Getting started with 3d printing 2023

The Best Resources for 3D Printing Beginners 2023

September 29, 2022

In the previous article, we’ve talked about the basics you need to know about 3D printing. Next we will discuss where you can get 3D models and download STL files for free. While many models are available to purchase, there are plenty of free models and STL files you can get for free. It’s an easy, time-saving way to get started on your 3D model adventures.

1, ALL3DP

All3DP is a website that provides information and resources on 3D printing. The site includes articles, tutorials, and a reviews section where they review 3D printers and 3D modeling software. The website has a "Basics" section where you can learn the fundamentals of 3D printing and a "Pro" section where you can dive into more advanced topics.

All3DP also includes its own online 3D printing service, CraftCloud. Whether you are designing complex 3D models or just simple ones, or you want to 3D print but don't have a 3D printer, you can simply use CraftCloud.

2, Thingiverse

Thingiverse is a popular website for 3D printing models and it’s completely free. It is a place where users are able to not only share their own individual pieces of work but also both acquire and mix other users’ work too.

Thingiverse also strives to ensure that all the 3D models presented here are licensed under their own creative commons license. In fact, this is the guiding spirit behind maintaining this open platform. This means that just about anyone can either use or alter the models, designs and free STL files present here.

3, YouMagine

On YouMagine, designs are gathered into collections, which is another way that you can search for new projects. It contains over 19,000 free and open models, free STL files, and designs for 3D printing. YouMagine is a great way to start your search for your very first 3D printing project. Even if you are an expert in the art and science of 3D printing, you can still learn a lot from the community here.

4, Thangs

On Thangs you can search for models based on similar geometric shapes, so it’s like a searching engine. You can upload a prepared STL file to the search box, or simply type a shape into the search engine. On each model page, neat viewing options can be changed to display the model from different angles, and with render modes and colors, before downloading the files. This website also allows you to limit your search for models only to the Thangs website, or else open the search to other sites on the internet.

5, Cults3D

Cults is one of the leading independent websites for 3D printer files. It is a digital marketplace for 3D printing and design. Use its 3D model library to discover everything you can do with a 3D printer (FDM, SLA, DLP, SLS) event with CNC machining and laser cutting. The formats you can download are in STL, OBJ, 3MF, CAD, STEP, SCAD or DXF, DWG, SVG format, they are all 3D printable guaranteed or CNC compatible.

6, Yeggi

Yeggi remains one of the top 3D printable model search engines available. It's a bit different from sites such as Thingiverse. Rather than a dedicated site for 3D STL files and other 3D printing downloads, it's essentially the Google of 3D printing. Merely search Yeggi, then download your files. It's a fantastic, comprehensive 3D printing search engine.

7, MyMiniFactory

MyMiniFactory is one of the primary repositories for 3D models and STL files. There are 18 categories on the website and they range from jewelry to fan art to education. You can download directly from the website or alternately, browse through their stores. You can even set up your own store on the website and earn via the original models you place there. Apart from that, the site regularly holds competitions for up and coming talent and there is even a blog section, in case you want helpful tips on 3D printing.

8, 3DExport

3DExport offers step-by-step tutorials on a whole range of 3D prints and it has a large variety of different models and STL files that may be downloaded for free or via paid subscription. The paid subscription offer entitles you to free promotions and high res 3D STL files are sent directly to your email address on a weekly base. There are no charges for this promotion. Apart from the 3D models and STL files, the site has a whole lot more to offer and provides detailed tutorials on scripting, CAD, rigging, sculpturing, texturing, game development, and heaps more.

9, TinckerCAD

Tinkercad is a product of Autodesk, leader of the most popular 3D modeling and CAD software. Its free software is available online. The subjects included are intuitive and you can learn the basics of 3D printing by using primitive shapes. It is easy to use and will save you time. Tinkercad is devoted to help users around the world think, create and make.

10, Elecrow

Want to 3D print an object but don’t have a 3D printer? Here is your best option. As a matured online 3D printing manufacturer, Elecrow will provide you with the latest and cost-effective Online 3D Printing Service. Elecrow commits to carefully and efficiently process every product complying fully with customers’ requirements. Elecrow ensures the proper operation of its quality control system and guarantees the quality of all the products/parts ordered.

Elecrow is launching an awesome

Autumn 3D Printing & Acrylic Promotion on the official website from September 19th. The price of Photosensitive resin (domestic 9400) for 3D printing starts from $10. All you need is to Upload your STL File for 3D printing on Elecrow 3D Printing Service page, and you will receive our instant quote. Can’t miss out!11, Reddit 3D Printing Community

Reddit 3D printing community is a place where makers of all skill levels and walks of life can learn about and discuss 3D printing and development of 3D printed parts and devices.

Besides, if you have problems related to your 3D printing projects, you can post it here for discussion.

Besides, if you have problems related to your 3D printing projects, you can post it here for discussion.

How to Start 3D Printing business as Freelancer [ Ultimate Guide]

As word of 3D printing spreads like wildfire throughout the world, many individuals and businesses have already established their own 3D printing businesses.

The good news is that competition is still surfacing, and you can get started right away to avoid much of the chaos.

It would have seemed impossible only a few years ago, but you can now build an entire business around 3D printing.

We have already seen examples of 3D printing being revolutionary in a variety of fields, including healthcare and education.

There are also many unlocked doors that can be unlocked using 3D printing.

You can use 3D printing to create your own unique ideas and give the world something new to try.

Any business needs basic skills and a way of thinking. 3D printing is a new area of business that needs more time to develop. Technology is still being made better.

Technology is still being made better.

I would prepare for this business in two steps. First, you need to learn how to be an entrepreneur and get a business mind. I’d recommend that you start by learning about the business opportunity analysis canvas. It will help you see your business plan and analysis in a bigger picture. You can also learn the basics of accounting and office work.

In the second step, you need to first know a lot about 3D printing & Software. You can do as much research as you want on 3D printing, or you can take a free 3D printing course on Coursera, which I did.

Depending on where you live, you may also need to do some basic market research. This is easy to do by asking people what kinds of products they want.

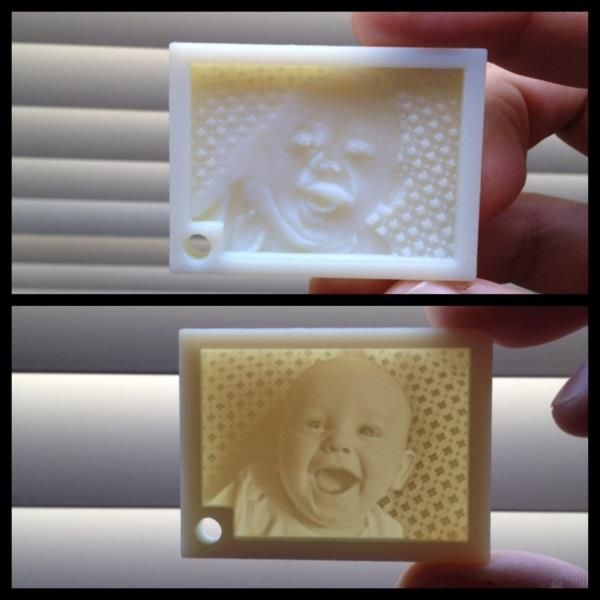

For example, kids in your area may want to put their pictures or name on their toys. Remember that what the customer wants is more important than what you think is the right product.

Alternatively, you can begin customizing the ones that have already been tried and tested by adding a unique twist through your creativity.

Let’s take a closer look at how this technology is constantly changing the way we do business and where you can fit your jigsaw piece to reap the most benefits.

Will 3D Printing Business be Profitable?

It will not be factually incorrect to consider 3D printing as a profitable business.

You can certainly turn your imaginations and ideas into profits if you are willing to explore and pursue a few small as well as large avenues required to start the business. You must seek to learn about technology in all of its forms.

There are often questions of this nature when a new business is started, including the following: How can one make a living off of 3D printing? Would there be a return on investment?

And so are all of the worries that individuals have about beginning a business that involves 3D printing, particularly when they do not know how to make use of it.

There are a lot of different applications for 3D printing, but picking the right one might be difficult because of the wide variety of printer and material costs, as well as the enormous variety in the mechanical qualities of the pieces that can be created.

To get started with 3D printing, you have two options: established business or freelancer services.

1 – Established Company:

If you have some money to invest in developing your own brand, you can launch a full-fledged company that accepts orders from customers (B2B or B2C) and ships the finished product. You can look for clients who require prototyping or customized items.

You can sell items printed on your 3D printer to local stores and accept customization requests.

2 – Freelance 3D Printing Services:

If you are new to 3D printing and do not have much experience, it is best to start as a freelancer. You can still start providing freelance services.

What you’ll need to start a 3D printing business as a Freelancer

Research your way out…Folks!

Research … a Lot. Reaching helps you Figure out what’s in and what’s out in the 3D printing Business.

Begin your investigation further with Kickstarter campaigns devoted to 3D-printable figures and then move to 3D-printing Facebook groups, which pointed you on the proper path for additional study. Who better to consult than your prospective clients?

Who better to consult than your prospective clients?

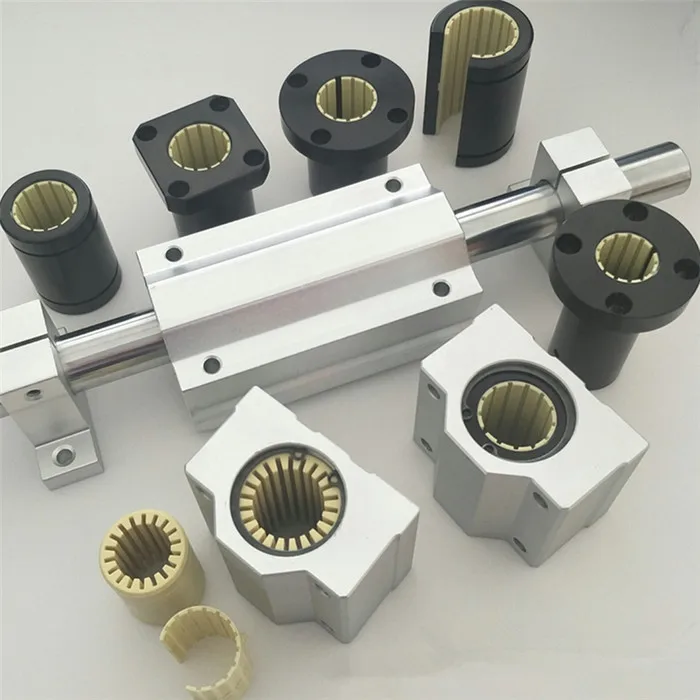

Attend a 3d Printing workshop and get to know the basics and the industry. Its a collaboration of two industries primarily for making a 3D printer(Electronics and Mechanical industry) , although the Printing industry is looking to adopt it in the field of personalization, packaging, and research.

