Fujifilm 3d printing

Education 3D Solutions | FUJIFILM Business Innovation

FUJIFILM Business Innovation Australia 3D printing solutions bring learning to life.

Designed to boost your innovative curriculumBanish boredom. Dismiss disinterest. Let your students loose with simple 3D printing technology and watch the creativity flow.

Ultimaker’s 3D printers are specifically designed to underpin everyday classroom and laboratory learning. Sparking new opportunities for hands-on learning and tangible results for STEAM, while encouraging design thinking skills to rapidly prototype and test ideas.

Investing in the next generation

Does your institution lead the way? Here’s why you should, and how we can help.Australia’s future workforce will compete on a global stage, coping with constant, dynamic technological developments. Printing as a tool is evolving rapidly, and the sky is the limit. Every student needs to be skilled and prepared.

Today, businesses are enthusiastically adopting 3D printing for prototyping, product design, and production – across a range of industries such as aerospace, automotive, defence and medical. And as additive manufacturing becomes globally recognised as a pillar of manufacturing technology, the demand for an additive manufacturing curriculum has also increased.

We believe Ultimaker’s desktop 3D printers are the ideal class-based solution to ‘mainstream’ this technology. They enhance engagement and inspire critical and creative problem-solving. Students learn to collaborate to formulate and build design ideas.

Through Ultimaker's technology and our experience in the education sector, we can assist your education institution to harness 3D printing power to enhance every day learning experiences.

We support over 3,000 education providers and have 60+ years’ experience in the education field. We understand the complexities of introducing new technology to multiple stakeholders.

A. When you invest in Ultimaker technology from FUJIFILM Business Innovation Australia, you’ll benefit from:

- Using a device designed for education - more sophisticated than a hobby printer, but relatively simple to use, maintain and service.

- An attractive pricing proposal.

- Support from a trusted partner. FUJIFILM Business Innovation Australia understands the education market and is a committed, experienced provider to over 3,000 institutions.

A. We understand that teachers need to have the knowledge and skills first. So we include:

- Access to Ultimaker Academy, offering online training to all stakeholders on how to set up, maintain and use 3D printing to its full capabilities.

- CAD design tips to using different materials and applications, Ultimaker e-learn gives you the latest in 3D learning resources.

- Access to simple lesson plans to get you familiar with the possibilities.

A. FUJIFILM Business Innovation Australia aims to simplify technology management and support for IT Managers. With Ultimaker 3D printers, you’ll discover:

- Fast set up and simple, intuitive controls means users minimise the need for technical knowledge and high levels of support.

- We can provide onsite hardware service and support, should you need.

- With Ultimaker Academy e-learn resources, your IT team have resources at hand to support both teachers and students.

Download printable information that summarises the benefits of Ultimaker printers here, so you can discuss the possibilities with your colleagues.

Download our 3D printer solutions flyer

The Ultimaker Range

The smart, efficient and cost-effective 3D printing solution to integrate into classrooms, laboratories and curricula.| Ultimaker S3 A powerful, cost-effective option for high-quality composite-ready performance. | Ultimaker S5 With a larger build volume, the Ultimaker S5 not only enables bigger models, but can also print multiple parts on a single build plate. Delivers leading solutions for a desktop 3D printer.

| Air Manager Provides a closed inside-out airflow, providing a better environment within the build chamber. Filters up to 95% of ultrafine particles.

| Material Station Seamlessly integrates with the Ultimaker S5. Allows for filament storage and delivery in a humidity-controlled chamber to help increase productivity. |

| Download data sheet | Download data sheet | Download data sheet | Download data sheet |

Dive into 3D printing with the experts. The Ultimaker 3D Printing Academy enables you to train your users, fluidly moving through a series of stepped online courses for all users.

