Maine 3d printer

First 100% bio-based 3D-printed home unveiled at the University of Maine - UMaine News

November 21, 2022 Advanced Materials for Infrastructure and Energy, Outreach, Signature and Emerging Areas, Sustainability Solutions and Technologies

On Nov. 21, the University of Maine Advanced Structures and Composites Center (ASCC) unveiled BioHome3D, the first 3D-printed house made entirely with bio-based materials. BioHome3D was developed with funding from the U.S. Department of Energy’s Hub and Spoke program between the UMaine and Oak Ridge National Laboratory. Partners included MaineHousing and the Maine Technology Institute.

The 600-square-foot prototype features 3D-printed floors, walls and roof of wood fibers and bio-resins. The house is fully recyclable and highly insulated with 100% wood insulation and customizable R-values. Construction waste was nearly eliminated due to the precision of the printing process.

“Our state is facing the perfect storm of a housing crisis and labor shortage, but the University of Maine is stepping up once again to show that we can address these serious challenges with trademark Maine ingenuity,” said Gov. Janet Mills. “With its innovative BioHome3D, UMaine’s Advanced Structures and Composites Center is thinking creatively about how we can tackle our housing shortage, strengthen our forest products industry, and deliver people a safe place to live so they can contribute to our economy. While there is still more to be done, today’s development is a positive step forward — one that I was proud to support through my Maine Jobs & Recovery Plan and my budget. I extend my congratulations and thanks to the University of Maine and its partners, and I look forward to continuing to tackle these problems with innovative solutions.”

The U.S. and Maine, in particular, are experiencing a crisis-level shortage of affordable housing. The National Low Income Housing Coalition reports that nationally, there is a need for more than 7 million affordable housing units. In Maine alone, the deficit is 20,000 housing units and growing each year, according to the Maine Affordable Housing Coalition. Nearly 60% of low-income renters in Maine spend more than half of their income on housing. This untenable situation is exacerbated by the twin challenges of a labor shortage and supply chain-driven material price increases.

In Maine alone, the deficit is 20,000 housing units and growing each year, according to the Maine Affordable Housing Coalition. Nearly 60% of low-income renters in Maine spend more than half of their income on housing. This untenable situation is exacerbated by the twin challenges of a labor shortage and supply chain-driven material price increases.

In addition to Mills, those participating in the unveiling event included U.S. Sen. Susan Collins; Jeff Marootian, senior advisor for energy efficiency and renewable energy for the U.S. Department of Energy; Rebecca Isacowitz, acting chief of staff for the office of energy efficiency and renewable energy at the DOE; Steve McKnight, acting advanced manufacturing office director for the DOE; and Xin Sun, associate laboratory director for energy science and technology with the Oak Ridge National Laboratory. The leaders toured ASCC, provided remarks and participated in the ribbon cutting ceremony. Also in attendance were legislators, housing advocates and developers, and Maine high school and university students.

“With today’s production of the world’s first ever 3D-printed house made from recycled forest products, the University of Maine continues to demonstrate its global leadership in innovation and scientific research,” said Sen. Collins. “This remarkable accomplishment was made possible by the tenacity and expertise of Dr. Habib Dagher, his team and students at the UMaine Advanced Structures and Composites Center. I commend them on pioneering this new market opportunity for Maine’s forest products industry, which could help alleviate our nation’s housing shortage. Their groundbreaking work will lay the foundation for the future of affordable housing and help create new jobs across our state.”

The technology is designed to address labor shortages and supply chain issues that are driving high costs and constricting the supply of affordable housing. Less time is required on-site building and fitting up the home due to the use of automated manufacturing and off-site production. Printing using abundant, renewable, locally sourced wood fiber feedstock reduces dependence on a constrained supply chain. These materials support the revitalization of local forest product industries and are more resilient to global supply chain disruptions and labor shortages.

These materials support the revitalization of local forest product industries and are more resilient to global supply chain disruptions and labor shortages.

Using the advanced manufacturing processes and materials developed at UMaine, future low-income homes can be customized to meet a homeowner’s space, energy efficiency and aesthetic preferences. Importantly, as the manufacturing technology and materials production are scaled up, homebuyers can expect faster delivery schedules.

