Hdfab 3d printer

HDFab 3D Printer Unveiled: Capable of Printing Advanced Materials Using New Pressurized Spray Technology - 3DPrint.com

This has already been a big year within the 3D printing industry. We’ve seen numerous new technologies as well as materials emerge as print speeds increase, prices decrease, and the number of machines sold skyrockets.

One company which is making waves within the space is HotEnd Works, a company who thrives on pushing the limits of advanced materials. They have recently unveiled a new patent pending method of printing called Pressurized Spray Technology (PSD), which is inherent in their soon-to-launch 3D printer, the HDfab. Utilizing this new technique, HotEnd Works is able to rapidly fabricate objects using advanced materials and ceramics such as alumina (AL2O3), zirconia (ZrO2), zluminum nitride (AlN), tungsten carbide (WC), silicon carbide (SiC), boron carbide (B4C), and a variety of ceramic-metal matrices.

“The PSD™ technology was developed from my and my team’s experience with spray technology while working in the industry,” explained Benjamin Becker, Managing Director of the Oberlin, Ohio-based company.

“We had been working on a thermoplastic-based binder system to incorporate powdered advanced materials for extrusion. When we discovered the inherent disadvantages of the extrusion method, such as voids within a component and the ‘stair-stepping’ effect, we drew on our spray technology experience and came up with the jetting nozzle that is used with the PSD™ technology. The idea is that the parent material being jetted, such as an advanced ceramic, has a high enough velocity to embed itself into the previously deposited layer, forming a stronger, more dense part.”

The PSD process, which is explained in greater detail here, works by using two different materials during the fabrication process — a main parent material and then a polymeric binding material. The binding material is pretty much for temporary support and adhesion of the parent material, and it can be removed using a heated finishing process. The majority of materials which have melting points over 250ºC can be used with this process, and the parts which are fabricated with the HDfab 3D printer are incredibly dense. This means no fillers are required, and the parts are pure. Not only is quality one of the outcomes of this new process, but it can all be done at speeds which seem almost unfathomable within the high-end additive manufacturing space. Becker tells us that his machines can dispense material at a rate of 2.5 cc/min, and would be perfect for numerous industries which rely on the manufacturing of components and prototypes using advanced materials.

This means no fillers are required, and the parts are pure. Not only is quality one of the outcomes of this new process, but it can all be done at speeds which seem almost unfathomable within the high-end additive manufacturing space. Becker tells us that his machines can dispense material at a rate of 2.5 cc/min, and would be perfect for numerous industries which rely on the manufacturing of components and prototypes using advanced materials.

“Every industry uses advanced materials,” Becker told 3DPrint.com. “I would say our biggest feedback has been from the Defense, Aerospace, and High Technology sectors. We’ve also worked with consumer goods companies as well as the price to manufacture components using our system is often less than traditional advanced material manufacturing methods, while allowing for more freedom during the design process.”

Becker expects that the HDfab printer will be released early next year at a price of around $55,000 per unit. The machine, which is the product of years of research and development, will likely be shipped with a build envelope of 8 x 8 x 8 inches, although Becker tells us that the system is incredibly easy to scale, so larger machines are feasible as well.

The machine, which is the product of years of research and development, will likely be shipped with a build envelope of 8 x 8 x 8 inches, although Becker tells us that the system is incredibly easy to scale, so larger machines are feasible as well.

“I became involved in the 3D printing scene because of the lead times and pricing, specifically within the advanced ceramics industry,” Becker told us. “Some parts the size of a half dollar would cost $500 in large quantities, and we would be waiting 12 weeks. That’s when it hit me that there needed to be an additive manufacturing solution for advanced materials, and that the comfortable, almost collusion-like advanced ceramics market needed a wakeup call. In my now day-to-day world, I like handling the business side of our company, as well as getting my hands dirty in the lab building up our next prototype. I’ve been working with many high-profile customers, many of which I’m unable to disclose, to develop this technology since 2013.

