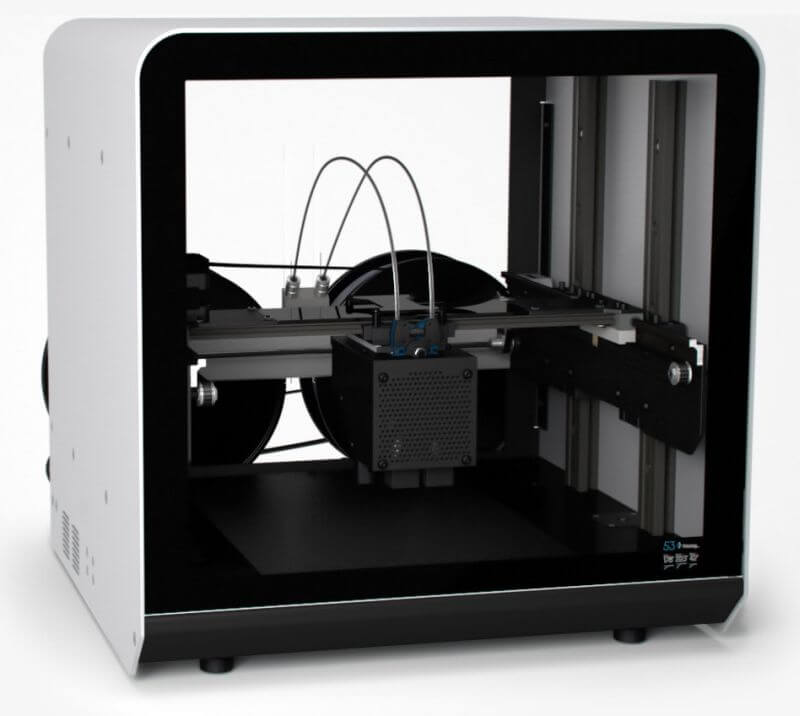

Igus drylin 3d printer

Various parts that can be used for 3D printer construction

- Home

- Industries Overview

- 3D Printers and Parts

Use the 3D Printing Service

Configure parts in the CAD Library

Shop 3D printing materials

Self-lubricating and maintenance-free technologies and components from igus® are already playing a central role in most assembly kits and blueprints for 3D printers. Tribologically optimized high-performance plastics insure better 3D printing and lower costs. With its modular motion plastics® system, igus® enables maximum design freedom for individual applications in the area of 3D printing. drylin® linear bearings are almost noiseless as no metal bearings are used and dryspin® lead screw nuts insure efficient and precise adjustment of the print bed. In addition, igus® energy supply chains increase machine operating times, making corkscrews and general cable failures a thing of the past. Extremely constricted installation spaces, very small bend radii, short assembly times are all benefits of our products, which have no minimum order quantity.

Benefits of igus parts for 3D printers:

- Self-lubricating and maintenance-free

- Silent operation and smooth sliding

- Long service life guaranteed

- Corrosion and dirt resistant

- A wide array of variants and material types

Interested in free samples, want to request quote or simply looking for more information? Click the button below to speak with a 3D printing expert!

Contact an Expert

Learn more about igus® products used in 3D printers

1) 3D print materials

iglide® filament

Laser sintering (SLS) Material

2) Cable carriers

E2 micro small cable carriers

2) Flexible cables

Motor, data, robot, fiber-optic cables

3) Linear bearings and slides

drylin® linear technology

4) Lead screw technology

dryspin® lead screws, nuts & assemblies

5) Linear, lead screw & belt-driven actuators

Linear actuators

Application Examples

House construction

3D printing and house construction? Do they go together? The example of the Netherlands "Europe Building" in Amsterdam's marine quarter shows that it works. drylin® E gantry robots and the engineering expertise of igus® made it possible.

drylin® E gantry robots and the engineering expertise of igus® made it possible.

House Construction 2.0: The house from the 3D printer

EVO-tech ready-to-install system

This 3D printer from EVO-tech GmbH uses a ready-to-install system solution from the motion plastics® specialist igus®. In addition to drylin® linear technology, e-chains® and chainflex® cables are used.

3D printer: ready to install

Kühling&Kühling GbR

Kühling&Kühling GbR was looking for special products for a 3D printer that were to offer freedom from lubrication, outstanding robustness and good temperature resistance. The drylin® range of products make it possible.

Previous NextOur laser sintering material and Tribo-filament are rigorously tested

For prototypes or small series, extremely abrasion-resistant and wear-resistant tribo plastics are used for additive production. Along with the laser-sintering (SLS) method or filaments (FDM/FFF) make it possible to directly use the printed bearing or test the functioning of the printed bearing reliably and conclusively. In our own igus® test laboratory, the Tribo-optimized materials are tested for resistance to wear and abrasion and compared with conventional materials.

