How to dissolve support material 3d printing

5 Effective Methods to Remove Soluble Supports From Your 3D Printed Parts

3D printed support structures make the most complicated geometries blissfully easy. Whether you use break-away or soluble structures, these must be removed afterward. The best way to do that is: quickly. Today I’ll show you 5 effective and affordable solutions to remove your soluble support materials (SSM). So, let’s get started!

Here are the three key elements to keep in mind when removing soluble support materials from your 3d printed objects: Solvent (The liquid where you dissolve supports), Solvent Temperature, and Solvent Agitation.

When these three things are right, removing your support structure becomes really easy. Your process is slick and your end results are precise and clean. I’ve been fortunate enough to test many products with homemade experiments to remove SSM. The wisdom that I’m sharing has been gained by spending many hours conducting detailed research, with some mishaps along the way!

I summarize the best techniques for you (and me) here.

A-B-C Factors For Effective Dissolution of Supports

Let’s briefly look at what actually matters when you want to dissolve SSMs effectively:

A. Solvent:

Your liquid must match your support material. You may choose water, orange oil, or a mildly alkaline solution. It really depends on your choice of the soluble support material. Some prefer to use water because it’s easily available and simple (I mean, it’s just water). However, water-soluble supports such as PVA have a few nasty properties that can turn the life of a 3d printer user into a nightmare. These materials can easily clog your nozzle and are difficult to store because they absorb humidity from the surrounding air. So if you’re not sure, this article helps you choose.

But where should you put your liquid?

The size of the tank determines how many parts (or how big the parts) you can dissolve at once. So you might want to take into account the maximum part sizes you typically 3D print. Then we suggest buying at least one size larger than your minimum desired project size.

Your tank also plays a role in the amount of SSM you can dissolve at one time. Over time, the liquid will get saturated and will lose its ability to dissolve more support material. So again, it makes sense to leave some space in your tank for more solvent.

B. Temperature:

There’s nothing worse than being in the shower and someone turns the cold tap off on. Scolding yourself is no fun at all!

Your plastic 3D printed parts may feel much the same way if your solvent temperature is too high. The truth is: every plastic has its own heat resistance. Some exotic thermoplastic materials like PEEK can withstand temperatures beyond 300 degrees C. But most common plastic materials settle in the range around 100 degrees C.

ABS will deform if you heat it beyond 90 degrees C. PETG withstands only up to 60 degrees C. I have already ruined many 3D prints from PETG because I wanted to speed up the dissolution time and came too close to the deforming point in my solvent tank. Although higher temperature typically increases the dissolution process (think: sugar dissolves faster in hot tea than in cold water) – it may also ruin your precious models.

Although higher temperature typically increases the dissolution process (think: sugar dissolves faster in hot tea than in cold water) – it may also ruin your precious models.

So help your models feel comfortable while dissolving in the bath. The key to this is to invest in the right temperature control that can keep the temperature high enough to dissolve your supports, but low enough not to damage your parts. A professional support removal station like the Vortex EZ can help you achieve this without much headache.

C. Agitation:

“Move. Move! Move!!” Hearing this from our high school gym coach may have been very annoying. But moving fast is essential for quickly dissolving our support materials.

Strong solvent agitation around support structures increases dissolution. The faster you stir your cup of tea, the faster the sugar will dissolve. Fresh liquid replaces the liquid near the support that has already been saturated.

There are several basic techniques to move fluids to help you dissolve your 3D printing supports: pumps, propellers, and ultrasonic. But they all have their own advantages and drawbacks.

But they all have their own advantages and drawbacks.

But what are the solutions now? Well, let’s see what’s out there.

1. The Tank With a Pump

To provide enough agitation, the most common dissolving tanks use a pump. The pump will move the solvent in a closed circuit washing 3D printed parts. This continuous water movement helps the support materials to come off more quickly and easily.

Although fluid pumps have been around for over a hundred years, not every pump is suitable for dissolving supports. When supports dissolve, they will stay in the solvent – often as a slurry (think: PVA). That slurry can clog the pump. In the case of alkaline solvents, the components of the pump need to withstand the high pH levels of the solvent.

2. Ultrasonic Tanks

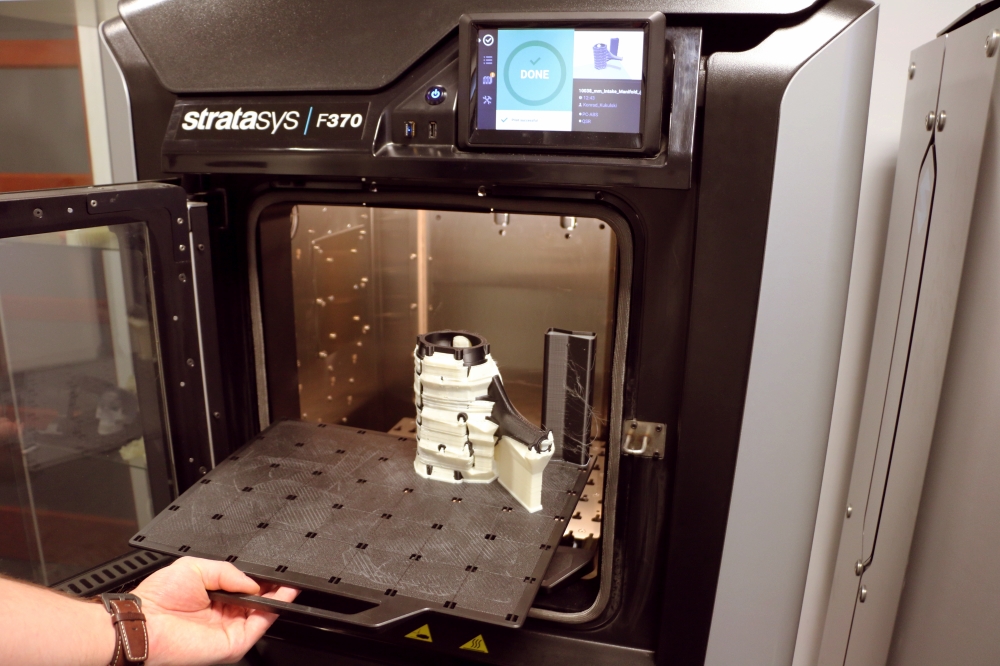

In ultrasonic tanks, powerful ultrasound is applied to the liquid to create microscopic bubbles. These bubbles remove the SSM more gently than flowing water. This can be useful for very small, delicate 3D printed parts.

However, one disadvantage of ultrasonic tanks that should not be underestimated is their high noise level. While you won’t hear the ultrasound itself, (assuming you’re not a bat), generating ultrasound frequencies also produces sounds at low hearable levels as a side-effect. And this can get very loud and annoying. If you don’t have a soundproof room for your tank, then we tend to advise against this technique.

3. Flow Jet Tanks

Regardless of whether you use simple tanks with water flow or ultrasonic tanks… You should be willing to wait. The dissolving process takes time. Smaller open parts will dissolve in less than an hour, but large complex parts with many cavities may take several hours to dissolve.

This brings us to the industrial (and very expensive) SSM removal solutions. So if you have enough budget (and room in your office), there are some high-end devices available on the market.

These machines usually work similarly to a dishwasher. Multiple water jets process your 3D part from different directions with low pressure. Your support structures thus typically come off faster than in simple tanks with moving water.

Your support structures thus typically come off faster than in simple tanks with moving water.

4. Affordable and Effective: New Devices

Not everyone has infinite space and budget at their disposal. However, waiting for eons for your support structures to finally dissolve is also soul-destroying and costly.

After our hardware experts got together with the team of BellandTechnology (the developers of VXL support material), we couldn’t find any affordable yet effective support removal station. So we decided to develop our own. And the result was a product we coined Vortex EZ.

Vortex EZ consists of a large double-walled stainless steel tank that can accommodate large parts up to 465 x 275 x 210 mm in size. The powerful heater can heat up to 36 Liters of solvent from room temperature to 70 degrees C in about an hour. The built-in temperature regulator will keep the temperature stable, while the double-walled tank will prevent the heat from easily escaping (or burning you).

Vortex EZ also has a powerful propeller that generates a real tornado inside the tank. But don’t worry, the propeller is powered by a silent motor – so you will hardly hear it working.

