Buy 3d laser printer

Your At-Home 3D Laser Printer

Buy today - every US Glowforge Pro & Plus printer ships in 3 days.

Glowforge 3D Laser Printer.

We believe in a future where anyone can create anything. That's why we made Glowforge, the 3D Laser Printer that cuts, engraves, & scores hundreds of materials.

Learn MoreBuy NowFor a limited time: Get 0% APR with Affirm. Ends 8/31

Learn More ➔

A wooden quad-copter made on a Glowforge.

A leather satchel bag made on a Glowforge.

Colorful macarons with unique, personalized names cut into them using a Glowforge.

An intricately decorated mandala laser engraved on the back of a laptop computer using a Glowforge.

An art-deco style lamp made from wood cut on a Glowforge.

A cute little A-frame model made with laser-cut acrylic and laser-engraved wood.

Several leather key-chains and jewelry pieces cut and engraved using a Glowforge.

A slate coaster with an adorable cow, pig, and chicken etched using a Glowforge laser.

See what people are making

Your Glowforge works with hundreds of materials.

Built on laser cutter & engraver technology, Glowforge uses a beam of light the width of a human hair to cut, engrave, and shape designs from a variety of materials.

Features that set Glowforge apart

Live Camera Preview

3D Autofocus

3D Hi-Res Engraving

Laser Precision

Design with just a pen

Cloud simplicity

Automatic Setup

Live Camera Preview

See your design take shape before you print. Onboard cameras show you a preview of your design on whatever material you choose. Place your design with your mouse or finger and position it exactly where you want.

Onboard cameras show you a preview of your design on whatever material you choose. Place your design with your mouse or finger and position it exactly where you want.

Need something outstanding, fast? Catalog designs are the perfect gift.

Print jewelry, toys, leather goods, lighting, containers, art, and more. Designs are thoroughly tested and guaranteed to print perfectly every time. Each comes with detailed photo instructions to make them a snap to finish.

Browse Catalog Designs“…the next wave of computer-aided creativity.”

Real people, real magic. Discover what’s possible.

For a limited time: Get 0% APR with Affirm. Ends 8/31

Learn More ➔

Glowforge 3D Laser Printer.

We believe in a future where anyone can create anything. That's why we made Glowforge, the 3D Laser Printer that cuts, engraves, & scores hundreds of materials.

Learn MoreBuy NowA wooden quad-copter made on a Glowforge.

A leather satchel bag made on a Glowforge.

Colorful macarons with unique, personalized names cut into them using a Glowforge.

An intricately decorated mandala laser engraved on the back of a laptop computer using a Glowforge.

An art-deco style lamp made from wood cut on a Glowforge.

A cute little A-frame model made with laser-cut acrylic and laser-engraved wood.

Several leather key-chains and jewelry pieces cut and engraved using a Glowforge.

A slate coaster with an adorable cow, pig, and chicken etched using a Glowforge laser.

See what people are making

Your Glowforge works with hundreds of materials.

Built on laser cutter & engraver technology, Glowforge uses a beam of light the width of a human hair to cut, engrave, and shape designs from a variety of materials.

Features that set Glowforge apart

Live Camera Preview

3D Autofocus

3D Hi-Res Engraving

Laser Precision

Design with just a pen

Cloud simplicity

Automatic Setup

Live Camera Preview

See your design take shape before you print. Onboard cameras show you a preview of your design on whatever material you choose. Place your design with your mouse or finger and position it exactly where you want.

Need something outstanding, fast? Catalog designs are the perfect gift.

Print jewelry, toys, leather goods, lighting, containers, art, and more. Designs are thoroughly tested and guaranteed to print perfectly every time. Each comes with detailed photo instructions to make them a snap to finish.

Designs are thoroughly tested and guaranteed to print perfectly every time. Each comes with detailed photo instructions to make them a snap to finish.

“…the next wave of computer-aided creativity.”

Real people, real magic. Discover what’s possible.

Glowforge

3D Laser Printer

Glowforge’s powerful desktop laser cuts, engraves, & scores hundreds of materials.

Learn more“…the next wave of computer-aided creativity.”

“…the next wave of computer-aided creativity.”

What will you create with Glowforge?

Swipe to see more ⭤

What will you create with Glowforge?

Craft with leather

Design home goods

Make custom signs & maps

Create intricate art

Personalize gifts

Start a side hustle

Customize anything

Bring your ideas to life.

Watch the magic happen.

Customize your prints.

Create with hundreds of materials.

Swipe to see more ⟷

Let's make something together.

Schedule a free virtual demo with a Glowforge Expert & experience the magic of Glowforge in real time.

Schedule a demoMade by creators like you.

Swipe to see more ⟷

Dear Glowforge,

Glowforge

3D Laser Printer

Glowforge’s powerful desktop laser cuts, engraves, & scores hundreds of materials.

“…the next wave of computer-aided creativity.”

“…the next wave of computer-aided creativity.”

What will you create with Glowforge?

Swipe to see more ⭤

What will you create with Glowforge?

