Do 3d printers smell

Are They Dangerous? – Clever Creations

Yes, 3D printer fumes can be dangerous. In the 3D printing process, the melting of plastic releases harmful particles into the air. Notably, the melting of ABS, PETG, and Nylon filaments emits particles that may induce headaches, nausea and irritate the eyes and nasal tract.

3D printers are getting increasingly common in households and industries alike. With this, there is a concern about whether or not they are entirely human-friendly. After all, fused deposition modeling (FDM) 3D printing works by melting plastic. This raises the question of 3D printing safety and long-term exposure to 3D printer fumes.

In this article, we’ll understand the various health-related concerns surrounding 3D printing. We’ll look at the multiple filaments and how safe they are. Then, we’ll go over some of the ways you can mitigate the risks associated with using a 3D printer. The article aims not to scare you away from 3D printing but instead make you more aware of the risks and associated measures you can take to protect yourself.

Let’s dive a little deeper and see if things really are that bad.

What are 3D printer fumes?

The smell that comes while you’re 3D printing with PLA, ABS, or any other filament, is due to the release of various chemicals in those filaments. These vapors of multiple chemicals are termed 3D printer fumes. There are two main elements in the 3D printer’s fumes – VOCs and UFPs.

Volatile Organic Compounds (VOCs) are a mixture of chemicals with a high vapor pressure at room temperatures. The sweet smell of PLA filament, the scent that comes when you melt ABS, or the pleasing scent of fresh paint are all due to the release of VOCs in the air. VOCs are not potentially life-threatening, but long-term exposure to them may cause severe side effects.

Ultrafine particles (UFPs) are particles with a size less than 0.1 μm or 100 nm in diameter. They are notoriously difficult to filter out due to their small size. These particles enter the body through our lungs and cause inflammation in the nasal areas and the eyes.

A 2016 study has demonstrated the excessive release of VOCs when using ABS, Polycarbonate, and Nylon filaments. Similarly, another study on Ultrafine particle emissions highlights 3D printers as high emitters of UFPs.

It is clear that using a 3D printer creates emissions in its environment. But are these dangerous or toxic for your health?

Are fumes from a 3D printer harmful?

The short answer to whether 3D printer fumes are harmful is yes. However, 3D printers can use various types of filament materials, and each material is made up of various compounds. Accordingly, the fumes emitted from these filaments vary as well.

In the same 2016 research paper mentioned above, researchers have thoroughly examined the various VOCs emitted by different filaments.

Let’s look at the most popular plastic filaments in more detail.

ABS filament fumes

Acrylonitrile-Butadiene-Styrene (ABS) is a commonly used 3D printing filament both by hobbyists and professionals. It is superior in its strength and rigidity and makes an excellent material for practical applications due to its high temperature resistance.

It is superior in its strength and rigidity and makes an excellent material for practical applications due to its high temperature resistance.

One of the biggest downsides of ABS filaments is that when it melts, it releases Styrene, a potentially harmful and carcinogenic VOC. Long-term exposure to ABS fumes is also related to nausea, headaches, and fatigue. The UFPs released by ABS are also higher compared to printing with other 3D printing filaments (∼2 × 1010 to ∼9 ×1010 particles per minute).

PLA filament fumes

PolyLactic Acid (PLA) is one the most popular 3D printing filaments used in hobbyist 3D printers. It is mostly made up of corn starch, sugar, or maize. These materials are renewable raw materials, and hence PLA is a comparatively sustainable 3D printing plastic.

When you melt PLA filament, it releases Lactide into the atmosphere. This is a non-toxic chemical, however, and is relatively safe to be around. PLA is a low emitter of VOCs and UFPs as compared to other 3D printing filaments. Still, you should be cautious of long-term exposure to PLA fumes as their long-term effects are unknown.

Still, you should be cautious of long-term exposure to PLA fumes as their long-term effects are unknown.

PETG fumes

Polyethylene Terephthalate Glycol (PETG) is a 3D printing filament favored by many. It combines the ease of printing with PLA and ABS’s strong chemical and mechanical resistance into a single material.

A recent study on PETG 3D printing noted that PETG releases Ethylbenzene and Styrene, both toxic and carcinogenic chemicals. While we cannot firmly determine the concentration and emission of VOCs and UFPs from this study, it still recommends caution with long-term exposure to PETG fumes.

Nylon fumes

Nylon is primarily an industrial 3D printing plastic. It offers extreme durability and more wear and tear resistance than ABS filament. That said, it also emits harmful fumes, of which over 90% consists of Caprolactam.