”

The company is currently seeking series A investment funding so that they “can grow within the trillion dollar advanced materials market.” If this machine is capable of what HotEnd Works says it is, investment is not something that will be difficult finding.

Let us know your thoughts on this new 3D printing process and subsequent soon-to-launch printer. Discuss in the HDfab 3D printer forum thread on 3DPB.com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: advanced materials 3d printer • ceramic 3d printer • hdfab • hotend works • Pressurized Spray Technology • psd 3d printer

Please enable JavaScript to view the comments powered by Disqus.

3ders.org - HotEnd Works' new HDfab ceramic 3D printer utilizes Pressurized Spray Deposition technology for high resolution prints

Apr. 22, 2015 | By Alec

While a new model FDM 3D printer seems to be released just about once a week, the unveiling of other types of 3D printers are much rarer to find. That’s why we were very interested to learn about a new approach to ceramic 3D printing that has been developed by Oberlin, Ohio-based high quality 3D printing service provider HotEnd Works (or HeW). As company founder Benjamin Becker explained to 3ders.org, his company has developed a custom ceramic 3D printer called the HDfab™ Advanced Materials 3D Printer, which produces high resolution and high quality components using Pressurized Spray Deposition Technology (or PSD).

That’s why we were very interested to learn about a new approach to ceramic 3D printing that has been developed by Oberlin, Ohio-based high quality 3D printing service provider HotEnd Works (or HeW). As company founder Benjamin Becker explained to 3ders.org, his company has developed a custom ceramic 3D printer called the HDfab™ Advanced Materials 3D Printer, which produces high resolution and high quality components using Pressurized Spray Deposition Technology (or PSD).

Now as you might know, ceramic 3D printing typically revolves around a custom FDM 3D printer that extrudes molten ceramic rather than plastic, which requires heating in an oven to harden after printing. But as the team from HotEnd Works explains, PSD technology can perhaps best be seen as a professional version of that approach. ‘Pressurized Spray Deposition technology fills the void between production-quality advanced ceramic components and current solutions requiring a post-fabrication infiltration process,’ they say. ‘PSD builds production-quality parts in quantities ranging between 1 and 500 using the highest performance, engineering-grade materials such as advanced ceramics. PSD is the undisputed leader in high strength ceramic parts in various ceramic materials such as alumina (Al2O3), silicon carbide (SiC), and aluminum nitride (AlN).’

‘PSD builds production-quality parts in quantities ranging between 1 and 500 using the highest performance, engineering-grade materials such as advanced ceramics. PSD is the undisputed leader in high strength ceramic parts in various ceramic materials such as alumina (Al2O3), silicon carbide (SiC), and aluminum nitride (AlN).’

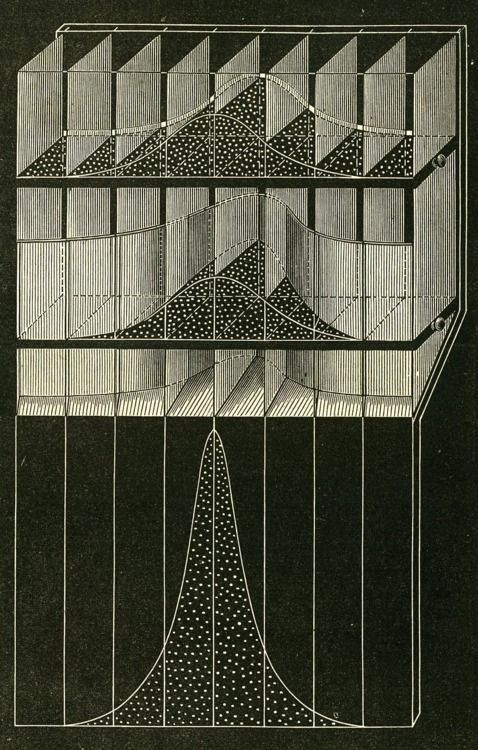

That all sounds impressive, but how does it actually work? Well, as they explain, Pressurized Spray Deposition revolves around depositing two different materials on a printbed simultaneously: the parent material (the high quality ceramic powder) and a polymeric binding materal, that serves as a support material. ‘Powder and binder materials are fed from external hoppers into the dispensing chambers, and are then deposited at the precise X and Y positions as dictated by the part being formed,’ they explain.