Learn more about the Academy

| Case Study: Old Dominion University – using 3D to boost employability ODU aims to give student engineers the edge they need for employability, and 3D printing plays a big part. Unexpected benefits turned out to be not only prototyping but producing end-use parts. And even remote students were able to participate, with the affordable S3. “Nothing replaces touching and holding a prototype,” commented one lecturer. | Case Study: Primary and Secondary Schools get results with 3D Printing 3D Printers provide great lessons in creativity and resilience. Technology mainstreaming resulted in surprising creativity and critical design-thinking techniques. One educator said, “we’d seen first-hand the ease of use and knew they were ready to go right out of the box —a must for us to successfully roll out across grade levels.” | Whitepaper: Enhancing school education with project-based learning and 3D printing Discover research, insights and tips on the different types of tools that can be used to enable project-based learning and how other learning institutions are using them to teach creativity and resilience. "It's incredibly powerful to see kids print something multiple times before it works, taking the time to understand what adjustments to make and not giving up," said one educator. |

| Read more | Read more | Read more |

Talk to us

Contact us today and discover how we can help you transform classroom learning – for real.

First name

Last name

School

Job title

Contact number

StateNSWVICQLDWASATASACTNT

How can we help you?

Campaign ID

Campaign Name

Websource URL

Lead source

Remarks

Captcha

Privacy Collection StatementFujifilm Makes a Unique Entrance into 3D Printing

0Shares

Since HP announced its entrance into the 3D printing space, other print and imaging leaders have looked for their own way into the market, as well. Companies like Canon have begun selling 3D printers, hinting at making their own, while Epson has implied that it’s hoping to develop the ability to 3D print “anything”. Even Kodak has partnered with Carbon to invent new 3D printing materials. The latest is Fujifilm, which has taken what might be considered a unique approach to getting into the 3D printing business. No, they won’t be making a printer or even materials for 3D printing (at least not yet). Fujifilm is going to be offering technical support services.

Companies like Canon have begun selling 3D printers, hinting at making their own, while Epson has implied that it’s hoping to develop the ability to 3D print “anything”. Even Kodak has partnered with Carbon to invent new 3D printing materials. The latest is Fujifilm, which has taken what might be considered a unique approach to getting into the 3D printing business. No, they won’t be making a printer or even materials for 3D printing (at least not yet). Fujifilm is going to be offering technical support services.

Just as Fujifilm Service implements inventory management, automated retail, and refurbishment services for photo-imaging and printing systems, and has been since 1983, the Japanese multinational will take on 3D printing services through their North American branch. They will be extending their expertise from these 2D platforms into the third dimensions, providing just about any service that consumers and businesses might need when dealing with 3D printing technology. These services run the gamut from installing a new machine to maintaining it and even training employees in the use of 3D printers. The company states on their website:

These services run the gamut from installing a new machine to maintaining it and even training employees in the use of 3D printers. The company states on their website:

Our technicians have significant experience in and knowledge of the mechanics and methods used to control diverse printing processes, including expertise in x, y, and z axis controlled devices, such as 3D printers. And, our in-depth understanding of the importance of printing in many organizations enables us to provide best practices coaching and training for printer operators across a wide range of industries.

Consistently excellent service translates into the best performance and value from your 3D printing systems. Our reputation for service excellence is exemplary. But our customers put it best: “Because of the job you do, we are able to do our job better.”

The goal with their service is to help customers get the most they can out of their 3D printers. And they plan to do so through their already extensive network of locations in North America. As an established corporation, Fujifilm Service already has two strategically placed parts distribution centers, three depot repair facilities across the US, four help desks, and 500 field service technicians. With these resources, the company has a pretty long list of what they can offer potential clients:

As an established corporation, Fujifilm Service already has two strategically placed parts distribution centers, three depot repair facilities across the US, four help desks, and 500 field service technicians. With these resources, the company has a pretty long list of what they can offer potential clients:

