How 3d printing is revolutionizing the housing industry

How 3D Printing Is Revolutionizing the Housing Industry

Search

Home / Blogs / Natalie Hutchins's blog

by Natalie Hutchins

23 April 2020

Tags:

architectural

3d printing

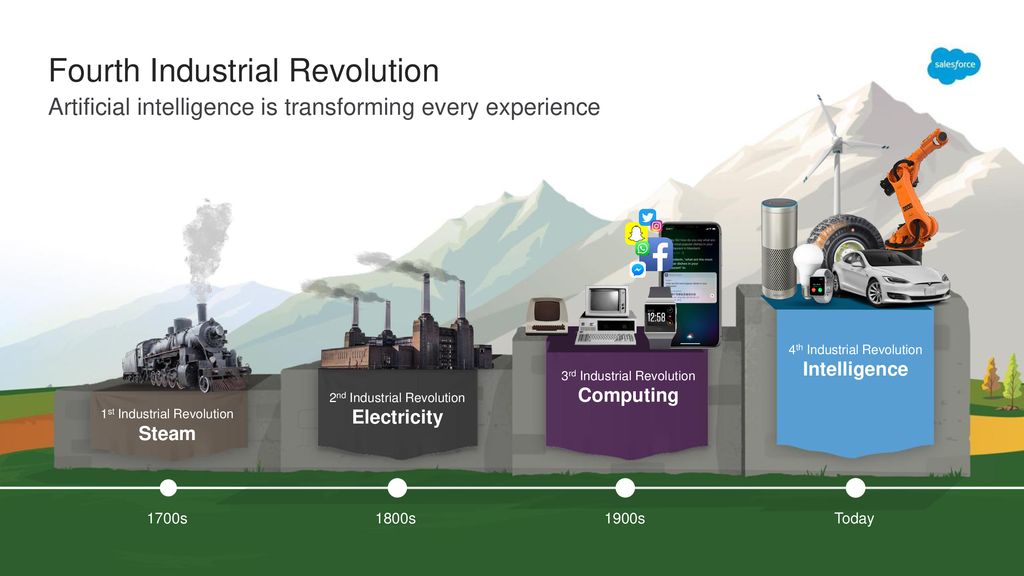

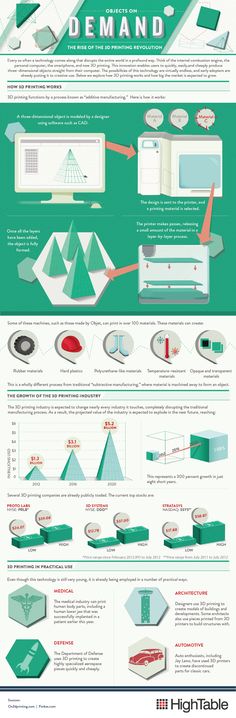

The housing industry has gone through some significant changes in the past couple of years. We are living in an age of rapid technology development, and new tech solutions are affecting various industries. When it comes to the housing industry, no other technology has been more impactful than 3D printers.

We have seen glimpses of what 3D printers can do, and we know there is a great future ahead of them. However, in the housing industry, 3D printers are already making a big change.

The future is now. Companies from all around the world have proven that they can use 3D printers to build (print) homes.

What’s even better is that this technology is applicable as it cuts down costs while giving amazing results. Here is how.

The Current State of 3D Printing in The Housing Industry

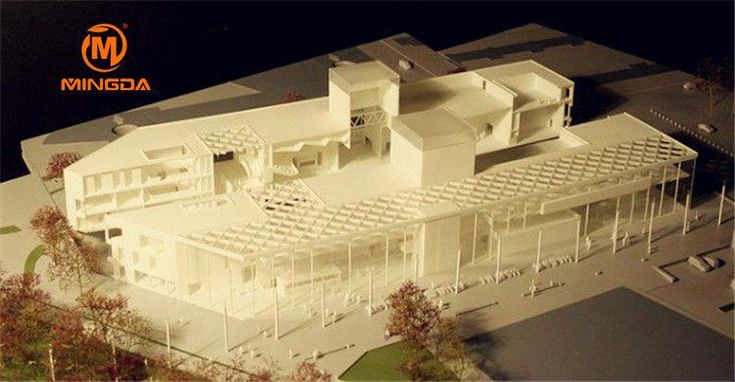

We are currently in a stage where the majority of real estate project scale models are made with 3D imagining. But we are seeing more and more people in the real estate world looking to explore the possibilities of printing 3D houses and buildings.

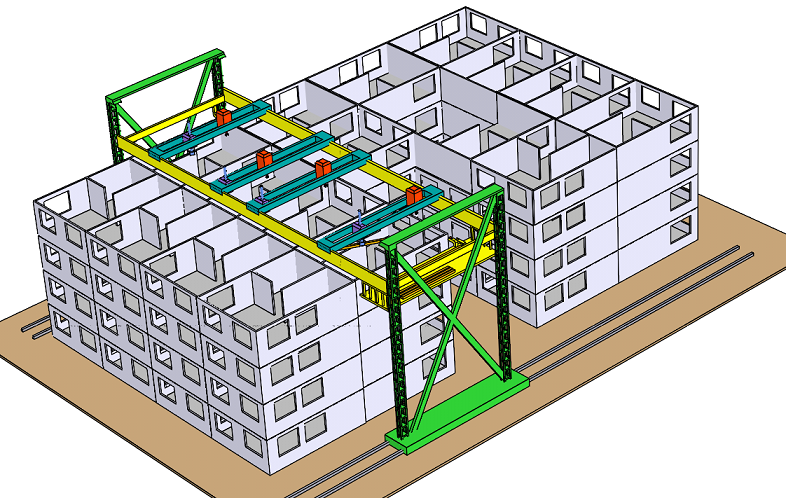

In 2019, a company by the name of Apis Cor built a 3D printed building in Dubai. This is the largest building ever to be published. It’s an office building with around 640 square meters, almost 10 meters high. The Winsun building located in Shanghai is another example of a 3D printed structure.

As we mentioned earlier, the future is now. There are dozens of companies all around the world that are using 3D printing to make homes and buildings. Skeptics predicted that it would take around a decade for the housing industry to feel the effects of this technology, but this is simply not true.

The whole construction industry is already seeing that this is a potential threat. They will have to get on board or lose the market altogether. Here is how 3D printing is changing the game.

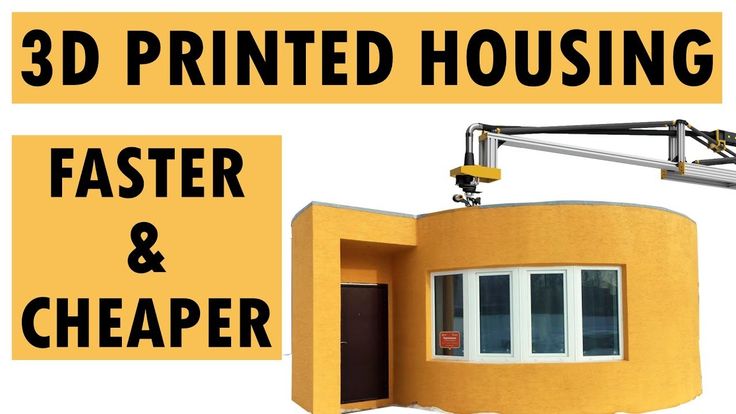

3d printing house

Housing is Cheaper

You might think that this kind of amazing futuristic technology would be super expensive, but it’s not. The housing industry has been struggling for a long time to provide affordable prices. Now more than ever, mainly because millennials don’t have a lot of money to invest in real estate.