These layers are deposited in a process that somewhat resembles FDM printing, but instead of just letting layers dry together, a polymeric matrix is applied at precise points between layers of powder. ‘In order to bond the powder material together and only at the intended area, a precision dispensing mechanism is used for the binding material in conjunction with computer-controlled paths.,’ the HeW team explains. The results are subsequently sintered.

‘In order to bond the powder material together and only at the intended area, a precision dispensing mechanism is used for the binding material in conjunction with computer-controlled paths.,’ the HeW team explains. The results are subsequently sintered.

The advantage of this approach is that it creates very dense and very pure ceramic materials (with a density of at least 98%). This means parts will be more precise and have a higher mechanical strength than what can be accomplished with other ceramic processing techniques. Optionally, the ceramic components can be further post processed to reach the optimal mechanical and visual qualities, though this will require grinding and hot isostatic pressing to increase density to 100%.

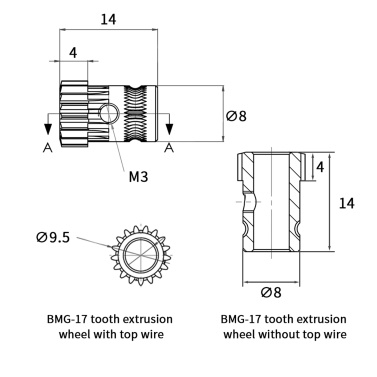

The HDfab™ Advanced Materials 3D Printer that uses this technology can apply PSD 3D printing to a variety of high quality ceramic powders, including: HotEnd Works Premium Alumina (AL2O3), Zirconia (ZrO2), Silicon Carbide (SiC), and Aluminum Nitride (AlN). Custom-made ceramic and metal materials can also be incorporated into the production process. The 3D printer itself prints layers at a resolution of 200 microns (deposition rate of 2.5 cc/min), with a maximum build volume of 8 x 8 x 8 inches. All this makes it a very interesting prototyping 3D printer, especially its ability to produce complex and highly detailed ceramic pieces in a single piece and in large qualities.

Custom-made ceramic and metal materials can also be incorporated into the production process. The 3D printer itself prints layers at a resolution of 200 microns (deposition rate of 2.5 cc/min), with a maximum build volume of 8 x 8 x 8 inches. All this makes it a very interesting prototyping 3D printer, especially its ability to produce complex and highly detailed ceramic pieces in a single piece and in large qualities.

Now as you can imagine, such a high quality and unique 3D printer isn’t exactly marketed to the garage tinkerer. Expected to be priced at $55,000USD, it will doubtlessly be aimed at manufacturing businesses upon release in early 2016. But for that money, the 3D printer will come with custom control and slicing software, 10 pounds of HotEnd Works Premium Alumina (AL2O3) advanced ceramic material, 10 pounds of post-processing agent and a thermal post processing system as well.

For more information about the HDfab™ Advanced Materials 3D Printer, go to the website of HotEnd Works here. And if you can’t wait until early 2016, they do already offer PSD 3D printing as a service for users. If you’re looking to try that, you can go here to upload an STL file and be provided with a quote.

And if you can’t wait until early 2016, they do already offer PSD 3D printing as a service for users. If you’re looking to try that, you can go here to upload an STL file and be provided with a quote.

