Ge 3d printing jet engine

GE's 3D-Printed Airplane Engine Will Run This Year

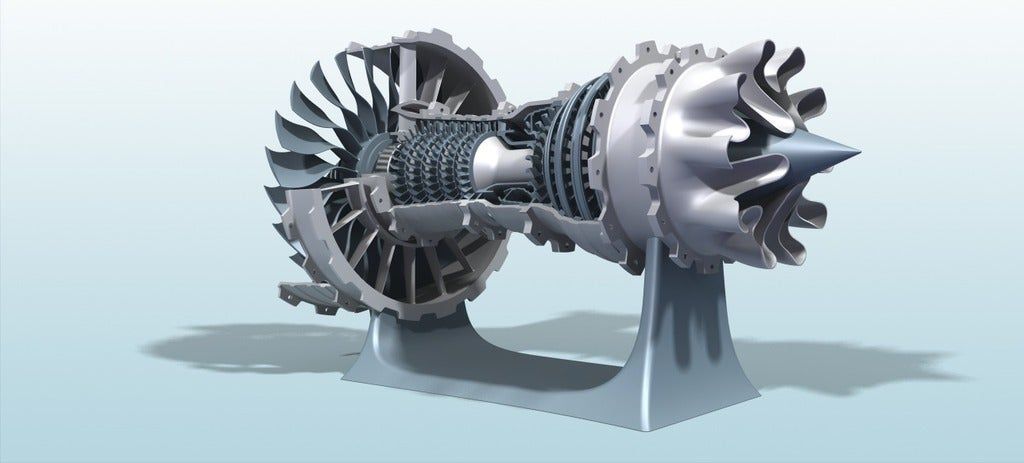

The last time engineers designed a civilian turboprop engine from scratch for mass-production, humans had not yet landed on the moon. Unlike jet engines, turboprops typically power small commercial shuttles and personal aircraft, but they still represent a multibillion-dollar market. As a result, a new machine created by a team at GE Aviation is now causing a stir.That’s because their engine, called the Advanced Turboprop (ATP), will be the first commercial aircraft engine in history with a large portion of components made by additive manufacturing methods, which include 3D printing. The designers reduced 855 separate parts down to just 12. As a result, more than a third of the engine is 3D-printed.

Engineers working on the ATP are planning to run it for the first time in a special test cell in Prague, Czech Republic, later this year. It should see its first test flight in late 2018, and full production is expected to begin in 2020. It will eventually provide the thrust for Cessna’s new single-engine, 10-person business aircraft design called Denali.

Additive manufacturing has helped the GE team bring the ATP from an idea to a working machine in record time. Announced in 2015, “the ATP is going from a dream to a reality in just two years,” says Gordie Follin, the executive manager of GE Aviation’s ATP program. The normal cycle to get to a running engine is usually twice as long, and it can take as much as 10 years to develop, Follin says. “With additive manufacturing, we’re disrupting the whole production cycle,” he says.

Overall, the 3D-printing effort will pay off by decreasing the finished ATP engine’s weight. The engine is 5 percent lighter, which means it will take the aircraft less fuel to attain the same speed. Design changes will allow the ATP to burn 20 percent less fuel and achieve 10 percent more power than its competitors.

Design changes will allow the ATP to burn 20 percent less fuel and achieve 10 percent more power than its competitors.

Additive design, which accounts for 35 percent of the engine, is also disrupting maintenance because the ATP will have fewer assembled parts and opportunities for wear. The engine is expected to run 1,000 hours longer between overhauls compared to its competitors. “We’re no longer constrained by traditional design and engineering processes,” Follin says. “3D printing is letting us be more creative than we’ve ever been before.”

