Chefjet 3d printer

The 10 Best Food 3D Printers 2022 (All Price Ranges!)

They’re here, and shaking up how we view and prepare food. Food 3D printers are usually hybrid FDM 3D printers that print food pastes rather than plastic filaments, printing delicious chocolate, jam or toffee layer-by-layer to create a custom dessert or savory dish based on your design.

Want to 3D print a model of your face in chocolate? Or print your company’s brand in biscuit to send to potential clients? You can do it all with food 3D printers.

Our ranking below features some of the best 3D printers for printing food, and compares them on accuracy, speed, variety of food types you can 3D printer, and more.

3DSourced is reader-supported. When you buy through links on our site, we may earn an affiliate commission. Learn more

The Best Delta 3D printers and where to buy them

| Name | Max Build Volume (mm) | Speed (mm/s) | Price | Where to buy for best price |

|---|---|---|---|---|

| Monoprice Mini Delta | 110 x 110 x 120 | 150 mm/s | $179 | Amazon here |

| FLSUN Q5 | 200 x 200 x 200 | 150-300 mm/s | $260 | Amazon here |

| He3D K280 Delta | 280 x 280 x 600 | 150 mm/s | $320 | Amazon here |

| FLSUN QQ-S | 255 x 255 x 360 | 300 mm/s | $379 | Amazon here |

| Frankensbox FX-800 | 150 x 150 x 175 | 150 mm/s | $299 | Amazon here |

| Monoprice Delta Pro | 270 x 270 x 300 | 150 mm/s | $699 | Amazon here |

| WASP Delta 2040 PRO Turbo | 200 x 200 x 400 | 500-600 mm/s | $3,400 | Amazon here |

- We’ve also written a feature story on 3D printed food.

- We also have a more specific ranking on the best chocolate 3D printers.

What is a Food 3D Printer?

Typical FDM 3D printing involves a 3D printer’s extruder depositing melted plastic filament along the dimensions specified in the STL file. It’s somewhat similar to icing a cake in that regard, but when you’ve completed one layer the next layer is then deposited on top of that existing layer.

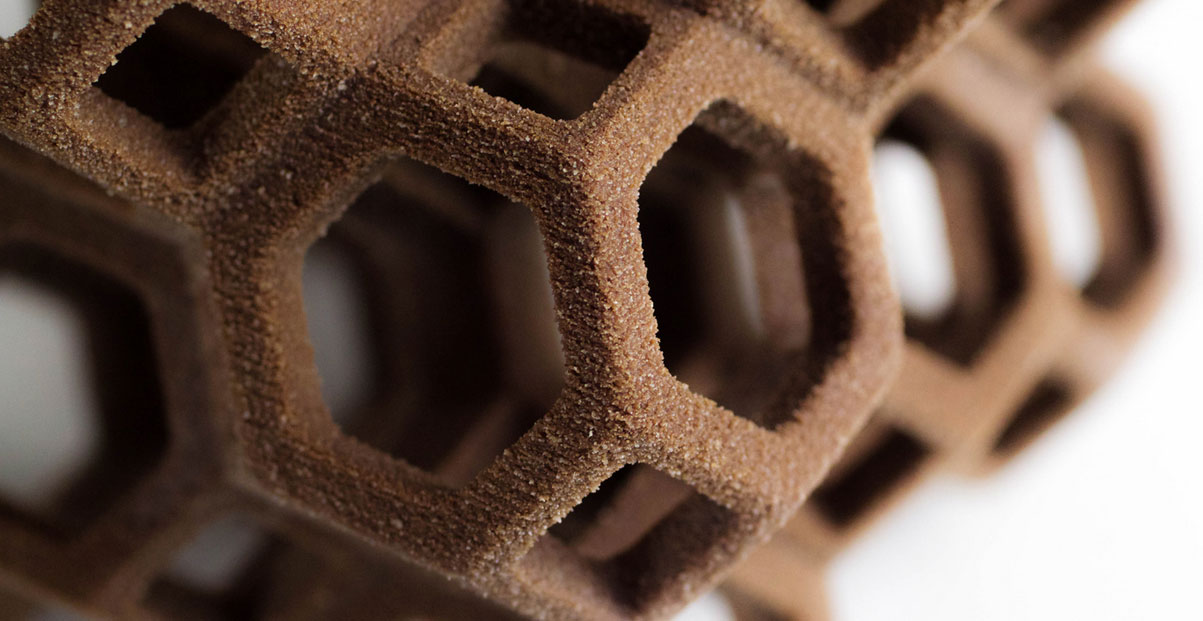

3D printed food will have a layered appearance as FDM parts do — if you look hard you’ll see the tiny layers at slightly jagged angles like the steps on a pyramid, or a spring being pressed together.

With the icing a cake analogy, now assume that instead of icing, you can do the same action but with any edible food type. Chocolate, toffee, sugar, jam and savory flavors like tomato sauce / paste and cheese. Instead of being limited in the shapes you can make by the type of cake tin you use, you can now create incredibly intricate structures by perfectly depositing each part of food exactly where it is supposed to be.

Food 3D printers are similar to FDM 3D printers — one printer on our list is a modified FDM printer — they deposit food instead of plastic filament in exactly the same way. This allows them to be more precise and accurate that any human could be, and also means that menial food jobs in restaurants and kitchens can be automated, saving time and energy.