The housing industry has been struggling for a long time to provide affordable prices. Now more than ever, mainly because millennials don’t have a lot of money to invest in real estate.

Some of the biggest reasons why the industry struggles to provide affordable housing are:

- Expensive building materials

- High labor costs

- Logistic costs

- Effective project management

3D printing has the potential to neutralize all of these problems with ease. This method of construction usually requires one or two types of materials. It also needs much fewer people working on the construction process as the printer does most of the work.

On top of that, there are already printers that have built homes in a day. All of these things drastically reduce costs. Even if the materials and labor weren’t the issues, big cities are very crowded, and having an active construction site can be really costly.

We Are Witnessing Construction Speeds That Never Happened Before

As we mentioned earlier, there are already examples of 3D printing companies building homes from scratch in a day. A day! This has never been done before in history. Imagine your typical day, going to work, coming home to spend time with your family, and when you get up the next day, your brand new house is finished.

A day! This has never been done before in history. Imagine your typical day, going to work, coming home to spend time with your family, and when you get up the next day, your brand new house is finished.

With the current standards in the industry, it takes months to build a home. Even then, customers need to pay a lot of money for additional labor, machinery, and materials to speed up the process. With 3D printers, this is so much easier.

There are also examples of transportable 3D printers that can be brought to the site and print a home on the spot. This has severe ramifications for the whole industry as construction companies cannot compete with this pace.

Just imagine giving customers the option to get a home in 9 months or a day, which one will they choose?

Better Approach

With current construction methods, the construction site also needs to be considered. Not every place is suitable for construction. Even if a piece of land has enough room for a house, there often isn’t room for equipment, materials, and construction machines.

This brings new issues like having to lease the area around for your construction efforts and so on. On the other hand, some areas are simply inaccessible by machinery, and construction can’t be done. With 3D printers, this is not that big of an issue.

Even those portable printers require far less space, and developers can use them in a much wider range of areas. What does this mean for the current housing industry? It means that these machines can even access markets that are currently unavailable to them.

Customers that are turned down by current developers will be able to get their projects executed by 3D printing companies.

3D Printing Materials Are Eco-Friendly

Most building materials for 3D printing are resistant to pests like insects and rodents. They are also resistant to exterior factors like mold, water, and sunlight. At the same time, these materials don’t harm the environment while offering sturdy constructions.

A lot of the companies that specialize in developing and using these technologies recycle various materials. Their build materials consist of glass, plastics, and other trash. So, this means that there is no need for new natural resources, but also that they’re cleaning up the environment.

Their build materials consist of glass, plastics, and other trash. So, this means that there is no need for new natural resources, but also that they’re cleaning up the environment.

Apart from this fact, this also reduces their development costs. These companies don’t need to buy as many new materials when they can recycle old ones. In the end, this means that buyers will benefit since they will have to pay a lower price.

They Are Easier to Design

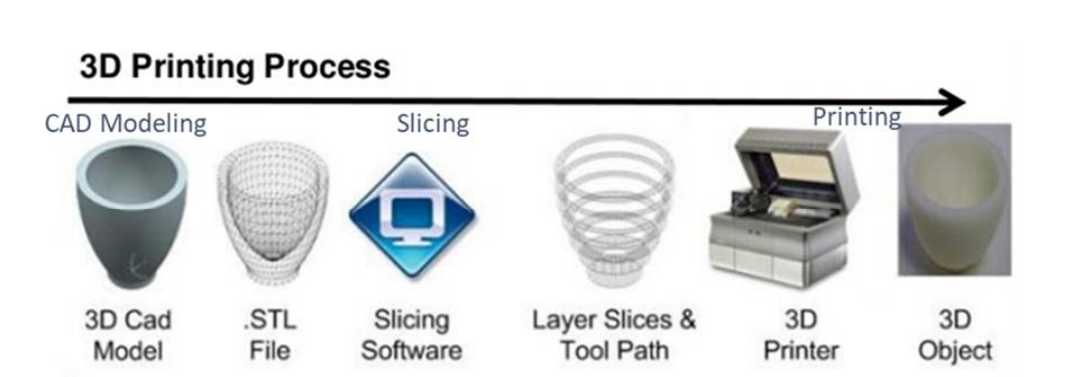

The introduction of 3D visualization and imaging has completely changed the way these projects are done. Construction projects have been brought into the digital world. They are designed and developed on a computer.

On top of that, with 3D visualizations, customers can see a realistic representation of their future homes. They can visualize how the whole place will look, suggest changes, and be deeply involved in the process. However, with typical development methods, the home is built from the ground up.

If a customer is unsatisfied with something and they want it changed, it involves backpedaling, more time spent, and additional costs. With 3D printing, the project doesn’t start until everything is set in place.

Furthermore, there is usually no need for a contractor, and customers can design their own dream homes from scratch. They have more control over the process and can give input that determines the outcome.

Conclusion

This is only the start of the house 3D printing era. We are already seeing major benefits that will shake the housing market to its core. What’s even more amazing is that this technology and processes are still developing, and there are unlimited potentials.

The whole industry will have to buckle up and make significant changes. Current housing developers will have to adopt 3D printing as well to stay competitive or lose the battle.

Popular blogs

What are the subdivision costs in Australia?

Best home building and design apps

Knowing the Difference between a Smart TV and an Android TV

What is an After builders clean ?

How to Build a Tree House

How to Repair a Hole in Your Gutter

Natalie Hutchins

Natalie has been an avid blogger for 5 years, with particular interests in CAD and related technologies. She is now associated with IndiaCADworks. Her other interests are in social media, movies and photography.

She is now associated with IndiaCADworks. Her other interests are in social media, movies and photography.

Message

Pictures

Blog archive

2020

April (1)

See previous newsletters

The ideas gallery

How 3D Printed Homes Are Changing the Industry

In the past, the idea of printing an entire home sounded like a far-fetched novelty. However, 3D printing is quickly becoming construction’s most promising solution.

In recent years, construction companies have made great strides in 3D printed homes. The revolutionary technology allows companies to explore new structural forms, reduce waste and costs, and improve the safety of construction sites. The 3D housing industry alone is estimated to reach $40 billion by 2027, a huge growth from the $70 million market in 2017.

When it comes to the housing market, building homes in time-intensive and costly — the average cost in the United States is almost $290,000 over a span of 6 months. Firms from around the world are innovating new projects to meet the challenge, from Russian firm Apis Core’s concrete home that was printed in a mere 24 hours to Austin-based startup ICON’s $10,000 650-square foot home. As housing costs and urbanization continue to escalate across the globe, 3D printing homes offers a solution that’s affordable, sustainable, and cost-efficient.