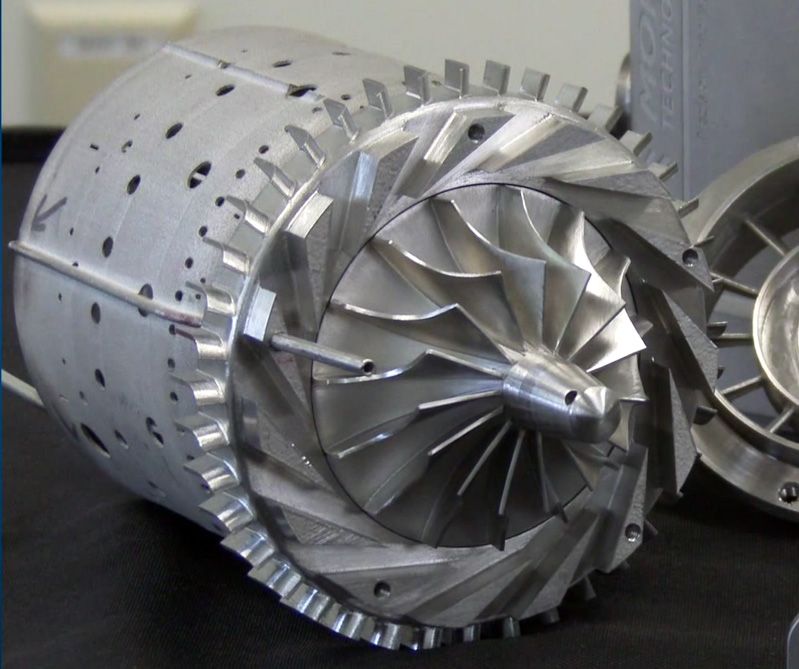

Follin’s group has already made all of the engine’s parts. They are now putting them together, adding instrumentation and getting ready to test critical sub-units.

Additive manufacturing also simplifies the supply chain and lowers the opportunities for delays. “These reductions are real,” Follin says. “We’re not putting so much effort into additive manufacturing because it’s a sexy new technology for its own sake. It’s demonstrably better. It lets us disrupt the process.”

It lets us disrupt the process.”

GE has been aggressively developing its 3D-printing capabilities in recent years, so far spending $1 billion to mature the technology for its businesses. Last year, the company acquired two manufacturers of 3D-printing machines and launched GE Additive, a new GE business dedicated to supplying 3D printers, materials and engineering consulting services.

Additive manufacturing makes products stronger and more durable. In production aircraft engines, those investments have started paying dividends. CFM International, a joint venture between GE Aviation and Safran Aircraft Engines, is producing the advanced LEAP engine, which is being installed on Airbus’ and Boeing’s new fleet of narrow-body commercial airliners. Complex 3D-printed fuel nozzles on the engine contribute to LEAP’s 15 percent cut in fuel burn and emissions.

3D Printing in Aerospace & Aviation

Additive Manufacturing

The aviation industry is an excellent proving ground for 3D-printed parts, given the stringent certifications and demanding safety approvals it must address. If 3D-printed components fabricated from superalloys and advanced thermoplastic composites meet federal aviation standards, confidence rises as to the relevance of additive manufacturing in other highly demanding environments.

If 3D-printed components fabricated from superalloys and advanced thermoplastic composites meet federal aviation standards, confidence rises as to the relevance of additive manufacturing in other highly demanding environments.