“We are finding solutions here at ASCC to the pressing problems that our world faces and that Maine faces, through research on transformative offshore wind technology, next-generation solutions for transportation infrastructure, advanced forest products and large-scale 3D printing, and of course, affordable housing,” said UMaine President Joan Ferrini-Mundy. “The work that goes on in this lab absolutely exemplifies the work of a land grant institution — an institution that was started in order to help to solve the problems of, and further the economic advancement of, the state of Maine in partnership with the people of Maine. I couldn’t be more proud to point to this lab and exactly how that’s happening right here.”

I couldn’t be more proud to point to this lab and exactly how that’s happening right here.”

The prototype is currently sited on a foundation outside ASCC, equipped with sensors for thermal, environmental and structural monitoring to test how BioHome3D performs through a Maine winter. Researchers expect to use the data collected to improve future designs.

BioHome3D was printed in four modules, then moved to the site and assembled in half a day. Electricity was running within two hours with only one electrician needed on site.

“Many technologies are being developed to 3D print homes, but unlike BioHome3D, most are printed using concrete. However, only the concrete walls are printed on top of a conventionally cast concrete foundation. Traditional wood framing or wood trusses are used to complete the roof,” said Dagher, ASCC executive director. “Unlike the existing technologies, the entire BioHome3D was printed, including the floors, walls and roof. The biomaterials used are 100% recyclable, so our great-grandchildren can fully recycle BioHome3D. ”

”

“It’s these type of public-private collaborations, supported by DOE’s Advanced Materials and Manufacturing Technologies Office, that will help spur innovation in our manufacturing sector. These partnerships across industry, academia, government and our national labs have ushered in critical new technologies that are reducing emissions, improving efficiency, and making our manufacturing stronger, more resilient and more sustainable,” said Marootian, also the nominee for assistant secretary of the DOE.

According to the United Nations Environment Programme, buildings account for nearly 40% of global carbon emissions. Sustainably grown wood fiber is a renewable resource that captures carbon during the tree growth cycle. BioHome3D may be thought of as a carbon storage and sequestration unit during its lifetime and after it is recycled.

This project is the product of strong partnerships in and beyond the UMaine community. The DOE-funded Hub and Spoke Program between UMaine and Oak Ridge National Laboratory is leading the research and development of sustainable, cost-effective bio-based 3D printing feedstock alternatives, such as the material used for BioHome3D. The Hub and Spoke program is a direct result of a request initiated in 2016 by Sens. Collins and Angus King for a U.S. Department of Commerce Economic Development Assessment team to help Maine bolster the forest economy and create jobs and opportunity in rural regions of the state following the closure of several large paper mills.

The Hub and Spoke program is a direct result of a request initiated in 2016 by Sens. Collins and Angus King for a U.S. Department of Commerce Economic Development Assessment team to help Maine bolster the forest economy and create jobs and opportunity in rural regions of the state following the closure of several large paper mills.

Oak Ridge National Laboratory’s Manufacturing Demonstration Facility, a leader in advanced manufacturing, and UMaine, home to ASCC, Forest Bioproducts Research Institute and School of Forest Resources, are natural partners in the field of large-scale, bio-based 3D printing. The Maine Technology Institute supported the design of the prototype, and MaineHousing was a key partner in developing and reviewing the specifications for the home in alignment with low-income housing standards.

“This program shows the power of scientific collaboration to address critical national needs,” said Sun. “Uniting the capabilities and facilities of ORNL with UMaine’s expertise and drive for innovation, we have together achieved a significant milestone in the development of sustainable materials and manufacturing technologies, and decarbonizing the buildings sector. ”

”

This effort has been made possible by advances in large-scale additive manufacturing coupled with innovations in bio-based material chemistries that have emerged from these partnerships.

“This project gives us a real possibility to achieve something that has eluded us to-date, and that is the speed of production, to be able to mass produce in a very fast way housing. …The idea that we can create housing units in a fraction of the time with a fraction of the workforce — that is an efficiency that we’ve never experienced before. It’s going to stretch our precious state and federal resources exponentially, and most importantly, provide — quickly — for those most in need in our state,” said Daniel Brennan, director of MaineHousing.