The EPA has not classified Caprolactam as a Carcinogenic substance in its findings; still, long-term exposure can irritate the eyes, nose and cause respiratory disorders in humans. The 2016 study also found out that the emission rate of VOCs while 3D printing Nylon was the highest ∼at 180 μg/min. This suggests that even short-term exposure to these fumes may result in unpleasant side effects of printing with Nylon.

The 2016 study also found out that the emission rate of VOCs while 3D printing Nylon was the highest ∼at 180 μg/min. This suggests that even short-term exposure to these fumes may result in unpleasant side effects of printing with Nylon.

Resin 3D printing fumes

Resin 3D printing doesn’t melt any material but instead cures 3D printer resin using a light source, typically an LCD screen or a laser. The process is notorious for its foul smell, and hence a majority of resin 3D printers come with a tightly sealed enclosure. Some of the best resin printers even include air filtration systems.

A recent study published by Chemical Insights concluded that although the VOCs emitted during resin 3D printing are significantly less than those from FDM printing, there are still potential toxic chemicals being released. Notably, formaldehyde (a carcinogen), acetaldehyde, and methyl isobutyl ketone are being emitted during the resin 3D printing process.

Even though these chemicals were well within the recommended limits, prolonged exposure to this mix of chemicals can irritate susceptible individuals’ eyes and the skin.

Recommended:

Resin vs Filament 3D Printers: What’s the Difference?

How to reduce risks from harmful 3D printer fumes?

We’ve now understood that there are indeed risks associated with 3D printer fumes. While they are not instantly deadly, we still need to take safety and health precautions to enjoy the 3D printing hobby and mitigate any risks. In this section, we’ll go over some of the techniques you can use to enjoy a harmless 3D printing experience without worry.

Ventilate your workspace

The one common thing that we’ve observed in all the studies is that the 3D printers emit a constant stream of VOCs and UFPs when in operation. The risks associated with these fumes have less to do with the chemicals themselves and more to do with their concentration in the air.

A closed room with a single 3D printer can be more harmful than a well-ventilated workspace with multiple 3D printers. The goal is to ensure good ventilation in the workspace using air filters, fans, and windows. This limits the concentration of harmful chemicals in the air and maintains good air quality in the room.

This limits the concentration of harmful chemicals in the air and maintains good air quality in the room.

Get a 3D printer enclosure

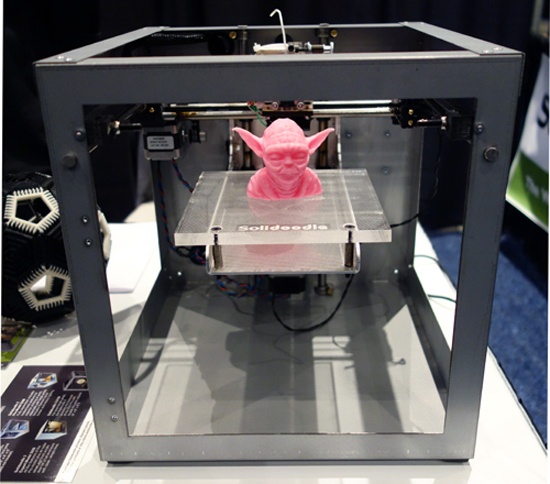

Many hobby-level 3D printers are of open-frame design. This helps manufacturers save costs associated with an enclosed structure. This does mean that, while in operation, the 3D printer releases toxic fumes directly into the atmosphere.

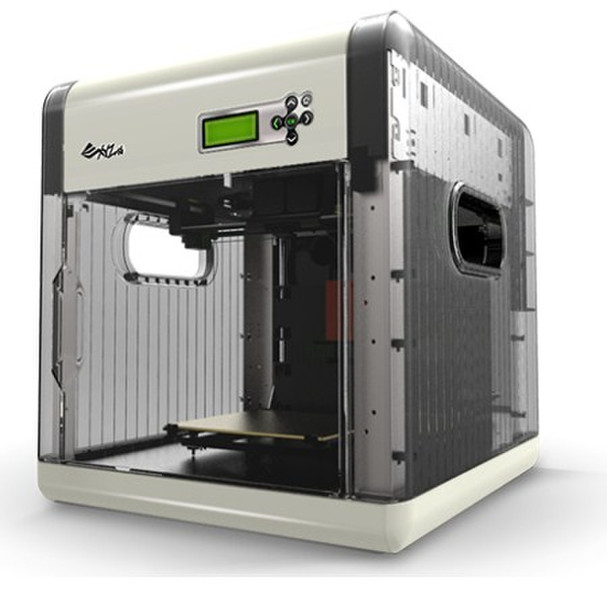

In the case of enclosed 3D printers, you can avoid this problem. These contain VOCs and UFPs significantly and prevent these compounds from freely spreading to your room. Some enclosed printers even come with a filtration system and fans.

