3D printing for architectural models

Guide to 3D Printing Architectural Models

Despite a move from the drawing board to digital screens, physical architectural models still play a significant role in helping architects visualize blueprints.

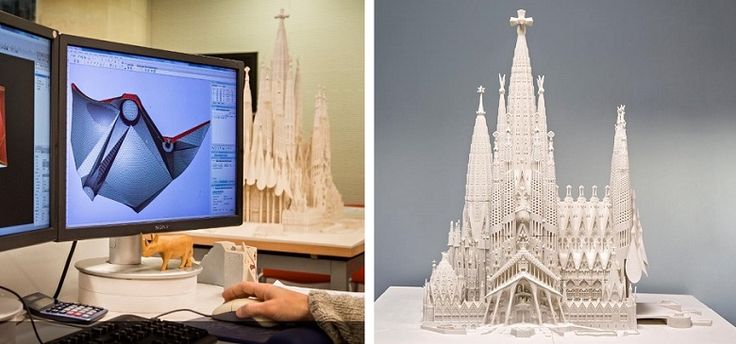

3D printing technologies help bridge the gap between digital and physical worlds and empower architects and model makers to create high-precision architectural models quickly and cost-effectively directly from digital drawings.

This guide provides comprehensive information about using 3D printing to produce architectural models, the different 3D printing processes for architecture, and the workflow for creating 3D printed models from architectural computer-aided design (CAD) software.

White Paper

This white paper covers how to make smart modeling decisions, from choosing scale to designing for assembly to post-processing, and how to use these strategies in common software ecosystems.

Download the White Paper

Since the age of the Pharaohs, architectural models have served as physical representations during structures’ development to help sell a project, support fundraising efforts, and solve construction challenges.

Traditionally, model-making is a manual craft that involves working with materials such as wood, ceramic, cardboard, or clay, which can be extremely time-consuming and repetitive. Architecture studios and practices today have access to a wider range of tools, including CNC milling machines, laser cutters, and 3D printers that can reduce labor needs and speed up the workflow.

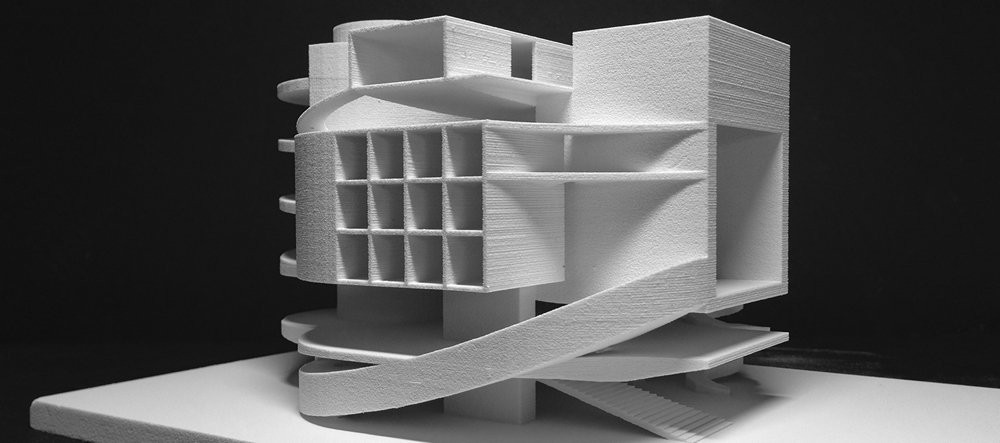

Modern 3D printing processes provide architects and model makers with the means to revolutionize how models are made. They do this by:

-

Speeding up the architectural model making process.

-

Translating CAD drawing directly into physical 3D models with a high level of precision.

-

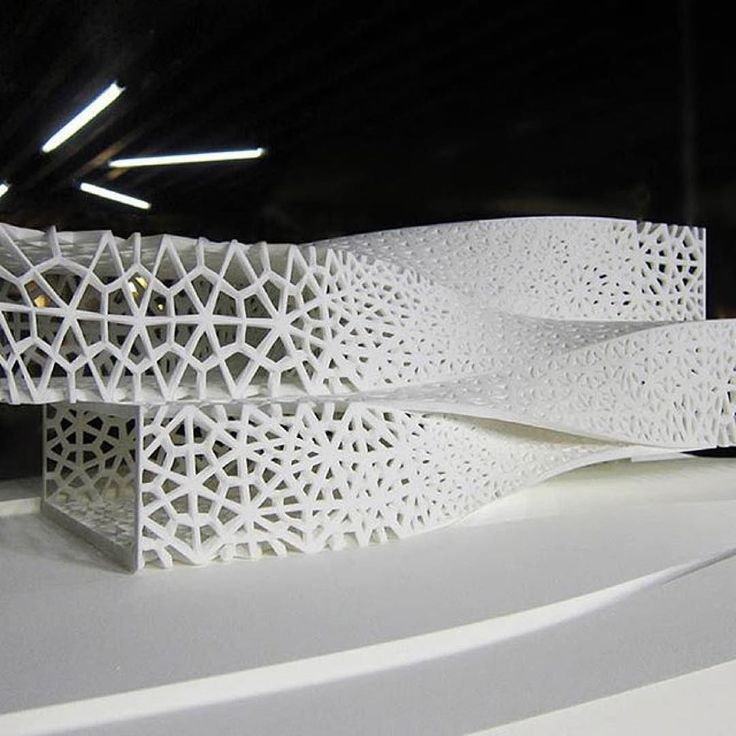

Developing intricately designed parts that’d be hard or impossible to produce by hand.

-

Simplify communication and showcase specific areas that would be hard to convey through conventional 2D drawings.

-

Creating more design iterations at reduced production costs.

For example, model makers Renzo Piano Building Workshop (RPBW), founded by the Pritzker Prize laureate architect, use an SLA 3D printer to quickly develop and fabricate accurate models.

“Our models change every day or even every hour. Because the architects change the project very quickly, most of the time, we don't have enough time to do it by hand. Therefore, we have to find a way to do it quicker,” said Francesco Terranova, model maker at RPBW.

3D printers can create models within a few hours and even operate overnight to save time. “The good thing is that we can launch the printer in the night, and when we come back in the morning, we find the model done. This way, we don't lose time during the day,” said Mr. Terranova.

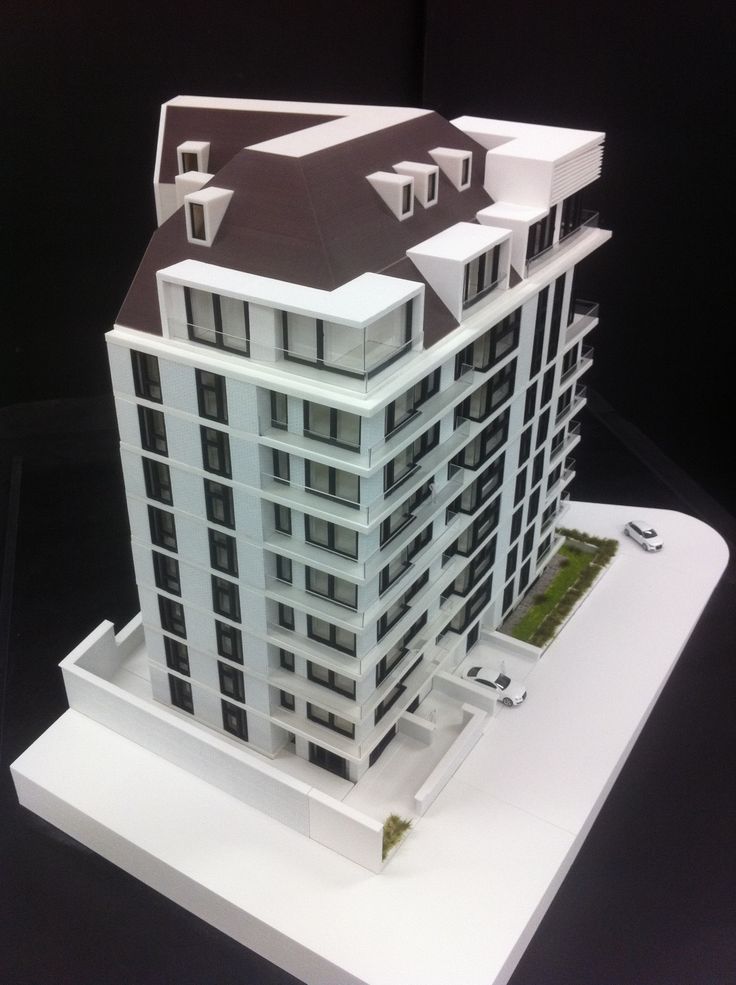

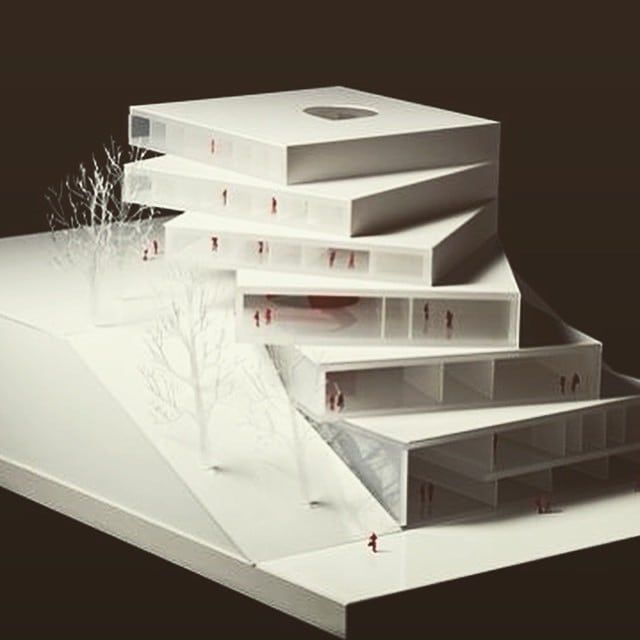

3D printing in architecture is ideal for intricate parts—the trees on this model were 3D printed on a Formlabs SLA 3D printer.

3D printing can be used to produce architectural models of entire buildings, but also in combination with other tools and processes. RPBW’s model builders may use CNC machining or laser cutting to produce the base parts of their architectural models and a 3D printer to develop more complex or intricate components like stairs, trees, spheres, and curved surfaces, which would be time-consuming to manufacture by hand. For example, the RPBW team 3D printed the complex joints of the columns for the model of the new San-Giorgio motorway bridge in Genoa that has recently replaced the Morandi bridge that collapsed in 2018. This combination of 3D printing alongside traditional manufacturing solutions speeds up the creative process and increases the accuracy levels of architectural models.

RPBW’s model builders may use CNC machining or laser cutting to produce the base parts of their architectural models and a 3D printer to develop more complex or intricate components like stairs, trees, spheres, and curved surfaces, which would be time-consuming to manufacture by hand. For example, the RPBW team 3D printed the complex joints of the columns for the model of the new San-Giorgio motorway bridge in Genoa that has recently replaced the Morandi bridge that collapsed in 2018. This combination of 3D printing alongside traditional manufacturing solutions speeds up the creative process and increases the accuracy levels of architectural models.

