3D printer moon base

NASA Gives ICON $57 Million to Build a 3D Printer for Structures on the Moon

Austin, Texas-based 3D printing construction company ICON has gotten some pretty significant projects off the ground in recent years, from a 50-home development in Mexico to a 100-home neighborhood in Texas. This week the company won a NASA contract that will help it get an even bigger project much further off the ground—all the way to the moon, in fact.

The $57.2 million contract is intended to help ICON develop technologies for building infrastructure on the moon, like landing pads, houses, and roads. The goal is for ICON to build these lunar structures using local material—that is, moon houses built out of moon dust and moon rocks.

“To change the space exploration paradigm from ‘there and back again’ to ‘there to stay,’ we’re going to need robust, resilient, and broadly capable systems that can use the local resources of the moon and other planetary bodies,” said ICON co-founder and CEO Jason Ballard in a press release.

Doing anything in space is ultra-expensive because you have to bring the materials and tools you need up from Earth. Imagine loading rockets with bricks or cement mix for 100 houses and flying them to the moon. Not only would this be cost-prohibitive, it could very well be a waste of time and resources because those building materials wouldn’t hold up on the lunar surface the same way they do on Earth.

“If you tried to plan a lunar settlement or a moon base and you had to bring everything with you, every time you wanted to build a new thing it’s like another $100M,” Ballard said. “But once you’ve got a system that can build almost anything—landing pads, roadways, habitats—and it uses local material, you are probably two or three orders of magnitude cheaper to build a permanent lunar presence than you would be in any other way that we can think of.”

ICON engineers plan to study lunar regolith to determine how it might behave when used as a building material. According to Payload, ICON’s regolith-based building process would look something like this: they’d put down an initial layer of moon dust and rocks in the shape of whatever they’re trying to build—say, the walls of a lunar habitat—then use a purpose-built laser to melt the regolith so that it would be permanently stuck together. Once the first layer solidified, they’d add another; it’s not so different from the way their 3D printers work on Earth.

Once the first layer solidified, they’d add another; it’s not so different from the way their 3D printers work on Earth.

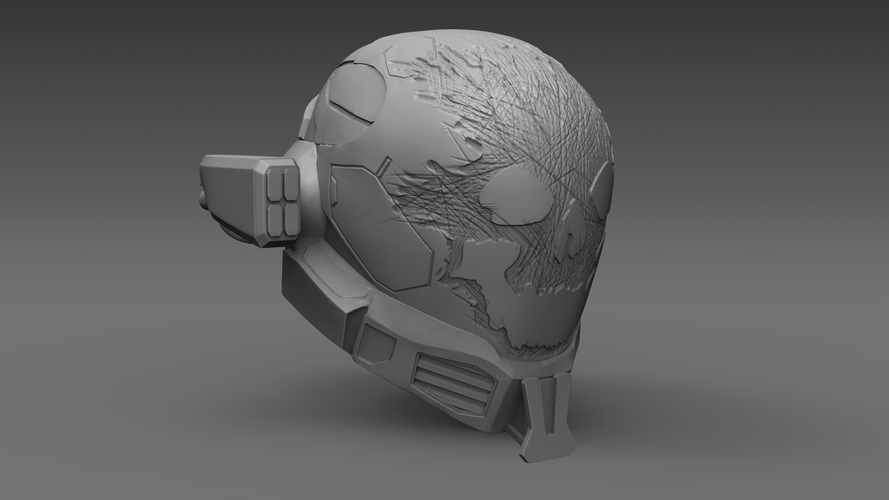

The “printer” ICON is developing for use on the moon is called Olympus, and it looks something like a giant mechanical spider with a crane attached. It would land on the moon via commercial lander and drive itself to the build site to start processing regolith for construction.

Similar to how soil on different parts of Earth can vary greatly in composition—in some places it’s rockier, in others it’s sandier, in yet others it contains clay (and that’s not even to mention the differences in its chemical makeup)—the moon’s regolith isn’t quite the same all over. ICON will need to test how Olympus functions with different materials to make sure the tool will be usable on various parts of the moon.

The new NASA contract is actually a continuation of an existing US Air Force contract, partially funded by NASA, under which ICON was tasked with exploring commonalities between Earth-based and off-Earth applications of 3D printing construction. The contract runs through 2028 and includes a demonstration on the moon’s surface in 2026.

