Ups 3d printing service

3D Printing | 3D Print Services

Find a 3D Printing Location

Print Functional Prototypes

You can use 3D printing for prototypes or one-of-a-kind items. Let The UPS Store® bring your ideas to life. We can even use your 3D CAD file.

Construct Manufacturing Jigs and Fixtures

We understand when you do your own manufacturing, jigs and fixtures are critical for insuring high-quality and efficiency during assembly and testing. Our 3D printer can create complex parts so you are not dependent on a CNC machine.

Create Custom Accessories

Want to design your own smartphone case or money clip? Most items that are smaller than a breadbox and can be made out of single color of plastic are perfect for 3D printing.

Build Architectural Models

You can work in just about any 3D architectural design program and then export to common 3D CAD file types. The finished product is ready to show off or you can sand and paint your building to give it just the right look.

3D Printing Services Expanded Across Nation

The UPS Store continues to expand 3D printing services nationwide to meet the growing demands of its small business customers. 3D printing now available at approximately 20 The UPS Store locations. Use the interactive map below to find a participating location near you, or check out the full list of all The UPS Store locations offering 3D printing services.

3D CAD and 3D Scanning Services

The UPS Store 3D print locations can now also offer you 3D CAD and 3D scanning services through HoneyPoint3D. Getting a custom 3D print has never been easier - you dream it, HoneyPoint3D designs it, The UPS Store prints it. Enjoy the HoneyPoint3D benefits of an easy quoting process, affordable and quality engineering, online viewing of your 3D files, and efficient turn-around times. Get your 3D CAD or scan quote today!

Netfabb® at The UPS Store®

Participating The UPS Store 3D print locations are utilizing Netfabb software for 3D print file preparation and customization. Services available at these locations include:

Services available at these locations include:

- File fixing

- Text labeling

- Logo labeling

- Cutting

Contact or visit these Netfabb locations to learn more about their advanced 3D offerings.

3D Printing Frequently Asked Questions

Here a few questions we frequently hear about 3D Printing.

Please feel free to contact your local The UPS Store for any other questions you may have

-

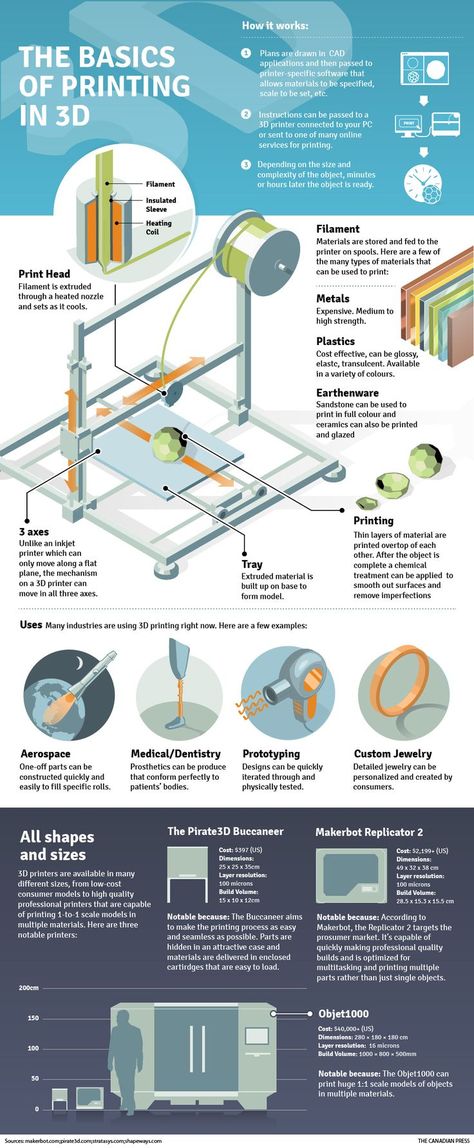

What is 3D printing?

-

3D Printing is a manufacturing process that uses a digital file to create three-dimensional objects one layer at a time. We run a system that uses ABS plastic and soluble supports to create realistic prototypes and marketing models.

-

What kinds of things can I 3D print?

-

Small business owners and aspiring entrepreneurs will have the opportunity to print prototypes as part of the new product development process. With this printer, The UPS Store locations will be equipped to produce items like engineering parts, functional prototypes, acting props, architectural models, fixtures for cameras, lights and cables.

-

How long does it take to print?

-

The time it takes to print an object will depend on the complexity of the design. A simple object may take 4-5 hours, while a complex object may take 24 hours.

-

Which UPS Store locations are offering 3D printing?

-

The UPS Store is in the process of rolling out nearly 100 3D printing locations across the country. Visit /print/3d-printing/locations for more information.