What’s more, since you only extrude the exact amount of food you need, this makes for more efficient use of food, saving both money and the environment! This is a key and reoccurring theme in additive manufacturing.

Food 3D printers are gradually making their way into STEM education as a novel and fun new way of teaching both 3D printing skills and about what we eat. Food 3D printers for kids are also a great way of family bonding while creating something delicious to eat after, as well as by small businesses who want a new way of creating custom, up-market chocolates and other treats.

Benefits of a food 3D printer

- Better for the environment. 3D printed food materials can be created from alternative proteins like algae, leaves, and even insects, which are ground into a paste ready to be 3D printed. These ingredients otherwise would not be used, and are a form of protein and nutrients which may be key to future diets.

- Increased food customization. Though everybody’s food is already arguably customized, it isn’t to the level that food 3D printers offer. Not only can you create and pick the exact ingredients you want, but you can also create custom shapes and geographies that you want your food to occupy. Want a rabbit-shaped chocolate bar? Or an emoji-shaped burger? Easy. 3D printers conquer conquer the first three dimensions for you, saving you the fourth dimension — time.

- Saves time & stress. 3D food printers can automate the boring and repetitive kitchen tasks for you so you don’t need to do them.

Simple tasks such as presentation and laying out of ingredients can be done by the food printer, and if you are creating food from pastes then you don’t need to chop those ingredients up yourself.

Simple tasks such as presentation and laying out of ingredients can be done by the food printer, and if you are creating food from pastes then you don’t need to chop those ingredients up yourself.

The Best Food 3D Printer

We have created our list of the best 3D food printers based on a number of criteria. These include price-performance ratio, speed, amount of materials available, print volume, among others.

Note: this article is not intended to be objective fact, and is based on opinions. This content is independent and features no paid or sponsored content, but we have included links where you can buy a food 3D printer, which we receive commissions on.

1. WiiBoox Sweetin — Food 3D Printer For Kids

- Country based: China

- Food 3D printer cost: $1,599 — Available on Amazon here

- Maximum food printing area: 90 x 90 x 70 mm

- Food 3D printing speed: 15 – 70 mm/s

- Accuracy: 100 microns

The WiiBoox Sweetin is sold as the easy to operate, accessible food printer perfect for families at home together. The printer itself comes with a number of models to print out, and you’re free to unleash your creativity by designing or downloading your own STL files to print. It’s super simple to use: just load your design onto the supplied USB and print away!

The printer itself comes with a number of models to print out, and you’re free to unleash your creativity by designing or downloading your own STL files to print. It’s super simple to use: just load your design onto the supplied USB and print away!

The Chinese company bring their extensive 3D printing and scanning expertise to food 3D printing. They also sell an LCD 3D printer, an upmarket dual extruder 3D printer, as well as a range of 3D scanners.

The WiiBoox 3D food printer works by preheating the chocolate filament packs (or other food filament type), setting the temperature and speed you want to print at, and then it’s ready to start! You can change the print speed based on how accurate you want your 3D printed chocolate piece to be. Comments on Amazon recommend that you leave any 3D printed chocolate model for at least 10 minutes before removing it however to ensure it has cooled down and solidified.

The WiiBoox Sweetin is accurate with 100 micron precision so any cakes you decorate or chocolate food you 3D print will look crisp and smooth. Unlike some of the other food 3D printers on this list, the WiiBoox Sweetin appears to only use a 0.6mm diameter nozzle, and though it comes with their own 3D slicer you can also set it up to use Cura.

Unlike some of the other food 3D printers on this list, the WiiBoox Sweetin appears to only use a 0.6mm diameter nozzle, and though it comes with their own 3D slicer you can also set it up to use Cura.

Overall, it’s a low price food 3D printer with good reliability and is easy to use. We recommend it as a great food 3D printer for kids and families to enjoy spending time together cooking and having fun, and creating delicious chocolates and sweets at the same time.The WiiBoox Sweetin printing Albert Einstein in white chocolate.

2. FoodBot S2

- Food printer price: $2,100 — Available on 3DPrintersOnlineStore here

- Max print volume: 150 x 150 x 73 mm

- Food print speed: 15 – 70 mm/s

- Accuracy: 100 microns

A versatile food 3D printer, the FoodBot S2 can print chocolate, biscuit, jam, cheese, mashed potatoes, toffee and more! You can change the speed between 15 and 70 mm/s based on the accuracy and intricacy of your print, and alter the temperature based on your preferences.

What stands out however is how great the printer itself looks — if Apple ever made a 3D printer, this is how I imagine it would look. The design is futuristic, elegant and modern; it really adds a sci-fi feel to any kitchen. The 5.2 inch touchscreen and sleek UI add to this atmosphere.

As for accuracy, you’ll have no problem creating detailed food 3D prints with its 100 micron precision, with the ability to use nozzles ranging from 0.3 to 1.5 mm based on your needs. It comes with its own free 3D software to slice and prepare prints, and prints via either USB or SD card.

FoodBot stress how hygienic their S2 food printer is. The actual food filament never touches the printer, as it comes in disposable plastic dispenser tubes and is extruded straight through the nozzle. This makes keeping the printer clean and safe very easy, as there are no innards to clean, just the nozzle. Overall, it’s an impressive and easy to use food 3D printer with a wide variety of materials and uses.