Along with the laser-sintering (SLS) method or filaments (FDM/FFF) make it possible to directly use the printed bearing or test the functioning of the printed bearing reliably and conclusively. In our own igus® test laboratory, the Tribo-optimized materials are tested for resistance to wear and abrasion and compared with conventional materials.

Test: Abrasion resistance of the laser sintering material

Test: Wear resistance of the Tribo-Filament

Discuss your project with a 3D Printing expert

Whether you're interested in turnkey, fully assembled solutions or looking to build your own customizable project, let us assist you with a solution based on your specific application and requirements. Contact us via the form below or call us at (800) 521-2747 to discuss your project today!

Contact an Expert

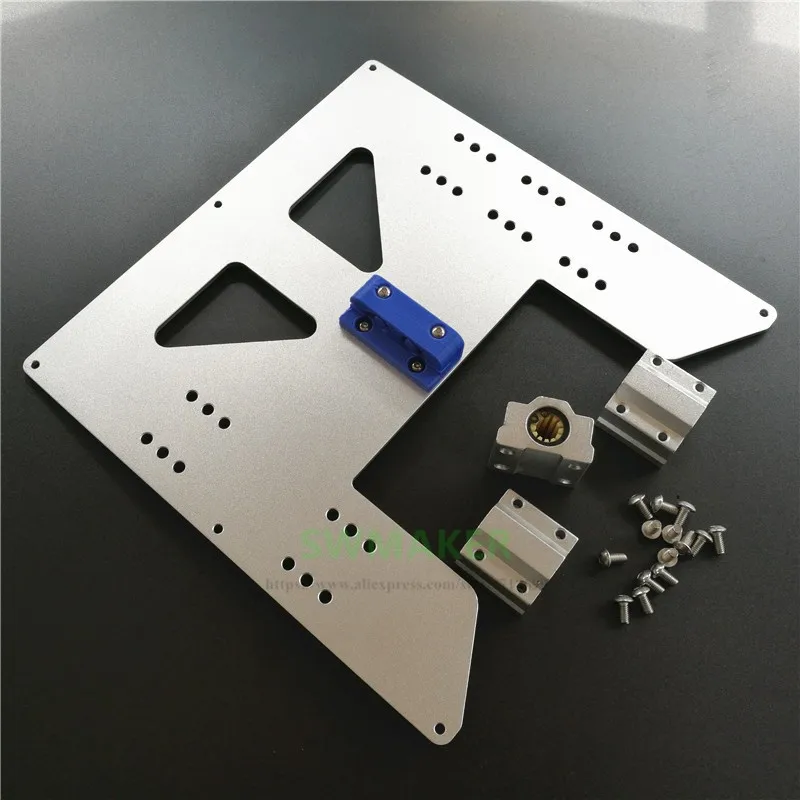

DIY 3D printers - frequently used products

DIY 3D printers - frequently used productsPlease choose your delivery location

The selection of the country/region page can influence various factors such as price, shipping options and product availability.

Go to www.igus.eu

2022 New Products - Browse all

24hMost Products Ship in 24-48hrs

Configure Online Now - Explore over 50 tools

- Home

- Products frequently used in 3D printers

Customer benefit - what's in it for you?

igus® gives designers of 3D printers access to a large construction kit - linear technology, plain bearings, energy supply chains and lead screw units - always completely self-lubricating, delivered from 24 hrs.

Freedom from external lubrication - a long life!

Silent run and smooth gliding

Long life

Wide variety of sizes and options

Lightweight, easy assembly

Low-priced

Delivery: from stock

Do you have questions? Contact us now!

Energy supply systems / cable guide on the print head / extruder

Solutions for smallest bending radii

Low weight, high dynamics

Versatile, modular inner separation

Energy chain Series E2-15, snap-open from outside, for unsupported lengths up to 4.27 ft and fill weights up to .84 lb/ft

Energy chain Series E2 mini B15-015-038-0

Linear motions of the XY axis

Best running properties

Corrosion-resistant

ø 8 mm compatible to ball bushings

Large linear construction kit

drylin® R ø 8 mm round shaft guide

drylin® RJ4JP-01-08 solid plastic Japanese standard, ø 8 mm, same dimensions as LM8UU