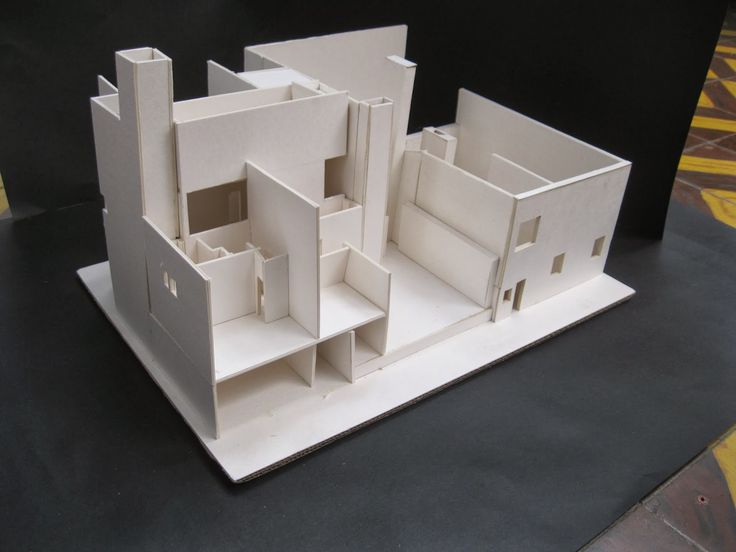

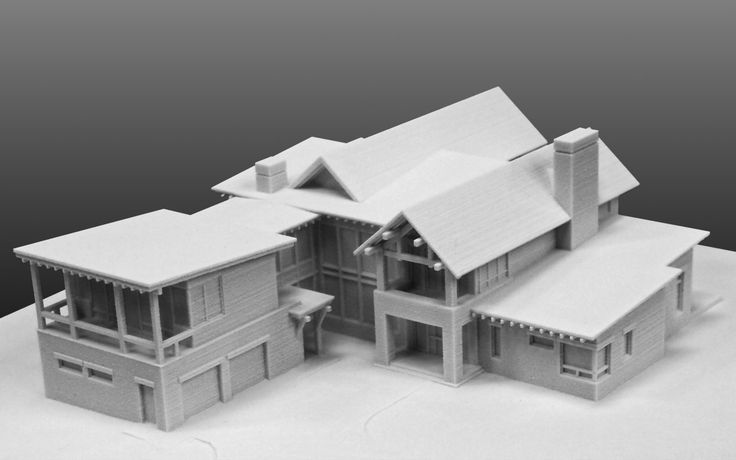

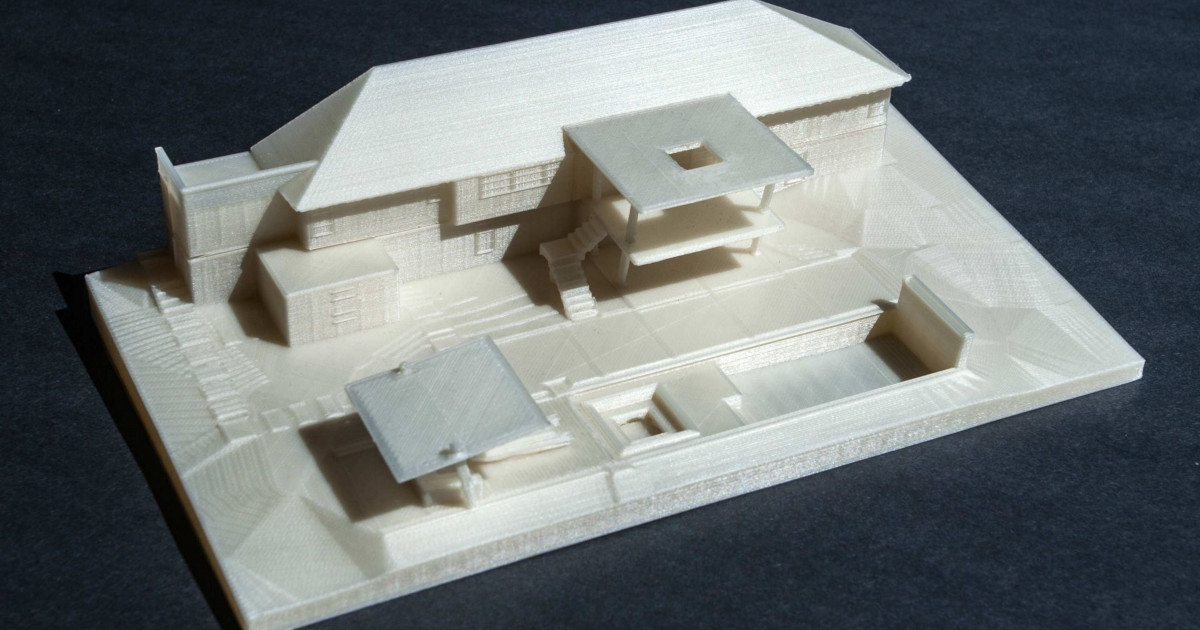

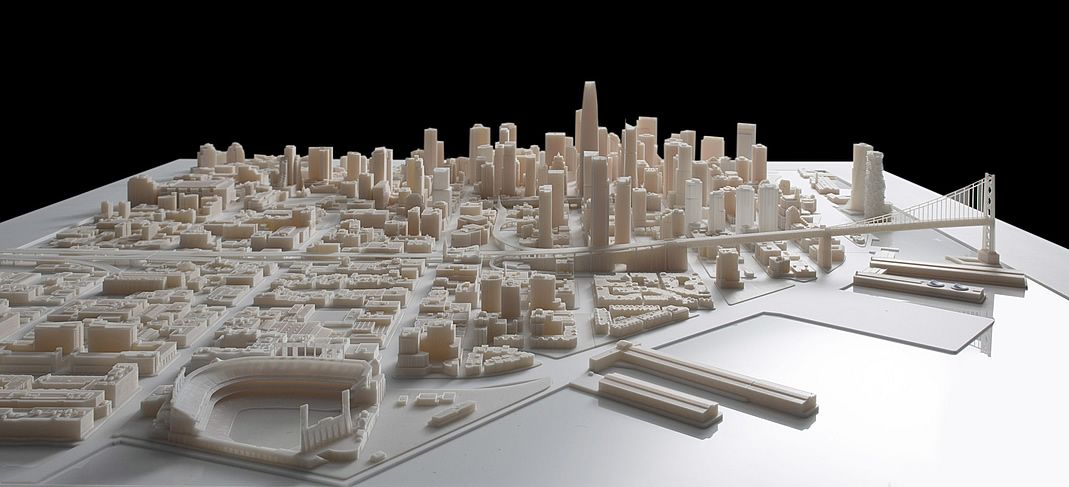

One of the main goals of 3D architecture models is to simplify communication between architects and to make it easier to showcase plans to clients. Los Angeles-based design firm Laney LA’s projects are mostly custom homes, so communicating the scale of a home or structure is particularly important. Architect Paul Choi and his team use 3D printing to showcase specific areas of the project that can be more complicated to convey through conventional 2D drawings.

Laney LA’s architects use 3D printing to create models that allow them to view the project from a fresh perspective while simultaneously providing vantage points.

“It's fun to always try to depict a certain idea about the project and isolate that through the model, whether it's a certain room or a space that we want to highlight through a section cut of the model, or even the topography of the site,” Choi said.

RPBW’s model makers use a Form 3 SLA printer to speed up the production of scale models.

When it comes to 3D printing architectural models, not all methods are created equal. It is important to choose the right printing technology for specific use cases.

The most popular 3D printing technologies for architectural models include stereolithography (SLA), fused deposition modeling (FDM), selective laser sintering (SLS), and binder jetting.

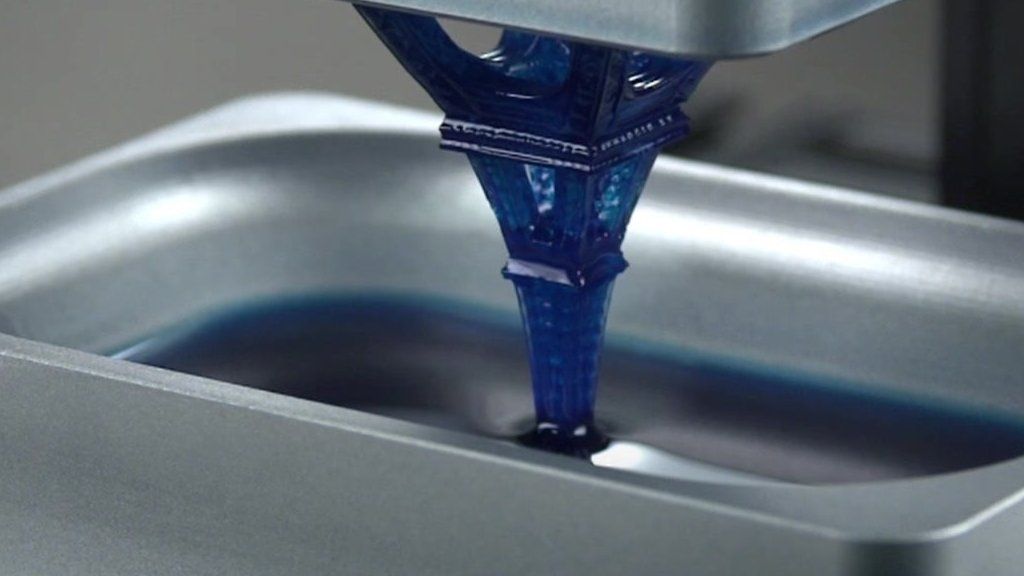

Stereolithography was the world’s first 3D printing technology, invented in the 1980s, and is still one of the most popular technologies for professionals. SLA resin 3D printers use a laser to cure liquid resin into hardened plastic in a process called photopolymerization.

SLA resin 3D printers use a laser to cure liquid resin into hardened plastic in a process called photopolymerization.

SLA parts have the highest resolution and accuracy of all plastic 3D printing technologies. SLA parts also offer the smoothest surface finish that is easy to paint.

SLA parts have sharp edges, a smooth surface finish, and minimal visible layer lines that are ideal for highly detailed presentation models. This model was printed on a Form 3 SLA printer.

SLA is a great option for highly detailed presentation models for presenting concepts and ideas to clients or the public.

Thanks to fast-printing materials like Draft Resin, SLA is also the fastest 3D printing process for most parts. While desktop SLA printers offer a more compact build capacity, with large-format SLA 3D printers like the Form 3L, architects and model makers can create truly large-scale models.

Sample part

See and feel Formlabs quality firsthand. We’ll ship a free sample part to your office.

We’ll ship a free sample part to your office.

Request a Free Sample Part

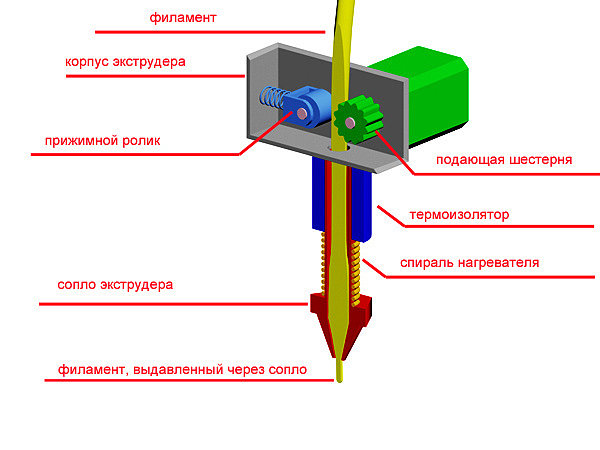

Fused deposition modeling (FDM), also known as fused filament fabrication (FFF), is the most widely used form of 3D printing at the consumer level, fueled by the emergence of hobbyist 3D printers. FDM 3D printers build parts by melting and extruding thermoplastic filament, which a printer nozzle deposits layer by layer in the build area.

FDM has the lowest resolution and accuracy from the four 3D printing processes and is not the best option for printing complex designs or parts with intricate features. It is ideal for basic concept design models produced during the initial stages of design as it can create relatively large models fast and at a low cost.

FDM printers struggle with complex designs or parts with intricate features (left), compared to SLA printers (right).

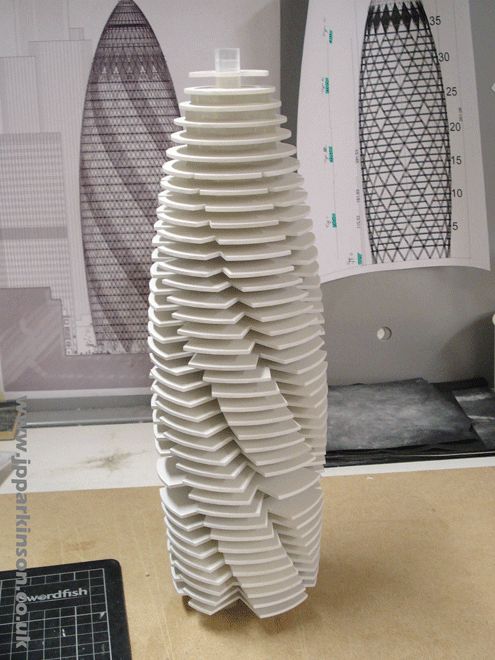

Selective laser sintering is the most common additive manufacturing technology for industrial applications. SLS 3D printers use a high-powered laser to fuse small particles of polymer powder. The unfused powder supports the part during printing and eliminates the need for dedicated support structures.

SLS 3D printers use a high-powered laser to fuse small particles of polymer powder. The unfused powder supports the part during printing and eliminates the need for dedicated support structures.