You can make money by printing cool little things, like figurines, art, and tools from Thingiverse. Bundle them in one lot and sell on Mercari.

A spool of filament costs 11.99 but I can print 60 chess rooks and sell them in bundles of 10 for $15, profiting $60 after filament cost and shipping, and all items on Thingiverse are free to download. Also, you can play around with the download to make your own unique item.

Websites I use for research include the following.

- To view other active projects and their triumphs on Kickstarter.

- To investigate other creators offering monthly 3D packs on Patreon.

- MyMiniFactory is one of the most prominent online 3D printing stores.

- Artstation – A global community for 3D and 2D artists working in games and visual effects.

- Thingiverse – A website with free printable 3D models

- Pinshape is a website that offers both free and premium 3D printable files.

- Cults3D – A website that provides both free and premium 3D printable files

- I would suggest watching tutorials for creating 3D figurines, as well as reviews of 3D printers and experienced miniature artists, on the world wide web and on Youtube.

- There are numerous Facebook groups devoted to 3D printing – Nomad Sculpt , Zbrush & Blender, and so on…simply search for 3D Printing Business and “3D printing” groups.

Get the right Tools & Training

So, what are the tools you need to start your 3D printing Business From home?

- You’ll need 3D Software to create 3D Characters – If you intend to be a Freelancer, Nomad sculpt is the Software that I recommend to Learn & Master.

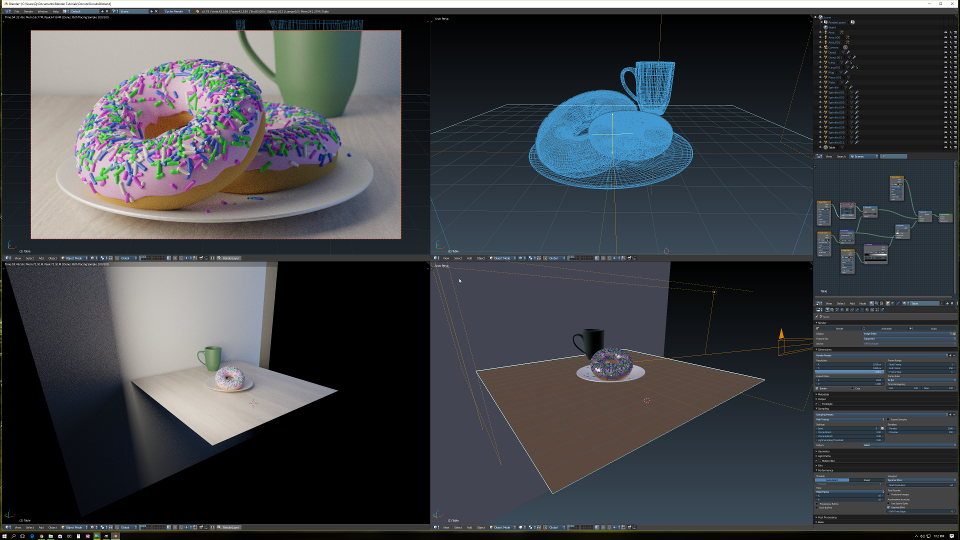

You can also Explore other 3D Softwares Like Blender, Forger, and Zbrush.

You can also Explore other 3D Softwares Like Blender, Forger, and Zbrush. - Computer, laptop, or iPad ( For Nomad Sculpt)depending on the 3D Software you choose

- Additional tools like Stylus, gloves, and iPad stand( for Nomad Sculpt)

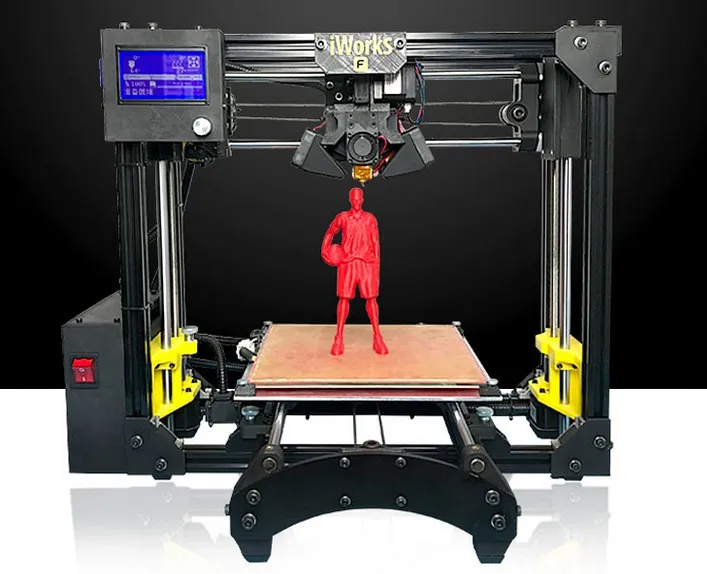

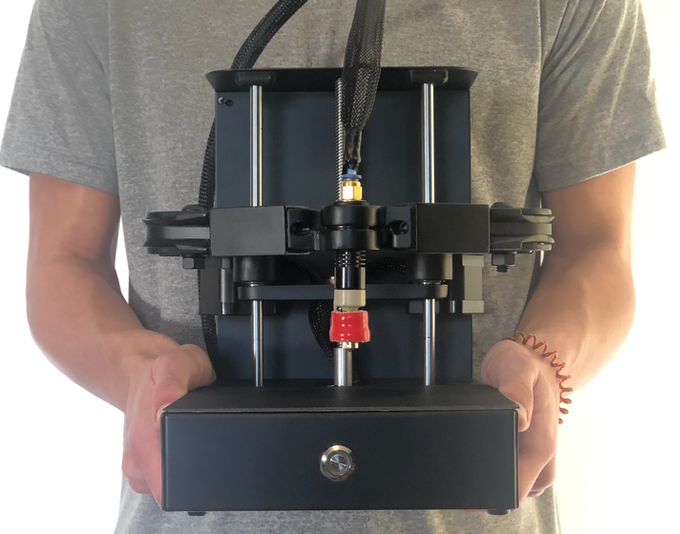

- What Type of 3D Printer to use Resin, FDM/PLA – Check out my Blog 11 best Budget-friendly 3D printers

- If you are a Newbie, you’d want to learn the Software to create 3D Models & Sculpts.

Also Read: The best iPad for Nomad Sculpt- 3D Art, The best Stylus for digital art in 2022

Decide your Niche or the Business idea

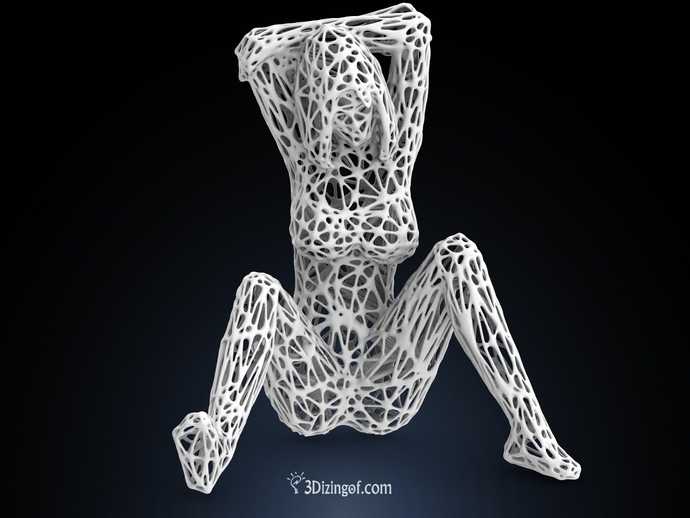

Sculpting in three dimensions requires time, patience, and practice. Technically, anyone can do it, but it takes time to learn, particularly if you have no prior experience with 3D modeling.

Based on your research and your personal Interests you decide your Niche/Business Idea. For instance, I decided, based on my study and personal preferences, that I wanted to develop personalities, & Characters and because of my own interests, I decided to create bust sculpting.

Use 3D printing for prototyping or commission work for things you design. That’s how to be profitable. Also, Deciding to start a Business really depends on how much money you have and happy to invest.

With less money to start a 3D printing Business: – You can buy just one 3D printer (FDM/FFF) and start offering 3D printing services in your area. But you can’t get rich with just one printer? But I guess it’s a start. Also, you can add a 3D scanner after that.

- You can work with advertising firms that don’t want to use 3D printers and have them send the work to you. Some new businesses also need 3D printing to make prototypes.

- If you know enough about 3D printing, you can start workshops or classes on the subject.

- And much, much more. Having a 3D printer will help you in many business areas.

If you have more money to invest, you can do all of the above, but better.

- You can make a farm for 3D printing.

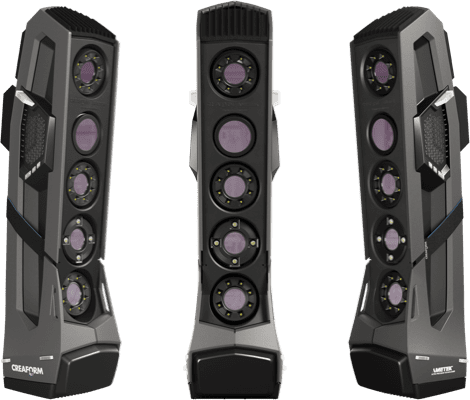

- You can buy different kinds of 3D printers (FDM, DLP, SLS, and full-color 3D printers) and some very good 3D scanners (with 5-digit prices) so you can give your customers a very good service.

- You can open a Makerspace or FabLab where people can use machines on their own.

- You can open an online store for Maker products (3D printers, 3D scanners, 3D filament, and so on).

With RepRap’s Open Source, you can build and sell your own 3D printers.

You can Try to be in 3D printing Jewelry, the Home Decor Industry, or even the Promotional Products Industry- Check out My Latest blog 11+ Innovative & Profitable 3D Printing Business Ideas that can help you decide on one Niche to move forward…

Just to make it simple, I am sharing below some of the top 7 Most Successful Business Ideas for 3D Printing

- Personalize Well-Known Characters

- Creating New Fashion Items like shoes or bags

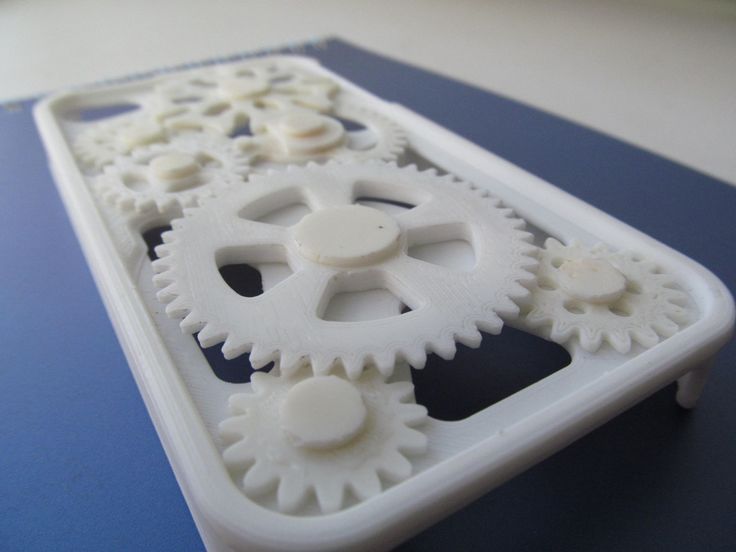

- Kids Toys printing

- Jewelry Designing, Casting & Printing – The term “3D printing jewelry” does not refer to the process of actually printing wearable pieces from filament or resin.