Craft with leather

Design home goods

Make custom signs & maps

Create intricate art

Personalize gifts

Start a side hustle

Customize anything

Bring your ideas to life.

Watch the magic happen.

Customize your prints.

Create with hundreds of materials.

Swipe to see more ⟷

Let's make something together.

Schedule a free virtual demo with a Glowforge Expert & experience the magic of Glowforge in real time.

Schedule a demoMade by creators like you.

Swipe to see more ⟷

Dear Glowforge,

Glowforge - the 3D laser printer

Pick Your Model

Glowforge Pro

$6,995

Choose the most powerful and capable Glowforge. The Glowforge Pro is the same size but can print enormous objects with the Pro Passthrough slot, and has upgraded cooling for all-day use. It also features upgraded components and increased laser power, with top engraving speeds 3 times as fast as the Glowforge Basic and cutting speeds 1.2 times as fast. The Pro has double the warranty. Class 4 laser product.

Glowforge Plus

$4,995

Our premium home offering for the ultimate personal printing experience. The Plus offers upgraded components and a top engraving speed 2 times faster than the Basic and has double the warranty. Class 1 laser product.

The Plus offers upgraded components and a top engraving speed 2 times faster than the Basic and has double the warranty. Class 1 laser product.

Glowforge Basic

$3,995

The Glowforge Basic creates beautiful prints on dozens of materials right at home. Class 1 laser product.

Glowforge Air Filter

The Glowforge Air Filter uses activated carbon and HEPA filters to clean the air that comes out of your Glowforge printer. It sits on the floor near your printer and comes with handles and wheels so it’s easy to move. It has an on/off switch and a dial to adjust the fan power for maximum filter life.

Dimensions

- Glowforge exterior (Pro, Plus, and Basic): 38″ x 20.75″ x 8.25″ (965mm x 527mm x 210mm)

Work Area

- Maximum material depth: 18" (455 mm) for Basic and Plus; unlimited for Pro

- Maximum material width: 20″ (515 mm)

- Cutting area: approx. 11″ (279 mm) deep and 19.5″ (495 mm) wide

- Maximum material height: 2″ (50mm)

- Maximum material height with tray: 0.

5″ (13mm)

5″ (13mm)

Material Capability

Can safely print on any laser-compatible material, with examples below. Glowforge recommends Proofgrade™ materials for automatic settings and perfect results.

Cuts & Engraves

- wood

- fabric

- leather

- paper

- cardboard

- plexiglass (acrylic)

- Delrin (acetal)

- mylar

- rubber

- cork

- sandpaper

- foods

- ...and more

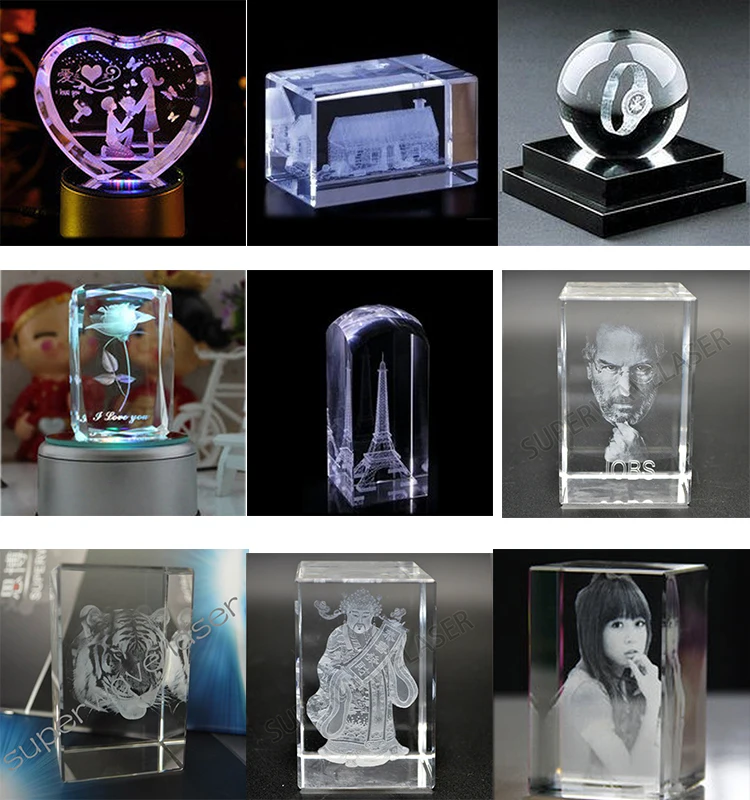

Engraves Only

- glass

- marble

- rubber stamps

- stone

- ceramic tile

- anodized aluminum

- titanium

- corian

- ...and more

Software

- Easy and powerful interface will have you printing in minutes

- Web interface works on Mac, PC, Linux, and many mobile devices (internet required)

- Compatible with JPG, PNG, SVG, PDF, and other file formats. Glowforge Premium includes support for DXF files

- Drag-and-drop layout with live camera preview to position designs on the material

- Automatically scan drawings and print without design software

- Catalog of premium, customizable, ready-to-print designs

One Button Print

When used with Proofgrade materials, automatically determines settings for perfect cutting and engraving

Cameras

- Wide Angle Camera — Mounted on the lid, provides a view of the entire printable area, accurate within 0.