Posted in 3D Printers

Maybe you also like:

- South African 3D printer maker unveils new supersized Mega Morgan 3D printer

- Singapore student builds a 3D food printer that prints cookies, mashed potato & chocolate

- New delta-style TIKO desktop 3d printer revealed at SXSW for just $179

- XYZprinting releases new da Vinci 1.1 Plus 3D printer with W-Fi, free mobile app upgrade

- Carbon3D Introduces breakthrough CLIP technology for layerless 3D printing, 25-100x faster

- Dutch TNO's 'racetrack' 3D printing factory line can build hundreds of products within minutes

- Ground-breaking 3D printer for small molecules could speed up custom drug development

Jessica wrote at 5/6/2015 2:43:16 AM:

Yes the screw is a rendering. This demonstrates the type of prototype one can expect to print once available in 2016.

This demonstrates the type of prototype one can expect to print once available in 2016.

Jessica wrote at 5/6/2015 2:41:27 AM:

Yes it is a rendering. It was meant to show the type of parts you can expect with this 3D printer once available in 2016.

Larry wrote at 4/22/2015 6:14:59 PM:

That screw looks an awful lot like a rendering to me!

HotEnd Works offers a 3D printer for ceramic sputtering

News

Oberlin, Ohio-based HotEnd Works has announced the development of a new HDfab Advanced Materials 3D Printer for printing ceramic products using the Pressure Spray Deposition (“PSD”) method. Most of the existing developments in ceramic 3D printing are based on the adaptation of FDM printers for clay extrusion and require firing of printed products, as in the usual pottery.

PSD, on the other hand, can be considered a kind of development of inkjet 3D printing, using a polymer binder to selectively bond the particles of a consumable material before completion of construction and subsequent firing. Consumables in this case may vary, including additives from alumina, silicon carbide, aluminum nitride and other components, depending on the required characteristics of the finished products. The most obvious advantage of this method over FDM printing will be the higher print resolution.

Consumables in this case may vary, including additives from alumina, silicon carbide, aluminum nitride and other components, depending on the required characteristics of the finished products. The most obvious advantage of this method over FDM printing will be the higher print resolution.

Filler and binder are sprayed in controlled proportions as required by the project. The method allows to achieve high density of finished products, reaching 98%. High density, in turn, means high strength and overall quality of workmanship. If necessary, additional processing by means of grinding and hot isostatic pressing is possible. The latter allows you to bring the density of the material to almost 100%. At a minimum, printed products require firing in a conventional pottery kiln.

Among the ceramic mixtures offered by the company are options containing alumina (aluminum oxide), cubic zirconia (zirconium dioxide), silicon carbide and aluminum nitride. In addition, it is possible to create customized mixtures, including the addition of desired metal particles. The printer provides the application of layers with a thickness of 200 microns with a maximum build size of 203x203x203 mm. The print speed reaches 2.5 cm³/min.

In addition, it is possible to create customized mixtures, including the addition of desired metal particles. The printer provides the application of layers with a thickness of 200 microns with a maximum build size of 203x203x203 mm. The print speed reaches 2.5 cm³/min.

It is clear that the unit is intended for professional use only. This is also indicated by the preliminary cost of the printer, estimated at $ 55,000. It is expected that the finished devices will be supplied complete with proprietary software, a five-kilogram supply of alumina ready for printing, as well as post-processing materials and an oven for firing printed products.

The commercial premiere of the HDfab Advanced Materials 3D Printer is scheduled for early next year, but those who want to get acquainted with the possibilities of the technology can place a 3D printing order on the company's website. You can download the .STL file and get an estimate of the cost of the product here.

Follow author

Follow

Don't want

1

More interesting articles

eleven

Follow author

Subscribe

Don't want

Simon Fraser University scientists have developed a self-learning system that matches in real time...

Read more

5

Subscribe to the author

Subscribe

Don't want

Establishment of the center will help improve the quality and reduce the cost of engineering products...

Read more

sarkazm

Loading

04/01/2016

39890

68

Subscribe to the author

Subscribe

Don't want

News from the world of printing in a short line

FDplast announced the release of a free. ..