After working with soluble materials for several years, we also included some helpful tweaks to make working with Vortex EZ a joy. The tank has a removable stainless steel basket to easily take out your parts. The device also has a tap to drain used solvent. And my personal favorite feature: the lid has additional protection for your fingers against escaping steam. My team built this feature into the product after complaining to me that I never wear gloves when working with hot liquids.

Take a look at our product Vortex EZ here.

5. Do It Yourself

Do you prefer to have a bash at everything yourself? Very understandable, because that’s exactly why we all love 3D printing so much!

However, when it comes to dissolving support materials, there are few things to consider when building your own support removal device. But basically, such devices are inexpensive and not too complex to build yourself. You will need a few things, which you can get at your next hardware store:

But basically, such devices are inexpensive and not too complex to build yourself. You will need a few things, which you can get at your next hardware store:

1. Heat-resistant waterproof tank (large enough for your models).

On the budget side, an HDPE or a PP tank should do the job for low temperatures. But for higher temperatures, we advise using a stainless steel tank. Some users also reported even using an aquarium (but beware that the silicon between the glass plates will get brittle with time when exposed to heat).

2. Heater with a temperature regulator

We already know that the liquid in your tank must be kept stable and as precisely balanced as possible at a certain temperature (think: deformation of models when they get too hot). So make sure you get a heater with a temperature regulator.

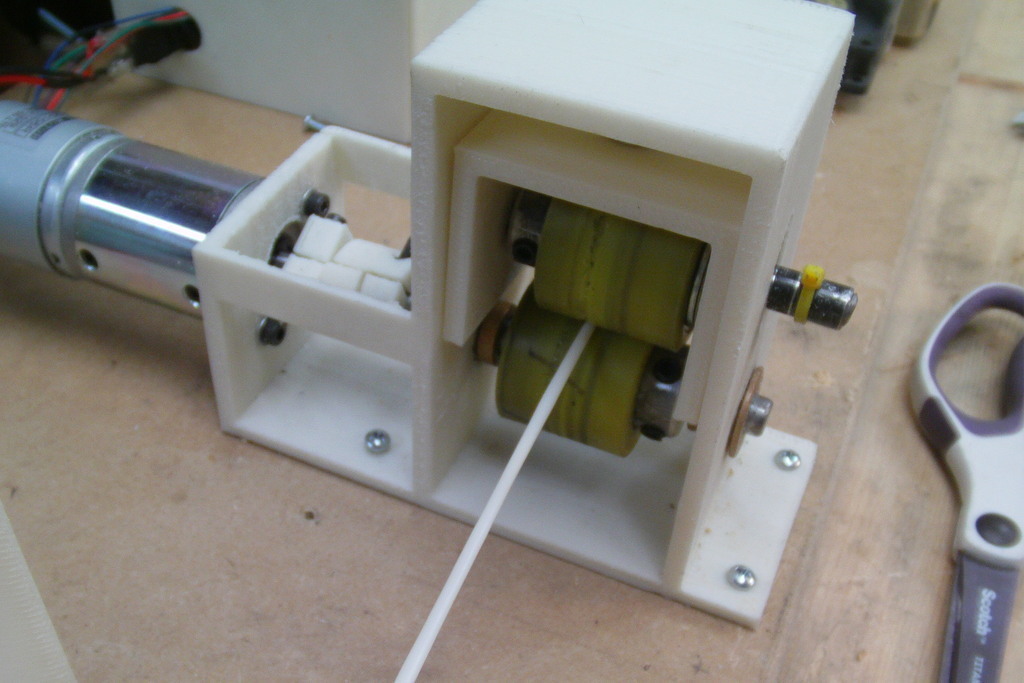

3. Pump

Many users reported success dissolving SSMs with a simple and inexpensive aquarium pump. You can get one under 10 bucks. But keep in mind, that these pumps have a limited lifetime once they get in contact with solvents and dissolved plastic slurry.

In our VXL-Go starter kit, we use something unconventional as a pump: a Sous-Vide stick. You may have heard of it when watching a late-night cooking channel. It’s a kitchen device for slowly preparing delicious steaks and veggies. The key advantages for using a Sous-Vide stick for dissolving supports: the stick heats and agitates the liquid simultaneously. So because it’s a 2-in-1 device, you don’t need an additional heater.

4. Siphon Pump For Draining

After a few dissolution cycles, your solvent will get saturated and will not be able to dissolve any more supports. So you also need to replace the fluid regularly.

This is when a siphon pump can come in very handy. It uses a small bellow and the height difference between your tank and the sink to drain your entire tank in minutes. The thing costs only a few bucks on Amazon.

When draining solvents, please consider your safety: the liquid can be hot.

5. Accessories

These come in handy when handling your support removal station. You may want to invest in a pair of thongs, some gloves, and eye protection.

You may want to invest in a pair of thongs, some gloves, and eye protection.

Finally, if you don’t want to scavenge your hardware store for all items above, you can have a look at our VXL-Go starter kit. We have included all of the above items to get you started dissolving supports. We even threw in a sample spool of our VXL support material.

Last But Not Least: Think Safety First

I mentioned it above, but I want to reiterate it here: No matter what solution you use, always make sure you’re safe. Wear safety glasses with the appropriate heat resistance and wear gloves. Much safer still, however, are tanks with a closed circuit. You don’t have to open them in between operations, reducing your exposure to hot liquids.

We wish you happy printing and dissolving.

If you have any questions, drop us an email.

