Frys 3d printer

MakerBot Partners with Fry's Electronics to Bring Their 3D Printers and Filament to 32 Stores - 3DPrint.com

What a week it has been for the two largest 3D printer manufacturers in the world, Stratasys and 3D Systems. While 3D Systems yesterday announced a deal to acquire Cimatron, a CAD/CAM software developer, and is also very busy rolling out a slew of new exciting products, Stratasys has managed to push their MakerBot brand of desktop 3D printers into dozens of new stores nationwide.

After announcing last week that they will be selling MakerBot machines in 26 new Home Depot stores across the US, and adding to that excitement yesterday with an announcement of an exclusive deal with Staples to carry their MakerBot printers in 50 retail locations across the US, today we get word of yet another major deal.

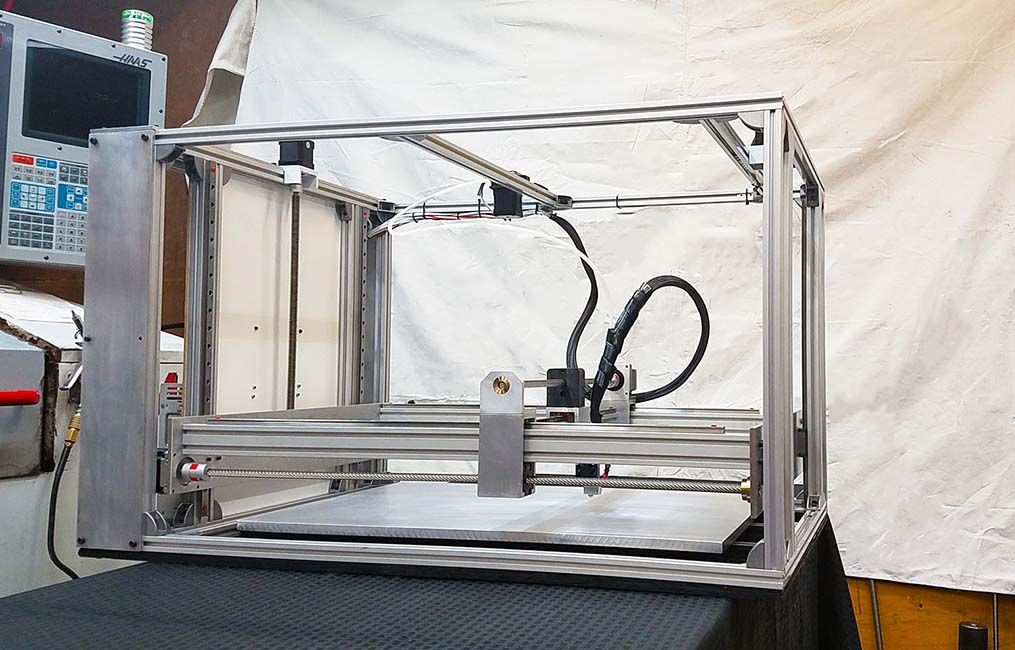

The MakerBot kiosk setup

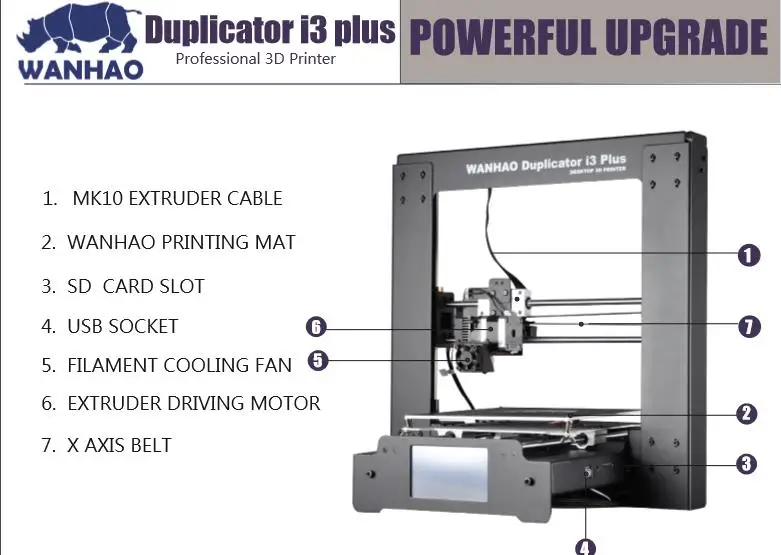

Silicon Valley-headquartered Fry’s Electronics, a company with approximately 14,000 employees and over $2 billion in annual revenue, has announced an agreement with Stratasys as well. As part of the agreement, 32 Fry’s stores in Arizona, California, Georgia, Illinois, Indiana, Nevada, Texas, and Washington will feature MakerBot 3D printers and filament within specially designed MakerBot in-store kiosks. Additionally, two Fry’s store locations, one in Sunnyvale, California and another in Wilsonville, Oregon, will each feature a printer in-action so that customers can see with their own eyes how the machine works.

“We are really excited to partner with Fry’s Electronics to bring MakerBot Replicator 3D Printers and Filaments directly to high tech professionals in more retail locations throughout the United States,” noted Jenny Lawton, acting CEO of MakerBot. “It’s also a great experience to be able to visit Fry’s and purchase multiple colors of MakerBot Filament when working on a 3D printing project.”

In addition to MakerBot’s physical presence within these stores, Frys.com will also begin carrying the full lineup of MakerBot 3D printers including the Replicator Z18, Replicator Mini, 5th Generation Replicator, and the experimental Replicator 2X. MakerBot will also be offering 20 different filament types, including their popular Glow in the Dark and Translucent filaments, in stores and on the website.