- Initial setup and testing

- Operator training and education

- Telephone technical support

- On-site repair service

- Product exchange/swap service

- Depot repair service

- Routine calibration and quality checks

- Regularly scheduled preventive maintenance

- Replacement parts

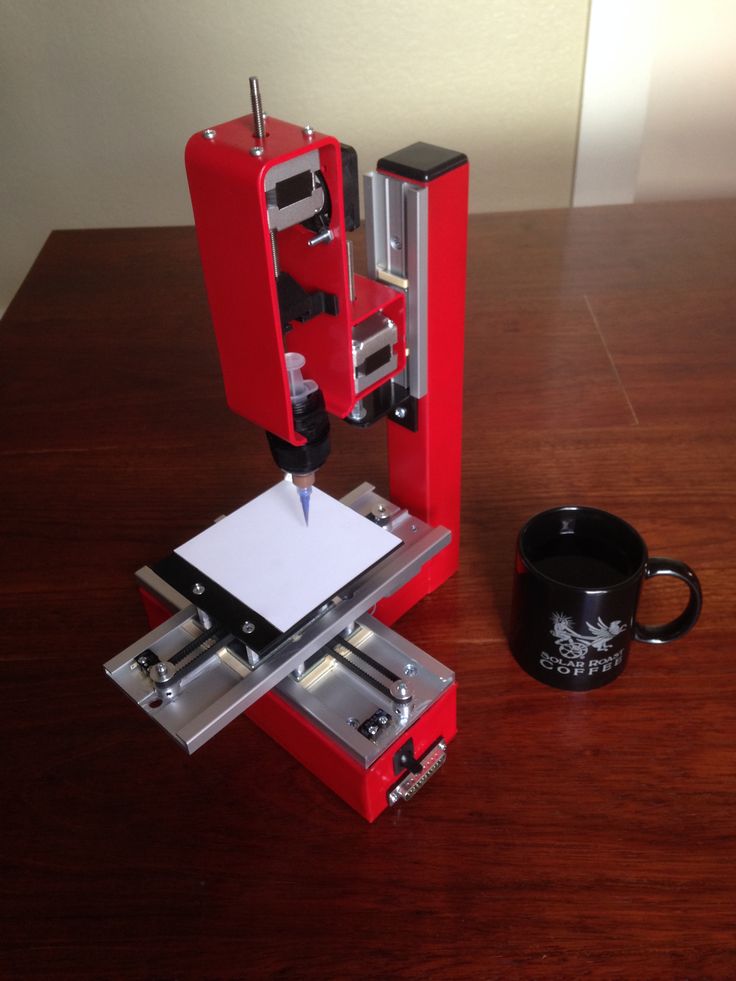

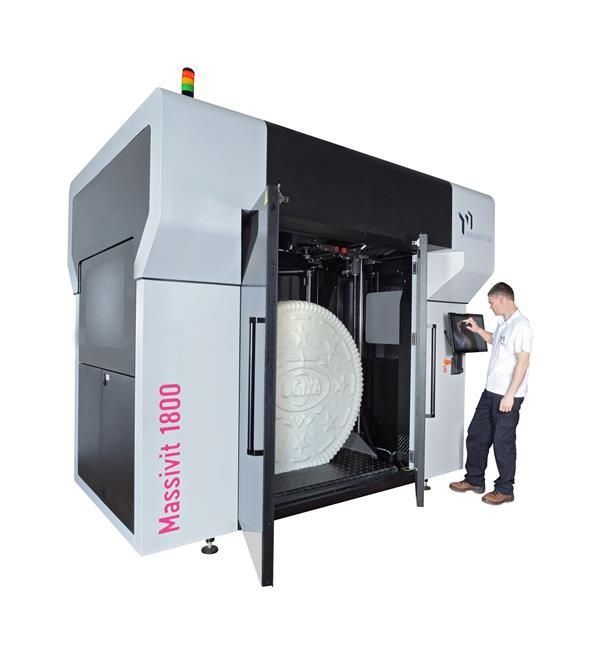

And, according to Fujifilm, these services can be applied to a number of different aspects associated with the technology, including CAD and 3D modeling software, computer maintenance, electro-mechanical systems, electronics repair, and more. And they say that they’ll tackle every type of printer out there, including inexpensive 3D printers used in the classroom or home up to the advanced additive manufacturing systems associated with industry.

Given the complexity of most 3D printing systems, as well as the relative unfamiliarity that the general populace has with the technology, this could be a necessary and lucrative business for the imaging giant to initiate. If Apple needs a Genius Bar for its user-friendly products, it’s easy to imagine the genius necessary to install, repair, and train employees around industrial manufacturing equipment. At the same time, Fujifilm won’t find themselves competing with other imaging corporations entering the space. In fact, you might even find yourself calling Fujifilm Services to fix your MultiJet Fusion 3D printer from HP.

Michael Molitch-Hou

Michael Molitch-Hou previously served as Editor-in-Chief of 3D Printing Industry, he is now the Editor of Engineering . com's 3D printing section. He has covered additive manufacturing technology day in and day out since 2012 and has hundreds of article to his credit. He is the founder of The Reality Institute.