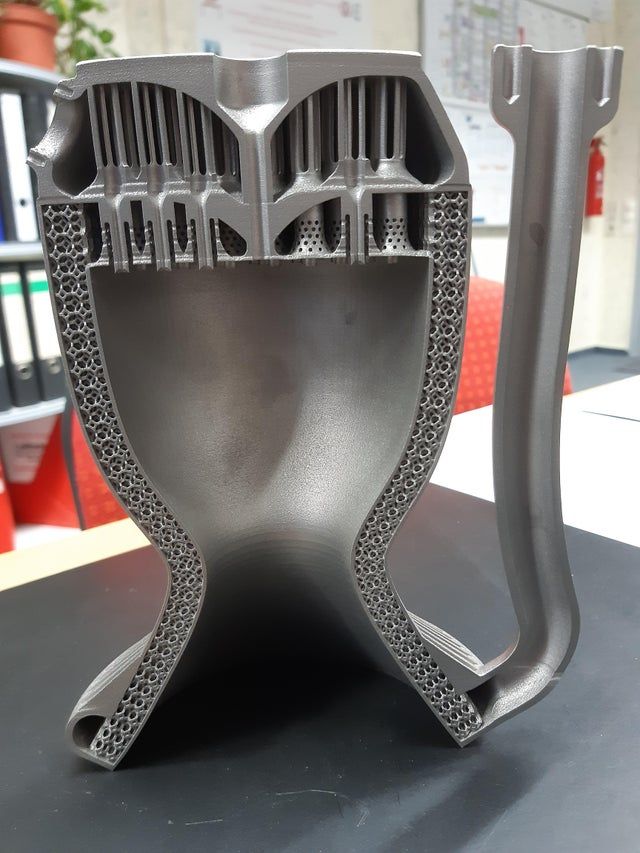

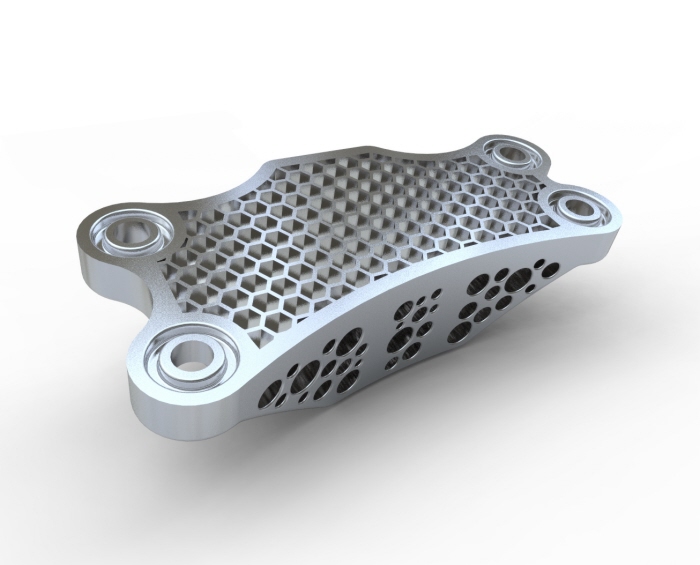

Better performance from fewer parts

Production direct from CAD data removes tooling restraints. Designers and engineers are free to design components with highly complex internal structures, and sophisticated rocket and jet engines are built with fewer parts. Sometimes, the intricate designs possible in 3D-printed components result in staggering reductions in the number of parts required. Since aviation and aerospace designs often require highly complex parts assemblies, any initiative to simplify assembly is welcomed. It saves time and money, and it also reduces potential failure modes through reduced joint welding.

Designers thrive in a new realm free of the manufacturing maxim that complexity increases costs. In the new reality of additive manufacturing, designers and accountants increasingly find common purpose. For example, in 2012, GE Aviation collaborated with Morris Technologies to test the limits of AM technologies available at the time. Engineers reduced the number of parts in a jet engine fuel nozzle from 20 to one, leading to a 25 percent weight reduction and reduced assembly times. In a new advanced turboprop engine, a dozen 3D-printed parts replace 855 components produced by multiple contractors. Reductions in the number of parts also streamline supply chains.

For example, in 2012, GE Aviation collaborated with Morris Technologies to test the limits of AM technologies available at the time. Engineers reduced the number of parts in a jet engine fuel nozzle from 20 to one, leading to a 25 percent weight reduction and reduced assembly times. In a new advanced turboprop engine, a dozen 3D-printed parts replace 855 components produced by multiple contractors. Reductions in the number of parts also streamline supply chains.

The impact of parts consolidation will grow as maximum part sizes and build rates increase in additive manufacturing. For example, Virgin Orbit expects to use AM to fabricate entire thrust chamber assemblies.

Millions saved per plane

Manufacturers also expect to increase productivity by more fully embracing additive manufacturing. By using 3D printing to produce parts for its 787s, Boeing expects to save approximately $2 million to $3 million per plane.

Market intelligence firm Netscribes projects that AM processes will generate $8. 7 billion in annual global revenue by 2020. Advanced AM technologies like electron beam melting (EBM) and direct metal laser melting (DMLM) will drive much of this growth, in part because these processes produce high-value parts and functional prototypes in aviation, aerospace and beyond.

7 billion in annual global revenue by 2020. Advanced AM technologies like electron beam melting (EBM) and direct metal laser melting (DMLM) will drive much of this growth, in part because these processes produce high-value parts and functional prototypes in aviation, aerospace and beyond.

3D printing jet engines for airplanes

The 3D printing of both jet engine prototypes and end-use parts is already having a significant impact on development and production.