More Than Logistics: UPS is Using 3D Printing to Completely Transform Their Industry and Business Model - 3DPrint.com

The thing that has always struck me as disruptive about 3D printing is the unpredictability of who and how it is going to be used. The fact is, you just never know where it’s going to show up, and who is going to be using it. 3D printing seems a natural extension of services for companies like Staples or Home Depot, as they have already been in the market of providing small business services to their customers. But who exactly could have predicted that a shipping company like UPS would be one of the fastest growing 3D printing service providers in the country, through The UPS Store?

But who exactly could have predicted that a shipping company like UPS would be one of the fastest growing 3D printing service providers in the country, through The UPS Store?

A growing number of The UPS Store locations are offering 3D printing services.

It started small of course, a handful of their physical locations started including a 3D printer on-site to offer customers an additional service while they stopped in to ship a package. But now, barely a year later and that additional service has spread to more than a hundred locations all over the country. But on-site 3D printing services are only part of the future of one of the largest private shipping companies in the world, and it is becoming evident than in a few years it may not even be accurate to call them a shipping company any longer.

It is important to remember that UPS has always referred to themselves primarily as a logistics company, and now, according to UPS vice president of marketing for global logistics and distribution Alan Amling, that is going to include light product assembly and manufacturing. In a conversation with InformationWeek, Amling detailed exactly how 3D printing is going to factor into the future of the company, and how they’re going to do it.

In a conversation with InformationWeek, Amling detailed exactly how 3D printing is going to factor into the future of the company, and how they’re going to do it.

“Excuse me sir, can you 3D print this small house that I have already 3D printed?”

For a company that sells customized golf clubs like Hopkins Golf the ability for UPS to store individual components, assemble them together when an order is placed and ship directly to the customer is a key part of their business plan. What is sort of brilliant about this particular partnership is the benefits that the relationship offers both companies. For Hopkins Golf they only need to source the parts and make sure that UPS is fully stocked, there is no need to assemble the clubs themselves, package them up and ship them off to customers. Not only does that save them time and allow for faster fulfilment in the age of Amazon Prime, but it reduces the amount of staff that they need as well as virtually eliminates the need for packaging or shipping materials.

UPS benefits by saving on the manpower required to physically pick up Hopkins Golf’s products from their shipping location and physically transport them to a UPS distribution hub. By having the products already in their central shipping facility, where staff can pick and ship what is needed, they can almost instantly be sent directly into their shipping network. This is a service that is already being implemented successfully and has proven itself to be viable. And according to Amling, light manufacturing using 3D printers is simply the next step of this type of service.

“You’d never want to make and store all the possible combinations [of Hopkins Golf clubs]. UPS stores shafts and heads and puts them together to order — this is light assembly that’s already being done. 3D printing coupled with pre-manufactured parts is the next evolution,” Amling told InformationWeek.

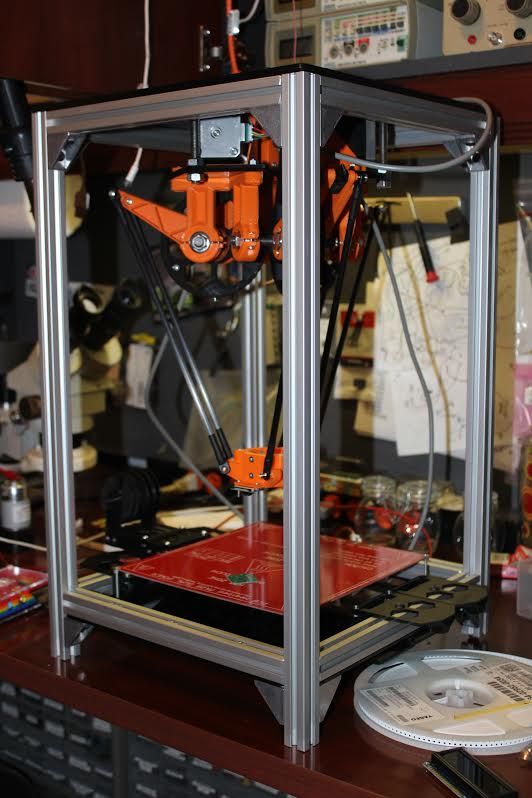

The new bank of CloudDDM 3D printers inside of the UPS facility.