25" (6mm)

25" (6mm) - Macro Camera — Mounted on the head, provides extreme up-close information for autofocus, accurate within 0.004" (0.1mm)

Autofocus

- Exquisitely precise — low-power laser measurement scans the surface of the material to determine the exact height

- Completely Internal — Lens moves internally up and down inside the head to print on materials up to 0.5” (13mm) thick

- Multipass — Focus can be shifted between engrave passes, allowing detailed depth engraves

- Manual focus option — the laser can be focused at a precise height to experiment with a range of techniques

Lighting

- Dual high-efficiency internal LED strips give your work broad illumination for a wide angle view

- Headlights under the lid give point illumination for precise precisioning

Laser System

- CO2 Laser — Custom CO2 glass laser tube capable of continuous operation at 10,600 nm; rated at 45 watts for Pro and 40 watts for Plus and Basic

- Fixed Alignment — Factory calibrated optical system does not require any alignment by the user

- Sealed Optics — Enclosed optical path with cleanable and replaceable windows protects the laser optics to avoid replacement or realignment

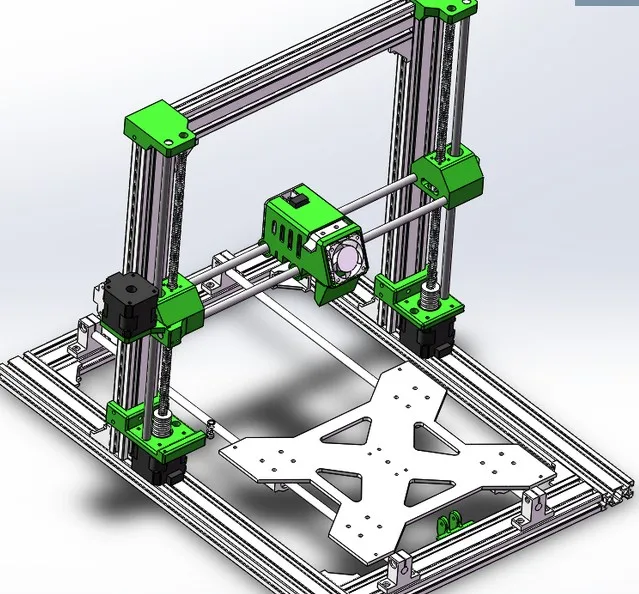

Mechanicals

- Case — High modulus injection molded plastic

- Linear System — Custom extruded aluminum linear rails with belt driven v-wheel carrier

- Motion — Dual hybrid stepper Y axis; single hybrid stepper X axis

- Cooling — Closed loop self contained internal cooling.

- Air Assist — Internal air assist with no external compressor hookup required

- Recommended Operating Temperature: 60F-75F (16C-24C) Basic and Plus; 60F-81F (16C-27C) Pro

Requirements

- Wi-Fi required (2.4 GHz b/g/n and WPA2, WPA, WEP, or open)

- Ventilation with either the Glowforge Compact Filter, or an open-able window within 8 feet

- 110/220 VAC, 50 or 60 HZ outlet

- Glowforge Basic, Plus, and Pro have 800W peak power consumption

- Compact Filter has an additional 350W peak power consumption

Miscellaneous

- Precision power settings allow enough control to draw lines on copy paper

- 3D engrave settings carve detailed surfaces

- Positioning precision to 0.001” (0.025mm)

- Engraving up to 1355 DPI

Pro Upgrade

- Pro Passthrough slot allows the use of material that’s up to 1/4″ (6.3mm) high, up to 20” (50.8cm) wide, and as long as desired

- Upgraded solid state thermoelectric cooling

Air Filter Upgrade

- Activated carbon gas filtration

- HEPA grade particulate filtration

- Cartridge full alert

- 350W brushless DC motor rated at 275 cfm

- 60db-70db (similar to a vacuum)

- 4" hose connector

- Rolling wheels

- Exterior dimensions (LxWxH): 16.

14” x 10.43″ x 16.92″ (410mm x 265mm x 430mm)

14” x 10.43″ x 16.92″ (410mm x 265mm x 430mm) - Weight: 48lbs (22kg)

Warranty

Safety

- Certified to UL standards

- Safety sensors alert in case of bumps or unplanned movement

- Safety sensors warn in case of overtemperature conditions

- Safety sensors notify when fan performance changes

- The Glowforge Basic and Glowforge Plus are Class 1 laser devices with no special training required

- The Glowforge Pro is a Class 4 laser device and comes with all necessary safety training materials

- Certified to UL/ANSI/IEC 60950-1-07 and CAN/CSA-C22.2 NO. 60950-1-07 (R16) by TUV Rhineland