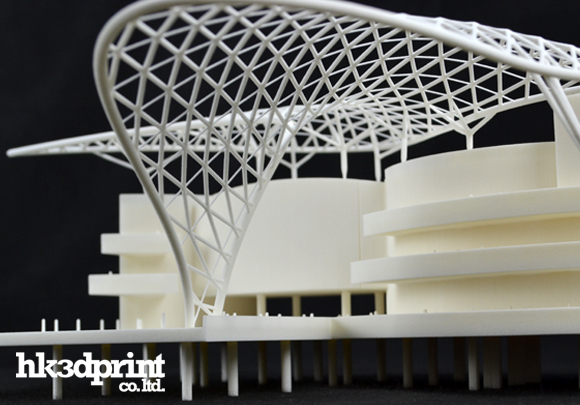

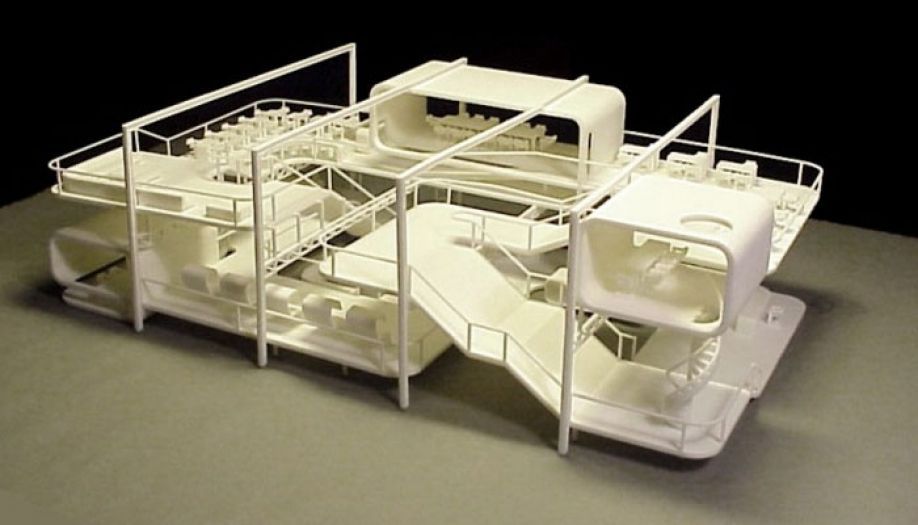

SLS printing is ideal for complex geometries, including interior features, undercuts, thin walls, and negative features. Parts produced with SLS printers have excellent mechanical characteristics that make them suitable also for structural parts.

SLS is ideal for complex geometries and intricate details. The details on this model were printed on a Fuse 1 SLS printer.

Binder jetting 3D printing technology is similar to SLS printing but uses a colored binding agent to bond powdered sandstone material instead of heat. Binder jetting printers can produce vivid, full-color 3D architecture models.

Parts produced with binder jetting have a porous surface and are very brittle, which means that this process is recommended only for static applications.

Binder jetting printers can produce vivid, full-color architecture models.

| Stereolithography (SLA) | Fused Deposition Modeling (FDM) | Selective Laser Sintering (SLS) | Binder Jetting | |

|---|---|---|---|---|

| Resolution | ★★★★★ | ★★☆☆☆ | ★★★★☆ | ★★★☆☆ |

| Accuracy | ★★★★★ | ★★★★☆ | ★★★★★ | ★★★☆☆ |

| Surface finish | ★★★★★ | ★★☆☆☆ | ★★★★☆ | ★★★☆☆ |

| Ease of use | ★★★★★ | ★★★★★ | ★★★★☆ | ★★★★☆ |

| Complex designs | ★★★★☆ | ★★★☆☆ | ★★★★★ | ★★★☆☆ |

| Build volume | Up to 300 x 335 x 200 mm (desktop and benchtop 3D printers) | Up to 300 x 300 x 600 mm (desktop and benchtop 3D printers) | Up to 165 x 165 x 300 mm (benchtop industrial 3D printers) | Up to 254 x 381 x 203 mm (industrial 3D printers) |

| Price range | Professional desktop printers start at $3,500, large-format benchtop printers are available from $11,000. | Budget printers and 3D printer kits start at a few hundred dollars. Higher quality mid-range desktop printers start around $2,000, and industrial systems are available from $15,000. | Benchtop industrial systems start at $18,500, and traditional industrial printers are available from $100,000. | Binder jetting 3D printers are expensive industrial machines, with prices ranging from $30,000 to $100,000+. |

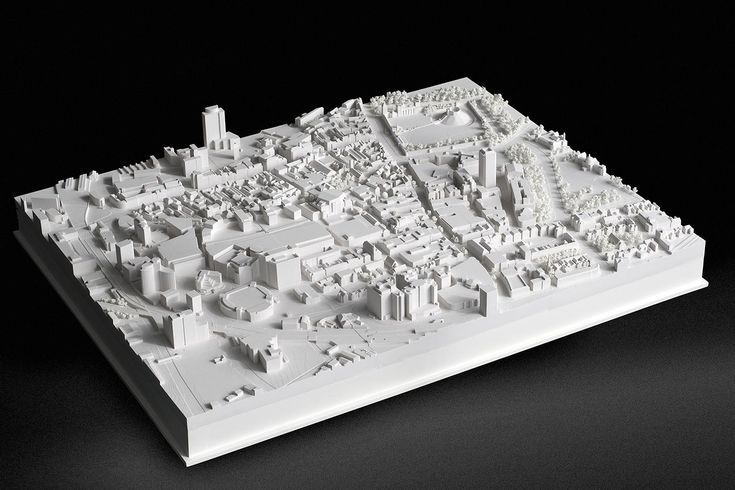

A team from the Institute of Architecture at the Hochschule Mainz - University of Applied Sciences reconstructed the medieval german cities of Worms, Speyer, and Mainz with large-scale 3D printed models.

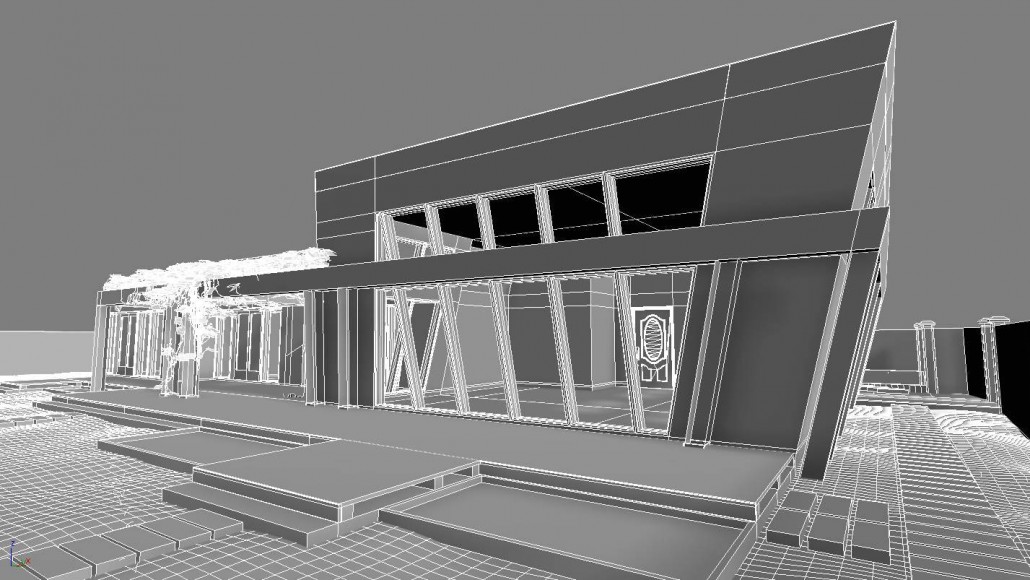

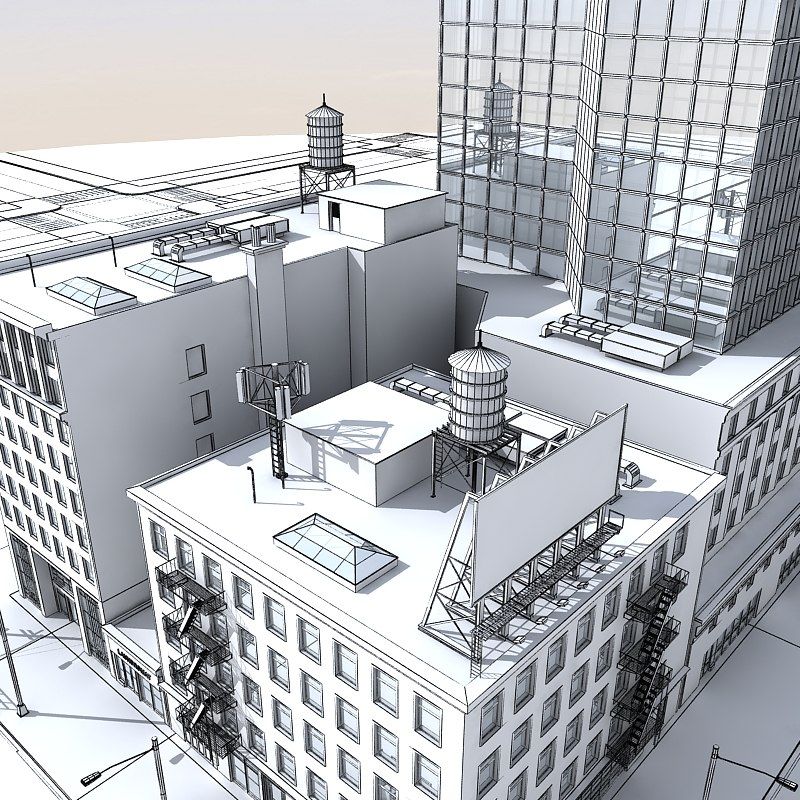

Most architects today already work in the digital space, using architectural CAD software like BIM (Revit and ArchiCAD), Rhino 3D, or SketchUp to create digital CAD designs. However, these digital files cannot always be used to create the physical scale models directly with 3D printing.

A successful transition from a CAD model to a 3D printable file relies on a baseline understanding of design for 3D printing, how regular modelmaking constraints relate to preparing a file for 3D printing, and how to approach and make smart modeling decisions, from choosing the right scale to designing for assembly to post-processing.

Architectural models are conventionally assembled with a variety of materials and components. 3D printers help fuse these components into as few individual parts as possible, but some assembly is still required for two reasons:

-

The constraints of the build volume: Unless you’re using a large-format 3D printer such as the Form 3L, you might need to divide the model into multiple parts to fit it inside the build volume of the 3D printer.

-

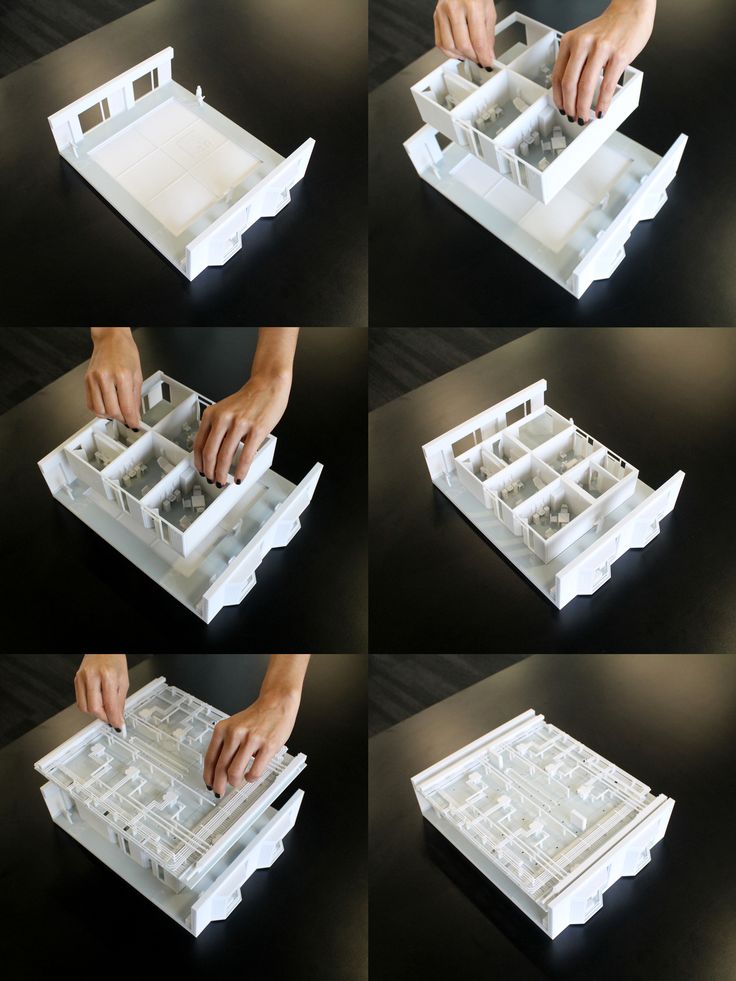

The need to show interior detail or materiality: Certain models require components that come apart to reveal more information about the design.

The size and geometry of different components within an architectural model are key considerations when preparing an architectural model for 3D printing. Generally, large models, models with multiple components, and models with intricate features are split into 3D printable components for assembly. Parts can then be easily joined together through chemical adhesion or mechanical assembly; the high accuracy of the prints with technologies like SLA and SLS ensures that the parts join together seamlessly.