3. Zmorph Fab (with Thick Paste Extruder Add-on)

- Price: $3,999 — Available at Matterhackers here / Available on 3DPrima Europe here

- Maximum print volume: 235 x 250 x 165 mm

- Thick paste extruder available here

Most people know of the Zmorph Fab as a workhorse 3D printer, drawing praise for its reliability, toughness and grit. It’s also known for being unbelievable versatile — it can be converted from a 3D printer into either a CNC mill or a laser engraver!

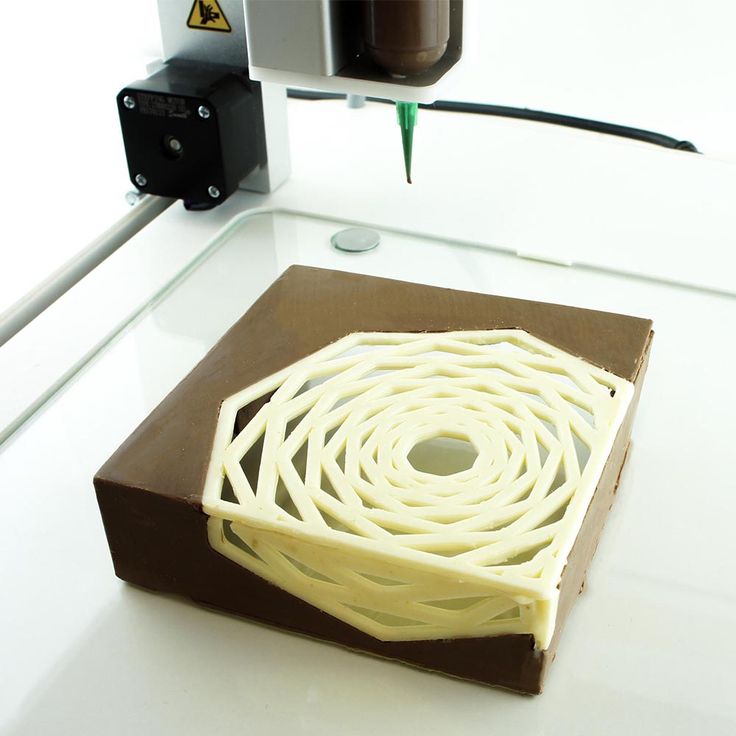

Now in addition to this, if you buy Zmorph’s thick paste extruder you can also print in chocolate, nutella, cookie dough and a few other food 3D printer filaments too. It prints pastes in a similar way to how it prints plastic filaments, so you benefit from the Zmorph Fab’s 50 micron layer resolution and excellent stability.Thick paste extruder add-on sold by Zmorph allows for chocolate 3D printing.

All the technology developed for the Zmorph Fab that makes it one of the best 3D printers around also works perfectly to make it a great food 3D printer. The accuracy, reliability and stability all apply in food 3D printing, and the Zmorph VX therefore is the perfect 3D printer for those who want a printer that can do it all. It’s ideal if you’ve been looking for both a food 3D printer and standard FDM 3D printer, but don’t want to buy two printers.

The accuracy, reliability and stability all apply in food 3D printing, and the Zmorph VX therefore is the perfect 3D printer for those who want a printer that can do it all. It’s ideal if you’ve been looking for both a food 3D printer and standard FDM 3D printer, but don’t want to buy two printers.

It is worth noting however that Zmorph do not certify that the printer’s food prints are edible or take any accountability for that. The add-on is therefore more of a fun extra to have fun at home with your family, but not for those looking to sell chocolate 3D prints or to use it in a restaurant. The printer was not built with food 3D printing strictly in mind, but it is a fun add-on for $250.

4. Createbot 3D Food Printer

- Price: $2,115 — Available on 3DPrintersOnlineStore here

- Max food 3D print size: 150 x 150 x 100 mm

- Speed: 20 – 30 mm/s

- Precision: 100 microns

There are definite similarities between the Createbot and Foodbot printers, in size, speed, price and appearance. One key difference however is that the Createbot food 3D printer comes in three different colors: Champagne Gold, Simple Silver and Rose Gold. All three options portray a stylish, expensive-looking machine.

One key difference however is that the Createbot food 3D printer comes in three different colors: Champagne Gold, Simple Silver and Rose Gold. All three options portray a stylish, expensive-looking machine.

It can print many of the same ingredients as the Foodbot S2 3D printer, including chocolate, biscuit, red and green bean paste, lotus seed paste, and other foods. The actual print speed depends on the material used: it is recommended to use 20 mm/s for chocolate printing, and 30 mm/s for other materials.

A cool feature with the Createbot is the ability to operate the printer from your laptop, tablet or smartphone. You can also carefully control the printer’s temperature to ensure prints retain their nutrition and print with the right consistency. Import your 3D printer model into Repetier-Host 3D slicer, slice it, and you’re ready to go!

5. Mmuse Delta Food 3D Printer

- Price: $1,140 — Available on 3DPrintersOnlineStore here

- Maximum print volume: 100 x 100 x 100 mm

- Speed: 150 – 300 mm/s

The only delta 3D printer on our list, the Mmuse delta brings the advantages of high printing speeds associated with these types of 3D printer to the food sector. Whereas some other food printers max out at around 70 mm/s, Mmuse claim the delta food 3D printer can print between 150 and 300 mm/s — depending on the quality of print and type.