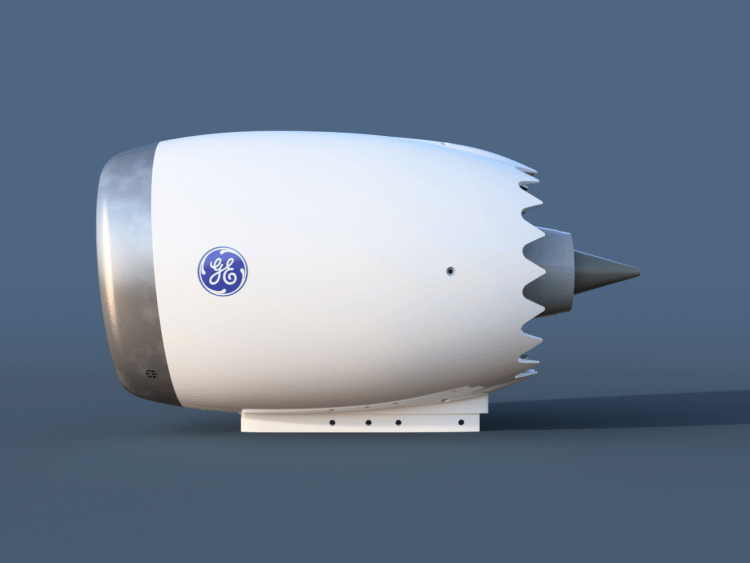

The GE90 series of high-bypass turbofan aircraft engines first entered service in 1995. Now, the next-generation GE9X from GE Aviation will use 19 3D-printed fuel nozzles to help power the next generation of wide-body aircraft like the Boeing 777X. The GE9X is the largest and most powerful jet engine ever manufactured — the front fan alone measures 11 feet in diameter. While it is approximately 10 percent more fuel-efficient than its predecessor, it still generates 100,000 pounds of thrust at takeoff.

In April 2016, Airbus took delivery of the first two LEAP-1A engines for its next-generation A320 passenger jet. GE Aviation and France’s Safran are equal partners in the engine’s manufacturer, CFM International. CFM has received more than 12,000 orders for the LEAP engine and its 3D-printed fuel nozzles. A manufacturing facility in Alabama will produce the thousands of nozzles required to fulfill the orders.

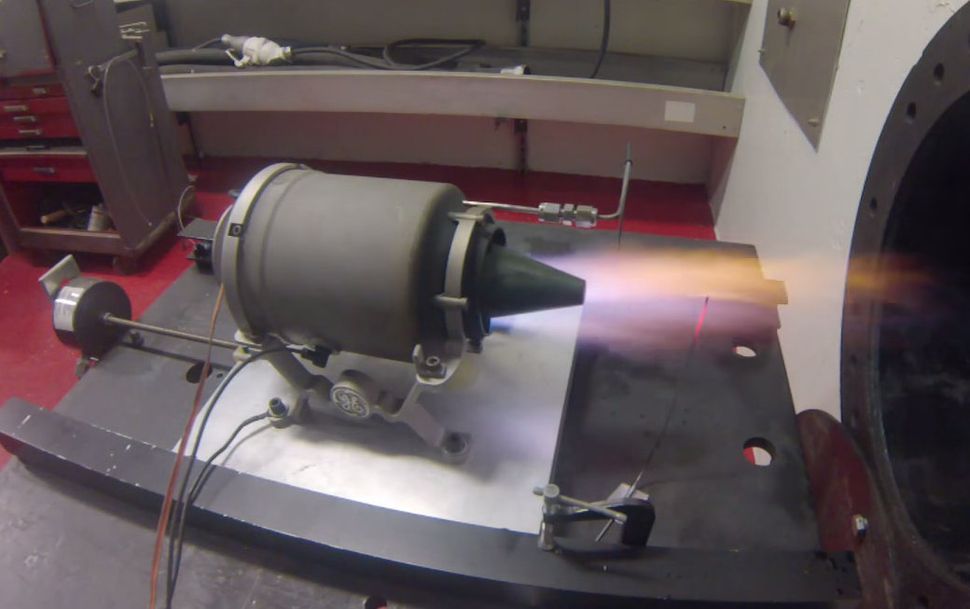

Functional prototype testing is often cheaper, simpler and quicker when AM processes are used. In late 2017, in collaboration with the United States Army, GE Aviation completed prototype testing of the Future Affordable Turbine Engine (FATE) engine. Additive manufacturing was key to the design and production of the prototype’s turbine rig. The FATE engine performs at heretofore unknown levels of efficiency and performance. Compared to current engines in the field, it reduces fuel consumption by 35 percent while cutting production and maintenance expenses 45 percent.