Recommended:

The 9 Best Enclosed 3D Printers

Aside from limiting the transmission of harmful fumes into the workspace, enclosures also reduce any filament smell and printing noises.

But these 3D printers can be expensive, and so many people accept the trade-off that comes with the open-frame design. You can, however, opt for one of the many DIY 3D printer enclosure ideas that are available.

Creality even offers official enclosures for their 3D printers, like the popular Ender 3, that you can upgrade with when you feel ready. It is one of the many popular Ender 3 upgrades or Ender 5 upgrades that you can do to improve your 3D printing experience.

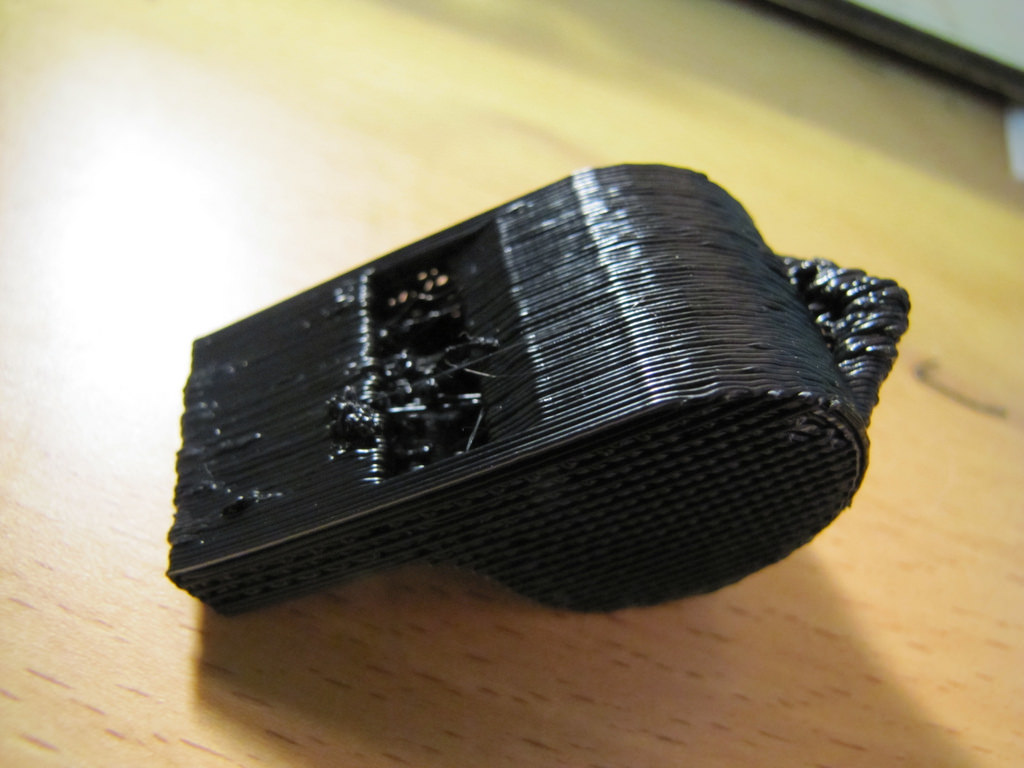

Image: cisardom via Thingiverse

A DIY 3D printer enclosureIf you are willing to put in the time and effort, you can also build your own DIY 3D printer enclosure. There are plenty of designs available, such as this IKEA Lack enclosure that fits many 3D printers.

Print with safer material

If you don’t want to deal with toxic fumes, the best solution is to avoid using 3D printer filament that gives off these fumes. ABS and PETG are made up of complex toxic chemicals and release high concentrations of VOCs in the air during the printing process. If you don’t strictly need to 3D print with these plastics, it is best to avoid them altogether.

If you do want to print with these materials, sticking to the best PETG and best ABS filament brands is recommended to avoid low quality brands that add harmful additives.

Then we have PLA filament. PLA is great for many reasons, the best of them all is that it is relatively safe and emits little to no harmful VOCs. Instead, what you get is the sweet smell from the melting of the sugars in the PLA. For settings like the classroom, home office, or kids’ bedroom where safety is extra important, PLA filament is the safest option.

Recommended:

The 10 Best PLA Filaments for 3D Printing

Air quality monitor

An air quality monitor is a great way to keep a check on the air quality in your 3D printer’s workspace. Not only can you get safety and health-related information like VOC and CO2 levels, but you can also track humidity levels to make sure you don’t expose your filament to too much moisture.