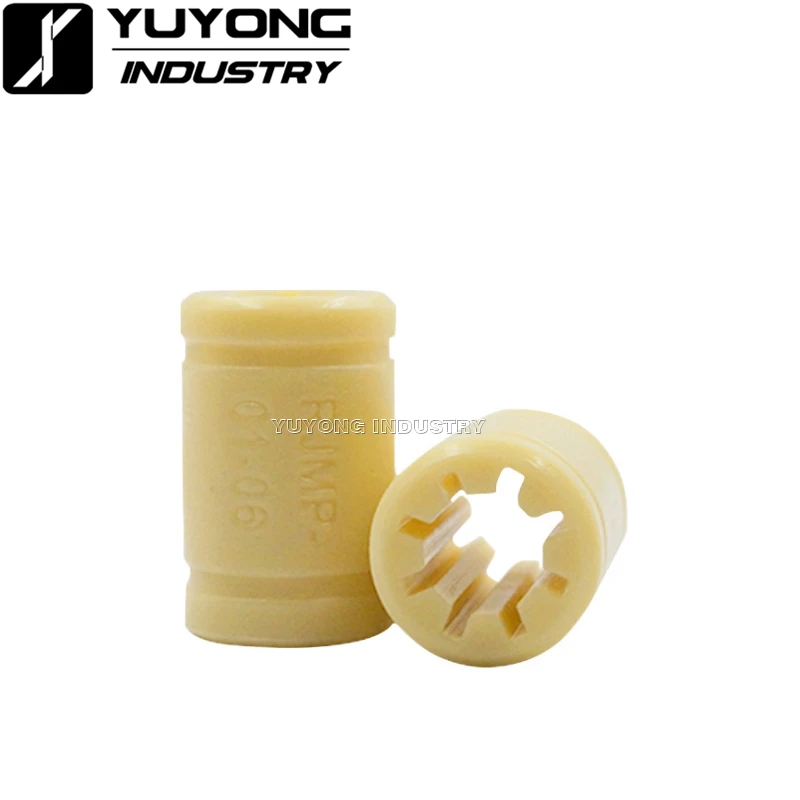

drylin® R linear plain bearing solid plastic RJMP-01-08, ø 8 mm

drylin® R linear plain bearing aluminium RJZM-01-08, ø 8 mm

Shaft aluminium AWMP-08, ø 8 mm

Shaft steel SWM-08, ø 8 mm

drylin® W linear construction kit installation size 06 or 10

drylin® W Linear Rails & Carriages

Height-adjustable Z-axis

Low profile linear guides

Quiet, lightweight, clean

Maintenance-free, dry operation

Predictable service life

drylin® N low-profile guide, installation size 27

drylin® N guide rail NS-01-27

drylin® N guide carriage with camber NW-01-27-P

drylin® N guide carriage with camber NW-02-27-P

drylin® W profile guide, single rails

drylin® W single rail, round WS-10

drylin® W linear housing, round WJ200QM-01-10

drylin® W profile guide / twin shaft profiles

drylin® W twin shaft profile WS-10-80

drylin® W twin shaft profile WS-10-40

drylin® W linear bearing housing WJ200UM-01-10

drylin® W adjustable bearing WJUME-01-10

Print table / bed lowering mechanism

Lead screw / nut with trapezoidal thread

Self-locking with high efficiency

Self-lubricating and low-noise

Vibration damping

drylin® SD trapezoidal thread

drylin® SD TR10x2 lead screw PTGSG-10x2-01-R

drylin® SD TR10x2 lead screw SWZ-W-104003

drylin® SD TR08x10. 5 lead screw PTGSG-08x1,5-01-R

5 lead screw PTGSG-08x1,5-01-R

drylin® SD TR08x1.5 lead screw SWZ-063009

drylin® SD metric thread

drylin® SD M8 lead screw PTGSG-M8

drylin® SD M8 lead screw nut SWZ-063001

Vertical guide in a delta tower

Slim structure

Maintenance-free, dry operation

Self aligning bearings

Reliable energy supply system for 3D motions

drylin® N low-profile guide, installation size 40 and 80

drylin® N guide rail NS-01-40

drylin® N guide carriage with camber NW-01/02-40-P

drylin® N guide rail NS-01-80

drylin® N guide carriage NW-12-80

igubal® rod end bearings

rod-end bearing with exterior thread EARM-05

rod-end bearing with inner thread EBRM-05

triflex® e-chain® system

triflex® R Series TRC-30-050-0

More information:

iglide® Tribo-Filament

Maximum wear-resistance with the iglide® tribo filament for 3D printers as piece goods.

iglide® Tribo-Filament

Application Assistance

For further questions or product information, please contact:

Customer Service:

Monday to Friday from 8 am - 8 pm

Online:

24h

Best STL Files for Igus・Cults

3D PrinterGeeetech x-Carriage upgrade for igus bearings

Free

Roller for 55 mm filament spool

Free

drylin® bearing for 8 mm shafts; outer diameter 16 mm

free

drylin® bearing for 10 mm shafts; outside diameter 19mm

free

drylin® bearing for 8 mm shafts; outside diameter 15 mm

free

igus Christmas ball 2018 "plastic world"

free

igus Christmas ball demonstrates "plastic movement"