Instead, the term refers to the use of a jewelry 3D printer to create high-resolution wax models of the eventual gold or platinum design. These wax models are then used to create a mold that is burned out and cast using investment casting or lost wax casting.

Instead, the term refers to the use of a jewelry 3D printer to create high-resolution wax models of the eventual gold or platinum design. These wax models are then used to create a mold that is burned out and cast using investment casting or lost wax casting. - Developing and Creating Prototypes

- Adult Toys printing

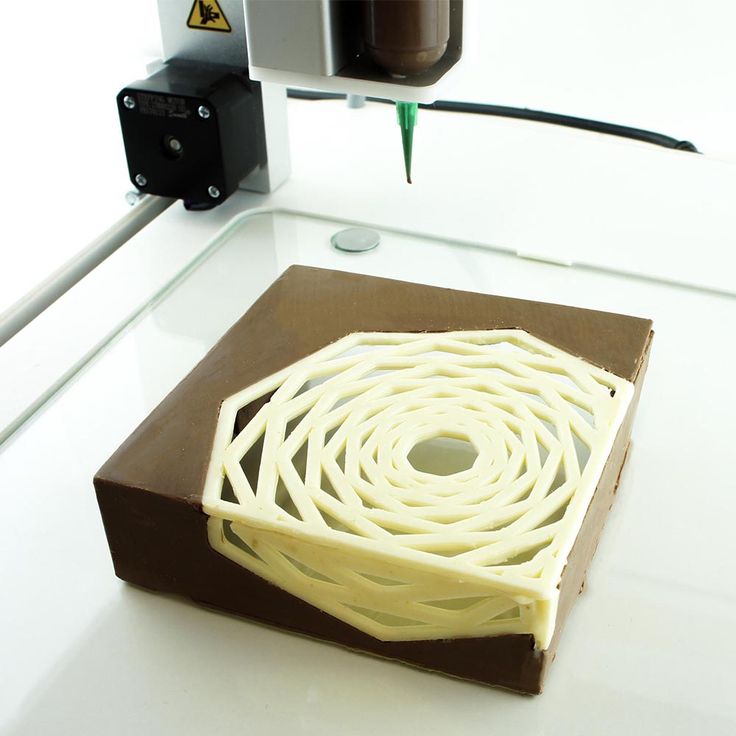

- Designing Culinary

- Utilizing 3D Printers for the Process of Bioprinting

- 3D Printing Personalized Medicines: A significant number of patients, particularly elderly persons, are required to take medication on a consistent basis. Ingesting medications is not a pleasant experience, and the process is made even more unpleasant when the pills do not dissolve quickly or when they are too large to be easily swallowed. In order to address this issue, there is a growing demand for individualized medical treatment. You can now get involved in the 3D printing of medicine, which has already begun by the pharmaceutical industry.

If you choose to operate a business in the field of medicine 3D printing, you will have a significant advantage over the competition due to the low number of existing competitors.

What Is The Best 3D Printer to start 3D Printing Business?

The selection of a printer is contingent on a variety of elements. Before you go out and buy a 3D printer, you need to consider the following.

When looking to purchase your first 3D printer for use in your office, lab, studio, or workshop, the ease of use and availability of customer assistance should be the first things on your list of priorities.

Your company’s printer needs to make a contribution to the overall productivity and speed to market of your business. It needs to reduce the amount of time and money you spend.

You can’t afford to squander time with a variety of manual controls that require the knowledge of seasoned professionals, prints that fail because the mechanics are unreliable, or no one to call for assistance.

Below is the list of top 3D printers for Freelancers & Small businesses

- Anycubic Photon Mono x – Resin 3D Printer(- Most suitable for Miniature Characters

- Phrozen Sonic Mini 4K – Best Printer Choice for Jewelry Printing

- FlashForge 3D Printer Creator Pro2 – Best 3D Printer for industrial design, tool design, architecture designer, mechanical designer

Other printers in the list:

- Formlabs Form 3+

- Ultimaker S5 Pro

- Markforged Mark Two

- Raise3D Pro3 Plus

- Formlabs Fuse 1+ 30W

- Original Prusa i3 MK3S+

Legalize your 3D printing business

Next, choose a business structure and register it with the Secretary of State in each state where you operate.

Five legal structures are typical.

Single-owner(Sole Propritership)

In a sole proprietorship, the 3D printing business owner is also the business. Sole proprietors are accountable for all debts and liabilities. A sole proprietorship requires no procedures and is easy to operate. A sole proprietorship is easy and cheap to form. The owner is responsible for all business debts and commitments.

Sole proprietors are accountable for all debts and liabilities. A sole proprietorship requires no procedures and is easy to operate. A sole proprietorship is easy and cheap to form. The owner is responsible for all business debts and commitments.

Partnerships

Small business owners often form partnerships. It’s an agreement between two or more people starting a 3D printing firm. Partners share gains and losses.

A partnership is straightforward to form, and partners share earnings and losses. Disadvantages of a partnership include joint liability for commercial debts and challenging partner arguments.

LTD (LLC)

LLCs limit their owners’ liabilities. This means LLC owners aren’t liable for business debts and obligations. A 3D printing LLC offers flexible management, pass-through taxation (which prevents double taxation), and reduced personal liability. LLC drawbacks include state availability and self-employment taxes.

C-Corp

C-Corporations are distinct from their owners. It has an EIN and stockholders. C Corporations offer minimal liability for 3D printing business owners. This means owners aren’t responsible for corporate debts and obligations. C Corporations are double-taxed. This implies both the firm and its owners pay taxes on profits and dividends.

It has an EIN and stockholders. C Corporations offer minimal liability for 3D printing business owners. This means owners aren’t responsible for corporate debts and obligations. C Corporations are double-taxed. This implies both the firm and its owners pay taxes on profits and dividends.

S-Corp

An S Corporation gives its owners limited liability protection and lets them pass corporate income through to their personal tax returns, avoiding double taxation. S Corporations have constraints, including the number of stockholders.

Your state will provide you with “Articles of Incorporation” once you register your 3D printing business. This is needed to open a bank account (see below). Consult an attorney to determine your company’s legal structure.

What Types Of Skills Are Necessary To Get Started With 3D Printing?

Printing in three dimensions successfully involves a few different skill sets, much like any other occupation.

It is not foolhardy to try one’s hand at a profession in the same sector, as the industry is expanding and has attracted people from just about every possible subfield to conceive of its applications.

If you channel your skills in the correct direction, you could make unimaginable amounts of money.

There are businesses out there that have integrated 3D printing into several stages of their production process.

If you have the necessary skill set, you have the option of either joining them or starting your own 3D printing business. Then, what exactly are those skills?

Knowledge of the 3D Printer

The inkjet printing process is far superior to the 3D printing process. It is not enough to just press the print button on the computer in order to pull the document directly from the mouth of the printer. Operating a 3D printer effectively calls for a high level of technical expertise.

It is not in your best interest to have to pay for a damaged 3D printer, since this will only drive up your manufacturing costs and delay your deliveries.

If you are unsure of how to operate the printer correctly or which filament to use with a particular 3D printer, you run the risk of causing irreparable damage to your 3D printer, which could range from minor to major.

Keep in mind that purchasing a 3D printer will incur an expense and if it breaks down, replacing it will require another significant financial outlay.

Therefore, you should make an effort to educate yourself as much as possible on your 3D printer. Normal inspections and material filling are both things you need to be familiar with. In order to ensure continuous operation, you need to be aware of how to work around specific bugs.

I use Anycubic Photon Mono X for all my miniature 3D prints and here is a review of the Anycubic 3D printer.

Expertise in 3D Software– for creating 3D Art

Despite this, there are certain jobs that can be completed with only fundamental familiarity with CAD and slicing software. Also Read: Do I Need to Know How to Sculpt as a 3D Modeler?

Softwares you need to be familiar with If you want to start your 3D printing Business

- Sculpting software like Nomad sculpt, Mudbox, Zbrush, Or Blender.

- Lychee Software for Slicing the 3D Object before printing

However, a specialist understanding of these two software packages is necessary for prototyping and a variety of other specialized areas.

You can study the software as well as how they work by enrolling in one of the many online courses currently available.

Even if they are not particularly difficult, you might need to spend some time thinking about them in order to get a better grasp on what they mean.

After all, any error in getting the plan perfect could end up costing you a lot of money. You should never settle for 3D printouts that are an exact reflection of the opposite of what you envisioned.

Spend some time getting familiar with the software. Be aware of the options that are available and determine which one would work best for the model of your organization.

Before moving further with the business plan, you should begin by using the free versions of the software to test your knowledge, learn how to produce CAD designs, and become familiar with the slicing program.

Also Read: How to Get Started with Nomad sculpt – The Complete Beginners Guide

Printing Expertise:Knowing the printer and 3D Software are on one side..another side of the 3d Printing Business is to print the selected Objects in any 3D printer.

Printing is no Brainer, I agree but printing a good Quality 3d Object has a bit of a Learning curve. There are many things to consider & learn like slicing software, how to create the support, how to wash & cure and so. Trust me it’s not Rocket science You can spend a day or 2 with a few Youtube Videos.. Voila, here you go..

I’ll explain how I 3d printed the Miniatures using Nomad Sculpt, Lychee Software, and Anycubic 3D printer.

Below are the steps and a 3D print I just made recently and Captured the flow.

Let’s assume, you selected to print on AnyCubic Photon Mono ( for Miniatures). Let’s again assume you created an Object let’s say Robot On Nomad Sculpt. So, Now let’s print the miniature Robot on an Anycubic Photon 3D printer.

So, Now let’s print the miniature Robot on an Anycubic Photon 3D printer.