Image: Gary Peng via hackaday

Air quality monitors can be home-builtIt can provide you with a sense of relief when it comes to harmful fumes. You don’t have to speculate about the air quality, and you can simply look at the data to see if what you are doing is safe or not. It also helps you to tweak your ventilation and filtration systems to ensure that you are always within a safe zone.

It also helps you to tweak your ventilation and filtration systems to ensure that you are always within a safe zone.

Airthings 2930 Wave Plus - Radon & Air Quality Monitor (CO2, VOC,...

2,972 Reviews

Check PricePick an optimal location for your 3D Printer

Good workspace ventilation and an optimal location for your 3D printer go hand-in-hand. Typically, a garage workshop is an ideal location for your 3D printer. A garage can be well ventilated and has a large volume, keeping VOC and UFP concentrations low. Plus you can choose not to stay in it while the 3D printer is in operation.

If you’re planning on using the printer in your living room or bedroom, an enclosure and a good ventilation system is a must. You must also be careful not to place the 3D printer near the kid’s area. Other than risking damaging your 3D prints, you do not want to risk their long-term health either with PETG or ABS filament.

Recommended:

PETG vs ABS: Which Filament Should You Use?

Air purifier

An air purifier is a great device to filter out unwanted toxic particles from the air. They are a must-have if you’re planning on printing indoors. Not only do these purifiers filter out the harmful VOCs, but they also remove any smell and provide clean air in your workspace. The most crucial element in these purifiers are their filters, so let’s look at the two common types of filters used.

They are a must-have if you’re planning on printing indoors. Not only do these purifiers filter out the harmful VOCs, but they also remove any smell and provide clean air in your workspace. The most crucial element in these purifiers are their filters, so let’s look at the two common types of filters used.

HEPA filters

HEPA stands for High-Efficiency Particulate Air filter. The HEPA filter is theoretically designed to remove almost 99.97% of air particles with a size of 0.3 microns. These filters have a MERV rating corresponding to the particle size they can filter out. You should get a HEPA filter with a MERV rating of 17 or above, as these are the effective ones against the 3D printer’s UFPs.

Carbon filters

Carbon Filters use activated carbon to filter out particles. Unlike HEPA filters, the carbon filters process the foul-smelling chemicals and essentially eliminate any odors or harmful fumes in the atmosphere.

These filters are primarily used in conjunction with the HEPA filters. The HEPA filters capture any dust, chemicals, or pollen in the air, and the carbon filters process this air to be as clean as possible.

The HEPA filters capture any dust, chemicals, or pollen in the air, and the carbon filters process this air to be as clean as possible.

Our pick

The Levoit Core 300 air purifier is one of the cheapest yet most effective air purifiers available on the market right now. It features both HEPA and carbon filters and can filter out VOCs, UFPs, dust, toxins, smoke, and pet hair. It operates almost silently at a noise level of just 24 dB.

Combine this with a sleek-looking design and a small size; this air purifier is an excellent match for any small-to-medium-sized 3D printing workspace.

LEVOIT Air Purifier for Home Allergies Pets Hair in Bedroom, h23 True...

76,273 Reviews

Check PriceWindow fan

In the end, there is no more straightforward solution than getting a window fan. Window fans are a great way to keep the air flowing in the room and ensure sufficient ventilation in the workspace. When mounted in a window opening, the fan ensures that there is sufficient fresh air coming in to prevent VOCs and ultrafine particles from building up in the room.

Comfort Zone CZ310R 9" 3-Speed, 3-Function, Expandable, Reversible...

10,811 Reviews

Check PriceFAQ

Are 3D printers safe for pets?

3D printers are generally safe to use around pets. There are no known direct effects on their health. However, some pets may be more vulnerable to certain VOCs and may even experience nauseating symptoms.

There is also the danger of hotends, the heated bed, and moving parts of the 3D printers. Your pet might not be aware of the danger of these components and get injured by being too curious. It is best to take adequate precautions while operating your printer around pets.

Does a 3D printer smell?

While a 3D printer by itself does not smell, it is the plastic filament that smells when melted. The strength of the smell partly depends on the type of filament you use. Printing with ABS creates a strong smell, whereas PLA fumes are barely noticeable.

How to filter 3D printer fumes?

To properly filter printer fumes you can use an enclosed 3D printer, add an aftermarket enclosure to your 3D printer, or add an air purifier with both HEPA and carbon filters.