Whereas some other food printers max out at around 70 mm/s, Mmuse claim the delta food 3D printer can print between 150 and 300 mm/s — depending on the quality of print and type.

It can print materials including chocolate, pancake, candy and tomato sauce, so you have the option of either sweet or savory. Unlike most delta printers it isn’t a DIY 3D printer, instead coming fully assembled and ready to print — saving time and effort. It’s also lighter than most of the other food 3D printers, at a very manageable 5kg.

Rather than offer a wide variety of nozzle sizes, the Mmuse delta sticks with the standard FDM 3D printer nozzle diameter of 0.4mm. It’s more of a fun food 3D printer for kids to enjoy and play with than an industrial food printer for restaurants. Don’t expect pinpoint accuracy and Michelin-level food presentation, but you can definitely still enjoy creating fun food prints of your favorite kids’ TV characters and other fun 3D printed food projects.

6. Foodbot D2 — Dual extruder food 3D printer

- Price: $5,999 — Available on 3DPrintersOnlineStore here

- Maximum print volume: 80 x 150 x 100 mm

- Print speed: 25 – 50 mm/s

- Precision: 100 microns

An upgrade on the Foodbot S2 that also features in our ranking, this extraordinary machine not only can print intricate food structures, but can print them with two materials concurrently!

The dual heads mean you can print either two different colors of the same food material, or two different materials. So you could create your own design in part toffee and part chocolate, or any other combination you want. Additionally, the 3.5 inch touchscreen and ergonomic UX makes food printing a breeze.

So you could create your own design in part toffee and part chocolate, or any other combination you want. Additionally, the 3.5 inch touchscreen and ergonomic UX makes food printing a breeze.

This second print head is very useful in commercial business opportunities such as creating custom edible brand logos that need to be in two different colors or materials. Custom cake decorations, intricate chocolate pieces, mini portrait pieces and busts, and general personalized gifts are made easy with the Foodbot D2.

Both the D2 and S2 food printers have solid, sheet metal frames which aid stability, accuracy and precision food 3D printing. The D2 prints at between 25 and 50 mm/s dependent on the material printed, and can be converted to use nozzles varying from 0.4mm to 1.5mm. It’s heavier however, at around 25kg — so keep this in mind if you need something very portable.

7. Mmuse Touchscreen

- Country based: China

- Food 3D printer price: $5,700 — Available on 3DPrintersOnlineStore here

- Print volume: 160 x 120 x 150 mm

Another chocolate 3D printer, the Mmuse is a food 3D printer that looks like something out of the matrix. It’s futuristic and beautiful, selling itself as a chocolate making experience, not just a 3D printer. It’s fast too, able to print between 30 and 60 mm/s of delicious 3D printed chocolate.

It’s futuristic and beautiful, selling itself as a chocolate making experience, not just a 3D printer. It’s fast too, able to print between 30 and 60 mm/s of delicious 3D printed chocolate.

There’s a reason for the high price. The Mmuse chocolate 3D printer is designed to be as convenient as possible to operate, so you can 3D print food via WiFi, USB or SD card. The beautiful touchscreen on the Mmuse makes printing a breeze, and features a strong aluminium shell. Mmuse also claim it utilizes an ‘intelligent temperature control technology’, allowing it to 3D print chocolate at the perfect temperature so the chocolate prints as smoothly and evenly as possible. Additionally, Mmuse have designed the printer nozzle to be as easy to clean and replace as possible to maintain hygiene over years of printing.

It comes fully assembled, so all you need to do is get hold of the chocolate bean filament, choose the print settings you prefer, and let it print away. The easy-to-use touchscreen makes delicious chocolate printing a pleasant experience. If you’ve got the money and you love chocolate enough, this may be the one for you. Also, if you’re a chocolatier and want to automate some aspects of production, this could be perfect.

If you’ve got the money and you love chocolate enough, this may be the one for you. Also, if you’re a chocolatier and want to automate some aspects of production, this could be perfect.

8. Natural Machines Foodini

- Country based: Spain

- Food 3D printer price: $4,000

- Print volume: 250 x 165 x 120 mm

One of the most well-known food 3D printers out there, the Foodini is a food 3D printer breaking barriers left, right and center in the foodtech sector. Foodini, made by Spanish firm Natural Machines, recognize that though cooking is an enjoyable process for many, there are many tasks that could be automated. The Foodini food 3D printer was therefore created to streamline the repetitive tasks which are time consuming and difficult to do by hand.

Foodini is a versatile food 3D printer, able to print pizza, spaghetti, and even burgers. Its glowing reviews led to fairly wide use in restaurants, like the byFlow Focus has similarly achieved. Restaurants which use the Foodini include London’s Food Ink restaurant, the entirely 3D printed restaurant, as well as La Endeca at Hotel Arts, in Barcelona.

Overall, the price is steep, but this is because of how advanced the Foodini is. It’s less of a cooking tool for use within homes and more of an industrial tool for professional kitchens, but this doesn’t make it any less of an incredible foodtech achievement.The Foodini food 3D printer has wide use across restaurants.

9. byFlow Focus

- Country based: Netherlands

- Food 3D printer price: €3,300

- Print volume: 208 x 228 x 150 mm

The byFlow Focus is a sleekly designed food 3D printer with a surprisingly wide reach in businesses around the world. Unlike most fanciful and futuristic machines that seem like they won’t see wide adoption for twenty plus years, the byFlow Focus is a 3D food printer which is already used in a number of restaurants and businesses.