Getting the best results requires applying modeling strategies for assembly, including:

Since each housing unit followed the same design, it made sense to simply print one removable unit that would allow the client to understand the generic unit typology. Model by Stanley Saitowitz | Natoma Architects Inc.

Advancements in CAD technology have drastically simplified the process of developing 3D printable files. Modern CAD platforms have dedicated 3D printing modules to help architects convert a CAD design into a printable model. However, do remember that you are still working at a 1:1 scale–some quick conversions will be required to achieve the correct dimensions at the print scale.

Developing architectural models require some important considerations depending on the CAD platform used. These CAD-specific considerations include:

-

BIM Workflow: Developing 3D printable models with BIM software that leverages parametric modeling such as Autodesk Revit or Graphisoft ArchiCAD requires some component management.

Components such as ductworks, double glazed windows, and HVAC systems do not translate in 3D prints and must be removed, while other parts such as doors, windows, walls, slabs need to be thickened.

Components such as ductworks, double glazed windows, and HVAC systems do not translate in 3D prints and must be removed, while other parts such as doors, windows, walls, slabs need to be thickened. -

Surface Modeling Workflow: This workflow is often an easier approach, starting from 2D drawings solely with the intention to 3D print. It involves exporting a simplified drawing, scaling it down, and extruding and trimming until there’s an external shell.

Download our white paper for step-by-step workflows in common architectural CAD software ecosystems.

The next step in 3D printing architectural models is transcribing your digital 3D model into a language your 3D printer understands. Accomplishing this requires the use of slicing or print preparation software, such as PreForm. Whether you’re new or experienced, slicing software is generally intuitive to use. The software highlights details such as walls that may require strengthening, unsupported areas, and closed volumes that affect the structure of the 3D print, which can be addressed before printing. Using the software, you can also optimize settings such as resolution, build platform position, and support structures.

Using the software, you can also optimize settings such as resolution, build platform position, and support structures.

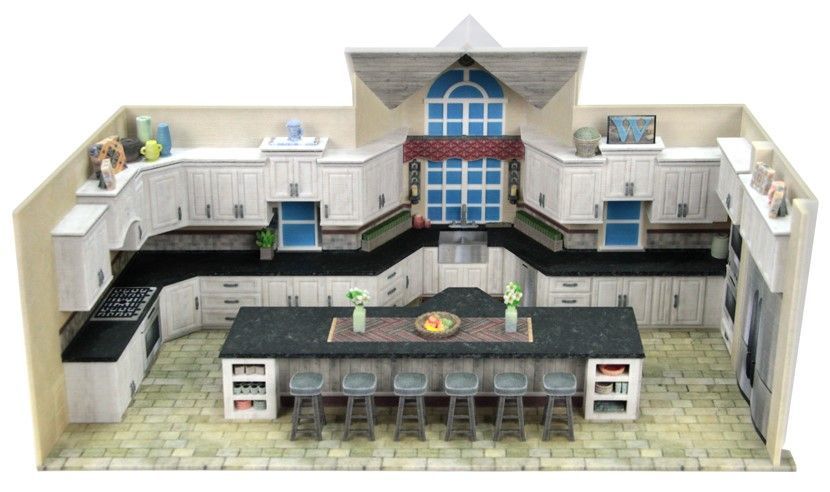

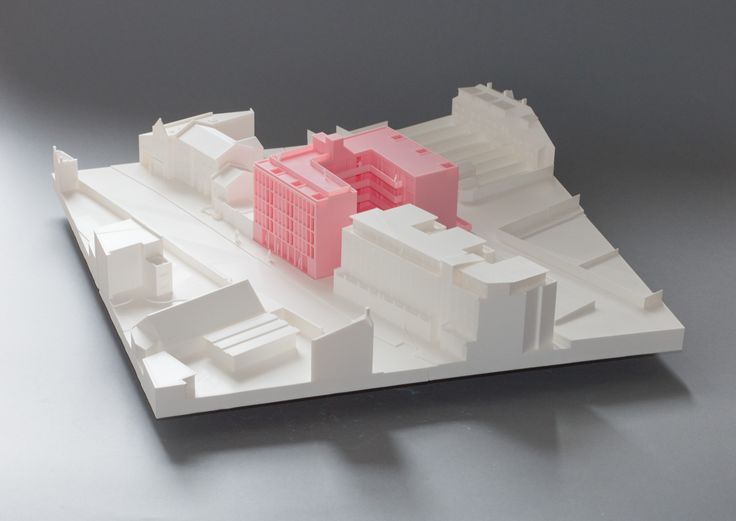

Materials play an important role in conveying the underlying concept of a design. It isn’t always imperative to simulate the exact color and texture of a material, but it can help to distinguish between different materials. Splitting a model by its components makes it possible to display materiality, as parts can be produced with various 3D printing materials, or individually painted with different colors.

This site model was created with laser-cut chipboard. The primary building was 3D printed with both Clear Resin and White Resin. Model by Schwarz Silver Architects.

Post-processing differs depending on your specific 3D printing technology, but generally includes sanding, bonding, and painting models.

Here’s an overview by 3D printing process:

| Post Processing Technique | Stereolithography (SLA) | Fused Deposition Modeling (FDM) | Selective Laser Sintering (SLS) | Binder Jetting |

|---|---|---|---|---|

| Sanding | Light sanding is recommended to remove support marks. | The lower quality of FDM prints means sanding is required to get a smooth finish. | No sanding is required due to the quality of the finished parts. | No sanding is required. |

| Bonding | Bonding of SLA components is done with super glue or liquid resins. | FDM components can be assembled using adhesives such as super glue. | SLA components can be assembled using adhesives such as super glue. | Components printed using binder jetting printers can be bonded using super glue. |

| Priming and painting | SLA components can be painted to achieve the desired finish. | FDM components can be painted to achieve the desired finish. | SLS components can be painted to achieve the desired finish. | No painting is required for full-color parts. |

Professional SLA and SLS 3D printers empower architects with the tools to create accurate and attractive 3D architectural models. Choose the Form 3 for a compact solution that can fit on a desktop, the Form 3L for high resolution large-format models, and the Fuse 1 for structural parts and the most complex shapes.

Choose the Form 3 for a compact solution that can fit on a desktop, the Form 3L for high resolution large-format models, and the Fuse 1 for structural parts and the most complex shapes.

See the Form 3See the Form 3LSee the Fuse 1

Download our white paper for an in-depth overview of modeling strategies, step-by-step workflows in common architectural CAD software ecosystems, as well as printing and post-processing recommendations.

Download the White Paper Now

10 Of The Best 3D Printers For Architects [Top Brands Compared]

The right 3D printer can be an absolute godsend for architects.

Using a 3D printer saves a lot of time in the initial phases of creation and designing. In the initial stages, a lot of different concepts are tested out, and as a result, multiple iterations are required.

Having a 3D printer to print those models can allow multiple iterations performed exceedingly fast. Making a model of a structure was a process that used to take weeks earlier. Now it’s just a matter of a few hours.

Now it’s just a matter of a few hours.

They are also cost-effective. Some estimates say you can save up to 75% more money by using 3D printers instead of traditional techniques. This is because the models are printed out of a single plastic material, keeping costs to a minimum.

3D printers are also capable of producing exceptionally detailed and intricate structures. This capability comes in particularly useful when you need to dazzle a potential client at a sales meeting or a presentation.

That’s why we have compiled this list of the best 3D printers for architects.

Best 3D Printers for ArchitectsContents

- Best 3D Printers for Architects

- 9676 – Ultimaker 3 Extended 3D Printer

- Creality3D CR – 10 3D Printer

- Creality3D CR – 10S Pro

- MakerBot Replicator+ 3D Printer

- Creality3D Ender – 3 pro-High Precision 3D Printer

- Dremel Digilab 3D45

- LulzBot Mini Desktop 3D Printer

- Robo R2 Smart Assembled 3D Printer

- da Vinci Jr.

2.0 Mix Wireless 3D Printer

2.0 Mix Wireless 3D Printer - Formlabs Form 2 SLA 3D

- 3D Printers For Architects Buyer’s Guide

- Build volume

- Printing speed

- What materials can be printed

- Software compatibility

- Wifi compatibility

- Final Words

- Related Articles

- 9676 – Ultimaker 3 Extended 3D Printer

This one from Ultimaker gives you choices for a wide range of printable materials and the print comes out looking great in every one of them. The extended version provides a larger build volume, faster print execution, and advanced print technology.

Ultimaker 3 Extended 3D Printer

- Newest large-format 3D printer from Ultimaker

- Dual extrusion capability for multi material...

Experience

The build volume is a maximum of 215 x 215 x 300 mm. This is large enough to accommodate most moderate architectural projects. 3/s.

3/s.

The fan system of this model is also very commendable. It makes very little noise and creates greater pressure buildup for increased airflow. This allows for better cooling, high-quality bridging, faster prints, and smoother print surfaces.

LED lights on the interface blink whenever any interaction is required. This allows for a worry-free printing experience.

Pros

- Dual Extrusion for combined printing

- Highly Reliable And Precise

- Powerful fans for better cooling

- High-speed printing

- Low maintenance

Cons

- Problems with ABS printing

- Slightly expensive

- Creality3D CR – 10 3D Printer

This one is another DIY assembly model, which is easy to assemble and retains that handmade charm, even though it has an LCD screen with a keypad for more comfortable offline usage. This printer is capable of printing pretty large structures in a short span of time. 3/s, which is pretty fast for how precise the printing is. A 100-micron layer resolution and an exceptionally stable metal plate lead make for a perfect recreation of your architectural 3D files.

3/s, which is pretty fast for how precise the printing is. A 100-micron layer resolution and an exceptionally stable metal plate lead make for a perfect recreation of your architectural 3D files.

It comes packaged with several tools for assembly, printing tools, and even a micro SD card and an adapter for the same. Using the tools and following the instructions, you can get the machine up and running in less than an hour. It is really very simple.

Pros

- Great Value For Money

- Brilliant print quality

- Sturdy design

- Large printing area

- Supports multiple 3D printing filaments

Cons

- The bed is not always level

- Fans make a lot of noise

- Creality3D CR – 10S Pro

This one from Creality3D is another excellent printer, for both beginners and professionals alike. A huge volume lets it tackle mammoth challenges. It has a huge host of features which address common issues facing most 3D printers of today. On top of that, it looks just as good as it prints.

A huge volume lets it tackle mammoth challenges. It has a huge host of features which address common issues facing most 3D printers of today. On top of that, it looks just as good as it prints.

No products found.

Experience

The volume of 300*300*400 is a lot larger than most 3D printers and lets you print bigger, more detailed models.

An automatic leveling functionality, powered by a very intuitive and intelligent four layer motherboard fills in all gaps dynamically and provides for greater printing accuracy. The statuses of all functions and parameters are on display on a full-color touch screen control, which makes using this printer an absolute breeze.

The motherboard has other functions as well. It can automatically sense changes in the filament being used and can even detect transparent filaments. It shuts down the system automatically when you are running out of filament.

If you accidentally power off the printing, it will simply just pause, and you can resume printing at your convenience. 3/s

3/s

Pros

- Double resume function for power outage and filament shortage

- Dual Gear extrusion for natural feeding

- High precision printing

- Automatic leveling for greater stability

Cons

- Heavy and big

- Makes a lot of noise

- MakerBot Replicator+ 3D Printer

The MakerBot Replicator has been designed for more precise, reliable and faster printing. It is sturdy, easy to use and has a huge amount of versatility because of the MakerBot print software you use with this product. Designed for architects and engineers, we think this is an excellent choice of printer.

MakerBot Replicator + 3D Printer, with swappable Smart Extruder+,...

- Your purchase includes One MarkerBot Replicator,...

- Item's dimensions – 17.4" W x 20.8" L x 16.2"H |...

Experience

The MakerBot Replicator prints 30% faster than previous models and has a much larger print volume as well. They have re-engineered and improved the hardware as well, with a redesigned gantry and Z-stage. All the hardware has gone through an intensive quality control check for many thousand hours.

They have re-engineered and improved the hardware as well, with a redesigned gantry and Z-stage. All the hardware has gone through an intensive quality control check for many thousand hours.

What we really like about this product is its seamless integration with the MakerBot print software and MakerBot Mobile. This software allows you to find, prepare new designs, and manage and share all of your prints. You can make your own designs or just use a model from their online library.

This software also lets you connect to the inbuilt camera inside the printer, which lets you monitor progress while you’re away from your computer. It allows cloud functionalities as well.

The MakerBot Smart Extruder has automatic jam detection and out-of-filament notifications. MakerBot SlatePLA Filament Bundle is as secure as they come and makes for prints high in tensile and flexural strength.