Quick Steps for 3D printing using Anycubic Photon Mono

- Select the sculpt to 3d print on Nomad Sculpt

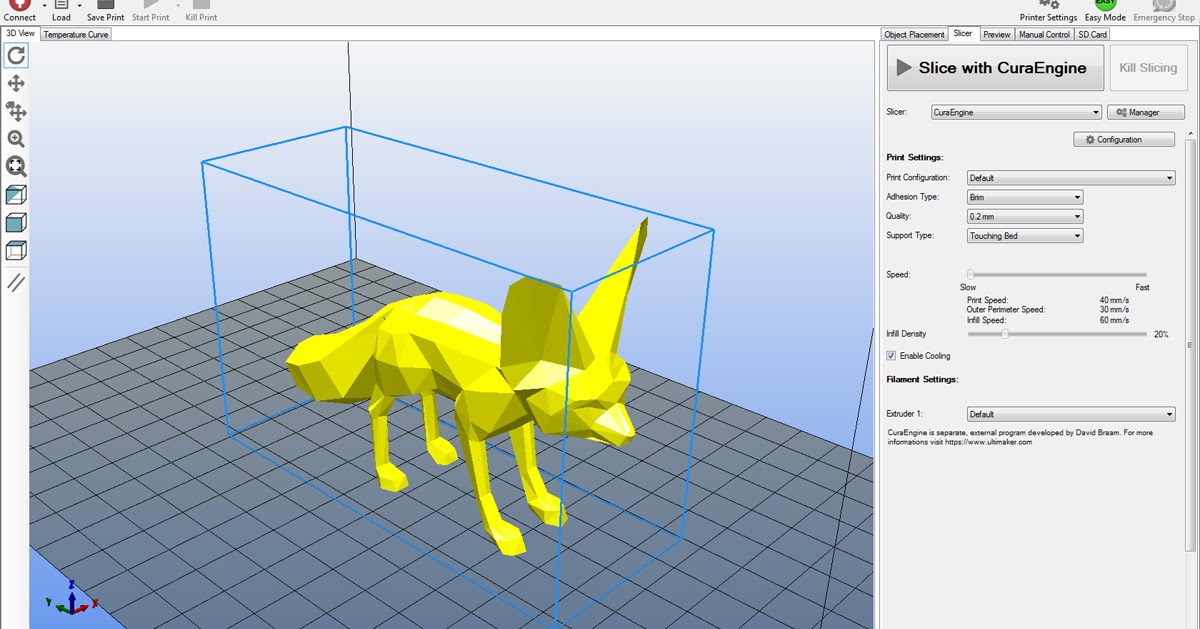

- Bring the selected sculpt on LYCHEE and Slice it on LYCHEE Software[ Download LYCHEE Software ]

- Export to USB

- Plug the USB onto the 3D printer

- Complete Leveling of 3D printer

- Add your selected Resin

- Fix the Exposure settings

- And let the 3D printing Begin(It takes Hours depending on the size of the sculpt)

- After printing wash it with Alchohol( IPA) and clean it in warm water

- Remove supports

- CURE your 3d Object using Anycubic Wash & Cure station

- Your model is ready to be Painted.

Which Software is Best For 3D Modelling or 3D Sculpting?

Which Software is Best For 3D Modelling or 3D Sculpting?

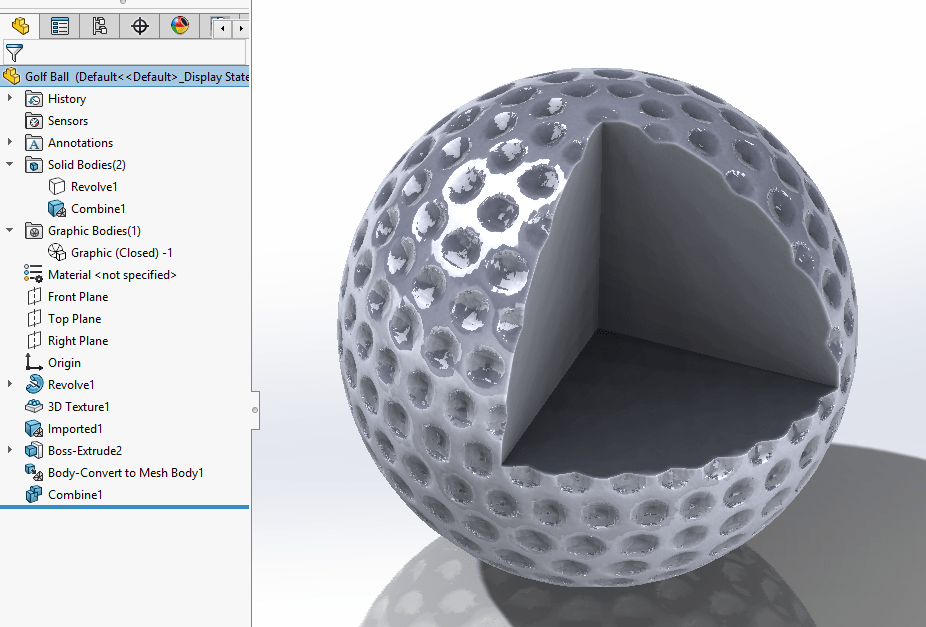

The use of 3D models is essential to the process of 3D printing. Making exceptional 3D prints calls for a high level of precision as well as talent at a very high level.

Additionally, 3D modeling software makes it simple for users to transform their own thoughts and ideas into tangible 3D models, which can then be printed when the necessary preparations have been made.

On the basis of your objectives, the following is a list of some of the 3D modeling software that you will need to consider learning…

I know its a long list… but You can select the one which you have an interest in

- Adobe Substance 3D — Best 3D modeling software overall (Editor’s Choice)

- Maya— One of the most powerful and versatile 3D modeling tools

- Nomad Sculpt – The best On-the-Go iPad Digital Sculpt App

- Adobe Dimension— An easy-to-use 3D software for simple product design

- Fusion 360 — best free software for CAD/CAM users

- Houdini— One of the most popular software used in the film industry

- Autodesk 3DS Max— Best 3D modeling software for products and industrial use

- Modo — One of the best software for texturing and rendering

- Blender— Best free 3D software tool overall

- Z Brush— The best 3D sculpting software

- Hexagon— A free versatile design tool

- Daz Studio— A powerful and reliable 3D design software

- Lightwave 3D – Best Production-Proven Sci-fi 3D Design Software

3D Software that I use for my 3D Sculpts

Practicing your 3D sculpting

Nomad Sculpt is what I use for my 3D creatives. Even though I am proficient to use Zbrush & Autodesk Maya( another Industry standard 3d software), I prefer Nomad Sculpt because it’s On the Go and I can Sculpt on my fave iPad. OK! You can use ZBrush as well but for a beginner or a newbie, Zbrush has a Steeper learning curve. So, I would prefer Nomad Sculpt.

Even though I am proficient to use Zbrush & Autodesk Maya( another Industry standard 3d software), I prefer Nomad Sculpt because it’s On the Go and I can Sculpt on my fave iPad. OK! You can use ZBrush as well but for a beginner or a newbie, Zbrush has a Steeper learning curve. So, I would prefer Nomad Sculpt.

Blender is an alternative free software with sculpting skills. It is incredibly popular and capable of fulfilling all of your business needs.

Personally, I do not use Blender due to the fact that I began 3D modeling in Maya before switching to Nomad Sculpt. Because Blender is quite different and I am a creature of habit, I prefer to stick with these two applications rather than learning a third one. I have no desire to learn a new UI.

The best courses, certifications, and training for 3D printing

To learn more about how 3D printing works, people must take courses that are right for their level of knowledge. These are the courses that are good for people at all levels, from beginners to experts.

These are the courses that are good for people at all levels, from beginners to experts.

Udemy has courses and tutorials on 3D printing.

Udemy is known for its useful courses that are easy to understand with the help of video lessons. From such a well-known website, you can be sure to get the best information about 3D printing.

The courses are easy to understand and are made for students of all skill levels. The best part is that the one for a beginner doesn’t need any skills you already have. You can use the course to get a job in the field or prepare for exams and certifications.

With a full lifetime membership, you can listen to lectures, read articles, and download resources. The cost of the course is very low and easy to handle.

Coursera has certifications and degrees in 3D printing.

If you want to improve your 3D printing skills, you can choose from about 20 different options. This is also made for people of all skill levels.

You can look for levels of programs that are split up by how hard they are.

You get to do a lot of exercises that help you learn about the subject. The due dates are flexible, so you can finish when it’s easiest for you.

After the courses, you take tests that give you a certificate for the course you took.

Where do you think the 3D printing business will be in ten years?Among the new 3D printing technologies I’ve seen so far, the new printer is made by Voxel at Voxel8.co is one of the things I’m most excited about. This printer can use both plastic ink and ink that conducts electricity. That means you can print your electrical circuit right into the part, so you don’t have to do as much wiring or soldering. I can see how this would be good for people who make drones and for people who like to fly them as a hobby.

I think this trend will keep going because being able to print a composite part is one of the best things about FDM printing. Right now, companies in China are 3D printing houses with cement. I could see them adding wiring, insulation, etc. as they go along within 10 years.

I could see them adding wiring, insulation, etc. as they go along within 10 years.

3D printing will always be a hobbyist’s best friend, so it’s safe to say that this will keep happening and get cheaper.

One of the most important uses of 3D printing will always be to make prototype parts on demand. Over the next 10 years, the big test will be whether or not technology can improve to the point where 3D-printed parts are as cheap and take as long to make as injection-molded parts. At the moment, there’s no doubt that injection molding is still the best way to make a lot of things.

Also, the kinds of things that can be 3D printed are getting bigger. Along with ABS and other more traditional materials, there are now also materials made of rubber, wood, and cement.

I also think that 3D printing will be used more and more in food markets. Chocolate 3D printers are being made by Hershey’s and a few other big companies right now. I also know of other printers that can print on frosting and other materials that are used to decorate.

3D printing is also going to play a big role in exploring and living in space. We now have the technology to print parts on the space station. Talk about ways to save time and money. One day, 3D-printed parts could save lives in colonies that don’t have any other way to get them.

As time goes on, 3D printing will become even more important to people who work in product design and engineering. Now that I have a 3D printer, it’s already paid for itself, and I’m optimistic about the future.

Time to Launch your 3D printing Business

Preparing for Launch

When you have created & Printed approximately 10-12 Objects you can begin marketing your campaign.

Create Your 3D Printing Business Marketing Materials

Your 3D printing company will need marketing materials in order to bring in new customers and keep the ones it already has.

The following is a list of the essential marketing materials that you will require:

Marketing is quite difficult. But you can make it easy by following the below steps

But you can make it easy by following the below steps

Start a website- Get a simple WordPress website and start Blogging about your 3D printing Journey It is vitally important to keep in mind that the appearance and feel of your own website will have an effect on how clients view you.

Websites: Professional 3D printing businesses should have websites that give potential consumers information about the products and/or services they offer, as well as information about the history of the firm and contact information.

Accounts on Social Media: Create accounts on various social media platforms using the name of your firm. Customers and other individuals will have an easier time discovering and interacting with your 3D printing company if it has a presence on social media networks such as Facebook, Twitter, and LinkedIn.