The ITEP engine is intended as a drop-in replacement for Apache and Black Hawk helicopters. The engine is to offer 25 percent fuel savings and a 35 percent reduction in production costs. The T901 prototype of the proposed production model makes use of functional prototypes of 3D-printed parts. The use of AM processes in the FATE and ITEP projects builds upon insights acquired in the previous development of the commercial LEAP engine.

The engine is to offer 25 percent fuel savings and a 35 percent reduction in production costs. The T901 prototype of the proposed production model makes use of functional prototypes of 3D-printed parts. The use of AM processes in the FATE and ITEP projects builds upon insights acquired in the previous development of the commercial LEAP engine.

When used to produce select lightweight, higher-durability jet engine parts, AM processes deliver a perfect trifecta of simplified design, reduced cost and shortened lead times.

3D printing airplane parts

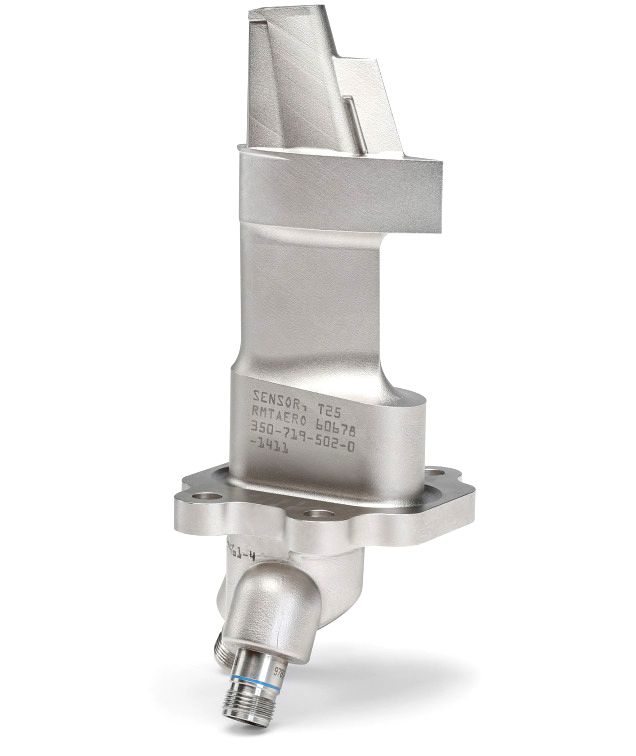

In April 2015, GE Aviation received its first FAA clearance to use a 3D-printed part in a commercial jet engine. The sensor housing for a compressor inlet temperature sensor is produced by a selective laser sintering (SLS) system. GE contracted with Boeing to use the part in more than 400 GE90-94B engines to be used on Boeing 777 jets.

Jet engine combustors are notoriously difficult to manufacture using traditional means. Using an AM process with cobalt-chrome alloy powder as the build material, high-quality components are fabricated that protect the highly sensitive electronics in the temperature sensor from surging airflows and significant icing inside the engine. AM processes are also being used to fabricate other aircraft parts, including those used in ducting systems.

Using an AM process with cobalt-chrome alloy powder as the build material, high-quality components are fabricated that protect the highly sensitive electronics in the temperature sensor from surging airflows and significant icing inside the engine. AM processes are also being used to fabricate other aircraft parts, including those used in ducting systems.

Additive manufacturing also produces sophisticated tools for the aerospace industry. In 2016, researchers at Oak Ridge National Laboratory (ORNL) fabricated a trim-and-drill tool that will help Boeing manufacture aircraft wings for its 777X aircraft.

The special tool is 17.5 feet long, 5.5 feet wide and 1.5 feet tall. The 1,650-lb device took approximately 30 hours to print from carbon fiber and composite plastics. The Guinness Book of World Records subsequently certified it as the largest solid object ever created on a 3D printer.

In one aviation and aerospace application after another, 3D-printed, lightweight products lead to energy savings, reduced carbon emissions and enhanced return on investment (ROI).

3D printing in space

In general, manufacturing for space applications requires a very high degree of precision. AM processes like EBM and DMLM excel at producing parts to close tolerances. A high degree of dimensional accuracy is attainable when layers are as thin as 20 or 40 microns, substantially less than the width of a human hair.