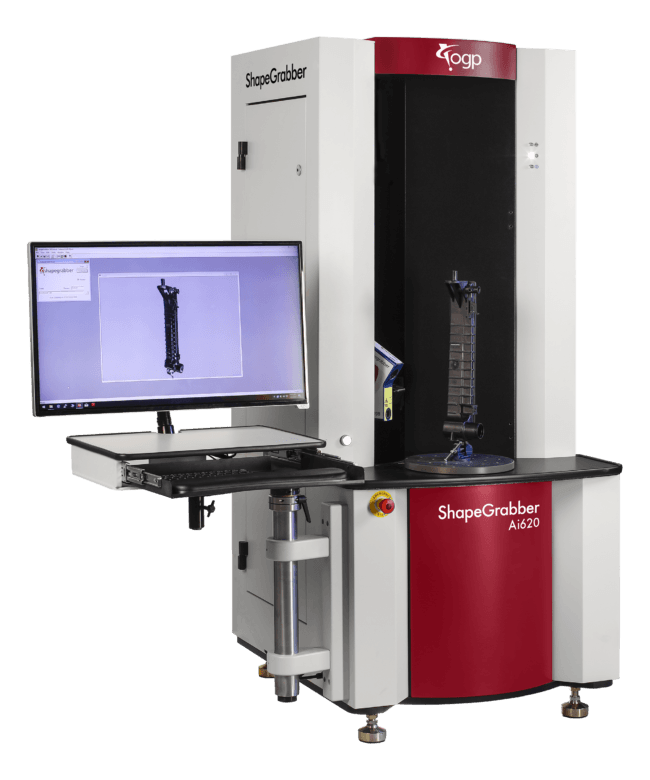

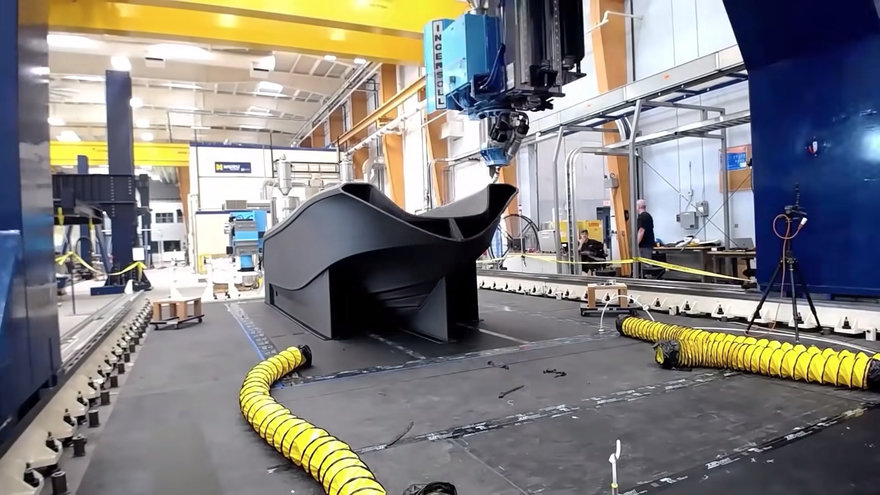

The successful print of BioHome3D builds on the ASCC’s demonstrated excellence in advanced manufacturing, design and modeling. The prototype was printed on the world’s largest polymer 3D printer, which, in 2019, produced the world’s largest 3D-printed boat.

ASCC will be able to scale its advanced manufacturing research in housing construction with the opening of the Green Engineering and Materials (GEM) research Factory of the Future. When complete, GEM will serve as a hub for AI-enabled large-scale digital hybrid manufacturing. The Factory of the Future will drive innovation-led economic recovery in Maine, with bays dedicated to scaling up the production of housing, such as BioHome3D, as well as boatbuilding, an important Maine industry.