MakerBot will also be offering 20 different filament types, including their popular Glow in the Dark and Translucent filaments, in stores and on the website.

This partnership should extend MakerBot’s reach and name recognition, as it will also take us all one step closer to seeing 3D printing enter the mainstream. Have you been to any of the Fry’s Electonics locations which carry MakerBot 3D printers? What do you think about this deal? Let us know in the Fry’s/MakerBot forum thread on 3DPB.com.

Stay up-to-date on all the latest news from the 3D printing industry and receive information and offers from third party vendors.

Tagged with: fry's electronics • makerbot • makerbot replicator • retail • stratasys

Please enable JavaScript to view the comments powered by Disqus.

3ders.org - MakerBot 3D printers and filament now available at Fry’s Electronics' 32 stores

Nov.25, 2014

Yesterday Staples announced it will begin selling MakerBot 3D printers in 50 retail stores across the US, today MakerBot announced that they have signed another agreement with Fry's Electronics. MakerBot and Fry's Electronics announced that its 3D printers and filaments will be available in select Fry's Electronics stores in the U.S. and online.

MakerBot and Fry's Electronics announced that its 3D printers and filaments will be available in select Fry's Electronics stores in the U.S. and online.

Based in San Jose, Calif., Fry's was founded as a Silicon Valley retail electronics store to provide a one-stop-shopping environment for the hi-tech professional. Fry's retails over 50,000 electronics items within each store, in a total of 34 stores. The stores range in size from 50,000 to over 180,000 square feet.

This national rollout positions MakerBot as a premier partner with Fry's Electronics in the 3D printing area. Visitors to Fry's Electronic stores in 32 locations in Arizona, California, Georgia, Illinois, Indiana, Nevada, Texas and Washington, will be able to purchase MakerBot Replicator 3D Printers and PLA Filament right in the store. MakerBot Filaments will be displayed in specially designed MakerBot in-store kiosks at Fry's.

Visitors to Fry's stores in Sunnyvale, California, and Wilsonville, Oregon, will be able to see MakerBot Replicator 3D Printers in action and get to experience the magic of 3D printing firsthand. Frys.com will also offer the full line of MakerBot Replicator 3D Printers.

