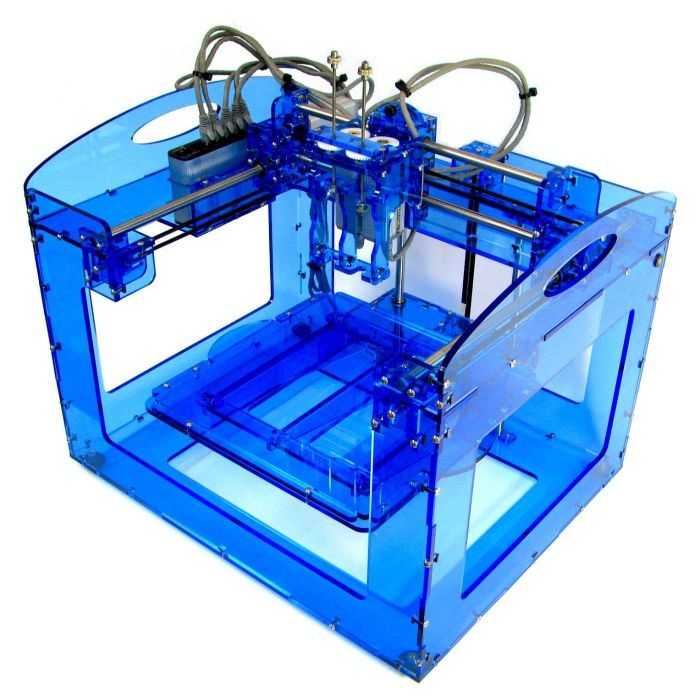

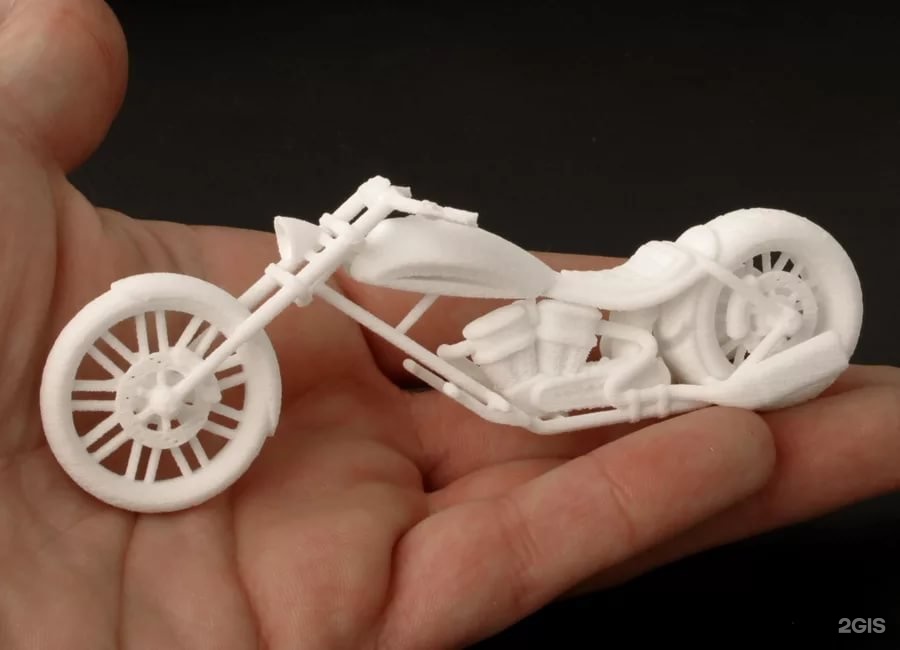

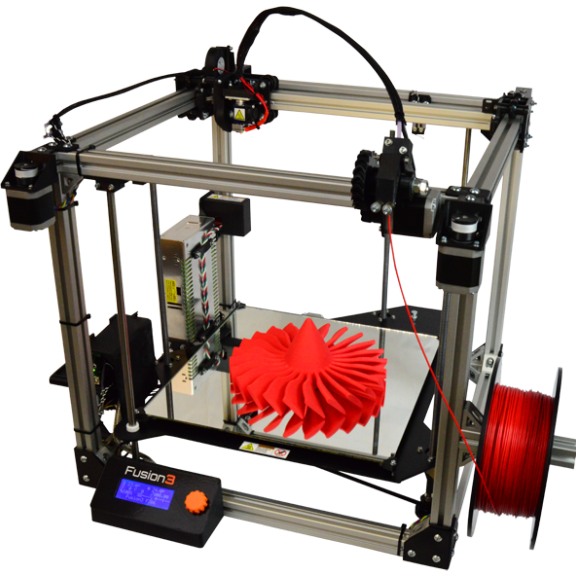

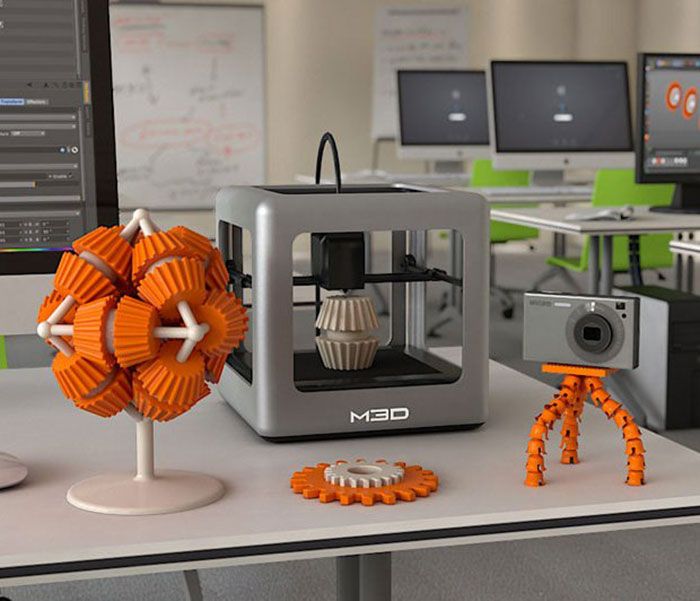

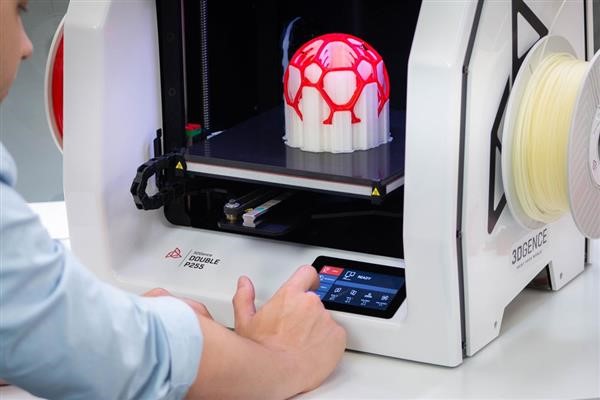

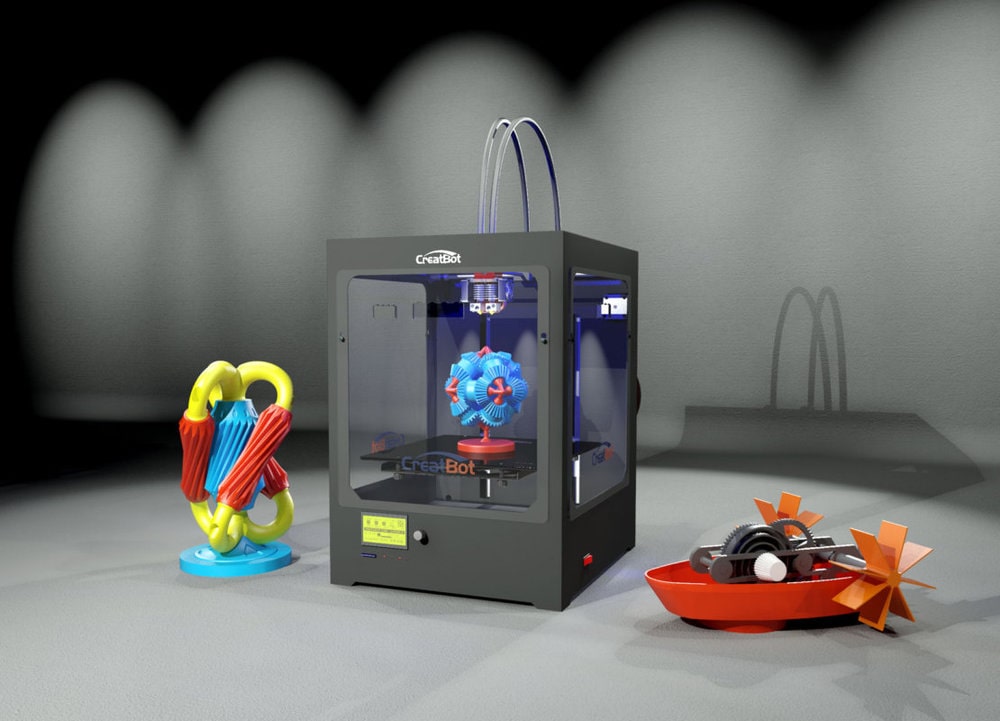

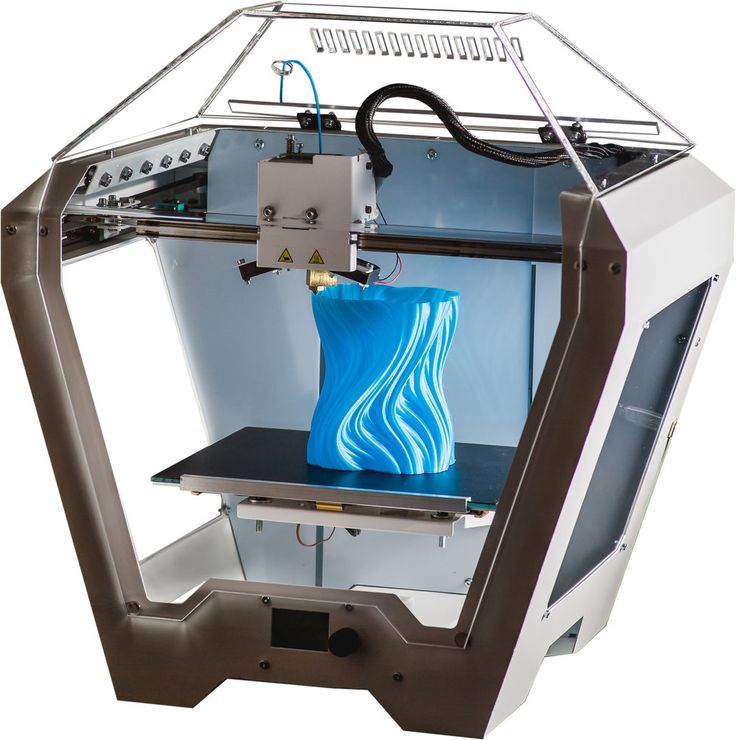

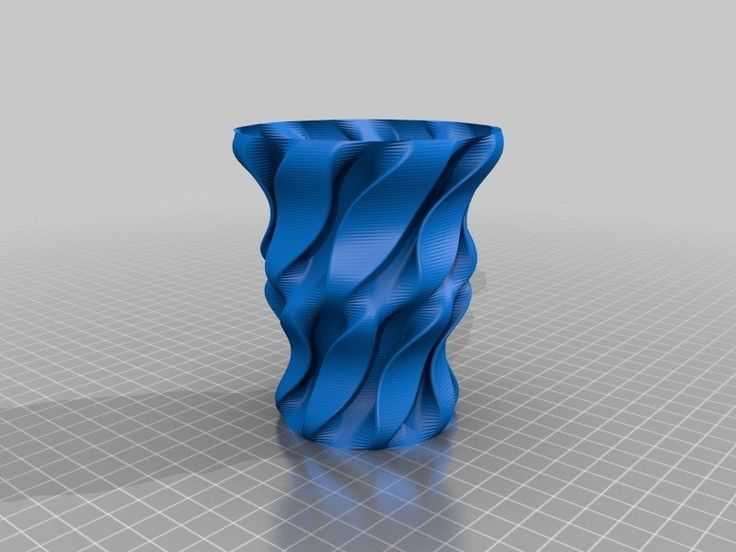

Examples of 3d printers

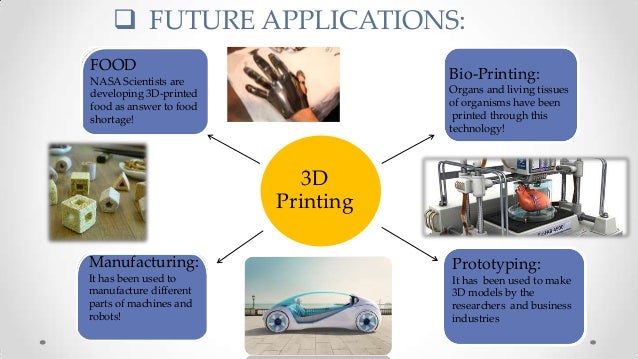

7 Examples of 3D Printing in the World Today

More and more, 3D printers are becoming much cheaper to purchase, and many experts don’t expect it to be too long before they become a commonality in households across the world. Manufacturing companies are also taking notice of the powerful abilities these machines provide companies and their production processes. Seemingly everyday brings forth another development that expands the limits of 3D printing. From medical devices to aircraft parts to shoes, 3D printing can virtually create anything you can thing of, it’s just a matter of scale. Below are 7 real-world examples of 3D printing that can be seen today.

Your Source for 3D Printers: NeoMetrix Technologies, Inc.

1. Prosthetic Limbs & Body PartsNeoMetrix 3D Prints Custom Prosthetics for Marathon Runner.

3D printing has had a significant impact across the medical industry, from producing custom prosthetic legs for a marathon runner, to creating a model of the human heart to aide surgeons to making a new tail for an alligator that had its tail bitten off as a baby. Recently, a team from Northwestern University Feinberg School of Medicine in Chicago successfully conducted an experiment in which a mouse with 3D printed ovaries actually successfully birthed healthy pups. This is an incredible breakthrough, as there is now substantial belief that this could potentially work with humans given further research and experimentation.

Here’s some examples of 3D printing‘s benefits in the medical industry:

- Open Bionics Introduces Affordable Prosthetic Arm

- Medical Researchers Develop Revolutionary 3D Printed Cornea

- Development of Quick Connect Prosthetic Joints

Believe it or not, 3D printing has the ability to produce entire houses in buildings. This is a remarkable feat for the technology because it could potentially save lives when areas are enduring tough times from things such as natural disasters and war because emergency shelters can be constructed quickly and on-demand using 3D printing technology. How fast can they be built? In Moscow, Russia, a team used 3D printing to create a 400 square foot house in less than a day, just to point out one instance of the production speed.