Firms from around the world are innovating new projects to meet the challenge, from Russian firm Apis Core’s concrete home that was printed in a mere 24 hours to Austin-based startup ICON’s $10,000 650-square foot home. As housing costs and urbanization continue to escalate across the globe, 3D printing homes offers a solution that’s affordable, sustainable, and cost-efficient.

Along with innovative materials and green buildings, 3D printed homes are opening a new frontier in housing. Read on to learn more about homes are 3D printed, the benefits they offer, and how they will shape the future.

The Benefits of 3D Printed Homes

Printing homes offer real cost, speed and waste advantages. They have the potential of solving the housing crisis with affordable housing, combating natural disasters with immediate shelter, and improving the construction industry with more efficient job sites. The construction industry faces also serious challenges with productivity and waste. With the ability to rapidly and precisely fill in walls, 3D printing can conserve resources while maximizing the use of staff for more hands-on processes, like using forklifts to build the roof and manually placing in windows.

With the ability to rapidly and precisely fill in walls, 3D printing can conserve resources while maximizing the use of staff for more hands-on processes, like using forklifts to build the roof and manually placing in windows.

The developments in 3D printed homes show that low-cost housing can be affordable, comfortable, and even elegant. The possibilities are real for the millions of people around the world who struggle with basic housing

Challenges

As promising as the technology is, 3D printing is still in its infancy. Buildings are complex structures that adjust to our living habits and provide shelter in all kinds of situations. Printed homes follow a set design, meaning it is less flexible to change or improve the design during construction. While concrete is efficient, the technology is still being refined and not yet capable of producing smooth and perfect surfaces.

New Trends

Despite its shortcomings, 3D printed technology continues to undergo innovations to become a viable, long-term housing solution. Firms are testing multiple printers on site to better execute projects, while experimenting with new methods and materials mixes such as wine and bioplastics.

Firms are testing multiple printers on site to better execute projects, while experimenting with new methods and materials mixes such as wine and bioplastics.

As construction companies continue to innovate, 3D printed homes are becoming even more sophisticated and accessible. With strong benefits and developing projects, the question is not whether 3D printing is an effective construction technique. Rather it’s how we can best implement the technology to solve the construction industry’s biggest concerns.

Additional Sources

Sculpteo | All3DP | Wired | CNet | Architectural Digest | Artsy | Compare My Move | The Guardian | Digital Trends | The National | Architect Magazine

Related Posts

How are 3D printers changing the real estate market right now?

LonGrad

Your next home can be printed

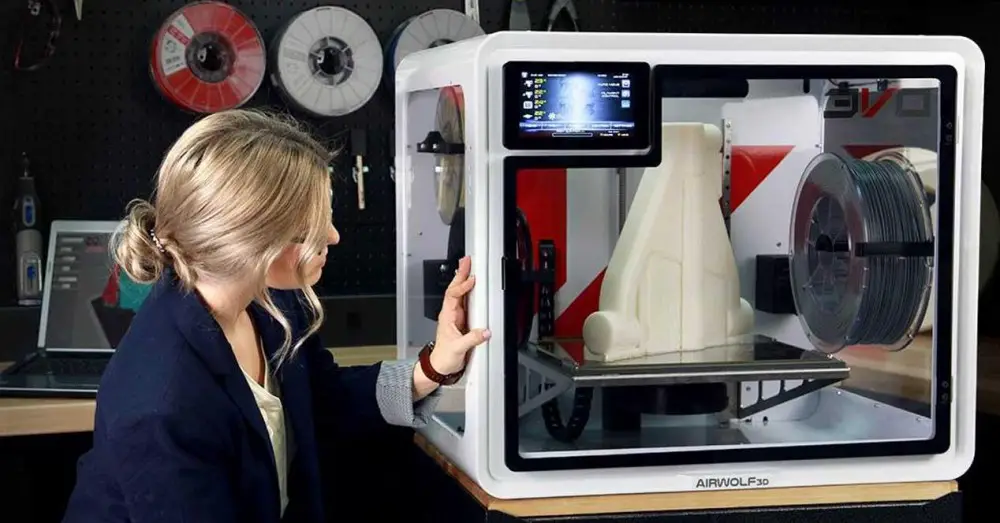

Several new homes across California are selling unusually fast. In the last two months, 82 houses have been sold out, and another 1,000 are on the waiting list. However, the wait doesn't have to be long: while a typical brick home can take weeks to build, Palari Homes and Mighty Buildings can build one in less than 24 hours. This is due to the fact that their objects are assembled from pre-assembled components at the factory. The idea itself is not new, but in this case the components are obtained in an unusual way: they are printed. nine0007

However, the wait doesn't have to be long: while a typical brick home can take weeks to build, Palari Homes and Mighty Buildings can build one in less than 24 hours. This is due to the fact that their objects are assembled from pre-assembled components at the factory. The idea itself is not new, but in this case the components are obtained in an unusual way: they are printed. nine0007

Plan of a five-acre 3D printed development in Rancho Mirage, California.

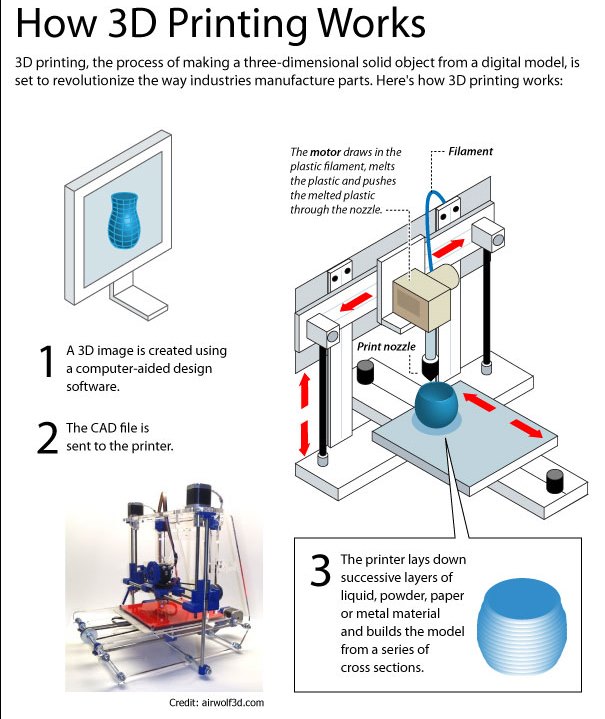

3D printing has been around since the early 1980s but is now gaining momentum. It is already being used to make everything from orthopedic implants to aircraft components.