A key aspect of the GEM facility is preparing the workforce of the future through immersive world-class educational opportunities at the nexus of engineering and computing. GEM is at the core of the university’s plan to create the new Maine College of Engineering, Computing and Information Science’s (MCECIS), which integrates engineering and computing education and research. The new GEM facility will be for engineering and computing comparable to a teaching hospital in the medical field, where engineering, computing and information science students learn by working in the lab next to world-class faculty and staff. This effort is supported by the Harold Alfond Foundation and UMS TRANSFORMS, with a goal to double the output of engineers and computing and information scientists to meet workforce needs of the state.”

This effort is supported by the Harold Alfond Foundation and UMS TRANSFORMS, with a goal to double the output of engineers and computing and information scientists to meet workforce needs of the state.”

“Workforce and economic development are essential components of ASCC’s world-class research,” says University of Maine System Chancellor Dannel Malloy. “Our federal and state policymakers know that an investment in Maine’s research university is an investment in the state’s future. We appreciate the shared vision and the opportunity to continue to show demonstrated return on investment through initiatives like BioHome3D and the students getting hands-on learning today to carry on the work tomorrow.”

Already, $25 million in direct investment has been secured for GEM, including $15 million through the Maine Jobs & Recovery Plan — the proposal put forth by Gov. Mills and supported by the Maine Legislature to invest the state’s share of federal American Rescue Plan relief funds — and $10 million in the FY22 federal budget thanks to funding requested by Sens. Collins and King. Nearly $40 million in other federal funds championed by Sens. Collins and King are pending for the project.

Collins and King. Nearly $40 million in other federal funds championed by Sens. Collins and King are pending for the project.

The Advanced Structures and Composites Center is a world-leading interdisciplinary center for research, education and economic development, encompassing material sciences, advanced manufacturing and engineering of composites and structures. Housed in a 100,000-square-foot ISO-17025-accredited facility, the center has been recognized nationally and internationally for cutting-edge research programs leading and impacting new industries, including offshore wind and marine energy, civil infrastructure, biobased composites, large-scale 3D printing, soldier protection systems and innovative defense-related applications.

Contact: Taylor Ward, 207.852.4530; [email protected]

UMaine Advanced Structures and Composites Center produces world’s largest 3D-printed logistics vessel for U.S. Department of Defense - UMaine News

Two 3D-printed vessels capable of transporting two shipping containers and a Marine rifle squad with three days of supplies mark groundbreaking composite manufacturing milestone

February 25, 2022 Economic Development, Research, Signature and Emerging Areas

Orono, Maine — The University of Maine Advanced Structures and Composites Center has achieved a groundbreaking milestone in composite manufacturing with the production of two 3D-printed prototype logistics vessels for the U. S. Department of Defense.

S. Department of Defense.

Marine Corps Systems Command’s Advanced Manufacturing Operations Cell (AMOC), in collaboration with the UMaine Composites Center, used advanced manufacturing techniques to successfully develop the expendable polymeric composite ship-to-shore vessels. The longer of the two vessels, the largest ever 3D-printed, simulates ship-to-shore movement of 20-foot containers representing equipment and supplies. The second vessel can transport a Marine rifle-squad with organic equipment and three days of supplies. The prototypes can be connected, maximizing the transport capability of a single-tow vehicle.

The ship-to-shore logistics vessels align with the 38th Commandant of Marine Corps Gen. David Berger’s vision to “seek the affordable and plentiful at the expense of the exquisite and few when conceiving of the future amphibious portion of the fleet,” due to relatively low-cost, speed and ease of production.

“Our national security and economic security depend on an innovative and robust American manufacturing base,” said Barbara K. McQuiston, director of Defense Research and Engineering for Research and Technology, Office of the Secretary of Defense. “I applaud the University of Maine’s Advanced Structures and Composites Center for their pioneering work in the field of additive manufacturing. The advancements made here will bolster domestic manufacturing and ultimately support our warfighters in the field.”

McQuiston, director of Defense Research and Engineering for Research and Technology, Office of the Secretary of Defense. “I applaud the University of Maine’s Advanced Structures and Composites Center for their pioneering work in the field of additive manufacturing. The advancements made here will bolster domestic manufacturing and ultimately support our warfighters in the field.”

