent years. In 2017, Research and Markets predicted in its " 3D Printing Services Market - Global Overview and Forecast 2017-2022" " that the market will exceed $13 billion, with a CAGR of over 28% during 2016-2022. Service providers are able to overcome the barriers that companies face in the early stages of integration, when they have not yet figured out how they will invest in 3D printing in the long term.

Recently, many solutions have emerged to facilitate the adoption of 3D printing, including communication with suppliers. For example, Dassault Systèmes' Make service, part of the 3DEXPERIENCE Marketplace, connects shoppers with over 200 manufacturers in Europe and the US, offering 3D printing, CNC machining, cutting, injection molding, and more. Benoît Schildknecht, Marketing Director at Dassault Systèmes, comments: “ Dassault Systèmes' on-demand manufacturing solution, 3DEXPERIENCE Marketplace Make, enables you to rebuild a more agile supply chain, securely and closer to you, to meet your long-term needs and short-term needs." .

Solutions have emerged, such as Dassault Systèmes' Make service that simplifies the adoption of 3D printing.

It's also interesting to note that Dassault Systèmes has addressed some of the common problems associated with using such a service. That's why 3DEXPERIENCE Marketplace allows the buyer to track the status of their transaction. Benoit Schildknecht adds: “ Members can communicate with each other and compare prices for all available inputs on demand thanks to our instant quotation system. Payment is simplified, leaving project teams to only care about the proper execution of the project, and not about administrative tasks. .

Benoit Schildknecht adds: “ Members can communicate with each other and compare prices for all available inputs on demand thanks to our instant quotation system. Payment is simplified, leaving project teams to only care about the proper execution of the project, and not about administrative tasks. .

As a result, COVID-19 has pushed companies to rethink and transform their supply chains, especially those that are highly dependent on other countries. Reworking production will in many cases provide more flexibility, lower prices and better part quality.

Source

3D printing technologies, supply chain, 3D printing, additive manufacturing benefits, 3D printed parts, 3D printers, 3DEXPERIENCE Marketplace, Dassault Systèmes : Here's how it works

Scientists have studied the impact of 3D printing on global trade and found that it affects it positively, although they used to be afraid that printers would disrupt supply chains.

A study by the School of Global Policy and Strategy at the University of California at San Diego and the World Bank found that this technology is more of a blessing than a bad thing. It allows countries to provide higher incomes and more opportunities for people.

It allows countries to provide higher incomes and more opportunities for people.

The impact of the technology on the market was studied using hearing aids, because this is perhaps the first market to fully switch to 3D printing back in the mid-2000s.

The analysis shows that the export of hearing aids increased by about 80% after the introduction of the new technology. There is no evidence of a localization effect, as overall hearing aid sales increased by the same amount. To test reliability, the paper looks at 35 partially 3D printed products and finds a positive and significant impact on trade. These effects are stronger for more complex and lighter products,” the study description says.

Previously, mankind was a little afraid that 3D printers would become a kind of cornucopia, "horns of plenty" that would allow printing everything. That is, you will need to buy one such printer - and that's it, the factory in China that produces toothbrushes is closed, because you print them yourself.

However, scientists present compelling evidence that 3D printing has expanded trade.

A study co-authored by Caroline Freund, economist and dean of the School of Global Policy and Strategy, shows that 3D printing has changed manufacturing processes, but supply chains have remained intact.

The shift to 3D printing has doubled or nearly doubled manufacturers' exports in five years, with technology being the main driver of export growth.

Freud et al also examined 35 other products such as sneakers, aircraft parts and prosthetic limbs that are increasingly being 3D printed and found a similar pattern.

“ This technology is a boon, not a curse for trade, ,” says Freund. — The export of hearing aids from the country has grown more than the trade of other similar products after local manufacturers introduced 3D printing. New manufacturing technology coupled with sales means that consumers worldwide with hearing loss are benefiting from better and often cheaper hearing aids. ”

”

One of the reasons for the expansion is that high volume printing of hearing aids requires a large investment in technology and equipment. The countries that were the first innovators - Denmark, Switzerland and Singapore - dominate the export of goods. Middle-income countries such as China, Mexico and Vietnam have also been able to significantly increase their market shares.

Hearing aids are lightweight products, making them cheap enough for international shipping. The same is true for other products that the authors studied - lighter products are associated with an increase in trade.

“Politicians often view 3D printing as a means to shorten supply chains, when in fact it is more likely to boost trade and change supply chains,” says Freund.

That said, although the analysis of the impact of 3D printing on trade is positive, it may be short-lived. If 3D printers become more accessible to local manufacturers or even consumers in some sectors, manufacturing may indeed become more localized, hindering development opportunities through trade.