Examples of using additive manufacturing in space and to get to low-earth orbit and beyond are more prevalent than ever. At the Marshall Space Flight Center (MSFC) in Huntsville, Alabama, NASA researchers designed and printed a functional prototype of a two-piece rocket injector that met the performance parameters of its 163-part predecessor. The highly simplified 3D-printed injector meets strenuous mechanical property and hot fire standards, while reducing manufacturing and assembly times.

In November 2017, the Tubesat-POD (TuPOD) satellite completed its mission. The tube-shaped deployment satellite was the first 3D-printed satellite launched from the ISS.

AM experiments on the International Space Station (ISS) test the feasibility of 3D printing in space. In 2014, astronauts aboard the International Space Station printed their first plastic part on a 3D printer. Objects printed aboard the ISS were returned to earth to determine if microgravity impacted mechanical properties or other essential characteristics in any material way.

Print-on-demand technology could be pivotal in carrying out plans to travel to Mars. The capacity to print tools and replacement parts millions of miles from Earth is vital in the quest to manage risk and control costs. In some anticipated scenarios, some of the build materials for 3D printing would be mined from the Red Planet itself.

© 2022General Electric

Win a GE 3D printed jet engine... or print your own today!

Archive

Subscribe author

Subscribe

Don't want

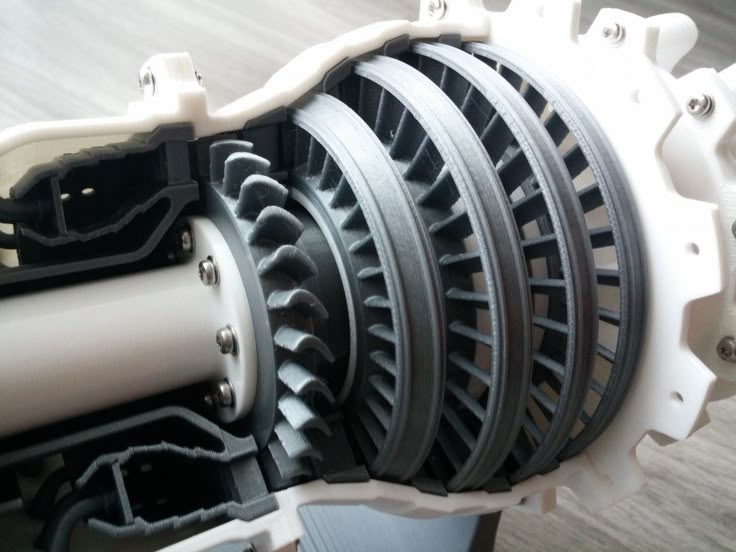

One of GE's 12 3D printed jet engines

General Electric is known as one of the largest 3D corporations in the world today -Printing not only for the manufacture of prototypes, but also in the production of final products. They use various forms of additive manufacturing to create jet engines, as well as parts for a range of other machines.

They use various forms of additive manufacturing to create jet engines, as well as parts for a range of other machines.