Joining McQuiston for the unveiling Feb. 25 at the UMaine Composites Center were U.S. Senators Susan Collins and Angus King, U.S. Department of Defense leadership and University of Maine officials.

“In 2019, UMaine unveiled the world’s largest 3D-printed object — a 25-foot patrol boat. Today, we celebrated the creation of 3D-printed vessels that will be more than twice as large and represent the next remarkable leap in innovation by UMaine,” said Senators Susan Collins and Angus King and Representative Jared Golden in a statement. “This accomplishment is a prime example of how UMaine is leading the nation in large-scale additive manufacturing technology. These new boats continue the Composite Center’s contributions to our national defense and will help fuel new breakthroughs in advanced manufacturing that will create good jobs here in Maine.”

These new boats continue the Composite Center’s contributions to our national defense and will help fuel new breakthroughs in advanced manufacturing that will create good jobs here in Maine.”

Using traditional materials and methods, landing craft utility vessels can take over one year to produce. The UMaine Composites Center printed and assembled one of the two vessels in a month. The vessels were produced using the world’s largest polymer 3D printer, which the center commissioned on Oct. 10, 2019, earning three Guinness World Records.

To demonstrate the printer’s capabilities, the Composites Center 3D-printed a 5,000-pound boat, 3Dirigo, in 72 hours, and printed a U. S. Army communications shelter in 48 hours. The printer, with both additive and precise subtractive manufacturing capabilities, enables rapid prototyping for both defense and civilian applications.

S. Army communications shelter in 48 hours. The printer, with both additive and precise subtractive manufacturing capabilities, enables rapid prototyping for both defense and civilian applications.

“This project demonstrates the art of the possible and the potential for AM to fundamentally alter how we think about connectors and their role in mobility and distribution within a contested environment,” said LtGen Edward Banta, Deputy Commandant – Installation & Logistics, U.S. Marine Corps.

“As the Marine Corps seeks to modernize logistics to better respond to current and future conflicts, advancements in additive manufacturing will ensure we remain agile, lethal and expeditionary,” said William Williford, executive director of Marine Corps Systems Command.

The latest project to create the two 3D-printed logistics vessels is a significant milestone toward demonstrating advanced manufacturing techniques to rapidly constitute critical DOD assets closer to the point of need. The previously successful prototype was 3D printed in 2020, made from 25% aluminum. The vessels manufactured by the UMaine Composites Center are multimaterial composites with engineering polymer and fiber reinforcement.

The previously successful prototype was 3D printed in 2020, made from 25% aluminum. The vessels manufactured by the UMaine Composites Center are multimaterial composites with engineering polymer and fiber reinforcement.

“The University of Maine is at the forefront of cutting-edge research and high-impact technologies, including advanced manufacturing, AI and 3D printing important for industries in Maine and beyond,” said University of Maine System Chancellor Dannel Malloy. “These prototype vessels are the latest innovations from the Composites Center that demonstrate the future of manufacturing. This is an exciting time for Maine’s Carnegie R1 research enterprise. Congratulations to the talented group of faculty, staff and students for this milestone achievement.”

“The leadership, vision and innovation of the Advanced Structures and Composites Center continue to make a difference in Maine and worldwide,” said UMaine President Joan Ferrini-Mundy, vice chancellor for research and innovation for the University of Maine System. “The center’s research and development capacity in collaboration with partners in Maine and beyond, its problem-solving capabilities and focus on workforce development are an important part of our Carnegie R1 top-tier research institution.”

“The center’s research and development capacity in collaboration with partners in Maine and beyond, its problem-solving capabilities and focus on workforce development are an important part of our Carnegie R1 top-tier research institution.”

“Two years ago, we demonstrated that it was possible to 3D print a 25-foot patrol vessel in three days. Since then, partnering with the DOD, we have been improving material properties, speeding up the printing process and connecting our printer with high-performance computers that can monitor the print. With these tools in place, we have now printed a prototype vessel that will be tested by the U.S. Marine Corps (USMC). The Advanced Structures and Composites Center is at the cutting edge of advanced manufacturing research and development, advancing state-of-the-art technologies like large-scale additive manufacturing and high-performance computing to develop practical, rapidly deployable and cost-effective solutions for defense and civilian applications,” said Habib Dagher, executive director of the UMaine Composites Center. “We thank our partners at the DOD, USMC, U.S. Army Engineer Research and Development Center (ERDC) and our Congressional delegation for their continued support. Today’s groundbreaking achievement couldn’t have been possible if not for the tremendous effort of our dedicated team of 260 ASCC faculty researchers, staff and students.”