Guide to Soluble, HIPS, PVA

Table of Contents

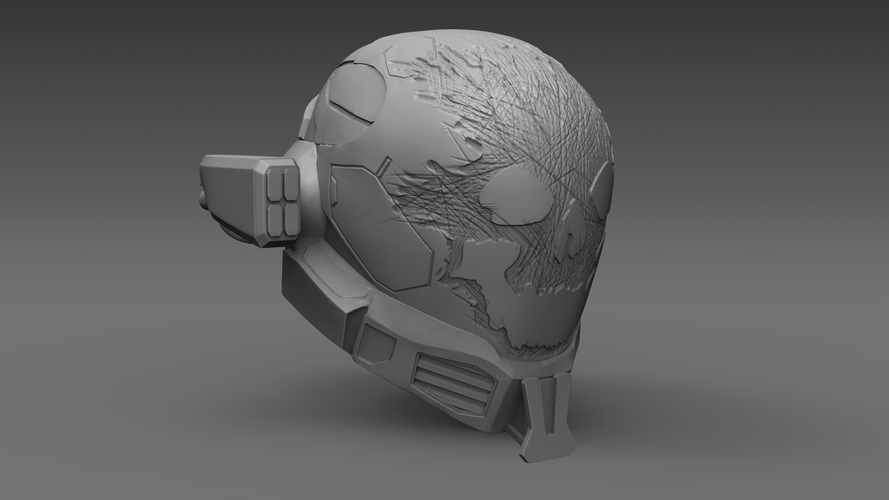

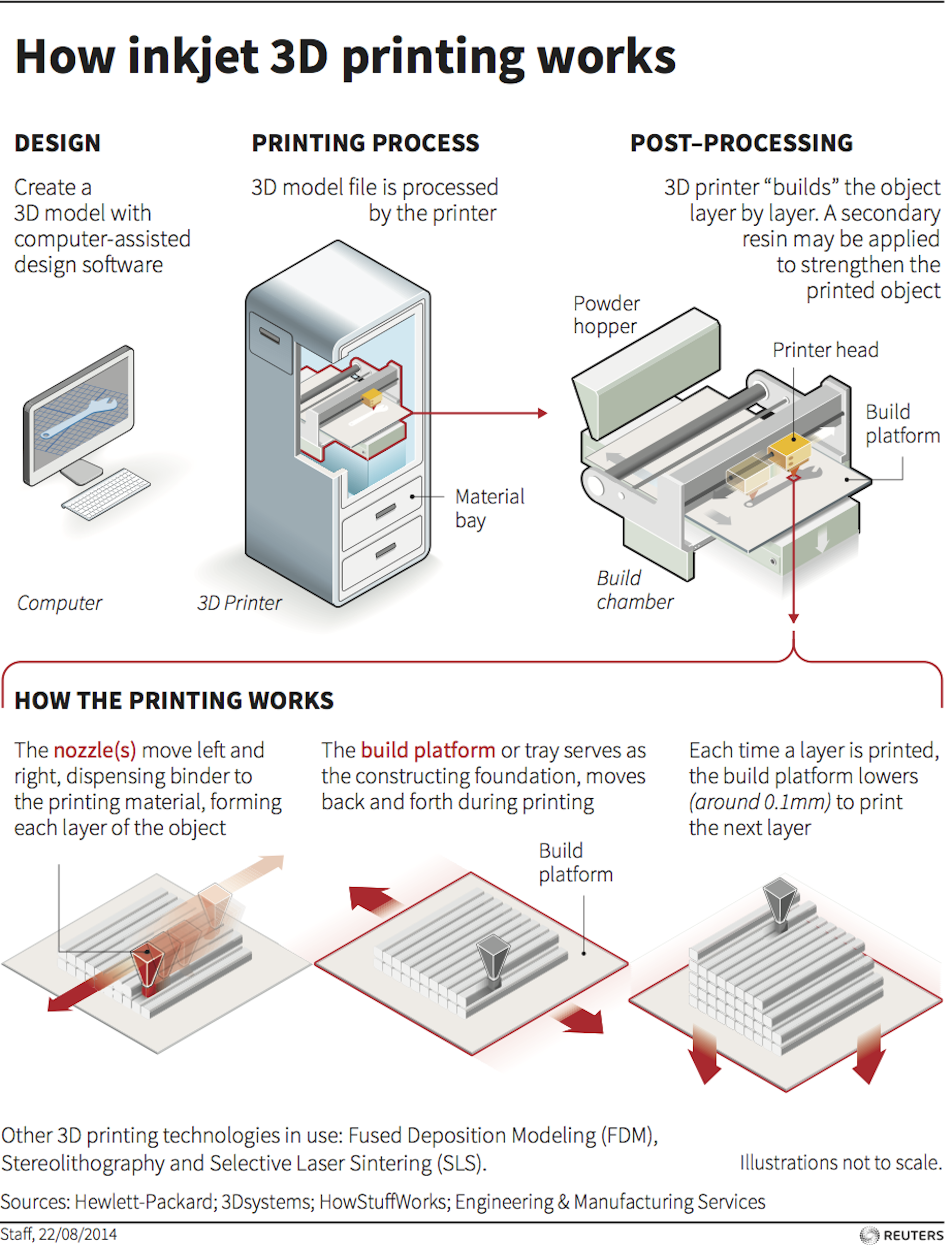

How to Get Cleaner Finishes and Remove 3D Printed Support Material Faster High-quality 3D printed parts overcome numerous construction and design barriers for outstanding results. 3D printing support materials allow for thermoplastics to set while an additive build is in the process of extruding and cooling. Tech-forward equipment such as ultrasonic cleaners and ultra-pure solvents such as acetone and isopropyl alcohol are critical for highlighting detail and surface finish, especially when removing support material. So what is support material, exactly?

3D printing support materials allow for thermoplastics to set while an additive build is in the process of extruding and cooling. Tech-forward equipment such as ultrasonic cleaners and ultra-pure solvents such as acetone and isopropyl alcohol are critical for highlighting detail and surface finish, especially when removing support material. So what is support material, exactly?Support Material Basics – What Is It?

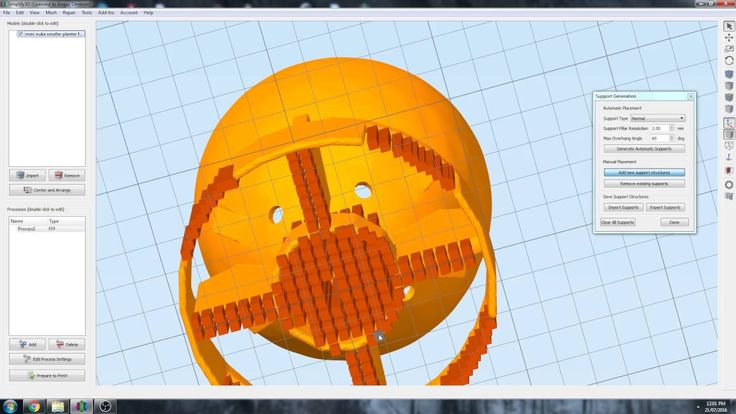

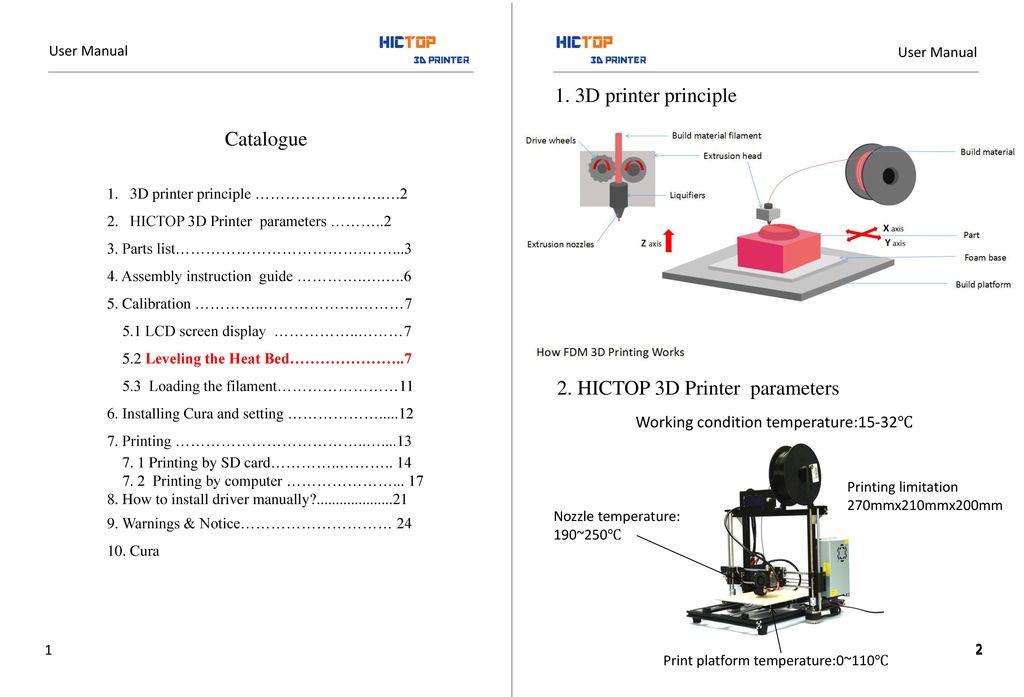

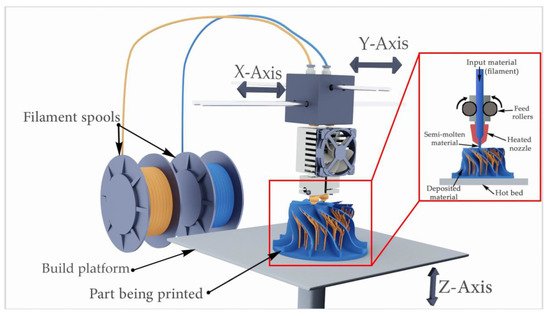

Gravity is a crucial consideration for the success of any 3D printed part. Support materials and structures ensure that extruded filament remains in its intended shape and form during the build and cooling process. With FDM 3D printing, support materials enable structures with an overhang of over 45° degrees.

CC: 3DHubSupport Materials Technologies and Applications

Binder Based Technology After Support RemovalTraditionally, removing support was messy. Binder based applications resembled something closer to archeological excavation rather than advanced prototyping technology. Removing the support material was wasteful and time consuming.

Removing the support material was wasteful and time consuming.

Snap-fits, hinges, and threaded fasteners require tight tolerances for functionality, therefore removing support material cleanly and thoroughly is potentially tedious, laborious, and time consuming.

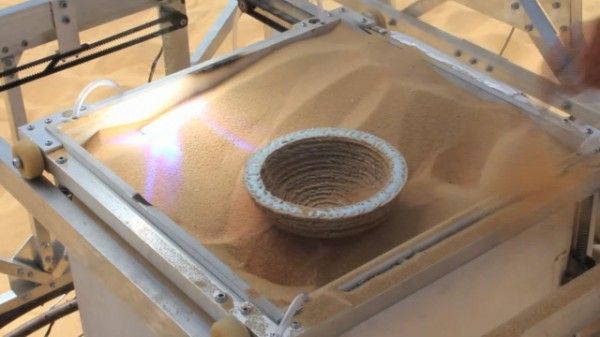

Today, there are two popular types of support material technologies used by the majority of 3D printers; one type is broken or cut away by hand like a kit-kat bar (HIPS) and the other in which the material is soluble (see below) and dissolved in a chemical or water-based bath. FDM, SLA, DLP, and material jetting all rely on support structures for complex architectures, each with slightly different processing and support material availability.