STL file Fujifilm X100V grip・3D printed design download・Cults

Alfa Romeo 147/Gt Windows button

10 €

Alfa Romeo 156 GTA Side Skirt Cap Set

10 €

Fiat Freemont shift knob cap

3 €

Mazda MX-5 Miata key holder

3 €

Alfa Romeo 159 door handle trim insert

2 €

Alfa Romeo 156/147 JTD Shift Knob

2. 50 €

50 €

Alfa Romeo Spider Electric Roof Motor, Replacement Gear

8 €

EV Charger Cable Holder for Type2 EVSE IEC 62196-2

10 €

The best files for 3D printers in the Tools category

Another Cap for COVID-19 MASK

Free

Deadbolt Combination Lock

Free

Rezz-Inspired NeoPixel Glasses

Free

Wersybot - a derivative of The Printrbot

Free

Iphone holder for Cage modular DSLR

Free

Bag holder with damper

Free

Arduino box

Free

Adjustable spool support

Free

Bestsellers in the Tools category

FAST PRINT STACKING STORAGE BOXES STACKING CONTAINERS

1,50 €

GEAR AND DRIVE

3. 58 €

58 €

Quick print ink bottle holder (6 sizes)

2.87 €

Business card embossing system

3 €

Case for Chill Buddy lighter

1.01 €

Fire hydrant storage container

2.05 €

INDICATOR FOR BETTER BED LEVELING FOR ENDER 3 V2

3,20 €

PRECISION CALIPER 3D PRINT DIY

3.04 €

Scissor Paint Rack (Citadel)

5.69 €

UNIVERSAL BED LEVELING INDICATOR FOR VERY ALL PRINTERS

3,20 €

Housing FLSUN SR

8,50 €

INDICATOR FOR BETTER BED LEVELING FOR ENDER 3 PRO

3,20 €

Quick Print Stackable Parts Containers / Storage Boxes

2.87 €

Filament shielding

2. 97 €

97 €

Version 2 Alligator 2 || Repeating crossbow || 3d printed shop || Inspired by Joerg Sprave

1.50 €

PET-Machine, make your own plastic bottle filament at home!

50 € -80% 10€

Do you want to support Cults?

Do you like Cults and want to help us continue our journey on our own ? Please note that we are a small team of 3 people, so it is very easy to support us in maintaining activities and creating future developments. Here are 4 solutions available to everyone:

-

ADVERTISING: Disable the AdBlock banner blocker and click on our banner ads.

-

AFFILIATION: Shop online with our affiliate links here Amazon.

-

DONATIONS: If you want, you can donate via PayPal here.

-

* INVITE FRIENDS: * Invite your friends, discover the platform and great 3D files shared by the community!