How fast can they be built? In Moscow, Russia, a team used 3D printing to create a 400 square foot house in less than a day, just to point out one instance of the production speed.

In addition to this, 3D printing is also enabling the development of new architectural designs and visions that before were never possible. The design innovations are seemingly limitless. In Holland, there will soon be a small neighborhood consisting solely of 3D printed homes.

3. Food3D printing is even breaking design barriers in the culinary arts. Using a plastic 3D printer, users can actually print chocolate based off a digital design from 3D software. Companies have even 3D printed edible foods using ice cream, cookie dough, marzipan and hamburgers.

4. Firearms & MilitaryA very controversial topic has been the ability to 3D print fully functional firearms. Defense Distributed’s “Liberator” has been subject of hot discussion as it is a working plastic gun, created using 3D printing technology. Many believe this to be an extremely dangerous ability as there is the potential for any person with a 3D printer and the design blueprints can produce their own guns.

Many believe this to be an extremely dangerous ability as there is the potential for any person with a 3D printer and the design blueprints can produce their own guns.

3D printed flip-top valve on the T-45 Goshawk breathing mask. Photo by Emanuel Cavallaro via NAVAIR.

In a more positive light, branches of the U.S. Military have benefited greatly from this ability. Already we have seen many instances of how 3D printing can aide soldiers in the battlefield and potentially save lives:

- U.S. Marine Corps Turns to 3D Printing

- U.S. Army Explores 3D Printing Stealthy Squid Drones

- U.S. Navy Will Depend On 1,000 3D Printed Parts by the End of 2018

- Marine Corps Seeks to 3D Print Drones, Save Thousands

- 3D Printed F-35 Part Saves U.S. Marines $70,000

- Department of Defense Unveils 3D Printed Drones Deployable from Fighter Jets

- EDA to Assess Usage of 3D Printing in Military Operations

NeoMetrix Firearm Case Studies:

- 3D Scanning and Reverse Engineering a Handgun Grip

- 3D Scanning & Reverse Engineering a Pistol Grip

- Development of a Magazine-fed Shotgun

- Reverse Engineering a Gun Component

Manufacturing

Manufacturing 3D printing has become an extremely disruptive force in the manufacturing world, and many refer to it as the manufacturing solution of the future. The automotive and aeronautical industries, to name a couple, have experienced the benefits of 3D printing technologies first hand, and are beginning to integrate it into their production processes. The ability to 3D print both replacement parts and functional, new parts saves them significant, time and money.