Get Your Glowforge Today

Buy Now

Photopolymer 3D printer

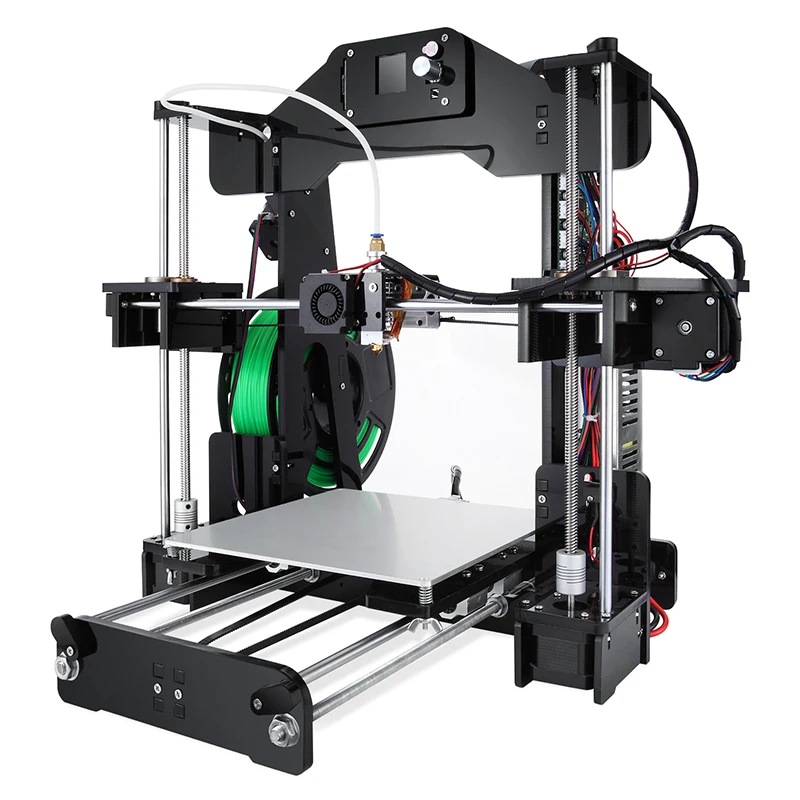

3D printers can be sorted not only by the printing technologies used, but also by the consumables used. In this section, we will look at devices that use photopolymer resins to build models.

- 1 Consumables

- 2 Laser stereolithography (SLA)

- 3 Projector stereolithography (DLP)

- 4 Multi-jet (MJM and PolyJet)

- 5 3D pens

- 6 Additional illumination

Consumables

Photopolymer resins are liquid polymers that harden when exposed to light. As a rule, such materials are sensitive to the ultraviolet range, which determines the design of photopolymer printers. One of the common design elements is a transparent colored cap or housing made of a material that filters ultraviolet radiation. This is done both to protect the user's eyes and to protect the supplies inside the printer from exposure to sunlight and background lighting. nine0003

Photopolymer resin loaded into Form 1 3D printer

The physical properties of resins after polymerization vary widely. Both rigid and flexible options are available, transparent and matte. A wide selection of colors is also available. Resin consistency and exposure times also vary, so a range of compatible media should be considered when choosing a printer.

A wide selection of colors is also available. Resin consistency and exposure times also vary, so a range of compatible media should be considered when choosing a printer.

The last aspect to consider when choosing a material is its toxicity. There are both quite toxic options and biologically safe ones. nine0003

The cost of consumables can be considered the Achilles' heel of photopolymer printing. The plants themselves are already reaching quite acceptable price levels, but it is still quite difficult to find inexpensive photopolymer resins. It is hoped that the proliferation of inexpensive photopolymer printers will lead to an increase in the production of consumables and lower prices.

Laser Stereolithography (SLA)

SLA Model

The firstborn of photopolymer printing and modern 3D printing in general. The technology was developed in 1984 by Charles Hall, who later founded 3D Systems.

SLA printers use laser emitters to cure the photopolymer supply.

A typical SLA printer consists of a consumable tray sitting under a build platform driven vertically by a raise/lower mechanism.

Alternatively, the cuvette itself can be driven - what matters is the relative movement of the platform and the container. Above the cuvette is a laser emitter and a mirror system for deflecting the laser beam. nine0003

During the printing process, the platform is immersed in the consumable for the thickness of one layer of the digital model.

Since photopolymer resins can be quite thick, a leveling mechanism is often used to speed up the process.

SLA printer operation scheme

After leveling, the process of illumination of the material begins. Illumination is produced by laser irradiation. Most photopolymer resins are designed to cure (polymerize) when exposed to ultraviolet light, which determines the choice of laser frequency. The movement of the beam along the X and Y axes is determined by the operation of the deflecting mirrors. nine0003

nine0003

After the drawing of the layer is completed, the platform is immersed in the material for the thickness of one more layer, and the process is repeated with the drawing of the next layer of the digital model.

Model building animation

SLA printing takes quite a long time, and printers using this method tend to have relatively small build areas.

This is mainly due to the high cost of laser emitters: printing large objects with a single laser will take too much time, and installing additional emitters and mirrors will complicate the design, increase the dimensions of the installation and raise the price to an unacceptable level for most users. nine0003

Despite the success of this technology, projected stereolithography is considered to be a more promising, although very similar method.