Frys.com will also offer the full line of MakerBot Replicator 3D Printers.

"We are really excited to partner with Fry's Electronics to bring MakerBot Replicator 3D Printers and Filaments directly to high tech professionals in more retail locations throughout the United States," noted Jenny Lawton, acting CEO of MakerBot. "It's also a great experience to be able to visit Fry's and purchase multiple colors of MakerBot Filament when working on a 3D printing project."

On the filament side, MakerBot offers more than 20 colors of its popular MakerBot PLA Filament, including specialty colors like Translucent and Glow in the Dark.

MakerBot 3D Printers and Filaments are Available at the Following Fry's locations:

Posted in 3D Printers

Maybe you also like:

- UK company Fripp Designs unveils Picsima silicone 3D printer

- The smallest, battery powered 3D resin printer launches on Kickstarter, $189 for early birds

- Polyes Q1 3D printing pen uses light to harden ink, Kickstarter launch coming soon

- Dutch company By Flow working on a truly portable 3D printer that can print in plastic, ceramic & food

- Peachy Printer released its latest 3D prints, now available for pre-order

- Polish company launches BlackJet 3D printer: 'the link between RepRap & professional printers'

- Russian man creates a €195 SLA 3D printer from old CD/DVD drives

- gCreate releases gMax 1.

5 & gMax 1.5 XT 3D printers boasting large build envelope

5 & gMax 1.5 XT 3D printers boasting large build envelope - Pi-Top 3D printed laptop launches on indiegogo, super early bird price $229 for full Kit

- 'The Bug', a 3D printer that prints in Fiber Composites

Adam wrote at 11/26/2014 2:44:43 AM:

No. They'll just shut down any forums or websites that mention how bad the new extruders work.

Disatisified Makerbot Owner wrote at 11/25/2014 9:57:06 PM:

Will they also service the printers there... and keep an ample supply of "Smart Extruders" on hand for when they break?