- Choose 3D Laser Scanners for Manufacturing Quality Control

- Disruptive 3D Printing Forces Companies to Reconsider Manufacturing

- 3D Printing Yields Huge Savings in Tooling Costs for GM

- 3D Printing Growth Surpasses Traditional Manufacturing

- 3D Printing: Moving from Prototyping to Production

- 3D Printing: The Benefits of a Growing Technology

Additive manufacturing technologies even have impact in music. Already, we have seen working violins, flutes, banjos and more produced using 3D printing. At Sweden’s Lund University, the first ever live concert featuring all 3D printed instruments has taken place, and the show was a smashing success. In addition to complete instruments, 3D printing can also be used to create accessories such as custom mouthpieces.

Already, we have seen working violins, flutes, banjos and more produced using 3D printing. At Sweden’s Lund University, the first ever live concert featuring all 3D printed instruments has taken place, and the show was a smashing success. In addition to complete instruments, 3D printing can also be used to create accessories such as custom mouthpieces.

Perhaps the most intriguing thing about 3D printing is that users can basically create anything that they can design in 3D software. Some examples of how NeoMetrix has enabled out customers to bring their designs to reality are:

- 3D Modeling and Printing Game Characters for Superhero 2044

- Reverse Engineering & 3D Printing Commemorative SunRail Bridge

- Reverse Engineering & 3D Printing “Spirit of America” Awards for Inspired Bronze

- 3D Scanning, Reverse Engineering & 3D Printing American Flag Pins

100 Examples of 3D Printing: Then, Now, and in the Future

Remember the Jetsons – that sci-fi cartoon from the early 60’s? Perhaps the cartoon was best known for flying cars and dinner served with the push of a button.

Today with 3-D printing we’re getting even closer to that reality. With this new technology we are reshaping the way we innovate and build products that even George Jetson would be proud of.

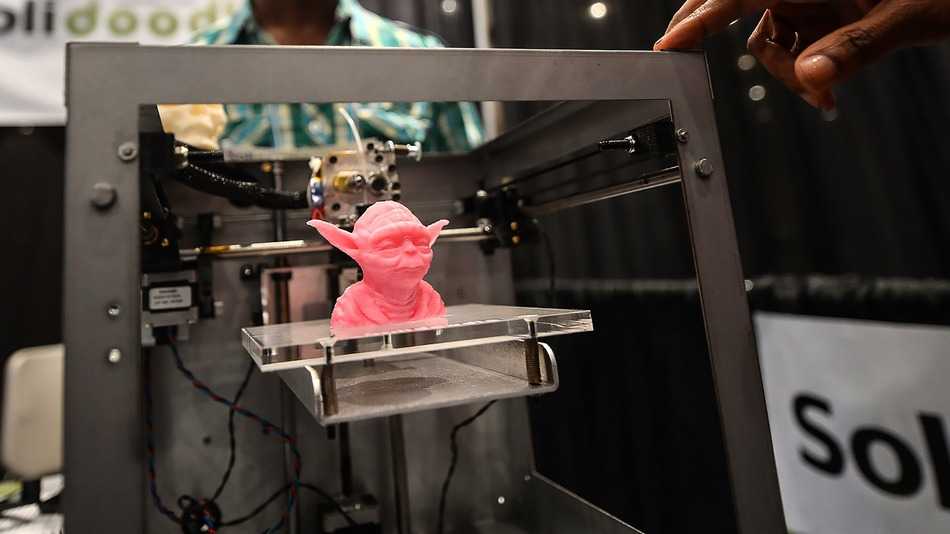

We’ve all seen those early examples of printed objects which ended up looking like tangled spaghetti more than anything else. While it’s true that 3D printing may be merely a fad for the hobbyist, it has also been used in defense, medicine and yes even for dinner.

So lets jump right in to the evolution of 3D printing. Explore our examples of 3d printing below – many interesting, lots useful, and some even entertaining.

Since 2008 when a the self replicating printer named RepRap was invented, 3-D printing has been on the “up swing” ever since.

Early Examples of 3D Printing

1. RepRap’s Self-Replicating Printer: In 2008 RepRap created a printer, named Darwin, that could print its own parts as well as many other 3D objects. This project opened up 3D printing to many new people and began an open-source movement.

RepRap’s Self-Replicating Printer: In 2008 RepRap created a printer, named Darwin, that could print its own parts as well as many other 3D objects. This project opened up 3D printing to many new people and began an open-source movement.

2. Prosthetic Limbs: In 2008, the very first person walked on a 3D printed prosthetic leg. This innovation opened the way for Bespoke Innovations to develop 3D printed coverings for prosthetic legs, customized to match each person’s remaining leg and style.

3. MakerBot’s Cupcake CNC: MakerBot Industry is a New York based company that produces 3D printers for consumers. In March 2009 they began selling their first device, the Cupcake CNC, a highly customizable do it yourself printer that could 3D print objects up to 100 by 100 by 130 mm large.

4. Organovo’s Blood Vessel: In 2009, Organovo produced the first 3D printed blood vessel, one of many medical uses of 3D printing. This example also can be referred to what is called Bio Printing.

5. Organovo’s Human Vein: Continuing to expand the uses of 3D printing for medical purposes, in 2010 Organovo printed a human vein that uses organ cells, built around a printed scaffolding of “bio ink.”

6. Kor Ecologic’s Car: Urbee became the world’s first 3D printed car in 2011, and Kor Ecologic will soon come out with the Urbee 2. Urbee is a 3-whelled hybrid car, with both the exterior and interior made from 3D printed parts. It weighs only 1200 pounds, meaning that it uses fuel very efficiently.

7. Wake Forest’s Kidney Prototype: Scientists at the Wake Forest Institute for Regenerative Medicine, led by director Anthony Atala, created a 3D mold of a human kidney using biocompatible materials combined with human cells. The printed kidney lacked the inner structures of a real human kidney but opened the way for further work that in the future might enable the transplantation of functioning 3D printed organs.

8. University of Southampton’s Robotic Aircraft: Engineers at the university built a robotic, unmanned aircraft in 7 days. They built the plane with elliptical wings, a feature that is expensive to manufacture using traditional methods, for a total budget of only 8,000 US dollars.

University of Southampton’s Robotic Aircraft: Engineers at the university built a robotic, unmanned aircraft in 7 days. They built the plane with elliptical wings, a feature that is expensive to manufacture using traditional methods, for a total budget of only 8,000 US dollars.

<div></div>

9. imaterialise’s Jewelry: For the first time, a company began using sterling silver and gold as materials for 3D printed goods. Their products included necklaces, rings, and other jewelry. This innovation opened the doors for other jewelry to be manufactured that is inexpensive and highly customized.

10. Instructables First Vinyl Record: A 3-D Printed record of Kurt Cobain Nirvana is printed by Amanda from Instructables – the grooves are 10x wider so one record is about 6 minutes of playtime. The video below demonstrates this record and others which are printed using high resolution file:

11. 3D Systems’ Drum Kit: 3D Systems, a US based company, used a strong form of nylon to print a 5-piece drum kit. The drums feature intricate cut-out designs and have been played as part of a whole 3D printed band.

12. Tristan Bethe’s Shoe Burger: Tristan Beth used Shapeways technology to create a 3D printed mold of his shoe. He then filled the mold with bread mix in order to bake a hamburger bun. He also made a chocolate shoe for those with a sweet tooth.

13. LayerWise’s Jaw: LayerWise in Holland produced the first 3D printed jaw in 2012, which was a total lower jaw that could be entirely customized for the individual patient.

14. Scott Summit’s Acoustic Guitar: While on vacation, Scott Summit designed a model of an acoustic guitar, which he then had printed by 3D Systems. The plastic model held up better than expected to the pressure of tuning and opens up new possibilities for instruments customized for exactly the bass and treble desired.

15. James Bond’s Aston Martin: For the film Skyfall, the film team hired voxeljet, a Belgian 3D printing company, to create mini replicas of the classic Aston Martin DB5 used by Bond in the 1964 film Goldfinger. The company printed 18 parts of the car individually, so that they would be fully functioning.

16. Inition’s Chocolate Brain: To show the power of 3D printing to create models of individual human organs, Andy Millions, the co-founder of Inition, created a chocolate 3D model of his own brain based on an MRI brain scan. Then, as might be predicted, he ate it.

17. Drexel University’s Dinosaur Bones: Paleontologists began using 3D printers to create replicas of dinosaur bones. They can scan the real bones to produce detailed, accurate models.

18. MIT’s Eat Your Face Machine: A team at MIT’s Media Lab built a 3D printer called the Eat Your Face Machine that uses a facial scan to make a 3D print into a block of chocolate.

19. Shane Graber’s Fish Breeding Equipment: Shane Graber used a personal Makerbot 3D printer to build custom pieces he needed for his fish hatchery. They are cheaper and faster to produce than buying them from the store.

20. Shapeway’s Infinite Bacon: Joaquin Baldwin used a Shapeways 3D printer to create a “bacon” mobius strip, made from vegan materials. The Mobius strip of bacon print file is made available by Shapeway for under $20.