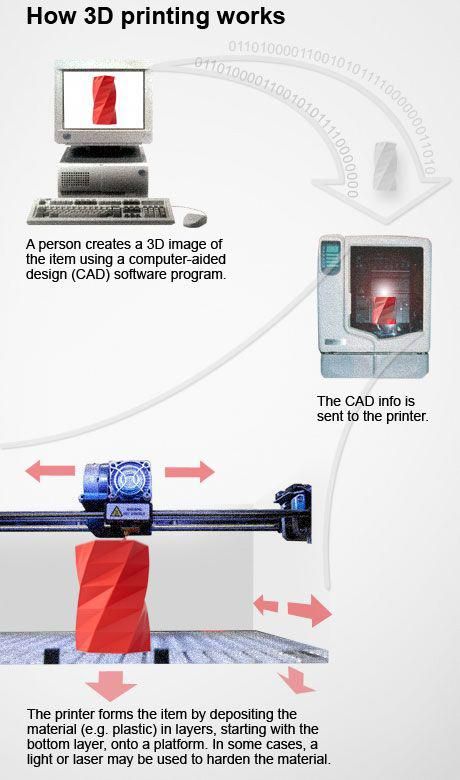

Details vary between products and processes, but the basic principle remains the same: a layer of material is laid and fixed, another one is placed on top of it, and then another and another. By changing the shape and sometimes the composition of each layer, it is possible to create objects that would be difficult or impossible to make with more traditional methods. In addition, unlike traditional manufacturing processes, there is no waste of materials. nine0003

In addition, unlike traditional manufacturing processes, there is no waste of materials. nine0003

3D printing houses is the greenest way to build

In the case of Palari Homes and Mighty Buildings, the printers are much larger than those required for artificial knees and airplane wings, and the materials are somewhat rougher. But the principle remains the same. The nozzles extrude a paste (in this case, composite), which then hardens under the influence of ultraviolet light. This allows Mighty Buildings to print details such as cornices and ceilings without the use of reference forms - as well as simpler things like walls. They are then assembled on site and attached to a permanent foundation by the builders of Palari Homes. nine0003

Not only does 3D printing provide versatility and faster construction, it also promises a lower cost and more sustainable approach than traditional construction methods currently offer. This could be the answer to two of the problems the world is currently facing: housing shortages and climate change. About 1.6 billion people - more than 20% of the world's population - do not have adequate housing. And the construction industry accounts for 11% of global anthropogenic carbon dioxide emissions. At the same time, the industry does not show success in reducing its carbon footprint. nine0003

This could be the answer to two of the problems the world is currently facing: housing shortages and climate change. About 1.6 billion people - more than 20% of the world's population - do not have adequate housing. And the construction industry accounts for 11% of global anthropogenic carbon dioxide emissions. At the same time, the industry does not show success in reducing its carbon footprint. nine0003

Automation brings huge cost savings. Mighty Buildings says computerizing 80% of the printing process means the firm only needs 5% of the workforce it would otherwise have. It also doubles the rate of production. This is good news for the construction industry, which has struggled for years to increase its productivity. According to the McKinsey consulting firm, over the past two decades, the industry has grown by only a third of the overall level of productivity in the global economy as a whole. Digitization is slower than almost any other industry. In many places, the industry also suffers from a shortage of skilled labor. And it is expected that the situation will not improve further. In America, for example, about 40% of construction workers are expected to retire within the next decade. nine0007

And it is expected that the situation will not improve further. In America, for example, about 40% of construction workers are expected to retire within the next decade. nine0007

3D printer at Mighty Buildings headquarters.

The environmental benefits come in many ways, but the important thing is that you don't have to move a lot of heavy objects. For example, Palari Homes estimates that assembling its products reduces the number of truck rides needed to build a home by as much as two tons of carbon dioxide emissions per home are reduced.

Palari Homes and Mighty Buildings are not alone in their endeavors: similar projects are being launched everywhere. The vast majority of structures are printed using concrete. 14Trees, a joint venture between Holcim (the world's largest cement producer) and CDC Group, the UK government's development finance organization, operates in Malawi. Its representatives claim that it is possible to print a house in just 12 hours for less than $10,000. 14Trees notes that this process is not only cheap and fast, but also environmentally friendly. Holcim says that by applying the exact amount of cement needed and thus reducing waste, 3D printing generates only 30% of the carbon dioxide produced by fired clay bricks. nine0003

14Trees notes that this process is not only cheap and fast, but also environmentally friendly. Holcim says that by applying the exact amount of cement needed and thus reducing waste, 3D printing generates only 30% of the carbon dioxide produced by fired clay bricks. nine0003

Meanwhile, in Mexico, the homeless charity New Story partnered with 3D printing firm ICON to build ten 46-square-meter houses. Each of these houses was printed in about 24 hours (although those hours were spread over several days), with the final elements collected by Échale, another local charity. In Europe, the first 3D-printed house on the continent was built in Eindhoven, the Netherlands - the keys to it were handed over to tenants on July 30. nine0007

First 3D printed house in Europe. Based in Eindhoven, The Netherlands.

Layer cake

The house in question, the first of five detached two-bedroom houses in a project coordinated by the Eindhoven municipal government and the City University of Technology, is the result of a collaboration between several firms. The Dutch division of the French building materials company Saint-Gobain developed the required concrete mortar. Construction firm Van Wijnen erected the structure, while consultant Witteveen + Bos was in charge of the design. The building is leased by its owner Vesteda, a Dutch residential property investor. nine0007

The Dutch division of the French building materials company Saint-Gobain developed the required concrete mortar. Construction firm Van Wijnen erected the structure, while consultant Witteveen + Bos was in charge of the design. The building is leased by its owner Vesteda, a Dutch residential property investor. nine0007

3D printed house project in Eindhoven, The Netherlands

However, using cement in these projects is not an environmentally friendly process. It converts calcium carbonate in the form of limestone to calcium oxide and carbon dioxide, and this process is believed to account for about 8% of anthropogenic emissions of this gas. So a group at Texas A&M University, led by Sarbajit Banerjee, developed a way to do without cement.

Dr. Banerjee's new building material was inspired by a project he initiated years ago. It was a program to build access roads to remote areas of the Canadian province of Alberta using materials at hand. The crushed stone he invented combined local soil with wood fiber mulch and was held together with liquid or water-soluble silicates, which then hardened and acted like cement. To build houses, he uses clay and stone debris that lie under the top layer of soil near the construction site, grinds them into powder and mixes with silicates. The resulting mixture can be squeezed out through a nozzle, after which it will quickly harden and gain strength to maintain its shape and withstand the weight of the next layer. This makes the process doubly "green": it eliminates both the cement and the need to transport to the construction site, often over long distances, the sand and aggregates used in conventional concrete. nine0007

The crushed stone he invented combined local soil with wood fiber mulch and was held together with liquid or water-soluble silicates, which then hardened and acted like cement. To build houses, he uses clay and stone debris that lie under the top layer of soil near the construction site, grinds them into powder and mixes with silicates. The resulting mixture can be squeezed out through a nozzle, after which it will quickly harden and gain strength to maintain its shape and withstand the weight of the next layer. This makes the process doubly "green": it eliminates both the cement and the need to transport to the construction site, often over long distances, the sand and aggregates used in conventional concrete. nine0007