The contract runs through 2028 and includes a demonstration on the moon’s surface in 2026.

It all sounds pretty ambitious, and like something straight out of a sci-fi film. We’ll see how ICON’s plans play out over the next four years; various wrenches could get tossed into the project’s spokes and slow things down.

But Ballard is characteristically optimistic. “The final deliverable of this contract will be humanity’s first construction on another world, and that is going to be a pretty special achievement,” he said.

Image Credit: ICON

NASA invests $57 million in a 3D printer for building on the moon

It turns moon dust into construction materials.

NASA has awarded high-tech construction company ICON a nearly $60 million contract to develop Olympus, a 3D-printing system specifically designed for building on the moon and Mars.

The challenge: NASA’s Artemis 1 mission launched in November, putting the agency a major step closer to its goal: not just getting humans back to the moon, but establishing a long-term presence there so that astronauts have time to perform the research needed to reach Mars.

The cost of sending all the construction materials needed to build a significant moon base from Earth to the moon would be astronomical, so NASA’s plans for building on the moon depend on using as many local resources as possible.

“The final deliverable of this contract will be humanity’s first construction on another world.”

Jason Ballard

What’s new? Now, NASA has awarded ICON, a Texas-based company specializing in advanced construction tech, a $57.2 million contract to develop Olympus, a 3D-printing system that could be used for building on the moon, and Mars, using local materials.

“[Olympus] will allow us to … build all the elements of infrastructure necessary for a lunar outpost and ultimately a moon base,” ICON CEO Jason Ballard told KVUE. “This is launch and landing pads, roadways, habitats, you name it — all the things we need on the moon.”

While the 3D printers ICON uses to construct houses on Earth utilize a water-based concrete “ink,” Olympus will take a different approach.

“[We’re] using a high-powered laser to actually transform moon dust into building material,” said Ballard, noting that his company has also experimented with microwaves, infrared light, and melting for off-world construction.

Space partners: This isn’t the first collaboration between NASA and ICON.

The agency has been helping fund the company’s plans for off-world construction since 2020, and in 2021, ICON unveiled Mars Dune Alpha, a 3D-printed facility at NASA’s Johnson Space Center that will be used for a year-long simulated Mars mission starting in 2023.

The new NASA contract runs through 2028, and during it, ICON will continue developing the Olympus system using actual samples of lunar regolith, brought back during NASA’s Apollo missions, as well as simulated moon dust.

ICON will also bring its hardware and software into space during a flight designed to simulate lunar gravity. Ballard told KVUE that the company hopes to be building on the moon by 2026, with the first structure likely to be a launch and landing pad.

“The final deliverable of this contract will be humanity’s first construction on another world,” he said, “and that is going to be a pretty special achievement.”

We’d love to hear from you! If you have a comment about this article or if you have a tip for a future Freethink story, please email us at [email protected].

Moon base 3D printed from lunar soil / Sudo Null IT News It is on such a project that the European Space Agency (ESA) is working in collaboration with renowned architect Norman Foster.

Human colonization of the Moon is no longer a utopian fantasy, but a promising goal. People do not want to build a base on the Moon “for show” - it can bring tangible benefits. The moon also has a variety of minerals, including metals valuable for industry: iron, aluminum, titanium. In the surface layer of soil (regolith), an isotope 9, rare on Earth, has been accumulated0007 helium-3 , which can be used as fuel for advanced thermonuclear reactors. Deep vacuum and the availability of cheap solar energy open new horizons for electronics , foundry , metalworking and materials science . The moon, due to its impressive landscapes and exoticism, would be an attractive object for tourists.

ESA is therefore experimenting with various approaches that could enable construction on our planet's satellite in the future. At this stage, with the help of industrial companies, ESA is developing a project for a 3D lunar base from space soil.

At this stage, with the help of industrial companies, ESA is developing a project for a 3D lunar base from space soil.

“On Earth, full-fledged structures are already being created using 3D printing. Our fellow industrialists have tried to see if it is possible to build a safe environment for humans on the Moon in a similar way.”Foster + Partners, led by renowned architect Norman Foster, creator of London's famous Gherkin skyscraper and other buildings, has proposed hinged "domes" as a supporting structure. The special structure of their walls will protect the inhabitants from micrometeorites and cosmic radiation. The astronauts will live inside the dome, in an inflatable "cocoon". The hollow structure, reminiscent of the bones of birds, should be a good compromise between strength and lightness. The base model is designed for 3D printing from a one and a half ton bar of lunar soil.