21. The Smithsonian’s Historical Replicas: The Smithsonian has immense collections but isn’t able to lend many of them out. They’ve begun using 3D printing, however, to digitally create accurate replicas of some of their collections that are suitable for traveling exhibitions.

22. YukiSUZIKI’s Camera Lens: Using MakerBot’s Thingiverse platform, user YukiSUZIKI shared a design for a 3D printed camera lens. A camera lens has many complex parts, which he was able to create efficiently using 3D printing.

Current Examples of 3D Printing

23. Defense Distributed’s Gun: Starting with a more controversial example of 3D printing – Cody Wilson, working with a business named Defense Distributed, manufactured a 3D printed gun. Wilson was asked to remove designs for the guns from his website, and his domain was temporarily seized by the government.

24. WobbleWorks’ 3Doodler: WobbleWorks put 3D printing into the hands of consumers with 3Doodler, a 3D printing pen. With a structure that looks much like a glue gun, the 3Doodler uses a plastic thread that will stand on its own to allow users to draw and build 3D models and shapes.

25. State Key Laboratory’s Airplane Spar: The State Key Laboratory of Solidification Processing at the Northwestern Polytechnical University in China used the technology of Laser Additive Manufacturing to 3D print a central wing spar 5 meters long for a Cormac C919 passenger plane. The plane is expected to fly in 2014.

26. Ivan Owen’s Robohand: Ivan Owen, working together with a man named Richard in South Africa, created a 3D printed prosthetic hand called “Robohand” to help Liam, a 5 year old boy who, due to a birth defect known as Ambiotic Band Syndrome, was born without fingers on his right hand.

27. Cornell University’s Human Ears: Researchers at Cornell University learned how to design and produce lifelike ears that look similar to and perform like real ears. They use a high-density gel made of living cells to mirror the flexibility and durability of an ear’s natural cartilage.

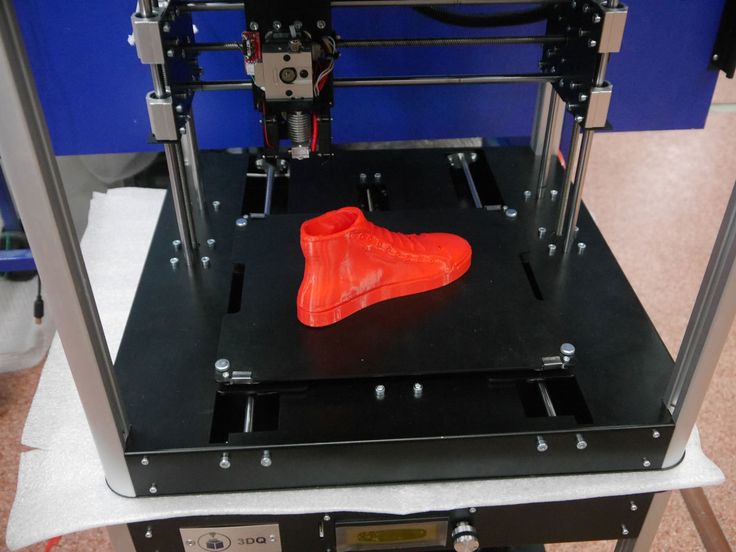

28. Nike’s Football Cleat: Nike used 3D printing to create a cleat specifically designed to help football players get up to speed and come up with their best 40 yard dash time. 3D printing allows the shoe to be contoured perfectly, and it weighs only 5.6 ounces.

29. Oxford University’s Artificial Human Tissue: Scientists at Oxford University have used a custom-built 3D printer to create a material that performs some of the same functions as human living tissues. The material is made of thousands of tiny, connected droplets of water enclosed within thin lipid films. Scientists say these materials may be used to deliver medicine through the body or replace damaged human tissue.

The material is made of thousands of tiny, connected droplets of water enclosed within thin lipid films. Scientists say these materials may be used to deliver medicine through the body or replace damaged human tissue.

30. Japan’s Micro-Bunny: A team of scientists from the Tokyo Institute of Technology, Yokohama National University, and C-MET created a tiny sculpture of a rabbit using 3D printing. This might not sound very exciting, but the bunny sculpture and a number of other whimsical sculptures are only the size of a bacterium. This development opens the door for other micro-printing applications, including fuel cells and biosensor interfaces.

31. MIT’s Artificial Bone: Using a combination of both stiff and soft polymers, researches at MIT successfully 3D printed an artificial bone. By using a combination of materials, they created a composite that is strong and highly resistant to fracturing.

32. NASA’s Rocket Engine Part: NASA, a major supporter of 3D printing, used 3D printing and additive manufacturing to create a rocket engine injector. During testing, the engine component created a record amount of thrust. NASA hopes that 3D printing will help reduce the cost of producing space hardware.

During testing, the engine component created a record amount of thrust. NASA hopes that 3D printing will help reduce the cost of producing space hardware.

33. Solid Concepts’ Metal Gun: Although a 3D gun had already been created earlier in 2013, Solid Concepts was the first to create a metal gun, using powdered metals and a laser sintering process to create a gun made from stainless steel and inconel. The gun has proven itself capable of firing 50 rounds, and because Solid Concepts has a Federal Firearms License, they can provide guns and gun parts to qualifying consumers.

34. Protocell’s Running Shoes: A London designer named Shamees Aden created a prototype for an exciting new kind of running shoes. They are 3D printed to precisely fit the user’s foot and can even by dyed any color for the utmost in customization. Even more excitingly, the shoes, called Protocells Trainers, are made of protocells, a kind of molecule that reacts instantly to light, movement, and pressure. This means that as a user runs, the material can instantaneously react to provide extra to support to areas of high impact. After a run, the shoes can be placed into a jar of protocell liquid, which can repair any tears in the material overnight.

This means that as a user runs, the material can instantaneously react to provide extra to support to areas of high impact. After a run, the shoes can be placed into a jar of protocell liquid, which can repair any tears in the material overnight.

35. Plasticity Production’s Flying Drone: Louis DeRosa of Plasticity Productions used a 3Doodler to create a working hexacopter framed drone. The propellers, computer board, and wires were not 3D printed, but they were fit into a 3D printed frame that could be made extra light because it was printed from plastic threads.

36. LUXeXceL’s Glasses: LUXeXceL became the first company to 3D print both the frame and lenses of a pair of glasses, which they nominally gave the king and queen of the Netherlands before putting them on display. Their project is the first in a number of possible applications of optics-related 3D printing.

37. Hot Pop Factory’s Customized Pez Dispensers: Pez Dispenser Enthusiasts will love the opportunity to have a Pez Dispenser customized with a 3D printed replica of their own head. Hot Pop Facotry in Toronto made these by simply snapping the tops off of typical Pez dispensers and adding on the 3D printed heads.

Hot Pop Facotry in Toronto made these by simply snapping the tops off of typical Pez dispensers and adding on the 3D printed heads.

38. Natural Machine’s Meals: Natural Machines has created a 3D printer called Foodini that can assemble entire meals, including pasta, pizza, chocolate, and cheeseburgers, that can then be cooked.

39. Buttercup the Duck’s Foot: Buttercup was a duck born with a backwards foot. She was unable to walk properly, causing her a lot of pain and limiting her chances of a long life. After her foot was amputated, a 3D Printing Company called NovaCopy designed a 3D printed foot based on a scan of Buttercup’s sister’s foot. Now Buttercup can walk properly.

40. Insects au Gratin’s Bug Biscuits: As part of an exhibition at the Wellcome Collection in London, Susana Soares designed a 3D printer that creates biscuits made from insect flour.

41. Victoria’s Secret Lingerie: Victoria’s Secret teamed up with Shapeways to create a 3D printed corset made of an intricate design with thousands of Swarovski crystals.

42. Automotive Industry’s Prototypes: Both General Motors and Ford have begun using 3D printing to more quickly create prototypes for car parts, such as brake rotors, floor consoles, and shift knobs.

43. Emma’s Magic Arms: A toddler named Emma was born with a rare disease called ARthrogryposis Multiplex Congenita, which left her unable to lift her arms. Researchers at Nemours created a 3D printed exo-skeleton that allows her to lift and control her arms. Because it is 3D printed, parts can also be replaced quickly as Emma grows or if they break.

44. FabCafé’s Gummy People: FabCafe, a company in Japan, enabled men to create 3D scans of themselves that were turned into gummy shapes, as an alternative to gummy bears. FabCafe envisioned them as gifts that men could give their girlfriends on romantic occasions.

45. Mixee Labs’ Mixee Me: Mixee Labs is drawing on the customizable power of 3D printing to make mini figurines that can be customized to look like you. They’re available through Amazon.

They’re available through Amazon.

46. Cubify’s Sculpted iPhone Case: There are many 3D printed phone cases out there. This one takes full advantage of 3D printing by turning photographs into 3D sculptures on the back of a phone case.