Fujifilm Dimatix company history, technology

News

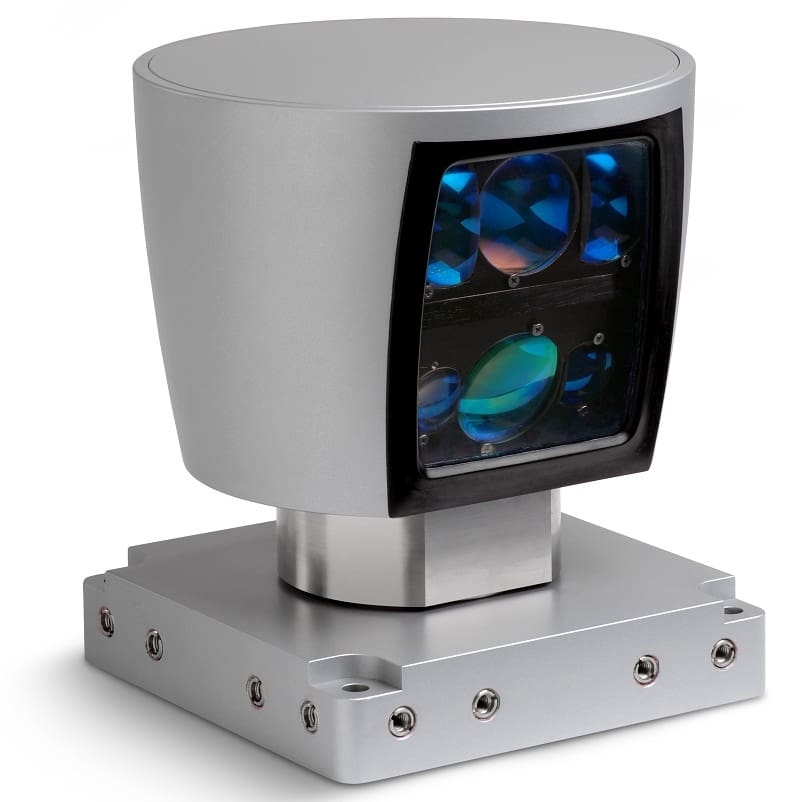

Fujifilm Dimatix, one of the world's leading manufacturers of inkjet printheads for commercial and industrial printing, is transforming inkjet printing into a micromanufacturing process that has revolutionized electronics and biology. Technological innovation and world-class process optimization enable high-performance, high-precision printing and application of nano-based inks and fluids on all types of surfaces.

Founded in 1984 as Spectra with an exclusive licensing relationship with Xerox, Fujifilm Dimatix has developed and patented numerous technologies and generations of inkjet printheads capable of producing high-quality digital images and micro-injections in a wide range of inkjet applications from commercial to 3D. - printing in industry and medicine.

- printing in industry and medicine.

The Spectra StarFire SG1024/SA-2C (10 pl) printheads are the latest innovation in inkjet printing. The new high-performance printing technology speeds up the process of industrial single-pass printing and marking. Components of Fujifilm Dimatix (Spectra) print head models have a modular design, durable, easy to repair. The design of the piezocrystal allows nozzles to be positioned at a high density of 400npi, which makes it possible to achieve high print density in a small number of passes.

When an ink head of the same color is inserted into both channels, the modern RediJet technology is implemented, which allows you to change the size of the droplets, for accurate drawing of small elements, uniformity of solid fills and smooth transitions of gradients. The drop size varies from 12 to 33 picolitres, the exact figures depend on the viscosity of the ink and the surface tension properties that form the meniscus on the nozzle and the shape of the formed drop. The high kinetic energy of the formed drop ensures a direct flight of the drop to the material, the deviation from the trajectory is minimal among competitive heads, even at a large distance between the print carriage and the material. The high frequency of operation up to 50kHz ensures high X-ray print resolution and high print speed.

The high kinetic energy of the formed drop ensures a direct flight of the drop to the material, the deviation from the trajectory is minimal among competitive heads, even at a large distance between the print carriage and the material. The high frequency of operation up to 50kHz ensures high X-ray print resolution and high print speed.

The high reliability of the print head and long service life make the maintenance cost very low. Easy to repair: it is enough to replace printed modules, a metal nozzle plate, or other damaged elements of the system from the donor head. The nozzle plate easily withstands harsh cleaning in ultrasonic baths, as well as straightening and polishing on the tool table in the event of deformation from a collision.

© 2019 SIGN SERVICE. All rights reserved.

Any copying of information from the site sign-service.ru should be made with a link to the source and with the consent of the administration of the resource.

Read also

News

Solvent ink SK-4

It is worth noting the acceptable cost of solvent ink. In the modern market, it is SK-4 ink that has long been the leader in sales.

In the modern market, it is SK-4 ink that has long been the leader in sales.

Read

News

Color correction for large format printers

Many owners of large-format printers have problems with mismatch of colors conceived by the designer of the layout, with the result of printing, change in color rendering when switching to other ink, or mismatch with the customer's corporate colors. And some customers are outraged even when the colors on the monitor diverge from the colors on the printed material.

Read

News

About head resolution and print resolution

Many manufacturers increase the maximum print resolution to 2880 dpi, and higher, visually you will not see an increase in dot density on the material, they will merge and the material will simply be more densely saturated with ink, which can lead to poor print quality due to spreading and mixing ink. Such printing in a large number of passes in 16 or 32 passes is called Overprint, and it is sometimes necessary to make light-transmitting materials completely non-transmitting after printing, or for relief printing on UV printers.

Designed with a small footprint, this dual extrusion printer is suitable for any classroom or maker space. Powered by Ultimaker’s latest 3D printing technology.

Designed with a small footprint, this dual extrusion printer is suitable for any classroom or maker space. Powered by Ultimaker’s latest 3D printing technology.