Lychee 3D printing slicer review. preparing models for printing

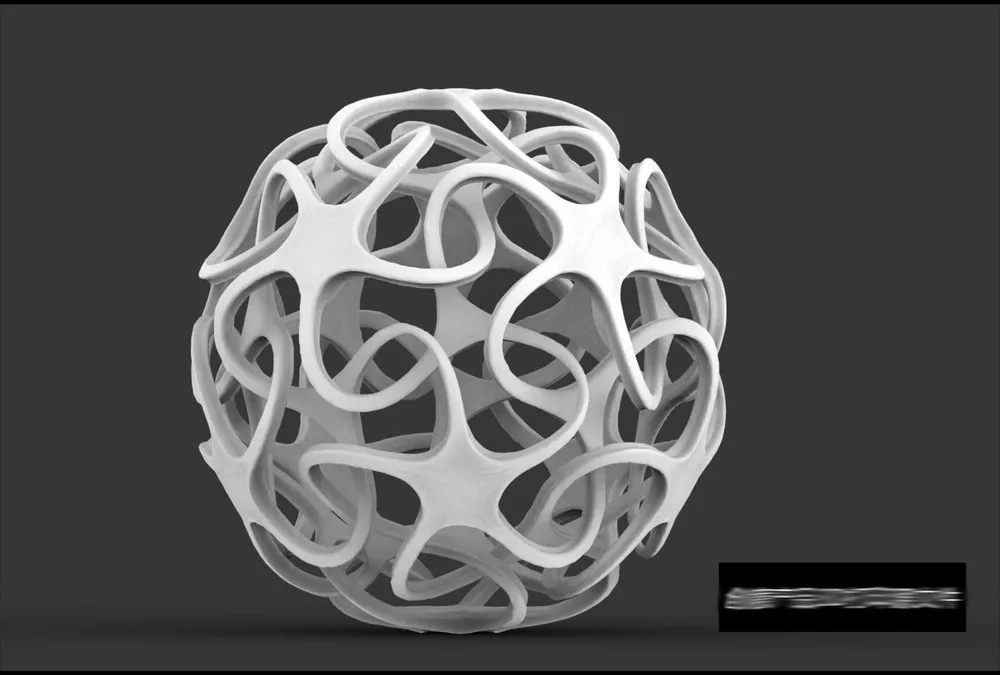

There are many variations of 3D printers that differ not only in materials, but most importantly printing technology . Nevertheless, two main most popular and sought-after types of 3D printers can be distinguished: FDM and LCD. The former are printed by fusing layer by layer with plastic filament. The latter print the model with resin, which, under the influence of light with a certain wavelength, polymerizes and hardens.

The former are printed by fusing layer by layer with plastic filament. The latter print the model with resin, which, under the influence of light with a certain wavelength, polymerizes and hardens.

Technologies have their own characteristics, advantages and disadvantages, but most importantly, they differ not only in material, but also in their very essence. LCD printers print section by section, while FDM printers print line by line. Thus, different slicers must be used for these devices. This is how the market for many companies emerged, because it was necessary to create new software, which Mango3D did with the development of Lychee Slicer.

Lychee Slicer software is based on the main features of popular slicers. This freeware offers a universal tool for fast model slicing for LCD printers of different models. Both amateur enthusiasts and professionals can work with the program.

Lychee Slicer aims to make printer operation easier and more efficient. It offers features such as support auto-creation, placement, deepening. The software is compatible with Linux, MacOS and Windows, supports more than 75 models of 3D printers. The developers offer three options for the program: a free version, a paid one with a monthly payment, and a paid one with an annual subscription. Paid versions offer an extended set of features. This program can be a great alternative to ChiTuBox and Formware 3D Slicer. But more on that later…

The software is compatible with Linux, MacOS and Windows, supports more than 75 models of 3D printers. The developers offer three options for the program: a free version, a paid one with a monthly payment, and a paid one with an annual subscription. Paid versions offer an extended set of features. This program can be a great alternative to ChiTuBox and Formware 3D Slicer. But more on that later…

Pricing and Subscription

The Lychee Slicer comes with three license options as mentioned above. Two of them are paid with a 30-day free trial, and one is free.

Free version available for download and installation. It has the basic functionality, as well as a number of unique tools, which are mentioned below. In the free version, you can also receive ads that are related to 3D printing issues.

Paid versions are available in two versions: with an annual subscription and with a monthly subscription. Payment is charged in euros, please note this. Paid versions contain all the tools of the free version, and also offer additional advanced functionality. An annual subscription will give users a discount of 3 euros per month, and the functions and tools will be the same.

An annual subscription will give users a discount of 3 euros per month, and the functions and tools will be the same.

Lychee interface

The Lychee slicer interface is almost the same as FDM slicers. The workflow is similar and consists of 5 main steps. In this case, the printer setup is carried out only when the software is connected to the printer for the first time.

- Printer setup

The Lychee slicer is compatible with 75 LCD printer models. If you have one of the supported models, then adding it will be an elementary task. To do this, go to the list of 3D printer manufacturers and select your device model. Next, you can import or create your own resin profile.

- Layout

After the printer setup is complete, the software loads the Layout view. Here you can add models, scale them, change orientation in space. It is possible to restore the object and work with the functions "Magic", "Measurement".

- Supports

The program allows you to automatically generate supports at this step. You can also put the supports yourself, create rafts. The step, as you know, is not mandatory, especially if automatic support generation is selected, but it is very functional for printing complex products. The menu allows you to adjust the density, support shape, diameter, and also change the characteristics of the raft.

- Preview

This is a convenient menu. In which you can render the model before physical printing. This section is similar to those of other slicers, but there are also a number of unique tools. For example, "Simulator", "To scale". The first allows you to visualize the progress of the print, while the "To scale" mode places the model with some objects so that you can compare the shape and size.