..

Read more

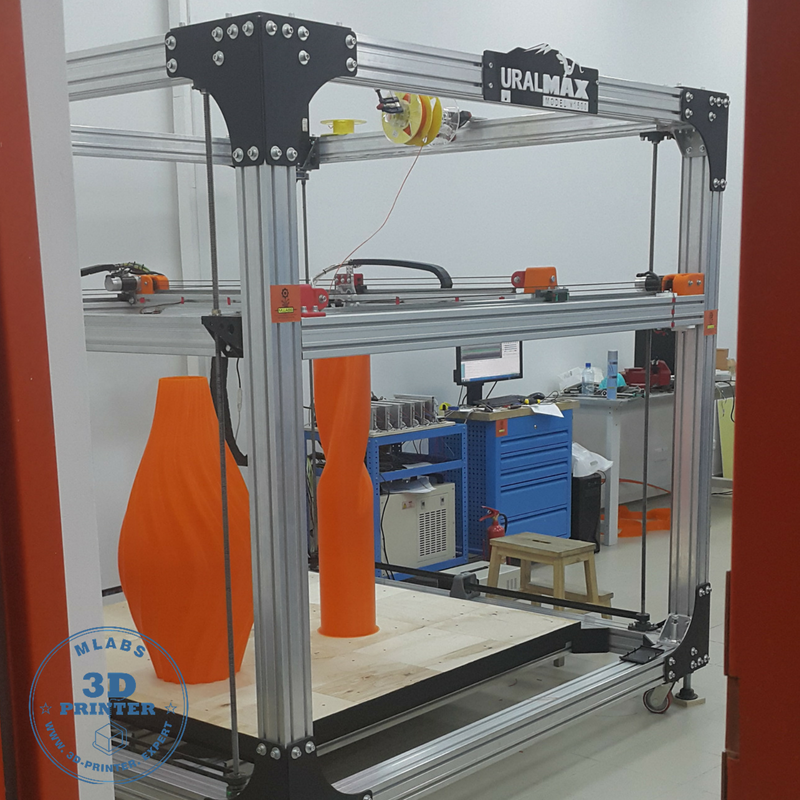

Large area 3D printer

Create functional plastic items up to 2.5 meters!

Learn more

Discovery 3D Printer is a range of industrial 3D printers made in Spain for creating large-sized products and prototypes using FFF/FDM technology.

Discovery 3D Printer Additive Machines produce high-strength thermoplastic objects for industries ranging from shipbuilding and automotive to architecture and medicine.

Problems solved

Replacement of spare parts or lost parts in engineering, shipbuilding, oil and gas and energy enterprises

Production of small and medium series of products as an alternative to casting or molding plastic parts

3D printing of large end products, components and tooling in the automotive, shipbuilding and oil and gas industries

Creation of outdoor and interior design objects and design products for construction, production of facing materials

Production of functional prototypes for R&D and design offices in mechanical engineering, ship - and aircraft industry

Manufacture of large-sized stencils or burnt-out master models for metal casting and metallurgy

Creation of auxiliary fixtures, printing of templates for robotic equipment (robots, cobots, robotic arms or carts)

Looking for a 3D printer for your needs?

Leave a request for a personal consultation!