Soluble Support Materials

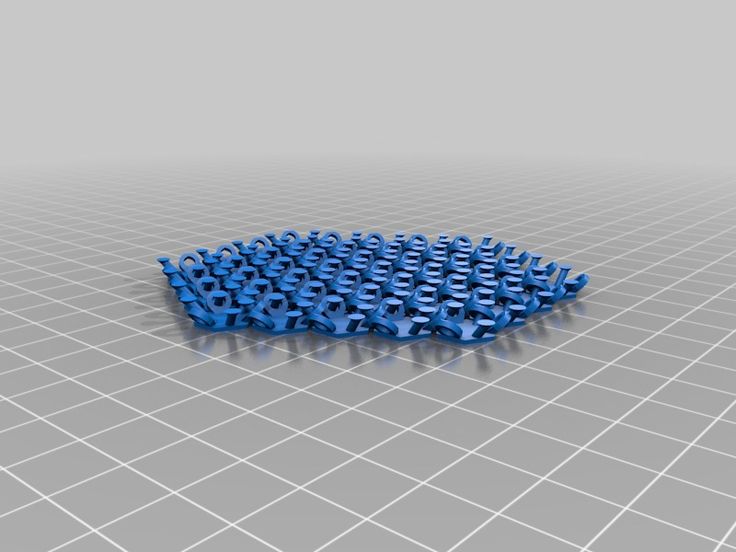

PVA (used with PLA), HydroFill (used with ABS), Infinity (3D Systems) and SUP 706 (FDM & PolyJet) are among the most popular 3D printing materials that easily break apart after exposure to water. Soluble support materials enable the hands-free removal of support material with minimal manual scrubbing or abrasive brushing. The advantage of soluble support material is dually functional: it does not require extensive human labor, therefore it not only saves time, but it extends the design freedom by standardizing the delicate processing of complex parts with internal cavities, lattice structures, and microstructures. It is soaked in warm water, and then the support material rinses off.

The advantage of soluble support material is dually functional: it does not require extensive human labor, therefore it not only saves time, but it extends the design freedom by standardizing the delicate processing of complex parts with internal cavities, lattice structures, and microstructures. It is soaked in warm water, and then the support material rinses off.

The downside of the soluble support is that it can take quite some time for the material to dissolve before it is ready for removal. The more extensive and dense the support material, the longer the process takes. Traditionally, water jets and chemical baths improved speed to removal, but often sacrificed intricate detail, increased potential for damage, and added overhead for chemical baths and waste disposal.

Ultrasonic cleaners have remodeled the traditional path to finishing and processing 3D printed parts with autonomous function and clock-like consistency. Likewise, a many other historically simple products, like specially formulated wipes and solvents from pure and high quality materials, help exceed benchmarks for final quality with faster workflow.

Ultrasonic Cleaners

Ultrasonic cleaners provide a clean, safe, quiet, and consistent outcome for post-processing 3D printed parts with soluble support materials. The gentle vibrational frequencies ensure that cleaning reaches within small geometries, internal cavities, and between build layers so that each section achieves the smoothest possible finish with the least risk of damage caused by handling, scrubbing, or brushing. Warm solvents speed up dissolving time and ensure a smooth surface where contact material is in contact with the part, which makes heated ultrasonic cleaners ideal for 3D printed pieces. For some the large tank volume of a commercial ultrasonic cleaner is essential for extra large parts, smaller benchtop versions provide an economical option for any 3D printing professional or enthusiast.

Compare SharperTek Ultrasonic CleanersCompare Ultrasonic Cleaners Online

Low-Lint Wipes for 3D Printing

The cleanroom wipe is historically the most effective and commonly used tool for the removal of contaminants, particulate, and residual material in critical manufacturing, production, and pharmaceutical compounding environments. Low lint wipes provide a number of advantages for post processing 3D printed parts. The reason low lint wipes are used in cleanrooms is for mitigating the spread of contaminants through shedding and unraveling. Ordinary paper towels or rags easy fall apart, create lint and particulate, and rip when cleaning crevices or abrasive edges. Low resolution FDM builds with wide angles, increased layer heights, and complex support or lattice structures benefit from a wipe that won’t tear and leave particles behind within crevices. Heavy-duty woven polyesters provide extreme durability, and reduce exposure of parts to chemical substrates which manifest during the manufacturing process of traditional wipes.

Low lint wipes provide a number of advantages for post processing 3D printed parts. The reason low lint wipes are used in cleanrooms is for mitigating the spread of contaminants through shedding and unraveling. Ordinary paper towels or rags easy fall apart, create lint and particulate, and rip when cleaning crevices or abrasive edges. Low resolution FDM builds with wide angles, increased layer heights, and complex support or lattice structures benefit from a wipe that won’t tear and leave particles behind within crevices. Heavy-duty woven polyesters provide extreme durability, and reduce exposure of parts to chemical substrates which manifest during the manufacturing process of traditional wipes.

The cleanroom wipe is historically the most effective and commonly used tool for the removal of contaminants, particulate, and residual material in critical manufacturing, production, and pharmaceutical compounding environments. Low lint wipes provide a number of advantages for post processing 3D printed parts. The reason low lint wipes are used in cleanrooms is for mitigating the spread of contaminants through shedding and unraveling. Ordinary paper towels or rags easy fall apart, create lint and particulate, and rip when cleaning crevices or abrasive edges. Low resolution FDM builds with wide angles, increased layer heights, and complex support or lattice structures benefit from a wipe that won’t tear and leave particles behind within crevices. Heavy-duty woven polyesters provide extreme durability, and reduce exposure of parts to chemical substrates which manifest during the manufacturing process of traditional wipes.

The reason low lint wipes are used in cleanrooms is for mitigating the spread of contaminants through shedding and unraveling. Ordinary paper towels or rags easy fall apart, create lint and particulate, and rip when cleaning crevices or abrasive edges. Low resolution FDM builds with wide angles, increased layer heights, and complex support or lattice structures benefit from a wipe that won’t tear and leave particles behind within crevices. Heavy-duty woven polyesters provide extreme durability, and reduce exposure of parts to chemical substrates which manifest during the manufacturing process of traditional wipes.

Pre-saturated isopropyl alcohol wipes provide a convenient way to wipe down parts quickly and with less exposure to volatile aerosol particles and minimal chemical adulterants. A neutral, non contaminating wipe is essential for SLA or multi-material parts in which the final texture and finish is paramount for a quality aesthetic. Abrasive wipes or chemical substrates may dull or discolor the final finish. Likewise, lint fabric could adhere or mesh to the parts surface when finishing with solvents like acetone, which is avoided with non-shedding wipes.

Likewise, lint fabric could adhere or mesh to the parts surface when finishing with solvents like acetone, which is avoided with non-shedding wipes.

Sterile isopropyl alcohol wipes are ideal for the support of dental 3D printing. Parts that come in direct contact with tissue or mucous membranes such as drill guides, abutments, and molds drive the growing need for 3D printed materials free of pathogenic microbes or other contaminants. Learn more about sterile 3D printing applications

Read More: Low Lint Wipe Buyers Guide

Autoclaves and Sterilization of 3D Printed Parts

One of the most demanding and intensive sterilization processes is autoclave sterilization. For many consumer-based 3D printed materials, the pressure and heat associated with autoclave cycles would quickly warp, melt, or compromise the tensile strength and shape of 3D printed parts. Autoclave heat cycles yield one of the most effective tools for sterilizing 3D printed parts and other thermoplastics. Methods such as ETO and Gamma sterilization often compromise the integrity or luster of the final part, but many 3D printed materials show promising integrity.

Methods such as ETO and Gamma sterilization often compromise the integrity or luster of the final part, but many 3D printed materials show promising integrity.