UPS recently invested heavily in a 3D printing services company called CloudDDM, who set up a large bank of about a hundred industrial 3D printers inside of the massive UPS facility in Louisville, Kentucky. The workflow is pretty simple, a company offers 3D printable products, or products that need light assembly with 3D printable components. When a customer places an order, it is sent over to UPS and any parts that need to be 3D printed are sent directly to CloudDDM. Once the product is printed and assembled, it is immediately shipped out to the customer. CloudDDM founder Rick Smith sees his new partnership with UPS as a way to set his company apart from his competitors.

The workflow is pretty simple, a company offers 3D printable products, or products that need light assembly with 3D printable components. When a customer places an order, it is sent over to UPS and any parts that need to be 3D printed are sent directly to CloudDDM. Once the product is printed and assembled, it is immediately shipped out to the customer. CloudDDM founder Rick Smith sees his new partnership with UPS as a way to set his company apart from his competitors.

“Most of the service companies in the space are mom and pop, but CloudDDM is trying to be a manufacturer with some scale. The target parts are things like low-volume replacement parts that might fall below the minimum order from a manufacturer,” explains Smith. “We talked about this huge disruptive tech over a 50 year span. UPS is a supply chain management company. They want to go to customers and tell them this is how to think about additive manufacturing.”

While it is still early days for this type of service, and both UPS and their customers have a lot of logistical issues to work out, creative logistics is what UPS is known for. Not only is this an evolution of the 3D printing service provider market, but it’s a complete disruption of the light manufacturing, shipping and fulfilment markets as well. UPS has a huge network of customers all over the country, and a sizable staff of people who manage them. If anyone can successfully proselytize the benefits of using this type of business model to their clients it is going to be UPS.

Not only is this an evolution of the 3D printing service provider market, but it’s a complete disruption of the light manufacturing, shipping and fulfilment markets as well. UPS has a huge network of customers all over the country, and a sizable staff of people who manage them. If anyone can successfully proselytize the benefits of using this type of business model to their clients it is going to be UPS.

According to Amling, the goal of their new light manufacturing and digital reordering business model will require the use of every resource that UPS has available to them. That means using both the CloudDDM printer farm in Kentucky and the 3D printing capabilities of local UPS Stores to to the work. They just need to put a system in place to figure out what can be done where, and how much time will it save them. UPS is a global company, so the plan is to put this new model into place everywhere, however the company is currently restricting it to the US until they get the new model just right. But honestly it is only a matter of time before they do, and I fully expect to see similar fulfilment models implemented by other large online retailers like Amazon (which already offers something similar without the 3D printing) and Wal-Mart.com.

But honestly it is only a matter of time before they do, and I fully expect to see similar fulfilment models implemented by other large online retailers like Amazon (which already offers something similar without the 3D printing) and Wal-Mart.com.

Soon to be more than logistics.

At a previous job I worked closely with UPS for several years, and the few times that I was able to look into their logistics network it was sort of like walking into an Escher painting come to life. Nothing seemed to make sense to me, but for some reason it all seemed to work both quickly and efficiently. With the plans that UPS has for 3D printing, it’s pretty clear that logistics is just another industry that is being transformed by 3D printing. Discuss this story in the UPS 3D Printing forum on 3DPB.com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d printing services • 3D printing UPS • Alan Amling • cloudddm • fulfilment • light manufacturing • logistics • printer farm • Rick Smith • the ups store • ups

Please enable JavaScript to view the comments powered by Disqus.

UPS Opens Industrial 3D Printing Units on Demand

Site searchCases November 11, 2016

Further

Nicholas Avelsnik November 11, 2016

Nicholas Avelsnik November 11, 2016

UPS, SAP and Fast Radius have created an on-demand 3D production printing service. Customers can use one of the factories and print an automotive part or a medical device - just leave a request on the site.