Benefits of cement

There are limits to building 3D printed houses. To begin with, it is necessary to create a legislative framework for the construction of such houses. To this end, UL, one of America's largest certification agencies, collaborated with Mighty Buildings to develop the first 3D printing standard. Its principles will be incorporated into the new International Housing Code, which is in use or has been adopted by every US state except Wisconsin. While this is a welcome move for a young industry, most governments have yet to develop country-specific standards. There are also questions about the quality and finish of houses built on 3D printers. nine0003

Its principles will be incorporated into the new International Housing Code, which is in use or has been adopted by every US state except Wisconsin. While this is a welcome move for a young industry, most governments have yet to develop country-specific standards. There are also questions about the quality and finish of houses built on 3D printers. nine0003

Nevertheless, the prospects look promising. Last year, Germany approved plans to 3D print an apartment building. The three-story structure of the German construction company Peri is assembled from parts made using printers developed by the Danish company Cobod. This building will have five apartments. The use of the technology is also expanding in the Middle East and Asia. The Dubai government wants a quarter of the country's new buildings to be 3D printed by 2030 and is dedicating an entire area on the outskirts of the capital to house 3D printing companies and their warehouses. Saudi Arabia plans to use 3D printing to build 1. 5 million homes over the next decade. India's Ministry of Housing and Urban Development wants to use 3D printing to solve the country's housing shortage. nine0003

5 million homes over the next decade. India's Ministry of Housing and Urban Development wants to use 3D printing to solve the country's housing shortage. nine0003

If successful, 3D printed construction could expand beyond the residential sector: warehouses, offices and other commercial buildings have good prospects. The US space agency NASA is exploring the use of 3D printing to build landing sites, living quarters and roads on Mars and the Moon. There is no soil on these two celestial bodies, only crushed rock called regolith. Dr. Banerjee's group, which works with NASA, says their 3D printing approach also works well with this material. “Ultimately we would like to have real estate on Mars and the Moon, but we won't be able to carry concrete with us there,” says Dr. Banerjee. "We'll have to work with the regolith." nine0007

If you are interested in options for alternative construction methods in order to increase the return on investment, then contact us! Longrad has been actively working with developers who build prefabricated houses for several years. These technologies are several times faster than traditional methods, which helps to achieve significantly higher returns. You can get a free consultation by phone +447792174059 (WA, Telegram), via email [email protected] or by filling out the form below. We will be glad to work with you! nine0066

These technologies are several times faster than traditional methods, which helps to achieve significantly higher returns. You can get a free consultation by phone +447792174059 (WA, Telegram), via email [email protected] or by filling out the form below. We will be glad to work with you! nine0066

You may also be interested

Billionaires invest in luxury real estate during the pandemic

In total, in the first 6 months of 2021, wealthy buyers from around the world spent 13.8 billion on the super premium real estate market

Why is Fulham attracting homebuyers during the pandemic?

The small-town atmosphere and the desire of many during the pandemic to live in a spacious house has rapidly increased the attractiveness of Fulham over the past year. nine0003

You may also be interested

Billionaires investing in luxury property during the pandemic

The UK property market is expected to slow down after the end of preferential holidays

Stamp duty when buying property in England in 2021

Save yourself £

1000free consultation

Future technologies: 3D printing

General technology trends

The first prosthetic hand was created for Gottfried von Berlichingen, who lived in Germany in the 15th and 16th centuries and lost his right hand during one of the battles. Medieval craftsmen made an iron hand for him, which not only allowed him to look like an ordinary person, but also to hold a sword in it. Today, this hand is in the museum of the Hornberg family fortress as a reminder of how the “bionic” prostheses began.

Medieval craftsmen made an iron hand for him, which not only allowed him to look like an ordinary person, but also to hold a sword in it. Today, this hand is in the museum of the Hornberg family fortress as a reminder of how the “bionic” prostheses began.

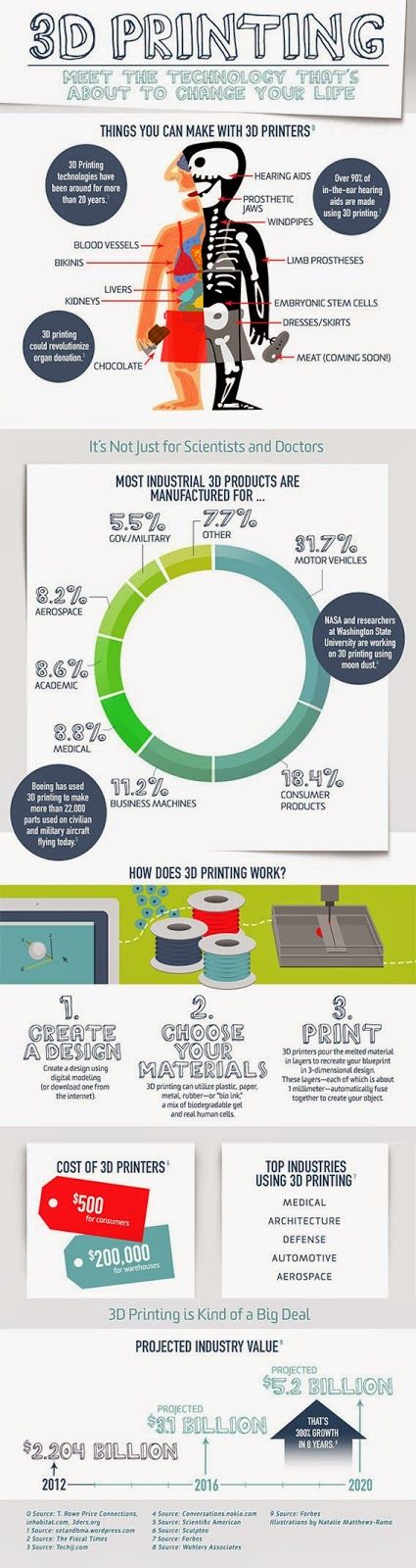

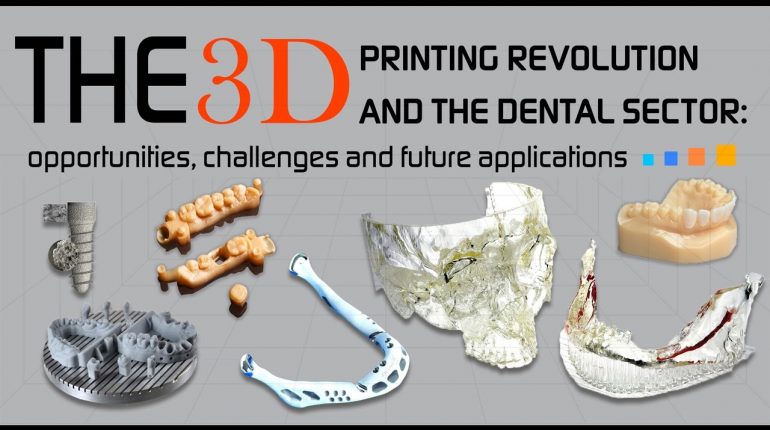

Over the past few years, 3D printing in the medical industry has moved from science fiction to practical applications, with its earliest and simplest use being in the manufacture of implants. The main advantage of such implants is the ideal size that fits a particular patient - because before it is made, a 3D scan and a model of the necessary organ are made. The fabric is created on a 3D printer using the same technology as conventional printing, but different types of cells are used instead of plastic. For example, three types of cells are used to create a liver prototype: hepatocytes, stellate cells, and epithelial cells. nine0003

There is already a patient in the United States who has a part of the skull printed: a successful operation was performed in the state of Connecticut. At the same time, the speed with which the 3D implant was made is amazing - only 2 weeks have passed from the day of the 3D scan to the operation. Entire organs have already been printed at Princeton University: for example, a bionic ear, which not only looks like a real one, but also contains an antenna sensitive to sound waves and living cells.