Get your Instagram & Pinterest accounts and relaunch them with the brand name you have chosen for your business. You then start sharing photographs of the printed figurines with pertinent hashtags.

You then start sharing photographs of the printed figurines with pertinent hashtags.

You start following the accounts of other designers, printers, and figure painters. Additionally, I began following similar creators on Twitter, Twitch, and Facebook.

Your brand is essential. You should determine this before launching a project if you wish to be noteworthy.

You also build a Facebook group (not just a page) for your new brand. Facebook’s algorithm typically consumes official page posts and holds them, prisoner, unless you pay for advertising. By forming a group, you increase the likelihood that its members will see your postings in their feed.

I recommend requiring potential members to answer some questions before joining your club in order to screen out spam and troll accounts.

This section is how you gain a solid start.

Make a few of your 3d art available for free download to everyone who subscribed to tour GetResponse – created email. Read How email marketing can help to grow your online Business. You can share this free download on 3D printing Facebook groups.

You can share this free download on 3D printing Facebook groups.

By giving away this one number, you can get more newsletter sign-ups, and these individuals joined can join your Facebook group. This is Marketing…

Invest some time and effort into designing a professional-looking logo for your 3D printing company. Your company’s stationery, business cards, marketing brochures, and other items will all feature printed versions of your logo.

Customers’ trust in your brand as well as their awareness of it can be increased with the correct logo.

What is the future of 3D printing?

Since the beginning of the 21st century, 3D printing has been all the rage. Even in 2020, you can still say that this amazing technology is still in its early stages. In just a few decades, it has made a lot of progress and changed some of the most important industries and fields around the world.

But is it even half as far along as what was planned? I don’t think we’ve even been able to get 30% of what 3D printers are actually capable of making.

Yes, 3D printers are used in homes, the food industry, the building industry, and the manufacturing units of many other industries. However, the range of what 3D printers can make is so large that we can’t even imagine getting all of it in the next few decades.

So, as far as I can tell, 3D printing has a bright future. Here are a few ways in which this technology will definitely get better over time.

Bioprinting:

You probably already know about 3D printers that use human cells as ink and can print organs that have been damaged in the body over time. These damaged organs can be replaced with organs that are made with 3D printing, which saves lives.

But even though researchers have been able to print 3D organs for the human body, they still can’t be used in the body. They need to be rethought and changed before they can be used in the human body.

3D Printing medicines

Even though 3D printers make it easy to make pills and other medicines for less money and with less waste, I think this technology is still in its early stages. 3D printing medicines could also lower the cost of making them and the cost of the final product as a whole.

3D printing medicines could also lower the cost of making them and the cost of the final product as a whole.

3D House Printed:

I think the best thing to make with a 3D printer would be a house. Big 3D printers can make houses that can be lived in a day, and these are also pretty good. But a house is more than just a concrete building; it has to have all the amenities to be called a real house.

Clothes and shoes that are 3D printed:

Again, this is not a new idea, and many fashion shows around the world have already shown off their best 3D-printed clothes, shoes, and other items.

But the future of this idea is definitely the mass production of products that people use every day and that are also affordable.

Quick Guide to start 3D printing Business as a Freelancer from Home

- Explore the Trends in the market Explore the niche you wish to fill Explore what buyers are seeking to purchase

- Join Facebook groups devoted to the particular Niche in order to engage with consumers and other creators — Additionally, there are a growing number of useful Discord channels.

- Select software to learn how to build printable 3D Objects.

- Discover online resources and tutorials to study the process of making printable figures.

- Determine how to evaluate your 3D printable Objects.

- Create a website for your brand and start Blogging

- Get your brand social Media handles on Pinterest, Instagram & Twitter

- Establish an Online storefront

- Maintain a constant supply of new products to improve your storefront revenue.

- Be open to exploring new markets and styles in your work.

Trending …Nomad Sculpt( 3D Sculpting Software)

3D printing the Objects

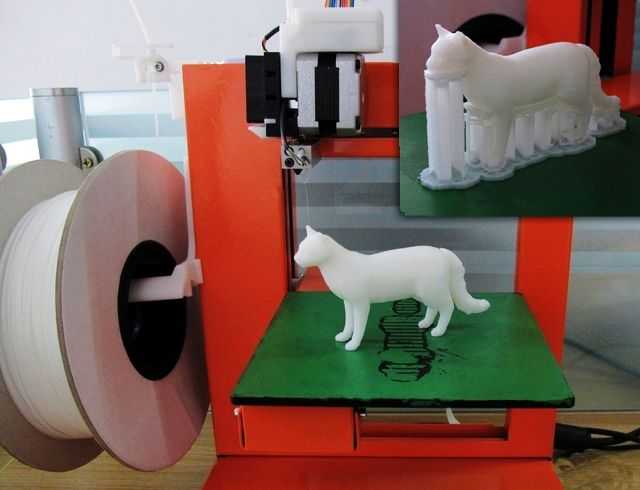

After finalizing your 3D design, it is time to put your creation into the physical world by using a 3D printer. Before relying on a 3D printer for your business, you should ideally be proficient in its operation (and, if necessary, its repair).

Most likely, you already have a 3D printer, but if you don’t, you should get one that is dependable and produces high-quality prints. Here is the list of 11 Budget Friendly 3d printers

Here is the list of 11 Budget Friendly 3d printers

Additionally, it is not a bad idea to have multiple printers. Since 3D printing is a slow process, it is prudent to run multiple printers concurrently to create multiple parts twice as quickly.

If you wish to avoid time-consuming filament or resin changes, you can even have a separate printer for each of your preferred materials.

You can create your Chosen sculpture( Tabletop Miniature) on Nomad sculpt and print it on the Resin printer to market & sell Online. My fave 3D printer is Anycubic Photon Mono X available at Walmart and at Amazon. I also like this Phrozen Sonic Mini 4k( the most Bidget-friendly). Read my article How to Prep 3D models for printing before you attempt to print your Sculpt. Also, Check out my Anycubic Photon Mono X Review

Made By Tim Timmons13 notes about 3D printing, after 3 years of owning a 3D printer / Habr

This article will be, first of all, of interest both to those who have directly dealt with 3D printing, that is, who owns a 3D printer, but also to those who are just about to join the ranks of 3D printers and are thinking about buying their own printer.

In the framework of this article, I want to present my observations, as a direct owner of a 3D printer, for more than 3 years.

Despite the fact that 3D printers have been known for a long time and, in my memory, have become widely used, judging by the information on various resources, starting around 2010 (I may be wrong, these are my subjective observations), for a long time I ignored this area, it’s hard to say why…

Probably thought it was some kind of "childish pampering", another hype topic for which there is simply not enough time. ..

..

The turning point happened when one of the wheels on my travel suitcase wore out. You know, a big plastic suitcase, with four spinning wheels on the bottom. Unfortunately, it is a “rather disposable thing”, due to the lack of bearings on the wheels, which is why the wear of the friction point of the axle and wheel allows the suitcase to last no more than one or two seasons.

And it’s like “lightning flashed in the middle of the day: 3D printer!” It is with his help that I can fix this problem! Looking ahead, I’ll say that I didn’t succeed in fixing the suitcase in this way, so I had to use a different approach ...

As a result, I “upped” it - installing wheels from unnecessary roller skates. Thanks to this “up”, the suitcase has become a real all-terrain vehicle and, even being very loaded, it rides easily - pushed forward even with “one finger”. And even in the snow, 5-6 cm thick. A tank, not a suitcase turned out! By the way - I took spinning wheeled "units" in Leroy. Then he took off and threw out his native plastic wheels from there, inserting from roller skates:

Then he took off and threw out his native plastic wheels from there, inserting from roller skates:

But this thought itself became a kind of trigger that allowed me to finally join the world of printers and buy my first 3D printer.

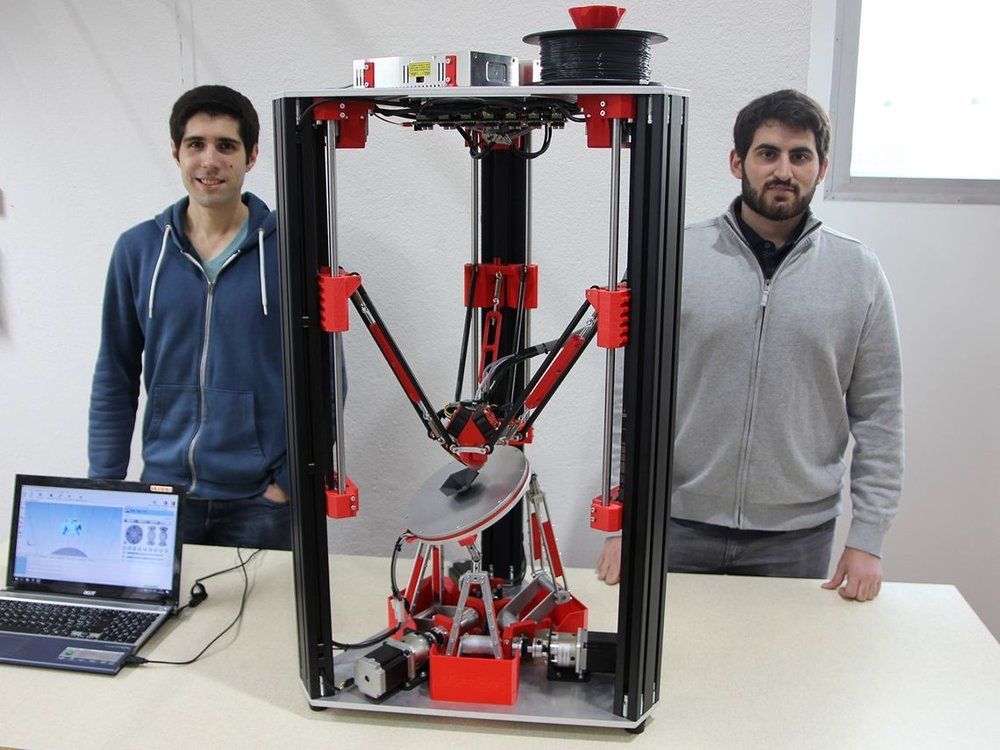

Like many, before buying it, I studied various forums and sites for a long time, delving into all the subtleties. And for some reason, I immediately liked the type of printer called the delta printer. Probably because during operation it looks like some kind of "alien device".