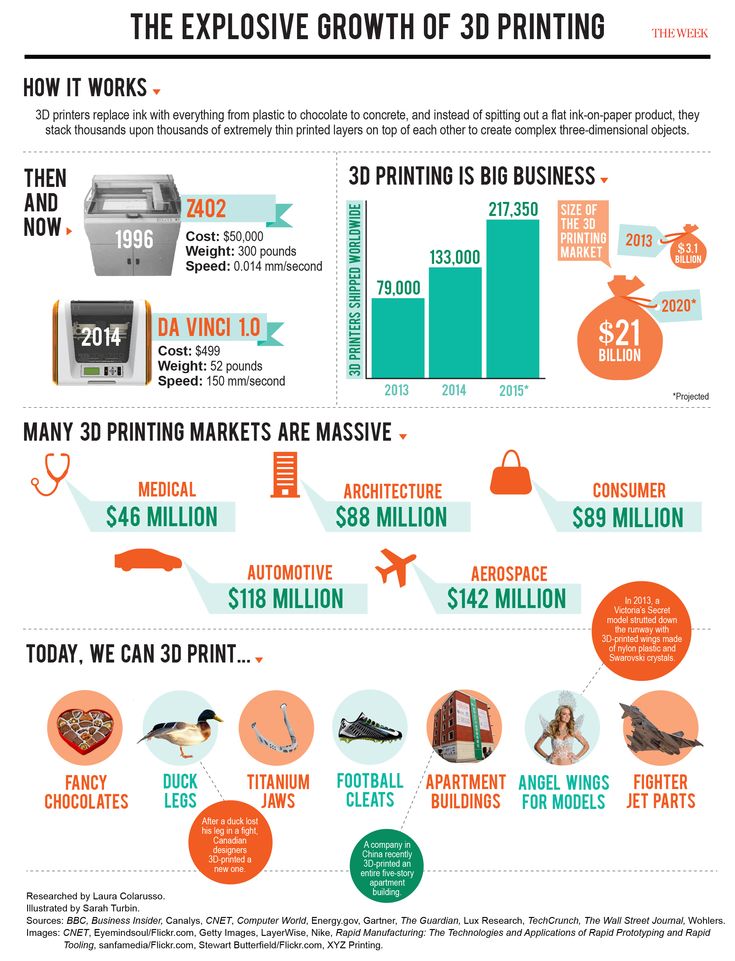

Read Hi-Tech in

According to Wohlers Assoc, the 3D printing market will grow from $5 billion in 2015 to $21 billion in 2021. If printing captures at least 5% of the manufacturing market, it will create an additional market of $640 billion. Based on these trends, the American logistics giant UPS, together with the German software maker SAP and the Fast Radius service, launched a 3D printing on demand service.

If printing captures at least 5% of the manufacturing market, it will create an additional market of $640 billion. Based on these trends, the American logistics giant UPS, together with the German software maker SAP and the Fast Radius service, launched a 3D printing on demand service.

Two factories are already operating in Louisville, Kentucky, with a new facility in Singapore by the end of 2016. As Business Insider reports, companies can print just about anything—from aircraft parts to small appliances—in high volume.

By 2021, the big seven IT companies will rule the world

Opinions

Customers place an order on the Fast Radius website or UPS House in Singapore. After that, the order is sent to the nearest factory that meets the stated requirements. UPS claims that you can receive the finished product the next day after placing the order.

"Just as e-commerce has transformed commerce, so too will 3D printing change how products are made," said Alan Amling, Vice President of Corporate Strategy at UPS.

Print-on-demand eliminates warehouse space and product storage costs. It is enough to produce a small amount of goods, and if necessary, replenish stocks on the printing press. In addition, manufacturers can release goods faster and customize them according to the wishes of customers.

The technology of a Russian startup will change the global footwear market

Cases

Devices for 3D printing can no longer be called a rarity: they equip classrooms in schools, offices, factories and even workshops in prisons. According to Gartner, 455,772 3D printers will be sold worldwide in 2016, and 6.7 million printers will be sold in 2020. The range of applications for industrial 3D printing will increase by 75% by 2020. Almost 65% of discrete manufacturing enterprises will use 3D printing to produce components. Already, technology allows printing electric vehicles and jet engines.

Read more

Congratulations, you have subscribed to the Hitech digest! Check your email

Thank you, your message has been sent successfully.

List of 3d printing services / Habr

AndreyPanov

Reading time 2 min

Views106K

3D printers

Good afternoon everyone!

On Habré, you can relatively often see articles on 3d printers, comparing their prices and ordering opportunities with us.

And what about the finished 3D models?

What if I don’t want to buy a printer yet, but it would be interesting to “feel” the printed model. And it is advisable to choose from a catalog of ready-made models, and not draw it yourself.

Are there many resources where they can be downloaded, bought or printed from the catalog?

Answering these questions, I decided to make a small list of resources with the ability to select ready-made models and order printing.

Foreign services:

- www.thingiverse.com is probably the most well-known in existence. The service was created for the free exchange of models under the GNU General Public License. The service has been operating since 2008. Owned by MakerBot Industries, USA.

- www.shapeways.com - custom printing. The service has been operating since 2011. Production (printing) is located in the Netherlands and the USA. You can add your own, you can even create your own store. Due to the extensive fleet of 3d printers, they provide a large selection of materials, including ceramics and steel. They deliver to Russia.

- i.materialise.com/gallery - Print models from the catalog. The company has been operating since 1990 and is located in Belgium.

- It is also possible to evaluate your model and choose material

- www.sculpteo.com/en/gallery/today - print 3d models and sell your own. There are quite complex and expensive models.

- www.

Learn more