Part of the reason is due to its reliability and ease of use. It can take a multitude of different 3D food printer materials, and switching them round is quick and easy. What’s more, you can even add your own recipes to the machine to 3D print with the ingredients you enjoy most. This allows you all the freedom you need to print any chocolate, pastry, or other 3D printed food dish you like, and byFlow even have over 50 downloadable 3D designs for free on their website.

This allows you all the freedom you need to print any chocolate, pastry, or other 3D printed food dish you like, and byFlow even have over 50 downloadable 3D designs for free on their website.

As a result, businesses such as B2B chocolatier Barry Callebaut giant use byFlow Focus food 3D printers, as well as well-reputed chef Jan Smink in his ‘Restaurant Smink’ restaurant.The byFlow Focus food 3D printer is another food printer used across restaurants, especially in Europe.

10. Choc Edge Choc Creator 2.0 Plus

- Country based: UK / China

- Food 3D printer price: €2,330

- Print volume: 180 x 180 x 40 mm

Originally based out of a uni campus, Choc Edge is now thriving as a leading food 3D printer manufacturer. The Anglo-Chinese chocolate 3D printer company’s third food 3D printer, the Choc Creator 2.0 Plus, is a picturesque and innovative machine. Though it prints edible objects, the Choc Creator still utilizes the same layer-by-layer method as with Fused Deposition Modeling. Retailing at just under $3,000, it’s a great option for niche bakers and chocolatiers out there.

Retailing at just under $3,000, it’s a great option for niche bakers and chocolatiers out there.

A few reasons why the Choc Edge Choc Creator 2.0 Plus is an industry leader are firstly how easy it is to use. The chocolate 3D printer features a large and responsive touchscreen for easy access and printing. The 0.8mm nozzle is easily removed and changed based on the 3D food material used, with the 30ml metal syringe just as easy to replace. Overall, it’s a one of the best chocolate 3D printer machines on the market, and prints in the same way as your average FDM 3D printer.The Choc Creator by Choc Edge is known as one of the best chocolate food 3D printers around.

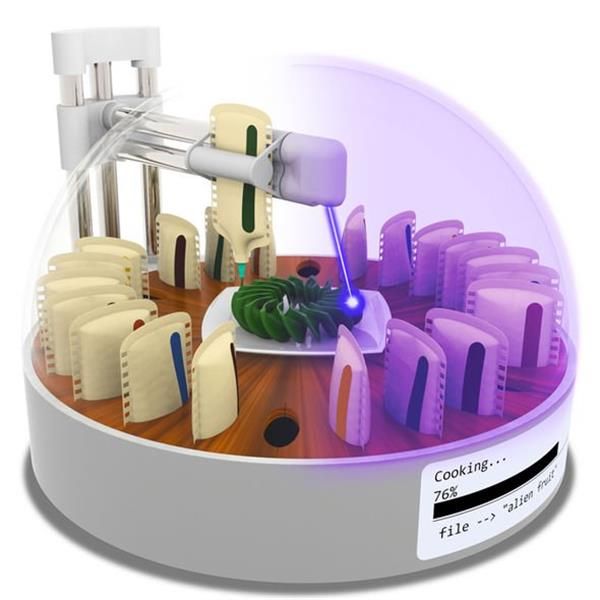

Bonus: The Food 3D Printer That Never Happened — 3D Systems ChefJet & ChefJet Pro

- Country based: USA.

- Food 3D printer price: $5,000 & $10,000.

- Print volume: 203 x 203 x 203 mm.

The ChefJet food 3D printer created by industrial 3D printer giant 3D Systems is an unfortunate case.

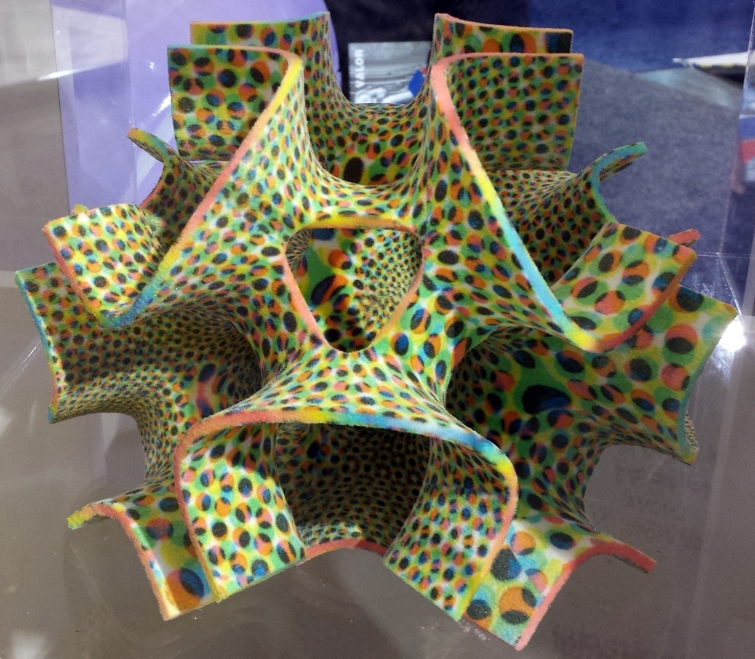

3D Systems bought Sugar Labs in 2013, suggesting there may be movements from the American company in the foodtech sector in the future. Then, when they announced and demonstrated the ChefJet Food 3D Printer throughout 2014 and 2015, people couldn’t wait to get their hands on this incredible piece of tech. It could make 3D food structures out of sugar with flavours including chocolate, vanilla, mint, sour apple, cherry, watermelon, and even more!