47. Eye of Gyre’s 3D Printing Photo Booth: The Eye of Gyre in Japan has used a traditional photo booth setup to produce 3D figurines. They take photos from all angles to create extremely accurate miniature replicas.

48. The Sugar Lab’s Sugar Sculptures: The Sugar Lab is using sugar as a building material for 3D printing, creating beautifully intricate sugar sculptures. Some may be used for intricate wedding cakes and decorative sugar cubes for coffee.

49. Emerging Objects’ Earthquake-Proof Column: Emerging Objects has used 3D printing to create columns modeled on an Incan building technique: closely interlocking blocks that fit together without mortar. They can shift slightly while remaining stable, making them resistant to damage from earthquakes.

50. Jin Hai Lake Resort’s Salt Rooms: Jin Hai Lake Resort in Beijing is 3D printing parts to make rooms out of salt for their resort. The salt walls are constructing from a matrix of geometric shapes that allow light to pass through.

51. Building Bytes’ Bricks: Architect Brian Peters has designed a 3D printer that produces bricks. He envisions them mass-producing bricks made out of ceramic, concrete, or cement right at a construction site.

52. ThinkGeek’s Play-Doh 3D Printer: ThinkGeek is selling a 3D printer targeted towards kids that connects to an ipad, printing any design out of Play-Doh. It’s available for $49.99.

53. Shapeways’ Silver Jewelry: Shapeway created a number of consumer products using 3D printing, including phone cases and jewelry. They can create customized silver jewelry by 3D printing a wax model, created a plaster mold around the model, then casting silver in the mold.

54. Continuum’s “Myth” Line of Shoes: Continuum uses carbon fibre and wood composite to make shoes that are inspired by classical myth. They aim to use 3D printing to create innovative designs and cut out almost all waste in their production process.

Continuum’s “Myth” Line of Shoes: Continuum uses carbon fibre and wood composite to make shoes that are inspired by classical myth. They aim to use 3D printing to create innovative designs and cut out almost all waste in their production process.

55. Continuum’s Bikini: Continuum markets their bikini as the first item of clothing that is made entirely from 3D printing. All of the pieces, including clasps, are made using a 3D printer. They use a material called Nylon 12 that is extremely flexible and strong even in thin pieces.

56. Designs for Hope’s Bicycle Generator: Engineers at the non-profit Designs for Hope designed a generator that could be attached to the back of a bicycle, using the bike’s rotational power to produce energy that can charge electronic devices. They are being used by workers in Uganda who have limited energy to charge their phones.

57. Cokreeate’s 3D Comic Book Cover: Comic Book company decided to make one of their comic books pop with a 3D cover. They used ColorJet Tech to produce a fully colorful 3D cover that matched the original.

They used ColorJet Tech to produce a fully colorful 3D cover that matched the original.

58. Riverhead Books 3D Slip Cover: For Chang-rae Lee’s book On Such a Full Sea, the publishing company wanted to do something a little different. They collaborated with Makerbot to create a limited-edition slip cover for the book, which features the title coming off the front in 3D slanted letters.

59. Bza.biz’s Sound Wave Jewelry: Bza.biz designs 3D printed jewelry, and they’re now using the technology to turn sound waves into 3D designs. Their most popular is a 3D production of the phrase “I love you.”

60. Shapeways’ Inception Top: 3D printing has a lot of potential for creating movie replicas. Shapeways has capitalized on this to create a replica of Cobb’s icon, a spinning top, from the movie Inception.

61. Steelblue’s 3D Map: Steelblue created a 3D printed map of San Francisco for use in showcasing real estate projects. It also sheds new light on city planning and was produced for far less of the cost of traditional 3D models of similar size.

It also sheds new light on city planning and was produced for far less of the cost of traditional 3D models of similar size.

62. Osteoid’s Cast: Turkish company Osteoid has designed a lightweight 3D printed cast for use in healing broken bones. It uses a latticework, which allows air to flow through it, and can be customized based on a scan of the broken arm.

63. Medicrea’s Spine Cage: Continuing the benefits of 3D printing for medicine, Parisian manufacturer Medicrea created a 3D-printed spine cage, which can replace damaged or deformed disks in patients who suffer from spinal instability or disc degeneration.

64. CSIRO’s Mouthpiece: Australian company CSIRO has designed a 3D printed mouthpiece that clears the airflow for people who suffer from sleep apnea.

65. University Medical Centre Utrecht’s Skull: For a woman suffering from a bone disorder that greatly thickened the bone of her skull, neurosurgeons in the Netherlands designed a 3D printed cranium based on her skull. They were then able to successfully implant it, saving her brain from damage.

They were then able to successfully implant it, saving her brain from damage.

66. RUAG’s Satellite Components: RUAG, a Swedish company, has partnered with Altair, a design company, to produce an antenna support for an Earth Observation Satellite. The 3D printed support will be lighter and more efficient.

67. Don Clucas’s Thermodynamic Engine: Don Clucan, a New Zealand man working with the University of Canterbury, has designed a small engine that is made entirely from 3D printing. It runs entirely off of thermodynamics, so all it needs to produce energy is hot and cold water.

68. EMS’s Facial Reconstructions: Typically, forensic facial reconstruction to identify a body is done by adding clay to the skull, but this can damage the skill. A Florida company, Engineering and Manufacturing Services, Inc., has developed a system to take a 3D scan of the skull and then print a lifesize 3D replica.

69. Joy Complex’s Conductors’ Batons: To celebrate Beethoven’s 244th birthday, Joy Complex designed a conductor’s baton that is a visual representation of the sound waves of part of Beethoven’s Symphony No. 5.

5.

70. Aleksandrina Rizova’s Table: 3D printing is an impressive tool for artists and designers, enabling very complex design. Architectural designer Aleksandrina Rizova took advantage of this and teamed up with 3DPrintUK to design a walnut table with intricately curving 3D printed legs.

71. Judith Klausner’s Cameo Replications: Sculptors have always struggled to find a way to reproduce their work in a way that can be sold to average consumers. Judin Klausner, a sculptor, has found a way to do this. She sculpts unique objects: cameos on Oreos made out of Oreo cream. She creates 3D printed replicas that maintain the detail of the originals, but they are relatively cheap to produce.

72. Len Chandler’s New Heel Bone: Len Chandler, and Australian man, has cartilage cancer and developed a tumor in his heel bone. He was facing amputation when his doctors at St. Vincent’s Hospital in Melbourne used 3D printing to create a new artificial heel bone capable of carrying his weight.

73. The Sound City Project’s Recording Device: The Sound City Project aims to capture the full soundscape of a number of US cities. To do this, they 3D printed a recording device that has 4 “ears” reaching out in different directions to capture sounds from all around.

74. Cunicode’s Espresso Cups: Cunicode embarked on a project to design one unique ceramic espresso cup per day and then have them 3D printed by Shapeways. The results are an impressive mix of the beautiful and the entertaining.

75. Tokyo Virtual World’s Landmark Replicas: A Japanese company, Tokyo Virtual world, specializes in making 3D models and dioramas. They are creating replicas of famous buildings, such as the Colosseum in Rome and the Eiffel Tower in Paris, with a high level of detail.

76. Ultimate Ears’ In-Ear Monitors: Most musicians need in-ear monitors to properly hear their music while on stage or recording. Ultimate Ears is using 3D printing to create customized in-ear monitors that will improve comfort and performance.

77. PetPrints3D’s Pet Replicas: Throughout the years, many people have wanted to create something to honor and remember their pets. PetPrints3D uses pictures taken from multiple angles to create customized small statues of pets, taking pet portraits to the next level.

78. University Hospital of Montepellier’s Embryo Model: Doctors at this hospital have a process to 3D print a model of the embryo of woman who will undergo in vitro fertilization. This allows them to fully examine the embryo and make preparations for the most successful fertilization attempt possible.

79. Morgan Stanley Children’s Hospital Infant Heart: A newborn baby at the hospital was suffering from a congenital heart defect. Surgeons created a 3D printed replica of the baby’s heart so that they could study it and prepare for exactly what they needed to do in surgery, enabling them to save the baby’s life.

Future Examples of 3D Printing

80. Plastic Bank’s Recycled 3D Printing: Plastic Bank is working on a project that will collect plastic waste and use it to 3D print everyday items. Their goals are to remove plastic waste from oceans and help poor communities by offering them credits for plastic collections.

Plastic Bank’s Recycled 3D Printing: Plastic Bank is working on a project that will collect plastic waste and use it to 3D print everyday items. Their goals are to remove plastic waste from oceans and help poor communities by offering them credits for plastic collections.

81. NASA’s 3D Printed Food: NASA is funding a project to develop 3D printed food, which could be used to provide astronauts on long duration journeys with more varied and nutritional food, with some en-route customization.

82. Marcelo Coelho’s Digital Chocolatier: Marcelo Coelho, using MIT’s lab, has created a digital printer for making and testing out different chocolate confections. It combines layers of different ingredients and allows users to keep track of calories and rate different recipes as they try them. So far, it only exists as a prototype.