Read Our Guide to Sterile 3D Printing

Cleaning 3D Printed Parts with Isopropyl Alcohol & Solvents

99.8% pure anhydrous (containing the least water possible and no denaturant) isopropyl alcohol is excellent for tape head cleaning, defluxing, stencil cleaning, other light cleaning, and as a flux thinner. Avoid “bargain” alcohols for critical electronic cleaning. Cheap alcohols contain much more water, which slows drying and can cause oxidation, while “denatured” alcohols leave residues.

99% isopropyl alcohol (IPA) is ideal as a solvent for cleaning 3D printed parts, extruders, print bed trays and removing support material. USP-Grade, 99% IPA provides the lowest presence of adulterants and is free from denaturants with minimal water content. A more aqueous solution, such as 70% IPA may be ideal for non-hydrophilic printing filaments. Increased water content prevents drying out and reduces reapplication of solvent.

Increased water content prevents drying out and reduces reapplication of solvent.

Learn: Difference Between 99% & 70% IPA

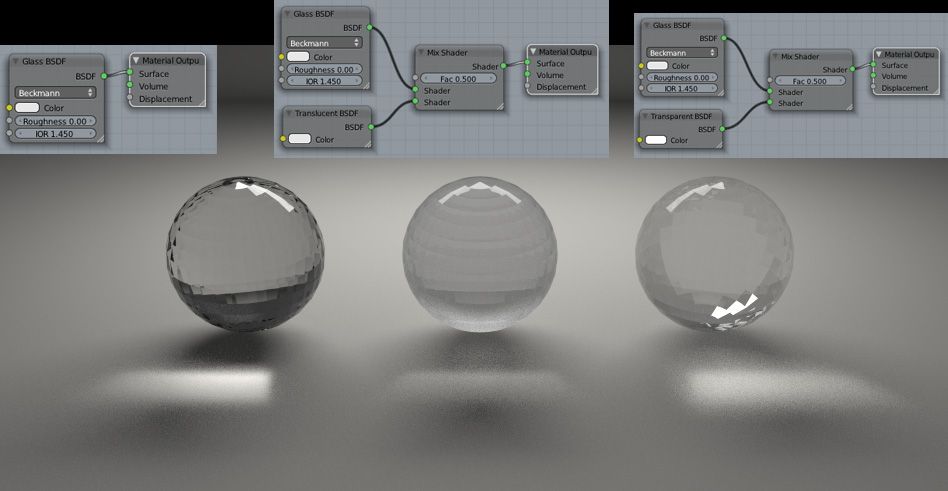

Cold Welding with Acetone CC: 3D HubsPolishing and Cold Welding with Acetone

ACS USP-Grade Acetone

Acetone is another valuable 3D printing solvent. It is ideal for vapor smoothing, cold welding, and ideal for preparing parts for painting. Acetone dissolves layer lines and improves paint adhesion with minimal sanding. The overall result is an increase in surface detail without the loss of delicate or subtle features. Cold welding adheres 3D printed parts without adhesive or sanding by applying a thin layer of solvent. For PLA parts, acetone generates a sufficient bond for mock prototypes or reconnecting pieces that broke off post-print.

Compare IPA and Acetone Prices

Share this Article:

Share on facebook

Share on twitter

Share on reddit

Share on print

Mitch Walleser

Mitch is a contributing writer for Production Automation Corporation. PAC is a factory-direct distributor of products and environmental solutions for industrial and critical requirements within electronics, medical device, life science, pharmaceutical, and general manufacturing industries. Mitch has worked with manufacturing engineers, in-house specialists, and factory experts to highlight and uncover manufacturing solutions. His background includes 3D printing, electronics, and cleanroom manufacturing.

PAC is a factory-direct distributor of products and environmental solutions for industrial and critical requirements within electronics, medical device, life science, pharmaceutical, and general manufacturing industries. Mitch has worked with manufacturing engineers, in-house specialists, and factory experts to highlight and uncover manufacturing solutions. His background includes 3D printing, electronics, and cleanroom manufacturing.

Was this post helpful?

PrevPreviousSafety Glasses Statistics and Effective Safety Precautions for Eyewear

NextFilament Storage, Dry Boxes and Spool Cabinets for 3D PrintingNext

Recent Posts

Search Posts

Search for:

About Production Automation

Production Automation Corporation (that’s us) is an essential business supplier for medical device, cleanroom, and general manufacturing industries.

All products featured on the PAC blog are available through the www. gotopac.com webstore. Online orders are shipped and fulfilled Monday – Friday from PAC warehouses in California, Minnesota, and Texas.

gotopac.com webstore. Online orders are shipped and fulfilled Monday – Friday from PAC warehouses in California, Minnesota, and Texas.

Production Automation Corporation (PAC) stands 100% behind a product catalog of over 40,000 products, which includes support for factory warranties, value added services, and returns. Get help from a PAC sales rep during business hours via email, phone, or live chat.

Shop Online: www.gotopac.com

Toll Free: (888) 903-0333

Email: [email protected]

Office Hours: 8am - 5pm CST

Using Dissolvable Filament to Create Supports

Using Dissolvable 3D Printing Filament is an easy and effective way to create support structures for your 3D printed part. In this article, we'll take a look at the different types of dissolvable filaments on offer, the benefits of using them over insoluble filaments, and tips and tricks for the smoothest possible printing process.

FDM 3D printing is a manufacturing technology that allows you to create parts with complex geometries that are usually impossible to obtain using traditional methods. However, when using this technology, each layer of the part requires supports, either on the structure of the part itself or on an additional support structure.

However, when using this technology, each layer of the part requires supports, either on the structure of the part itself or on an additional support structure.

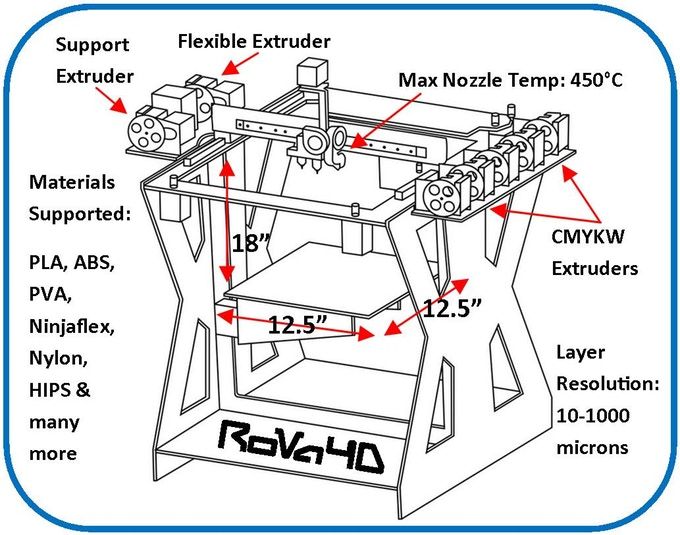

With a single extruder 3D printer, you are limited to using the base material of the printed part to create the support structure. Things are different with dual-extruder printers, since dissolvable filaments can be used to create support structures.

Soluble 3D Printing Filament Types

Water Soluble 3D Printing Filaments

Such materials are known for their solubility in ordinary water without any aggregates. This makes them an excellent option, as their dissolution does not pose any danger, and also does not cause any reaction to the base material of the product.

One of these materials is PVA, which is the most commonly used support material in 3D printing. BVOH is another widely used material with better material compatibility than PVA as well as faster dissolution time.

Water Soluble Chemical 3D Printer Filaments

Some industrial grade materials are not compatible with filaments such as PVA or BVO due to their chemical properties and/or heat resistance. For this reason, materials like BVOH or PVA have been designed with additional properties to make them compatible with high temperature materials such as PEEK, PEKK, PPSU, PP and others.

In order to dissolve these supports, the pH of the water must be acidic in order to break down the sugar that this type of material normally contains, as this is less dangerous than the use of solvents.

Soluble 3D Printer Filaments with Organic Solvents

These are the least used materials due to the difficulty of using organic solvents with polymers most used in 3D printing as the solvent can react with the print material and damage it.

The advantage of using these materials is their high compatibility with the construction material. The most common example is HIPS as a support material for ABS.

Insoluble and dissolvable filaments for 3D printers

Soluble filaments for support structures have advantages and disadvantages compared to using insoluble filaments:

- Easy to remove supports

- Since the supports are soluble, simply dip the model in the appropriate solvent and wait until the supports are gone. This is very useful for parts with a very complex structure.