3D Systems’ ChefJet Food 3D Printer now looks like it will get a worldwide release, thanks to a new distribution deal.But it wasn’t to be. Some internal friction within the company meant that the project was put on hold for several years. Then in late 2017, 3D Systems announced a partnership with CSM Bakery Solutions to create and distribute the food 3D printers along with custom-made food 3D printer material.

Therefore, though the ChefJet 3D printer isn’t out yet, we still felt it was worthy of its place on this list as it will get a release soon, and has demonstrated its ability to 3D print food. We look forward to seeing how far the ChefJet and ChefJet Pro can push 3D printed food in the future. The ChefJet is to retail at $5,000, whilst the ChefJet Pro will retail at $10,000.

We look forward to seeing how far the ChefJet and ChefJet Pro can push 3D printed food in the future. The ChefJet is to retail at $5,000, whilst the ChefJet Pro will retail at $10,000.

3D Systems' ChefJet Pro Helps Serve Up a 3D Printed Edible Palace of Versailles - 3DPrint.com

Marie Antoinette, who famously did not say ‘let them eat cake’ when told about the inability of France’s poor to afford bread, is perhaps one of the most polarizing figures from the French Revolution. While she wasn’t directly involved in the events that led to the storming of the Bastille fortress in the wake of the growing French Revolution, Antoinette found herself an easy target for the revolutionaries’ rage. Not only because of her Austrian heritage, but because of her efforts to maintain the power of the monarchy throughout the transition.

While historians continue to separate fact from propaganda and revisionist history, one thing has always been clear–Antoinette never would have told the poor to eat cake; had she said anything, she would have told them to eat brioche. The extremely rich, expensive and decadent bread was usually served to French nobility and well out of reach for the average citizen. During an exceptionally long period of scarcity of bread and flour, a frustrated and hungry mob stormed the Palace of Versailles and forced the king and queen to return to Paris and address the growing resentment of their subjects. So it seems that regardless of the accuracy of the quote, bread still played an important role in the abolition of France’s monarchy.

The extremely rich, expensive and decadent bread was usually served to French nobility and well out of reach for the average citizen. During an exceptionally long period of scarcity of bread and flour, a frustrated and hungry mob stormed the Palace of Versailles and forced the king and queen to return to Paris and address the growing resentment of their subjects. So it seems that regardless of the accuracy of the quote, bread still played an important role in the abolition of France’s monarchy.

So when the cooking lab at Modernist Cuisine in Bellevue, Washington was contacted by 3D Systems to team up and produce an elaborate 3D printed food creation, they decided to pay tribute to the historic palace and the infamous bread. The cooking lab was already close to perfecting their recipe for brioche, so they decided to design a 3D printed sugar structure shaped like Versailles as an elaborate decoration for the dessert bread. Modernist Cuisine started with a hand drawn sketch of a simplified version of the iconic palace. Conceived by their head chef Francisco Migoya, the elaborate dessert included a 3D printed sugar structure, meringue topiaries, as well as an elaborate acrylic base cut to resemble the gardens of Versailles. Once Migoya was happy with his design, he passed his sketch on to 3D Systems Culinary to be converted into a 3D model, and ultimately 3D printed from pure white sugar using 3D Systems food 3D printer the ChefJet Pro.

Conceived by their head chef Francisco Migoya, the elaborate dessert included a 3D printed sugar structure, meringue topiaries, as well as an elaborate acrylic base cut to resemble the gardens of Versailles. Once Migoya was happy with his design, he passed his sketch on to 3D Systems Culinary to be converted into a 3D model, and ultimately 3D printed from pure white sugar using 3D Systems food 3D printer the ChefJet Pro.

The structure needed to be able to fit completely around a brioche while still maintaining the look and feel of Versailles. Because the ChefJet is based on powder 3D printing technology, the team at 3D Systems Culinary was able to design and print a very detailed recreation of the château’s Baroque architecture, distinctive windows and ornate gates. Realistically, the sugar structure’s complex geometries could only be created in sugar using a 3D printer like the ChefJet. In order to maintain such a high level of detail in an object printed in such a fragile material, massive supports would have needed to be included in order to even try to use a typical extrusion style printer. However the ChefJet Pro uses technology very similar to an inkjet printer to print a design on thin layers of sugar. The geometry is completely supported by the excess material, which is then simply blown away using compressed air.

However the ChefJet Pro uses technology very similar to an inkjet printer to print a design on thin layers of sugar. The geometry is completely supported by the excess material, which is then simply blown away using compressed air.

“Once the 3D printed sugar structure was delivered by the 3D Systems Culinary team, head chef Migoya baked an incredibly rich brioche. True to the project, it’s totally decadent—eggy, buttery, subtly sweet, and utterly delicious. He began construction by coating the brioche in a glaze of pectin and water, then topped it with gold leaf as a nod to the façade of Versailles. Gold leaf is safe to eat and has been consumed throughout history; ancient Egyptian royalty mixed gold in with their food, even incorporating it into breads,” Modernist Cuisine explained on their blog.