Maintaining sufficient ventilation in your room is a good addition as well. This removes leftover fumes, eliminates foul smells, and carries in fresh air.

Conclusion

3D printing is a great hobby and a fun one at that. However, to enjoy it fully and stress-free, you need to take certain precautions. While we cannot wholly avoid fumes, we can very well limit them and save ourselves from some headaches.

A well-ventilated workspace, an air purifier, and a 3D printer with an enclosure are all things you can integrate into your setup to keep yourself safe from toxic and harmful 3D printing fumes. While you can never avoid all possible risks, these are enough to make a worry-free experience.

When none of these options are realistic for you, then sticking to PLA filament is the safest thing you can do.

If you still have any questions or would like to add something, let us know in the comments below.

What Does 3D printing Smell Like? Things You Should Know

Curtis Satterfield, Ph.

D.

D. Sometimes my students will ask me if 3D printers smell while they are printing. Other people ask me because they want to get into 3D printing and worry it will smell up their house. In this article we will examine the smells behind 3D printing.

All 3D printers will have some amount of smell when printing. With filament printers the smell can range from sweet honey-like to burning plastic. Resin printers often have strong chemical smells of plastic and solvents.

The smell that happens when printing depends on the type of printer and the material used in the printer. With Fused Deposition Modeling (FDM) printers the smell comes from the heating of the plastic filament. Resin printers use vats of resin that hardens with exposure to UV lights or lasers. The smell from these printers come from the chemical makeup of the resin.

The Smells of 3D Printing

I want to limit the scope of our discussion to smells that a home user would want to know about. We will split our answer between the two major types of printers that you would buy and use at home, FDM and Resin.

We will split our answer between the two major types of printers that you would buy and use at home, FDM and Resin.

FDM Printer Smells

FDM printers work by melting the plastic and fusing it together. To melt the plastic an extruder nozzle heats to temperatures between 190° to 270° Celsius. As the plastic passes through the nozzle the plastic melts and fuses to the previous layer as it cools. This heating and melting of the plastic cause the plastic to release gases and volatile organic compounds (VCOs). The gases and VCOs are what you smell when 3D printing.

Common Filament types and Their Smells

Acrylonitrile Butadiene Styrene (ABS) is a common filament type known for being tough and impact resistant. ABS prints at a nozzle temperature of 240°C – 270°C and gives off a harsh burning plastic smell.

Polylactic Acid (PLA) is one of the favorite filaments of the 3D printing community. It is a biodegradable thermoplastic derived from renewable sources such as cornstarch, sugar cane, and potato starch. PLA requires a much lower nozzle temperature than ABS printing between 180°C and 220°C. Along with a much lower printing temperature PLA produces less odor when printing. Due to the plant-based materials it gives off a smell that can have a honey-like aroma. This is subject to opinion as some people cannot stand the smell of PLA while it is printing.

It is a biodegradable thermoplastic derived from renewable sources such as cornstarch, sugar cane, and potato starch. PLA requires a much lower nozzle temperature than ABS printing between 180°C and 220°C. Along with a much lower printing temperature PLA produces less odor when printing. Due to the plant-based materials it gives off a smell that can have a honey-like aroma. This is subject to opinion as some people cannot stand the smell of PLA while it is printing.

Polyethylene Terephthalate (PET) is used for mechanical parts that need flexibility and impact resistance. PET offers more flexibility than ABS while maintaining strength. PETG is printed at temperature like ABS between 220°C and 250°C. Unlike ABS it does not give off noxious fumes when printing. PET does not produce an odor when it prints.

Glycol modified Polyethylene Terephthalate (PETG) is a variant of PET filament that increases the materials durability and impact resistance. Unlike PET this material will not absorb water. PETG is also considered food save and can be used for cups, plates, and food containers. It prints at the same temperature range as PET and does not produce an odor when printing.PolyEthylene coTrimethylene Terephthalate (PETT) is another modified version of PET. PETT is considered food safe and is approved by the FDA. It prints cooler than PETG between 210°C and 230°C. PETT does not give off an odor when printing.

Unlike PET this material will not absorb water. PETG is also considered food save and can be used for cups, plates, and food containers. It prints at the same temperature range as PET and does not produce an odor when printing.PolyEthylene coTrimethylene Terephthalate (PETT) is another modified version of PET. PETT is considered food safe and is approved by the FDA. It prints cooler than PETG between 210°C and 230°C. PETT does not give off an odor when printing.