- Improved contact surface quality

- This advantage is related to the first point; since the material is easily removed, a strong base can be created in the area where supports are required, resulting in a smooth surface without filament residue.

- Less need for post-processing of the model

- The ability to print complex 3D models with high surface quality using dissolvable filaments also reduces the need for post-processing tasks such as polishing, sanding, gluing, etc.

- Longer print times in increasing the time of 3D printing, since materials need to be changed in the process.

However, there are techniques for optimizing the support structure to reduce this problem.

However, there are techniques for optimizing the support structure to reduce this problem.

Tips for creating support structures with dissolvable filaments

By changing some settings in your slicer, you can get solid supports to improve the quality of your 3D model.

Strengthening the Supports

It is quite common to create thin supports for very thin parts of a model, however they are not strong and tend to break during the printing process. To increase their durability, you can adjust the following support configuration options:

Horizontal Support Extension: Increases the overall thickness of the support, allowing the tower to be thicker and stronger.

Avoid breakage of supports during printing

The thickness of supports is equal to the diameter of the hot end, so they are usually quite fragile and can break during printing. By changing the pattern and other parameters, the strength can be increased:

- Support pattern: Patterns such as grid and triangle are quite resistant to tearing during printing.

It is recommended to print such patterns only on soluble material, as they are quite difficult to remove.

It is recommended to print such patterns only on soluble material, as they are quite difficult to remove. - Supports printing speed: If the supports are printed too fast, there is a risk of breaking the structure. Reducing the speed avoids vibration or damage to the structure as the head passes.

Improving the quality of the surface of the model

The quality of the contact surface depends on the distance Z from the support pattern, the direction of the upper and lower perimeter lines and the amount of material holding the base of the model. Changing these parameters can improve the quality of the surface, but will complicate the process of extracting supports.

- Density of supports: The higher the density, the better the model will hold and therefore the surface finish will improve.

- Top/Bottom Line Direction: Changing the direction of the perimeter pattern helps hold the bottom layer of the model, as it allows the support and the perimeter pattern to intersect better.

- Support Pattern and Top/Bottom Pattern: The support and perimeter patterns affect how the support model attaches, ideally the patterns should overlap as often as possible to better secure the first layer.

Always remember that it is important to keep filaments in a dry environment, as soluble materials readily absorb moisture and can cause printing problems. Materials such as PVA and BVOH can be dissolved in normal water. This water can also be heated to shorten the removal time of supports.

We hope you follow our advice and recommendations to improve the surface quality of your 3D printed parts and make the process faster and more efficient.

We will keep you updated with the latest news!

Your iGo3D Russia team

Our groups in social networks:

VKontakte

Telegram

YouTube

Plastic processing for 3D printer. Plastic post-processing after 3D printing ABS, PLA, Nylon, Petg

Contents:

- Post-processing of FDM parts

- Remove supports

- Removal of soluble supports when printing with a 3D printer with two extruders

- Sanding plastic 3D printed products

- Application of Acetone in ABS plastic processing

- Filling irregularities in ABS plastics

- Polishing ABS/PLA

- Priming and painting 3D printed products

- Acetone baths for ABS products

- Chemical solvent baths

- Using epoxy to finish prints

Hello everyone, Friends! With you 3DTool!

With FDM 3D printing you can quickly and economically produce plastic parts of any geometric shape. Finished parts show visually the lines of the layers they were printed on, making post-processing an important consideration if a smooth surface is required. Some post-processing techniques can also increase the strength of finished products by helping to reduce their anisotropic properties.

Finished parts show visually the lines of the layers they were printed on, making post-processing an important consideration if a smooth surface is required. Some post-processing techniques can also increase the strength of finished products by helping to reduce their anisotropic properties.

This article will discuss the most common post-processing techniques in FDM 3D printing .

Catalog of FDM 3D printers

Post-processing of FDM parts

This picture above (left to right) shows the post-processed parts FDM :

- gap filling

- raw

- sanded

- polished

- painted

- epoxy coated

Remove supports

Support removal is typically the first step in post-processing for any 3D printing technologies if the part requires support for precision manufacturing. Supports can usually be divided into 2 categories: standard and instant .

Supports can usually be divided into 2 categories: standard and instant .

Unlike other post-processing methods discussed in this article, support removal is a requirement and does not result in improved surface quality.

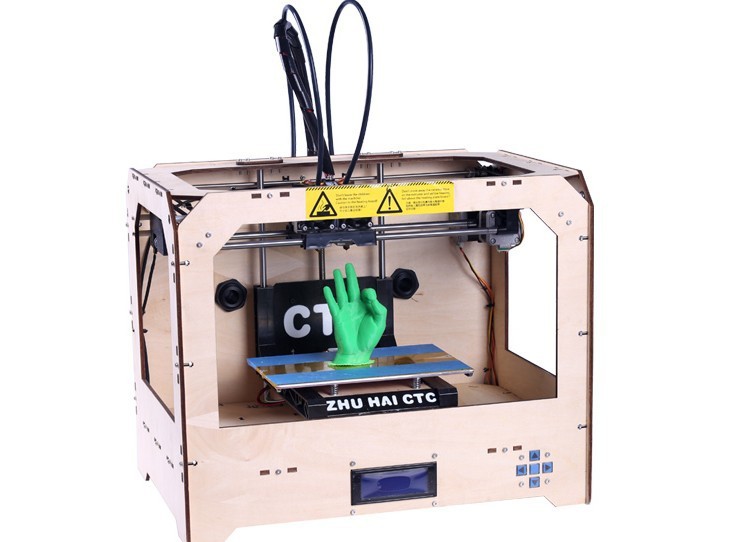

Removing supports mechanically is necessary when printing with a 3D printer with a single extruder (for example, PICASO Designer X, Hercules 2018, Zenit, Prusa i3 Steel Bizon) When using 3D printers with two extruders, as a rule, the supporting part of the product is made of special soluble materials.

Catalog of 3D printers with two extruders

Left to right. Original printing with support, poor support removal and quality support removal.

Tools and materials you will need for this job:

- Pliers

- Set with small tools (eg watchmaker's set).

Support Removal Process: The support material can usually be removed from the finished model without much effort. Cleaning of the substrate material in hard-to-reach places (for example, in holes) can be done using an awl and pliers. Properly positioned support structures and proper print orientation can greatly reduce the impact of the support material on the aesthetics of the final result.

Cleaning of the substrate material in hard-to-reach places (for example, in holes) can be done using an awl and pliers. Properly positioned support structures and proper print orientation can greatly reduce the impact of the support material on the aesthetics of the final result.

Pluses

- The overall geometry of the part does not change

- Fast on time

Cons

- Does not remove visible layer lines, streaks or smudges on print surface

- If support structures leave excess material or marks behind, the accuracy and appearance of the part will be reduced

Removal of soluble supports when printing with a 3D printer with two extruders

As we said earlier, the removal of supports printed from soluble materials is done differently than manually, mechanically, so the use of 2 or more extruder printers is preferable. (e.g. PICASO Designer X PRO, Raise3D PRO2)

Catalog of 3D printers with two extruders

Tools and supplies you will need for this job:

- Solvent safe container

- Thinner

- Ultrasonic cleaner (optional)

Process : the final model is placed in a bath with the appropriate solvent (for example, for PVA plastic it will be ordinary water, for material HIPS will be D-limonene ) until the support material dissolves. Support is usually printed with:

Support is usually printed with:

- HIPS (in conjunction with ABS )

- PVA (in conjunction with PLA )

Glass storage containers such as jars are excellent receptacles for diluting limonene. For dissolution in water, any non-porous container will do. For prints using HIPS/ABS bath with 1:1 ratio of limonene to isopropyl alcohol works very well for quick support removal. Many other support materials such as PVA (used with PLA ) are water soluble.

Helpful Hint: Speed up the dissolution time of the support material by using an ultrasonic bath and changing the solution as soon as it becomes saturated with plastic dissolved in itself. Using a warm (not hot) solvent will also speed up the dissolution time if you don't have an ultrasonic cleaner available.

Catalog of ultrasonic baths

Pros

- Great for complex geometries where standard support removal would be impossible without damaging the base model.

- The result is a smooth surface where the support structure is in contact with the base piece.

Cons

- Improper dissolution of the material can lead to discoloration and deformation of the entire part.