Here is a video showing the dessert Palace of Versailles being constructed:

Once he had all of the various components for his dessert in one place, Migoya assembled his eatable palace just in time for France’s Bastille Day. He glazed the acrylic base and coated it with green panko to simulate grass and added several meringue bushes. Migoya placed the gold leaf topped brioche at the center of the base and covered it with the 3D printed details.

He glazed the acrylic base and coated it with green panko to simulate grass and added several meringue bushes. Migoya placed the gold leaf topped brioche at the center of the base and covered it with the 3D printed details.

His brioche recipe is just as decadent as history tells us that it was back in the 18th century. With its rich and slightly sweet taste, brioche is not the type of bread that you make a ham sandwich out of. You probably could, and it would probably be delicious, but before you could tell anyone about your dessert bread sandwich your heart would probably seize.

Migoya and the rest of the cooking lab served the dessert the same way that it would have been served in 18th century France, topped with a generous heaping of whipped cream. Although they also went ahead and added some raspberries for the pop of color. And because fresh berries make everything better, especially desserts. So how delicious does this modern reinterpretation of the traditional French dessert look? Let us know over on our ChefJet Pro 3D Printed Palace of Versailles forum thread at 3DPB. com.

com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: 3d food printer • 3d printed food • 3d systems • ChefJet Pro • food 3d printing • Modernist Cuisine • palace of versailles • sugar 3d printer • versailles

Please enable JavaScript to view the comments powered by Disqus.

| 3DNews Technologies and IT market. 3D Technology News The Chef Jet 3D printer will be able to print... The most interesting in the reviews 01/15/2014 [02:13], Dmitry Prikhodko 3D Systems booth attracted enough attention at the last CES 2014. The company decided that it was time to create real edible masterpieces that will be taken not from the oven, but from the 3D printer. Modern 3D printers already have a fairly wide range of applications, from confectionery to gas turbine parts. The MakerBot CEO called the Replicator Mini unveiled at CES the ultimate breakthrough in 3D home printing. He even suggested that the model would mimic the iPhone when it first entered the mobile device market. Such a development of the industry was unimaginable a few years ago. Now, 3D printing technology could make it possible to produce fuel injectors for aircraft, a full-fledged sport bike, and even decorative alcohol patterns in jelly. Chef Jet and Chef Jet Pro, announced by up-and-coming 3D Systems for edible 3D printing, are representative of the relatively recent trend in safe 3D food printing. Both printers have passed all the necessary certifications and are ready to appear in the kitchens of the world's most famous restaurants this year. Both devices are aimed at professional bakeries and pastry shops, restaurants and chocolate makers. The Chef Jet and Chef Jet Pro are still devices not for home use by amateur enthusiasts. 3D printers will become part of professional kitchen equipment. Unlike modern devices that reproduce models not from food components and present the finished product mainly in one or several colors, the Chef Jet can work like a real color printer, using the entire range of food coloring to create an object. The procedure itself is quite clear and unpretentious. First, the workpiece, which is a layer of fine dried sugar, is treated with a jet of water from the printer's print head to those parts that should harden in accordance with the concept of the future sugar model. Both Chef Jet and Chef Jet Pro printer models will be available in the second half of 2014. The simpler model will cost about $5,000, while the Pro version will cost the buyer twice as much - about $10,000.0007 Source: If you notice an error, select it with the mouse and press CTRL+ENTER. Related materials Permanent URL: https://3dnews.ru/794394 Headings: News Hardware, 3D technologies, Tags: hardware, 3d printer, 3d, ces 2014, printing ← В past To the future → |

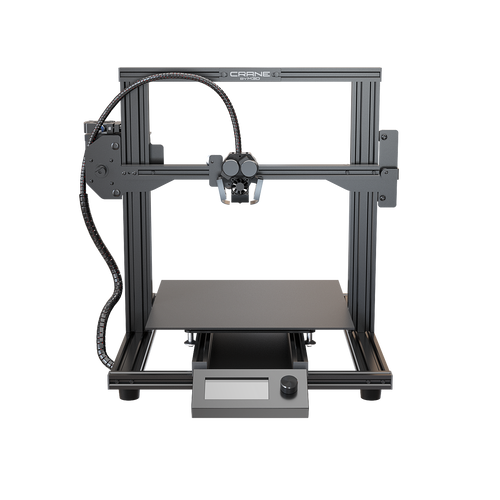

How a 3D Printer Can Save You Money How a 3D Printer Can Save You Money

The justification for investing in a new, modern 3D printer is that it actually saves money.

New research confirms that buying a 3D printer to make plastic iPhone cases (or paper towel holders) at home saves money in the long run. This does not mean that 3D printers will soon crowd out stores or lead to the closure of factories in China or Vietnam. But it's fair to assume that this technology creates a world where you could end up printing a lot of products at home or at your local workshop.

“Printing money” (or rather, saving money)

For example, purchasing an open source RepRap 3D printer can not only pay off, but actually lead to money savings if you print on it (by at least) 20 household items per year (for example: shower curtain rings and safety razors). A recent study (known to the general public as the “life-cycle economic analysis of distributed manufacturing using open source 3D printers”) challenges not only the skepticism of the world’s major manufacturers, but also the wariness of 3D printing experts who believe that this technology is still in its infancy.

Today we already have the ability to print with plastic, and this opens up a huge potential for making thousands of products that are already in our homes and that we use every day. The range of printed material is expanding rapidly, and it is likely that consumers are likely to print many products themselves instead of buying them.