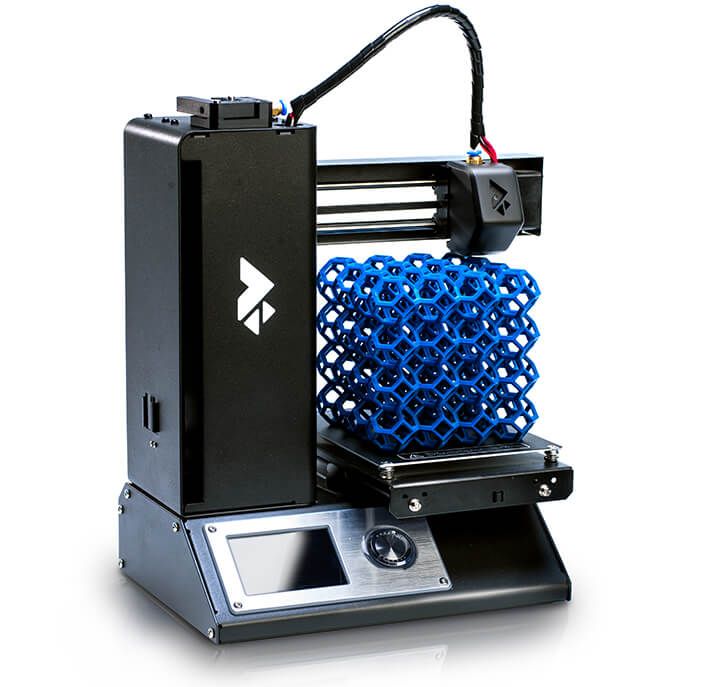

The 3D printing (additive manufacturing) technology most commonly used by GE is DMLM (Direct Laser Metal Melting Technology), in which the printer progressively melts metal powder to create three-dimensional objects. GE Aviation purchases metal powder in bulk, in 15lb and 30lb bags. They use this technology for various aspects within the production of jet engine components.

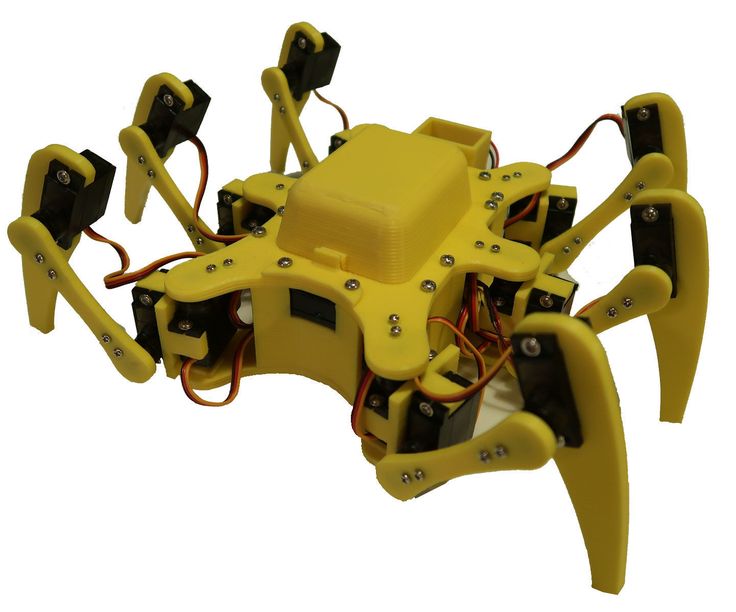

Wouldn't each of us want to own our own 3D printed jet engine? Now we have such an opportunity. GE Aviation is holding a raffle called "Build Your Own Jet Engine" to give away a dozen 3D printed jet engines to winners.

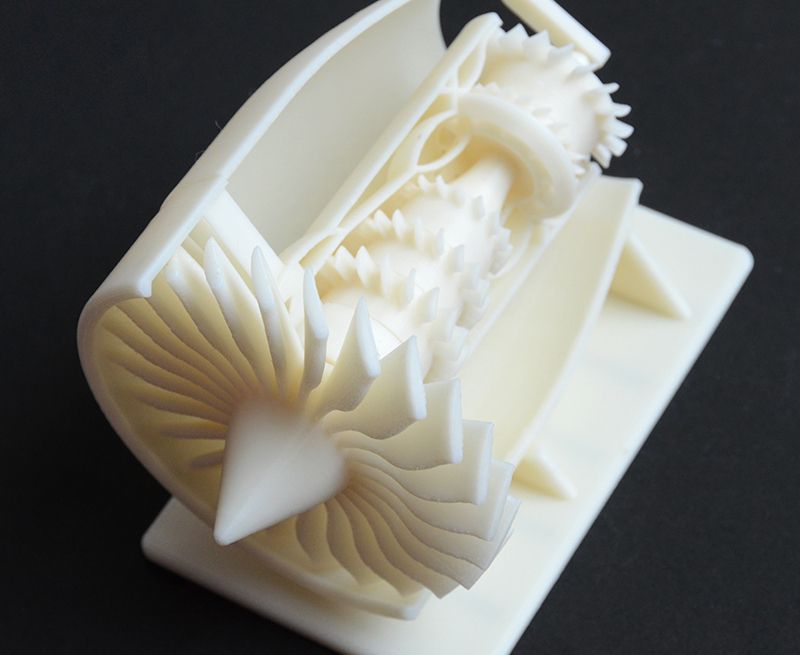

3D printed jet engine assembly from GE

But it's probably worth clarifying that these are not real jet engines, but plastic 3D printed models. However, they still look mesmerizing and would look great on any table, fireplace or coffee table.