- Does not remove visible layer lines, streaks or spots on part surface

- May cause small spots or holes in the final print if soluble material gets on the object during printing

-

3D plastic sanding

Sanded brown ABS plastic part

Tools and materials you will need for this job:

- Sandpaper up to grit 1000

- Rags

- Toothbrush

- Soap

- Face mask

Sanding Process: After the supports have been removed or dissolved, sanding can be performed to smooth the part and remove any visible stains or traces of the supports. The initial grit size of the sandpaper depends on the layer height and print quality.

For layers with a height of 0.2 mm or less, or if there are no spots left on the part after printing, sanding can be started with a paper grain of - 150.

If there are visible spots or the object was printed at a layer height of 0.3 mm or more, start sanding with 100 grit paper.

purity. The print should be cleaned with a toothbrush in soapy water and then with a rag, between sanding gradations to prevent dust build-up and " sintering ". Your FDM parts can be sanded down to 5000 grit to achieve a shiny part surface.

Helpful Hint:

Always sand in small circular motions evenly over the entire surface of the part. Of course, it is more convenient to sand perpendicular or even parallel to the print layers, but this can lead to indentations in the model. If the part becomes discolored or if there are many small scratches after sanding, you can use a blow dryer. With it, you gently heat the part, thereby softening the surface a little and visible unnecessary defects will weaken or disappear altogether.

Pros

- With this method you get an extremely smooth surface

- This method facilitates additional post-processing (such as painting, polishing, or epoxy coating)

Cons

- Not recommended for thin wall prints as this may damage part

- Difficult for surfaces with difficult geometries and fine details

- Can affect overall print accuracy if sanding is too aggressive and too much material is removed

Acetone for ABS plastic

Two white printed halves of ABS bonded with acetone and diluted plastic.

Tools and materials you will need for this job:

- Acetone

- Cotton buds or brush

Machining process: When the size of the finished part exceeds the maximum size of the 3D printer's camera, the model often has to be broken into smaller parts and assembled later by gluing. For PLA and other materials, bonding can be done using the appropriate adhesive (selection of adhesive will depend on the plastic) . For ABS plastic, multi-piece assemblies can be glued with acetone. The mating surfaces should be lightly moistened with acetone and held firmly together or, if possible, clamped until most of the acetone has evaporated. At this point, the two parts of your model will stick together.

Helpful Hint: increasing the contact area with acetone will increase the strength of the joint. This can be done by including block connections in the design.

Pros

- Acetone will not discolor the surface of the part like other adhesives

- After drying, the seam will exhibit ABS properties, making further processing easier and more uniform

Cons

- The joint formed by this cold welding is not as strong as a solid impression

- Excessive use of acetone can lead to aggressive dissolution of the part and adversely affect the final result and tolerances

-

Filling irregularities in ABS plastics

The gray ABS model had voids after sanding. The surface became smooth.

Tools and materials you will need:

- Epoxy (for small voids only)

- Automotive Putty (large voids and joints)

- ABS plastic and acetone (for small voids only and for ABS parts only)

Process: After sanding or removing soluble backings, gaps often appear in the print. During printing, gaps are sometimes formed, and often this pattern is unavoidable. Small gaps and voids can be easily filled with epoxy and no further treatment is required. Large gaps, or gouges, left from attaching model assembly parts can be successfully filled with automotive putty, which will require additional sanding after drying.

The putty gives excellent results and can be easily sanded and painted after it has fully cured. The connection will be strong, and will not weaken the plastic. Conversely, autofiller parts tend to be stronger than native plastic.

Gaps in an ABS print can also be filled by making a slurry of ABS filament and acetone ( ABS juice or ABS juice ) that chemically reacts with the part and penetrates any surface voids. A ratio of 1 to 2 between ABS and acetone is recommended. This method will not significantly affect the cleanliness of the surface around the gap if properly applied.

Tip : If gaps are visible on FDM parts before sanding, fill them with epoxy and then sand once until dry. This will greatly reduce the overall time required to achieve a smooth surface.

Pros

- Epoxies are easy to sand and prime, making the surface easy to paint

- ABS juice will be the same color as your part, as long as you use the same filament by color and manufacturer. Therefore, there will be no discoloration of the surface

Cons

- Auto putty or other polyester epoxy will dry opaque resulting in discolored spots on print

- Requires additional sanding to achieve uniform coverage

- Can affect overall print accuracy if sanding is too aggressive and too much material is removed

ABS and PLA polishing

Catalog of ABS plastics

Catalog of PLA plastics

Tools and supplies you will need

- Polish

- Sandpaper

- Nonwoven wipe

- Toothbrush

- Microfibre cloth or polishing pad

Process: Plastic polish can be applied after sanding to give standard filaments such as ABS and PLA a glossy finish. After the part has been sanded to 1000 grit, wipe off any excess dust from the Non-woven » cloth, then clean it in a bath of warm water with a toothbrush.

Allow the piece to dry completely and buff it with a buffing pad, or by hand with a microfiber cloth and a jewelry polish designed specifically for plastic and synthetics that provides a long lasting shine.

Other plastic polishes, such as car headlight polishes, work on the same principle, but some may contain chemicals that can damage the original material.

Helpful Hint: For polishing small parts, attach the polishing pad to the variable speed drill (or other rotating tool such as a drill) . Bench grinders equipped with a polishing wheel can be used for larger, stronger prints, but don't polish too long in the same place. This can cause the plastic to melt due to friction.

Pros

- Polishing is applied without the use of any solvents that can deform the part and change the accuracy tolerances.

- When properly ground and polished, the part will give the impression of a mirror finish, imitating plastic injection molding

- Plastic polish and cleaner is very economical, making this method quite profitable for a quality finish

Cons

- The part must be carefully sanded before polishing if a mirror finish is required. This may affect tolerances

- Primer/paint may not adhere to surface after polishing and you will need additional products

Priming and painting 3D printed products

White PLA part spray painted gray

Tools and materials you will need:

- Non-woven cloth

- Toothbrush

- Sandpaper

- Aerosol Acrylic Primer

- Polishing agents

- Masking tape (only if using multiple colors)

- Gloves and petal mask

Process: after the part has been sanded properly (up to 500 grit sandpaper is required at this stage) , the print can be primed. The primer should be applied in two coats using an aerosol can.

An aerosol primer designed for painting models will provide an even coverage and be thin enough not to darken the part before painting.

A thick primer, such as one available at the hardware store, may stick together and require more sanding.

Apply the first coat in short, quick strokes at a distance of about 15 - 20 cm from the part to avoid the formation of a thick layer of primer. Let the primer dry and sand down any imperfections with 9 grit sandpaper.0013 500. Apply the final coat of primer with light, quick strokes.

Once the primer is complete, painting can begin. Painting can be done with acrylic paints and artist's brushes, but using an airbrush or spray can give a smoother surface.

Hardware store spray paint tends to be thicker and harder to control, so it's best to use paints made specifically for painting models.

The primed surface should be sanded and polished (sanding and polishing sticks used in nail salons are ideal for this application) and then cleaned with a non-woven cloth.

Paint over the model using very light layers; the first few layers will look translucent. Once the paint has formed an opaque coat of (usually after 2-4 coats) of , allow the model to dry for 30 minutes to allow the paint to set. Carefully polish the paint layer with nail sticks.

Multi-colour models can be painted with masking tape. Once all layers of paint are ready, remove the tape and buff the paint using polish paper. Polishing paper such as 3M or Zona can be purchased in a variety of grit sizes. You can buy it in a pack in many online stores. It will give the paint a shine that cannot be achieved in any other way.

Helpful Hint: Do not shake the can when using spray paint! The goal is to mix the pigment or primer, shaking the propellants will cause bubbles to form in the aerosol. Instead, rotate the jar for 2-3 minutes. The stirring ball should roll, not rattle.

Pros

- Professional results with attention to detail

- Excellent appearance of the final product, regardless of the material/color in which the object was originally printed

Cons

- Paint and primer will increase the volume of the model, which will change the tolerances and can cause problems if the part is part of the assembly

- Buying a high quality spray paint or airbrush is not cheap

Acetone baths for ABS products

Smoothed black model of a petal with a spherical surface made of ABS plastic after an acetone bath.

Tools and materials you will need:

- Non-woven cloth

- Sealed container

- Thinner

- Paper towels

- Aluminum foil (or other solvent resistant material)

- Face mask and chemical resistant gloves

Process: Line the chosen container with paper towels along the bottom and, if possible, up the sides. It is very important that the steam does not disturb the chamber itself. The chamber may be sealed.