Pros

- Rigorous quality testing

- MakerBot Print Software integration

- Large build volume & high-speed printing

- Great customer support

- Access to millions of online designs

Cons

- Poor adhesion at parts

- Little distortion at corners

- Creality3D Ender – 3 pro-High Precision 3D Printer

First up on our list comes this very efficient 3D printer, that is precise, works fast and is easy to use. It is simple with a very humanized design yet fulfills a wide variety of printing purposes from architectural models to movie props to furniture design.

It is simple with a very humanized design yet fulfills a wide variety of printing purposes from architectural models to movie props to furniture design.

Creality3D Ender - 3 pro High Precision 3D Printer

- CMAGNET BUILD SURFACE PLATE: Provide all-round...

- SAFE POWER SUPPLY: Ender 3 Pro comes with a Mean...

Experience

Straight out of the box, it’s a DIY model and comes packaged with pliers, nozzles, pneumatic fittings, cable tie, blade, Allen key, screwdriver and plenty more. Following the instructions, it is pretty easy to assemble the printer with all the included tools.

Because of the technology used, the risk of spillage and plugging is really small, and the high-quality structure ensures smooth and stable function with minimal wear and tear.

What we also liked was that it heated up in only 5 minutes to the temperatures required to print certain filaments. We also found the mounting groove and structure to be very stable, and the printing was exceptionally precise.

We also found the mounting groove and structure to be very stable, and the printing was exceptionally precise.

Another feature we really liked was you can resume printing while the printer is powered off. Thus it is not necessary to keep the rest of the device powered on while you are printing.

Pros

- Oversized nuts for greater stability

- Precise printing

- Great customer service

- Quick Heating Up

Cons

- The mat doesn’t always sit flat

- Dremel Digilab 3D45

One of the most popular choices of 3D printers out there, it has won several awards, and it is easy to see why. It has every feature you can think of in a printer included in it and then some more. Designed for engineers by its parent company (Bosch) this is indeed a great choice, as testified by hundreds of satisfied customers.

Dremel DigiLab 3D45-01 3D Printer with Filament - Heated Build Plate &. ..

..

- ADVANCED 3D PRINTING: The Dremel Digilab 3D45 Idea...

- BEST IN CLASS: The winner of PCMag.com’s 2022...

Experience

What we really enjoyed about this product is the host of things they offer along with just the printer:- 1-year warranty, stellar customer support, UL safety certification, free desktop, and cloud-based slicing software and also one nylon and one eco-ABS filament roll. That’s an awful lot of perks for just a 3d printer.

The build volume is a very large 6. 7″ x 10″ x 6″. The design is a very sturdy plastic which provides for enhanced security and less warping. It also includes a carbon and particulate filter.

There are no compromises when it comes to reliability. A sensor technology makes this extruder functioning smooth as silk without ever clogging up.

But what is by far, the best feature is its filament recognizing technology. This technology automatically updates extruder and build plate temperatures, along with print speeds depending on the kind of filament being used.

The glass plate can heat up to 100-degree Celsius, and the full metal 0.4mm nozzle can go up to a whopping 280 degree Celsius. This level of heat easily allows it to print nylon and ABS.

It has a semi-automatic leveling technology for easier calibrations and greater accuracy. The 5-inch full-color touchscreen lets you precisely level the plate in real time, with just turning a knob.

Pros

- WIfi Enabled for Cloud Printing

- HD camera for monitoring

- Unsurpassed reliability

- Large build volume

- High heat generating capability

- Filament recognizing technology

Cons

- Does not accept many aftermarket filament spools

- Sensitivity on the touchscreen can be better

- LulzBot Mini Desktop 3D Printer

This is a desktop 3D printer which literally looks like a desktop CPU. This model has a lot of versatility like it can be used with any 3D printing software program, and it has open source hardware. All this means you’re free to use this 3D printer any way you like. This opens up a world of possibilities.

All this means you’re free to use this 3D printer any way you like. This opens up a world of possibilities.

LulzBot Mini 2 Desktop 3D Printer

- Maximum print size: 160 mm x 160 mm x 180 mm (6. 3...

- Tool Head: E3D Titan Aero with . 50mm Nozzle –...

Experience

What we think is the best feature of this printer is the self-leveling and self-cleaning nozzle. Each print starts with a nozzle cleaning and probing sequence that guarantees a neat and perfectly smooth first layer.

Next up comes the build volume of 6in x 6in x 6.2in. There’s a large range in layer resolution as well. It can be as fine as only 50 microns, and it can also be as coarse as 500 microns. All of it depends on the geometry and speed requirements.

The all-metal hexagon hot end provides temperatures of 300-degree celsius and also as low as 120-degree Celsius. Active heat sinks ensure the heat stays where you need it to be. 3/sec at 0.18 mm layer height.

3/sec at 0.18 mm layer height.

You can even take out the tool head and plug in different print heads for printing on a variety of materials, even filaments which are mixed with real wood, stone or metal. We find this functionality to be astounding.

Pros

- High temperatures on the hot end

- Large build volume

- Heated printing surface for better adhesion

- One year warranty

- Self-cleaning nozzle

Cons

- Customer service isn’t all that great

- Expensive for its range

- Robo R2 Smart Assembled 3D Printer

This one is hands down the fastest and the printer with the biggest build volume in this price range. It has won a ton of awards for its innovation and has a multitude of smart features and sensors that are sure to make your life a lot easier.

Robo R2 Smart Assembled 3D Printer with WiFi, 8”x8”x10”. ..

..

- 3D printing has never been easier than with the...

- Print BIGGER and BETTER 3D prints than ever before...

Experience

What we found very impressive about this printer was its huge build volume of 8” x 8” x 10”. On top of that, it has a print range of 20 to 300 micron in layer height. All this ensures it can tackle whatever project you have in mind.

It has an open source filament system. What that means is that you can print on any material available in the market, even carbon fiber, nylon, and wood. You can try out anything you want.

What’s also impressive is its whole host of smart features like automatic detection leveling, sensors which alert you when the filament runs out, an onboard camera so you can see your prints and wifi connectivity through the Robo App.

It can directly print 3D models in .stl format. You can slice it right on the intuitive 5 inch touch screen, and you can even store up to 4 GB of 3D models. 3/s.

3/s.

Pros

- Open Source Filament System

- Large Build Volume

- Fast printing

- Online repository of models

- Automatic Sensors

- Onboard cameraa

Cons

- Prone to crashes

- Not that durable

- da Vinci Jr. 2.0 Mix Wireless 3D Printer

This is a very attractive product which is sure to make for a very aesthetically pleasing addition to your repertoire. On top of that, it can produce prints just as colorful as its own color scheme.

No products found.

Experience

The primary advantage this printer has over other printers in the market is that it has a very innovative dual feeding single extruder module. What this allows it to do is you is you can blend two different colors in a single model. As a result, you can have two different colors on different parts of the same model.

You can even print in gradient mode. This allows you to mix two colors partially and slowly allowing you to come up with many other shades formed by the mixture of those two colors. 3/s.

3/s.

It has wifi connectivity so you can send files over your computer or mobile device without ever having to worry about wires.

Pros

- Dual color printing

- Color gradient implementation functionality

- Wifi connectivity

- Good customer support

- Fast printing

Cons

- Can’t print third party filaments

- Jams sometimes

- Formlabs Form 2 SLA 3D

The last 3D printer on our list, this one from Formlabs is an excellent option for budding architects. It is simple, yet highly functional and makes for a nice polished print whenever you give it a run.

Formlabs Form 2 SLA 3D Printer Complete Package

- Form 2

Experience

It has a pretty impressive build volume of 5.7″ * 5.7″ * 6.9″. Although that’s not very big, it’s still sufficient for most projects. The layer height range is 25 to 100 microns, which is again decent enough.

The layer height range is 25 to 100 microns, which is again decent enough.

Where this printer really scores its point is the finish. It has several washing and post-curing facilities which make sure every part that comes out of this printer looks absolutely gorgeous. It is excellent for printing detailed models which require a dazzling finish.

This printer has an integrated resin system which lets you switch between different materials by simply swapping cartridges. They have 20 different materials, and as soon as you load one of them, the printer automatically detects the resin type and starts configuring settings for it.

When making designs, you can design it in regular CAD software, or you can import an STL or OBJ file into the PreForm print preparation software. You can send prints over WiFi, or reprint previous jobs, and directly from the touchscreen interface.

Pros

- Great finish

- Switching between different materials is easy

- Easy designing and printing

- Good customer support

Cons

- You can only use their cartridges

- Small layer resolution

- Build volume

This is the single most important factor in a 3D printer. The larger the build volume, the bigger and more detailed your architectural models can be.

The larger the build volume, the bigger and more detailed your architectural models can be.

If you’re designing a whole apartment complex or a government building, large build volumes help you build the whole thing at once, without individually creating separate parts and then amalgamating them together.

- Printing speed

Printing speed is also critical. Some of the more complicated models may take hours to get done, even overnight. The faster it prints, the faster your job gets done.

- What materials can be printed

You need to know what kind of filaments can be printed by your printer. Some printers can only print a couple of materials, and others can print only proprietary materials, i.e., materials manufactured by the company itself, while there are other printers which can print all available filaments on the market.

If you want more choices, get a printer which has versatility in selection of the filament.

- Software compatibility

Some printers can print files created on any CAD software whereas others require you to use their own software or they require you to convert your designs into a specific format.

This conversion can be cumbersome and might also cause a few errors. It’s best to get a printer that is compatible with all designing software.

- Wifi compatibility

If it has Wi-fi compatibility, it entirely removes the hassle of wires. What it also does is, it opens up mobile phone compatibility. This lets you use your phone to control your printer, and you don’t always need to be logged into your computer.

Wi-fi compatibility also gives you cloud functionality allowing you to store your designs online, so you can access them wherever you go.

Final WordsIn conclusion, buying a 3D printer requires a fair amount of research beforehand. There are plenty of different types available out there, and each one has different features.

Be sure of what features you need and then check the system specs to see if those features are there. The products listed above are tried and tested, and they do a pretty good job. Just go through the specs to see which one is the best fit for you.

Related Articles47 of the Best Gifts for Architects

23 Best Gifts for 3D Artists

25 Best Gifts for 3D Animators

Architect vs. 3D Artist Differences | All You Need to Know

3D Printing – Eco-Friendly Tech Changing the Construction Sector

5 Best 3D Pens [Reviewed & Buyer’s Guide]

Simply the Best Computer [Desktop] for Architects

22 Best Apps For Architects to Consider

Architectural 3D Printing Modeling Strategy and Software Usage Guide

At a Glance

3D printing provides tremendous benefits to the conventional architectural workflow. You can print complex designs without the need for skilled craftsmen, and quickly modify these designs without too much difficulty. Stereolithographic (SLA) 3D printing delivers incredibly high surface quality and detail, making it suitable for architectural applications. This paper explores modeling strategies and software workflows that enable architects and designers to easily integrate 3D printing into existing design methodology, create best practices based on internal testing by Formlabs and architecture firms, successfully using Form 2 to create 9 models0005

You can print complex designs without the need for skilled craftsmen, and quickly modify these designs without too much difficulty. Stereolithographic (SLA) 3D printing delivers incredibly high surface quality and detail, making it suitable for architectural applications. This paper explores modeling strategies and software workflows that enable architects and designers to easily integrate 3D printing into existing design methodology, create best practices based on internal testing by Formlabs and architecture firms, successfully using Form 2 to create 9 models0005

WHAT YOU WILL LEARN:

Strategies for designing 3D printed architectural models

Tips for improving your workflow Pre-print processing software

- Building information model (Revit, ArchiCAD)

- Surface modeling (Rhino, SketchUp)

Good post-processing techniques

- Compound

- Finishing

Introduction

The 3D printing market today offers affordable options in both price and scale. While professional-grade technology used to be costly, desktop stereolithography 3D printers allow architects, designers, and model makers to offer high-quality, in-house fabricated parts.

While professional-grade technology used to be costly, desktop stereolithography 3D printers allow architects, designers, and model makers to offer high-quality, in-house fabricated parts.

Most models cost less than $10 per part.

3D printing opens up opportunities to create complex designs with less effort and fewer materials, but the successful transition from a CAD model to a printable file is based on a basic understanding of design for 3D printing. This document will help you understand how standard modeling constraints relate to preparing a file for 3D printing, as well as approaches and decision making for intelligent modeling - from scale selection to design and assembly for post-processing.

To integrate these strategies into existing workflows, this booklet explores ways to approach modeling strategies tactically by examining three of the most common software ecosystems: allows you to include small details even on the smallest models. This example of a small city model has a scale of 1/32″ = 1’ and is completely printed on a Form 2 3D printer. Many small details and parts of this design will take significantly longer if cut and assembled by hand. Model from LaneyLA Inc.

Many small details and parts of this design will take significantly longer if cut and assembled by hand. Model from LaneyLA Inc.