In total, 12 winners will be selected at the end of the competition, each of whom will receive one of these unique 3D printed jet engine replicas. The contest kicked off tonight and will run until 4:00 pm on July 21st or until all 12 winners are announced. You can read more about the rules of participation on the competition website.

But even if you don't win, there's absolutely no reason to be upset. As you will still be able to download the design files for this jet engine model from the Thingiverse website. If you choose to print your own engine, this design is made up of 13 individual 3D printed parts that will then need to be assembled. Detailed assembly instructions can be found here.

3D printed jet engine from GE

What do you think about this? Would you like to participate in the competition? Or do you just download the model and print it at home? We'd love to see what you've got. Share photos of finished engines and what you think of this GE idea.

Individual printed parts to be assembled after 3D printing at home.

Article prepared for 3DToday.ru

Subscribe to the author

Subscribe

Don't want to

More interesting articles

6

Subscribe to the author

Subscribe

Don't want

One of the newest developments in 3D printing devices has been the advent of extruders. No, it's not...

Read more

four

Subscribe to the author

Subscribe

Don't want

3D printing has progressed so rapidly in recent years that we will soon stop...

Read more

3

Subscribe to author

Subscribe

Don't want to

We recently reported on an interesting engineering and architectural project directly related to the application of. ..

..

Read more

GE tested a three-circuit jet engine with 3D printed components

You are here

Home

General Electric Corporation has completed testing of a prototype XA100-GE-100 adaptive three-circuit turbofan engine built using 3D printing technologies. The three-circuit scheme allows you to choose between modes of increased efficiency and power.

The XA100-GE-100 competes with the XA-101 from Pratt & Whitney. The project provides for the development of a new generation power plant, which is characterized by increased efficiency, power and stealth in the infrared spectrum while maintaining weight and size characteristics. It was possible to achieve all the goals at once by adding another, “adaptive” contour.

Depending on the mode, the engine either operates similarly to a conventional bypass turbofan engine, or redirects some of the flow to an additional external circuit, essentially increasing the bypass ratio. In the three-circuit mode, higher fuel economy is achieved, as well as a decrease in exhaust temperature, which favorably affects stealth, but at the cost of a decrease in acceleration performance. In other words, the three-circuit mode is planned to be used in flight at cruising speed to increase the range and reduce visibility, especially at low altitudes.

In the three-circuit mode, higher fuel economy is achieved, as well as a decrease in exhaust temperature, which favorably affects stealth, but at the cost of a decrease in acceleration performance. In other words, the three-circuit mode is planned to be used in flight at cruising speed to increase the range and reduce visibility, especially at low altitudes.

Since we are talking about stealth, it should be clear that the new power plants are designed primarily for military aircraft. The fifth generation Lockheed Martin F-35 Lightning II fighter-bombers are considered as the first and main potential recipient. These machines are currently equipped with F135-PW-100 engines, on the basis of which the first competitive bid from Pratt & Whitney was created with the same gas generator, that is, the first circuit. Later, the company decided to offer the third circuit for the F135-PW-100 as an upgrade, and to develop a new gas generator for the XA-101 project. Potentially, adapted versions of the new engines could also find application in advanced sixth-generation fighters, fifth-generation F-22 fighters, and fourth-generation aircraft, in particular the F-15 and F-16.

Referring to the General Electric application, the XA100-GE-100 prototype showed a 10% increase in power with a 25% increase in fuel economy. Ceramic matrix composites, polymer composite materials and parts made using 3D printing technologies are widely used in the design of the new power plant. Bench tests of an experimental engine began in December last year and ended the other day.

General Electric is equally active in applying new technologies and materials in the civil aircraft industry. There is a separate GE Additive division in the structure of the corporation, which is responsible for the introduction of 3D printing technologies and serial additive manufacturing. The aviation division of GE Aviation operates an entire additive manufacturing facility in Auburn, Alabama, equipped with dozens of industrial 3D printers using Selective Laser and Electron Beam Fusion (SLM and EBM) technologies for metal powder compositions.

In the fall of 2016, General Electric reached agreements to purchase German 3D printer manufacturer SLM Concept Laser and Swedish EBM 3D printer manufacturer Arcam.