83. Cornell’s 3D Printed Meals: Scientists at Cornell University’s Computational Synthesis Lab are working on creating a syringe-based 3D printer that can make any kind of meal. They’re still working on developing liquid-based ingredients, but they imagine the printer can be used to create meals with customized taste and texture and with exactly the nutrients people need.

They’re still working on developing liquid-based ingredients, but they imagine the printer can be used to create meals with customized taste and texture and with exactly the nutrients people need.

84. NASA’s Houses on Mars: Working for NASA, the University of Southern California’s Viterbi School of Engineering is working on 3D printer that uses concrete to build entire houses. They hope they’ll be able to use natural materials on Mars to construct buildings as part of a settlement there.

85. Airbus Cabins and Parts: Airbus is already using 3D printing to manufacture a small number of parts. They hope to expand their use of 3D printing to create more parts and eventually entire cabins.

86. ESA’s Lunar Base: One of the challenges of building in space is that transporting materials is very difficult. 3D printing allows local materials to be used. ESA is planning to use a 3D printer to construct walls of a lunar base out of lunar soil, which will go around an inflatable core.

87. University of Toronto’s Skin: Engineering students at the University of Toronto won a grant from the James Dyson Awards program for their PrintAlive Bioprinter, which can create 3D printed, skin-like material that will hopefully one day be able to do for grafting procedures following severe wounds.

88. NASA’s Microgravity 3D Printer: NASA recently granted funding to Made in Space Inc. to work on building a 3D printer that can function in the microgravity of space. This printer should be able to manufacture parts without the need for supplies coming from Earth.

89. Harvard’s Batteries: Harvard is working on 3D printed lithium-ion microbatteries. These are so small that they’ll be thinner than a human hair, opening up opportunities for powering medical implants and tiny robots.

90. Mink’s Makeup: Mink or working on launching a 3D printer, targeted towards young women, that allows them to choose any color and print it into eye shadow, lip gloss, or blush. It aims to drastically expand the color palette available at most makeup stores.

It aims to drastically expand the color palette available at most makeup stores.

91. Modern Meadow’s Meat and Leather: A US startup called Modern Meadow is working on producing leather and meat products without animal tissues. He believes he can use a stem cell sample to create hundreds of live cells, then print them into meat-like products.

92. Contour Crafting’s Houses: The same team working on designing a Mars base for Nasa, Contour Crafting, is developing very large 3D printers that can build entire houses based on a computer design. It even includes the necessary conduits for plumbing and electrical work.

93. NASA’s Wood: NASA has given a grant to researcher Lynn Rothschild at Stanford University to develop the technology for 3D printing wood. Her printer will print out culture cells that will then be able to excrete wood, just like that from a tree. This will enable astronauts to have building supplies without carrying heavy lumber into space.

94. Organovo’s Human Livers: Organovo is doing a lot of exciting work with 3D printing and human implants. One project they’re working on is 3D printed liver tissue made from human tissue. The livers can be used to test pharmaceutical drugs for liver toxicity and may eventually be available for implants.

95.The American Academy of Ophthamology’s Prosthetic Eyes: Eye cancer can be a devastating disease, and surgery can leave patients missing an eye. Researchers are developing a project to use 3D scanning and printing to create prosthetic eyes that perfectly match the patient’s remaining eye. They should be able to be produced more quickly and cheaply than traditional false eyes.

96. WASP’s Homes: A group named the World Advanced Saving

Project (WASP) is working on a 3D printer which they hope will enable them to 3D print homes for people in third world countries, enabling them to improve people’s living conditions at a low cost.

97. U.S. Army’s War Heads: The U.S. Army is working on a project to 3D print warheads. They’ll be able to control the geometry and add metallic shapes that make the warheads more effective than is possible with traditional manufacturing techniques.

98. Yahoo’s Hands on Search: Yahoo in Japan is creating a search tool, called Hands on Search, that allows blind children to search for objects online. When the computer finds a prototype of the object being searched for, it 3D prints a solid representation of that object, allowing blind children to touch it and learn about it.

99. Freedom of Creation’s Pasta: Janne Kytannen, a founder of the design studio Freedom of Creation, is developing technology to 3D print a range of food, including pasta. She believes that in the future, everyone will be able to 3D print creative and unique shapes for their meals using 3D printers at home.

100. Rescue missions and military operations: Super high-tech on-board 3D printers, via Additive Layer Manufacturing and robotic assembly techniques are used in the video example below:

Some additional notes on 3D Printing

Well we hope you have enjoyed our examples of 3D printing.

As 3D printing becomes ever more popular, we think it will be interesting to see how regulations of intellectual property surrounding this technology might change.

Among the many controversies surrounding 3D printing, one of the most famous is gun control. In 2012, a group in the U.S. called Defense Distributed created a 3D printed plastic gun and published the design online, allowing anyone with a 3D printer to create their own gun.

Currently though, in the U.S. it is legal for individuals to produce their own firearms for personal use (excluding assault weapons and Title II weapons such as machine guns). In most of Europe, it is illegal to produce a gun using 3D printing.

3D printing also poses some complicated challenges to intellectual property and copyright. It is possible, for instance, to create a design based on a physical product that already exists, 3D print it, and sell it yourself.

Many online 3D printing communities, such as Thingiverse and Shapeways, include designs for figurines of movie and TV show characters, for example. Usually, these designs stay up unless a copyright holder asks for them to be removed.

Despite these complications, it seems certain that 3D printing is going to continue growing. Companies such as Organovo, Stratasys, MakerBot, and Shapeways are continuing to find new applications for 3D printing and bringing it to an ever-growing audience.

3D printing is also gathering investments and partnerships from many large names, including NASA, Hewlett-Packard, and Amazon. These companies and individuals everywhere are recognizing the potential that 3D printing has.

Perhaps what is most exciting about 3D printing, however, are the possibilities that we can’t yet imagine. The technology of 3D printing has already come so far. It has helped many people and industries and become increasingly accessible.

Furthermore, it is characterized by enthusiastic and creative people constantly creating new uses for it. It seems certain that 3D printing will continue to surprise us in the future.

It seems certain that 3D printing will continue to surprise us in the future.

Examples of positive and negative applications of the 3D printer

Every year 3D printing becomes more and more popular. The 3D printer, as a tool for turning a digital model into a physical object, is gaining popularity, outperforming other production methods in many ways due to its affordability.

But do not forget that a 3D printer is just a tool. A lot depends on how this tool will be used.

Available 3D printing technologies

All 3D technologies can be conditionally divided into 4 types.

Layer by layer welding with molten material.

The principle of operation is similar to the familiar glue gun. The print media is melted to a semi-liquid state in the print head and applied with a nozzle to the print surface where it solidifies. This is how the finished 3D model “grows” layer by layer on the printing table. Not only thermoplastics can be used as consumables, but, for example, chocolate, icing, concrete, etc.

This is the most common type of printer. Inexpensive FDM printers are often used as home assistants. This is facilitated by an inexpensive price and a variety of consumables.

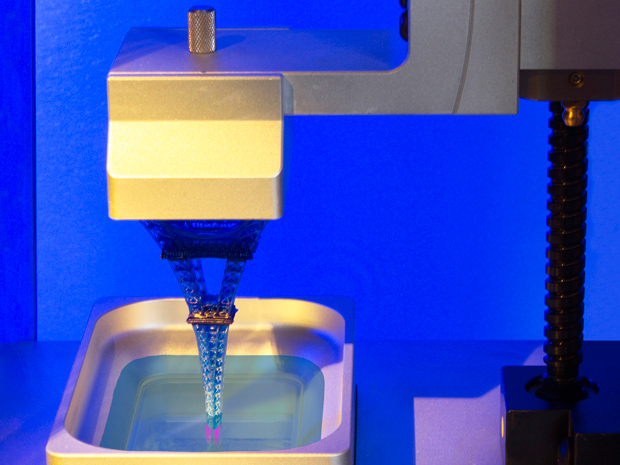

Selective curing of resin (photopolymer printers).

The material used is a photopolymer resin that hardens under the influence of UV radiation. As a source of UV radiation, a thin laser beam, a DLP projector or an LCD screen with a UV matrix, or any other design can be used. For example, some industrial 3D printers apply a photopolymer using thin nozzles and immediately illuminate it with a UV lamp.

Previously, these printers were quite expensive. Today, with advances in technology, photopolymer 3D printing has become affordable and photoresin printers have become popular as home hobby printers.

Selective bonding of powdered material.

On the print head of the printer there are several nozzles through which a binder is supplied, which is selectively applied to the powdered material. Various materials can be used as a material: for example, gypsum or metal powders. But gypsum is most often used.

Various materials can be used as a material: for example, gypsum or metal powders. But gypsum is most often used.