If at your leisure you like to sit “looking into the carpet”, then with the advent of such a printer you will have a much more interesting activity, even hypnotizing, one might say :-))

And this, in fact, is my delta (if anyone is interested), which went through, let's say, the "ultimate up": all the electronics are placed upstairs, on a self-made welded frame, covered with polyethylene and a magnetic door is made. The coil with a bar is installed at the top, on the frame. The axis on which the coil is put on is machined on a lathe from aluminum and a bearing from the VAZ timing is inserted into it. As a result, the coil - "rotates even from the passage of a fly nearby":

The coil with a bar is installed at the top, on the frame. The axis on which the coil is put on is machined on a lathe from aluminum and a bearing from the VAZ timing is inserted into it. As a result, the coil - "rotates even from the passage of a fly nearby":

Well, yes, I won’t argue for a long time, let’s start reviewing the main facts that I have accumulated as a result of owning this car ... The facts are purely subjective and may differ from your vision. In any case, I will be glad to comments, clarifications, etc.

▍ NOTE 1. Delta is good, but...

Here I should give a number of my observations regarding the delta printer:

- It contains a completely finished frame of the future box, which makes it easy to form a heat chamber. I understand that many printers are made in the form factor of a “certain box” (but this point cannot be ignored), which greatly facilitates the process of wrapping this box with heat-insulating material.

In my case, as such a material, I used a plastic film.

In my case, as such a material, I used a plastic film. - Already thanks to its design, delta allows you to work at much higher speeds than XY printers. By the way, it is on the delta principle that many modern high-speed industrial robots are built to sort various parts directly on the conveyor belt:

However, this plus does not allow to fully realize the occurrence of parasitic vibrations, even despite their suppressors:

Thus, accurate printing is possible, only at speeds (at least that was the case for me), no more than 60 mm per second. A complex procedure for aligning the movement of the head parallel to the table, which is why, for many, the so-called "lens" appears. People struggle with it with varying degrees of success, but I have not encountered this on my printer and for me, therefore, the “lens” has never been a problem. At the same point, it is worth noting the calibration of the table, which was initially absent on the first deltas, and I had to use an external third-party solution from one American do-it-yourselfer called EZBED. This solution was a hardware-software complex that allows you to quickly and easily calibrate the printing table, that is, to let the printer understand its geometry. Modern printers do not have this issue as they come with a built-in calibration solution. It is worth noting that I solved this problem by attaching a limit switch to the print head, and using the Marlin-1.1.9 firmware.

This solution was a hardware-software complex that allows you to quickly and easily calibrate the printing table, that is, to let the printer understand its geometry. Modern printers do not have this issue as they come with a built-in calibration solution. It is worth noting that I solved this problem by attaching a limit switch to the print head, and using the Marlin-1.1.9 firmware.

▍ NOTE 2. "Size doesn't matter..." :-)

When I got the printer, I was impressed by the possibility of huge printouts, a la the handguards of some futuristic rifles, huge body parts, etc.

However, if you try to analyze the results of your many years of practice, it turns out that in most cases, rather small objects were printed that easily fit in the palm of your hand, a maximum of two palms. Despite such a seemingly small size, the printing of these details took a significant amount of time. Of course, this very much depends on which nozzle you print with. But, despite this, it is difficult to disagree with the fact that most of the printed parts will be quite utilitarian and small in size.

But, despite this, it is difficult to disagree with the fact that most of the printed parts will be quite utilitarian and small in size.

Therefore, to be honest, the need for a printer that allows you to print "Venus de Milo in life size" is not obvious.

Of course, you can object to me that “I’m going to buy a printer, I’ll get used to it a little and I’ll get started!!!”

One simple point must be taken into account here: there are no universal things. And in order to understand how much 3D printing in general and your printer, in particular, you will need to solve your problems, and how much it will be able to solve such problems, you just need to first try the 3D printing method personally and then a lot will become clear to you .

Therefore, for a beginner, I recommend taking a small printer that allows you to print extremely small items that fit in the palm of two. With such a device, you will definitely never lose, as it will always be needed. In addition, with its help you will be able to get used to the printing process and, if necessary, purchase a larger device, already clearly understanding its capabilities and ability to solve your set of tasks.

▍ NOTE 3. "What type of printer to get."

Based on the foregoing, I do not recommend taking a delta printer and this can be said right away.

Not because it is bad, in fact, it prints quite accurately, its main problem (in my opinion) is the inability to print rectangular flat, fairly large case components, as well as the inability to fully realize high-speed work, since the quality drops critically. Here it turns out to be a rather offensive situation - the printer can work quickly, but this cannot be done, since the quality will be “nothing”.

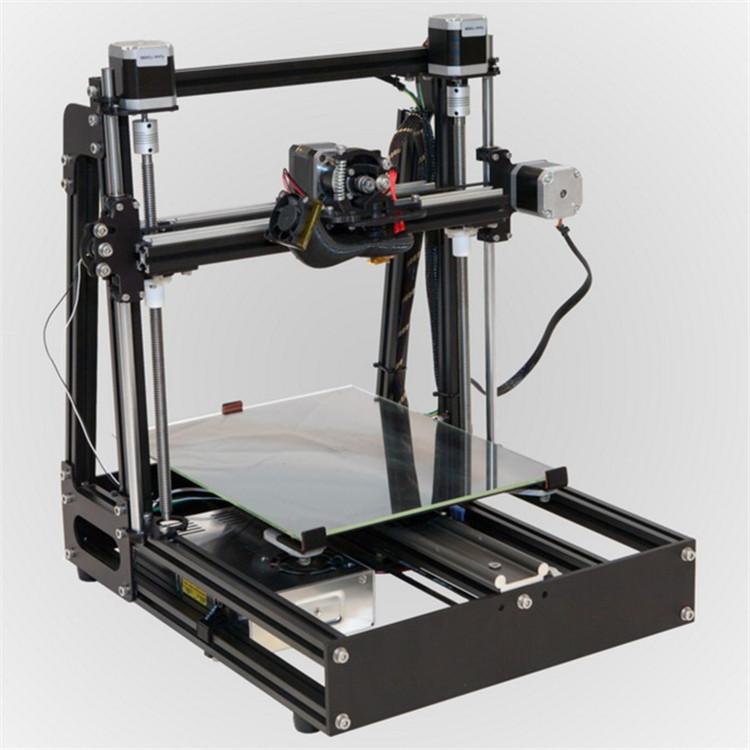

And then what kind to take? Depending on the budget and capabilities, I recommend taking any cube printer, for example, the same Core XY (the head moves, and the table goes down as the model “grows”, from top to bottom):

Image source: thingiverse.com

Such a printer allows you to easily print fairly large flat parts of cases, has good speed and accuracy. In addition, the presence of a rigid box-shaped frame allows it to be easily covered with polyethylene to create a sealed heat chamber. In addition, the very fact that the table does not move while working reduces the number of problems with model peeling.

In addition, the presence of a rigid box-shaped frame allows it to be easily covered with polyethylene to create a sealed heat chamber. In addition, the very fact that the table does not move while working reduces the number of problems with model peeling.

However, the advantages of this printer will not be fully revealed if it has a direct extruder. On the one hand, it will allow printing with rubber-like materials, on the other -

large inertia and head weight. And these are parasitic vibrations, wear of the fur. parts, etc. (like everything in life, “we treat one thing and cripple another” :-))

At the initial stages, this may not be necessary, but in the future it may be necessary to print, for example, tires for your homemade car. And with this, the Bowden extruder has obvious problems. Although, in fairness, printing with such a rubber-like material is far from a daily need. However, whoever seeks will always find: over time, I found a way to “upgrade” my printer with a Bowden extruder to print with flexible materials. "Crutches" of course. But even so.

"Crutches" of course. But even so.

By the way, there are printers of a cheaper type, the so-called "drygostol", printing by moving the table and head:

They are inexpensive, moderately accurate, but they require a sufficiently high-quality gluing of the printed model to the table, because the table moves, and the model can come off when the table is jerked sharply. When printing large models, this can be a problem.

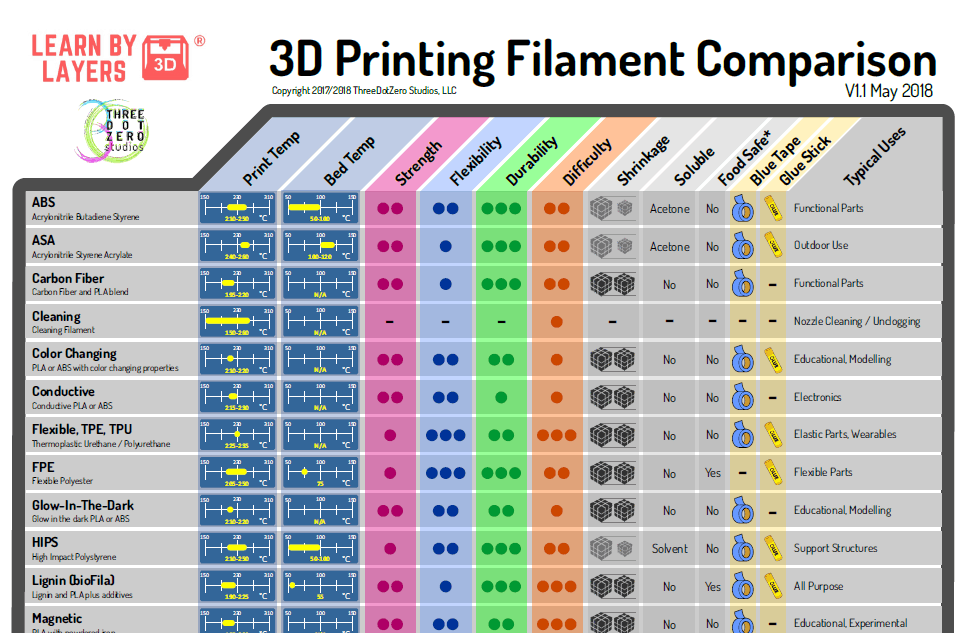

▍ NOTE 4. What to print with?

It's only a matter of taste and purpose. That is, if your printout will only stand on a shelf and should differ in some kind of aesthetic appearance, these are some requirements, if the printout is an engineering part that will be operated under conditions of increased mechanical load, these are different requirements. That is, in the first case, you can use any PLA, SBS plastics, and others with similar properties.

For engineering parts, for example, I only use ABS. It combines high hardness, strength and low price. Although I understand that now this last statement will cause a storm of comments in the style of “no! - there is even stronger, even better, the same PETG, etc. ":-)

Just here I wanted to say that thanks to the low price and the practical experiments that I conducted with ABS plastic, I realized that it is completely meets all my requirements.

However, the fact that ABS plastic releases carcinogenic substances when heated is quite annoying and forces you to take measures to prevent poisoning. For this, my printer prints completely closed and on an open balcony. After printing, the printer chamber opens, and it remains open in this form until it is completely ventilated and cools down.

▍ NOTE 5. "ABS is difficult to type on, it flakes, peels off the table, etc..."

With a properly configured printer (in my case, at a print temperature of 205 degrees, a thermal chamber and a desktop temperature of 100 degrees), the use of auxiliary techniques, for example, among which, one can name the so-called ABS juice (which is ABS- plastic dissolved in acetone), you can create wear-resistant and durable things, without any hypothetical problems.