It is recommended to use glass and metal containers.

Pour in enough solvent to dampen but not drown the paper towels. This will also help them stick to the side walls of the container.

Acetone is well known for its ability to smooth out ABS parts. For PLA, smoothing is possible with various solvents, they work well, but as a rule, with PLA, it is more difficult to get a smooth surface, unlike ABS.

IMPORTANT! When working with any solvent, please follow the safety regulations for the chemical and always follow the appropriate safety precautions !

A small "raft" of aluminum foil or other solvent-resistant material should be placed in the middle of a lined paper towel container.

Next, place your part on this raft (either side selected as the bottom on the raft) and close the lid of the container.

Steam polishing can vary in duration, so check the print periodically. Heat can be used to increase polishing speed, but care must be taken to prevent the buildup of potentially explosive fumes.

When removing the part from the chamber, try not to touch it at all, leaving it on the raft and removing it from the container. Any points of contact with the part will generate surface defects because the outer shell will be half dissolved. Allow parts to dry completely before use.

NOTE . Many aerosol and/or spray solvents are flammable/explosive and solvent vapors can be harmful to human health. Be especially careful when heating solvents and always work in a well ventilated area.

Pros

- Smooths out many small spots and reduces layer lines present in the print without any additional work

- Creates a very smooth "shell" around part

- A very fast method that can be implemented with improvised means

Cons

- Doesn't "heal" gaps or completely mask layer height

- The dithering process "dissolves" the outer shell of the print, and therefore this greatly affects the tolerances

- Negatively affects print strength due to changes in material properties

Chemical solvent baths

Tools and supplies you will need:

- Solvent safe container

- Thinner

- Hook or small screw

- Wire

- Drying rod or rack

- Face mask and chemical resistant gloves

Process: Make sure the container you are using is wide enough and deep enough to hold the part and solvent. Fill the container with the appropriate amount of solvent, taking care to minimize splashing. As with steam smoothing, acetone should be used to dip the ABS.

PLA is sufficiently resistant to solvents, so it may take several passes to achieve the desired result.

Prepare the part for dipping by screwing an eye hook or small screw into an inconspicuous surface of the imprint. Pass the wire through the eye of the hook or around the screw so you can lower your piece into the wire bath. If the wire is too thin, you won't be able to submerge the part in the solvent.

Once the part is prepared, quickly immerse the entire object in the solvent for no more than a few seconds using wire. Pull out the print and attach it to a wire over a dryer rod or rack to allow the solvent to completely evaporate from the surface. The part should be gently shaken after you remove it to facilitate drying and avoid solvent build-up in depressions on the surface.

Helpful Hint: If the part has an opaque whitish color after drying, it can be hung over a solvent bath for a while so that the evaporating vapors slightly dissolve the surface. This will restore the color of the print and provide a glossy outer layer.

Pros

- Print surface smoothes much faster than steam polishing

- Much less fumes than other solvent polishing methods and is safer

Cons

- Very aggressively smoothes the surface of the part, so the tolerances deviate greatly from the specified

- Immersion too long can lead to complete deformation of the part and a significant change in material properties

Using epoxy to finish prints

The part is sanded and coated with epoxy resin.

Tools and materials you will need:

- Two-component epoxy (such as XTC-3D)

- Foam applicator

- Brushes

- Mixing container

- Sandpaper 1000 grit or higher

Process : After the print has been sanded (sanding first will give better end results) , completely clean it with a non-woven cloth.

Mix the correct ratio of resin and hardener as directed in the resin instructions. Make no mistake about the proportions. Epoxies are exothermic when mixed, so glass containers and containers composed of low melting point materials should be avoided.

Containers specifically designed for mixing epoxy resins are recommended. The wrong ratio will lengthen the drying time and the epoxy may never be able to fully cure, resulting in a disastrous and sticky part.

Mix resin and hardener thoroughly according to instructions. Stir gently to minimize air bubbles. The faster the epoxy dries, the better. Most epoxies have a working dry time of only 10-15 minutes, so do your post-processing in the proper order.

Apply the first coat of epoxy using a foam applicator and try to minimize resin buildup on recessed surfaces or other details of the print. Once your part is sufficiently covered with resin, allow it to fully cure according to the manufacturer's instructions. One coat may be enough to smooth the detail, but for optimum appearance, the print should be lightly sanded with fine sandpaper (1 000 grit or finer) . Remove dust with a non-woven cloth and apply a second coat of epoxy in the same manner.

Pros

- A very thin coat of epoxy will not significantly affect part tolerances (unless the part has been sanded first)

- Resin provides an outer protective sheath around part

Cons

- The layer lines will still be visible, they are under the "smooth" shell

- Applying too much epoxy can cause surface dripping and over-smoothing of print details

Tools and supplies you will need:

- Electroplating solution. It can be prepared by mixing a metal salt with acid and water, but if the proportions are not accurate, it will be difficult to get a professional result.

Buying a ready-made solution guarantees that there are no problems with plating.

- Sacrificial anode. The anode material must match the metal of the plating solution, so if copper sulfate is used in the solution, then a copper anode should be used. You can use any item made of metal plating (copper wire, for example), or you can purchase a thin strip of metal plating that is made specifically for electroplating.

- Conductive paint or acetone and graphite. The print surface must be conductive for coating, which can be achieved with conductive paint or a 1:1 solution of graphite and acetone. Conductive ink will work on any printed material, but a solution of acetone and graphite will only work on ABS.

- Power Rectifier - A battery can be used instead of a rectifier, but a battery is not as efficient and will not produce results as quickly and consistently as a rectifier. A rectifier is also a safer option. It can simply be turned off to stop the current flow during electroplating.

- Conductive screw or eyelet

- Non-conductive vessel

- Lead set

- Non-conductive gloves and goggles.

Electrophoresis solutions are acids and can cause eye damage if splashed, so appropriate goggles are required. Also, these solutions can irritate the skin and conduct a charge when used. Therefore, non-conductive gloves should always be used.

Process: metal plating can be electroplated at home or in a professional workshop. Proper plating requires a deep knowledge of materials, and what you can do at home has certain limitations compared to what can be done in a professional workshop.

For a better finish and a wider range of plating options, including chrome plating, a workshop would be the best option. For clarity, the copper plating process will be described below.

At home, galvanization can be done using copper or nickel plate. It is imperative that the surface of the print to be processed is as smooth as possible before coating; any unevenness and visible lines of the layers will start to stand out after coating.

Prepare a cleaned and sanded print. By coating the plastic with a thin layer of high quality conductive paint or a solution of acetone and graphite (if made of ABS) . Allow the conductive coating to dry completely and sand if necessary to ensure a smooth finish. It is extremely important to minimize contact with the print or wear gloves as the sebum on your fingers will interfere with the coating process.

Insert a screw or hook with an eye into an inconspicuous surface of the part, similar to dipping in solvent.

Attach to one of the rectifier leads. This will serve as the cathode. The connection must be made to the negative terminal of the rectifier. Connect the copper anode to the positive terminal of the rectifier using the second power wire and fill the container with enough electroplating solution so that the imprint and the copper anode are completely hidden. Turn on the power rectifier. After the rectifier is turned on, make sure that the part does not touch the anode in any way.

IMPORTANT! Be very careful at this stage. After the part is lowered into the bath and the system is energized, any contact with the solution, anode or cathode may result in personal injury !

Set the power supply rectifier to 1-3 volts. After that, the metallization process will begin until the part is completely covered with metal. Voltage may be increased to reduce coating time, but should not exceed 5 volts. Simply turn off the straightener and remove the print after a satisfactory finish has been applied. Dry the print with microfiber towels. Coat the part with a special varnish for metal after drying. This will protect it from corrosion.

Pros

- The metal shell increases the strength of the plastic part, which greatly expands the possibilities of its application and use

- The outer metal coating is very thin so if properly applied, tolerances of 9 can be held tightly0048

- Creates a beautiful surface that, if done correctly, will not look like a 3D printed object

Cons

- Typically very expensive to do this at a professional level and home plating requires a decent amount of professional processing equipment

- Electroplating at home can cause electric shock if not followed

Well, that's all we have! We hope this article was useful for you!

Order 3D printer or FDM consumables , you can