At the same time, the speed with which the 3D implant was made is amazing - only 2 weeks have passed from the day of the 3D scan to the operation. Entire organs have already been printed at Princeton University: for example, a bionic ear, which not only looks like a real one, but also contains an antenna sensitive to sound waves and living cells.

With the help of 3D printing technology, temporary crowns for dentistry, parts of the liver for transplantation, and the like are made. Probably, one of the most important aspects of using 3D printing technology is the production of individual prostheses, which not only perfectly repeat the shape and anatomical features of a particular person, but also contain microscopic holes to increase their strength. nine0003

Today, several models of artificial arms and legs with a fairly high functionality have been developed and printed, allowing even small objects to be used. These models differ slightly from each other, but what they have in common is the high price, which makes them out of reach for most people with disabilities. However, enthusiasts are already developing models using cheaper materials that can be made at home using 3D printers. nine0003

However, enthusiasts are already developing models using cheaper materials that can be made at home using 3D printers. nine0003

For example, at the age of 14, Colorado schoolboy Easton LaChapelle created his first robotic prosthetic hand at home, and eight years later he founded Unlimited Tomorrow, which focused on the production of modern technological prostheses. Such robotic prostheses, perfectly adapted to human needs, can be created using a 3D printer at a cost much less than those that exist on the market today. So the story of the iron hand of Baron von Berlichingen continues through half a millennium. nine0003

...

Impact on society, economy, state

First of all, prosthetics as such allows to keep people with disabilities as an active part of society - this is the basis of inclusion, which is of particular importance in our modern society. And 3D printing allows you to significantly expand the boundaries of both prosthetics and transplants for people who need it, but it is far from being limited to these possibilities. nine0003

nine0003

Already, Aimee Mullins, who is perhaps the most famous athlete and model in the world, is changing her height and forming her own identity with the help of prosthetic legs. In addition to her, one can recall Victoria Modesta, a British singer and fashion model with an amputated left leg below the knee, who turns her own prosthesis into part of her image.

It became possible to print upper limb prostheses on a 3D printer for victims of military conflicts, in particular, for refugees from Syria. The cost of such prostheses does not exceed $20, while the usual price is several hundred. In addition, printed prostheses are lighter than traditional ones, which is also important. nine0003

In addition to limb prosthetics, which is already being done more or less massively with the help of 3D printing, another direction of its development has appeared: for example, printing cells for transplantation into the pancreas. The first bioprinter for such printing has already been transferred to the Adelaide clinic (Australia) and is being used to treat patients with diabetes.

It is also now possible to 3D print the middle ear and restore hearing to a person - the relevant successful research was carried out at the University of Maryland in Baltimore. With the help of 3D printing technology, it is possible to achieve submillimeter level accuracy, which allows to successfully perform operations that, using conventional technologies, are successful in the number of 1 in 1,300 cases. nine0003

And, finally, 3D printing technology in the near future will make it possible to successfully fight infertility — at least, this is evidenced by the first experiments on mice that were printed with an artificial ovary, which made it possible to restore reproductive function. It is worth noting that scientists have not completely created the ovary, but only its basis, since the entire ovary is still too complex in structure to reproduce.

The mass technology of 3D printing in medicine, according to the famous American inventor and futurist Ray Kurzweil, will become only after 2030. And in 15 years, a technology may appear that will allow creating new organs for a person inside the body. nine0003

And in 15 years, a technology may appear that will allow creating new organs for a person inside the body. nine0003

...