“We thank our partners at the DOD, USMC, U.S. Army Engineer Research and Development Center (ERDC) and our Congressional delegation for their continued support. Today’s groundbreaking achievement couldn’t have been possible if not for the tremendous effort of our dedicated team of 260 ASCC faculty researchers, staff and students.”

“These demonstration vessels represent an initial step toward defining future forward manufacturing capabilities, and also a balance between expendable system cost, performance and ease of manufacture,” said Kyle Warren, UMaine senior program manager and principal investigator on the project.

The Advanced Structures and Composites Center is a world-leading interdisciplinary center for research, education and economic development, encompassing material sciences, advanced manufacturing and engineering of composites and structures. Housed in a 100,000-square-foot ISO-17025-accredited facility, the center has been recognized nationally and internationally for cutting-edge research programs leading and impacting new industries, including offshore wind and marine energy, civil infrastructure, biobased composites, large-scale 3D printing, soldier protection systems and innovative defense-related applications.

The Marine Corps’ AMOC, established in 2019, conducts testing, experimentation and analysis to source innovative techniques and leverage advanced manufacturing technology. AMOC also provides 24/7 3D printing help desk support for the Fleet Marine Force and all equipment program offices.

Contact: Meghan Collins, [email protected]

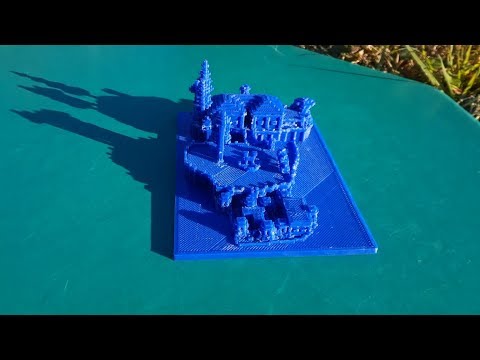

Kuna. Maine Coon. A little about Sculptris.

alorlov

Loading

08/28/2017

4738

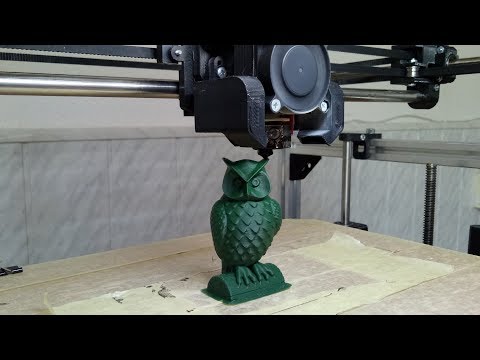

3D printing

ZENIT DUO ZENIT

Hello ladies and gentlemen!

'Stop pumping, it's time to sculpt!' - this idea has been sitting in my head for a long time, it's time to implement it. A cat was chosen as a test subject, resulting in the following model: http://3dtoday.ru/3d-models/art/sculptures/kot_porody_meyn_kun/ .

This fat animal version 1. 0 was molded in an evening in the simplest free 3D editor Sculptris.

0 was molded in an evening in the simplest free 3D editor Sculptris.

The basis was the real prototype and its pictures (almost a Daimon cat, only black, thicker and Maine Coon).

The editor is intuitive - after reading the mini-guide https://vk.com/topic-18320487_31951777 anyone will be able to repeat the selected animal in 3D, the main thing is to have a full-face and profile photo - this way the structural features are better visible.

If it's more interesting to watch a video, then there is this: https://www.youtube.com/watch?v=jPULeP9V0cE. Thanks to the author of the videos with a stern voice for the instructions for sculpting a tiger.