- Export

Finally, we got to the last step called "Export". Here you select the final print settings, and you can also check the estimated print time. If you are going to print to one of the preconfigured printers, then the menu options are limited. The options relate to the type of resin and the smoothing method.

Here you select the final print settings, and you can also check the estimated print time. If you are going to print to one of the preconfigured printers, then the menu options are limited. The options relate to the type of resin and the smoothing method.

Functionality of the program

Let's dwell on the basic functions of Lychee Slicer, which, in principle, any slicer has.

Resin profiles and specialty printers

Lychee Slicer has the ability to set up its own printer from the "free zone" or a custom printer. The printer from the free zones is very easy to set up. After that, access to the main functionality of the program opens. When setting up a printer from free zones, keep in mind that Lychee Slicer will not be able to create a file that will be compatible with your equipment. Therefore, the finished object, along with supports and everything necessary that will be formed in Lychee, will need to be exported to the slicer that comes with your equipment.

Similar or based on the same principles, you can create resin profiles, which will require you to specify parameters such as layer thickness, print speed. You can also specify the cost of a bottle of resin. In general, these profiles can be used as a way to customize printing.

- Scaling, moving, rotating, mirroring

After importing an object into Lychee Slicer, you can perform all the above functions, just like in any other slicer. There are also undo and redo functions. They allow you to correct any errors made during the setup.

- Supports

Lychee Slicer can auto generate support. But there is a mode and manual creation of supports. At the same time, you can customize the structure and appearance, and paid versions of the program allow you to use support for different forms and manipulate various placement methods in manual mode.

- Dimensions

The PRO license also allows measurements. The built-in measuring tool Lychee Slicer is quite useful. With it, you can measure various parameters, such as the distance between supports. A good tool for checking work before sending it to print.

Unique functionality

In addition to the basic functionality, the developer has provided Lychee Slicer with a number of unique features that are difficult to find in other slicers.

- Magic Mode

The function is an automatic optimization of the position, support structure, orientation of the model or models. It is implemented in the form of a button and turns on with one click. It is very useful as it saves a lot of time.

- Overhang Detector

This function helps to automatically detect overhangs that do not have any supporting structure. This feature is not new, it is implemented in other slicers, in the same Formware, but in Lychee Slicer, advanced users have the opportunity not only to find the overhang, but also to customize the support structure according to their requirements. In the free version, this mode is not available, it implements protrusion scanning.

This feature is not new, it is implemented in other slicers, in the same Formware, but in Lychee Slicer, advanced users have the opportunity not only to find the overhang, but also to customize the support structure according to their requirements. In the free version, this mode is not available, it implements protrusion scanning.

- Real-time filling, drainage, cavities

This function is not required for the slicer in principle. But Lychee Slicer has it implemented and allows you to save on expensive resin, while maintaining the highest quality of prints.

- Variable Layer Height

This feature is available in a paid version and is not supported by all 3D printers. However, variable layer height allows you to optimize print time by changing the layer height in some areas. Among SLA slicers, only Lychee Slicer has this feature. It is implemented only in FDM slicers, for example, Cura.

- Pixel Perfect Mod

Another mode that is implemented only in paid versions. It allows professional users to achieve the highest level of accuracy. That is, this mode allows you to cut the model so that this cutting matches the resolution of your equipment as much as possible.

It allows professional users to achieve the highest level of accuracy. That is, this mode allows you to cut the model so that this cutting matches the resolution of your equipment as much as possible.

KFC will print chicken nuggets on a 3D printer - Agroinvestor M. Stulov

Fast food restaurant chain KFC and technical research laboratory 3D Bioprinting Solutions announced the beginning of a collaboration to develop an innovative technology for creating chicken meat using a 3D bioprinter. The idea of developing "meat of the future" is a response to the growing popularity of healthy eating and increasing demand for traditional meat substitutes, the companies said in a joint statement. The result will be the world's first lab-created chicken nuggets that taste and look as close as possible to the original KFC product, while being more sustainable than regular meat. Product testing is expected to begin this autumn in Moscow.