For example, my printer has been printing for many hours at temperatures well below freezing. And this happened more than once, not twice, not three! And the print quality was excellent:

12-hour ABS printing at -4 C

▍ NOTE 6. Acetone for post-processing and ABS juicing

At one time, I wrote a fairly detailed article on this topic and I will try to give the main excerpts from it. The essence of the issue here is as follows: due to the fact that different GOSTs are used for the production of acetone, acetone differs in quality. Despite the fact that it would seem that “acetone is also acetone in Africa,” nevertheless, one type of acetone can differ significantly from each other. For example, ordinary acetone, which can be bought at any hardware store, such as "1000 little things", "store near the house" and the like, is very low quality acetone, smells disgusting (although someone like it, maybe someone likes its pleasant building aroma and "aftertaste" :-))).

In contrast to it, there is a much higher quality acetone, which, however, is not found at all in any household stores, even large chain stores, such as Auchan or Leroy Merlin.

This type of acetone is found exclusively in shops that sell varnishes and paints for automotive work, i.e. these are highly specialized shops for car workshops:

Acetone, which can be purchased there, is of excellent quality, smells almost like alcohol, quickly disappears,

:-) - this is a joke, of course, don't even try it.

However, its main advantage, compared to household type acetone, is that it perfectly dissolves ABS plastic and does not allow it to precipitate. For me personally, it was a very surprising observation when the same ABS plastic was perfectly dissolved with acetone from an auto shop, and completely precipitated when I tried to use household acetone (I just ran out of good acetone, and I had to use "what is ").

Therefore, if you want your results to always be excellent, then here is the right acetone. It should be labeled "for professional use":

▍ NOTE 7. What about ABS juice?

"ABS juice" is what printers call a mixture of acetone and pieces of ABS plastic dissolved in it. This mixture is smeared on the surface of the desktop before printing and allowed to dry. Thanks to this spread, the model easily sticks to the desktop and does not peel off during the printing process. After printing is completed and the platen has cooled down, the model can be easily separated.

All that needs to be said here is that, after trying different approaches over time, I settled on using flexible metal spatulas, also called "Japanese type spatulas":

According to the results of many tests, this method of spreading turned out to be one of the most convenient options, such spatulas can be cleaned very quickly and easily after work. In other words, highly recommended!

In other words, highly recommended!

▍ NOTE 8. "Yes, nothing sensible can be done on it, I indulged a little and decided to sell it - you can't use it for anything good anyway"

I absolutely disagree with the statement above, which is periodically heard from newcomers to 3D printing. You can even say more: at the moment I can’t even imagine how I used to live without a 3D printer! Since it is he who makes it possible for any do-it-yourselfer to significantly expand their capabilities and make piece products, almost of factory quality! Of course, for this, appropriate hands must be applied to the 3D printer, but that’s another question… and take on things that I would never have thought to take on before!

For example, among my homemade products, the following can be listed:

- Heated sole for boots, which is a hose integrated into the insole (and filled with household silicone from a household store), through which water flows, heated with a catalytic type hand warmer.

Water is pumped using a small peristaltic pump. The engine with a metal gearbox, which is used in the creation of this pump, allows you to develop a force of 3 kg, which is even redundant for this homemade product. The engine is powered by Peltier elements mounted next to the catalytic heater. The project is currently in progress.

Water is pumped using a small peristaltic pump. The engine with a metal gearbox, which is used in the creation of this pump, allows you to develop a force of 3 kg, which is even redundant for this homemade product. The engine is powered by Peltier elements mounted next to the catalytic heater. The project is currently in progress.

- Centrifugal water pump mounted on the shaft of an internal combustion engine that drives a high pressure wearable air compressor with a pressure of 500 bar. The pump pumps coolant through the casing of the high pressure pump, or rather its second stage. Despite the fact that the pump is 3D printed and runs at over 6000 rpm, nothing “fell apart, fell apart, didn’t break.” As you can see in the photo, the pump is installed instead of the “starter”, that is, the armstarter. The compressor scheme as a whole is as follows: 2 engines. Connected by clutch. One is heavy duty. The second is modified and turned into a high pressure compressor:

Yes, before assembling this, I also did not believe that this was possible. Moreover, even when I collected it, I did not believe my eyes :-))). However, it is a fact…

Moreover, even when I collected it, I did not believe my eyes :-))). However, it is a fact…

- I printed a number of Rank-Hilsch test tubes, the essence of which I have described in detail in this article.

- Printed mass of parts, more than 100 pieces, to create 10 web-controlled robots. There was also a detailed article about this here.

Well, and a bunch of all sorts of useful and not very crafts. As you can see from my crafts above, I have a special passion for creating some useful things, a utilitarian direction. That is, so that the printout is useful, and does not belong to the type “yyy breathe, Mikola, what am I doing here” :-), and then put it on the shelf and that's it. Although, engineers are also not alien to beauties, and this will be my next fact below.

▍ NOTE 9 Proper placement of the model when printing is half the battle

It would seem an obvious fact, but many underestimate it. Here I mean the following: by experience, I accidentally discovered that when printing various statues (in which I, completely unexpectedly for myself, discovered another passion of mine), it is advisable to place the statues at an angle to the printing table.

Here I mean the following: by experience, I accidentally discovered that when printing various statues (in which I, completely unexpectedly for myself, discovered another passion of mine), it is advisable to place the statues at an angle to the printing table.

This allows the layers in the printout to run at an angle of approximately 45-50 degrees to the model. The result of this is that the printed model is almost completely invisible layers and the model looks like it has been post-processed, but at the same time retains a deep matte color, which, to my personal taste, is more like a marble than a glossy result of processing in an acetone bath :

An additional advantage of this method is that the layers going at an angle of 45-50 ° to the model give it additional strength. This is especially true for printing statues, which contain many thin elements that are easily chipped when the statue is accidentally dropped from a table or shelf (learned from bitter experience, this happened to me many times, and ruined some fairly decent prints).

That is, the layers going across the model, if the model has a large length in height, does not allow it to maintain sufficient strength. For better understanding, I tried to illustrate this point in the figures below:

▍ NOTE 10. Bleeding must be taken into account when printing, especially if the model is composed of separate parts and must be assembled by joining these parts to each other, entering into each other, etc.

I tried to illustrate this point in the figures below. The implication here is that if you're printing a composite model, you need to correct for the amount of bleed on the plastic (I'm not sure what it's called, but at least I tried to convey what I mean). If this is not taken into account, then the model will not fit.

For example, in my case this correction is 0.2 mm per diameter - if I want the model to fit more tightly; if I need a free joint, without excessive density, then 0.3 mm per diameter:

That is, suppose that the blue part has a size of 10x10mm. So it must be modeled in a CAD program as 9.8x9.8 mm (if we want it to sit tight) or 9.7x9.7 mm (to sit freely). Well, or expand the hole in the green part, and leave the blue one as it is.

So it must be modeled in a CAD program as 9.8x9.8 mm (if we want it to sit tight) or 9.7x9.7 mm (to sit freely). Well, or expand the hole in the green part, and leave the blue one as it is.

This is often a problem when you download a prefabricated model from the Internet - but it is not going to, even if you crack! And because no amendments have been made…

For your particular case, the amendments may be different.

▍ NOTE 11. What if...

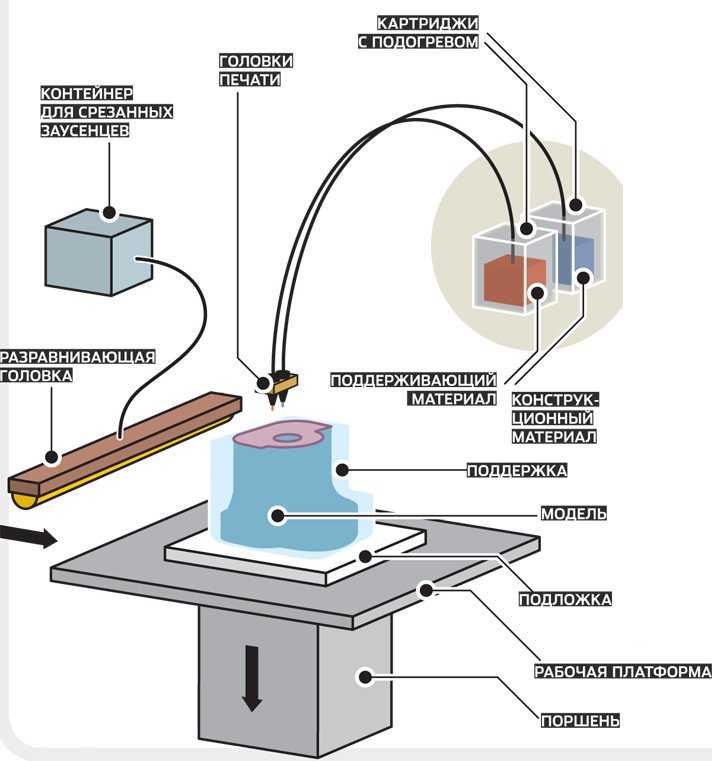

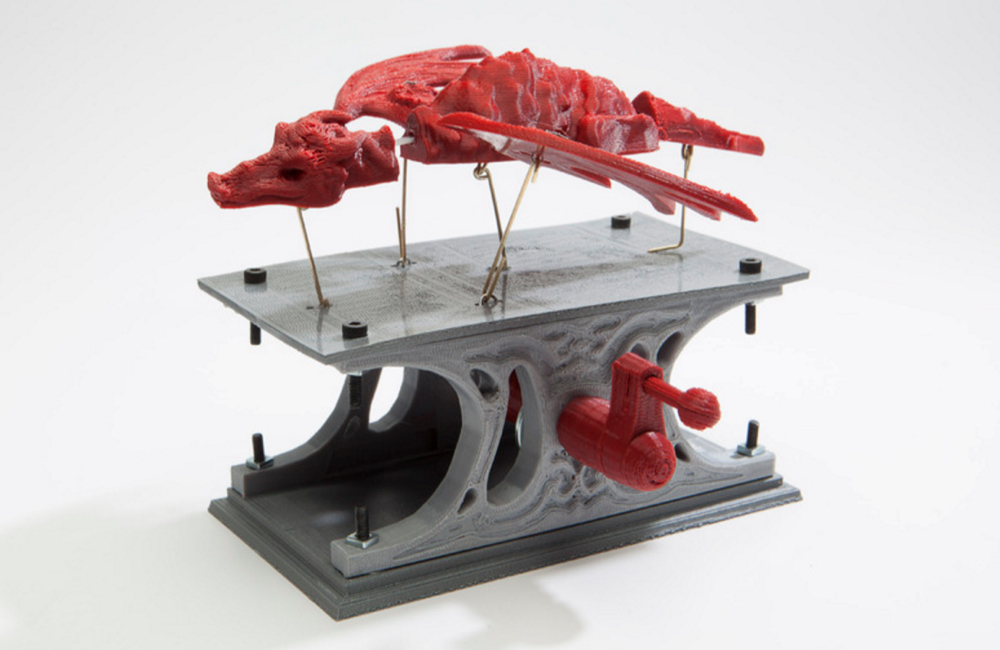

In fact, this note complements note number 8. Using a 3D printer allows you to create metal parts using a printed 3D model. For this, the casting method is used according to the lost wax or burnt model. In our case, we will deal mainly with metal casting on a burnt model.