Polyamide (Nylon) filament is a synthetic polymer used in industrial applications. Nylon is strong, durable, and flexible. Printed between 220°C – 250°C, Nylon is perfect for industrial parts such as; gears, bearings, and mechanical components. The downside to nylon is that it emits toxic fumes when printing. This is important to know as nylon does not produce and odor when it prints. Nylon is toxic and should be used in a well-ventilated area.

Wood filament is made with recycled wood and polymer binding. It is used for more decorative applications as it is one of the weaker printing materials. Printed in the same nozzle temperature range as PLA at 195°C-220°C and will give off a smell of burning wood.

It is used for more decorative applications as it is one of the weaker printing materials. Printed in the same nozzle temperature range as PLA at 195°C-220°C and will give off a smell of burning wood.

Resin Printer Smells

Courtesy of Elegoo.comThe smell produced from resin printers is a byproduct of the chemicals the resin is made from. Unlike FDM, the resin has a consistent smell even when not printing. Most resins are toxic to breathe and get on your skin. Caution should be used when working with resin printers.Each manufacturer will use different formulas in their resins and each type will have different smells. Resin types include:

Standard resin is your basic and usually lowest priced resin. It can come in a variety of colors and is opaque in appearance. Standard resin typically has low viscosity allowing the resin to flow freely during the printing process. Standard resins are designed to reduce part shrinkage when cured. Standard resins also tend to be brittle when cured and may not work well for functional parts requiring high strength.

Transparent resin is another form of standard resin. Transparent resins differ from other standard resin as their appearance is transparent instead of opaque. An interesting aspect of transparent resin is that the UV light can past through the current layer into preceding layers of the print. Because the transparent resin does not absorb the UV light as readily, exposure times for transparent resin tend to be longer. Transparent resin shares the same mechanical characteristics of standard resin.

Casting resin is used in various industries like jewelry making and metal casting. This resin is designed to be “burned out” in a process like lost wax casting. Castable resins tend to be made with waxes that melt when exposed to high temperatures. These resins are designed for this specific purpose and do not work well for other uses.

Tough resin is designed to have higher strength than standard resin. Tough resin is designed to mimic the mechanical characteristics of ABS plastic. Tough resin is ideal for functional prototypes as it produces strong parts that are less likely to shatter. With tough resin you typically need your parts to have a minimum wall thickness. Trying to print models with thin walls can result in failed prints.

Tough resin is ideal for functional prototypes as it produces strong parts that are less likely to shatter. With tough resin you typically need your parts to have a minimum wall thickness. Trying to print models with thin walls can result in failed prints.

Flexible resin is ideal for medical devices, anatomical models, special effects props, and anything that needs to bend and move. The main difference between flexible resin is how much flex the final part has.

Unlike filaments all resins give off some amount of odor even when not printing. These resins are not heated up to high temperatures like the FDM filaments. The resin will warm up to around 40°C due to ambient heat of the printer but the resin itself is not heated. The resin temperature will rise during the printing process increasing the odor. It is important to keep a resin printer in a well-ventilated area especially if you have pets or children.

Some resins, like FormLabs clear, have less smell than others. For me, FormLabs clear does not have a noticeable smell while the printer is not running. Again, the smells are subjective, and opinions will vary person to person.

For me, FormLabs clear does not have a noticeable smell while the printer is not running. Again, the smells are subjective, and opinions will vary person to person.

I have three brands of resin at home; Elegoo Standard, Anycubic Standard and Sain Smart Rapid. All three resins are grey and all three have a noticeable smell. When comparing the three, Sain Smart has the strongest smell. I do not think any of the three resins smell bad, but they all have a distinct odor.

How Long Does the Smell Last?

This answer depends on the type of printer and material you are using. For FDM printers, the smell only lasts while the machine is printing. The smell may linger for a few minutes after printing as the filament cools to room temperature.

For Resin printers the smell is persistent even when the printer is not printing. While the printer is running the odor can become stronger. As the machine finishes and cools down the odor will reduce but it will not completely dissipate. You should return the unused resin from the vat back to its sealed container. Clean the vat of any unused resin and replace the vat in your printer. Following these steps will help remove any lingering odors from the print.

You should return the unused resin from the vat back to its sealed container. Clean the vat of any unused resin and replace the vat in your printer. Following these steps will help remove any lingering odors from the print.

Minimizing the Smell

There are ways to reduce the odors that come from your printer. The easiest way is to place your printer in a well-ventilated area away from the living spaces of your home. For example, a garage or utility room where you can open a window or door to circulate fresh air.