3D Bioprinting Solutions will develop a 3D bioprinting technology using chicken cells and plant materials that will reproduce the taste and texture of chicken meat. KFC will provide breading and spices. There are currently no analogues of 3D bioprinting technology on the market that allow creating complex products based on animal cells, the report says. The developers claim that craft meat contains the same trace elements as regular meat, but at the same time, various additives typical for traditional animal husbandry cannot be included in the products. In addition, cell meat products are “more ethical,” the report notes.

KFC will provide breading and spices. There are currently no analogues of 3D bioprinting technology on the market that allow creating complex products based on animal cells, the report says. The developers claim that craft meat contains the same trace elements as regular meat, but at the same time, various additives typical for traditional animal husbandry cannot be included in the products. In addition, cell meat products are “more ethical,” the report notes.

3D Bioprinting Solutions co-founder and managing partner Yousef Hesuani believes that the development of such technologies in the future will make 3D bioprinted products more affordable. “We hope that the technology created as a result of our cooperation with KFC will help accelerate the introduction of such products to the market,” he says (quoted from a press release). The use of technologies based on 3D bioprinting can become one of the promising areas for the uninterrupted provision of food to a growing population and reduce the negative impact on the environment, the companies say.

Now there are several companies in the world that develop technologies for cellular printing of meat and fish food products, for example, the Japanese IntegriCulture, commented Andrey Zyuzin, CEO of Efko Innovations. “But the agreement between KFC and 3D Bioprinting Solutions on the development of technology for creating nuggets using cell culture technology is a new stage in the development of food technology both in the world and in Russia,” he told Agroinvestor.

Fast food tried vegetable "meat"

In January, Bloomberg reported that KFC would introduce Beyond Meat's fake chicken nuggets to menus in two U.S. cities as an experiment. In the summer of 2019, KFC already tested similar products. Last fall and January 2020, McDonald’s tested the plant-based P. L. T. (Plant. Lettuce. Tomato) burger, which was also based on Beyond Meat’s plant-based “meat” patty, at select Canadian restaurants.

Burger King in the US last year experimented with veggie burgers developed in conjunction with startup Impossible Foods. Peas, soybeans, wheat, potatoes and vegetable oils are used as raw materials for cutlets. In Russia, in restaurants and retail chains, vegetable "meat" Beyond Meat, created on the basis of pea protein, appeared in September last year.

Executive Director of Rincon Management Konstantin Korneev considers the idea of KFC a good marketing ploy to expand the line. The network is quite youthful, and young people positively perceive all kinds of innovations, so this is fertile ground for the promotion of cell meat. At the same time, the Russian market is one of the priorities for the company, since it shows fairly high growth rates compared to other countries, he adds.

Restaurant chains in America, Europe and even Russia have already experimented with alternative meats, but these were products based on vegetable protein texturing technologies, not 3D cell printing, Zyuzin notes, adding that 3D printing allows you to make products as similar in composition as possible. to natural. “Most likely, this is a long-term project. But what will be the price of this innovation, and is the consumer ready?” he asks.

to natural. “Most likely, this is a long-term project. But what will be the price of this innovation, and is the consumer ready?” he asks.

Are you ready for the "meat of the future"?

“The price of new products will depend on production technologies, but now they hardly think about it: this is not about business yet, this is a new feature,” Korneev commented to Agroinvestor. In his opinion, the price of such nuggets for consumers may well be even higher than traditional ones. The main thing is how the company will position them. If you say that this is a product for a healthy diet, for those who follow a sports diet and rely on insights that are relevant for young people, then the new nuggets may turn out to be popular, he believes.

True, the long-term prospects for such products and regular consumption, and not one-time for the sake of curiosity, is another story, continues Korneev. “If we talk about Western markets, then there consumers are more informed about the impact of animal husbandry on the environment and when choosing a product, they also take into account its level of “negative impact,” he explains.