Printed version (on Zenit, 0.6 nozzle, layer 0.3, FD-plast natural, 240 degrees, 20 cm high, 25 towards the tail, camera closed):

[IMG ID=117357 WIDTH=780 HEIGHT=624][IMG ID=117359 WIDTH=780 HEIGHT=672][IMG ID=117360 WIDTH=781 HEIGHT=519][IMG ID=117361 WIDTH=780 HEIGHT=519]

sculpting professionally - tell me where you get brushes for Sculptris - I want to reproduce the texture of wool on a cat version 1. 1. ?

1. ?

Thank you)

Subscribe to the author

Subscribe

Don't want

8

Article comments

More interesting articles

one

Subscribe to the author

Subscribe

Don't want

Introduction

So, good day to all! This is my second post...

Read more

302

Subscribe to the author

Subscribe

Don't want

Hello dear community!

If the experiment was successful, then something is wrong here...

Read more

dagov

Loading

11/08/2017

195

Follow the author

Subscribe

Don't want

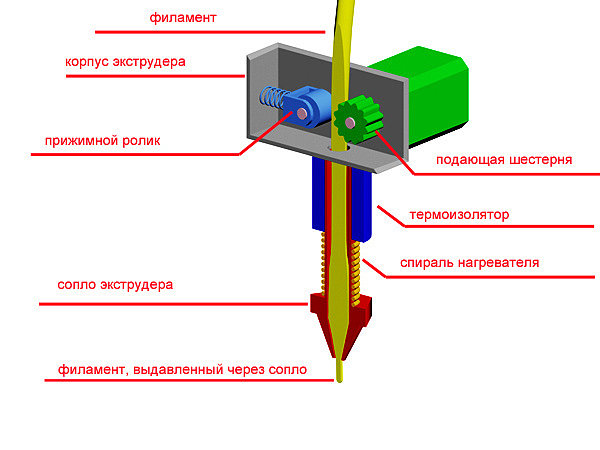

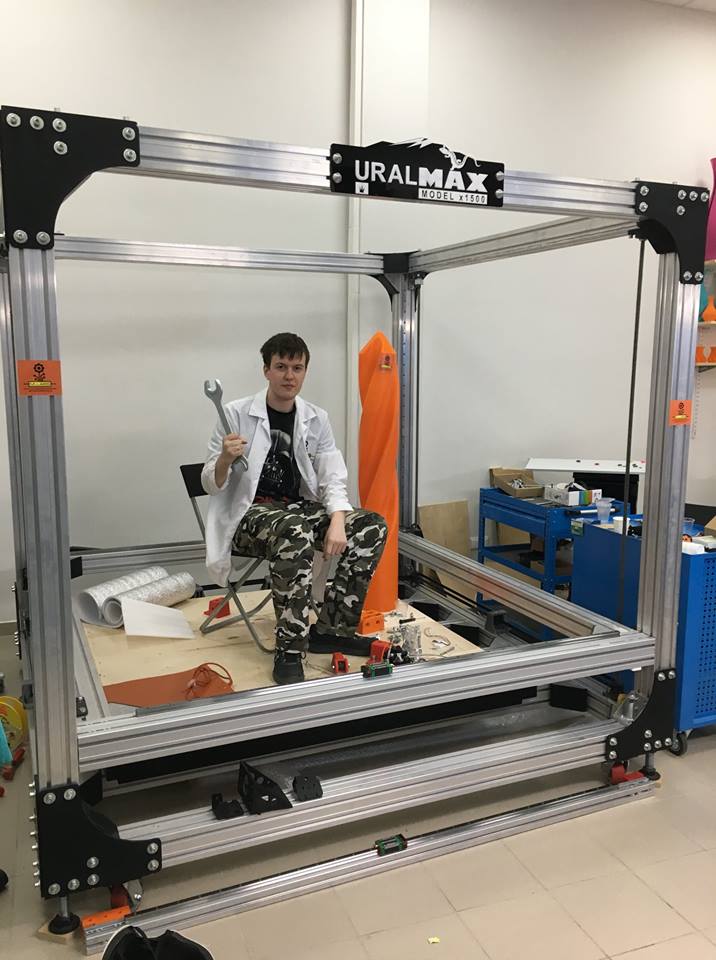

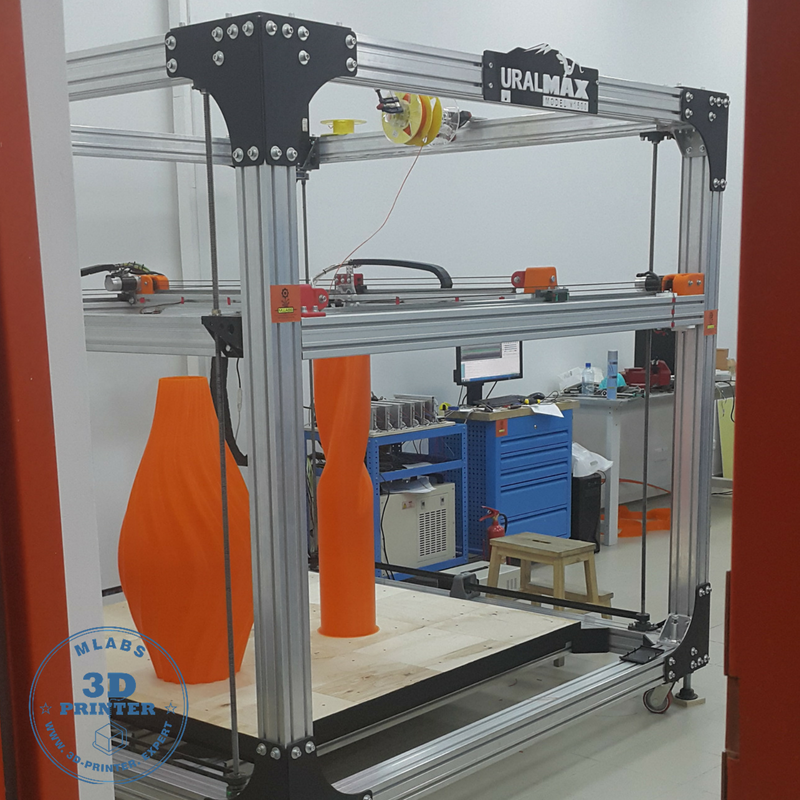

In this article, we will understand what is 3D printing and what is the kinematics of 3D printers. ...

...

Read more

STL file

Harry Potter Clock

1.30 €

mickey watch

1.30 €

Pokemon Clock

€1.30

Alice in Wonderland

1.30 €

World Of Warcraft Clock 1

1.25 €

Dragon Ball Clock

1 €