I understand that a dedicated 3D printing space is not an option for everyone. If you do not have a space that you can dedicate as your 3D printing area there are other options. Another solution is to only buy and use filament that has low to no odor. Filament types such as PLA, PET, PETG, and PETT are great low odor filaments. Each has its own pros and cons for usage with PET/G/T being harder to use than PLA. However, PLA has a very low odor and you may find that it is not strong enough to bother you.

However, PLA has a very low odor and you may find that it is not strong enough to bother you.

Another option is to buy a 3D printer with an enclosure to help keep the smell inside the printer. If you already own an open 3D printer there are many options for building a DIY enclosure. If you prefer to buy rather than build, there are options such as the Creality 3D Printer Enclosure.

Finally, if you are using a resin printer it will be hard to escape the smell. Even using an enclosure, the ever-present odor of the resin itself is hard to contain. Regardless of the brand there will always be some amount of odor. Be sure to return any unused resin back to the bottle and keep it sealed. The best option is to use a resin printer in a dedicated well-ventilated area for your resin printer. Be sure to keep your family and pets out of the area while using the printer.

Related Questions

Are 3D Printers Toxic? This depends on the type of printer and material used. All consumer grade printers and materials give off VOCs that can contain toxic chemicals. The harshest of these come from resin printers but filaments can give off toxins as well. Nylon is a great printing material, but it gives off toxins when heated for printing. That is why it is important to use 3D printers in a well-ventilated area away from children and pets.

All consumer grade printers and materials give off VOCs that can contain toxic chemicals. The harshest of these come from resin printers but filaments can give off toxins as well. Nylon is a great printing material, but it gives off toxins when heated for printing. That is why it is important to use 3D printers in a well-ventilated area away from children and pets.

Are 3D printers noisy? Like smells, all 3D printers will make some amount of noise. The amount depends on the type of printer and the surface that it sits on. The average 3D printer is around 50 decibels, about as loud as a conversation between two adults. The noise level can be attenuated by using an enclosure and other methods.You can read my article here about 3D printer noise and how to reduce it.

Techno Print 3D Company

This is our first review of the most popular and inexpensive 3D printers for 2020. The list will include the best-selling devices in two price ranges (up to 30 tr and up to 60 tr). Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

Printers working with both plastic filament (FDM) and photopolymers (LCD/DLP) will be presented. This list will always be up to date, as it is periodically updated and supplemented. Read more→

The Chinese company Dazz3D announces the launch of the project on KickStarter and accepts pre-orders for Dazz3D Basic and Dazz3D Pro 3D printers. These revolutionary new devices are aimed at both the professional and amateur markets. Read more→

We all know that precise calibration of the 3D printer desktop is the foundation and the key to successful printing on any FDM printer. In this article we will talk about the main and most popular ways to level the "bed". So, as mentioned above, 3D printing without desktop calibration is impossible. We face this process Read more→

It's hard to go through a day today without hearing about 3D printing technology, which is bursting into our lives at an incredible speed. More and more people around the world are becoming addicted to 3D printing technology as it becomes more accessible and cheaper every day. Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

Now almost anyone can afford to buy a 3D printer, and with the help of Read more→

The FormLabs Form 2 and Ultimaker 3 are perhaps the most popular 3D printers today, capable of high quality printing with incredible surface detail. Moreover, these two devices use completely different technologies, and therefore, there are a lot of differences between them. Many will say that it is wrong to compare them or Read more→

XYZprinting, best known for its daVinci line of desktop 3D printers, is bringing five new devices to the professional and industrial environment. One will use laser sintering technology, the second full color inkjet printing and three DLP machines. First of all, the novelties will be of interest to dentists and jewelers. Read more→

Cleaning the nozzle of a 3D printer is a fairly common process that any user of such a device has to deal with. This is not at all a complicated procedure that anyone can handle. You can complete this task in 15 minutes, using only handy tools and accessories. Read more→

Read more→

Acetone steam polishing of ABS plastic is a process for smoothing the surface of 3D printed models. The result of this treatment makes your printed products look as if they were made by a professional mold casting method. If you want to understand how this is done correctly, then read this article. Aceto Read more→

Does 3D printing smell? Why and the best materials to prevent odor

Contents

Since 3D printing was invented, its use and popularity has skyrocketed and become more and more in demand in the market, especially in the last decade. One thing that worries a lot of people is the potential fumes and odors that 3D printing is said to give off.

Does 3D printing smell? 3D printing can have a noticeable smell because it uses heat technology to make "ink". These inks can be made from a variety of materials that release strong odors when heated.

Be aware that the smell emitted by 3D printing can be very harmful to health, especially in large quantities.

If you're interested in learning more about how 3D printing works and how you can use 3D printing yourself, keep reading to find out more.

What causes the smell of 3D printing?