“3D printing could potentially enable the construction of a lunar settlement without massive supplies of materials from Earth.

The new possibilities this idea opens up can be taken into account by the international space agencies in the context of their own lunar exploration projects.”added Scott Hovland, ESA's manned flight manager.

“On Earth, we have already adapted to building in extreme conditions and have learned to take advantage of a particular environment, focusing on local natural materials. We are guided by the same logic in the lunar project”explains Xavier de Questellier of Foster + Partners.

Lunar Base 3D PrinterThe D-Shape printer that prints the base has a 6 meter frame nozzle array that sprays an adhesive solution onto the sand-like building material. 3D prints are made in layers. Monolite is now using it on artificial coral reefs to create protection against the destruction of powerful sea waves.

“We first mixed our model lunar soil with magnesium oxide.This is the “paper” that we can print on. Then we apply our "ink" - a special saline solution that holds the "paper" together into a solid structure.

Right now our printer is printing at about two meters per hour, but the next generation printer will already be able to reach 3.5 meters per hour, so the whole building can be completed in a week.”Enrico Dini, founder of Monolite, explains.

The adaptation of the "terrestrial" printer to space work was carried out by the Italian space company Alta SpA in collaboration with the technical university Scuola Superiore Sant'Anna in Pisa. Particular attention was paid to the peculiarities of working in a vacuum: after all, under these conditions, the liquid will instantly boil.

“To avoid this, we place nozzles under the regolith layer. We have found that 2mm droplets are successfully retained in it by capillary forces, so the printing process can take place in a vacuum.”

, explained Giovanni Cesaretti, Alta employee.

An interesting side result of the work was the discovery of a source of "lunar" soil in Europe. In general, regolith is produced and sold by specialized companies in kilogram quantities, but this project needs tons of it.

The solution was found in the Apennines. The basalt rock of a dormant volcano in central Italy was 99.8% identical to the lunar soil.

The validation of the concept itself has now been completed, further work is still ahead. Other threats must be taken into account: lunar dust dangerous for people to inhale, the temperature features of the Moon. 3D printing works well at room temperature, but due to the absence of an atmosphere on the moon, the difference between night and day temperatures is very large. Only the poles differ in a more “mild” climate.

Moon dust 3D printer

CosmonauticsTechnology

09/08/2019

4,042

Building a moon base is a real challenge.

To avoid the transfer of heavy materials from the earth, scientists are developing the possibility of using lunar dust in special 3D printers. They should be able to print building blocks directly on the spot - the so-called additive manufacturing.

Ross Friel, senior lecturer at Halmstad University, leads a team of researchers working on autonomous additive manufacturing (also called 3D printing) that can be used on the moon.

Earth's resources are limited, so our continued existence requires that we look beyond our planet. There are endless resources in space. To be able to explore, both inside and outside, our solar system, a lunar base is needed that can serve as a "springboard" for space travel. According to Ross Friel, it is economically and technically advantageous to use the Moon as a launch pad because of its low gravity, extremely thin atmosphere and clear skies, and the ability to use hydrogen and oxygen from lunar ice for rocket fuel.

The task of building a moon base

Building a moon base is not an easy task.

The building material must withstand and protect people and scientific instruments from harmful cosmic radiation and meteoroids. It is impossible to transport heavy concrete from the Earth to the Moon - it is too expensive. Therefore, being able to use materials already on the Moon to create building blocks and other useful components such as spare parts could be a better solution.

Lunar dust, i.e. fine gravel on the Moon called lunar regolith, is a natural ceramic material - much like volcanic ash on Earth. In our study, we used material from the earth with properties similar to moon dust. Real dust is hard to come by, says Ross Friel.

3D printer on the moon

By melting moon-like material from the earth, you can print various types of structures on a specially designed 3D printer, such as cubes, filter elements and screws, directly on the surface of the moon.

By melting material from the earth, which has properties similar to moon dust, various types of textures can be printed using a specially designed 3D printer.

Learn more