Naruto Clock 1

1.25 €

Star Wars Watch

1.30 €

Best Files for 3D Printers in the Art Category

Dragon egg

50 €

Muscular Santa

0. 96 €

96 €

The Fifth Element Mangalore Bust (50mb)

Free

SNCF lighting pylon

15 €

Spiderman Far From Home Stealth suit S.H.I.E.L.D Version

0,70 €

Death Mask - Darksiders 3D print model

20 €

Mr. Potato Face STL

1 €

Text flip - Fox 2.0

1.50 €

Art category bestsellers

Jointed toy "Python Snake", imprinted body, snap head, cute flexi

3,79 €

Adorable articulated axolotl, imprinted body, snap head, cute flexi

3,34 €

Articulated bat toy, imprinted body, snap head, cute flexi

3,34 €

Cute skeleton with flexi print

2. 83 €

83 €

CUTE CROCODILE WITH FLEXIBLE PRINT IN PLACE

2.83 €

Biting Dragon

3 €

Flexi print-in-place Phoenix

3,79 €

Flexi Print Imperial Dragon

€3.79

Cute circus baby elephant with flexi print

2,83 €

Gingerbread man ornament with flexi print

1,39 €

Cute sloth with flexi print

2,83 €

Cute frog with flexi print

1,87 €

Flexi PRINT-IN-PLACE Hand

1,87 €

Triceratops on flexi printer

2,83 €

Item

7 €

Articulated toy "Leopard gecko", imprinted body, snap head, cute flex

3,34 €

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so supporting us in maintaining activities and creating future developments is very easy.