Since dye can be added to the "glue" during printing, such printers are usually used for the production of color demonstration models or souvenirs.

Laser sintering of powdered materials.

The youngest technology, but with great potential for use in large-scale industries. With the help of a laser or a heated print head, selective sintering of the metal powder occurs in an environment filled with an inert gas.

These are already serious industrial printers that are used for the production of functional metal assemblies and parts. Currently, such 3D printers are actively used in the aerospace industry.

Unethical use

3D piracy

Where there is duplication of objects, there are always disputes about copyright and piracy.

The production of any product is a long and painstaking work, and often more than one person. Before you get a finished decorative product, for example, a figurine, you need to think through everything to the smallest detail. Usually, before modeling, the artist draws a lot of sketches, the details of clothing and accessories are thought out. Only after that the 3D modeler gets to work and begins painstakingly recreating the 3D model.

Before you get a finished decorative product, for example, a figurine, you need to think through everything to the smallest detail. Usually, before modeling, the artist draws a lot of sketches, the details of clothing and accessories are thought out. Only after that the 3D modeler gets to work and begins painstakingly recreating the 3D model.

Functional models are often redesigned by engineers after the prototype has been made. There can be a very long way between the initial idea and a stable working mechanism. And it’s very disappointing when such work is simply copied and posted in the public domain.

LEGO

It was one of the first mass manifestations of "3D piracy". At that time, 3D printing was only gaining popularity, and many users, having printed a dozen figurines, were looking for a useful application for a 3D printer. Given the low plastic consumption, the printed LEGO blocks were very inexpensive.

3D printed LEGO bricks

Despite the far from ideal surface, many were satisfied with such a copy. Some have argued that the accuracy of a home FDM printer is not enough for the bricks to fit well with the original LEGO, but for most users everything fit perfectly.

Some have argued that the accuracy of a home FDM printer is not enough for the bricks to fit well with the original LEGO, but for most users everything fit perfectly.

At the moment, LEGO is actively removing models that copy the original sizes of the famous bricks and men from the network. On popular sites, only custom elements of LEGO-men and LECO are left that are not the original size.

Custom heads for LEGO men

Games Workshop

Games Workshop, which produce the most expensive table soldiers in the world, sued Thomas Valenti (USA) back in 2012. Thomas has modeled, printed and made publicly available several miniatures based on the Warhammer universe. The court sided with Games Workshop and the models had to be removed.

3D Printed Chaplain

Chaplain 3D model from Warhammer 40k

Games Workshop went one step further by banning fans from creating art and other work based on the original settings and characters. As a boycott, users of the Warhammer 40,000 section on Reddit are proposing to abandon the company's products as much as possible - print game figures on 3D printers, use paints from other companies, or switch to other universes.

As a boycott, users of the Warhammer 40,000 section on Reddit are proposing to abandon the company's products as much as possible - print game figures on 3D printers, use paints from other companies, or switch to other universes.

Hollywood

The production of modern films is not a cheap pleasure, and film companies try to recoup their costs not only by showing them in cinemas, but, for example, by producing souvenirs.

DreamWorks has an entire consumer goods division that helps recoup the cost of a movie if it fails at the box office. Film companies recognize that fan-made productions often surpass the official "souvenir" in accuracy and detail.

DC Universe Batman fan model

Many film companies are closely following the development of 3D printed merchandise, but do not yet know how to respond. For example, Paramount Pictures, Marvel Studios and Warner Bros. They themselves began to upload models for 3D printing to the network, before the release of new films.

Weapon Seal

Seal of weapons

24-year-old law student Cody Wilson was the first to make a gun on a 3D printer. Cody designed and 3D printed a combat pistol on his own. After 8 years, the idea of making firearms using 3D printing has not only not died out, but flared up with a bright fire.

It started in Texas in 2012. It was there that the company Defense Distributed was registered, the ideology of which was the development of models of firearms that anyone could make on a home 3D printer.

Guns

Liberator

The first “swallow” was the Liberator - a compact plastic pistol printed on a 3D printer from ABS plastic. The only thing that could not be made on a 3D printer was the striker, which was successfully replaced by an ordinary nail. The first printed pistol was made on a Stratasys Dimension SST 3D printer.

Liberator - the name is borrowed from a cheap pistol that was developed in 1942 in the USA.

The Liberator fired a fairly weak .380 ACP round and could only last a dozen rounds at most.

Failed Liberator

Zig Zag

In the spring of 2014, a video appeared on the Internet with a man shooting from a plastic revolver with a huge drum. The video greatly stirred up all of Japan.

Zig Zag

Unknown was Yoshitomo Imura (Yoshitomo Imura) - 28-year-old employee of the Shonan Institute of Technology. Despite Imuru's claim that he fired blanks on the tape, he was arrested and sentenced to 2 years in prison.

The Zig Zag design was a reimagining of revolvers popular in the 19th century, which used a rotating .38 caliber barrel block mounted on a pistol grip.

Washbear

In 2015, mechanical engineering student James Patrick posted a video online showing a 3D printed PM522 Washbear in operation.

PM522 Washbear

The PM522 visually resembled a children's pistol from a science fiction movie, but at the same time the pistol had a strong and rigid frame. Washbear is also safer than its predecessors. At rest, the firing mechanism was not in line with the primer, so the PM522 was protected from accidental firing, for example, when dropped. The only metal part was the nail that replaced the striker.

Washbear is also safer than its predecessors. At rest, the firing mechanism was not in line with the primer, so the PM522 was protected from accidental firing, for example, when dropped. The only metal part was the nail that replaced the striker.

Rifle

Grizzly

Canadian with the nickname CanadianGunNut, ThreeD Ukulele or simply Matthew, inspired by the Liberator project, designed and posted his project - Grizzly. Grizzly is an ABS+ plastic rifle. It took the Canadian 3 days to design the rifle and another 27 hours to manufacture it using a Stratasys Dimension 1200es industrial 3D printer.

Grizzly 9 Rifle0063

The first version of the Grizzly had a smooth and straight .22 barrel. But this turned out to be not a very good decision, and the barrel cracked after the first shot. Subsequently, Matthew replaced the barrel with a tapered barrel with rifling inside.

Plastic “cutting” could not affect the ballistics of the bullet in any way, but added strength to the barrel.

Shotgun

Liberator 12k

The Liberator 12k is a 12-round shotgun made by a well-known, in narrow circles, enthusiast in the world of 3D printing - Jeff Rodriguez.

Liberator 12k

Rodriguez managed to create a simple and at the same time reliable design, "mixing" a pistol and a pump-action shotgun in the design of the Liberator 12k. A huge plus for manufacturing and reliability was the absence of small parts in the shotgun mechanism.

Since the plastic was not strong enough, Rodriguez reinforced the design of the Liberator 12k with metal pins and added metal tubes inside the barrel and drum. The metal parts were purchased from a regular hardware store, so anyone could easily make a Liberator 12k with their home 3D printer.

Semi-automatic weapons

Shuty-MP1

The first sign was the Shuty-MP1, a semi-automatic pistol made by an amateur gunsmith with the nickname Derwood, in April 2017.

Shuty-MP1

Shuty AP-9

The Shuty AP-9 still uses a pistol barrel, but the trigger and return spring are taken from the civilian version of the M16. This improved the reliability of the rifle.

Ethical use

Despite the negative examples of application, 3D printing is actively used in many areas, helping to save time and create products that cannot be produced by other methods.

Medicine

Implants

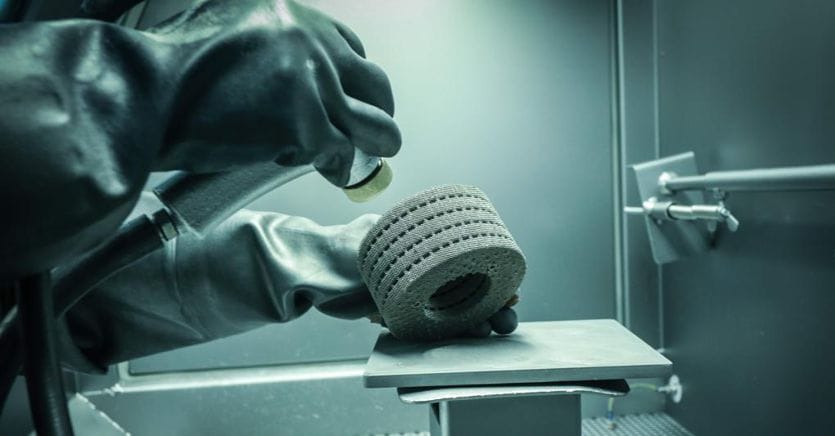

Metal-printing 3D printers are actively used in medicine for the manufacture of titanium implants. For example, a patient needs to have a hip joint implant made. According to the results of CT, the necessary area of bone tissue replacement is agreed with the doctors and a prosthesis model is created that is ideal for this patient. After all approvals, the finished model is sent for printing.