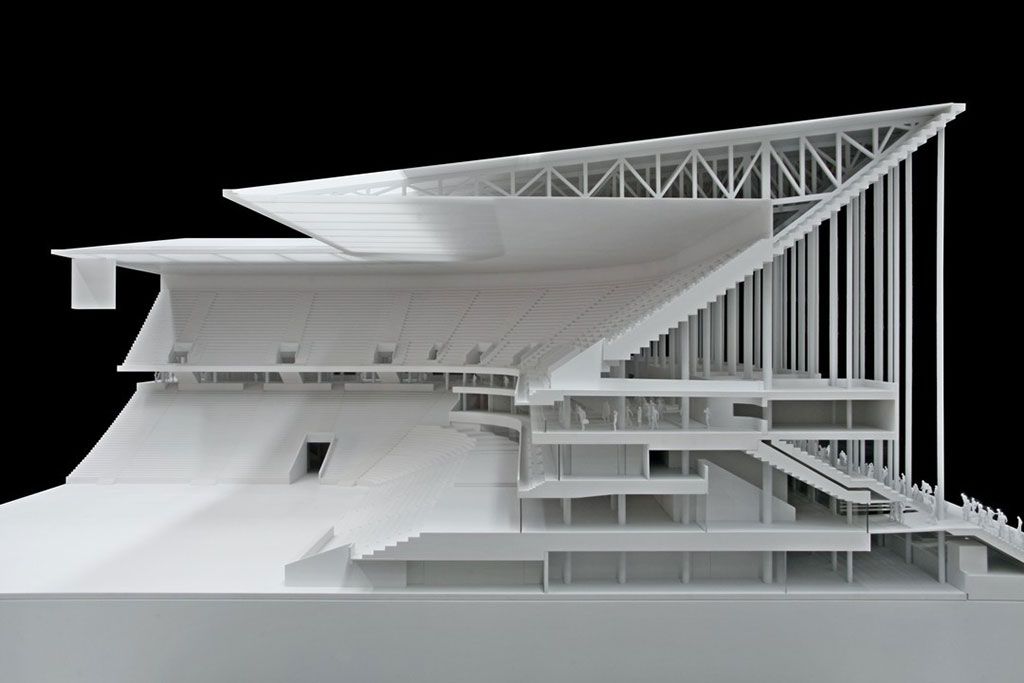

This auditorium section was 3D printed as one piece on a black resin Form 2. Model from DLR Group.

Modeling strategy

Architectural models are usually assembled using various materials and components. 3D printers help combine these components into as few separate parts as possible, but assembly manipulation is still necessary for two reasons:

- Build Volume Limitations : High build volume printers are either expensive or compromise on surface quality. Form 2 build volume is 57 x 57 x 69 inches (145 x 145 x 175 mm)

- Need to show interior details or materiality : Some models require components to be separated to show more design information.

DESIGN FOR ASSEMBLY

All 3D models require preparation before they can be sent to the 3D printer. In the case of architectural models for the Form 2, this often involves splitting the model into smaller parts to fit the scope of the Form 2 build. The parts can then be easily joined together by chemical adhesive or mechanical assembly; high precision printing ensures that the parts fit together.

In the case of architectural models for the Form 2, this often involves splitting the model into smaller parts to fit the scope of the Form 2 build. The parts can then be easily joined together by chemical adhesive or mechanical assembly; high precision printing ensures that the parts fit together.

Dimensioning for parts to be separated must take into account the final orientation of the model. Most architectural prints need to be oriented at a 45 degree angle due to floor slabs being considered large horizontal projections. Dividing the model into long, thin parts helps maximize the diagonal length of the build volume while achieving perfect orientation

Strategy overview

There are several strategies for assembling 3D printed models. Your strategy will depend on what you hope to represent with the design, as well as the scale and geometry of the model. Consider the following parameters:

- Need to show internal or external parts

- Easy Split (You want to split the model by the least complex part of the model)

It is necessary to show a certain part of the program: typology, structure, floor layout

| Seam separation | Separation by component |

| Section model | Separation by program |

| Straight cut | Separation by structure |

| Aligners |

Splitting at the seam

STRAIGHT CUT

The easiest way to split the model is with a straight cut. This is a simple command to execute in most CAD software. The bridge model is divided lengthwise using straight cuts into four parts, one of which is shown above. Each support post is inserted into

This is a simple command to execute in most CAD software. The bridge model is divided lengthwise using straight cuts into four parts, one of which is shown above. Each support post is inserted into

mating hole that does not require glue. Regardless of which method you choose, if you have a large number of parts (more than 10), it can be helpful to add a unique identifier for each part to help solve the puzzle during assembly.

Pros:

- Least heavy use of CAD

- Greater tolerance for prints that warp or have a higher degree of dimensional change

Cons:

- Assembly requires manually leveling each piece and fixing it in place until the adhesive is fully bonded

Try to print all components in the same orientation so that the layer lines and subsequent dimensional inaccuracies follow the same pattern.

ALIGNMENT TOOLS

Another approach is to add features to the design that will allow the prints to align. When adding mate fixtures, try to subdivide the model in areas with the least complex geometry. Use the CAD tool of your choice to split your model and add basic alignment fixtures such as slots, pins, grooves, recesses and flanges, or more complex fixtures such as dovetails and cuts that follow existing model curves. In addition, it is important to create a design with ~0.25 mm tolerance between mating parts to prevent additional sanding at the post-printing stage.

When adding mate fixtures, try to subdivide the model in areas with the least complex geometry. Use the CAD tool of your choice to split your model and add basic alignment fixtures such as slots, pins, grooves, recesses and flanges, or more complex fixtures such as dovetails and cuts that follow existing model curves. In addition, it is important to create a design with ~0.25 mm tolerance between mating parts to prevent additional sanding at the post-printing stage.

Pros:

- Easy alignment Parts that are not accurate

- Easy to assemble (mating parts help create a large surface area for adhesion)

- High precision SLA allows tight fit with high tolerance and can be used without adhesive

Cons:

- Parts that are not true to size will not fit well. High fine details are often less accurate.

SECTION MODEL

The separation of the model with a seam has the additional task of showing the section model for structures with irresistible interior details. Initially, the model can be presented as a whole to the client, and then disassembled to reveal interior details as desired. These LaneyLA examples show how the same model conveys different types of information based on open and closed configurations

Initially, the model can be presented as a whole to the client, and then disassembled to reveal interior details as desired. These LaneyLA examples show how the same model conveys different types of information based on open and closed configurations

This model from LaneyLA was printed on a White Resin Form 2.

Using devices for combining: Methods component

SOFTWARE DIVISION

By splitting a building with software, you can represent the building as a set of parts, providing a clear understanding of all design components without a plan and section drawings. You can print each floor slab separately and then assemble using mates, or just print one component of the entire building separately from the rest. A good example is the model from Stanley Sitetowitz | Natoma Architects Inc (SSNAI), who used the Form 2 to model the residential complex.

Model by Stanley Sitetowitz | Natoma Architects Inc.

Since each body block followed the same pattern, it makes sense to simply print one detachable block that will allow the customer to understand the typology of the typical device. to print as a single block or separate along the seam.

This method usually works for models that do not have straight lines, such as typical building blocks, but complex structures, such as detailed building sections, bridges, pavilions, or airports.

First, break these models down into components that can be 3D printed with minimal supports. This saves post-processing time (removing supports for delicate models can be tedious) and reduces material costs and print times.

This bridge example demonstrates multiple partitioning methods. First, the model is divided into several parts (Figure a). Although they fit the

Form 2 build platform, they require painstaking removal of supports around more delicate areas such as cables and railings.

To solve this problem, each part is broken down into three sub-components: base plate and railing, vertical tensile cables and solar panels on top (figure b). They can be printed with significantly fewer supports, making it easier to finish,

They can be printed with significantly fewer supports, making it easier to finish,

Once completed, the components simply need to be assembled using the alignment functions that were included in the design phase. Smaller parts are also easier to place on a single build platform, with the entire bridge being printed from five 100ml parts.

Model from T.Y. Lin Architects

This site model was created using laser-cut fiberboard. The primary building was 3D printed from clear and white resin. Model by Schwarz Silver Architects

Materials

Materials play an important role in conveying the basic design concept. It is not always necessary to model the exact color and texture of a material, but it can help separate different materials. Dividing a model into its components allows for the display of materiality, as parts can be printed in different materials or individually dyed in different colors.

The transparent façade is illuminated from within, simulating the visual conditions of this site at night.

Formlabs Matte Resins

Black, White and Gray out of the printer have a smooth, opaque finish and provide an excellent neutral palette for architectural models. Gray and white resins are also easy to process and can be finished with just a few coats of paint, as discussed further in the finishing section of this document.

Formlabs Clear Resin is excellent for printing features that mimic translucent materials. If your model requires more transparency, you can simply dip the printed part in clear resin and let it dry evenly, as described in this article on making clear resin parts. You can also spray any clear coats on the model to increase the transparency and glossiness of the surface.

3D PRINTING AND TRADITIONAL MATERIALS

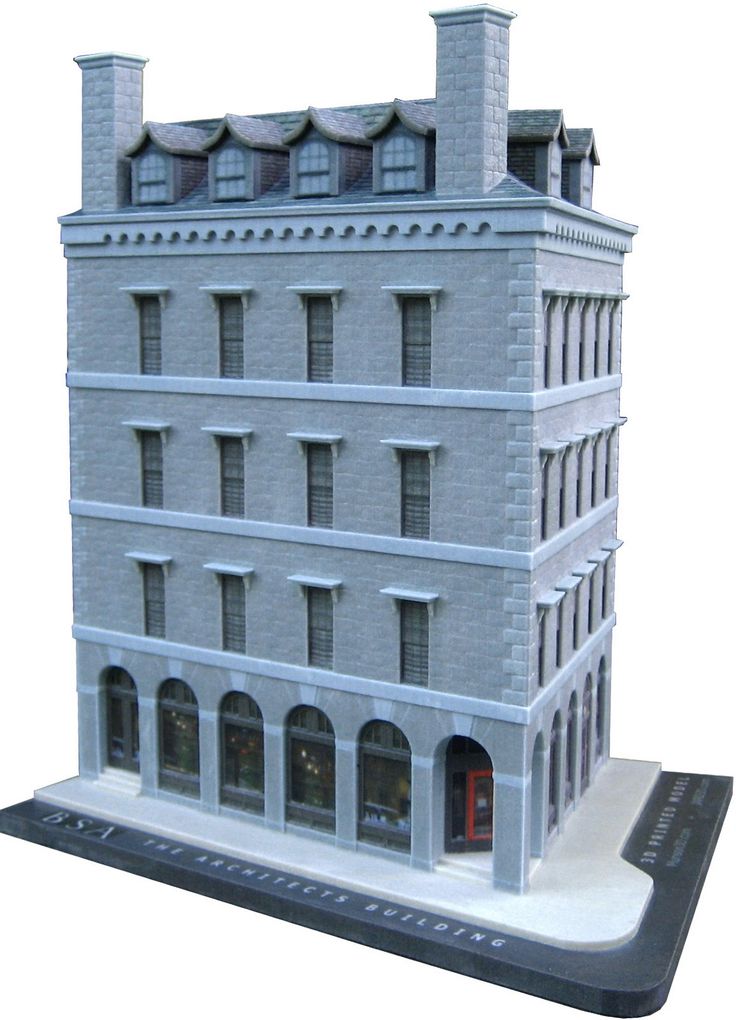

This model uses the Form 2 to print very fine details such as the cornice, clock and railing. Model by Miles Burke Architectural Models Inc.

Model by Miles Burke Architectural Models Inc.

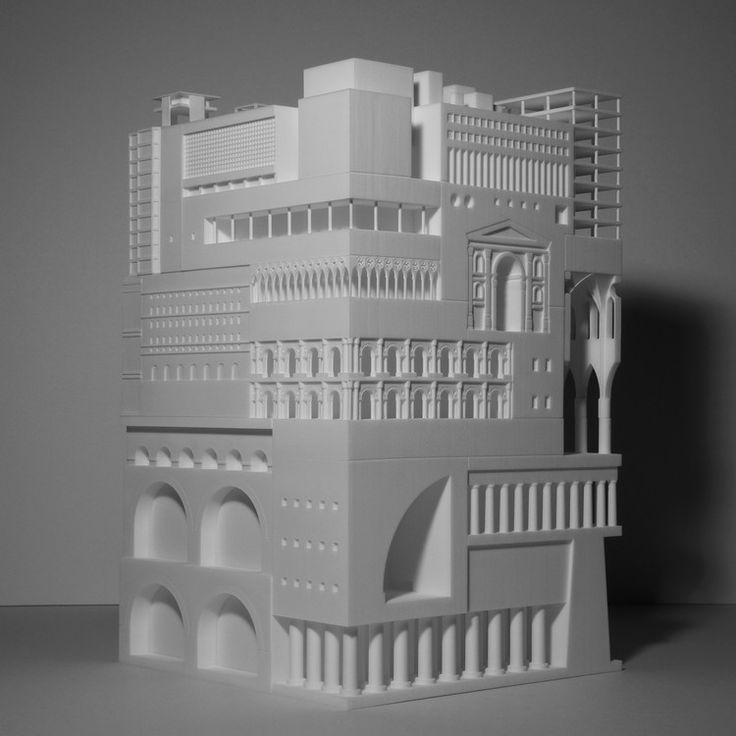

Instead of 3D printing an entire building, sometimes it's better to print just the complex components. Complex facades, slings and cornice details are excellent candidates for SLA 3D printing. Flat walls, floor slabs and topography can be laser cut or even hand-drawn

This complex façade is parametrically designed from solar trajectory analysis and would be incredibly difficult to fabricate in any other way at this scale.