Projector Stereolithography (DLP)

Formlabs Form 1 Desktop DLP Printer

A close relative of laser stereolithography, this method uses digital LED projectors instead of laser machines with mirror deflection systems. The method became popular due to the development of technology for the production of low-cost high-resolution digital projectors by Texas Instruments. nine0003

The method became popular due to the development of technology for the production of low-cost high-resolution digital projectors by Texas Instruments. nine0003

Layers are illuminated using a digital projector that highlights patterns of the entire layer, which distinguishes this method from SLA, where the "picture" emerges progressively using an ultraviolet laser.

A similar approach has previously been used on SGC-type plants, but this technology used physical photomasks, making the process costly, time consuming, slow and noisy.

At the moment, the FTI technology continues to exist - the development of SGC, almost indistinguishable from DLP printing, since it also uses digital LED projectors. nine0003

DLP printer design

Simultaneous illumination of an entire layer using projectors can significantly speed up the printing process even compared to SLA printers that have a high scanning speed (ie beam movement).

In addition, these printers are less sensitive to rough physical impact due to the absence of delicate mirror systems.

The absence of mechanical mirror systems improves accuracy. Finally, the cost of projectors sets them apart from laser systems. nine0003

Projection size can be quite significant, reaching the average of popular FDM printers.

An interesting feature of DLP printers is the ability to "reverse" or "reverse" printing.

In this case, the projector is installed under a transparent (material choice for transparency in relation to ultraviolet light) cuvette, and the platform does not sink into the material, but gradually rises, pulling out the layers of exposed polymer. nine0003

This approach eliminates the alignment mechanism and achieves even higher Z resolution than SLA printers.

In addition, the size of models in height is not limited by the depth of the cuvette, which favorably affects the dimensions of the printer and the possibility of increasing the build area.

Multi-jet printing (MJM and PolyJet)

3D Systems ProJet 3500HDMax MJM printer

MJM and PolyJet technologies are practically indistinguishable from each other. The name difference comes from the respective patents: Multi Jet Modeling is owned by 3D Systems, while PolyJet is owned by rival Stratasys. nine0003

The name difference comes from the respective patents: Multi Jet Modeling is owned by 3D Systems, while PolyJet is owned by rival Stratasys. nine0003

The very principle of multi-jet polymer printing was developed by the Israeli company Objet, which eventually became a division of Stratasys.

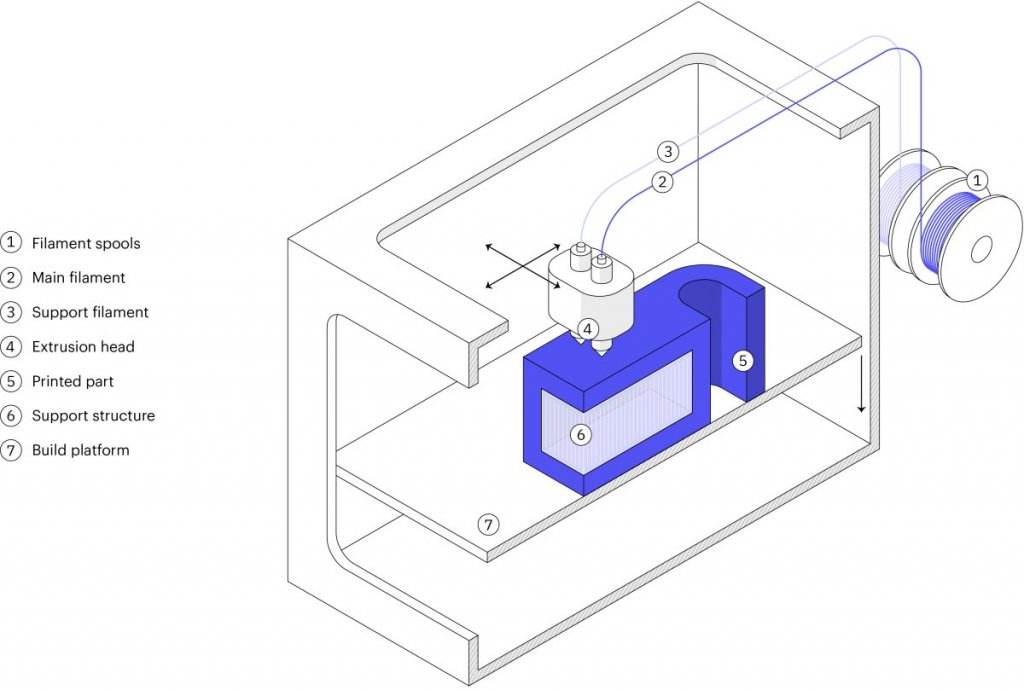

Multi-jet printing technology combines features of 3D inkjet printing (3DP) and projection stereolithography (DLP).

How the MJM PolyJet printer works

Models are built by spraying photopolymer using linear arrays consisting of multiple nozzles.

The applied layer is immediately exposed to ultraviolet lamps - as a rule, two processes occur simultaneously.

By the time the array reaches the end of the build chamber, the previously deposited material is hard enough to print a new layer.