3D model of implant

The main areas of 3D printing of implants in medicine are maxillofacial surgery, traumatology, orthopedics, oncology and veterinary medicine. A big advantage over classical methods of manufacturing implants is the ability to create a cellular or porous structure. This allows for better integration of the prosthesis into the bone tissue.

A big advantage over classical methods of manufacturing implants is the ability to create a cellular or porous structure. This allows for better integration of the prosthesis into the bone tissue.

Samples of printed implants and pins

Dentures

The manufacture of even a relatively simple traction prosthesis is a rather laborious and lengthy process. 3D printing has reduced costs and accelerated the production of prostheses. In addition, it became possible to customize the prosthesis.

Customized child prostheses

Some enthusiasts are modeling and posting models and detailed instructions for assembling traction prosthetic hands and fingers in the public domain so that any user can print and make a prosthesis at home.

Simple Traction Hand Model

Production

Building custom drones

Aerialtronics is a small Dutch company that specializes in building unique, customized drones. Aerialtronics manufactures and develops unique drones, the characteristics of which can vary depending on the needs of the customer.

Initially, a basic concept model was designed, which consists of a platform and a set of elements that can be changed at the request of the customer. Changes can affect almost any part of the drone. The customer can choose the number of motors and their power, payload, flight time, supported software and much more.

Aerialtronics base model

But any, even minor changes in the characteristics and design of the drone required the manufacture of new elements and design changes. Classical manufacturing methods turned out to be quite laborious and long. To save time and money, a Stratasys uPrint SE Plus 3D printer was purchased.

Drone Assembly

Thanks to 3D printing, it was possible not only to speed up production, but also to devote more time to improving individual components, because the finished model is ready the next morning. Rapid manufacturing allows you to print a part, test it, make the necessary changes to the 3D model and make a new sample. Aerialtronics engineers manage to manufacture and test 8-10 variants of a part in a few days in order to achieve maximum quality.

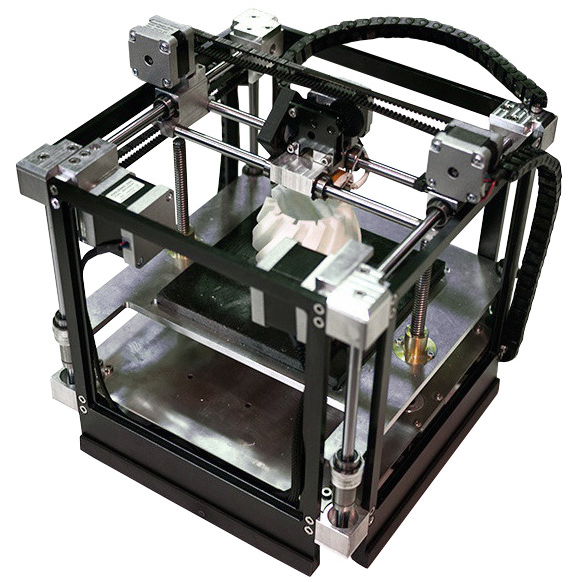

Prototyping

Gas turbine prototyping.

Prototyping by traditional methods is often time consuming and expensive. Because of this, the price of an error in calculations and 3D modeling can be very expensive.

For example, the production of turbine engine parts is usually based on careful preparatory calculations, but even this does not always prevent errors in the production of a test prototype. After all, even the most modern software methods cannot replace physical tests. But due to the high cost (over $20,000), it becomes impossible to produce multiple prototypes for testing.

Turbine Technologies (Wisconsin, USA) and its subsidiary Kutrieb Research have found a way out - 3D printing. Thanks to the 3D Systems ProJet 3D printer, it was possible to reduce the cost of prototyping by about 10 times to $2,000.

3D model and printed part of turbine

A turbine model is printed on a wax 3D printer, tested and then cast from metal. In addition to the cost, it was possible to significantly speed up production. After all, the production of traditional stencils with filling in molds took up to 5 weeks, and the 3D printed model is ready by the morning.

Totals

Despite the unethical side of 3D printing, there are still more positive use cases. 3D printers have become indispensable assistants in various industries - from home hobbies to serious industries. With the help of 3D printers, unique products are made that could not be obtained using other machines.

Popularization of 3D printers is a matter of time. But do not forget that 3D printing is just a tool, just like a drill or a hammer. It depends only on the user how it will be used.

10 most impressive examples of the use of 3D printing

Probably, in 100 years, textbooks will write that the 3D printer has become one of the most brilliant achievements of mankind, and, frankly, our descendants will not be much mistaken. A device that out of the blue makes something out of nothing - isn't this what science fiction writers dreamed of? Of course, the current models of 3D printers are still limited in their capabilities today, but the technology is no more than 5 years old! Nevertheless, truly amazing and useful things are already being created with the help of 3D printing. Let's see what a person needs a 3D printer for today.

Food printing

The most obvious and, admittedly, convenient application of 3D printing technology is, of course, the mass production of food. Hunger times are a thing of the past: a helpful kitchen unit will print at least a juicy steak, at least a chocolate hare, in half an hour. A test model of a food printer was even sent to the ISS in 2015 - astronauts who tasted the “printed” pizza claim that it tastes no worse than a hand-made dish. There is, however, one "but" - printing food is still more expensive than producing it in a proven "grandfather" way.

A house from a printer

Printing houses on a printer is not such an absurd idea. At the same time, several construction corporations from all over the world are working on this technology. In the Netherlands, designers are building an entire skyscraper, assembling it from blocks of composite polymers printed on the spot. In the Celestial Empire, 3D printing technology is used to create both individual houses and entire “boxes” with apartments. A distinctive feature of printing houses is that a huge industrial printer produces them immediately with all communications. Water and sewer pipes, wiring boxes, windows and doorways are built right into the wall. The assembly time of such houses does not exceed several days.

Integrated electronics

Still in testing, this new technology allows you to charge a 3D printer with various materials and polymers, resulting in a working chip. Research teams in Japan and the United States are already doing similar experiments with varying success. A 3D printer capable of producing ready-made and working electronic devices at once will completely revolutionize mass production. In the future, such systems can be bought at home and simply downloaded from the Internet circuits of devices of interest - from a TV to a vacuum cleaner.

Weapon creation

The first working plastic Liberator pistol was 3D printed back in 2012 - since then the technology has been actively improved and finalized. While the “legislators” are discussing the legal aspects of applying the development, the engineers managed to print an assault rifle and a combat pistol on a printer already out of steel. The weapon comes out of print disassembled - the user just needs to assemble it and buy ammo. Is it a blessing or a curse is too complicated a topic that requires a separate article.

Bioprinting

A few years ago, scientists from the MIT biolab created a full-fledged living ear using a special bioprinter, which can be implanted in an injured person. Today, 3D printing technologies make it possible to print bones, vessels and capillaries that are not rejected by the immune system. Medical scientists, meanwhile, are not going to stop working on the existing internal organs. In the future, by donating a drop of their blood, a person will be able, if necessary, to receive spare kidneys, a new liver, or even a heart. In this case, the organs will be grown from the tissues of the carrier itself, which means they will be perceived by the body as “native”.

Cars from the printer

In the summer of 2015, the American company Divergent Microfactories introduced the world's first racing car, completely printed on a 3D printer from an ultra-dense polymer. The only parts of it that were not created on a printing device were the engine and wheels. According to the designers, the assembly and refinement of the car took them no more than an hour. Perhaps, in the future, anyone will be able to print new car cases for themselves, changing them according to their mood.

Printed clothes

An obvious, although not very developed direction of 3D printing of allows people who are completely ignorant of thread and needle to create their own wardrobe in a short time. So far, clothing printing is the lot of single designers and fashion designers, but in the future, this technology can come at least to model houses. Couturiers will finally get rid of threads and needles, creating new clothes on the tablet in just a couple of movements. Meanwhile, Japanese engineers are experimenting with making clothes for medical purposes - such shirts come out of the printer immediately with heartbeat, temperature and pressure sensors.

Gold printer

Oddly enough, 3D printers were almost the first in the jewelry business. Creating blanks, "printing" fitting stands, even making demonstration samples - all this becomes much easier with the use of 3D printing technologies. As technology progressed one step further, jewelers got prototypes of devices that could print with molten gold, producing finished rings, frames, earrings, and other jewelry. The master only needs to refine the finished product, if necessary, grind it, and then encrust it with precious stones, which greatly simplifies any work.

Prosthetics and cybernetics

A custom-fitted prosthesis is just the tip of the iceberg. 3D printing technology makes it possible to create a complete set of parts for the manufacture of prostheses of any complexity in record time. At the same time, the use of a printer gives engineers the opportunity to take into account the individual anatomical features of a person, after which the artificial prosthesis becomes literally an extension of the limb.