Free

igus bearing generator - fully customizable

Free

igus - Christmas planetary gear

Free

X-carriage for GT2 belt and Igus bearings

Free

Ender 2, 3, CR10, CTC A10S E3Dv6 Hotend Mount and IGUS TWE 04-12, MGN9c Rail Mount

Free

Line socket holder for Prusa I3 Rework

Free

Mount GEP1402 for igus robolink 5-axis robot

Free

IGUS sample table vice

Free

Y axis Anet Evolution (For 24mm IGUS)

Free

Anet A8 X-Carriage Mounts - Igus Version

Free

IGUS RJ4JP-01-08 Holder

Free

Chain igus compatible for nema 17

Free

Igus JSM-1012 holder for HyperCube

Free

Igus 27i.

07.100

07.100 3.75 €

New X Axis / CTC i3 Pro B / Drylin RJ4JP-01-08 / LM8UU

Free

K8200 X Y Axis Full rebuild GT2

Free

Adapter Rostock Delta - LM8UU to Igus-DryLin-R-RJMP-01-08 magnetic carriage

Free

Hypercube Evolution Upgrade All Parts

Free

igus hypercube nut holder

Free

Rick's beefy x-carriage for Igus/GT2

Free

X-Ends Igus bushings Misumi Leadscrew

Free

Anet E10 X-Axis Guide Rod System Complete - IGUS Bearing

Free

C-Carriage

Free

Workhorse 3D Printer

Free

Pilot Printer

Free

LM8UU (Ø15mmx24mm) split Housing (24mmx18mm attachement)

0. 61 €

61 €

RJMP-01-08 (Ø16mmx25mm) split Housing (24mmx18mm attachement)

0.61 €

BEARING HOLDER AND LINEAR BEARING LM 12mm

0.54 €

igus linear guide plate

Free

IGUS camera slider return pulley holder

Free

Sliding Bearing Gear 1:5/1:6

3 €

Linear Bearing holder IGUS compatible, updated!

Free

support drylin igus tronxy X5SA

Free

LMF8LUU IGUS-profiled bushing

0,93 €

Remix chariots Z(X) améliorés pour écrous trapézoidaux symétriques

Free

Chariots Z(X) améliorés pour Dagoma DiscoEasy & DiscoVery

Free

Remix main_body with no Z sensor

Free

Remix for BLtouch

Free

Compact 3 fans head for Dagoma DiscoEasy & DiscoVery 200 Printers

Free

RJMP 01-08 Igus Holder for Prusa i3 MK3

0,60 €

DAGOMA HEAD V3 IGUS

Free

Remix of Anet A8 Jan 2017 model Prusa X carriage remix

Free

igus systems 3D printer for printing large objects

- Material Information

- News

In the theater and film industry Opportunity 3D printing of large objects is very attractive. The traditional approach, which is to machine a block of polyurethane foam using a 5-axis milling machine, is a slow, expensive and very limited solution. A key advantage of 3D printing over milling is that hollow objects can be produced.

The traditional approach, which is to machine a block of polyurethane foam using a 5-axis milling machine, is a slow, expensive and very limited solution. A key advantage of 3D printing over milling is that hollow objects can be produced.

Looking for a solution to 3D print larger models and special items for the theatrical industry, engineer and designer Richard Grant decided to go the route of building a 3D printer of his own design. As a base component, he used the system drylin ® E from igus ® .

After earning a multi-disciplinary engineering degree from Brunel University and then a postgraduate degree in 3D printing from Stafford College, Richard Grant used cutting-edge technology years before it became mainstream.

"I often have to combine conceptual ideas into technologies," he says, "that's my niche." “I have two very good FDM 3D printers that I have been using for several years and they fit me well. Due to the fact that I was tasked with creating large structural elements, I was looking for a larger 3D printer. Being an engineer, I decided to build my own. With a large format 3D printer, I can print anything large, whether it's a stage element or a prop,” says Richard.

Due to the fact that I was tasked with creating large structural elements, I was looking for a larger 3D printer. Being an engineer, I decided to build my own. With a large format 3D printer, I can print anything large, whether it's a stage element or a prop,” says Richard.

Wanting to expand the possibilities of 3D printing, igus ® wanted to support the developer's project. “The advantage of igus is that we can examine system performance data,” explains Adam Sanjurgo, igus ® Specialist for Engineering Plastics and Linear Automation Systems. “Collecting real data in this unique large 3D printer project is very important to us.”

igus 9 linear system0214 ® drylin ® W proved to be a great asset to Richard Grant's project. drylin ® W is supplied as standard with a 500x500 mm working space and a short 100 mm pick-up. Richard removed the vertical axis and created a large frame with homemade (3D printed) parts to give a printable area of approximately 450x450x1600mm.