Owners of RepRap 3D printers can save between $300 and $2,000 per year, depending on which 20 household items they print. RepRap 3D printer owners can also continuously improve their open source 3D printer and even print new parts (as technology advances) rather than having to purchase a new 3D printer every few years.

3D printed cups

Other costs associated with the 3D printing process

Despite its merits, assembling an open source 3D printer is a labor-intensive DIY process. RepRap spare parts cost $500-600 and in order to assemble them, you need to spend about 24 hours of working time. And a beginner may need to first learn the assembly process at an appropriate workshop or use an online assembly guide. However, beginners can pay double the price of a collected RepRap. (It's still a good deal compared to so-called polished models like the $2,000 Makerbot Replicator 2.)

And a beginner may need to first learn the assembly process at an appropriate workshop or use an online assembly guide. However, beginners can pay double the price of a collected RepRap. (It's still a good deal compared to so-called polished models like the $2,000 Makerbot Replicator 2.)

Also, don't expect, for example, that the iPhone's plastic case (made from 3D printing) will have the same quality or gloss as a store-bought one. Today, 3D printers still render objects with very small steps or ridges on the sides (no smooth finish). Of course, the object can be smoothed with a nail polish remover and painted, but this is additional labor.

Is the quality of products resulting from the 3D printing process on par with the quality of products that are made in a traditional production and then sold? Unfortunately not: it doesn't even come close to factory quality.

Disadvantages of 3D printing

Today, 3D printers are able to print products with unusual shapes and unique customer requirements: they are well suited for printing a limited number of expensive parts for jet fighters or a custom implant to restore a destroyed part of the skull (both of which are already happened). However, this technology is not yet capable of making items from a variety of materials, and is too slow and too expensive to produce a large number of items.

However, this technology is not yet capable of making items from a variety of materials, and is too slow and too expensive to produce a large number of items.

Very inexpensive and relatively uncomplicated mass-produced items (such as plastic trash cans) will be made in large industrial centers for a long time. Such products, which are produced in the hundreds of thousands or millions, are not good candidates for 3D printing due to the speed and cost of the process.

No one has done a definitive study comparing the cost of 3D printing plastic products locally with the cost of making plastic products in a Chinese factory and then shipping around the world. But some experts believe that industrial production is still able to easily compete with 3D printing. One reason for this is that industrial grade 3D printing requires more energy per unit than traditional industry.

How 3D printing could be used in mass production

3D printing technology could improve over the next 10 to 15 years to the point where it can compete with industrial production. This can be compared to how personal computers took over large electronic computers in less than 10 years.

This can be compared to how personal computers took over large electronic computers in less than 10 years.

3D printers still have a long way to go in order to take their place among the must-have household gadgets.

You can make toys (like McDonalds Happy Meal), but no one likes having to buy a $300 or $400 device (the price range of cheap modern 3D printers) in order to make such toys themselves. For this to happen, print quality needs to go up and the price of the device goes down.

However, 3D printing is still able to compete with factory-made products. 3D printing allows the customer to customize the final product design and have it produced on site immediately. For example, toy stores may someday be able to offer a custom doll with unique characteristics based on a 3D scan of a customer's face or body. (One company (3D Systems) is already offering custom 3D printed Star Trek figurines.)

Even a savvy engineer can construct many simple 3D printable pieces that snap together as easily as Lego bricks to create larger or more complex objects such as chairs and cabinets. It could be called a 3D printed version of IKEA furniture that needs to be assembled by yourself.

It could be called a 3D printed version of IKEA furniture that needs to be assembled by yourself.

Order and print anywhere

The ability to print anything, almost anywhere, gives 3D printing a huge advantage over factories. The military in the US has recognized this advantage by placing 3D printers on ships and in remote battlefields in order to recreate equipment prototypes and possibly someday make vehicle replacement parts.

Global shipping company DHL is already thinking about how 3D printing will impact the way and where you shop for products in the future. According to a 2012 DHL report, the full opportunity for a "customizable lifestyle" scenario is given to 2050. It will be a world in which 3D printing devices in homes or local shops will replace the mass production industry in most cases. In such a world, only raw materials and digital developments will cross national borders.

A small glimpse of this future can already be seen at Kraftwurx. It is a Houston-based company that operates in the digital marketplace with orders for simple 3D printed products (such as metal jewelry and plastic figurines) around the world.

The junior model of the printer - Chef Jet and its advanced version with the Pro index are real culinary devices.

The junior model of the printer - Chef Jet and its advanced version with the Pro index are real culinary devices.  The material that culinary 3D printers predominantly work with is sugar. Candies can also be printed from edible ingredients that harden quickly, such as starch. The most popular material for a rather exotic way of making confectionery masterpieces promises to be chocolate with coconut powder.

The material that culinary 3D printers predominantly work with is sugar. Candies can also be printed from edible ingredients that harden quickly, such as starch. The most popular material for a rather exotic way of making confectionery masterpieces promises to be chocolate with coconut powder.  As a result, thanks to the recrystallization of sugar, the edible object is durable, as far as the material allows. After the sculpture has an almost complete appearance, the excess sugar is cleaned.

As a result, thanks to the recrystallization of sugar, the edible object is durable, as far as the material allows. After the sculpture has an almost complete appearance, the excess sugar is cleaned.