Composite models created on the ProJet 3500 DP dental printer

This approach allows to achieve very high printing speed, but is characterized by high design complexity, which negatively affects the cost of such installations and limits their distribution to professional use. nine0003

nine0003

One of the advantages of MJM and PolyJet technologies is the ability to create composite structures from photopolymer resins with different physical characteristics.

It is therefore possible to create models with easily removable supports, use multiple colors and use flexible and rigid materials in parallel within the same model.

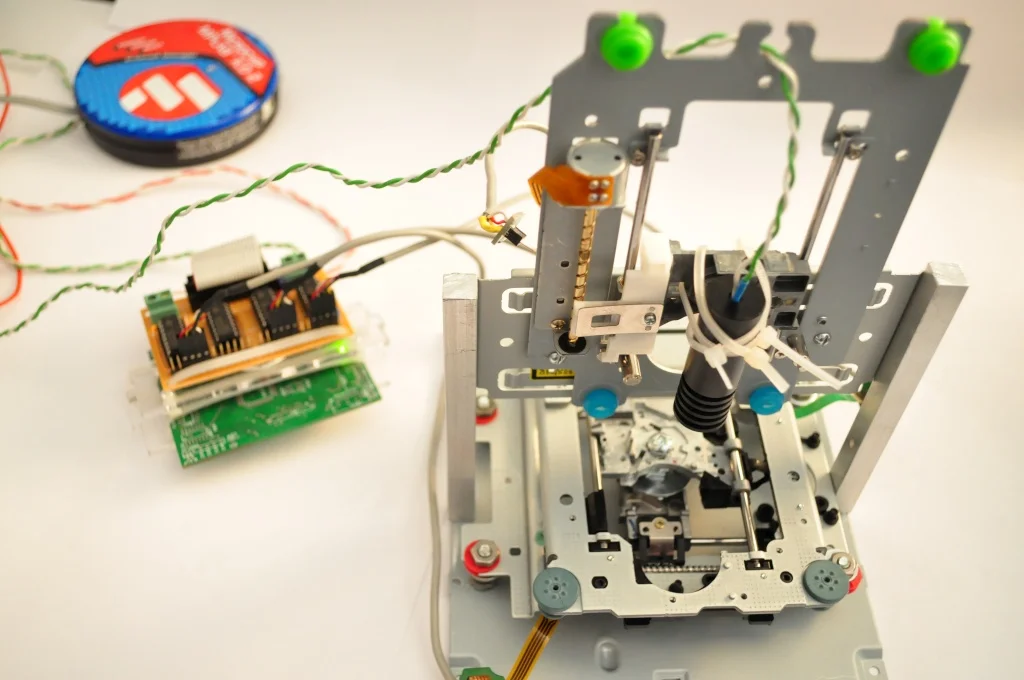

3D Pens

CreoPop 3D Pen

Recently, there has been a craze for hand-held printing devices called 3D pens. At the moment, there are three main options for such devices: drip-jet pens (DOD), called BioPen and used in the development of new methods for treating damaged tissues, FDM 3D pens, which are manual extruders (essentially similar to the usual hot glue guns, but using thermoplastics) and developments in 3D-drawing with photopolymer resins.

CreoPop 3D pen was the first "handheld resin printer". The design of this device is quite simple, because the most complex function, positioning, is performed by the user himself. The pen only extrudes resin through the tip surrounded by LED emitters. nine0003

The pen only extrudes resin through the tip surrounded by LED emitters. nine0003

CreoPop 3D pen in action

This way the resin hardens immediately after application, allowing you to literally draw on air.

The advantage of such handles over FDM-analogues is the low operating temperature - there are no heating elements in the device. As a result, with such pens you can even draw on the skin.

In addition, a wide range of photopolymer resins with different physical properties can be used with such devices, which greatly expands the range of possible applications. At a minimum, this is a relatively inexpensive, but entertaining toy. nine0003

The only drawback is the relatively high cost of consumables, but such devices are unlikely to require large volumes of photopolymer resin when used in everyday life.

Additional Lighting

Final Lighting of Resin Models in a Homemade Camera

Full curing of models can take quite a long time, so models during SLA and DLP printing are only partially polymerized, sufficient to maintain the physical shape of the part. nine0003

nine0003

After production, the models are usually placed in chambers equipped with ultraviolet lamps until fully cured. Of course, if possible, you can simply lay out the models in the sun - the effect will be the same.

Just keep in mind that ordinary glass practically does not transmit ultraviolet light, so exposure to sunlight must be direct.