Solutions catalog

3D Printers

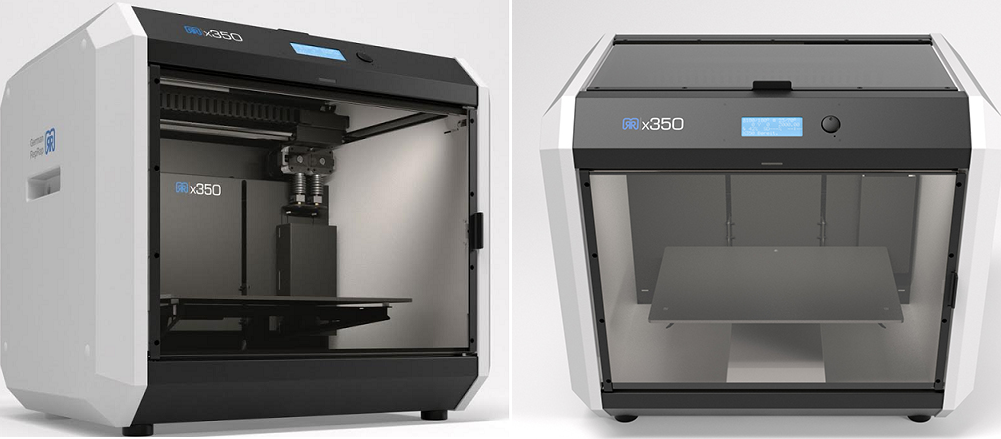

Discovery 3D Printer 2021 3D Printer

Compact Solution for Large Size 3D Printing

Learn More

Super Discovery 3D Printer Compact 9 3D Printer0003

Combination of compactness and high productivity up to 2 kg/h

Learn more

Super Discovery 3D Printer Hybrid 3D Printer

Advantages of printing with granules and filaments in one device build chamber and print speeds up to 6 kg/h

Learn more

Super Discovery 3D Printer Workstation

2 in 1: unique combination of large format 3D printer and milling system

More details

Your unique 3D printer

Do you need to print a product larger than 6 meters?

We will develop an individual solution with any build chamber for your needs. tasks - for printing products of any size!

tasks - for printing products of any size!

Choose the right solution for you - compare specifications by model

Compare 3D Printer

Solutions catalog

3D printing consumables

Do you have questions about 3D printing materials?

Set them to our experts online!

Discovery 3D Printers work with all thermoplastics, including:

- PLA / PLA

- biodegradable polymer provides a smooth and gliding surface products. Designed to obtain detailed and ready-to-use objects

- ABS / acrylonitrile butadiene styrene

- impact-resistant material is able to withstand heavy loads and high temperature, resistant to heat, moisture and various alkalis

- PET / polyethylene terephthalate

- is a hard and strong material with high abrasion resistance.

Excellent suitable for making gears, carriages and guides

Excellent suitable for making gears, carriages and guides - PA / polyamide

- hard engineering plastic with excellent mechanical properties characteristics. Widely used in various industries

- ASA / acrylonitrile styrene acrylate plastic

- analogue of ABS, characterized by increased weather resistance, minimal shrinkage and high impact strength

- Nylon

- is flexible, wear-resistant and remarkably durable. Good suitable for printing functional parts and mechanisms

- HIPS / polystyrene

- Lightweight, alkali and acid resistant polymer. deserved popular in traditional manufacturing due to its impact resistance

Advantages of Discovery 3D Printer Solutions

ISO 9001 certified products

3D printers with the largest build chamber in the world

Ability to design a custom printer

The only 3D printer on the market with an integrated CNC system for finishing milling of the part after printing

Accelerate new product development with dual extrusion system

Repair and replace products faster and more economically than contractors

Ability to use a large number of third-party materials

Self-leveling platform function for automatic compensation of unevenness

Case Studies

FDM 3D Printing of Airbus Parts

| Industry: | Aircraft industry |

| Equipment: | Super Discovery 3D Printer |

| Material: | CFRP SABIC LNP™ THERMOCOMP™ AM EZ006EXAR1 |

Created a strong mold for autoclave forming parts with a sealed surface and a low thermal expansion coefficient.

3D printed car bumper

| Industry: | Automotive |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

A prototype car bumper is printed, measuring 1800 x 600 x 4500 mm and weighing 12 kg.

Create a chair with large format 3D printing

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer |

| Material: | 3D850 |

Printed design armchair measuring 45 x 50 x 95 cm and weighing 18 kg.