Software workflow

Good printing comes from a well-designed 3D model. This section will cover modeling best practices and workflows for printing in some of the most common CAD environments:

Revit, SketchUp and Rhino

CAD software is typically the bottleneck in the transition from drawing to 3D printed model

General workflows

IMZ workflow

IMZ workflow

Model → Revit3Diagnostics → Sketch3Diagnostics 900 PreForm

Although BIM (Building Information Model) software is popular with architecture firms, it is not always used for direct 3D printing models. There are some high level steps that you can take

There are some high level steps that you can take

take to create a 3D printed model from these programs. This workflow is widely applied to Autodesk Revit or Graphisoft ArchiCAD software, both of which are IMZ parametric modeling programs.

PREPARE THE FILE

STEP 1: Prepare a stand-alone file

STEP 2: Component Management: remove ducts, double glazing, HVAC units and internal parts that will not be visible in model

STEP 3: Select all components to be sealed (eg doors, windows, walls, slabs). The parametric nature of the model allows you to simultaneously compact the dimensions of several objects.

EXPORT FILE

Select the scale at which you want to export the file. Select export options depending on the needs of your model:

EXPORT AS STL

Exporting the file as a mesh is very difficult to manipulate, so this is only useful if you don't want to edit any geometry after this step. You can then use your software to correct the mesh of your choice, as well as subdivide the mesh along the main Cartesian planes.

You can then use your software to correct the mesh of your choice, as well as subdivide the mesh along the main Cartesian planes.

EXPORT AS 3D DWG

Export as surfaces allows you to easily manage and edit geometry in Rhino or SketchUp. This step is recommended for those who want to split the model programmatically or by component, or split by a seam that is not on the normal Cartesian plane. You can then export the STL file from Rhino or from SketchUp using the plug-in

EXPORT USING ARCHICAD

Perform a geometry transformation to Morphs and a "consistency check" before exporting the model as STL. When printing in parts, use tool

"Divide" to cut the model for multiple print platforms, if needed. This operation basically creates printable files, but a quick check in mesh repair/analysis software never hurts.

USING STL REVIT EXPORTER

This method automatically removes smaller details such as doorknobs and railings. However, it is not reliable and still often requires some post-processing in other CAD environments before being sent to print.

However, it is not reliable and still often requires some post-processing in other CAD environments before being sent to print.

Surface Modeling Workflow

AutoCAD → Rhino/SketchUp → Model Diagnostics → PreForm

This workflow is often an easier approach and starts with 2D drawings solely for the purpose of 3D printing

FILE PREPARATION

STEP 1: Hide unwanted layersSTEP 2: Identify and remove unnecessary elements such as furniture, trees, etc.

EXPORT FILE

STEP 1: Export the simplified drawing from Rhino as DWG

STEP 2: Import into Rhino

STEP 4: Start extruding and trimming until you get the outer shell.

STEP 5: Export as STL STEP 6: Mesh Analysis/Correction STEP 7: Import to PreForm

Note: If the model will be printed in several parts, split it before exporting as STL

THICKNESS WITH RHINO

Instead of parametrically controlling the thickness of components directly in the BIM file, you can also use the BoxEdit component in Rhino.

This allows you to simultaneously scale a number of elements with respect to their center lines. BoxEdit is ideal for models that need to be scaled parallel to three Cartesian axes. Non-uniform scaling is a little trickier.

For non-rectilinear geometries, we suggest converting the part to a mesh and then using the Weaverbird thicken command, which simply offsets any non-standard mesh geometry outward by a given distance. Alternatively, it is possible to "split" complex parts into surfaces and then offset them instead of importing volumes from Revit.

SELECTING SMALL GEOMETRIES WITH RHINO

Another valuable Rhino feature is the SelSmall command, which allows you to select all elements in the Stage that are smaller than a custom bounding box. You can then select those objects and use

BoxEdit for individual scaling or just remove them. This is useful when you are dealing with a file that does not have a well organized layer system.

Although performing a logical connection on all geometries is ideal, often the problem can be solved with simple overlapping geometries. PreForm will interpret them as one closed geometry in most cases, but be sure to check printability with the "slicer" tool in the right pane in PreForm

. CONTINUOUS / LOGICAL JOINT GEOMETRY

Note : PreForm is Formlabs free software that prepares your 3D model for printing in Form 2. Once the part is set up, you can save it as a FORM file for future use in preform.

COMPUTATION WORKFLOW

Although it is a less common workflow, computational design is slowly being introduced into mainstream architectural workflows. Software such as Grasshopper and Dynamo are used to create parametrically generated geometries that are often so complex that they can only be created with 3D printing.

Since geometries are already easy to manipulate, it's usually best to create a separate component that allows you to easily control the basic dimensions of all thin objects. In this case, it's a simple matter of trial and error; running the exported geometries with a print test (PreForm,

In this case, it's a simple matter of trial and error; running the exported geometries with a print test (PreForm,

MeshMixer) and resizing until you arrive at a printable file.

Model Diagnosis

All workflows described below share a potential "generic diagnosis". This is an optional (but often necessary) step to ensure that the model is fully printable. Free programs such as Autodesk's MeshMixer and Netfabb are tools that allow you to repair, smooth, cavity, and split 3D print files.

MESH FIX

Formlabs PreForm software uses Netfabb's built-in mesh fix, so NetFabb and MeshMixer must be used for custom fixes or to preview problem spots in print. Materialize Magics is a great proprietary tool that covers the entire preprint workflow for a wide variety of printer types. The mesh patching software part is most important to the Form 2 print workflow and can save you a decent amount of preparation time. Netfabb has a beautiful built-in model cutter that allows you to effectively split and restore large files along any Cartesian plane.

SPLITTING THE MODEL

You can also split the model in NetFabb, which splits and fixes the split parts into printable volumes. In Rhino, you will need to close open volumes. Be sure to leave a tolerance of ~0.25mm between adjacent parts, this will allow them to be inserted without friction.

For more information on tolerances, see our white paper.

PREFORM SLICER

Architectural models are very detailed and it is often difficult to isolate each print issue. A combination of the above practices and mesh repair software is usually used for almost all problems, but it's always wise to use the PreForm Slicer tool to make sure there are no thin unsupported areas and enclosed volumes (such as rooms with no doors, elevator shafts, and parking spaces) .

“Building and architecture structures are not meant to be 3D printed, they are meant to be built. This creates problems of scale and complex geometry. By combining Netfabb's powerful mesh repair tools with the precision of the Form 2, you can prototype and visualize designs faster and in more detail, benefiting more for your business and speeding up your project's design review process. ”

”

Matt Lemay. Lead Enterprise Solutions Provider, Autodesk Customer Service

Post-Processing

Joining

The modeling strategy section of this booklet covers some ways of splitting and aligning parts together, but glue is always needed to securely join. Architectural parts are bonded in two main ways:

CYANOACRYLATE

Cyanoacrylate (CA or Super Glue) creates a fast, strong enough bond, ideal for small to medium sized parts. CA does not bond dirty surfaces well, so be sure to thoroughly clean the part before applying adhesive to the surface of the model.

POLYMER

For smaller prints, you can use liquid resin as a binder. Dispense a small amount of resin into the tray from a bottle or cartridge, use a dropper or syringe to lift it up, and place it on the surface of the part to be bonded.

Join parts and wipe off any excess resin that may be spilling around the edges. To cure the resin and bond the parts, use a 5 mW laser pen at 405 nm and point it at the bonding area around the parts.

This method creates a chemical bond, just as if the part had been printed on your SLA 3D printer, but only applies to small bonding surfaces because a low power laser pen cannot penetrate the model deep enough to create a strong bond .

FINISHING

Parts printed on Form 2, especially matte standard resins, have a smooth surface as soon as they exit the printer. However, visible areas with supports almost always require sanding. In addition, you can prime and paint parts in any desired color.

GRINDING

Sanding will help you remove the support marks and any remaining inaccuracies from your model. Start by carefully dry sanding the surface of the part using ~150 grit sandpaper to remove large support marks and smooth out the edges of the joint. Once the surface of the part is smooth, wet sand with 320mm sandpaper to remove any remaining layer lines. Move the sandpaper randomly to avoid grain formation.

In most cases these two steps will create a fairly even finish, but you can continue to increase the grit size of the sanding paper by a factor of 2 and wet sand the entire piece until the surface is smooth enough.

Once you have finished sanding your model, wash the model in soapy water to remove any dust or debris and dry thoroughly before proceeding to the last step.

The architectural models are very detailed and it is quite difficult to access certain areas with only sandpaper. You can use different sizes of nail files to get to problem areas of the model.

PRIMER AND PAINTING

Priming is required before parts are painted to ensure the paint adheres to the surface. Priming can also make it easier to find areas that require additional finishing. A quick spray of primer over the model makes the support marks very visible, so you can instantly identify areas that need additional sanding.

General plastic primer gray matt shows details very well. Apply it to surfaces in several thin layers for best results. Continue sanding in critical areas, reapply a light coat of primer and repeat this process until the entire part is smooth. Most spray paints work best in warm, slightly damp conditions with no airflow, but always check the specific paint or data sheet for manufacturer's recommendations.

“Models are becoming rarer in a field where photorealistic renderings and virtual reality technology are advancing, but physical models allow architects to test spatial qualities in ways that digital models cannot. If we weren't using a 3D printer, we would be forced to spend more time visualizing designs through renderings and drawings. Being able to get a physical model of a complex design straight from a 3D CAD model gives us several impressive looks in less time.”

Paul Choi

3D printed architectural models • How can 3D printing help your business?

Article applies to printers:

QIDI Tech i-Box ANYCUBIC Photon Mono X Anycubic Vyper

No blueprint or 3D digital model can reproduce the real perspective seen on a printed 3D architectural model. 3D printing helps to make architectural models many times faster and more visually than traditional visualization methods.

The advances of the past 20 years in 3D printing have created new ways of working across industries, and architecture is no exception. 3D printing has found its way into a wide range of real estate developments, so it's safe to say that 3D printing brings the most benefits in terms of speed, detail, cost, and efficiency.

3D printing has found its way into a wide range of real estate developments, so it's safe to say that 3D printing brings the most benefits in terms of speed, detail, cost, and efficiency.

Follow us on social networks: VKontakte, Telegram, Instagram, YouTube, Ya.Zen, Twitter, Facebook to be the first to receive the most interesting materials!

There are many companies that make layouts using 3D equipment. For example, the British company Hobs 3D has been exclusively manufacturing architectural models for many years and has succeeded in this business.

In this article we will look at the different components of making your own architectural models yourself:

- Software for creating 3D models.

- Preparation of 3D models for printing.

- Slicing a model in a slicer.

- Print.

- Additional processing and assembly of layout parts.

Benefits of 3D printing for the architect

Before you decide to 3D print an architectural model, it's worth looking at why it's important to visualize a project at this level.

An architect in his importance in the design and construction of buildings is second only to the owner of a new property. The specialist is involved in the creation of the project from the development of the concept to the construction itself. Thus, the success of an architect's work depends entirely on the ability to find contact with the client, understand all his desires, but still find original solutions.

Design

Any designer will tell you that the creation of a new project means constant changes in search of successful solutions. Each detail is thought through several times, drawn physically or digitally, and then goes through several stages of editing.

Video source: YouTube channel BigRep GmbH

3D printing helps the architect quickly and relatively inexpensively make a physical representation of the object, being able to improve the concept with minimal time and cost.