Before we discuss exactly how 3D printing works and why it has become so popular in recent years, I think it's important to reiterate and explain why the misuse of 3D printing should be avoided.

While I'm going to go into more detail about how 3D printing works and what smells can come from 3D printing, basically the "ink" used to develop the structure being created is actually a molding material that can be made from various materials.

The most popular 3D printing ink materials are usually various types of plastic. The smell of burning plastic can be hazardous to your health.

Therefore, make sure that if you are near 3D printing or do it yourself, always stay in a well-ventilated area and take other necessary precautions. I will cover more details on how to do this later.

This process has been shown to produce two by-products from plastic-based inks that you should be concerned about: ultrafine particles (UFPs) and volatile organic compounds (VOCs).

Research has been done into how both of these by-products can enter the body and potentially lead to cancer. However, further research remains to be done in this area.

How does 3D printing work?

3D printing has other names, including desktop fabrication, additive manufacturing, or rapid prototyping. Before proceeding to 3D printing, the designer creates a digital 3D blueprint of the model/mold to be printed.

A 3D plan file is used to develop a 3D object layer by layer, as if it were cut into many thin horizontal pieces, stacked together and then glued together to form the final product. If you think about how a bunch of blocks can be stacked into a tower, you can understand what's going on in a 3D printer.

It's just that the process takes place on a much finer scale, allowing for greater detail in the final product.

The three most widely used 3D printing technologies are Selective Laser Sintering (SLS), Fused Deposition Modeling (FDM), and Stereolithography (SLA).

The first two are methods in which a material that is liquefied or softened by heat to create multiple layers of an object.

What materials are used in 3D printers?

Various materials can be used in 3D printers, such as:

- plastics (ABS, PLA, polyamide nylon)

- glass-filled polyamide

- epoxy resins (thermosetting plastics)

- metals (silver, titanium, steel)

- wax

- photopolymers

- polycarbonate

It is thanks to the fact that 3D printers can use so many new materials that the industry has developed so much in recent years.

What can be 3D printed?

Currently, anything that can be made from materials that have been found suitable for 3D printing can be produced with one of these machines. Many companies have already used 3D printers to prototype a number of things that you might find surprising.

This list includes prototypes such as:

- specialized running boots

- Jet engines

- Bridges

- Jewelry

- Construction equipment

- Automotive components

Almost anything you can imagine could someday be 3D printed, and new advancements are constantly being made in this area. There have even been 3D printed prostheses such as prosthetic ears, spinal implants, jaw implants, teeth and prosthetic limbs.

What types of 3D printing materials often produce odors?

As I explained earlier, the "printing" mechanism in 3D printers relies on heat to soften the filaments that become the ink that forms each horizontal layer of the printed object. This process can lead to various noticeable odors that can be emitted by different types of materials used in 3D printers.

Below, I'll show you which common 3D printing materials produce odors and fumes that can pose a risk to your health.

What precautions should be taken when 3D printing?

While 3D printing odors may be the most obvious sign that fumes are being emitted, a strong odor does not always mean a major health hazard.

As you can see from the table above, although PLA filament does produce a noticeable odor when printed, its fumes are generally considered non-toxic.

On the other hand, nylon threads, which are plastic, are odorless, but their vapors can release gaseous compounds that are very hazardous to health. No matter what filament you use, if you're into 3D printing, it's important to take consistent precautions to protect your health.

In addition to choosing the safer materials you will use, another precaution is to use a 3D printer with certain safety features. If you have access to a closed 3D printer, this limits the amount of particles released into the air. In addition, 3D printers can have built-in air filters that further reduce exposure to toxic fumes.

In addition to making sure that the machine you are using can provide safer printing, you can also take steps to prepare the room where you use the printer. Make sure the room has access to adequate ventilation, such as windows, additional air filtration devices, and/or an air quality monitor.

Long-term exposure risks

Although the problems associated with inhaling filament fumes may seem minor if you are exposed to them for long periods of time while working or using a 3D printer at home, the effects of inhaling toxic fumes will increase over time time.

Long exposure means that even if you use "safe" filaments such as PLA or PETG, which emit little fumes, you are still potentially risking your health.

After all, since 3D printing has only recently exploded in popularity, the long-term effects of inhaling its fumes are not yet fully understood.

The longer you plan to 3D print, the more important you are to implement and practice reasonable 3D printing precautions as soon as possible.

The Future of 3D Printing

3D printing is expected to continue to evolve as an industry as more materials can be adapted for use in these innovative printers. Already, there are many industries that use 3D printers to develop complex and stable products that people need.