3D printed architectural statue

| Industry: | Architecture |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with cellulose fiber |

Printed solid statue, 1. 87m high and 45kg weight.

87m high and 45kg weight.

3D printed rail components

| Industry: | Railway industry |

| Equipment: | Super Discovery 3D Printer |

| Material: | plastic |

The front part of a tram for CAF was made in one printing session.

Helicopter seat 3D printing

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Printed helicopter seat measuring 120 x 70 x 45 cm and weighing 20 kg.

3D printed internal combustion engine

| Industry: | Engineering |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | Premium PLA |

Prototype of an internal combustion engine was created, the dimensions of which were 100 x 60 x 50 cm and the weight was 5. 5 kg.

5 kg.

3D printed exclusive piece of furniture

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS plastic |

A custom and exclusive chair created without the need for any further finishing.

Architectural 3D printed in durable ABS with cellulose

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS plastic |

A street sculpture has been made that fully implements the initial decorative idea of the project.

Window dressing for Dior boutiques

| Industry: | Advertising |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | plastic |

Huge bottles 3D printed for exclusive display at Dior's flagship stores.

FDM Cap Prototype

| Industry: | Design |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | 3D850 |

Prototype cap printed at 29 x 19 x 4.5 cm and weighing 146 g.0219 Industry:

A prototype modular toilet is printed, measuring 2200 x 1700 x 1200 mm and weighing 250 kg. At the same time, the weight of the product was reduced by almost 50%.

3D printed marine ventilation grille

| Industry: | Shipbuilding |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

Printed ventilation grille measuring 59 x 89 x 4. 5 cm and weighing 3500 g.

5 cm and weighing 3500 g.

3D printed functional motorcycle part

| Industry: | Automotive |

| Equipment: | Discovery 3D Printer 2021 |

| Material: | PACF |

Printed motorcycle part measuring 42.5 x 16.5 x 4.5 cm and weighing 165 g.0218

Prototype printed with support measuring 10 x 9 x 2.5 cm and weighing 18 g.

Created a square mold that measures 10 x 10 x 2 cm and weighs 67 g.

Printed fender for a wheel measuring 55 x 16 x 20 cm and weighing 645 g.

3D printed and post-processed high-strength mold for wind turbine blades.

3D printed car wheel

| Industry: | Automotive |

| Equipment: | Super Discovery 3D Printer |

| Material: | ABS with carbon fiber |

A wheel for a car was made, the diameter of which was 440 mm, and the weight of the product was 5 kg.

3D printed designer vase

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS with carbon fiber |

Printed vase in ABS for excellent interlaminar adhesion and minimal warping.

Geometric 3D printing

| Industry: | Design |

| Equipment: | Super Discovery 3D Printer Workstation |

| Material: | ABS with carbon fiber |

Pyramid printed with an 8mm extruder with a smooth surface thanks to the built-in milling system.

More projects and examples of 3D printing in production - in the blog 3D experts

Go to blog

Useful materials

Webinar on 3D printing large objects with complex geometry

- How can 3D printing help you optimize production?

- Features FDM technology for printing products up to 2.

5 meters

5 meters - Benefits of using 3D plastic printing

- Real cases

Large Format Plastic 3D Industrial Printing Brochure

Benefits of FDM Technology, Overview of Equipment and Consumables, industries and implementation examples - this and much more in one material!

About the manufacturer

CNC Barcenas / Spain

is one of the leaders in the European market for large format 3D printing.

The company specializes in the production of industrial 3D printers Discovery 3D Printer for printing large-sized products and prototypes based on FFF/FDM technology.

discovery3dprinter.com

Explore Discovery 3D Printer Solutions - Go Virtual tour of companies!

3D TOUR OF COMPANY

About us

iQB Technologies is a Russian distributor of 3D printers, consumables, 3D scanners and software from the world's leading manufacturers.