If desired, a UV-transparent quartz glass container can be used. nine0003

Go to the main page of the Encyclopedia of 3D Printing

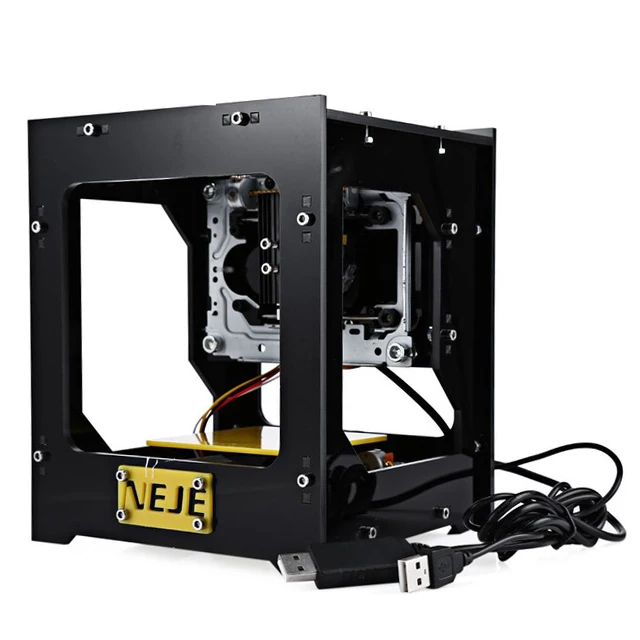

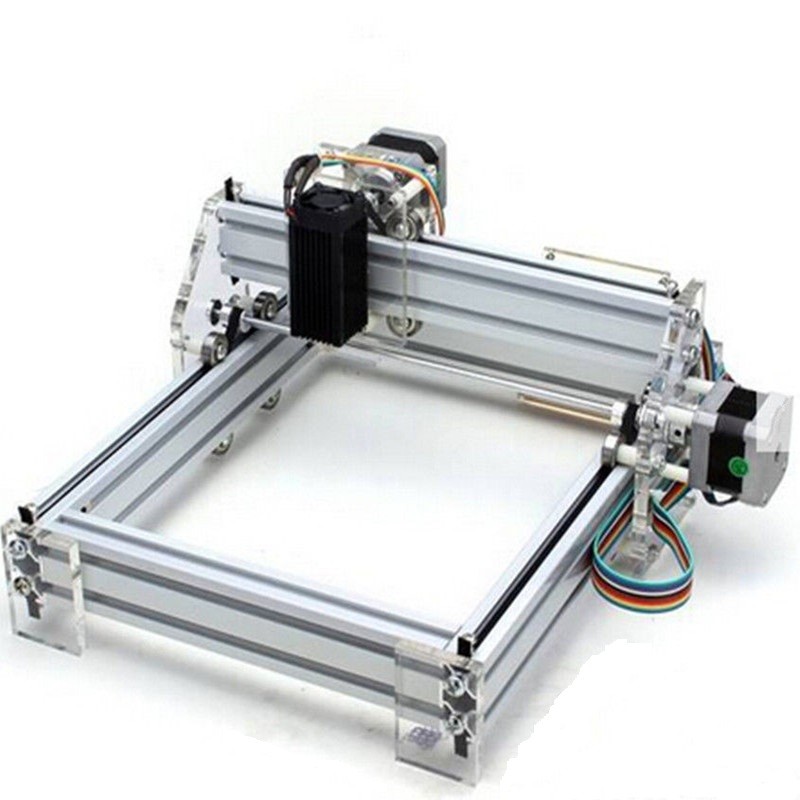

3d printer laser engraver in the category "Engineering and electronics"

Teflon FEP film 260×175mm Anycubic for 3D printers Photon Mono X, Mono X 6K, M3 Plus

In stock in Cherkasy

Delivery in Ukraine

600 UAHBuy

Teflon FEP film 173x115.4 mm Anycubic for 3D printers Photon Mono/Mono 4K/Ultra

In stock in Cherkasy

Delivery across Ukraine

400 uah

Buy

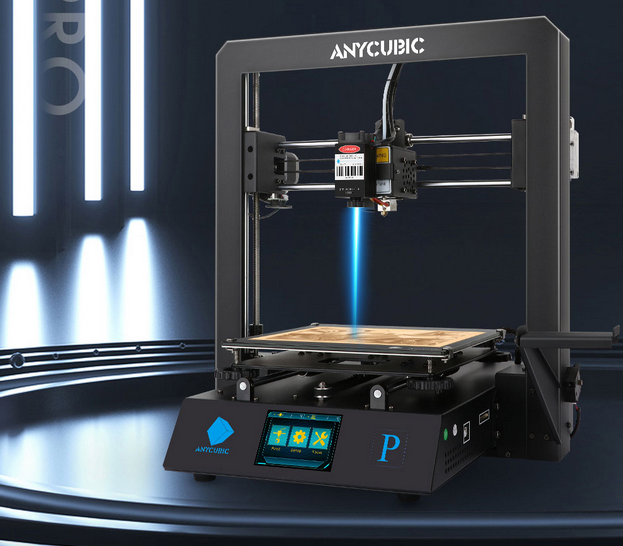

Creality CP-01 3-in-1 3d-printer, CNC cut and laser engraving (PACKAGE 10 CUTTERS) 9000 Delivery3