General trends in technology development

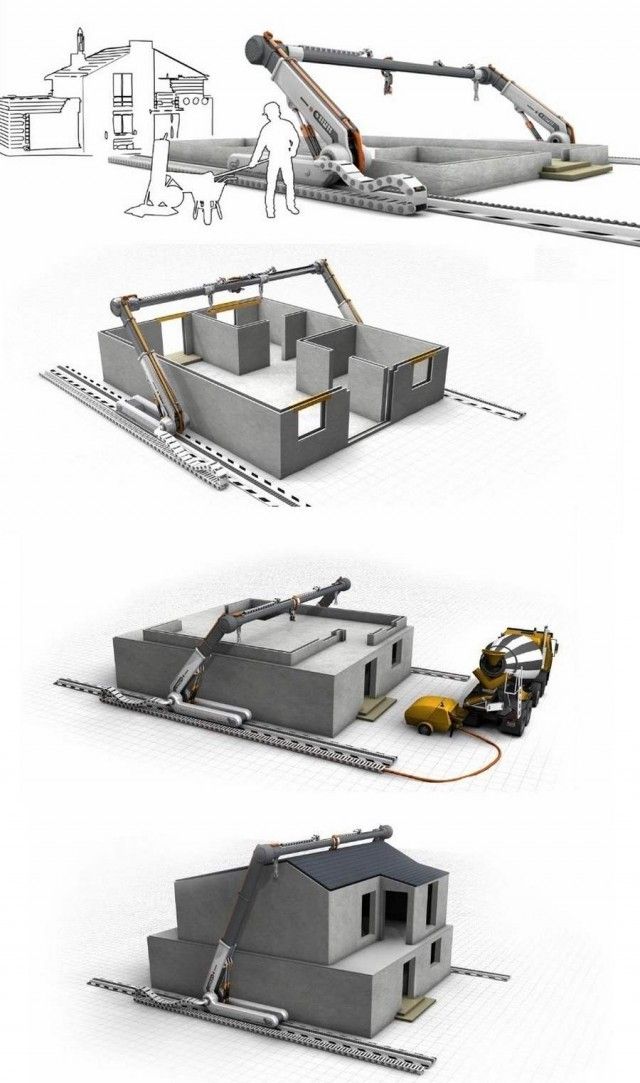

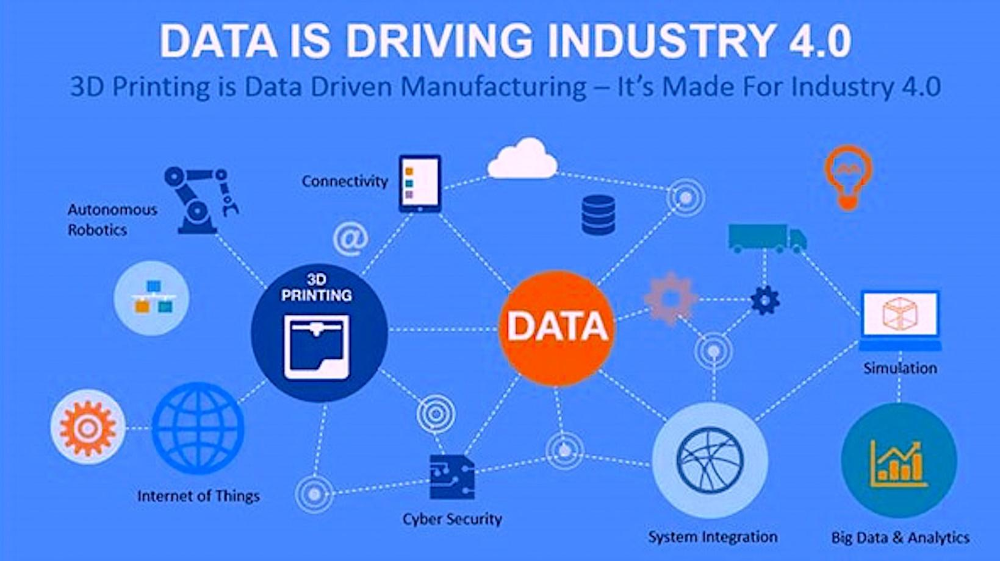

The development of 3D printing technology could not leave such an industry as construction aside. Over the past few years, several projects of 3D printers have been presented that can print housing from various materials.

WASP (World's Advanced Saving Project) has unveiled a 12-meter high Big Delta 3D printer designed to build low-cost housing using local materials. nine0003

3D Print Canal House was launched in Amsterdam in 2017, a three-year project in which an international team of partners from various sectors worked together to 3D print a full-size house printed on a large mobile Kamermaker 3D printer designed by the architects. The aim of the project is to revolutionize the construction industry and offer new customized housing solutions around the world.

In Minnesota, StroyBot was created, a 3D printer for printing houses from cement mortar, the inventor of which is Ukrainian Andrey Rudenko. He was the first to print the first 3D hotel room for the Lewis Grand Hotel in the Philippines back in December 2015. nine0003

The Chinese company ZhouDa in 2015 created a 3D villa from six 3D modules weighing approximately 100 kilograms each in just three hours (however, it is worth noting that the printing of finished elements took longer). An interesting fact is that for the production of this villa, materials obtained from industrial and agricultural waste were used. The printed house can withstand an earthquake up to 9 points, is not afraid of water and fire.

Another Chinese company, Winsun, printed a standard 5-storey house and a 1,100-square-meter luxury villa to demonstrate its own capabilities. The main advantage of building in this way is significant savings in building materials, which can be 30-60% due to the use of recycled materials, and the cost of 1,100-meter villa is only $161,000.

In Russia, the Spetsavia company from Yaroslavl, using its own model of the S-1160 3D printer, prints building elements using standard cement grade 500, which is available for sale in any building materials store. The working surface of the construction 3D printer is 10x11x2.7 meters.

American architectural firm WATG offers Curve Appeal and Branch Technology design development for construction using 3D printing technology. In doing so, WATG uses the experience of the Case Study Houses program (1945-1966), who studied light and cheap technologies for building in the post-war years. To date, technologies have been added to the old experience that can make houses energy efficient.

The most progressive and innovative today is the D-Shape system, which was developed by Enrico Dini. It allows the creation of full-sized sandstone buildings without any human intervention using a stereolithographic process that requires only sand and a special inorganic substance. At the same time, the resulting material makes it unnecessary to use reinforcement to reinforce the structure, and at the same time it cannot be externally distinguished from artificial marble, and chemically it is 100% environmentally friendly. nine0003

At the same time, the resulting material makes it unnecessary to use reinforcement to reinforce the structure, and at the same time it cannot be externally distinguished from artificial marble, and chemically it is 100% environmentally friendly. nine0003

...

Impact on society, economy, state

3D printing techniques may lead to a cultural revolution, as what seemed impossible just a few years ago is already being realized in concrete projects. Cheaper construction through 3D printing technologies and the use of recycled industrial waste can enable poor people around the world to get their own homes. The infrastructure of social protection and rehabilitation may also experience irreversible changes due to the spread of these technologies. nine0003

New construction technologies will not only make it possible to build buildings cheaper and faster, which is already possible, but will also change the structure of society as a whole. New urban formations will be constantly expanded with innovative construction works and supplemented with new structures to meet the needs of the people. This constantly changing organism at every moment of time will be somewhat reminiscent of Web 2.0 technologies, with the help of which wiki sites are formed, but everything will no longer be online, but offline. nine0003

New urban formations will be constantly expanded with innovative construction works and supplemented with new structures to meet the needs of the people. This constantly changing organism at every moment of time will be somewhat reminiscent of Web 2.0 technologies, with the help of which wiki sites are formed, but everything will no longer be online, but offline. nine0003

In order to build a house, it will no longer be necessary to call workers and construction equipment. It will be enough to order the necessary file with a housing project, adjust it according to your own wishes and call one construction robot that can print and assemble a house from suitable materials.

At the same time, the spread of 3D printing technology will lead to the development of "smart" and "green" cities that will be friendly to the environment, which will be significantly different from the globalized economy of today, which can be replaced by the hyperlocal and personalized economy of the new time. nine0003

nine0003

...

General technology trends

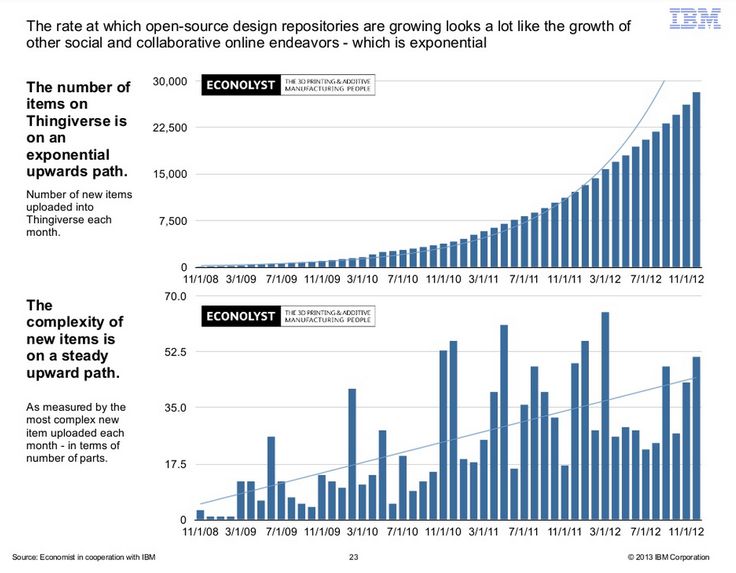

3D printing technology is not new enough compared to other technologies - its active development is in the 2010s, although the patent for this technology was obtained as early as 1984. The use of this technology was delayed due to a lack of business prospects according to the French General Electric Company, but already in the 90s the first commercial companies began to appear in the United States that applied it. nine0003

Today, 3D printing is used in manufacturing, medicine and, of course, as a hobby, as the cost of 3D printers has decreased by orders of magnitude. And one of the opportunities for the development of technology has become the personalization of things.