We develop complete 3D solutions, provide printing services and scanning, as well as training specialists in the use of 3D technologies in their work.

iQB Technologies is the exclusive distributor of Discovery 3D Printer solutions in Russia.

3D printers are available for order

in this section .

iqb.ru

Why order a 3D printer from iQB Technology?

The best prices for this class of equipment

3D printer training

A wide range of integrated solutions: 3D printer + 3D scanner + software

Provision of services for the implementation, maintenance and repair of 3D equipment throughout Russia

Participation in public procurement and tenders

Still have questions?

Our experts will advise you free of charge on Discovery 3D Printer solutions

Frequently Asked Questions

Which technology should I choose: the method of fusing granules (FGF) or polymer filaments (FFF / FDM)?

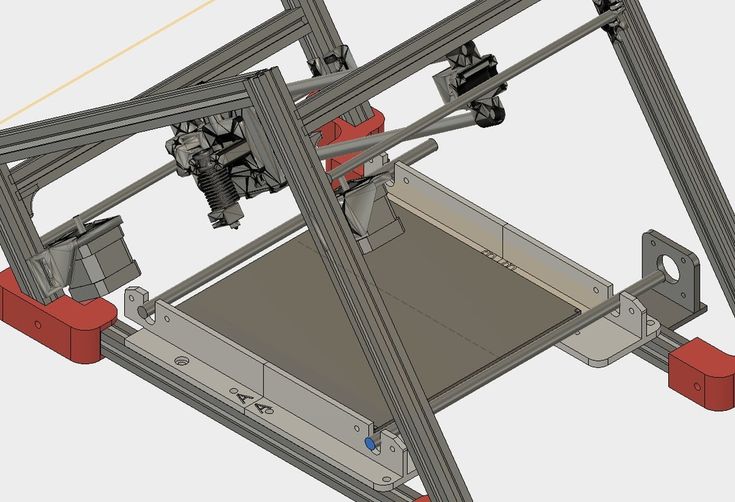

What are the kinematics and mechanics of the Discovery equipment?

In this respect, all Discovery equipment differs from budget additive solutions. The products are based on the kinematic diagram of a CNC machine. Gears, pulleys, lead screws, no belts. HIVIN rail guides are used. The entire structure is made with European quality from advanced products in the machine tool industry.

The products are based on the kinematic diagram of a CNC machine. Gears, pulleys, lead screws, no belts. HIVIN rail guides are used. The entire structure is made with European quality from advanced products in the machine tool industry.

What consumables can be used with Discovery products?

Any material (other than PEEK and PEKK) sold in bars or pellets. First of all, thanks to the heating of the table to 175 ° C and vacuum fixation, as well as due to the installed nozzles made of hardened steel.

How is such a large print platform heated?

A matrix of separate equidistant heaters is built into the platform from the bottom side; these modules provide uniform heating of the surface of the printing platform. The maximum recorded temperature difference over the entire area is 3°C.

How to speed up printing on such large dimensions?

There is a special method for properly emptying the internal volume, which you can learn more about from our technical experts. This procedure will have very little effect on the strength and elasticity of the print object, but will still reduce the time by up to 60%.

This procedure will have very little effect on the strength and elasticity of the print object, but will still reduce the time by up to 60%.

It is important to consider that with a large range of large-sized products, it is better to consider Super Discovery 3D Printer or Super Discovery 3D Printer Workstation with a capacity of up to 11 kg / h (depending on the material used).

Is it possible to upgrade this equipment for a specific enterprise?

Yes. Most of the Discovery machines can be upgraded for a specific production project. This is possible, since the equipment was designed for the tasks of Production 4.0, and our specialists will help to integrate it correctly.

What is the warranty for this equipment?

24 months, which is 1.5 - 2 times more than analogues from Europe, Russia and China. Permanent customer support is provided directly by the vendor or iQB Technologies specialists.

How to get a high quality product so that it can be handed over as a final product?

3D printing is basically a high quality preform process.