In warehouse0 in Lviv city 00023 In Ukraine

28 000 UAH

Buy

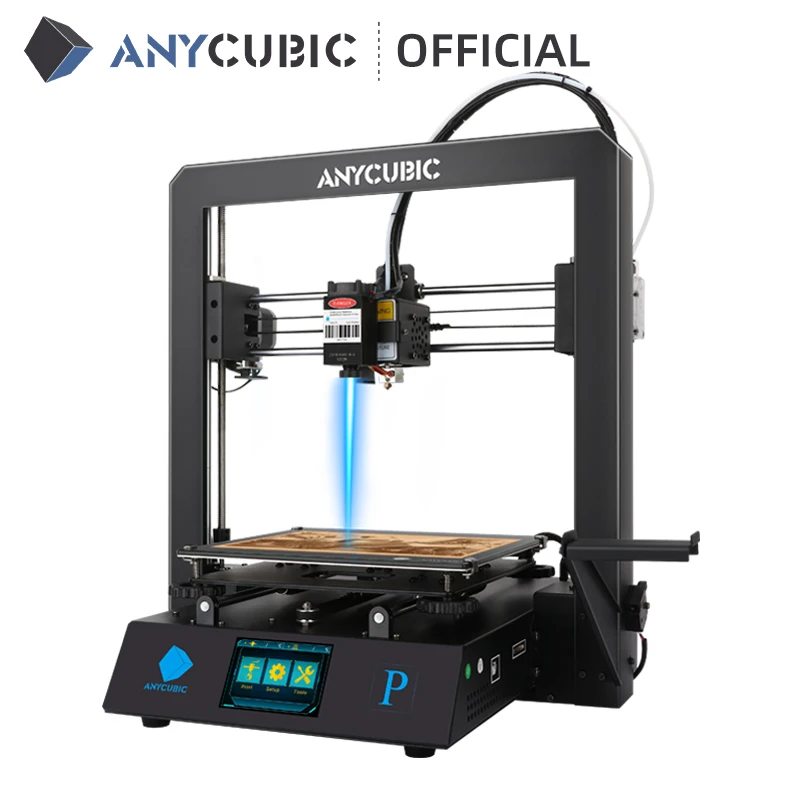

3D printer Anycubic Photon Mono 4 K

in a warehouse in Lviv

Delivery in Ukraine

14 500 UAH

Original Samsung ML-1210D3 CAR Printer Samsung ML 1010 1020M 1200 1210 Z 1220 M MR 1250 Z 1430

Delivery in Ukraine

2 082 UAH

Buy

Original Samsung ML-1710D3 cartridge for printer ML 1410 1500 B 1510 1710 D P 1740 1745 1755 1780 N

Delivery

1 830 UAH 9000 9000 9000 9000 9000 9000 9000

Toner-cartridge TN-118 Black (A3VW0D0) for the printer INEO 215 218 Bizhub 195 215 226 235 7719 7721 7723

Delivery

3 336 UAH

Original Toner Cartridge Samsung SMAS-4100DRA to Prostera to Prostera to Prostens SCX4100

Delivery in Ukraine

2 460 UAH

Buy

Flexible coupling D19XL25 (aluminum spring, CNC, 3D printer) 6 and 6. 35 mm

35 mm

in a warehouse in Pavlograd

Delivery in Ukraine

35 UAH UAH

Buy

Flexible coupling D19XL25 (aluminum spring, CNC, 3D printer, engraver) 5 and 10 mm

in warehouse

Delivery in Ukraine

35 UAH

Buy 9000

Flexible coupling D19XL25 3D printer, engraver) 5 and 6 mm

In a warehouse in Pavlograd

Delivery across Ukraine

Delivery across Ukraine

35 UAH

Buy

Flexible coupling D19xL25 (aluminum spring, CNC, 3D printer, engraver) 6 and 10mm

In stock in Pavlograd

Delivery across Ukraine

3

30023 Buy

Cartridge Samsung ML-1210D3 for printer ML-1010, ML-1020M, ML-1210, ML-1220, ML-1250 analogue

Delivery from Kyiv

ML-1710D3 for printer ML-1510, ML-1710, ML-1750 analog

Delivery from Kyiv

1 400 hryvnia

Buy

Delivery from Kyiv

UAH 1,300

Buy

Flexible coupling D19XL25 (aluminum spring, CNC, 3D printer, engraver) 4 and 8mm

in a warehouse in Pavlograd

Delivery

35 UAH

Flexible clutch D19XL25 (ALYUMIENEY , CNC, 3D printer, engraver) 4 and 4mm

In stock in Pavlograd

Delivery across Ukraine

0003

5 590 UAH

Buy

Smol American TGM-7 for 3D DRUKU LCD Prinatili

Delivery in Ukraine

4 085 UAH

Buy

3D PHROZEN SONIC XL 4K 4K 4K 4K 4K

189 200 UAH

Buy

3D printer Phrozen Sonic Mighty 8K

Delivery across Ukraine

53 750 UAH

Buy

3D printer Phrozen Sonic9 Mini 3 9023 Delivery across Ukraine0003

51 600 UAH

Buy

3D printer Anycubic Photon Mono SE

on order

Delivery in Ukraine

25 000 UAH

Buy 9000 Delivery across Ukraine

32 250 UAH

Buy

Monochrome MFP Ricoh MP 2014D.