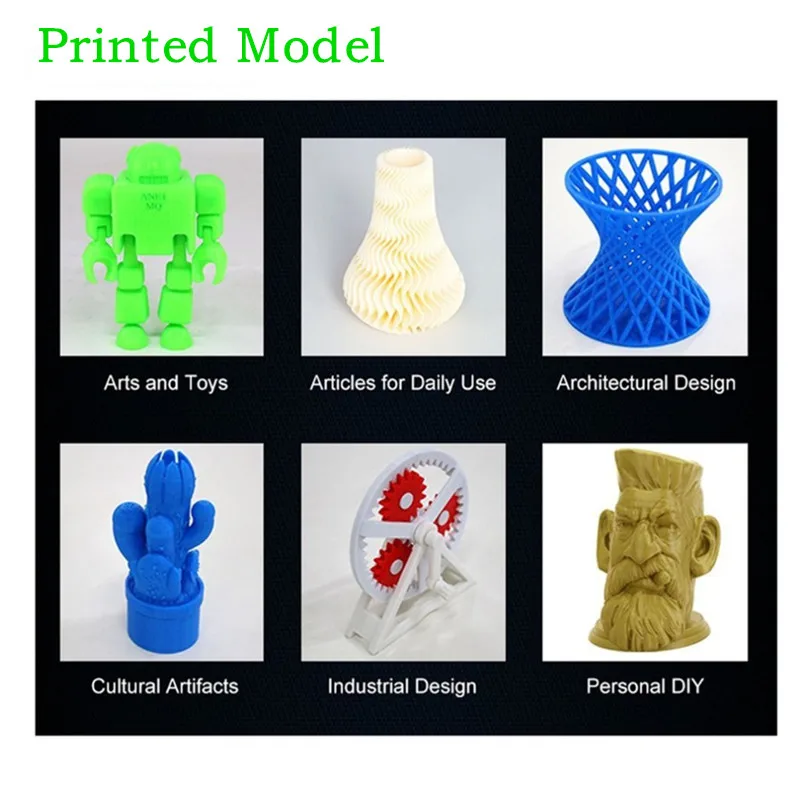

More than 50,000 projects can be found on Thingiverse, a collection of 3D models for the general public — from one of the simplest models, such as a spoon holder that can be useful among kitchen utensils, to a scale model of a shark skull in the form of cufflinks or puzzles . However, these are far from the only designs that can be personalized — anyone can print their own watch band, orthopedic insoles, docking station, iPhone case, or shower curtain rings. nine0003

However, these are far from the only designs that can be personalized — anyone can print their own watch band, orthopedic insoles, docking station, iPhone case, or shower curtain rings. nine0003

At the moment, the main limitation for 3D printing is the material, since most home printer models work with photopolymers. However, with the wider use of other materials in everyday life, personalization of things in the near future can achieve much more.

Swedish supercar manufacturer Koenigsegg has already announced that it uses a lot of 3D-printed components in the production of its One:1 hypercar. In May 2015, Airbus reported that the Airbus A350 XWB has over 1,000 parts that were also created using this technology. Therefore, in the near future, we will be able to print a car or even an airplane according to our own preferences using 3D printers. nine0003

Separately, it is worth mentioning that 3D printers make it possible to print firearms — and this may lead to a new discussion in society on the realization of the right to the protection of the individual. In the United States, there have already been attempts to combat the spread of 3D printer weapon models, but each ban only contributes to the spread of information. A certain compromise in the United States was the permission to print firearms, which can be determined by traditional methods (for example, a metal detector). However, for example, the UK government has already stated that the production of 3D weapons will be illegal in the kingdom. nine0003

In the United States, there have already been attempts to combat the spread of 3D printer weapon models, but each ban only contributes to the spread of information. A certain compromise in the United States was the permission to print firearms, which can be determined by traditional methods (for example, a metal detector). However, for example, the UK government has already stated that the production of 3D weapons will be illegal in the kingdom. nine0003

Thus, we see how the evolution of new technology raises a whole layer of old problems (patents, intellectual property, copyright, industrial design rights) - all this should be reconsidered as part of the development of 3D printing. However, the spread of technology, and, above all, the ability to independently assemble a 3D printer and thus, under the conditions of regulation, be “invisible” to the state, requires the construction of new rules of the game.

...

Impact on society, economy, state

3D printing technology is one of the breakthrough technologies in modern society today. For a long time there have been disputes that it is this technology that, through personalization, will change the mass consumption market of many products. If there is a massive adaptation of this technology to the market and society, then, indeed, many products can be printed on their own at home 3D printer, and not spend money on their purchase. In the meantime, even after several years of its active development, it remains in the sphere of interests of geeks and lovers of creating something with their own hands. nine0003

For a long time there have been disputes that it is this technology that, through personalization, will change the mass consumption market of many products. If there is a massive adaptation of this technology to the market and society, then, indeed, many products can be printed on their own at home 3D printer, and not spend money on their purchase. In the meantime, even after several years of its active development, it remains in the sphere of interests of geeks and lovers of creating something with their own hands. nine0003

An important factor influencing innovative development in general, which must be taken into account, is the use of industrial 3D printing, which makes it possible to reduce the cost of components and make them easily replaceable. Theoretically, it is in such small personalization that the vector of economic development in the coming years may lie, when the goods will be produced by industry, however, the personalization of things will be given to buyers.

Another factor that has been actively discussed for some time now is the even greater blurring of the boundaries between home and work with the spread of 3D printing technology. At the same time, for businesses, this technology opens up opportunities to spread the design of new things around the world, which can lead to changes in the delivery of goods. At the same time, production becomes as local and personalized as possible, since each owner of a 3D printer will be able to show their individuality. Already, anyone can buy custom Nike cleats that are 3D printed from scans of the customer's feet. nine0003

Building a 3D printer that can self-replicate sounds most fantastic—but such developments are already underway under the RepRap project, which allows you to print parts of yourself (however, it still needs a person to assemble!).

For the state, the development of 3D printing technology means greater trust in citizens, since it will be difficult to create total control over the spread of technology. At the same time, home production of things will change both the employment of the population and the structure of tax payments. The democratization of the means of production may raise many new questions: the processing of nanomaterials, the regulation of intellectual property, the proliferation of weapons, and others like that. nine0003

At the same time, home production of things will change both the employment of the population and the structure of tax payments. The democratization of the means of production may raise many new questions: the processing of nanomaterials, the regulation of intellectual property, the proliferation of weapons, and others like that. nine0003

Also, society will face many new challenges — for example, there are already fewer people working in manufacturing in the United States than they receive unemployment benefits. A decrease in the share of industrial production due to its automation and the spread of 3D printing can further exacerbate the problem of unemployment among the productive population, causing a wide public outcry.

Globally, the least developed countries and societies are more in need of 3D printing technology, as it allows you to create the necessary tools for local needs and at the same time not spend time and money on delivering the necessary industrial goods.