Video source: YouTube channel ProtoFab

Competition

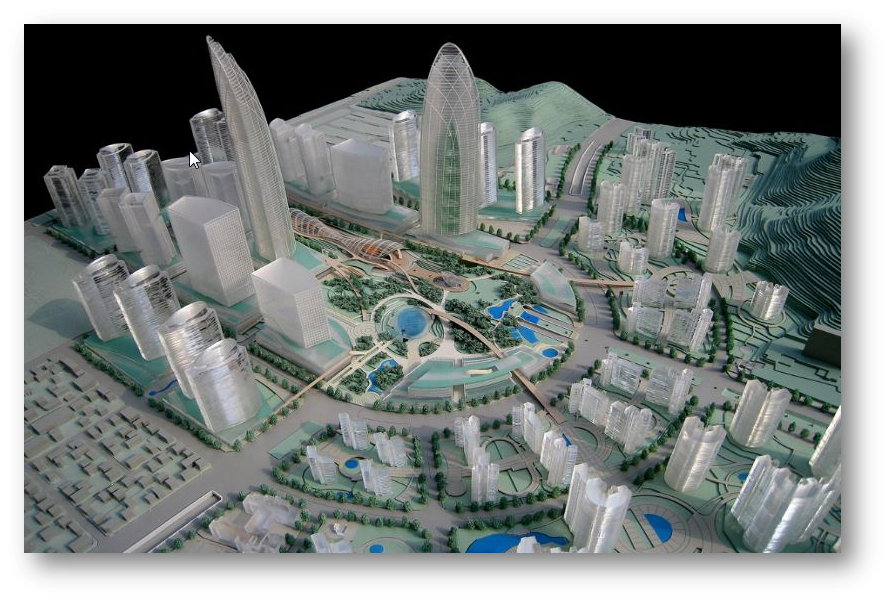

Most architectural and construction companies find themselves in competition for the right to implement the project. A 3D printed layout will be able to surprise the customer and help win the contract.

Customer presentation

Project presentation to the client may be more successful. A ready-made 3D layout helps the customer quickly and confidently make a decision on the approval of the project or the purchase of real estate.

Video Source: RJ Models YouTube Channel

Project Approval

Some projects require approval from the local government or urban planning organizations. Presenting the project to these departments, as well as to public representatives, will help to fit the future building into the existing city plan and show the significance of the project.

Sales and Marketing

When building is completed, developers often build scale models from existing architectural drawings. This helps to interest the client in the sale of commercial and residential premises. The object itself, made using traditional modeling methods, can become a real decorative object.

Which type of 3D printing to choose for an architectural layout

If you decide to print an architectural model, the first question that will bother you is: which printer should you choose?

Video source: YouTube channel Zmorph

The choice of equipment depends on the budget, the level of 3D printing technology, as well as many other features of a particular business. We will look at three types of printers (printing technologies) that are most commonly used to create architectural layouts.

FDM printers

The most affordable category of printers that print with plastic filament. In addition to the low price of the printer itself and consumables, you have the opportunity to print multi-colored layouts, as well as use decorative wood or metal plastics.

In addition to the low price of the printer itself and consumables, you have the opportunity to print multi-colored layouts, as well as use decorative wood or metal plastics.

Almost all products printed on FDM printers (regardless of cost) require additional processing. Sanding, removal of supports and priming are mandatory steps before painting and assembling the layout.

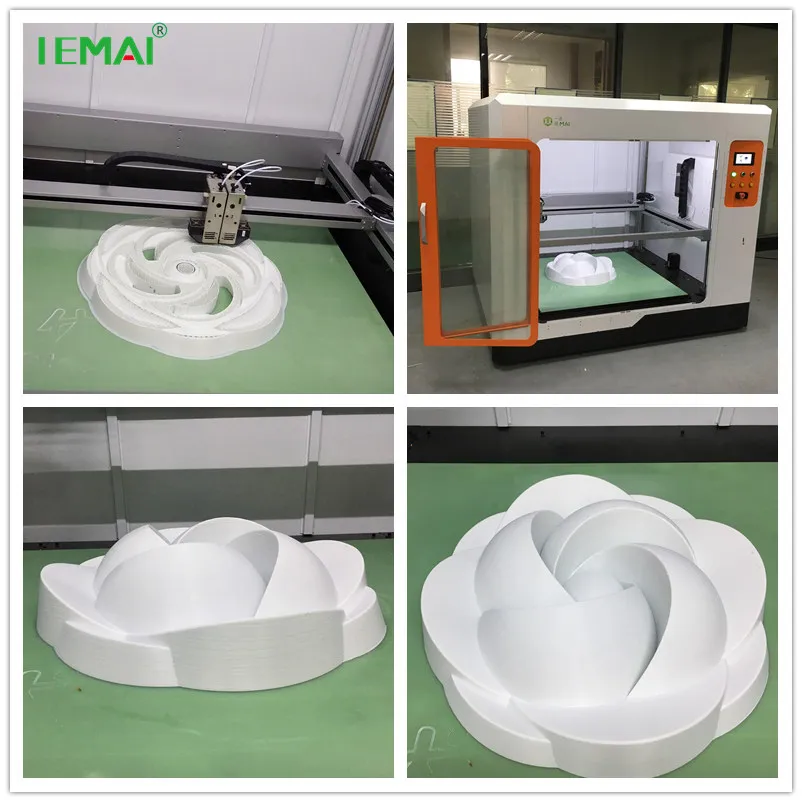

These printers use a liquid resin that cures when exposed to ultraviolet light. A high degree of detail, as well as a perfectly smooth surface of the models, reduces the time for post-processing. Despite the availability of desktop printers, large-format professional 3D printers must be purchased to print architectural models. A large build area will allow you to immediately produce bulk products and parts, reducing printing time.

The disadvantage of photopolymer printers is that printing is only possible in one color, and the range of materials themselves is not as wide as that of plastics.

Video source: YouTube channel Materialize Manufacturing

Video source: YouTube channel Luke Towan

Color Binder Jetting printers

Printing with plastic powder with color binders allows you to create support-free, full-color layouts that require minimal rework. After removing excess powder, the layout is immersed in a special adhesive that seals the outer layer and gives the product strength.

This printing technology is suitable for final designs that can be presented at a presentation.

Although there are FDM printers that can print multiple colors at the same time, printers that use Color Binder Jetting or MultiJet Fusion technology are usually used to create architectural layouts. Monochrome printing on such printers allows you to achieve sculptural quality.

Video source: YouTube channel Espacio 3D

Equipment of this type can cost tens of thousands of dollars, which is an unbearable sum for small and medium-sized organizations. Fortunately, such equipment is used by specialized companies to create architectural models.

A selection of articles from the "Knowledge Base" section from the LIDER-3D website: 1) Robotic airship on a 3D printer • 2) How to choose a good portable 3D scanner • 3) SLS 3D printing: what it is and how it works • 4) Characteristics and settings of 3D printing filament from LIDER-3D

Post-printing

Despite all the advantages of 3D printing for architectural modeling, this method of creating layouts is labor intensive (to a lesser extent than traditional methods of creating layouts). Almost all printed models need additional processing, which helps to give the layout a neat and presentable look.

Most models are made from clear or neutral plastics and hand painted if required.

3D printing can create accurate and detailed layouts, but printing technologies have their own characteristics. Models can be brittle due to material properties. The installation of internal support structures made of wood or metal will help to solve this problem.

The skillful combination of traditional modeling and 3D printing will help you achieve stunning results.

How to print 3D model

Before purchasing equipment and materials for printing, you need to decide whether it is worth creating 3D printed layouts on your own or you can entrust this work to professionals. Many 3D printing services specialize specifically in creating architectural models.

Essentially, you need to consider how much investment you are willing to make in equipment, supplies, people, and workspace to achieve the desired print quality.

Some companies have their own equipment, but turn to professionals to create a correct 3D model.

Own production of layouts

3D printing of architectural models on your own 3D printer makes it possible to visualize any project. This helps to find new design solutions and facilitates communication with the client.

Video source: YouTube channel BigRep GmbH

3D modeling software

Before considering printing with a 3D printer, the 2D images must be converted into a 3D model. Every architect is familiar with at least one of these programs: AutoCAD, Rhino or SketchUp Pro, as well as BIM building modeling software Revit or MicroStation.

Preparing a 3D model for printing

No matter which software you choose, architectural layout is done by printing individual elements and then assembling them. A model can consist of tens, hundreds or even thousands of parts.

Each detail of the future layout must be represented by a separate 3D model, which is launched for printing. Precise geometry, uniform wall thicknesses and no holes in the mesh allow you to achieve the best results. If the 3D model does not meet the printing requirements, it must be prepared using a special assistant program.

Precise geometry, uniform wall thicknesses and no holes in the mesh allow you to achieve the best results. If the 3D model does not meet the printing requirements, it must be prepared using a special assistant program.

Most 3D printers come with software to prepare files for printing (slicers). But if you need full control over all parameters, then there are special programs for correcting errors in STL files.

Many of them, such as the free Blender, have special algorithms for preparing architectural models and small miniatures.

For serious projects, you can use Netfabb or Magics professional software with many automatic functions. To move the model from CAD to the slicer, you need to convert the document to STL format.

Cutting and placing supports

Once the 3D model is ready to print, you need to consider how it will be positioned on the printer. For efficient use of resources, you can place several parts on the printing platform at once. The slicer program automatically orients the object on the platform, divides it into sectors convenient for printing and, if there are protruding parts, indicates the need to install supports. With a minimum number of supports, the post-print processing time is reduced, but if they are not enough, the geometry of the model may be violated.

The slicer program automatically orients the object on the platform, divides it into sectors convenient for printing and, if there are protruding parts, indicates the need to install supports. With a minimum number of supports, the post-print processing time is reduced, but if they are not enough, the geometry of the model may be violated.

If you are using an SLA and FDM printer, then you need to consider the resolution of the future model. High resolution takes longer to print and is good for creating visible layout details. Printing at low resolution will allow you to make a test print or make hidden parts of the layout.

3D printing services

If you're not satisfied with the print quality you can achieve yourself, it's worth finding a partner to print architectural layout details.

Many companies offer 3D printing services, but not all specialize in printing for architecture. We offer you a list of questions that will help you find a suitable partner:

Does the company have equipment that works on the required technology?

Not all printing technologies are suitable for making architectural models. Large format 3D SLA printers can achieve high quality prints, as well as Color Binder Jetting equipment. SLS and SLM printers are generally not suitable for printing layout details.

Large format 3D SLA printers can achieve high quality prints, as well as Color Binder Jetting equipment. SLS and SLM printers are generally not suitable for printing layout details.

Is there a service for preparing 3D models for printing?

If you or your employees are new to creating 3D models, then most likely the files presented will need to be finalized. It is important to know that the chosen company has specialists who are ready to quickly solve any problem.

Does the company offer layout services?

Sometimes simply printing and assembling a layout is not enough. Some details need to be realistic, textured, or painted. Companies that specialize in creating architectural layouts, in addition to 3D printing services, offer complete assembly and finalization of the layout in accordance with your wishes.

3D printed eternity

The goal of any architectural project is to develop and deliver a unique product that will satisfy the client's needs, strengthen the company's reputation and help sell its services. 3D printing contributes to the realization of all these ambitions and gives a competitive advantage over those who do not use modern opportunities.

3D printing contributes to the realization of all these ambitions and gives a competitive advantage over those who do not use modern opportunities.

If you are not already using 3D printing in your design and sales process, please contact your 3D printing service providers. Understanding the benefits of 3D printing for your business will help you implement modern technologies in the creation of architectural models.

LIDER-3D offers services for printing architectural models, as well as related services - finalization and creation of 3D models. Choose a reliable partner to implement the most daring ideas!

Follow us on social networks: VKontakte, Telegram, Instagram, YouTube, Ya.Zen, Twitter, Facebook to be the first to receive the most interesting materials!

You can buy a 3D printer for printing layouts and other tasks from LIDER-3D.

Write to us in messengers for advice on products: Telegram - WhatsApp

In the field of prototyping, we can recommend these models of 3D printers.

For fine detail products:

- QIDI Tech i-Box Mono - Check current price ◄

- Anycubic Photon Mono X - Check current price ◄

- Anycubic Photon Mono 4K - ◄ Anycubic0 9 Mono SE - Check current price ◄

- Creality HALOT-SKY - Current Price ◄

- Creality HALOT-MAX - Current Price ◄

- Creality HALOT-ONE - Current Price ◄

:

- QIDI Tech i-Mate S - Check current price ◄

- QIDI Tech X-Max - Check current price ◄

- QIDI Tech X-Plus - Check current price ◄

- QIDI Tech i-Fast - Check current price price ◄

- FlashForge Adventurer 3 / Adventurer 3 Lite - Check current price / price ◄

- Creality Ender 7 - Check current price ◄

- Creality Sermoon D1 - Check current price ◄

- Creality CR-200B - Check current price ◄ 901 FlyingBear06 Ghost 5 - Current Price ◄

- FlyingBear Reborn - Current Price ◄

- Anycubic Vyper - Current Price ◄

- Anycubic 4Max Pro 2.

Learn more