Briefly, it looks like this: printing a 3D model (using PLA plastic) → pouring it with plaster → burning PLA plastic, simultaneously with burning the mold, in a conventional stove oven → pouring the resulting mold with molten metal (melted in a conventional microwave) .

Image source: 3dtopo.com

I told about a simple method of melting metals in a home microwave oven here.

There was even a good article about casting on Habré.

▍ NOTE 12. Durability?

Despite the fact that ABS plastic is called exposed to ultraviolet radiation and, accordingly, burns out, losing its strength in the sun, in my practice, even printouts that are constantly exposed to the sun have not lost their strength and color at all, continuing to be successfully used and Currently.

It should also be added here that printouts are constantly exposed not only to the rays of the sun, but also work continuously in damp conditions!

As such printouts, I can give an example of winglets for technical cranes, which I printed out, but, unfortunately, did not photograph this process; as well as fasteners on shoes that I use “both in the snow, and in the heat and in the pouring rain, and in general are always with me”:

▍ NOTE 13.

And what about the thread?

And what about the thread? Periodically, there is a need to print parts containing a particular thread. Modeling such products requires a good understanding of what a thread is in general, as well as what corrections need to be made in your particular case, which I have already described above.

But since I've owned a metal lathe for a long time, I'm not at all happy with the 3D printed carving that looks like "something very carving-like".

I am satisfied with an exceptionally perfect carving. Therefore, I keep in stock a large set of various taps and dies, with which I cut all my threads in plastic printouts:

I posted a photo of dies and taps not to brag, but to make the reader understand that serious carving requires a serious approach (unfortunately). And considerable costs for all this thread-cutting iron ...

To create your own threads (both threaded channels and threaded pins), I recommend the following reference materials: for holes, for pins.

Well, that's where I want to end my story and note that he does not claim to be exceptionally accurate and exhaustive. Nevertheless, I tried to state a number of my observations. It will be interesting to read yours, in the comments!

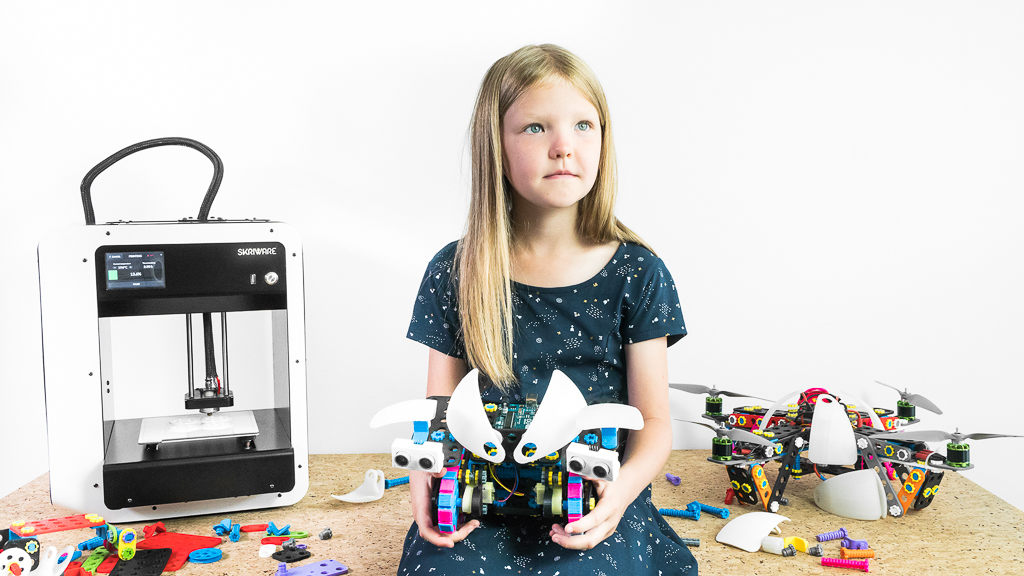

Additional general education program "3D technologies"

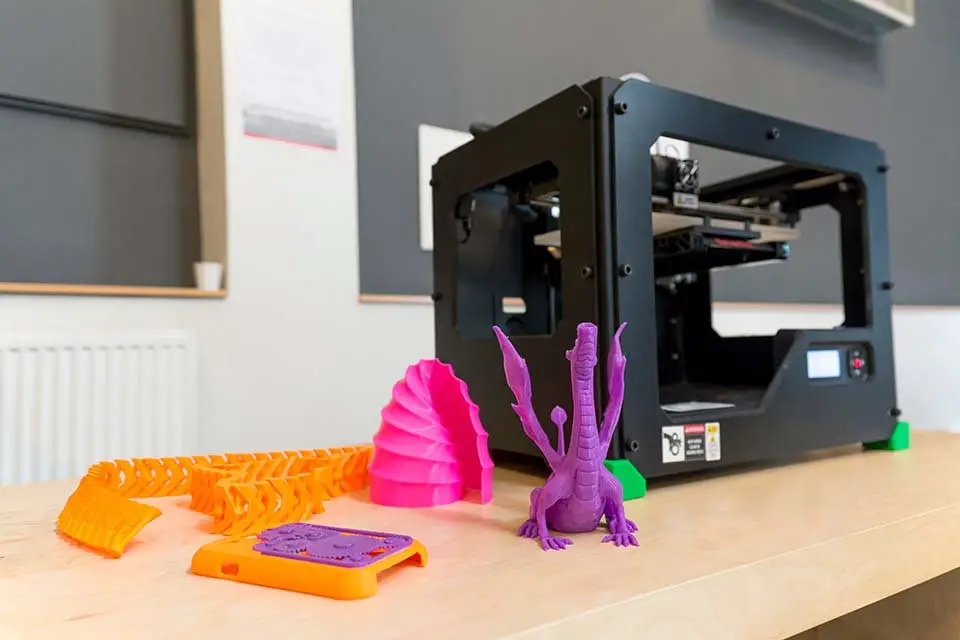

3D printing technology is fairly new and is developing really fast. More recently, rapid prototyping has been limited in children's educational settings due to the high cost of equipment and consumables. But layer-by-layer building technology appeared, and 3D printing became an accessible tool for students. They are happy to use this technology for rapid prototyping and small-scale production.

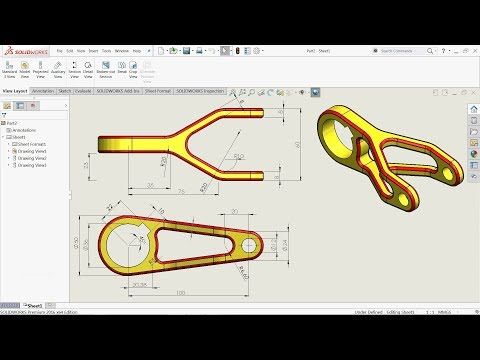

At present, 3D technologies are so accessible (both the purchase of the machine itself and consumables) that one can not only talk about this technology, but also actively use it in the classroom. The use of 3D printing opens up a fast path to iterative modeling. Students can design 3D parts in various CAD programs. The use of 3D technology inevitably leads to an increase in the share of innovations in student projects. Children are involved in the process of development and production of the part being created.

The use of 3D technology inevitably leads to an increase in the share of innovations in student projects. Children are involved in the process of development and production of the part being created.

Once students have drawn their idea on paper, modeled it in CAD software, and printed it on a 3D printer, students will 3D print more and more.

Since 2018, our university in schools No. 645 of the Pushkinsky district of St. Petersburg, secondary school No. 547 St. Petersburg, secondary school No. 690 St. Petersburg has been implementing an exciting additional general educational program "3D Technologies". The program is aimed at introducing students to and mastering modern design technologies, three-dimensional modeling and manufacturing their own parts on a 3D printer.

Lessons in secondary school No. 645 of the Pushkin district of St. Petersburg

Lessons in secondary school No. 547 St. Petersburg

Classes in secondary school No. 690 St. Petersburg

690 St. Petersburg

Educational process for students contributes to the development of elements of technological culture, as important components of the culture of modern man. Children develop knowledge about the basic principles of design, three-dimensional modeling, and acquire practical skills in working with modern 3D equipment and various software.

A schoolchild is preparing a 3D printer for printing on the left, a printed structural element on the right

Unlike the already existing pre-school educational programs in this area, students in this program from the first 4 classes are immersed in 3D technologies. Making your own parts and using them in various designs demonstrates the visibility and reality of the application of the mental and creative abilities of the child in practice. Working with the latest design engineering tools (CAD and 3D printer) allows students to start mastering modern design and information technologies that contribute to the development of a person in a technical direction.

The program is designed for boys and girls aged 10-17 who have basic PC skills and want to learn how to implement their ideas using modern equipment.

The program is designed for two years of study. The total volume is 258 hours. Its purpose is to develop students' creative and design abilities based on the transformation of virtual ideas into material ones using 3D equipment.

During their studies, students not only successfully cope with the curriculum, but also prove the high level of knowledge gained. So schoolchildren of secondary school No. 645 are winners of the All-Russian Olympiad for schoolchildren in 3D technologies. Schoolchildren of secondary school No. 547 are preparing a project for the Lunakhod layout for participation in the XI All-Russian Conference with international participation "Information Technologies for the New School" as part of the St. Petersburg Educational Forum 2020. Team of schoolchildren of secondary school No. 690 took part in the CanSat Air Engineering School competition.

A team of schoolchildren from secondary school No. 645 became the winners of the All-Russian Olympiad in 3D technologies.

A team of schoolchildren from school No. 547 is preparing a project for an exhibition at the XI All-Russian Conference with international participation "Information Technologies for the New School" as part of the St. Petersburg Educational Forum 2020

A team of schoolchildren from school No. CanSat School of Engineering"

The organizer of this additional general education program is the Reception Center (CSC) of BSTU "VOENMEH" named after. D.F. Ustinov with the active support of the Center for Scientific and Technical Creativity of Students (CNTTS).

The strategic goal of CNTTS is to create a self-organizing community of enthusiasts of different ages who accept the technological challenges of new markets and successfully cope with them.

DDOP "3D Technologies" is organized and successfully implemented thanks to the well-coordinated work of its main organizers:

Kuzmin A.